Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

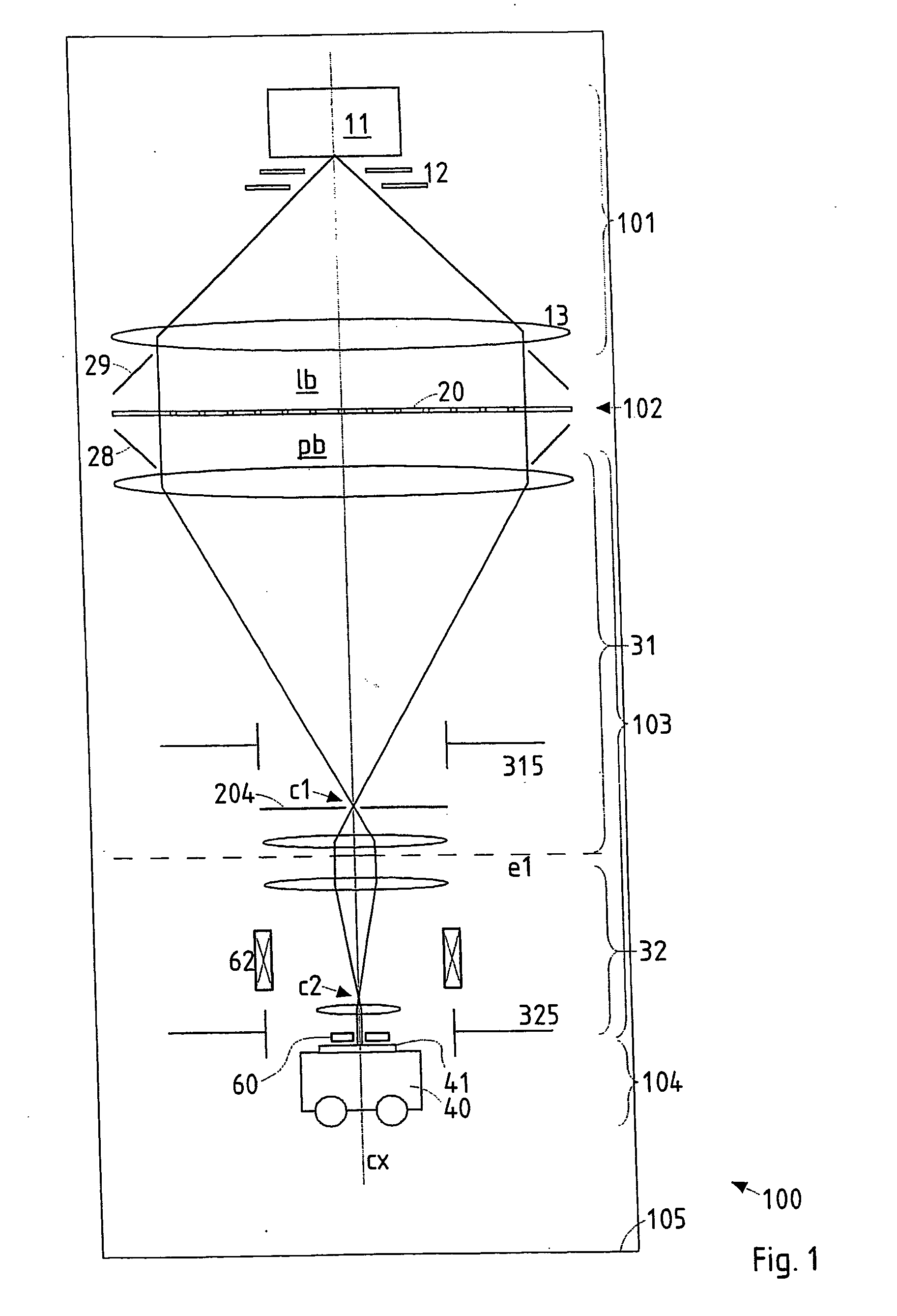

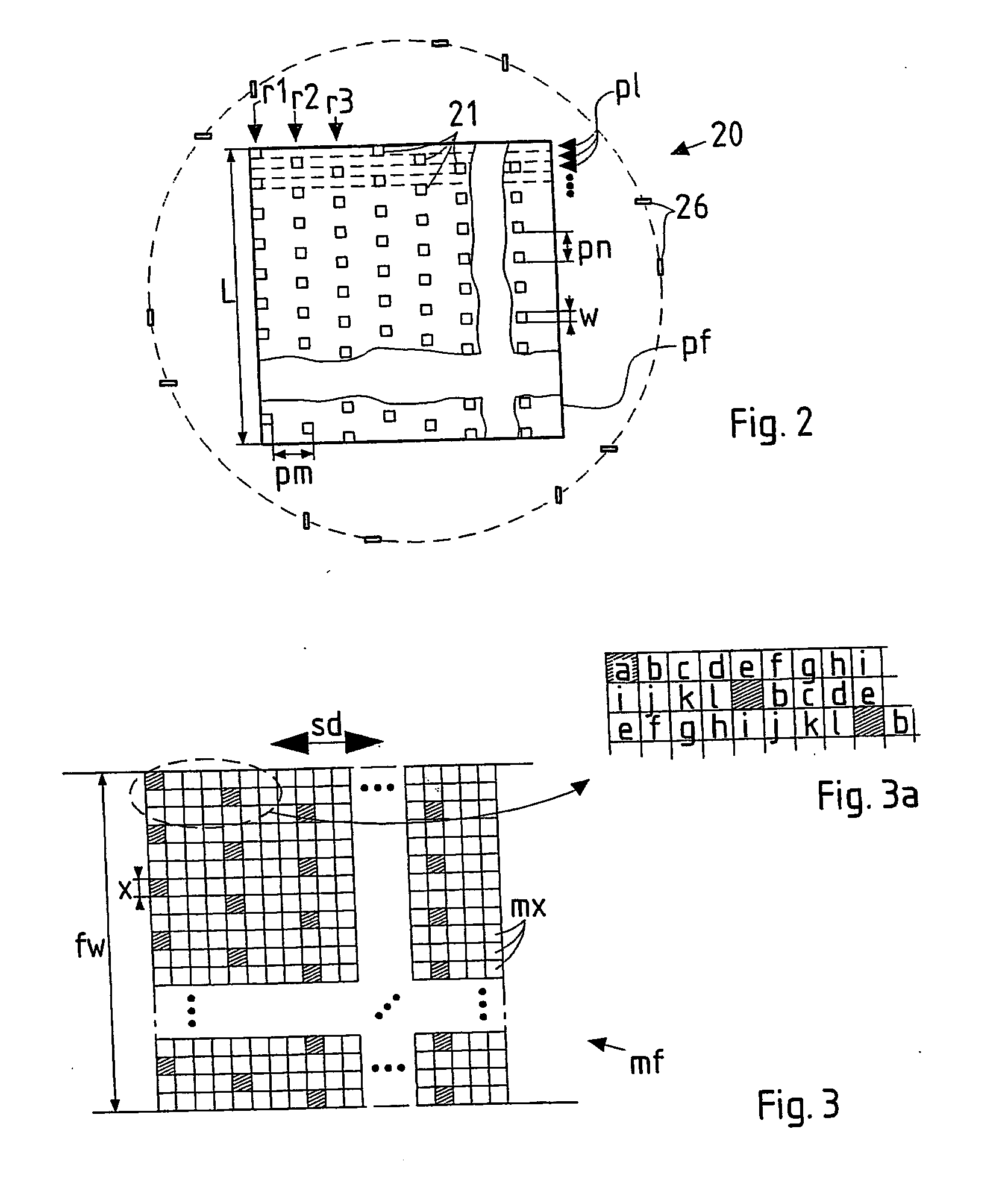

Advanced pattern definition for particle-beam processing

ActiveUS7276714B2High resolutionReduce roughnessElectric discharge tubesNanoinformaticsParticle beamMechanical engineering

