Floor surface structure assembled with internal keels and external formworks

A technology of inner keel and outer formwork, applied in the direction of floors, building components, building structures, etc., can solve the problems of labor-intensive and low construction safety, achieve economical steel consumption, superior mechanical performance of trusses, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The above-mentioned embodiments are only descriptions of preferred implementations of the present invention, and are not intended to limit the scope of the present invention. Variations and improvements should fall within the protection scope of the present invention.

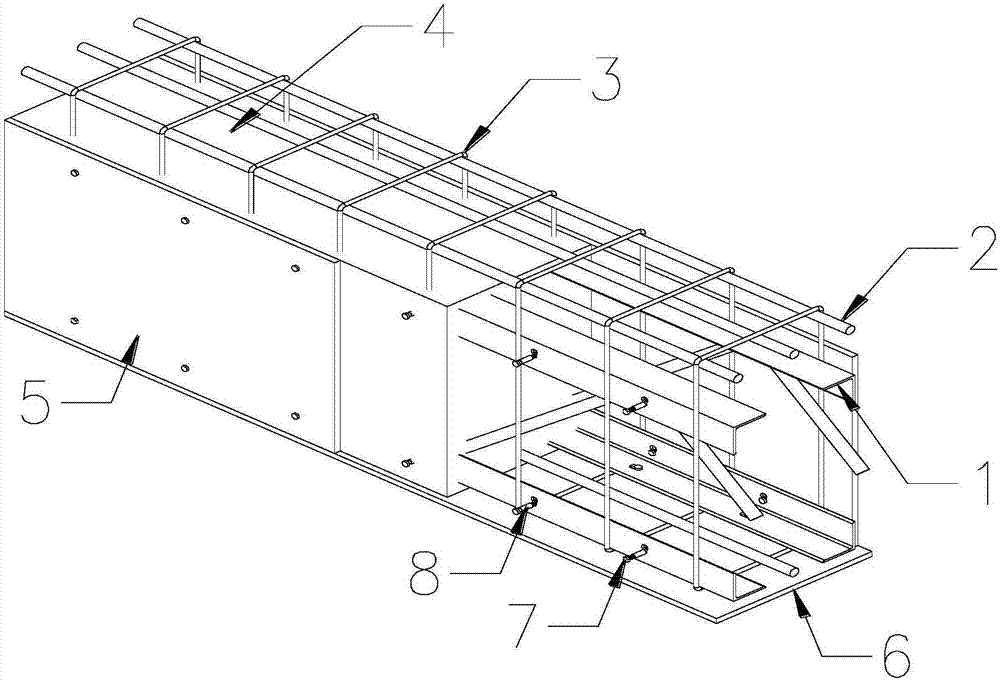

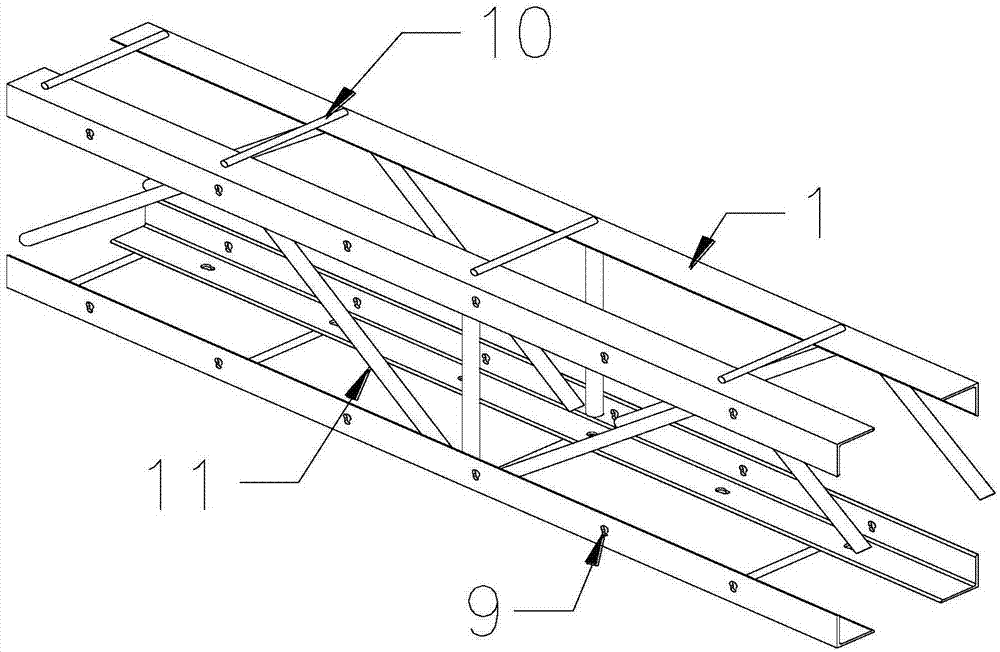

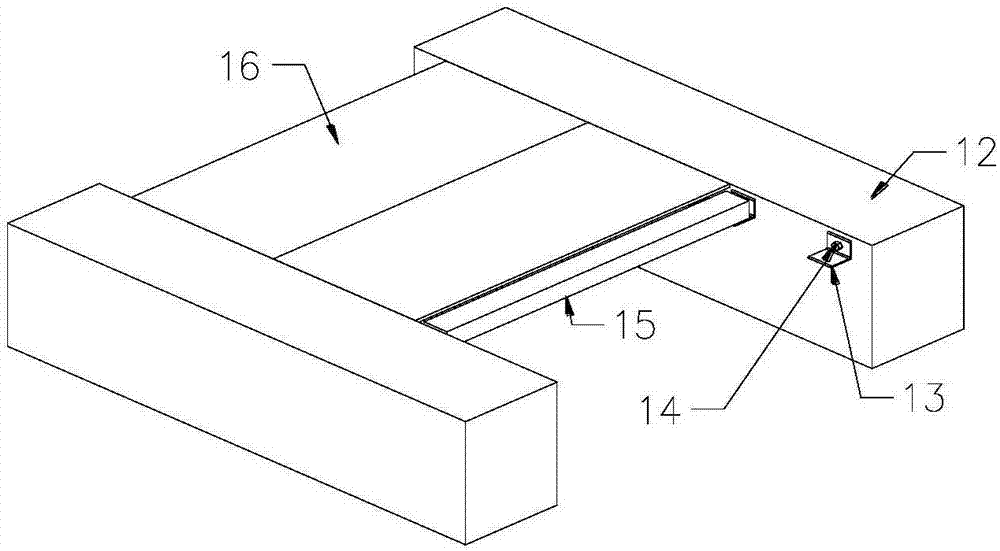

[0028] The floor structure is assembled with the inner keel and outer formwork, including the inner keel truss 1 which doubles as the stress reinforcement in the use stage, the longitudinal stress main reinforcement 2, the stirrup 3, the concrete 4 and the side bottom formwork 5, 6, and the inner keel truss 1 passes through The connecting rods 11, 10 form an integral force-bearing truss, the concrete 4 is poured into the area surrounded by the bottom side forms 5, 6, and the formwork 5, 6 and the inner keel truss 1 are connected as a whole through the connecting bolts 7, because The mechanical performance of the truss is good. During the whole construction stage, there is no need to add formwork support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com