Structure of super-large cofferdam based on marine environment and construction process thereof

A marine environment and construction technology technology, applied in infrastructure engineering, construction, etc., can solve the problems of prone to flood disasters, vulnerable to typhoons, complex underwater environment, etc., to reduce financial pressure, shorten construction period, and prevent seepage Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

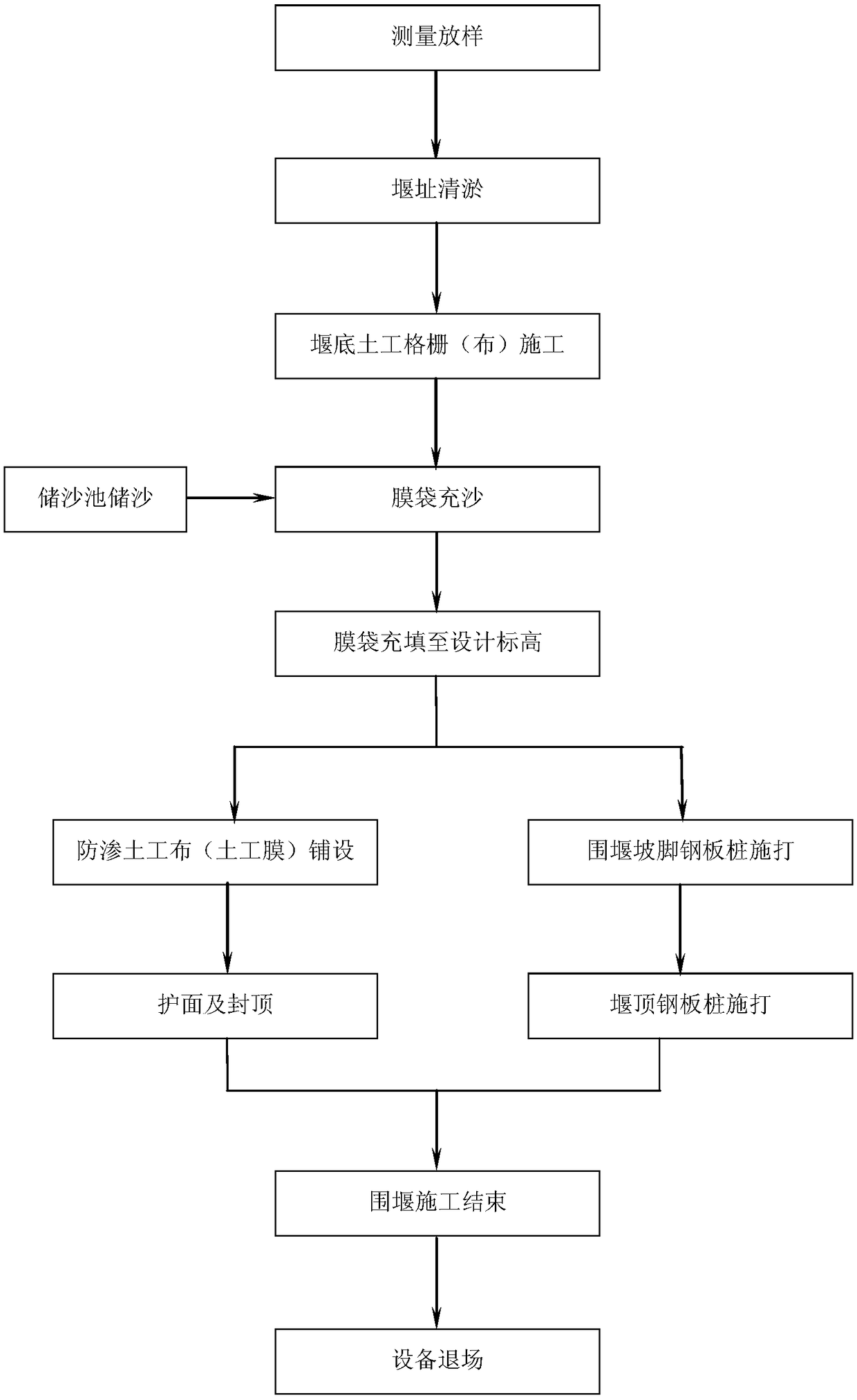

Method used

Image

Examples

Embodiment Construction

[0039] The details of the present invention are described below through the examples, and the examples are provided for the convenience of understanding, and are by no means limiting the present invention.

