Circular mold pelletizer

A granulator and ring die technology, applied in the direction of die extrusion granulation, etc., can solve the problems of poor overload protection capability, rising production cost, poor material feeding, etc. The effect of smooth material feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

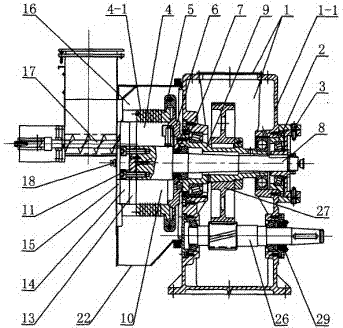

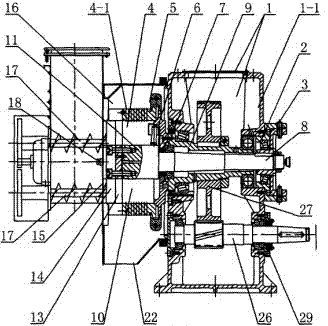

[0024] Such as figure 1 and figure 2 as well as Figure 5 to Figure 7 As shown, a ring die granulator includes a granulator host 1, a host safety pin seat 2, a safety pin 3, a ring die 4, a hoop 5, a transmission wheel 6, a bearing 7, a main shaft 8, and an empty shaft of the host 9. Press roller assembly 10, spindle press plate 13, cutter 28 and door cover 16, also includes gear shaft 26 connected with power, also includes forced feeder 17, material inlet 21 and material outlet 22 , also includes a partition plate 14 and a door cover pressing plate 15, and also includes a mold roller gap adjustment mechanism 31. One end of the door cover 16 is connected with the box body 1-1 of the main machine 1 of the granulator through a door hinge 19, and the other end is connected with the box body 1-1 through a door lock 12. The discharge port 22 is arranged at the lower end of the door cover 16 . The door cover 16 can rotate around the casing 1-1 of the granulator host 1 through a...

Embodiment 2

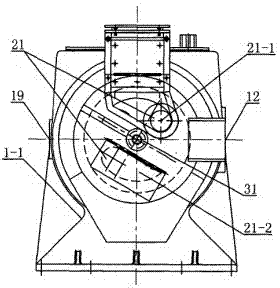

[0028] Such as image 3 and Figure 4 as well as Figure 5 to Figure 7 As shown, a ring die granulator, the structure of the ring die granulator of this embodiment is basically the same as that of Embodiment 1, the difference is: (1) the upper feed port 21-1 and the lower feed port 21 -2 Compulsory feeders 17 are arranged at the opposite places of the two feeding ports. That is to say, the ring die granulator in this embodiment is provided with two forced feeders 17, one forced feeder 17 is opposite to the upper feed inlet 21-1, and the other forced feeder 17 is connected to the lower feeder. Mouth 21-2 relative. The two forced feeders 17 can force feed the pressing chamber through the two feeding ports 21 at the same time, so that the production efficiency is greatly improved. (2) The eccentric shaft 25 of the pressure roller is connected to the gap adjustment wheel 24 through a gear type, and the central shaft 20 and the center wheel 23 are also connected through a splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com