Arrow-shaped check valve

A check valve, arrow-shaped technology, applied in the direction of wellbore/well valve device, wellbore/well parts, sealing/packing, etc., can solve the problems of affecting spring life, short service life, waste of energy, etc., to achieve The effect of prolonging the service life, improving the service life and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

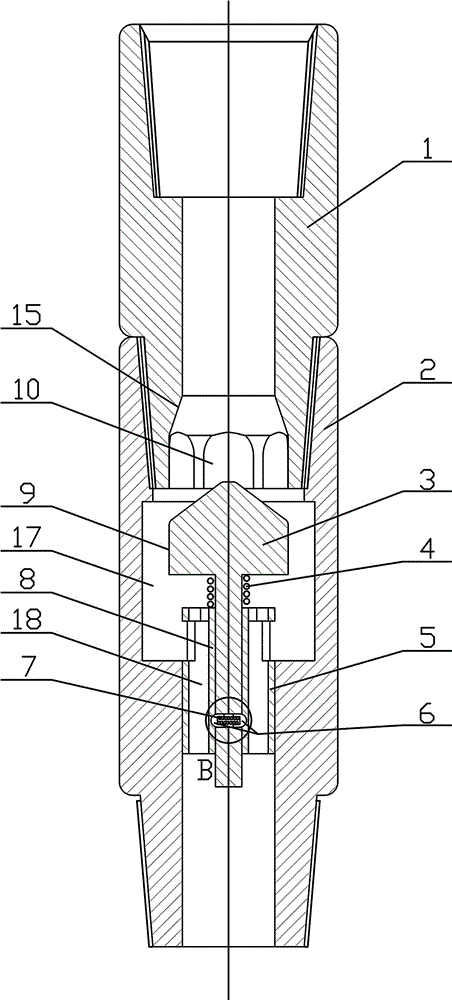

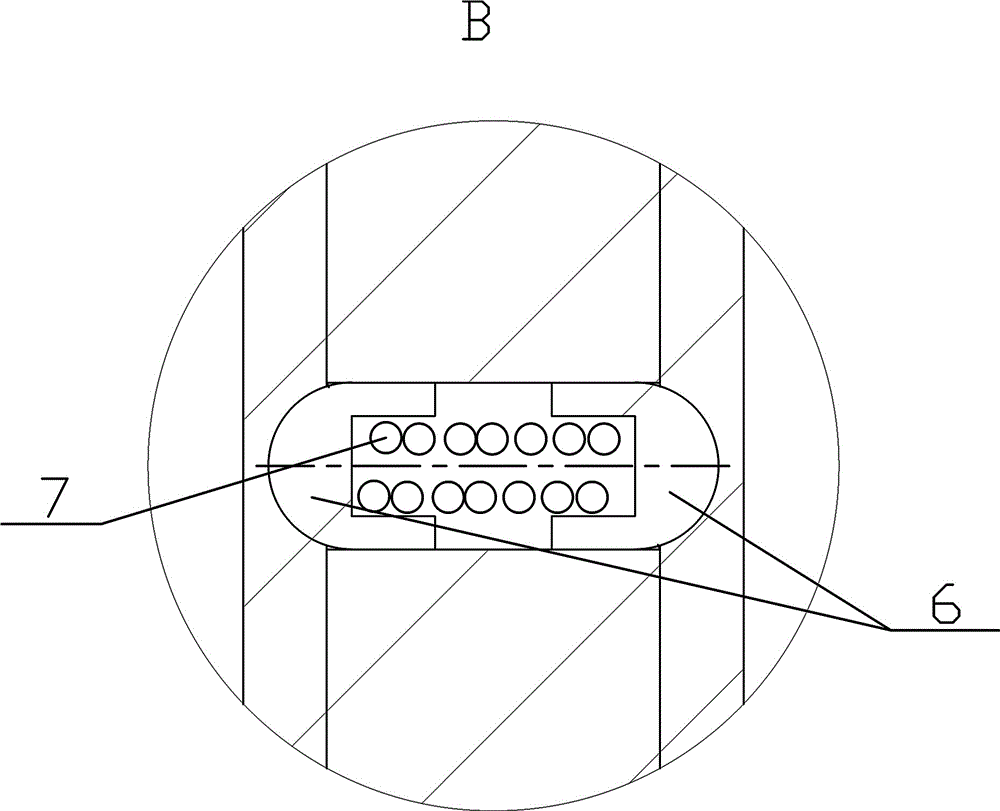

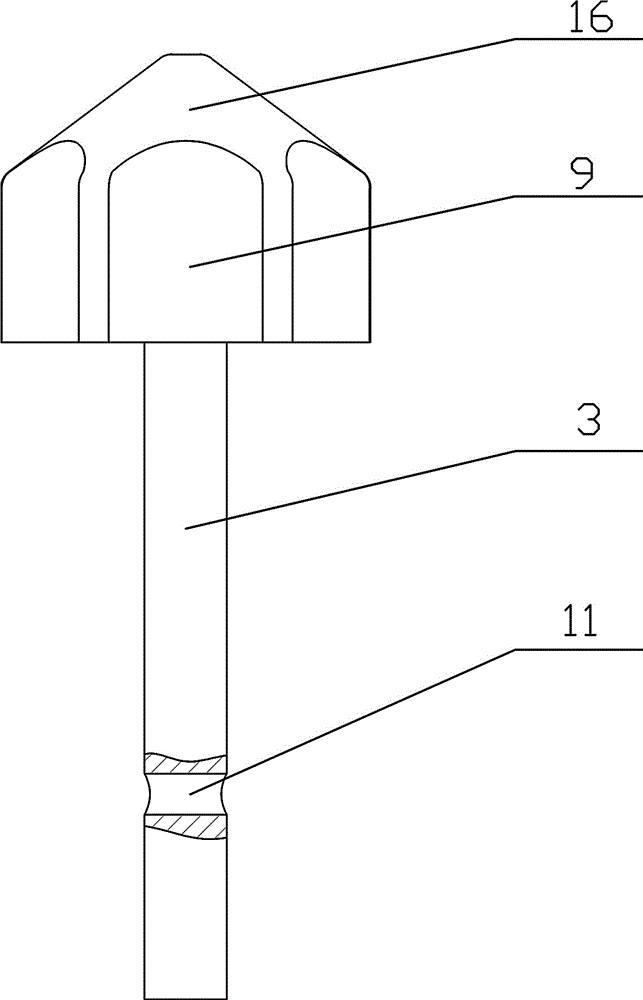

[0030] like Figure 1~6 Among them, an arrow-shaped check valve, including an upper valve body 1 and a lower valve body 2 connected to each other, the upper valve body 1 is provided with a through hole, and the bottom of the through hole is sequentially provided with a cone that expands in diameter relative to the through hole. Shaped surface 15 and first splined surface 10;

[0031] In the lower valve body 2, there is an arrow-shaped spool 3 that slides axially along the lower valve body 2, and the top of the arrow-shaped spool 3 is provided with a conical frustum 16 that is sealingly matched with the conical surface 15, and is connected with the first spline surface 10. The second splined face 9 for a sealing fit.

[0032] In a preferred solution, the first splined surface 10 is a cylindrical through-hole with a plurality of arc-shaped protrusions or depressions on the inner wall. In this example, a structure in which the inner wall of the through hole is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com