Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Big hit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

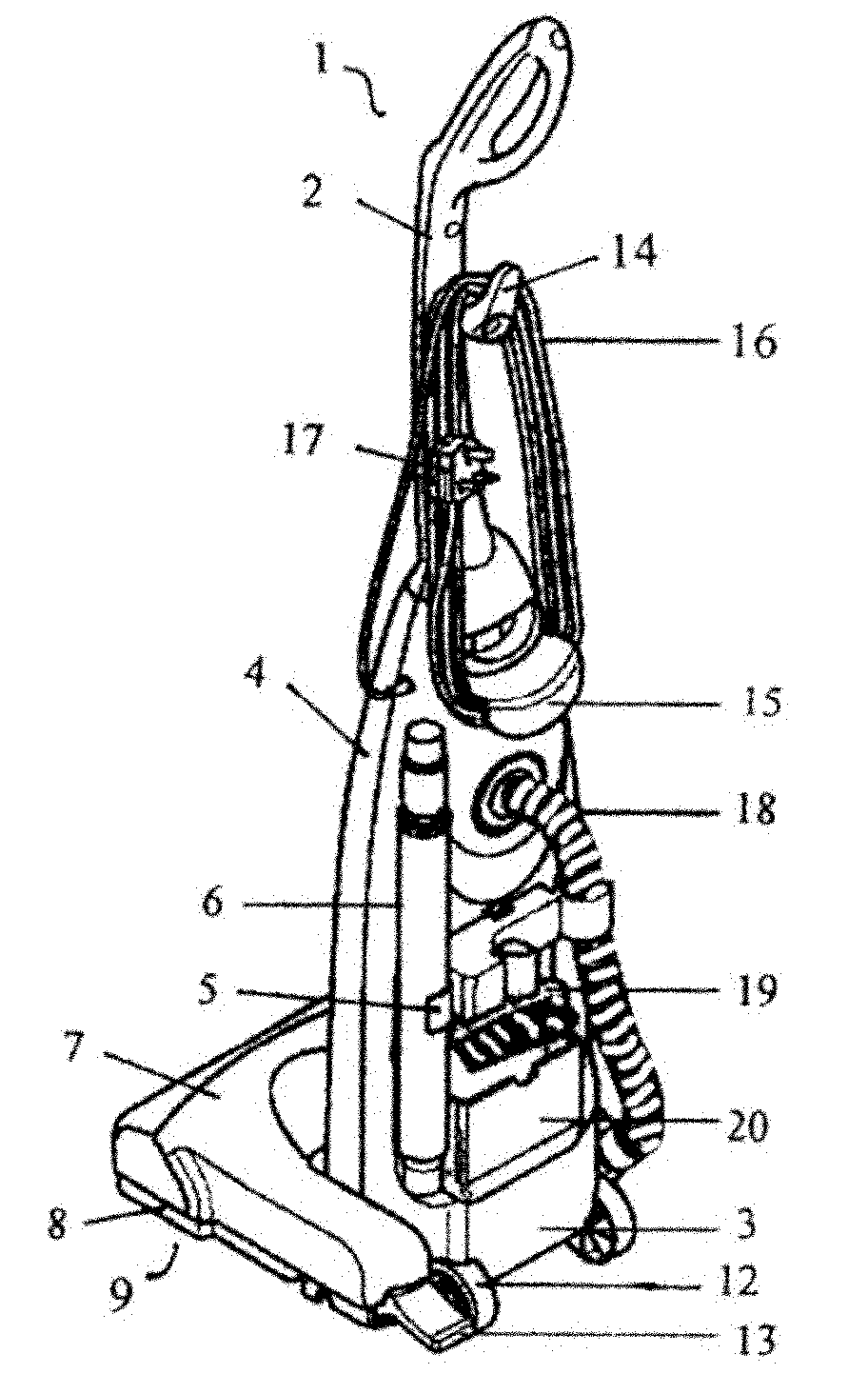

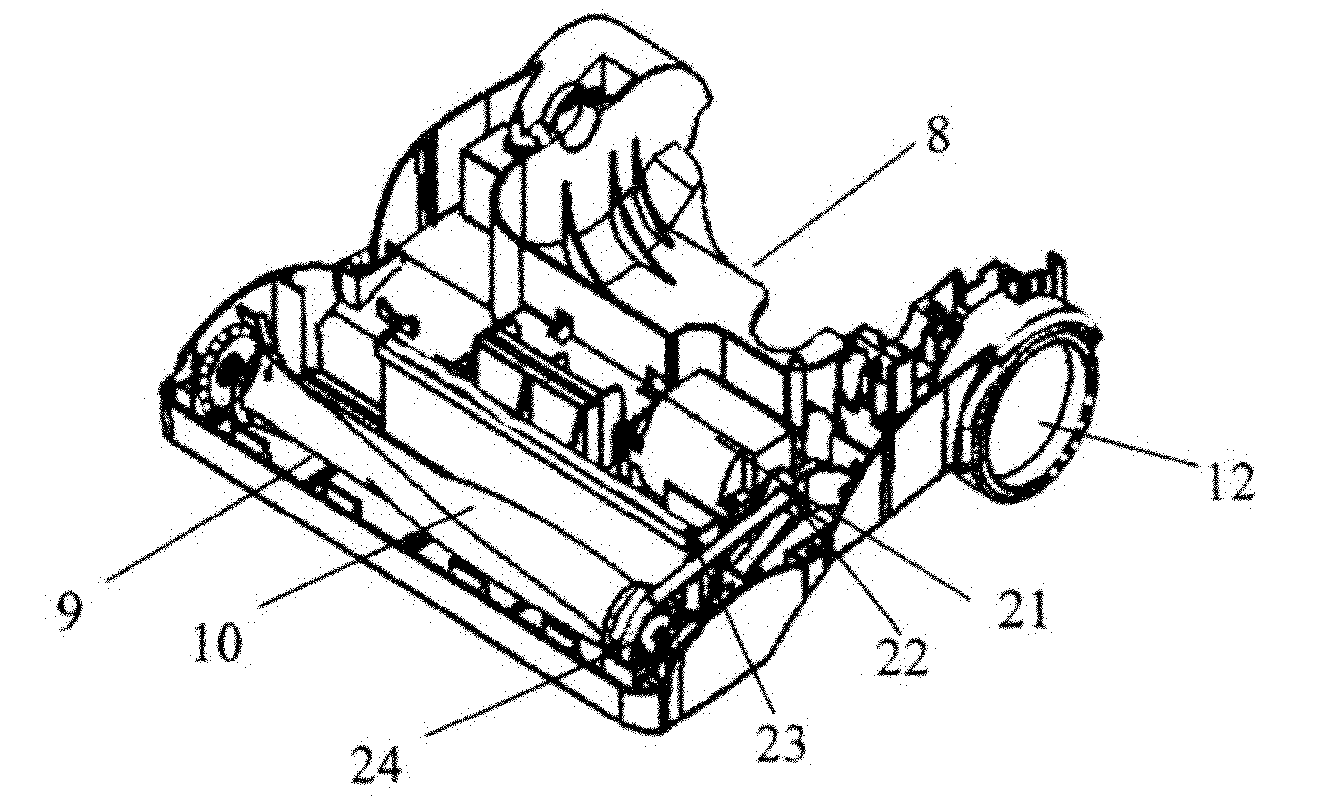

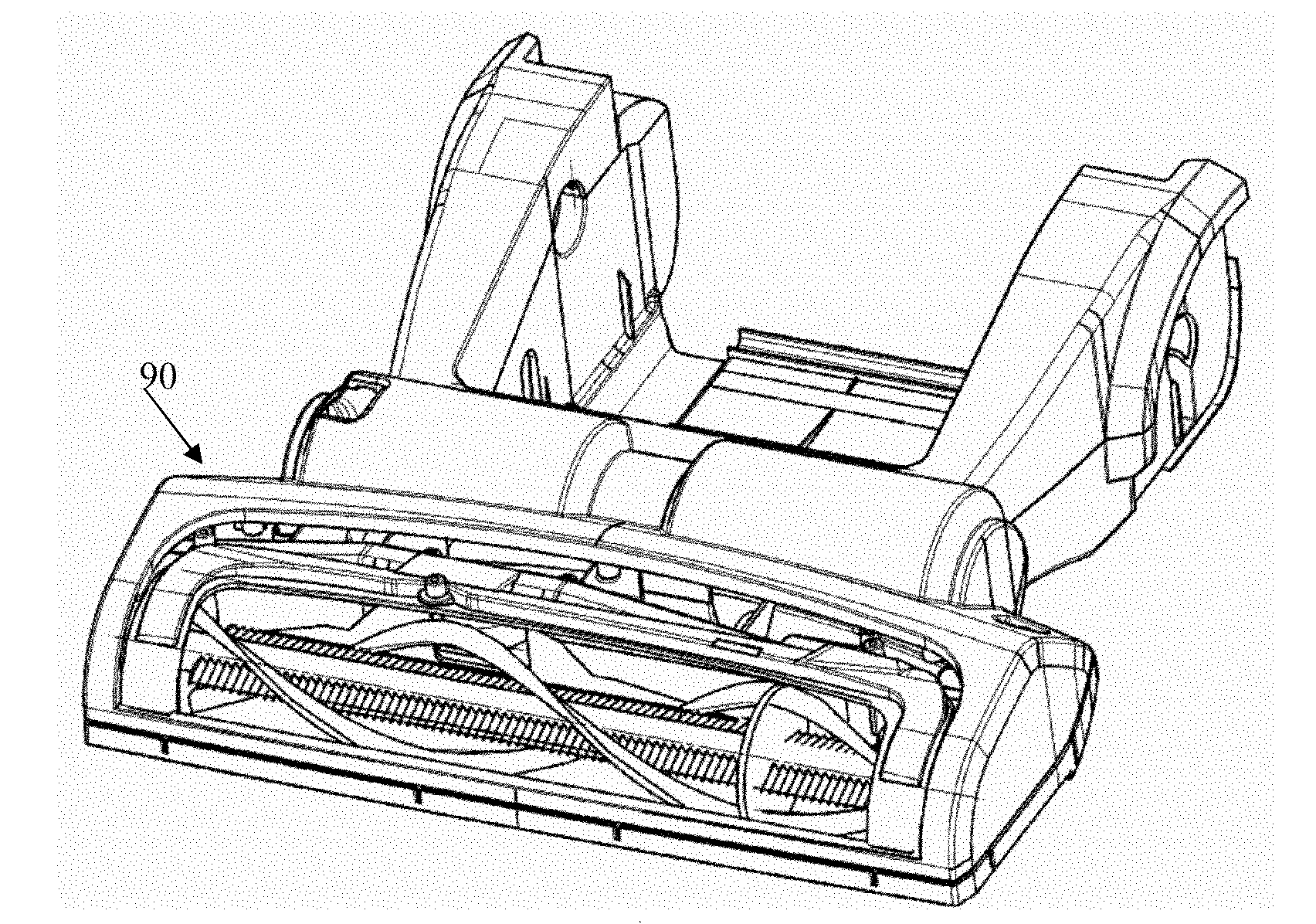

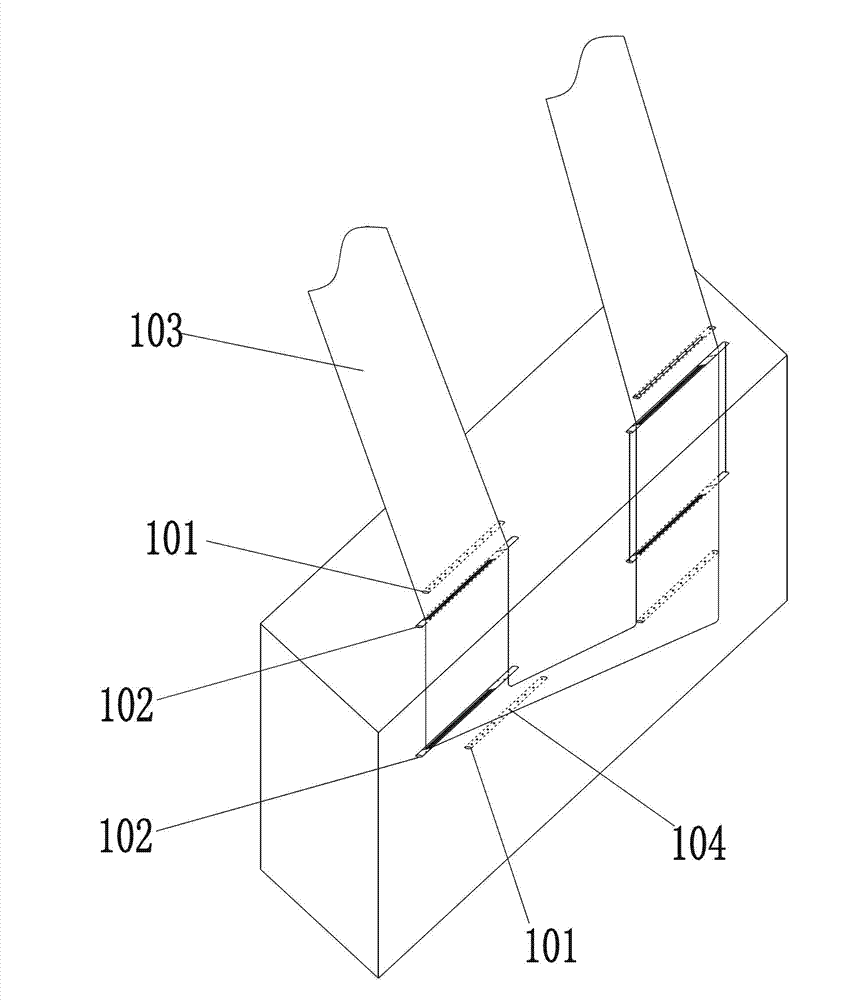

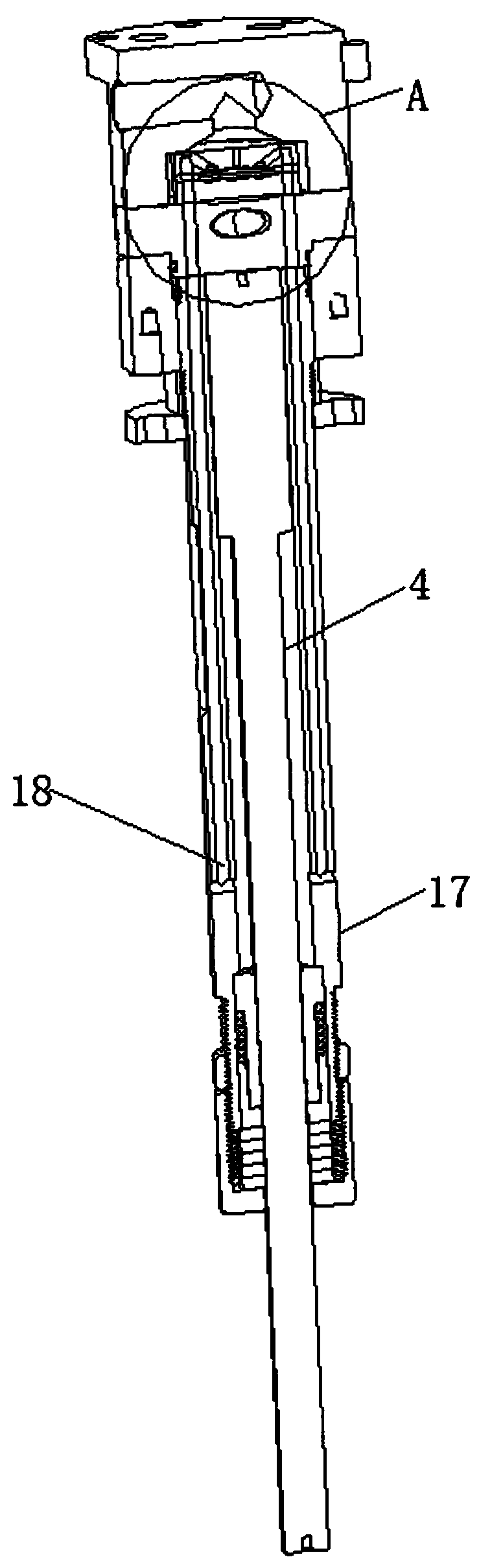

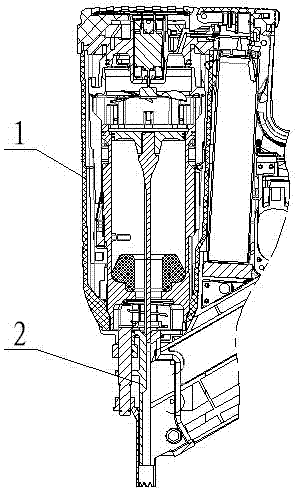

Rolling brush of dust collector

The invention discloses a rolling brush of a dust collector. The rolling brush is characterized by comprising a rolling shaft, a baffle, a transmission column, a blade and a rolling brush strip, wherein the rolling shaft is arranged at the air inlet of the rolling brush; the baffle and the transmission column are rotatably fixed at the two ends of the rolling shaft; the transmission column and a rolling brush driving device are in transmission connection with each other; the blade is fixedly connected with the rolling shaft and arranged between the baffle and the transmission column; and the rolling brush strip is arranged between the baffle and the transmission column and can be used for realizing the linkage of the baffle and the transmission column. In the brush head structure of the rolling brush disclosed by the invention, the long thin garbage wound on the rolling brush is cut off by the blade so as to prevent hair and the like from being wound on the rolling brush, realize a smoother cleaning process and improve the user satisfaction; and moreover, the suspended rolling brush strip can be used for increasing the striking force against the ground during rotation, and the cleaning power of the rolling brush against deep garbage is improved. Furthermore, as bristles are fragile components and the rolling shaft is a durable product, the bristles or cleaning cloth are fixed on the rolling brush strip so that the bristles or cleaning cloth can be simply replaced and the product use cost is reduced.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