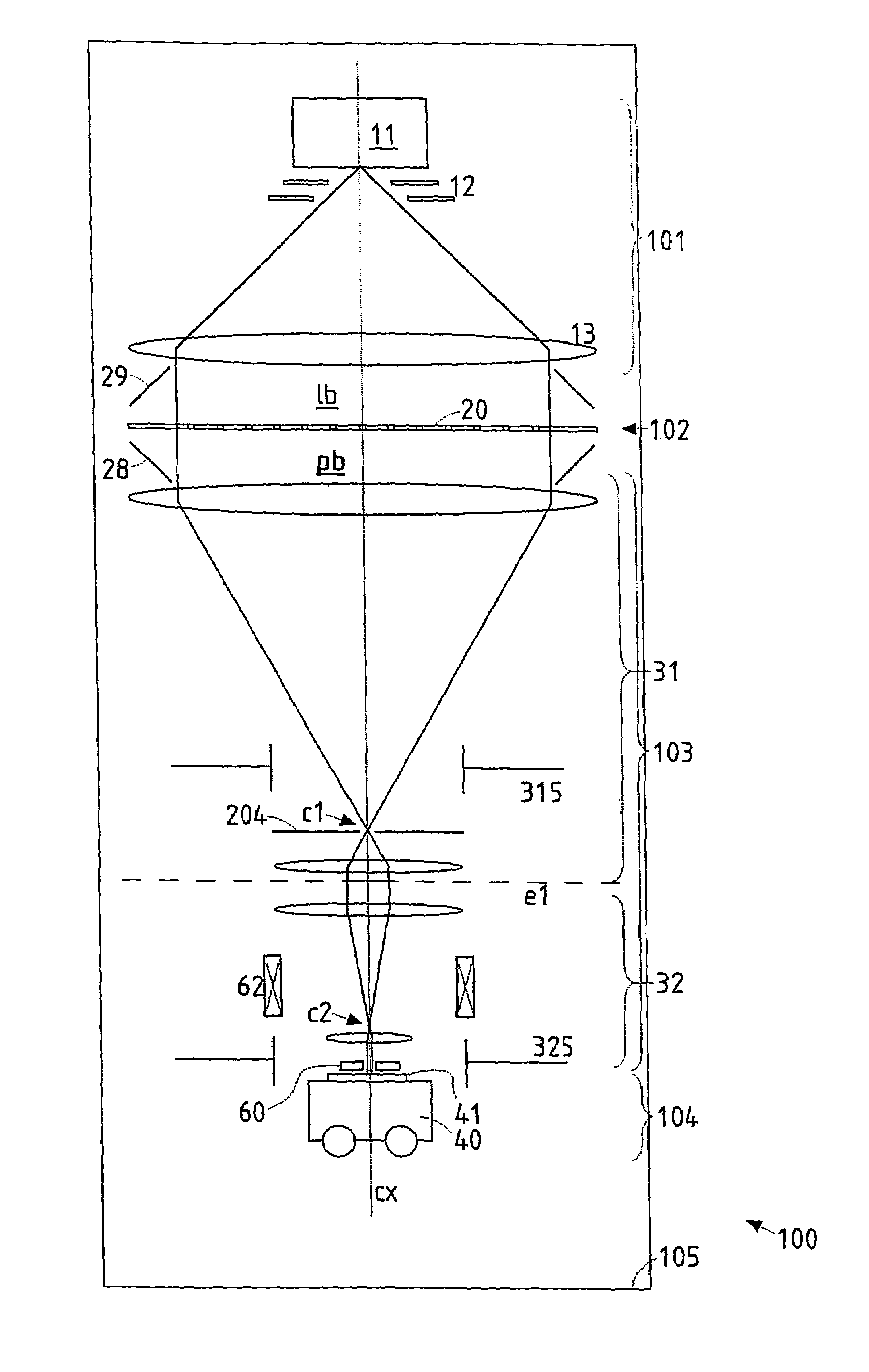

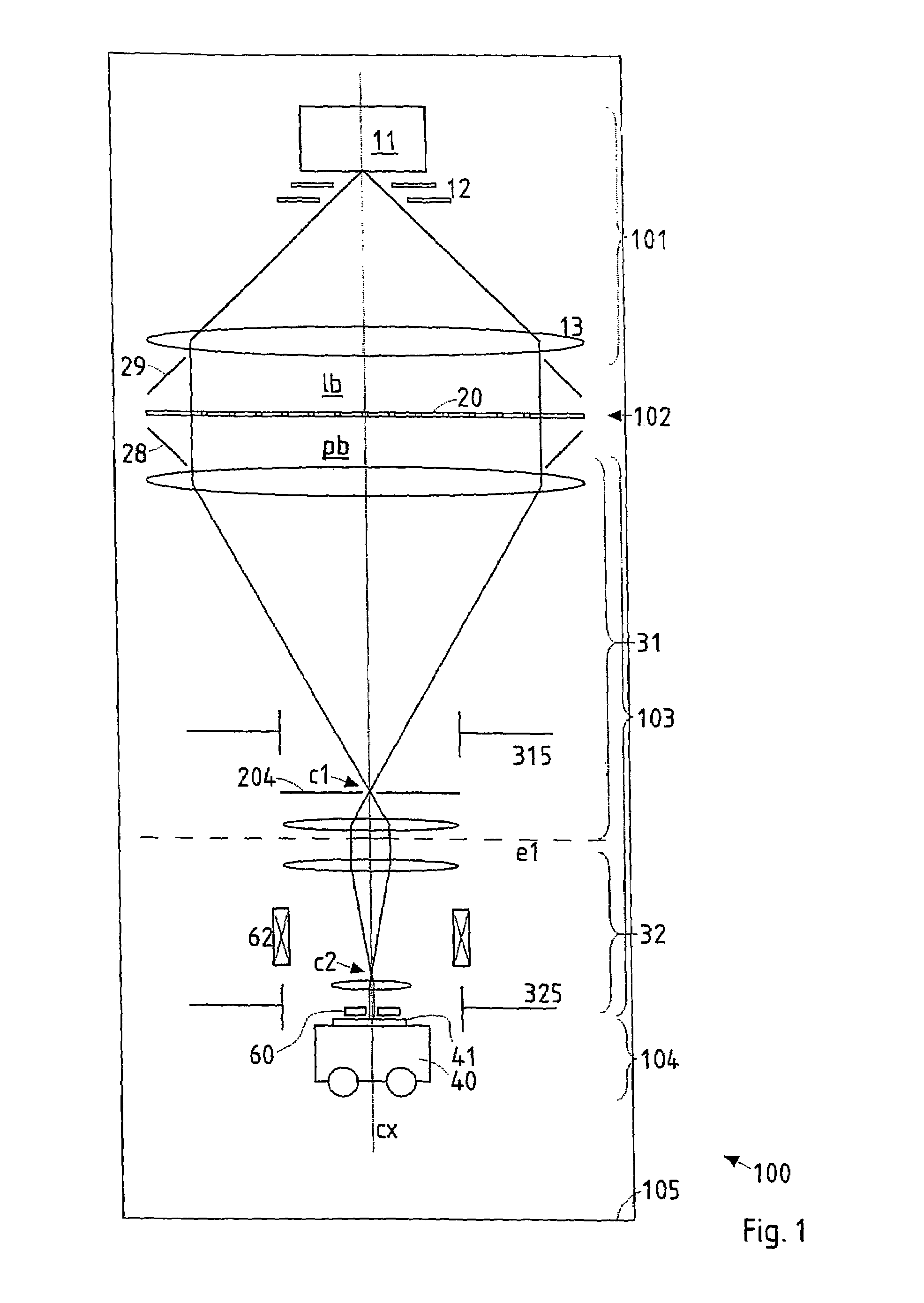

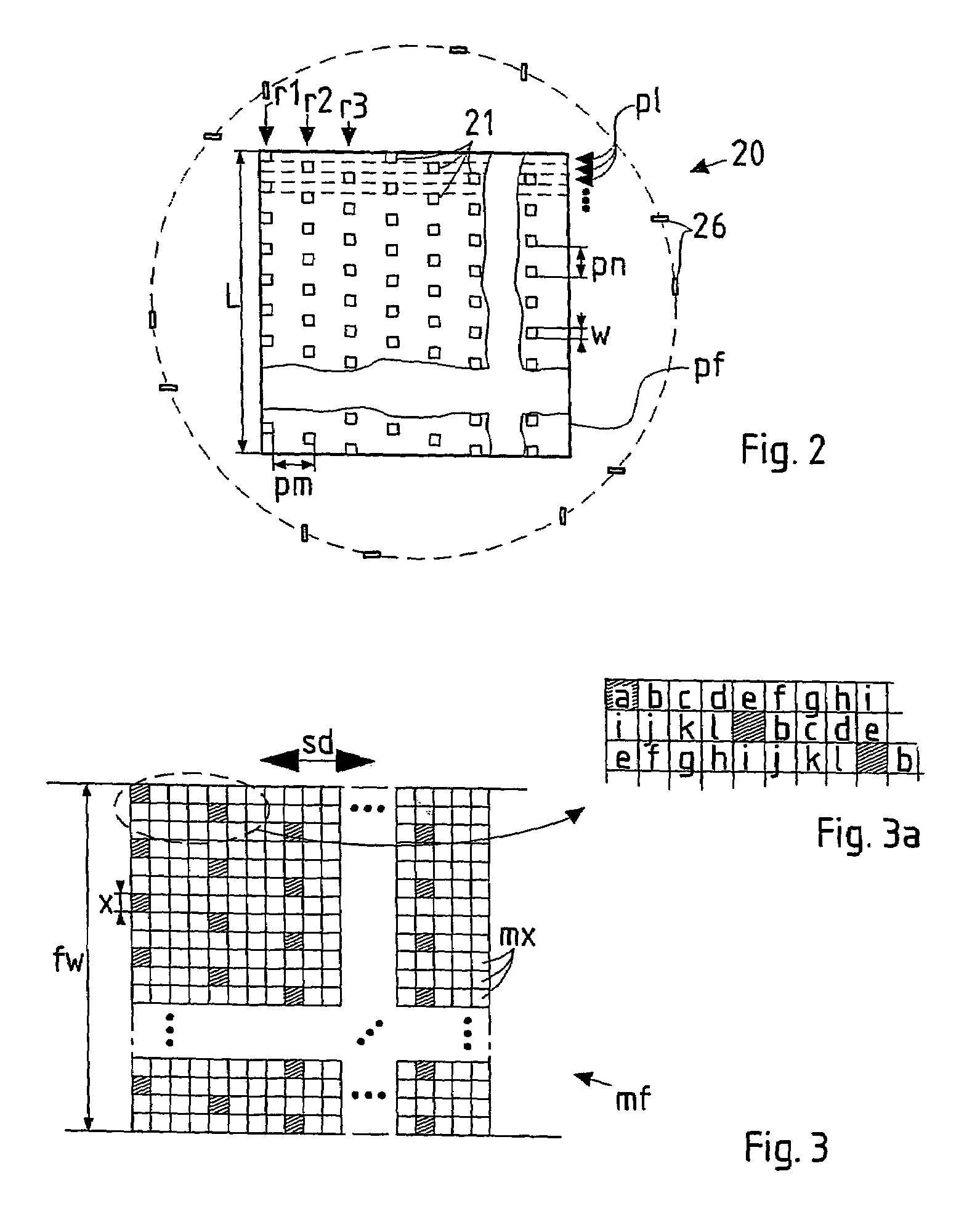

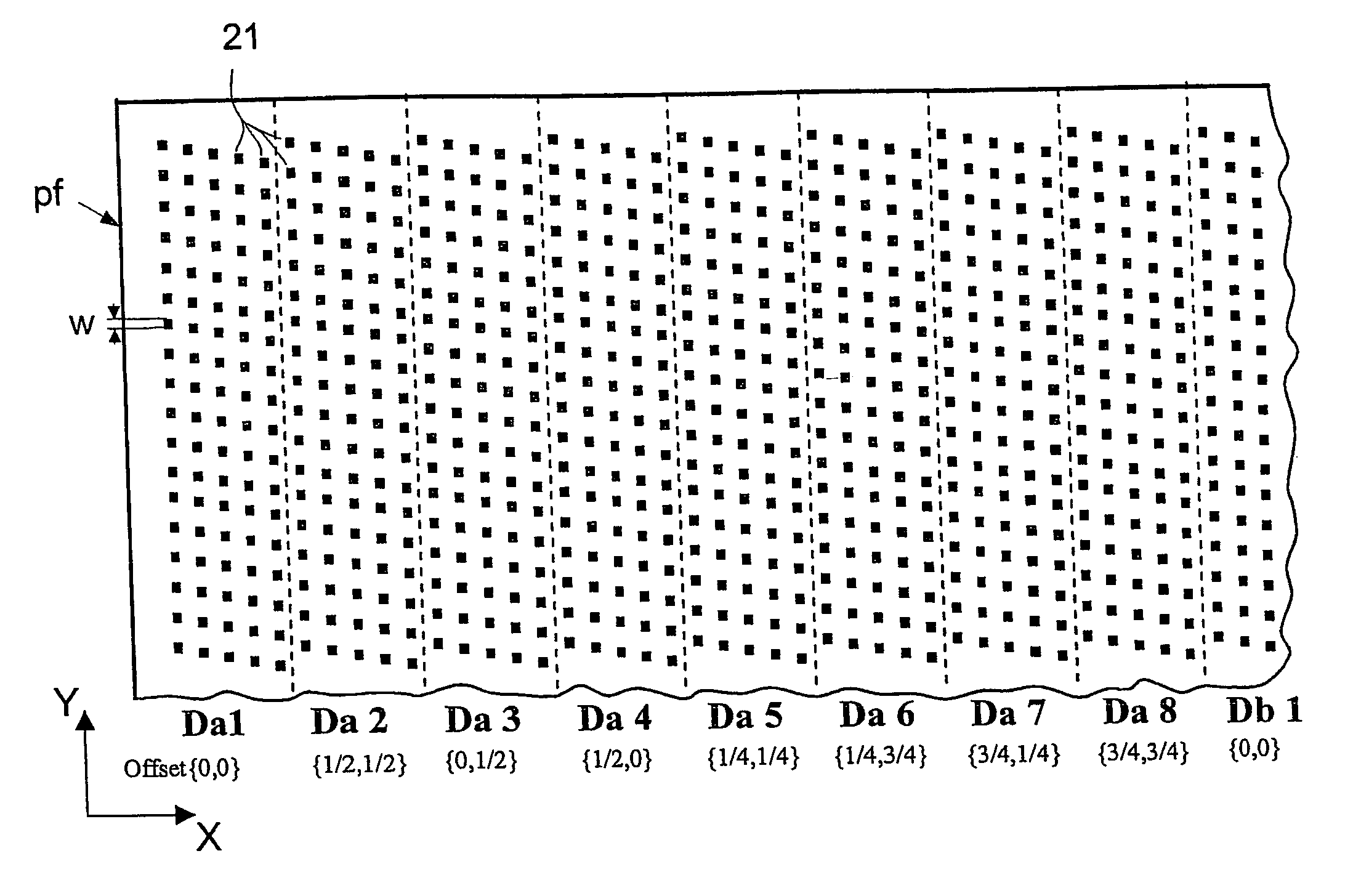

In a pattern definition device for use in a particle-beam processing apparatus a plurality of apertures (21) are arranged within a pattern definition field (pf) wherein the positions of the apertures (21) in the pattern definition field (pf) taken with respect to a direction (X, Y) perpendicular, or parallel, to the scanning direction are offset to each other by not only multiple integers of the effective width (w) of an aperture taken along said direction, but also multiple integers of an integer fraction of said effective width. The pattern definition field (pf) may be segmented into several domains (D) composed of a many staggered lines (pl) of apertures; along the direction perpendicular to the scanning direction, the apertures of a domain are offset to each other by multiple integers of the effective width (w), whereas the offsets of apertures of different domains are integer fractions of that width.

Owner:IMS NANOFABTION

Advanced pattern definition for particle-beam processing

ActiveUS20050242302A1High resolutionReduced line edge roughnessElectric discharge tubesNanoinformaticsParticle beamA domain

In a pattern definition device for use in a particle-beam processing apparatus a plurality of apertures (21) are arranged within a pattern definition field (pf) wherein the positions of the apertures (21) in the pattern definition field (pf) taken with respect to a direction (X, Y) perpendicular, or parallel, to the scanning direction are offset to each other by not only multiple integers of the effective width (w) of an aperture taken along said direction, but also multiple integers of an integer fraction of said effective width. The pattern definition field (pf) may be segmented into several domains (D) composed of a many staggered lines (pl) of apertures; along the direction perpendicular to the scanning direction, the apertures of a domain are offset to each other by multiple integers of the effective width (w), whereas the offsets of apertures of different domains are integer fractions of that width.

