Surface cleaning machine and surface cleaning machine self-cleaning method

A surface cleaning and self-cleaning technology, applied in cleaning equipment, cleaning machinery, manual floor scrubbing machinery, etc., can solve the problems of container pollution, poor user experience of surface cleaning machines, and lack of convenience, so as to improve user experience and improve The effect of ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] The inventors of the present application have found that, in the prior art surface cleaning machines, it is often necessary to disassemble the roller brushes for cleaning them.

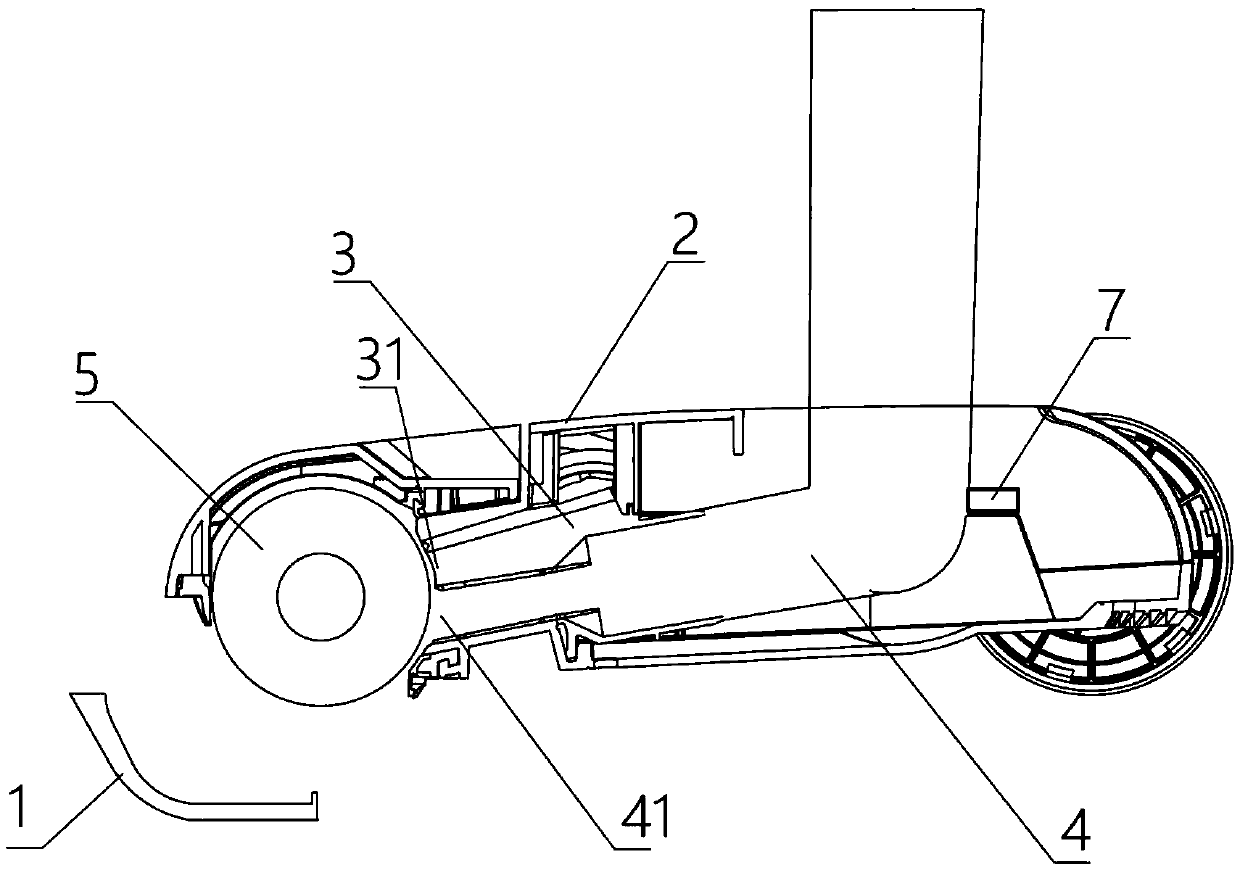

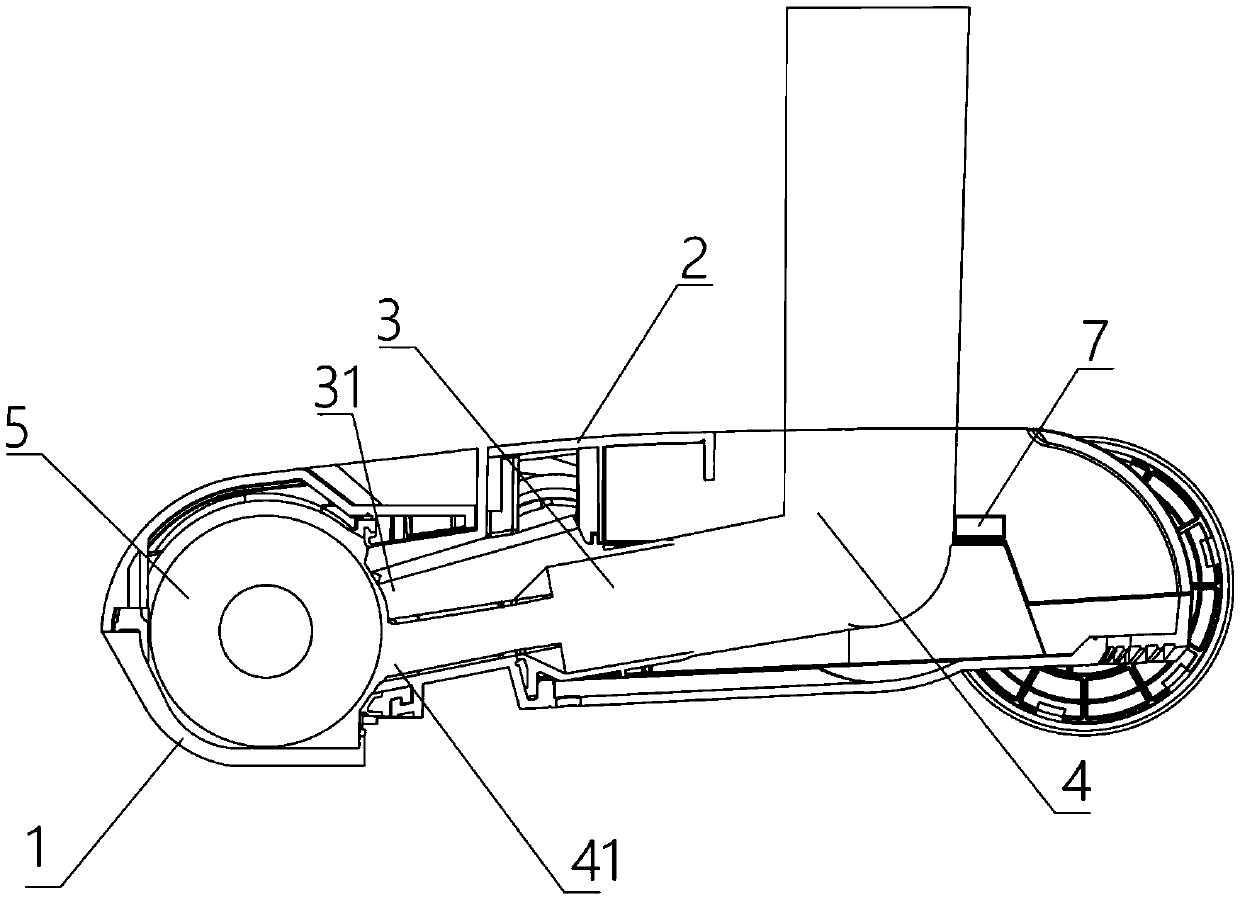

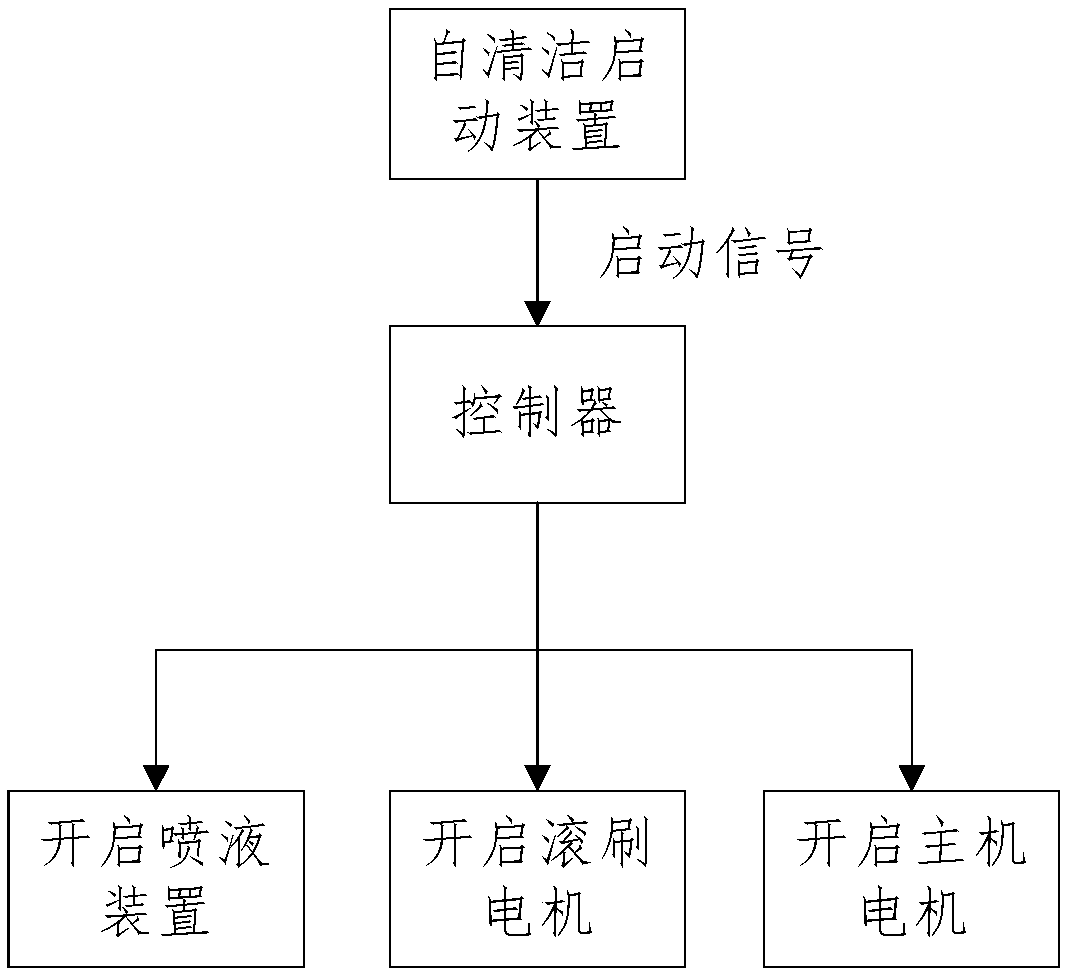

[0039] In view of this, the first embodiment of the present application provides a surface cleaning machine, see figure 1 , figure 2 Shown, it comprises: controller 7, spraying device 3, rolling brush 5 and the rolling brush motor (not shown in the figure) that is used to control rolling brush 5, suction device and the main engine motor that is used to control suction device ( not shown in the figure);