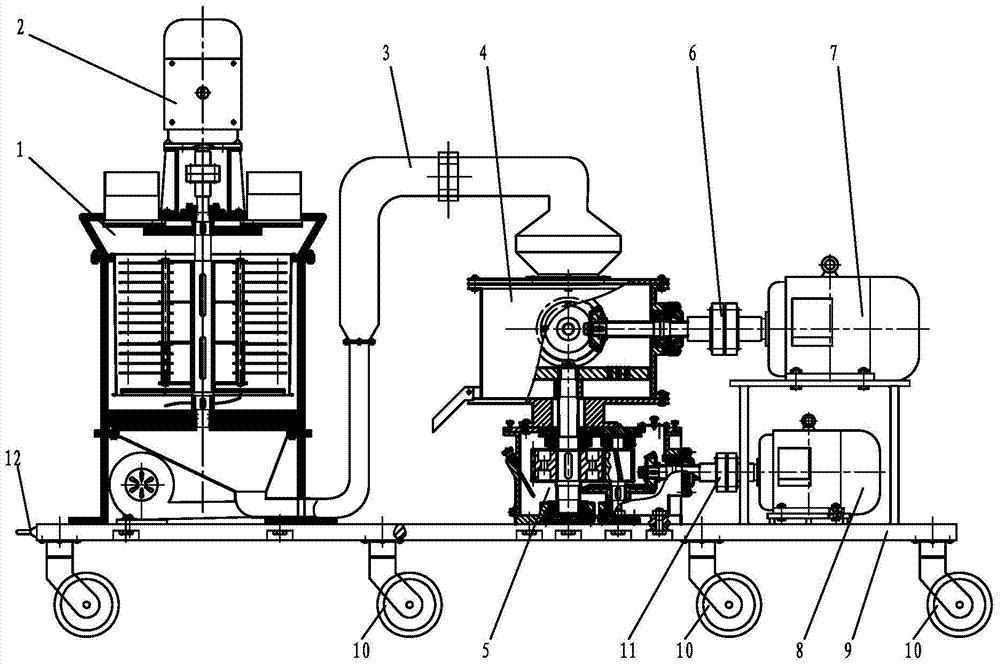

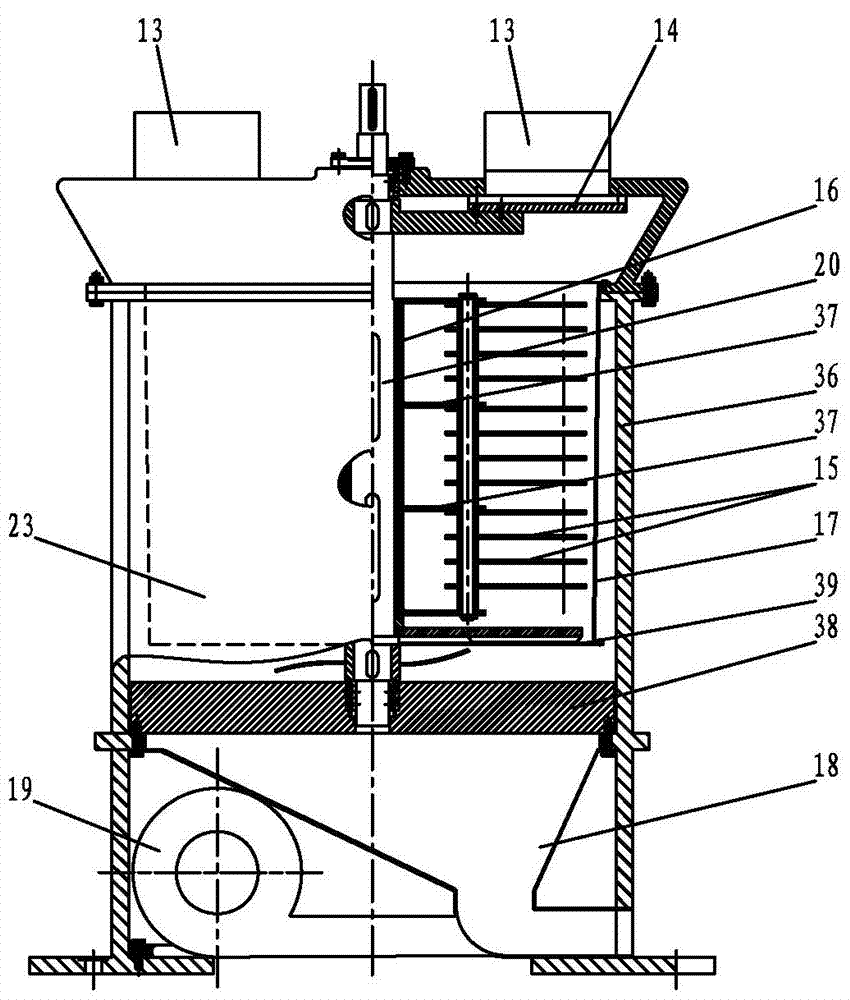