Owner:IMS NANOFABTION

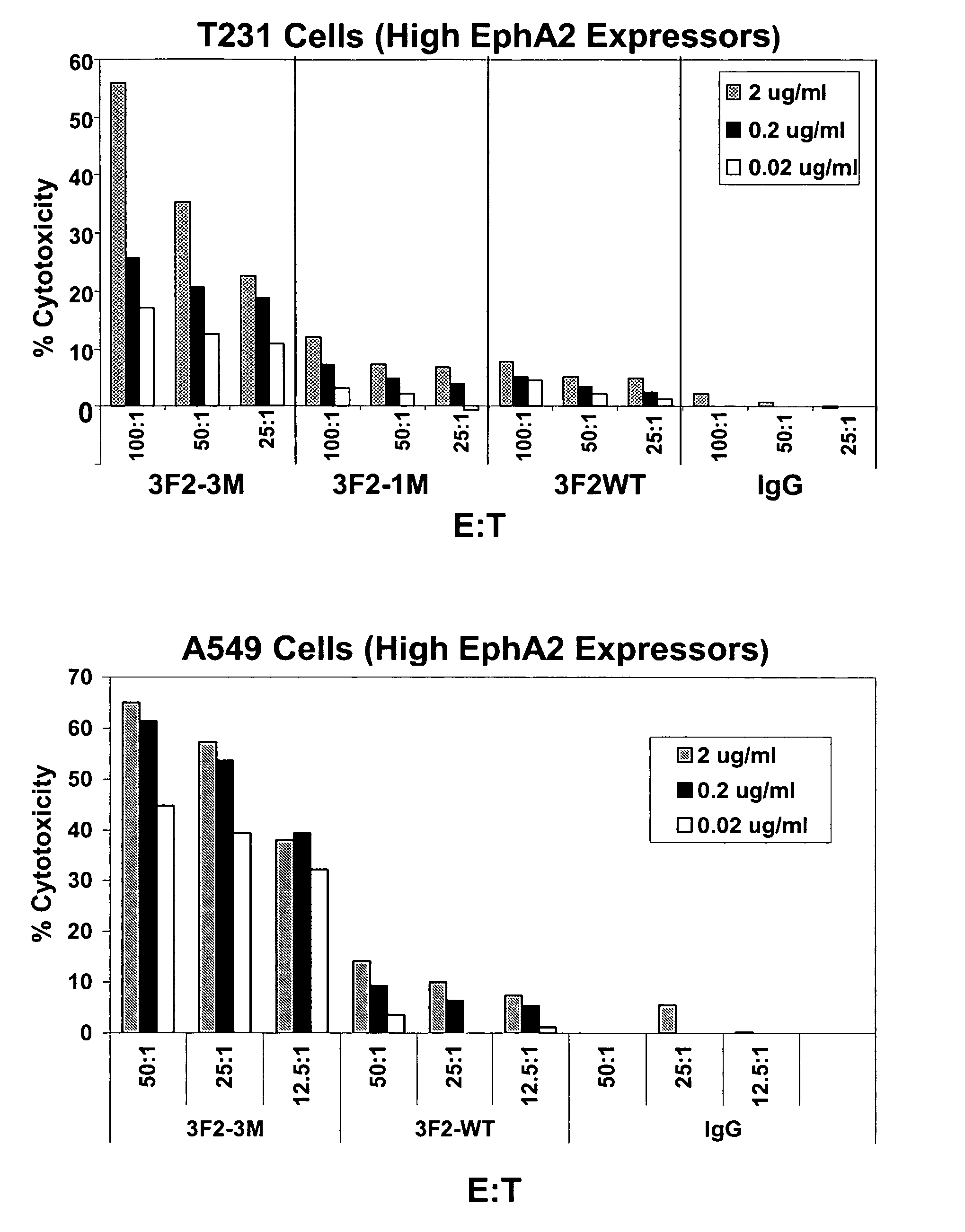

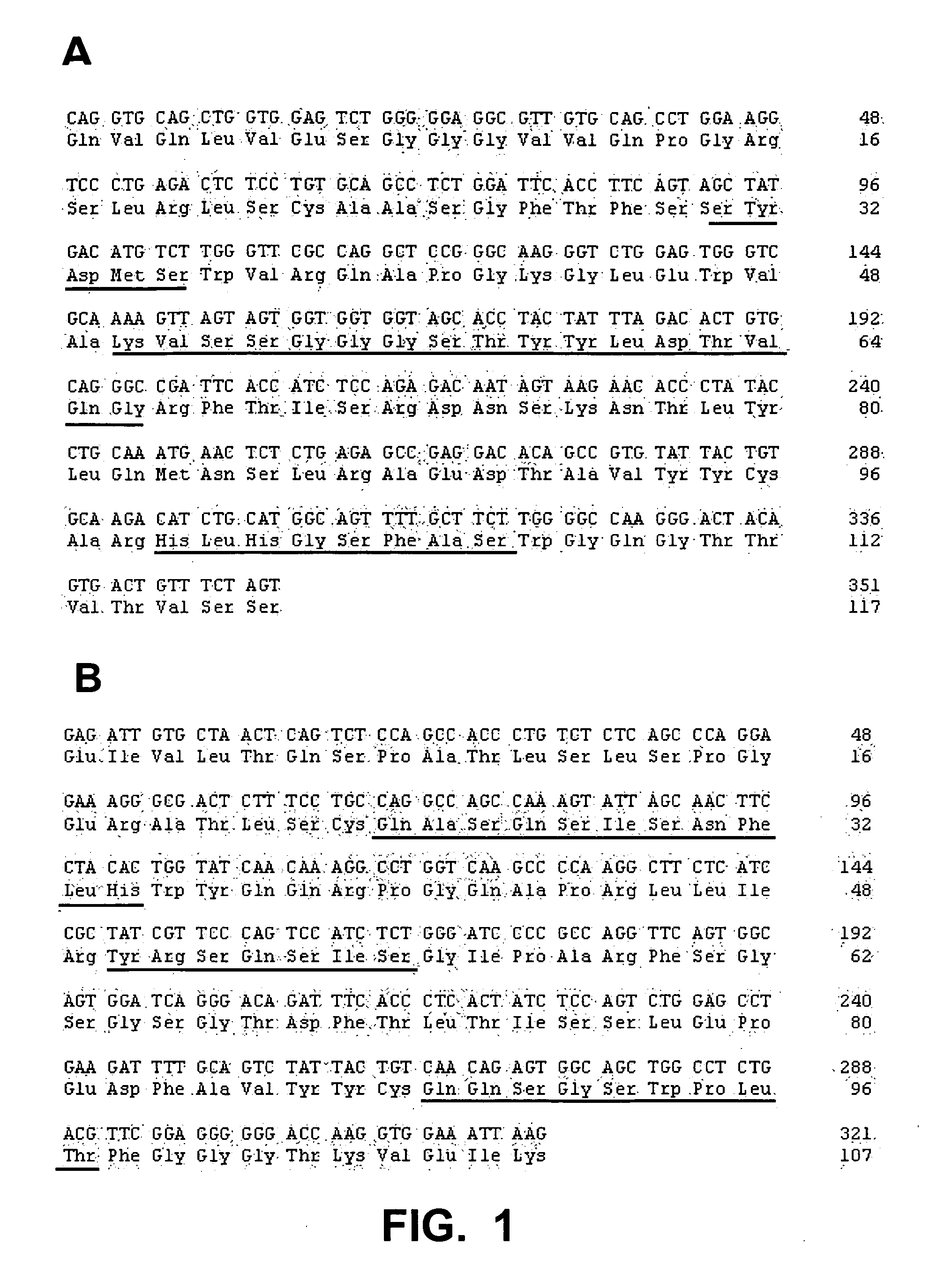

EPH receptor Fc variants with enhanced antibody dependent cell-mediated cytotoxicity activity

InactiveUS20060039904A1Altered binding affinityHigh binding affinityCompound screeningApoptosis detectionComplement-dependent cytotoxicityReceptor

The present invention relates to novel Fc variants that immuno-specifically bind to an Eph receptor. The Fc variants comprise a binding region that immunospecifically binds to an Eph receptor and an Fc region that further comprises at least one novel amino acid residue which may provide for enhanced effector function. More specifically, this invention provides Fc variants that have modified binding affinity to one or more Fc ligand (e.g., FcγR, C1q). Additionally, the Fc variants have altered antibody-dependent cell-mediated cytotoxicity (ADCC) and / or complement dependent cytotoxicity (CDC) activity. The invention further provides methods and protocols for the application of said Fc variants that immunospecifically bind to an Eph receptor, particularly for therapeutic purposes.

Owner:MEDIMMUNE LLC

Eph receptor Fc variants with enhanced antibody dependent cell-mediated cytotoxicity activity

InactiveUS7659374B2Altered binding affinityHigh binding affinityCompound screeningApoptosis detectionComplement-dependent cytotoxicityImmunologic specificity

The present invention relates to novel Fc variants that immuno-specifically bind to an Eph receptor. The Fc variants comprise a binding region that immunospecifically binds to an Eph receptor and an Fc region that further comprises at least one novel amino acid residue which may provide for enhanced effector function. More specifically, this invention provides Fc variants that have modified binding affinity to one or more Fc ligand (e.g., FcγR, C1q). Additionally, the Fc variants have altered antibody-dependent cell-mediated cytotoxicity (ADCC) and / or complement dependent cytotoxicity (CDC) activity. The invention further provides methods and protocols for the application of said Fc variants that immunospecifically bind to an Eph receptor, particularly for therapeutic purposes.

Owner:MEDIMMUNE LLC

Dipping solution and preparing method thereof

InactiveCN1552794AImprove stabilityUnchangedSurface treatment compositionsWater solubleAqueous solution

An impregnating solution for preparing hydrocatalyst contains at least two metal components in VIB family and at least one metal component in VIII family. It is prepared through dissolving a water-soluble Mo-contained compound in water, and adding organic carboxylic acid, the compound containing metal in VIB family and the salt containing metal in VIII family. Its advantages are high stability and no irritative volatile component.

Owner:CHINA PETROLEUM & CHEM CORP +1

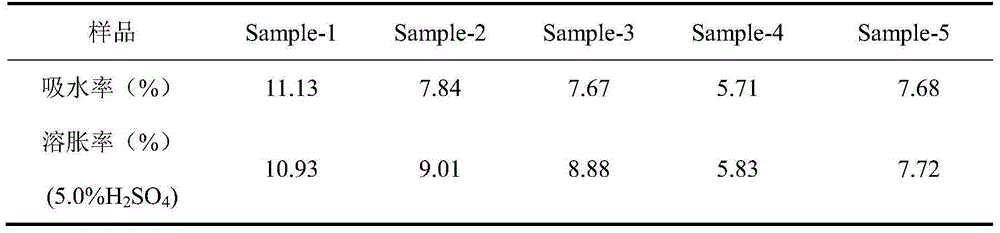

Synchronous grouting material used for tunnel and preparation method thereof

InactiveCN101928122AUnchangedImprove technical effectSolid waste managementCarboxymethyl celluloseHigh energy

The invention discloses a synchronous grouting material used for a tunnel and a preparation method thereof. The grouting material is the grout which is prepared by taking sediment grout as a main raw material, wherein the sediment grout comprises 30 to 65 percent of clay and fine sand totally and the weight ratio of soil to sand in the sediment grout is 0.1-0.18:1; and adding 80 to 120 kg of cement, 300 to 450 kg of coal ash, 200 to 500 kg of water or mud water and 3 to 10 kg of sodium carboxymethyl cellulose into per cubic meter of the sediment grout, wherein the grout density is between 1.85 and 2.05 g / cm<3> and the grout consistency is between 10.5 and 12 cm. In the preparation method, sediment and the mud water generated in a construction process are adopted as grouting materials, so that the sediment and the mud water can be changed into treasure from waste; and therefore, the preparation method has the characteristics of great reduction of the dosage of high-energy consumption cement, capability of working inside and outside tunnels, and convenient construction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Synergic reagent for separating glycolic acid from water solution containing inorganic salt and uses thereof

InactiveCN101264394AConstant sourceWide variety of sourcesLiquid solutions solvent extractionChemical recyclingInorganic saltsKerosene

The invention discloses a synergistic extract for separating glycollic acid from water solution with inorganic salt and the application, the components and the volume percentage are as follows: trioctylamine 30 to 70%, tributyl phosphate 5 to 30%, coal oil 5 to 40%, and octanol 5 to 40%. The synergistic extract has the advantages of excellent extraction and stripping separation performance for glycollic acid, good effect, less liability to emulsification, and low extractant loss.