[0040] Optionally, the body of the surface cleaning machine can often be wrapped by the casing 2, and the rotating shaft of the roller brush 5 is fixed on the casing 2 and can rotate. The controller 7 can be arranged in the casing 2, and can also be arranged outside the casing 2 in a discrete manner, without figure 1 , figure 2 The positions shown in are limited. The liquid spraying devi...

Embodiment approach 2

[0079] The second embodiment of the present application also provides a self-cleaning method for a surface cleaning machine, and the self-cleaning method for a surface cleaning machine provided in the second embodiment of the present application is based on the self-cleaning method for a surface cleaning machine in the first embodiment The main improvement is that a second cleaning mode is also provided to improve the cleaning effect.

[0080] Specifically, see Figure 5 As shown, in the second embodiment of the present application, the controller 7 receives the first switching signal, stops the first cleaning mode, and starts the second cleaning mode; wherein, the second cleaning mode includes the following sub-steps:

[0081] Close the spray device 3;

[0082] Keep the roller brush motor rotating (i.e. keep the roller brush 5 rotating);

[0083] Keep the host motor rotating (ie keep the suction unit running).

[0084] It is worth mentioning that if the suction force provi...

Embodiment approach 3

[0100] The third embodiment of the present application also provides a self-cleaning method for a surface cleaning machine. The self-cleaning method for a surface cleaning machine provided in the third embodiment is a further improvement based on the self-cleaning method for a surface cleaning machine in the second embodiment. The main improvement is that, in the third embodiment of the present application, the cleaning process is reciprocally switched between the first cleaning mode and the second cleaning mode.

[0101] Specifically, see Figure 8 As shown, the controller 7 receives the second switching signal, stops the second cleaning mode, and restarts the first cleaning mode.

[0102] Optionally, the detection module can also send a second switching signal to the controller 7 when detecting the following conditions:

[0103] It is detected that the duration of the second mode reaches a second preset time.

[0104] That is to say, this embodiment also provides a combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com