[0040] research material:

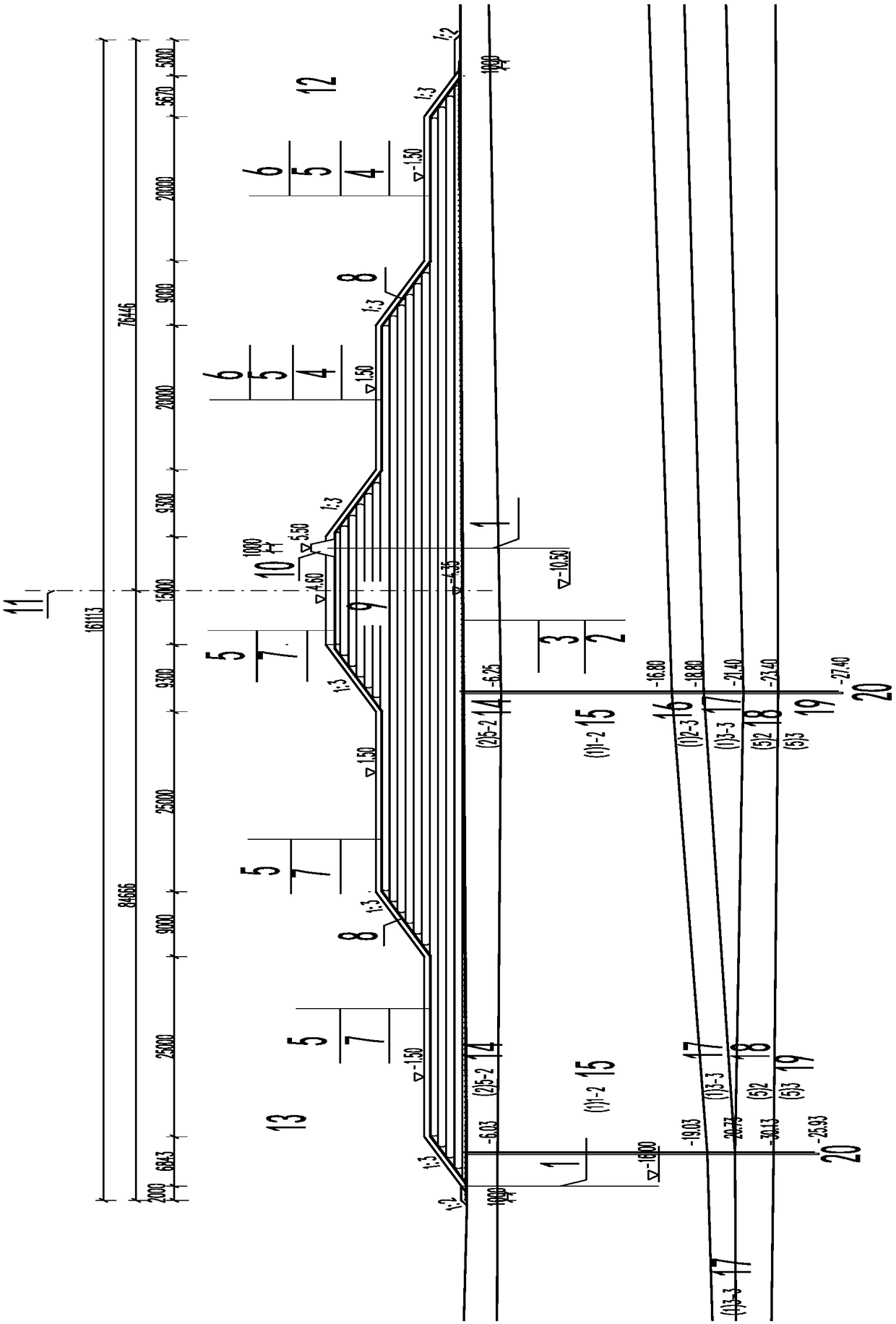

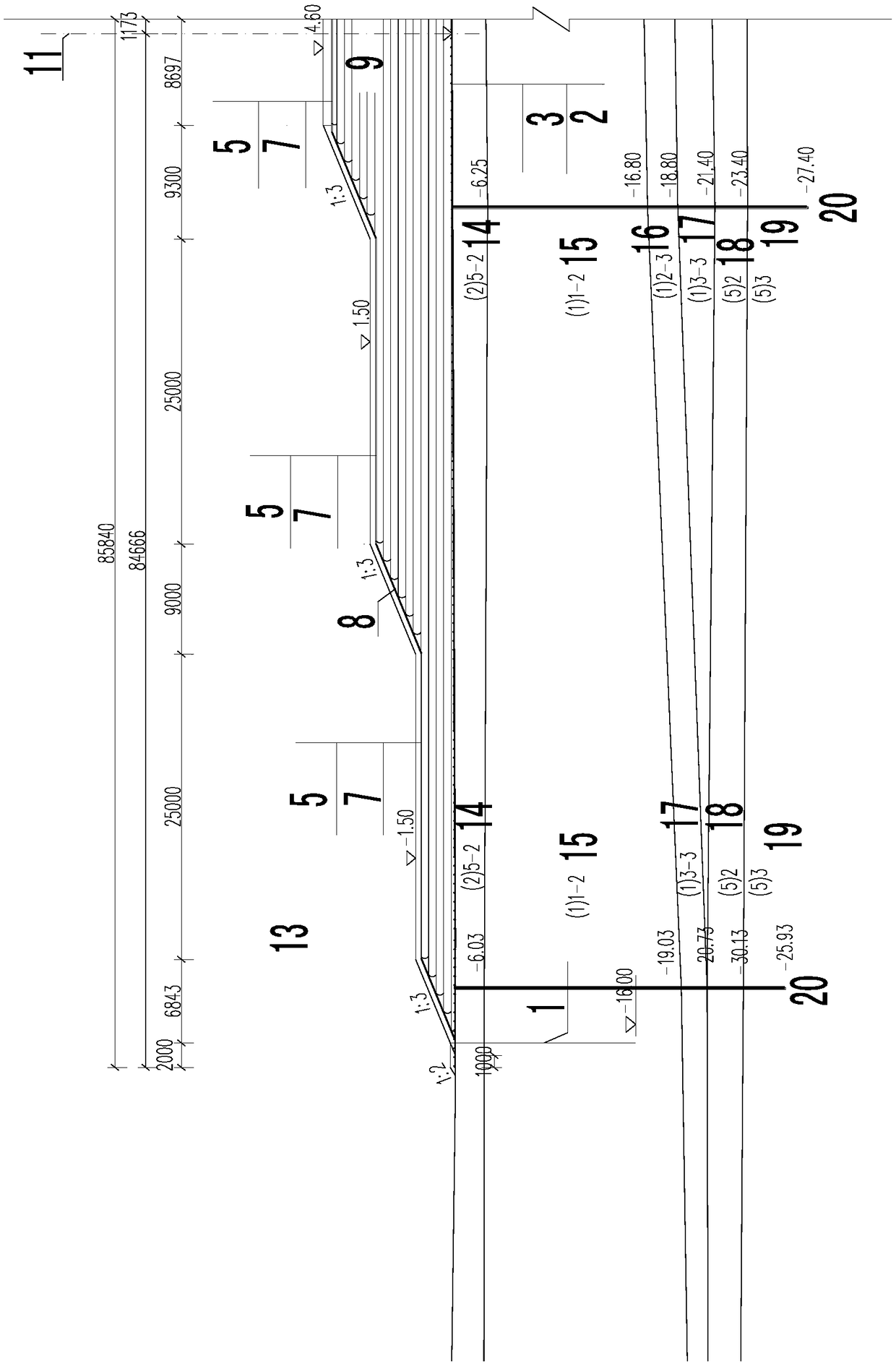

[0041] This research material involves a tunnel project in a marine environment with a total length of 1.2 kilometers (0.8 kilometers in length across the sea). It adopts the standard of two-lane secondary road, with a design speed of 40 km / h, two-way two-lane, and a lane width of 2*3.75m. The lane boundary height is 5.0m. The lateral net width is 0.5m on the left and right sides, and the remaining width is 0.25m. The structure of the open section on the north bank (K0+180-K0+330) is a U-shaped trough structure, and the total length of the open section on the north bank is 150m. The buried section (K0+330-K1+190) has a rectangular structure with a total length of 860m, and the open section on the south bank (K1+190-K1+360) has a U-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com