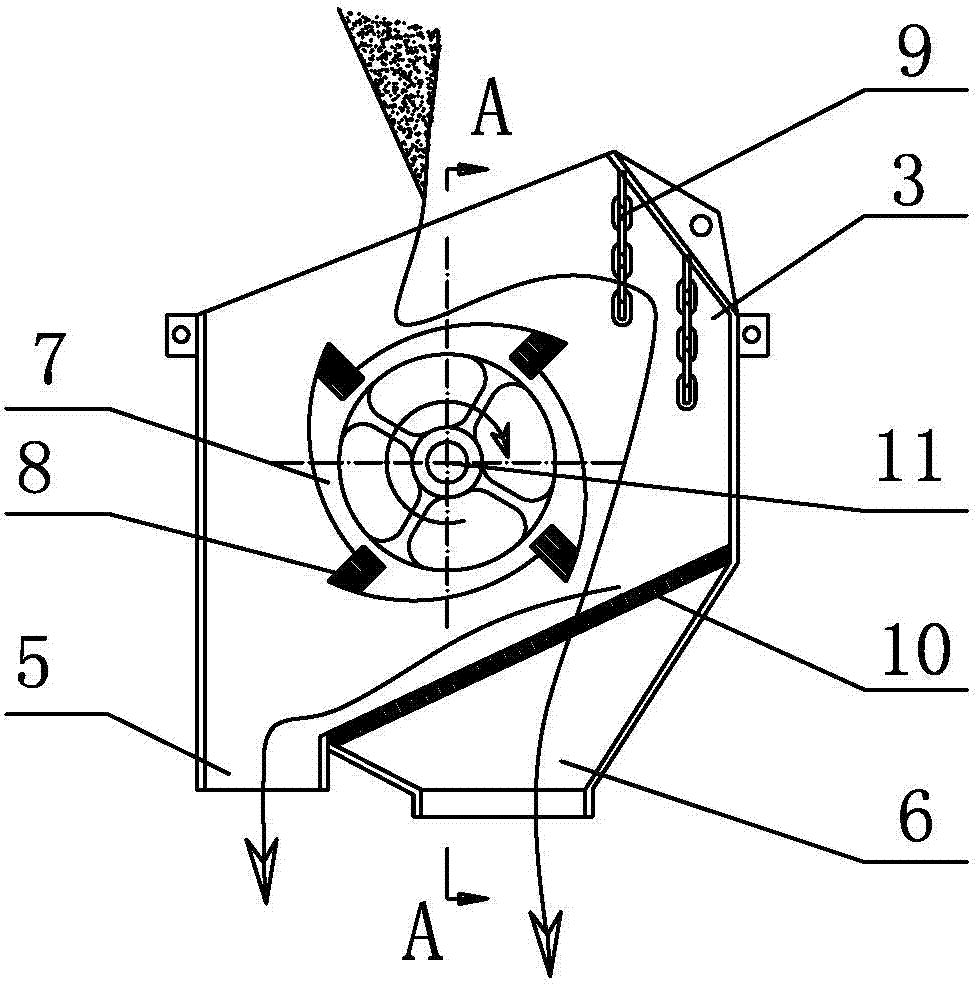

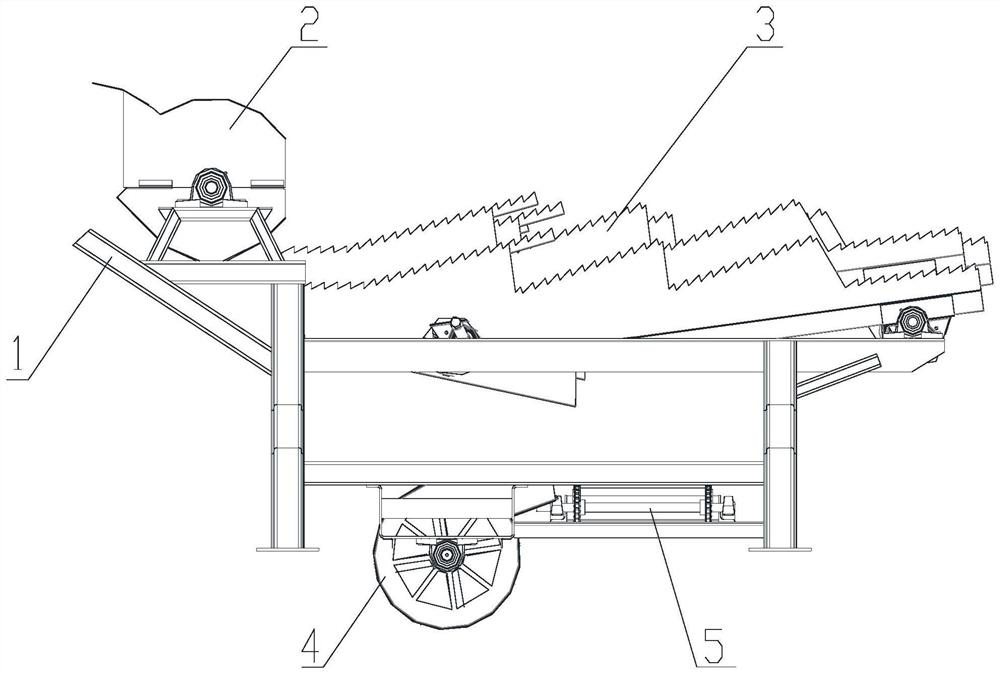