Owner:EAST CHINA UNIV OF SCI & TECH

Reinforcing liquid and reinforcing method for protecting ancient silk fabric cultural relics

The invention discloses a reinforcing liquid for protecting ancient silk fabric cultural relics. The reinforcing liquid is a solution, which is formed by dissolving sodium caseinate and glutamine transaminase in a Tris-HCl buffering liquid, wherein the mass concentration of the sodium caseinate is 0.5-3.0%, the ratio between enzyme activity of the glutamine transaminase and mass of the sodium caseinate is 5-50 U / g; the pH value of the Tris-HCl buffering liquid is 6.0-8.0, and the concentration of the Tris-HCl buffering liquid is 0.05-0.5 M. According to the invention, as the sodium caseinate is catalyzed through the adoption of an MTG (Microbial Transglutaminase) enzyme to be polymerized on a silk fabric cultural relic main body so as to generate proteins with large molecular weights and a net-shaped structure is formed in a silk fiber, the mechanical strength is enhanced; and it is proved by experiments that a good effect of reinforcing silk fabric materials is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of fluorosilicone acrylate/epoxy resin polymer and application of polymer to protection of surfaces of stone cultural relics

InactiveCN105176004AEasy to operateGood storage stabilityNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionN-butyl acrylate

The invention belongs to the technical field of polymer material synthesis and relates to fluorosilicone polymer synthesis and modification and in particular relates to a preparation method of a fluorosilicone acrylate / epoxy resin polymer and an application of the polymer to protection of the surfaces of stone cultural relics. The composite emulsion with a core-shell structure is prepared by using modified silica sol as a core and epoxy resin (E-44), vinyl acetate (VAc), methyl methacrylate (MMA), n-butyl acrylate (BA) and hexafluorobutyl methacrylate (HFBMA) as shells and is applied to protection of the surfaces of the stone cultural relics. The preparation method disclosed by the invention has the beneficial effects that the preparation method is simple to operate; the obtained material has good storage stability, relatively low viscosity and good compatibility with stone, has excellent water and acid resistance and meets the requirements of stone application indexes; besides, a film of the obtained material has transparent appearance and does not change the original appearances of the cultural relics, thus satisfying the protection principles of not changing the original appearances of the cultural relics and restoring the old as the old.

Owner:JIANGSU UNIV

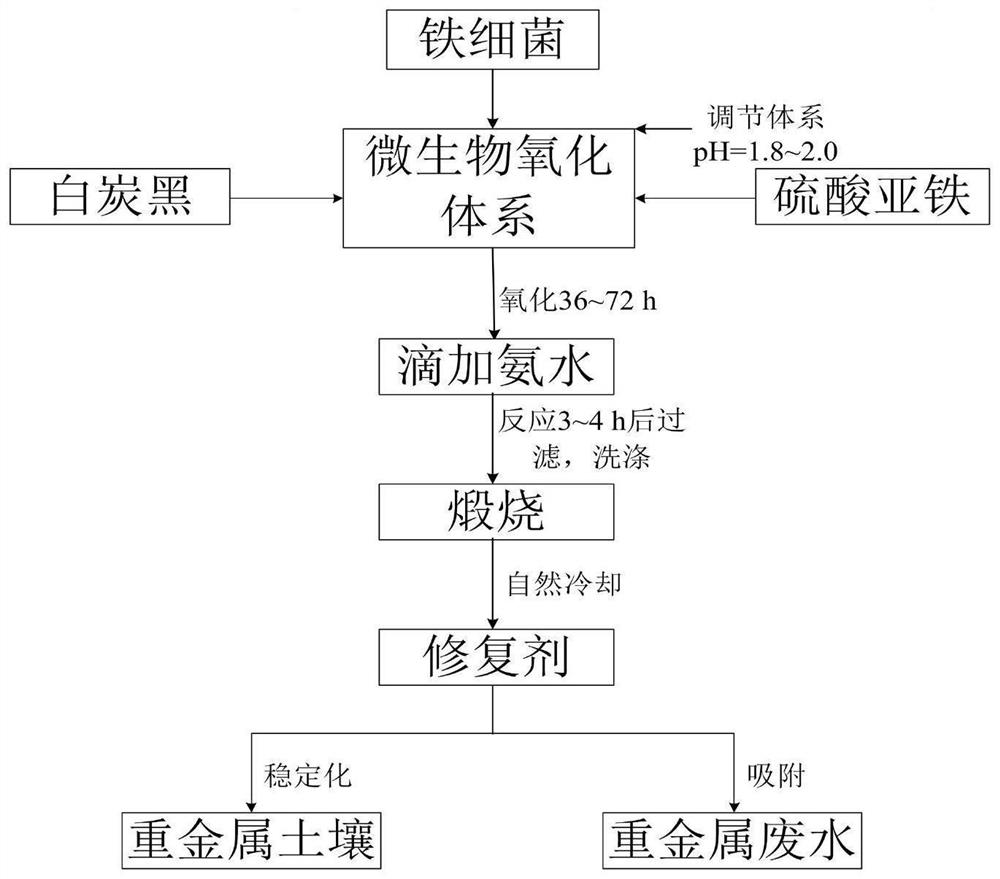

Biological heavy metal contaminated soil remediation agent as well as preparation method and application thereof

ActiveCN112342029ALarge specific surface areaGood dispersionWater contaminantsContaminated soil reclamationIron bacteriaAdsorption effect

The invention provides a biological heavy metal contaminated soil remediation agent as well as a preparation method and application thereof, and belongs to the technical field of heavy metal contaminated soil remediation. The preparation method comprises the steps of inoculating a template material with good stability and dispersibility and iron bacteria into a 9K culture medium, loading the surface and pores of the template material with the iron bacteria so as to add various active groups to the material and enhance the adsorption effect of the template material on metal ions, oxidizing ferrous ions into ferric ions under the action of the iron bacteria at the same time, and after reacting with ammonia water, calcining at high temperature to form the biological heavy metal contaminated soil remediation agent. The remediation agent has the adsorption performance of iron bacteria and iron oxide at the same time and has good dispersing performance. The adopted raw materials are environmentally friendly, the preparation process of the remediation agent is simple, the adsorption efficiency is high, and the effect of remediating soil or water contaminated by heavy metal arsenic and antimony for a long time can be achieved.

Owner:CENT SOUTH UNIV

Protective reinforcing liquid for ancient silk culture relics, preparation method and protective reinforcing method

The invention discloses a protective reinforcing liquid for ancient silk culture relics. The protective reinforcing liquid is prepared from the following raw materials in percentage by weight: 0.05-0.5% of alcohol ether carboxylate, 0.05-0.5% of sodium dodecyl benzene sulfonate, 0.08-0.12% of fatty alcohol-polyoxyethylene ether, 0.2-0.3% of cyclodextrin, 0.2-0.3% of isinglass, 0.1-0.2% of bletilla striata gum and the balance of deionized water. The invention further discloses a preparation method of the protective reinforcing liquid as well as a protective reinforcing method of the protective reinforcing liquid for the ancient silk culture relics. The reinforcing material has a good effect of reinforcing the ancient silk culture relics and can be directly applied before discovering silk culture relics excavated. The reinforcing material is completely penetrated and cured to form a protective film among fragile excavated silk culture relic layers which are overlaid in multilayers, so that the silk culture relic layers are not adhered, the original states of the excavated silk culture relics are not changed, and the reinforcing material is non-toxic and pollution-free.

Owner:UNIV OF SCI & TECH OF CHINA +1

Composite absorption filtering material contg. porous aerogel, and its preparation method

InactiveCN100400153CUnchangedOvercome the disadvantage of low mechanical strengthFiltration separationSilicon compoundsTrimethylsilyl chlorideFiber

Owner:TONGJI UNIV

Sampling device and method for mercury in high temperature flue gas

The invention relates to the field of mercury sampling in high temperature flue gas, in particular to a sampling device and a method for mercury in high temperature flue gas. The device comprises a sampling gun system, a condensation system, a flue gas flow control system, and a mercury test and analysis system. The sampling gun system comprises a sampling probe, a sampling tube I, a sampling tubeII, and a cooling water system provided outside the sampling tube I. The sampling probe is connected to the rear of the sampling tube I, and the sampling tube II is connected to the rear of the sampling tube I. The sampling probe comprises a top that is gradually smaller in size. An air inlet is provided at the top. The inner diameter of the air inlet is 0.05-0.1mm. The length of the top is 1-3mm. The sampling probe has a diameter of 0.5-1 mm. The diameter of the top gradually increases from the air inlet to the rear of the sampling probe. In the device of the invention, the front end of thesampling probe is designed as a structure with a gradually decreasing diameter. After the gas enters the structure, the sudden expansion of the space causes the gas to suddenly expand, thereby quenching the high-temperature flue gas, so that the properties of the high-temperature flue gas can remain unchanged.

Owner:NANJING UNIV OF SCI & TECH

Method for effectively reducing peroxidation value of nature fats

ActiveCN101717695ALow peroxide valueNo change in natureFatty acid chemical modificationSolubilityLowering plants

The invention provides a method for effectively reducing the peroxidation value of nature fats, such as vegetable fats, animal fats, fish oil, and the like. The method comprises the following steps of: mixing NaHSO3 solution with the mass concentration of 3-5 percent as a reducing agent with the natural fats under the oil temperature of 80-85 DEG C and then standing more than 6 hours, washing by adopting a NaCL and NaOH mixed water solution under the temperature of 83-84 DEG C after waste liquid is discharged, respectively washing once by using a NaCL water solution and filtered water, and dehydrating oil liquid in vacuum to obtain a qualified product. In the method for effectively reducing the peroxidation value of the nature fats, the additive NaHSO3 which is available for food is adopted as the reducing agent so as to generate NaSO4 with good solubility, and the addition amount of the reducing agent is less, thereby being easy to wash; the final product does not contain any additive; the invention is easy and reliable, simple in operation and low in cost, and especially suitable for treating the index rising of peroxide in the fats as unsaturated fatty acid in the fats is oxidized during the storage or the production of the fats; the fats treated by the method has unchangeable property and effective ingredients contained in the fats.

