Cation-type hydrophobic association polymer and its preparation method and application

An associative polymer and hydrophobic association technology, which is applied in the field of environment and chemistry, can solve the problems of increasing sewage treatment costs and on-site construction difficulties, affecting the effect of crude oil electric dehydration, filter clogging, etc., and achieving good water treatment effects and products Good stability, strong adsorption and bridging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

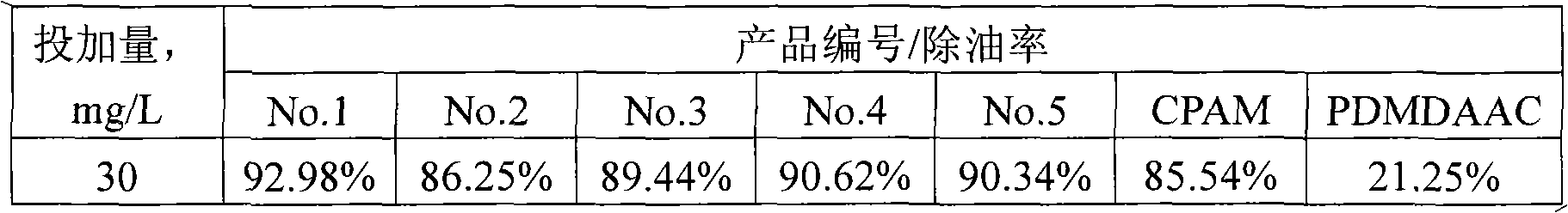

Examples

Embodiment 1

[0024] Add acrylamide, dimethyl diallyl ammonium chloride, cetyl trimethyl ammonium bromide, urea, deionized water into the reaction vessel, feed nitrogen and stir, then add butyl acrylate and initiator ( Potassium persulfate, sodium thiosulfate and azobisisobutyronitrile in a weight ratio of 2:1:1), after continuing to feed in nitrogen and stirring, react for 6 hours to prepare a cationic hydrophobic association polymer. Wherein the molar percentage of acrylamide and dimethyl diallyl ammonium chloride is 70:30, the weight ratio of cetyl trimethyl ammonium bromide is 0.5%, the urea content is 0.75%, reactant and deionized The weight percentage of water is 30:70, the mole percentage of butyl acrylate is 2%, and the initiator content accounts for 0.15% of the reaction monomer. The product is represented by No.1.

[0025] The specific preparation method is as follows:

[0026] (1) Add 14.80g of acrylamide and 14.42g of dimethyl diallyl ammonium chloride into the reaction vessel...

Embodiment 2

[0032] Add acrylamide, dimethyl diallyl ammonium chloride, cetyl trimethyl ammonium bromide, urea, deionized water into the reaction vessel, feed nitrogen and stir, then add butyl acrylate and initiator ( Potassium persulfate, sodium thiosulfate and azobisisobutyronitrile in a weight ratio of 2:1:1), after continuing to feed in nitrogen and stirring, react for 4 hours to prepare a cationic hydrophobic association polymer. Wherein the molar percentage of acrylamide and dimethyl diallyl ammonium chloride is 40:60, the weight ratio of cetyl trimethyl ammonium bromide is 0.5%, the urea content is 0.75%, reactant and deionized The weight percentage of water is 30:70, the mole percentage of butyl acrylate is 2%, and the initiator content accounts for 0.15% of the reaction monomer. The product is represented by No.2.

[0033] The preparation method was the same as in Example 1, but the difference was that the added acrylamide was changed to 6.66 g, the dimethyl diallyl ammonium chlo...

Embodiment 3

[0036] Add acrylamide, dimethyl diallyl ammonium chloride, cetyl trimethyl ammonium bromide, urea, deionized water into the reaction vessel, feed nitrogen and stir, then add butyl acrylate and initiator ( Potassium persulfate, sodium thiosulfate and azobisisobutyronitrile in a weight ratio of 2:1:1), after stirring with nitrogen gas, react for 8 hours to prepare a cationic hydrophobic association polymer. Wherein the molar percentage of acrylamide and dimethyl diallyl ammonium chloride is 70:30, the weight ratio of cetyl trimethyl ammonium bromide is 0.5%, the urea content is 0.75%, reactant and deionized The weight percentage of water is 20:80, the molar percentage of butyl acrylate is 2%, and the initiator content accounts for 0.15% of the reaction monomers. The product is represented by No.3.

[0037] The preparation method is the same as in Example 1, but the difference is that the added acrylamide is changed to 9.87g, the dimethyl diallyl ammonium chloride is changed to 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com