Steel corrugated shell and prestressed concrete composite beam and construction method thereof

A concrete and prestressed technology, applied in the direction of joists, girders, trusses, etc., to achieve good shear and seismic performance, overcome cracks, and prevent concrete cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

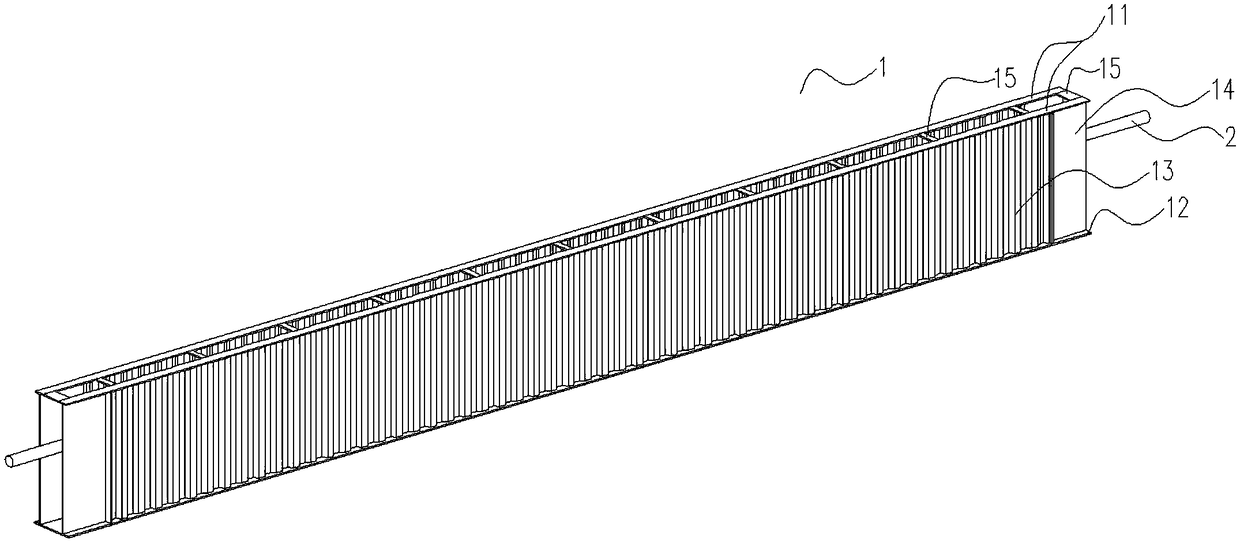

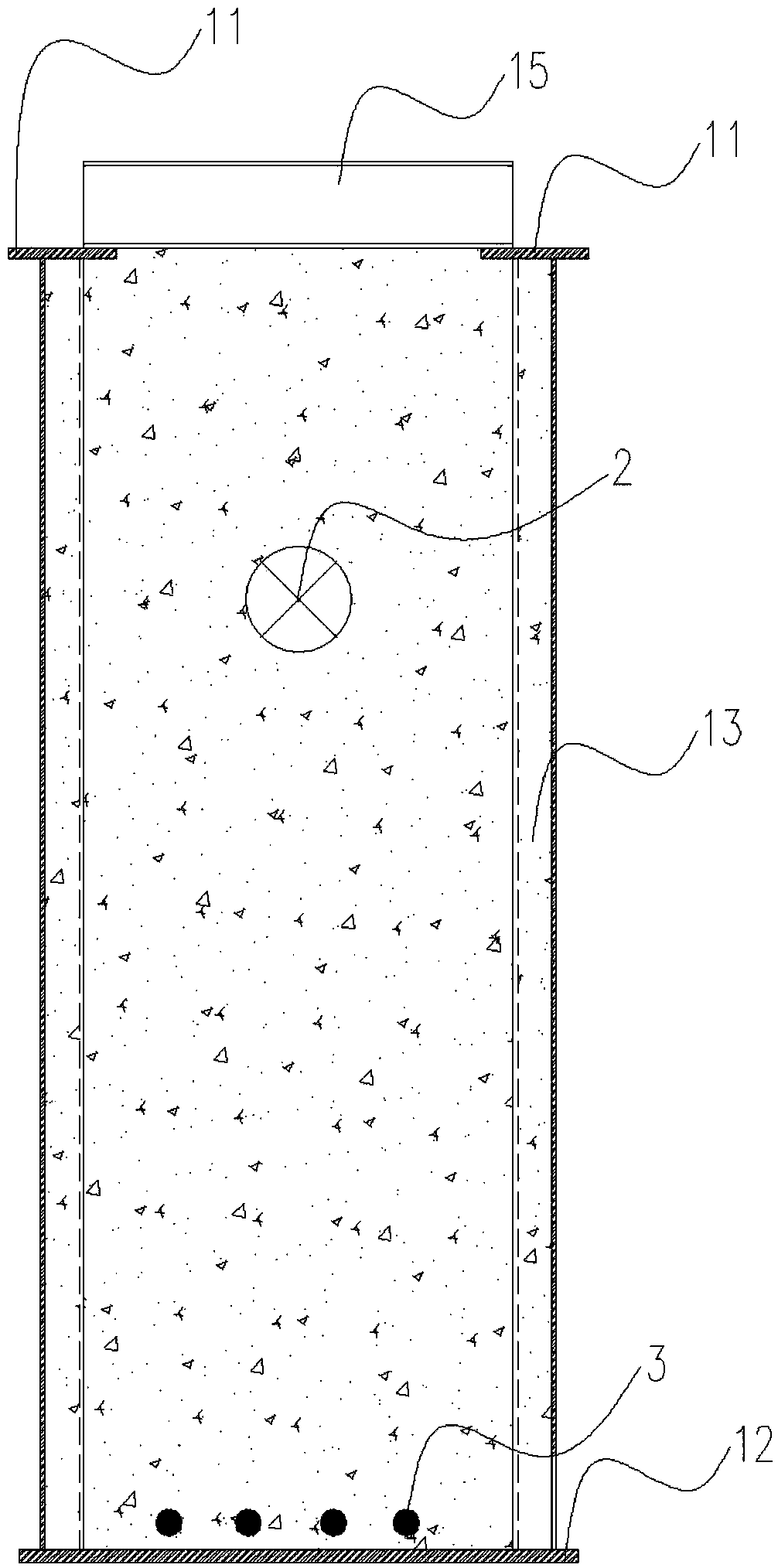

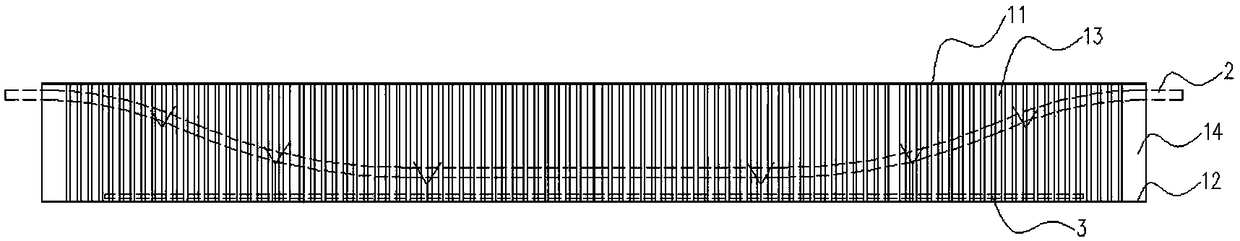

[0031] The present invention proposes a steel corrugated carapace and prestressed concrete composite beam, including a steel corrugated carapace 1, a prestressed steel strand 2 and a concrete layer, wherein the steel corrugated carapace 1 includes an upper flange 11, a lower flange 12, a corrugated belly Plate 13 and end web 14, two upper flanges 11 are arranged in parallel left and right, the upper flanges 11 are connected by at least one upper flange connector 15, two lower flanges 12 are arranged in parallel left and right, and the lower flanges 12 They are connected by at least one lower flange connector, the upper flange 11 and the lower flange 12 are arranged in parallel up and down, the corrugated web 13 is arranged between the upper flange 11 and the lower flange 12, and the end web 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com