Owner:GUANGDONG YICHAO BIOLOGICAL

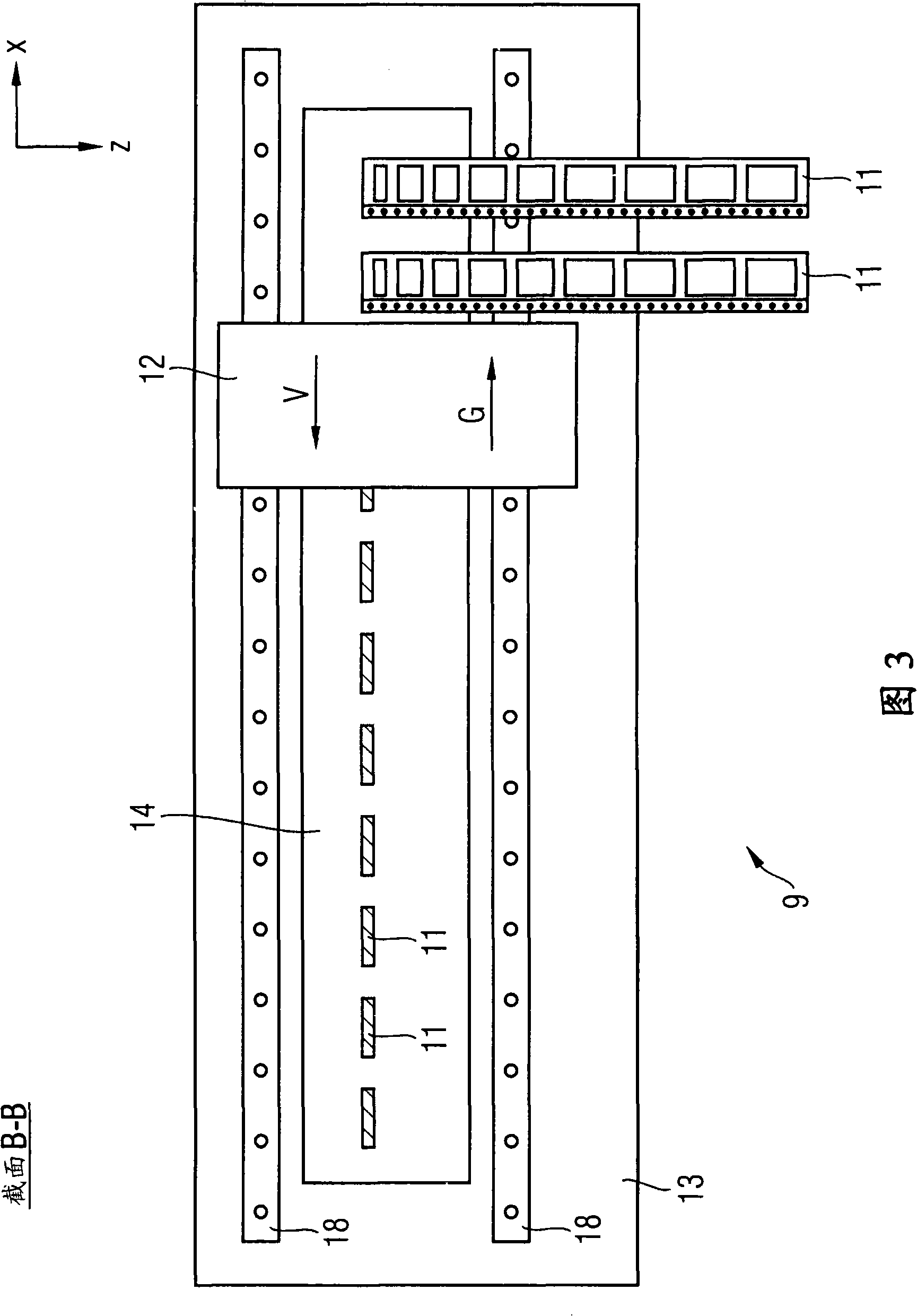

Cutting device for shortening component belts, supply device and automatic loader

InactiveCN101293356AImprove operational reliabilityAvoid stickingMetal working apparatusElectrical componentsEngineeringMechanical engineering

The cutting device for cutting the component belt (11) must be fitted to any cutting length agilely. A cutting device (9) is represented, including a housing (13), a belt passage (14) provided in the housing (13) for the component belt (11) cut short to penetrate in a convey direction (F) and a cutting device (12) moving along a moving direction (V) horizontal to appoint of the convey direction in the housing (13). The cutting device (12) includes a cutting unit (19) and a leaning unit (23), wherein the cutting device has a cutting piece (20) with a cutting blade (21) around capable of rotating and the leaning unit has a leaning piece (24), wherein the cutting unit (19) and the leaning unit (23) act such that the component belt (11) guided in the belt passage (14) is cut horizontal to the convey direction (F) when the cutting device (12) moves.

Owner:SIEMENS ELECTRONICS ASSEMBLY SYST LLC

Thermosetting organic coloring printing ink and stained paper for decorating silicate and metal base materials

ActiveCN101857743AEasy to operateUnchangedDecorative surface effectsSpecial ornamental structuresEpoxyCross-link

The invention discloses thermosetting organic coloring printing ink and stained paper for decorating silicate and metal base materials. The coloring printing ink comprises 20 and 30 weight percent of epoxy resin, 20 to 30 weight percent of cross-linking agent, 10 to 30 weight percent of organic pigment, 20 to 38 weight percent of solvent and 0.01 to 0.5 weight percent of aid. For the stained paper of the invention, thermosetting resin which is similar to epoxy resin materials is utilized, the thermosetting resin can be combined with a certain amount of cross-linking agent to generate a compound, and patterns of the stained paper can achieve the satisfactory effect of combining with utensil surfaces through the simple low-temperature curing treatment at the temperature of between 160 and 200 DEG C.

Owner:SHENZHEN YONG FENG YUAN IND

Composite modified asphalt for high-grade high road and preparation thereof

InactiveCN101508789BImprove stabilityAdd quick coverageBuilding insulationsDistillationMixed materials

Owner:WUHAN UNIV OF SCI & TECH

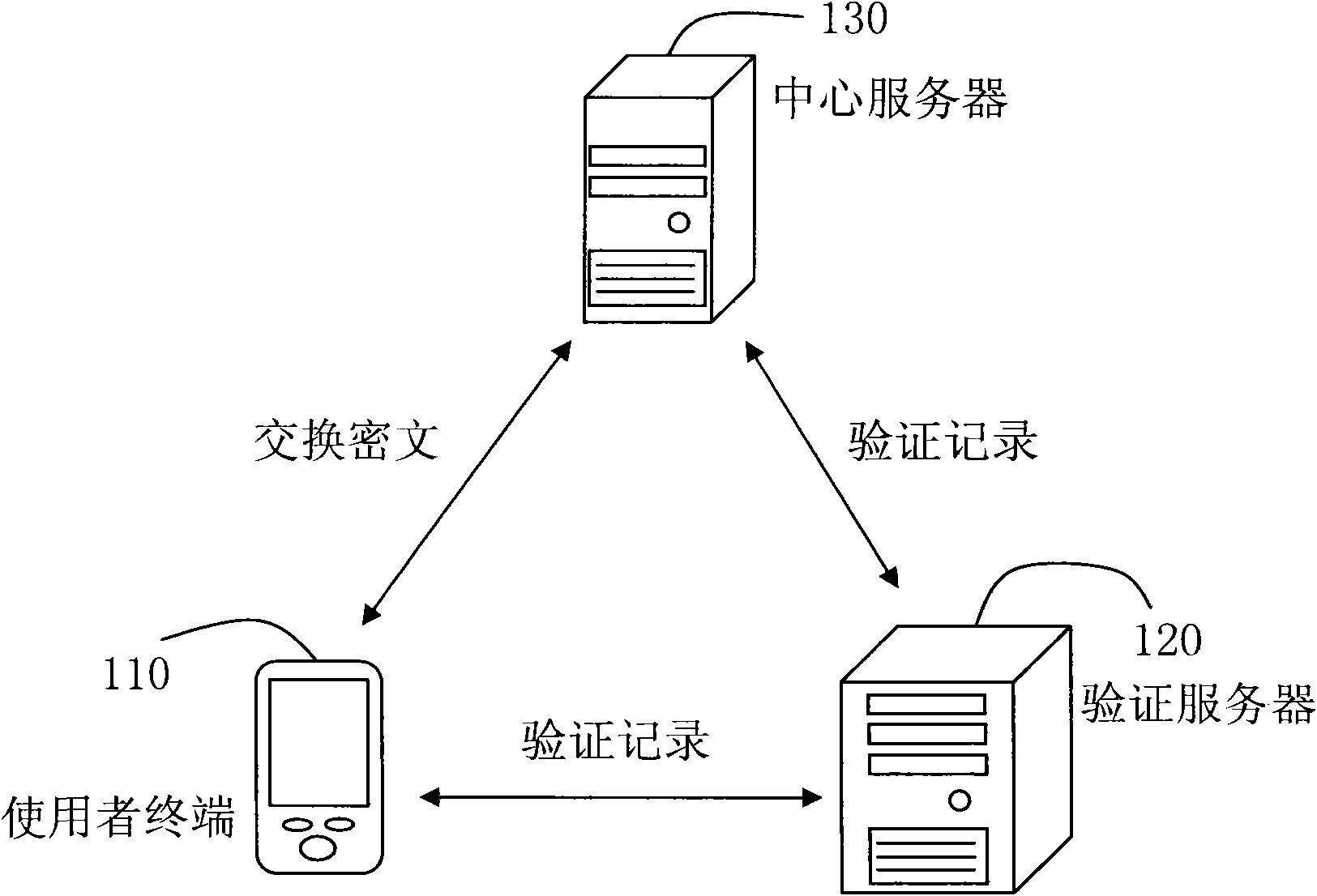

Recording system and method based on one-way hash function

InactiveCN101527631ADetect tampering recordsUnchangedUser identity/authority verificationDigital data protectionHash functionComputer terminal

The invention discloses a recording system and a method based on one-way hash function. The system comprises a user terminal, a center server and an authentication server. The method comprises that: the user terminal records a record file and initializes an information authentication key and a map code; when the authentication server requests the user terminal for a record unit corresponding to an operation course, the user terminal calculates a test value by using the one-way hash function, and transmits the test value and a map code sequence back to the authentication server; the authentication server authenticates the accuracy of the test value and the map code sequence through the center server; and the center server checks that a phase of the map code sequence acquired by hash calculation is equal to the test value through the one-way hash function so as to check that the record file of the user terminal is not subjected to modification.

