Preparation method of fluorosilicone acrylate/epoxy resin polymer and application of polymer to protection of surfaces of stone cultural relics

A technology of fluorosilicone acrylate and epoxy resin, applied in the direction of epoxy resin glue, ester copolymer adhesive, adhesive type, etc. secondary damage, poor elasticity of inorganic materials, etc., to achieve good storage stability, excellent water resistance, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

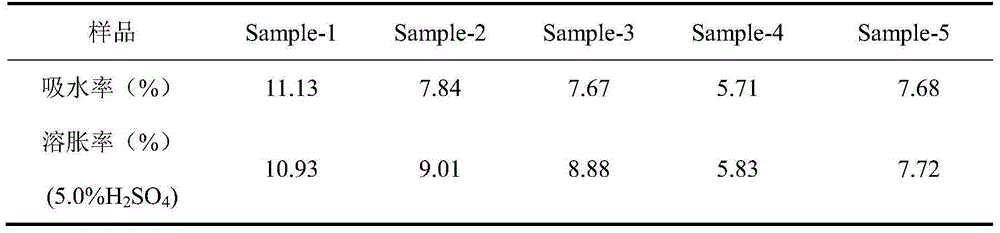

Examples

Embodiment 1

[0032] (1) Add 5mLTEOS, 20mL deionized water and 40mL absolute ethanol into a 250ml three-neck flask, stir and mix evenly, adjust the pH to 3 with hydrochloric acid, stir and react at 30°C for 2h; then raise the temperature to 60°C , add 1.86g of KH-570, and continue to react for 3 hours to obtain KH-570 modified silica sol.

[0033] (2) Add 0.3524g of OP-10, 0.1762g of SDS, and 10g of deionized water in sequence into a 250mL four-necked flask equipped with a stirrer and a reflux condenser, and stir well and evenly. Dissolve 1.92g of E-44 into 1.6g of VAc, then add it into the three-neck flask, add 4.8g of MMA, 25g of BA, 1.28g of MAA and 0.64g of HFBMA into the three-necked flask, at 40°C Stir at high speed and pre-emulsify for 30 minutes to obtain a pre-emulsion.

[0034] (3) Add the remaining compound emulsifier 0.3524g of OP-10, 01762g of SDS and 11g of deionized water into a 250mL four-necked flask equipped with a mechanical stirrer, a reflux condenser, and a thermometer...

Embodiment 2

[0036] (1) Add 5mLTEOS, 20mL deionized water and 40mL absolute ethanol into a 250ml three-neck flask, stir and mix evenly, adjust the pH to 3 with hydrochloric acid, stir and react at 30°C for 2h; then raise the temperature to 60°C , add 1.86g of KH-570, and continue to react for 3 hours to obtain KH-570 modified silica sol.

[0037] (2) In a 250mL four-necked flask equipped with a stirrer and a reflux condenser, add 0.4695g of OP-10, 0.2347g of SDS, and 15g of deionized water in sequence, and stir well. Dissolve 3.2g of E-44 into 6.4g of VAc, then add it into the three-necked flask, add 12.8g of MMA and 8.97g of BA, 0.64g of MAA and 3.2g of HFBMA in the there-necked flask, 45 Stir at high speed at ℃, pre-emulsify for 40 minutes, and obtain a pre-emulsion.

[0038] (3) Add the remaining compound emulsifier 0.4695g of OP-10, 0.2347g of SDS and 18g of deionized water into a 250mL four-necked flask equipped with a mechanical stirrer, a reflux condenser, and a thermometer, and ad...

Embodiment 3

[0040] (1) Add 5mLTEOS, 20mL deionized water and 40mL absolute ethanol into a 250ml three-neck flask, stir and mix evenly, adjust the pH to 3 with hydrochloric acid, stir and react at 30°C for 2h; then raise the temperature to 60°C , add 1.86g of KH-570, and continue to react for 3 hours to obtain KH-570 modified silica sol.

[0041] (2) Add 0.705g of OP-10, 0.3525g of SDS, and 10g of deionized water in sequence into a 250mL four-necked flask equipped with a stirrer and a reflux condenser, and stir well and evenly. The E-44 of 4.8g is dissolved in the VAc of 4.96g, then it is added in the there-necked flask, the MMA of 7.07g and the BA of 15.7g, the HFBMA of the MAA of 0.8g and 1.92g are added in the there-necked flask, 60 Stir at high speed at ℃, pre-emulsify for 60 minutes, and obtain a pre-emulsion.

[0042] (3) Add the remaining compound emulsifier 0.705g of OP-10, 0.3525g of SDS and 11g of deionized water into a 250mL four-necked flask equipped with a mechanical stirrer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com