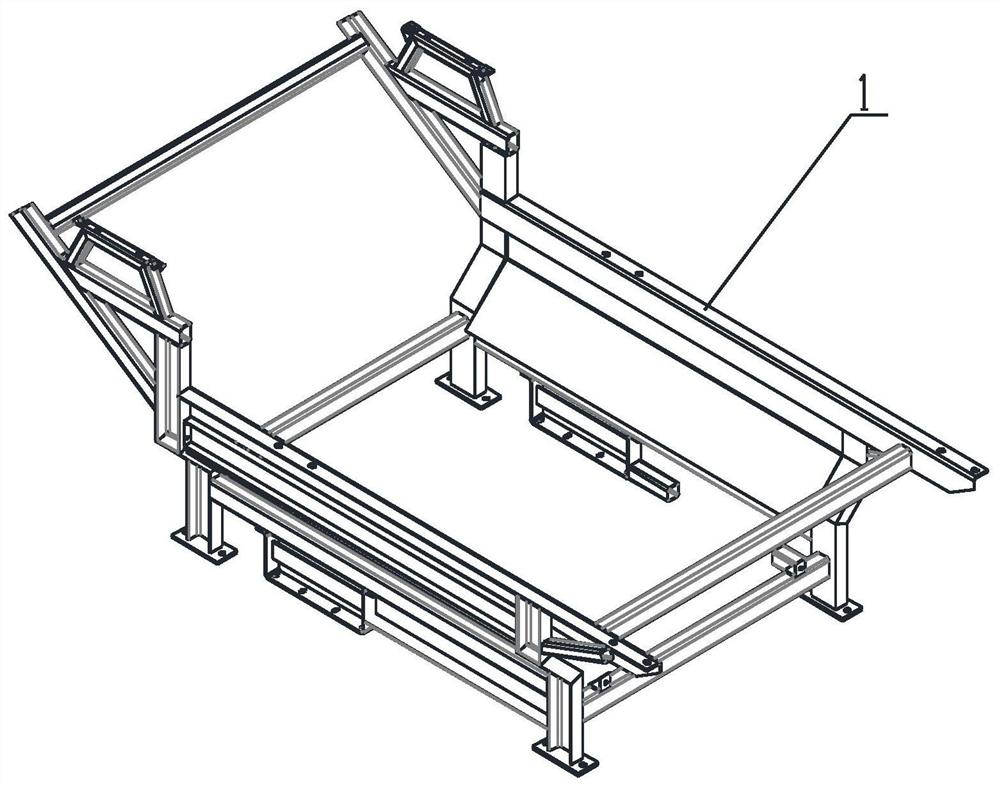