Owner:IND TECH RES INST

Frozen addition agent containing trehalose, for aquatic products and using method of frozen addition agent

InactiveCN108684807AUnchangedGood rehydrationMeat/fish preservation by freezing/coolingOligosaccharide food ingredientsChemistrySeawater

The invention relates to a frozen addition agent containing trehalose, for aquatic products. The frozen addition agent can be used for frozen fresh aquatic products (comprising seawater fish and shrimps and freshwater fish and shrimps), frozen cooked fish and shrimps, frozen-fried shrimp meat and minced fillet and minced shrimp products. The preparation manner of the frozen addition agent lies inthat trehalose and algin oligosaccharide are compounded in different proportions, mucus on the surfaces of the fish and shrimps needing to be frozen is thoroughly cleaned, and then according to different kinds of the fish and shrimps, the frozen addition agent of different composition proportions is used for soaking or spraying or mixing, and then refrigeration is performed.

Owner:JIANGNAN UNIV

Valve

InactiveCN111433499AReduce wall thicknessImprove stabilityOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringMechanical engineering

The invention relates to a valve comprising a housing (1), a solenoid (5) arranged in the housing (1), a pin (7) that can be moved by the solenoid (5), a cup-shaped piston (8) which is connected to the pin (7), and a seal (14) arranged in the housing (1) for sealing the piston (8) against the housing (1). The seal (14) is a disk having a radially internal sealing surface (15), which is clamped atthe radially outer edge in the housing (12, 11).

Owner:CPT GRP GMBH

Recording system and method based on one-way hash function

InactiveCN101527631BDetect tampering recordsUnchangedUser identity/authority verificationDigital data protectionHash functionComputer terminal

The invention discloses a recording system and a method based on one-way hash function. The system comprises a user terminal, a center server and an authentication server. The method comprises that: the user terminal records a record file and initializes an information authentication key and a map code; when the authentication server requests the user terminal for a record unit corresponding to an operation course, the user terminal calculates a test value by using the one-way hash function, and transmits the test value and a map code sequence back to the authentication server; the authentication server authenticates the accuracy of the test value and the map code sequence through the center server; and the center server checks that a phase of the map code sequence acquired by hash calculation is equal to the test value through the one-way hash function so as to check that the record file of the user terminal is not subjected to modification.

Owner:IND TECH RES INST

Production process of insulating layer of railway signal cable

ActiveCN109054227AReduce brittlenessFast crosslinkingPlastic/resin/waxes insulatorsWater bathsNitrocellulose

The invention discloses a production process of an insulating layer of a railway signal cable, and relates to the field of signal cables. The production process comprises the steps of evenly mixing nano titanium dioxide modified polyvinyl chloride with dibutylhydroxytoluene, corundum modified polycarbonate and isoprene rubber, stirring by using a high speed mixer, then putting the obtained mixtureinto a potassium cyanide solution of basic copper carbonate and stirring, centrifuging, drying, and then adding a calcium chloride solution; adding tert-butyl-4-hydroxyanisole, dicumyl peroxide, acetic acid-nitrocellulose and 2-methyl methacrylate in a water bath; finally, adding boron fibers, nano-alumina and methyl methacrylate-n-butyl acrylate-sodium allyl sulfonate, carrying out ball milling,adding sesame oil, fumigating under saturated steam pressure, and sending to an extruder for extrusion molding. The prepared insulating layer is high in strength, good in aging resistance and corrosion resistance, and longer in service life.

Owner:ANHUI TIANCAI CABLE GRP

A production process of railway signal cable insulation layer

ActiveCN109054227BReduce brittlenessFast crosslinkingPlastic/resin/waxes insulatorsNitrocellulosePolyvinyl chloride

The invention discloses a production process for the insulating layer of railway signal cables, which relates to the field of signal cables; mixing nano-titanium dioxide modified polyvinyl chloride, dibutyl hydroxytoluene, corundum modified polycarbonate and isoprene rubber evenly, and using high-speed Stir with a mixer, then stir in the potassium cyanide solution of basic copper carbonate, centrifuge, add to the calcium chloride solution after drying, add tert-butyl-4-hydroxyanisole, dicumyl peroxide, Acetate-nitrocellulose and 2-methyl methacrylate are stirred, and finally boron fiber, nano-alumina and methyl methacrylate-n-butyl acrylate-sodium allyl sulfonate are added, ball milled, and saturated vapor pressure of sesame oil is added Medium fumigation, sent to the extruder for extrusion molding; the prepared insulating layer has high strength, good aging resistance, good corrosion resistance and longer service life.

Owner:ANHUI TIANCAI CABLE GRP

Synchronous grouting material used for tunnel and preparation method thereof

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

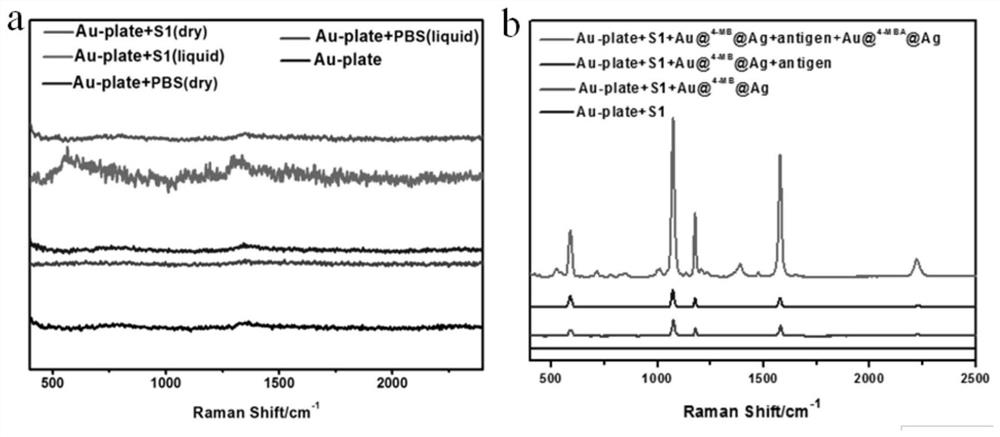

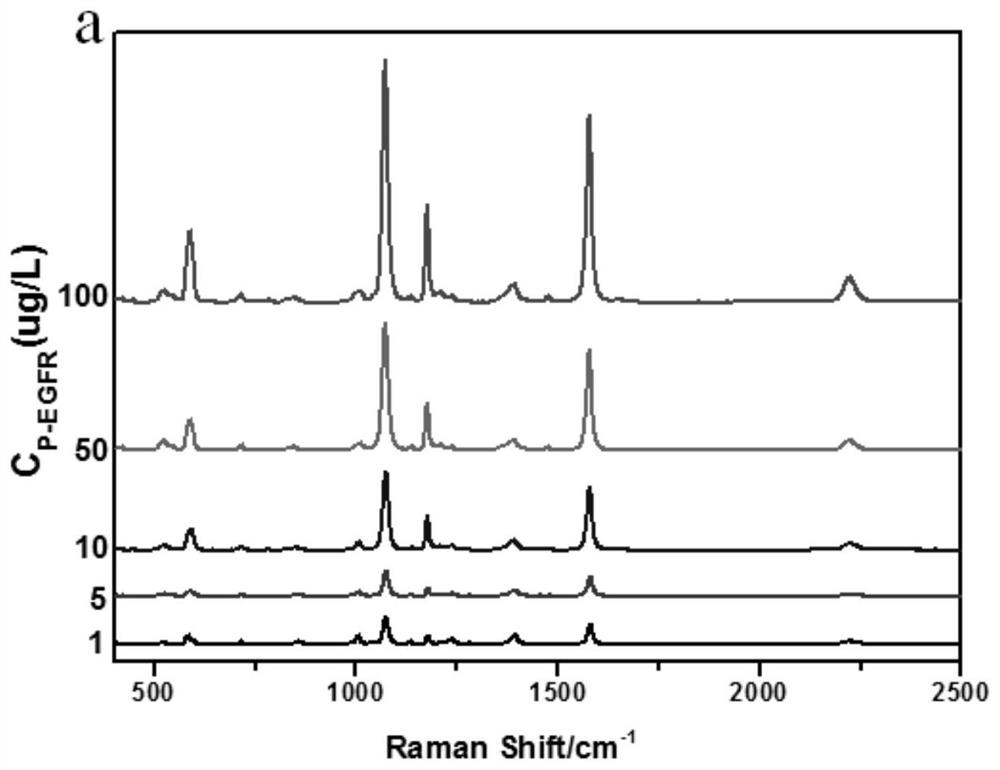

A method for constructing sers spectral probe to detect breast cancer marker EGFR phosphorylated tyrosine

