Amphoteric ionic polymer water base fracturing fluid thickening agent and preparation method thereof

A zwitterionic, water-based fracturing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc. In order to avoid problems such as weak thickening ability, achieve high residue-free, strong shear stability, and high sand-carrying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 30 parts by mass of 40% 2-acrylamido-2-methylpropanesulfonate aqueous solution and 315 parts by mass of deionized water into the reactor, stir evenly, and then add 10 parts by mass of N,N-dimethylpropene Amide, 80 parts by mass of acrylamide, 5 parts by mass of methacryloyloxyethyltrimethylammonium chloride, 3 parts by mass of vinylpyrrolidone, 0.01 parts by mass of 2-acrylamidotetradecylsulfonic acid, 0.05 parts by mass EDTA disodium salt, and then adjust the pH of the reaction mixture to 6 with a 15% aqueous sodium hydroxide solution, transfer the reaction mixture to a polymerizer, heat up to 40°C, and add 0.05 mass ammonium persulfate and 0.05 parts by mass of sodium bisulfite, nitrogen gas until the oxygen is completely removed, react for 12 hours, dry and pulverize to obtain the zwitterionic polymer water-based fracturing fluid thickener.

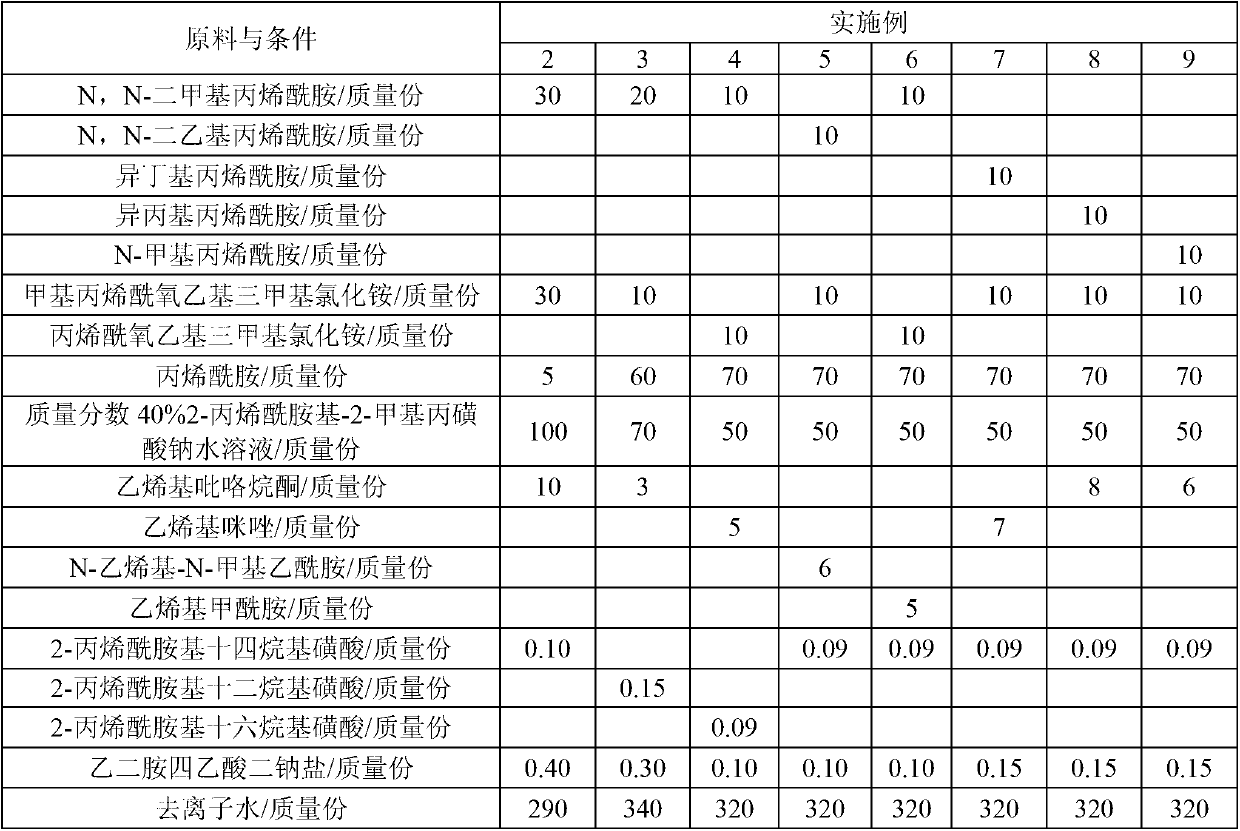

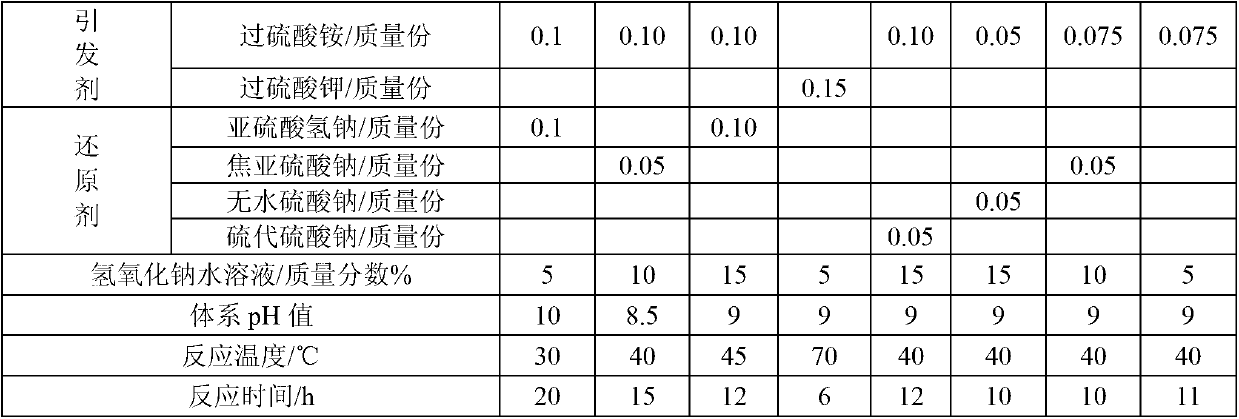

[0019] Embodiment 2~9 according to the method for embodiment 1, formula and condition see the following table:

[0020] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com