Early-strength cement soil as well as preparation method and application thereof

A technology of early-strength cement and cement, which is applied in the field of early-strength cement-soil and its preparation, can solve the problems of low bearing capacity of lime-soil, non-waterproofness of lime-soil, and increase of overall construction cost, achieving low construction speed, short construction period, The effect of fewer process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The second aspect of the present invention provides the preparation method of described early-strength cement soil, comprising the steps of:

[0035] After the excavated earth is screened, the quick-setting anti-seepage agent, cement and water are mixed in proportion and mixed evenly to obtain the product.

[0036] The third aspect of the present invention provides the application of the early-strength cement soil in the backfilling of the foundation pit fertilizer tank.

Embodiment 1

[0038] Prepare early-strength cement soil according to the following ratio:

[0039] Water 23%; soil 69%; early cement soil quick-setting anti-seepage agent 1%; cement 7%.

[0040] The mass ratio of fly ash and water glass in the early cement-soil quick-setting anti-seepage agent is 90:10.

[0041] The soil excavated on site is screened and mixed with early-stage cement-soil quick-setting anti-seepage agent, ordinary Portland cement and an appropriate amount of water, and fully mixed with mechanical equipment to obtain early-strength cement with pumpable fluidity earth.

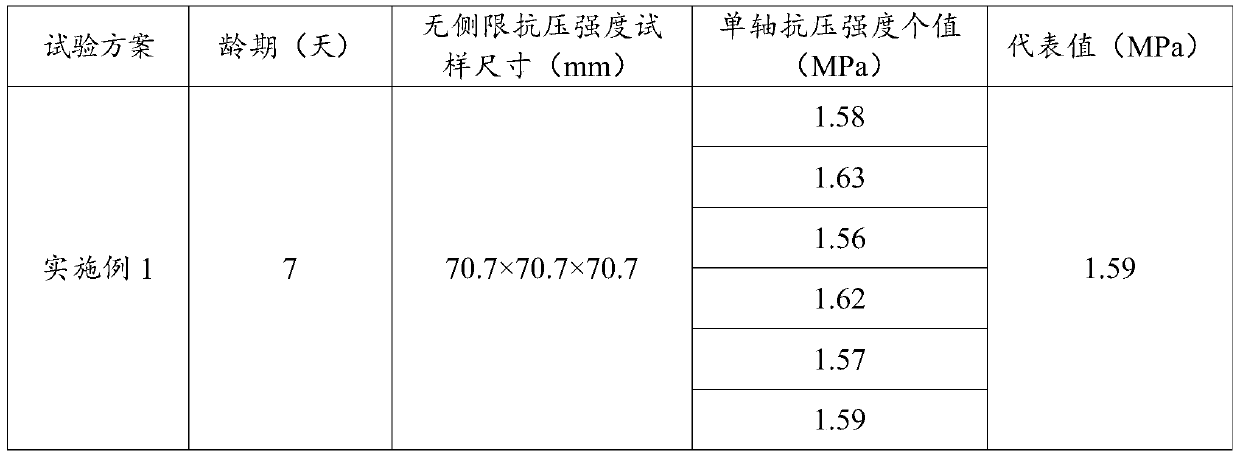

[0042]Compressive strength test: static pressure test and penetration test are adopted at the optimum water content, and the compaction degree is 96%.

Embodiment 2

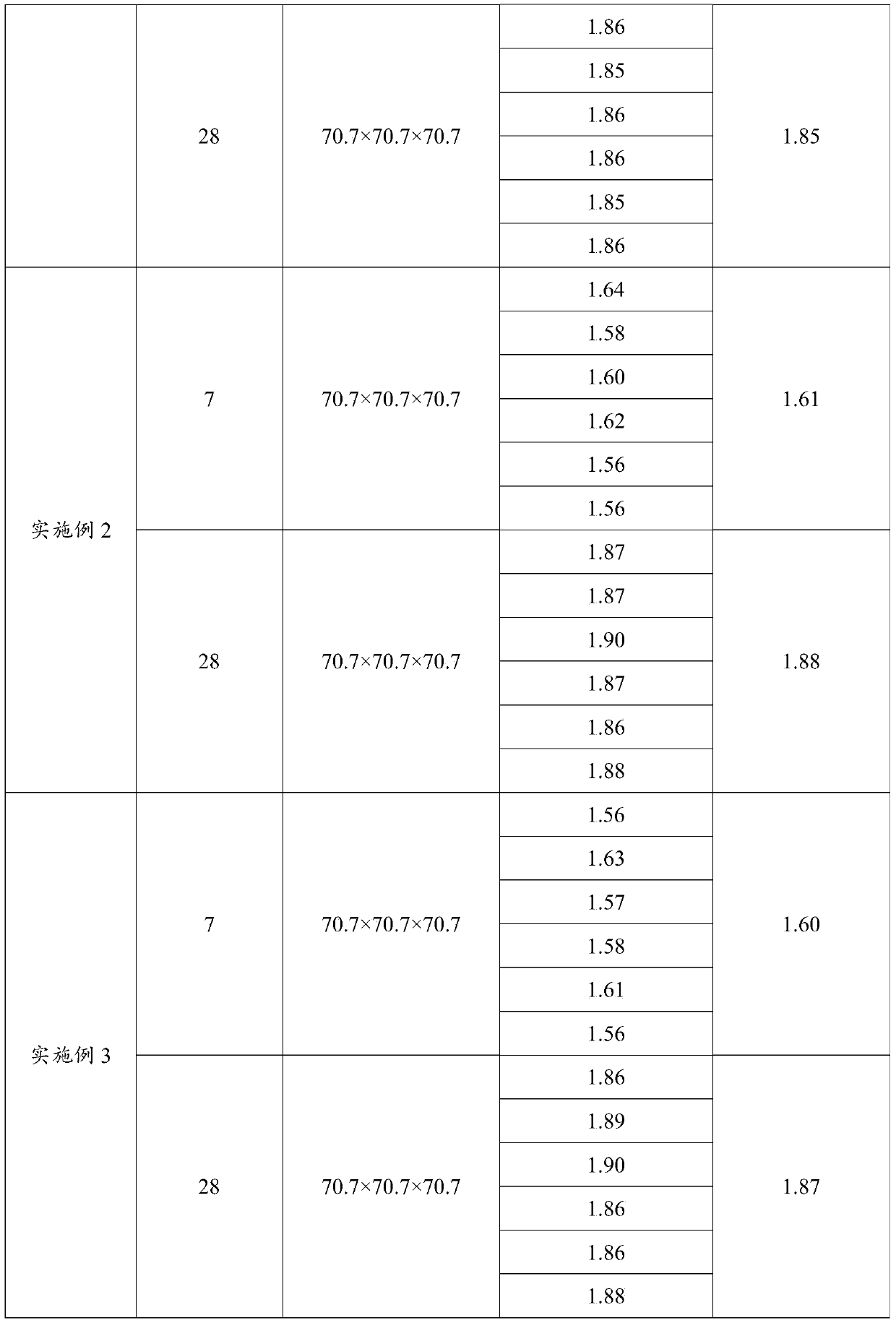

[0044] The difference from Example 1 is that the mass ratio of fly ash to water glass in the early cement-soil quick-setting anti-seepage agent is 93:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com