ActiveCN110412291BHigh detection sensitivityGuaranteed reliabilityRaman scatteringBiological testingBio moleculesPhotochemistry

The invention discloses a method for constructing a SERS spectral probe to detect breast cancer marker EGFR phosphorylated tyrosine: a gold plate is used as a substrate, and core-shell structure nanoparticles are used as a substrate for SERS detection to develop high selectivity and high sensitivity A "sandwich" configuration probe molecule to detect the phosphorylation of breast cancer marker EGFR tyrosine. Using the 4‑MB Raman spectrum, the peak position in the Raman silent zone of biomolecules is 2221cm ‑1 The intensity of the SERS spectrum of the marker molecule was used as an internal standard to normalize the intensity of the spectral signal of the marker molecule 4-MBA, which can avoid the influence of the Raman signal in the biomolecular fingerprint region on the quantitative detection, and make the concentration of the EGFR phosphorylated tyrosine solution and the SERS intensity The linear relationship is greatly improved, further improving the detection sensitivity of the SERS spectral probe. 4-MB and 4-MBA are located in the middle layer between the gold core and the silver shell, which ensures that its properties, spatial structure and quantity remain unchanged, thereby ensuring the reliability of the data. The method of the present invention shows great potential in ultrasensitive detection of cancer markers.

Owner:FUJIAN NORMAL UNIV

Wood-plastic type engineering plastic composition

The invention discloses wood-plastic type engineering plastic composition. The composition comprises components in parts by weight as follows: 100-110 parts of polyvinyl chloride, 50-60 parts of wood flour, 3-5 parts of an acrylate type macromolecular copolymer ACR-401, 6-9 parts of a plasticizer, 1-3 parts of an anti-ageing aid and 5-7 parts of titanium dioxide. Through the scheme, the wood-plastic type engineering plastic composition is long in service life, properties are not changed after long-term use, replacement is not required, the cost can be reduced, and the composition has the very good elasticity modulus and very good physical and mechanical properties such as compression resistance, bending resistance and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Production process of winding layer of logging signal cable

ActiveCN108933005AImprove plasticityHigh strengthCommunication cablesCable/conductor manufactureWater bathsPolyvinyl chloride

The invention discloses a production process of a winding layer of a logging signal cable, and relates to the field of signal cables. The production process comprises the steps of firstly uniformly mixing nano-titanium dioxide modified polyvinyl chloride, polystyrene, corundum modified polycarbonate and isoprene rubber, putting the mixture into a high-speed mixer to mix, then adding a urea solution, putting the mixed solution into a closed environment filled with the mixture of hydrogen and nitrogen, filtering after standing, dissolving the precipitate in a calcium chloride solution, placing the solution in a water bath with the temperature being 35-45 DEG C, adding coconut oil fatty acid diethanolamide, dicumyl peroxide, zinc oxide and 2-methyl methacrylate into the solution, finally adding viscose fibers, nano-aluminum oxide and methyl methacrylate- n-butyl acrylate-sodium allylsulfonate, putting the mixture in sesame oil saturated vapor pressure for fumigation, recycling ethyl alcohol and sesame oil by vacuum concentration, and delivering the mixture to an extruding machine for extrusion molding. The prepared winding layer of the logging signal cable is high in strength, toughness and bending resistance, good in corrosion resistance and long in service life.

Owner:ANHUI TIANCAI CABLE GRP

A protection and reinforcement solution for ancient silk cultural relics, a preparation method and a protection and reinforcement method

The invention discloses a protection and reinforcement solution for ancient silk weaving cultural relics, which contains the following raw materials in the mass ratio: alcohol ether carboxylate: 0.05%-0.5%, sodium dodecylbenzenesulfonate 0.05%-0.05% 0.5%, 0.08-0.12% fatty alcohol polyoxyethylene ether, 0.2%-0.3% cyclodextrin, 0.2%-0.3% isingassing gum, 0.1%-0.2% bletilla striata gum, and the rest is deionized water. The invention also discloses a preparation method of the protection and reinforcement solution and a protection and reinforcement method when it is applied to ancient silk cultural relics. The reinforcing material of the present invention has a good effect of reinforcing the silk cultural relics, and can be directly applied before unearthing the unearthed silk cultural relics. After the reinforcing material of the present invention is fully infiltrated and solidified, a protective film can be formed between layers of fragile unearthed silk cultural relics, so that no adhesion occurs between layers of silk cultural relics, the original state of silk cultural relics is not changed, and it is non-toxic and pollution-free.

Owner:UNIV OF SCI & TECH OF CHINA +1

Dipping solution and preparing method thereof

InactiveCN1221632CImprove stabilityUnchangedSurface treatment compositionsCarboxylic acidWater soluble

An impregnating solution for preparing hydrocatalyst contains at least two metal components in VIB family and at least one metal component in VIII family. It is prepared through dissolving a water-soluble Mo-contained compound in water, and adding organic carboxylic acid, the compound containing metal in VIB family and the salt containing metal in VIII family. Its advantages are high stability and no irritative volatile component.

Owner:CHINA PETROLEUM & CHEM CORP +1

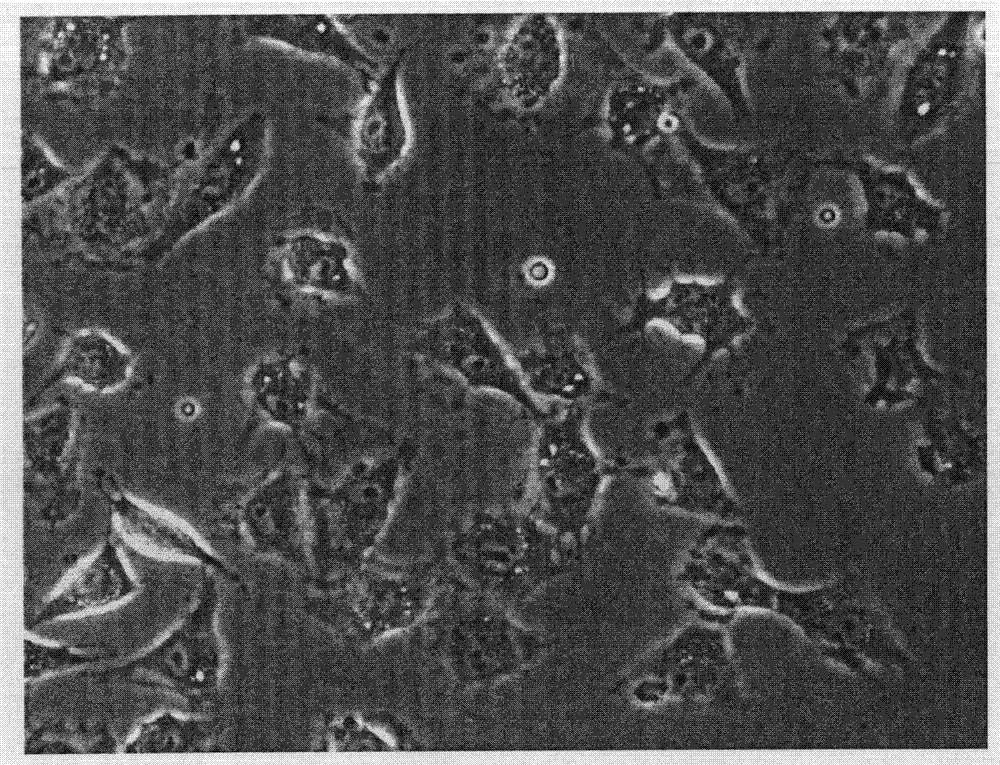

Chordoma cell line and application thereof

InactiveCN102618499BUnchangedMicrobiological testing/measurementTumor/cancer cellsChordomaWilms' tumor

The invention discloses a chordoma cell line and application thereof and belongs to the field of oncobiology. The preservation number of a human chordoma cell line (BHC2) is CGMCC (China General Microbiological Culture Collection Center) NO: 5321. The cell line is obtained by separating culture in a chordoma tissue cut from a basicranial chordoma patient operation and is subjected to in vitro subculture for over 14 passages. The cell has the biological characteristics of a notochord-derived cell that the cells are physaliphores arrayed in a cord shape under an optical microscope and a large amount of cavity structures exist in cytoplasm under the transmission of an electron microscope; and the cells expresses various marker proteins of the notochord-derived cell, namely Brachyury, S100, Galectin-3 and Fascin-1. The cell has the tumor characteristic that chromosome is of a heteroploid karyotype; the percentages at each phase of a cell cycle are as follows: 51.3 percent at G1 phase, 23.6 percent at S phase, 25 percent at G2-M phase and the ratio of the G2 to the G1 is approximate to 2, and thus the cell proliferation feature of tumor cells is shown; and the cells obtain tumorigenesis ability after being injected into a nude mouse body. The chordoma cell line can be cultured in vitro for a long term and keeps the cell stability unchanged and is a powerful tool for researching a targeted chordoma tumor medicament.

Owner:BEIJING NEUROSURGICAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com