Cutting device for shortening component belts, supply device and automatic loader

A technology of automatic assembly device and cutting equipment, applied in the direction of electrical components, electrical components, metal processing, etc., can solve the problems such as bending and problems of cutting knives or beam-type blades, improve operation reliability, and avoid dust particles. Accumulation, contamination minimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

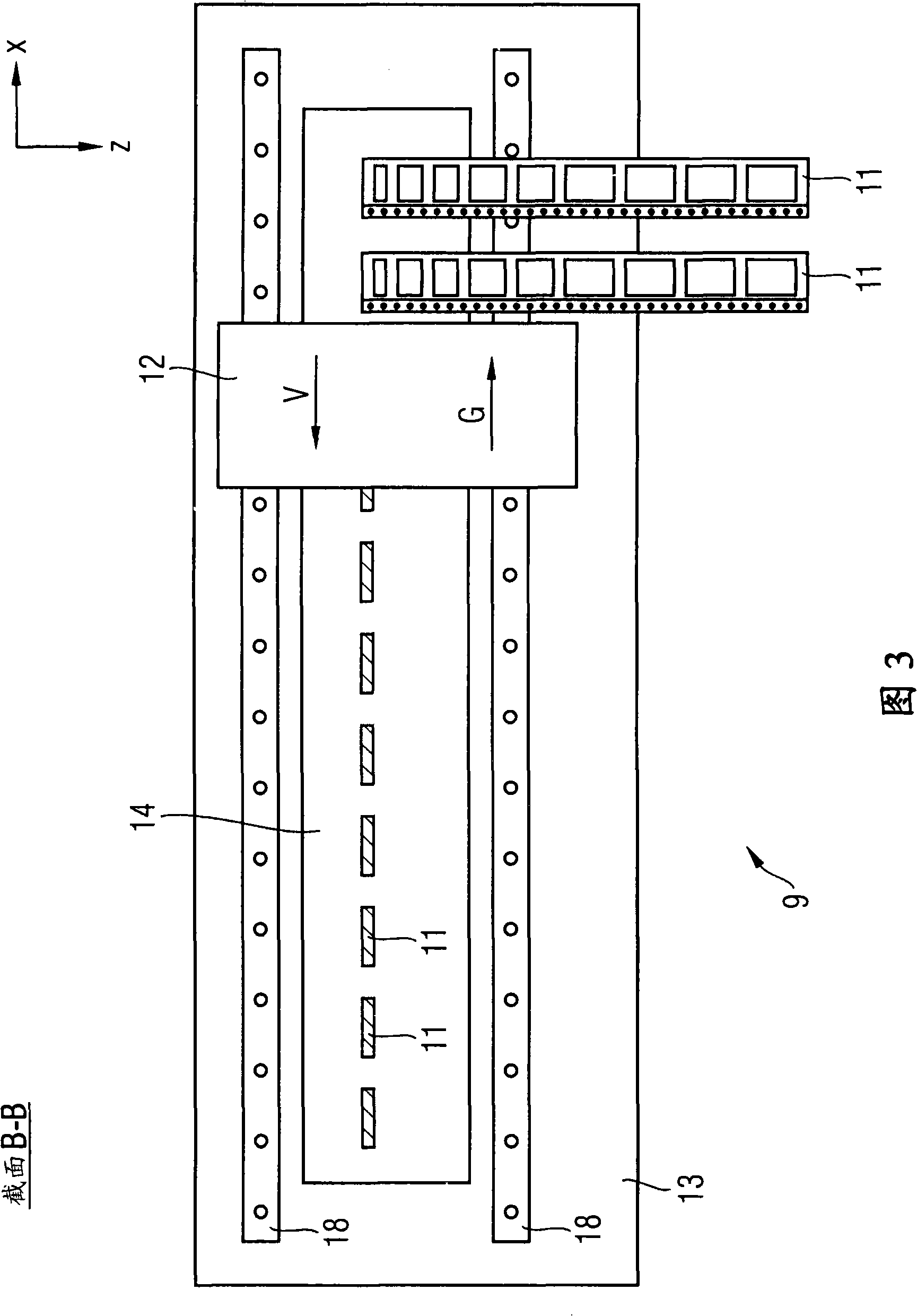

[0051] FIG. 1 schematically shows an automatic assembly device 1 for assembling components 3 for a base plate 2 . The automatic assembly device is formed by a crossbeam 7 which extends in the y-direction and is fixedly connected to the machine frame. Arranged on the transverse beam 7 is a door arm 8 which extends in the x-direction and is fastened displaceably on the transverse beam 7 in the y-direction. Mounting head 6 is mounted displaceably in the x-direction on door arm 8 . Furthermore, a transport path 4 for transporting the substrate 2 to the assembly position is provided. In addition to the transport path 4 , a supply device 5 is arranged in the vicinity of the assembly position, at its defined pick-up position 10 the electronic components 3 in the component strip 11 are supplied. A cutting device 9 for cutting off empty component tapes 11 is arranged between the supply device 5 and the transport path 4 .

[0052] In order to assemble the substrate 2 , it is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com