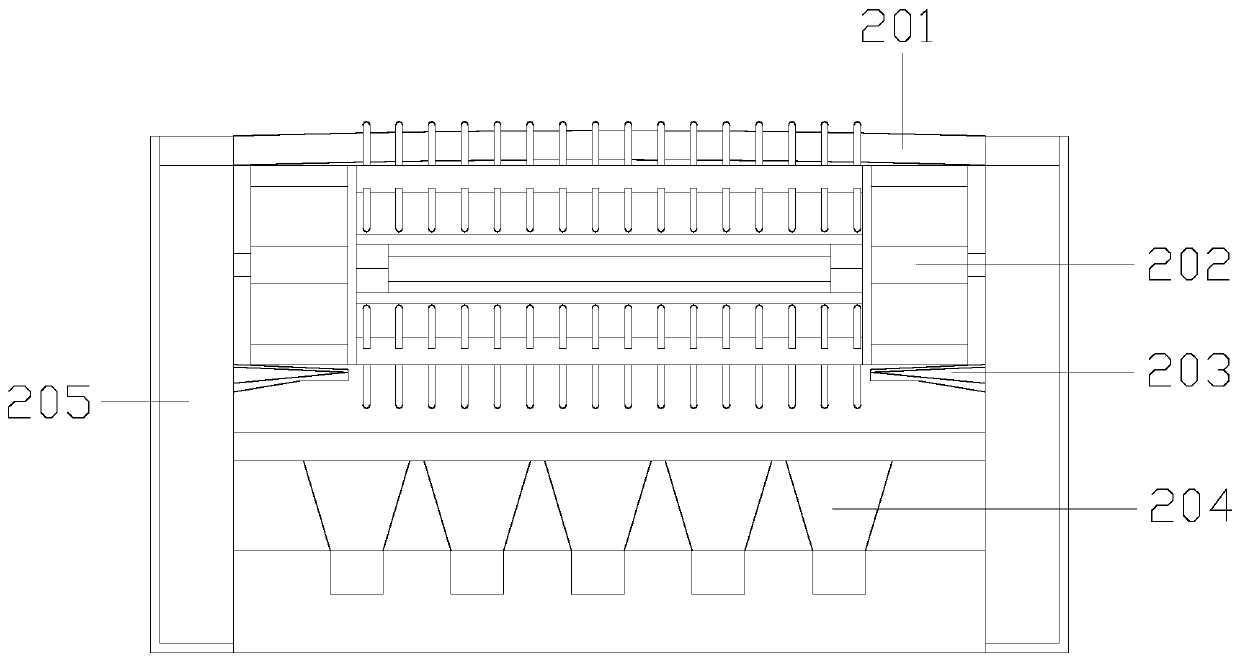

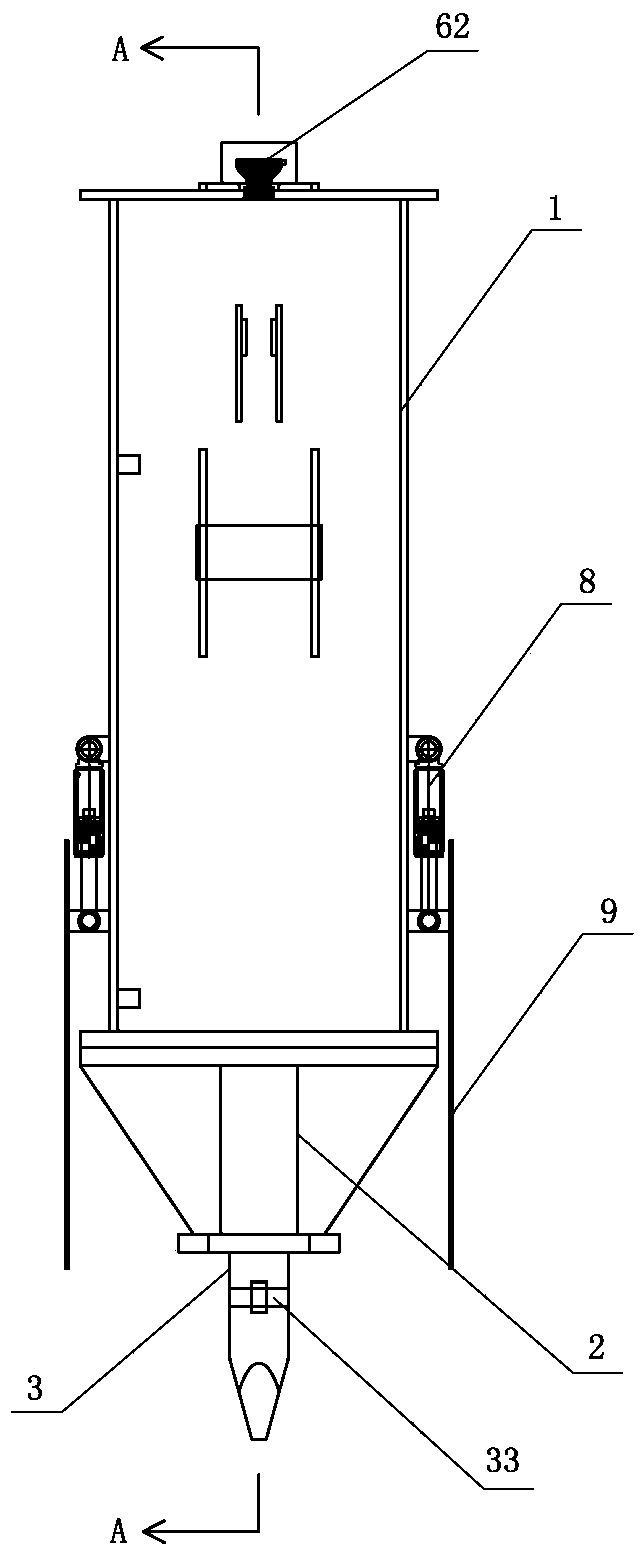

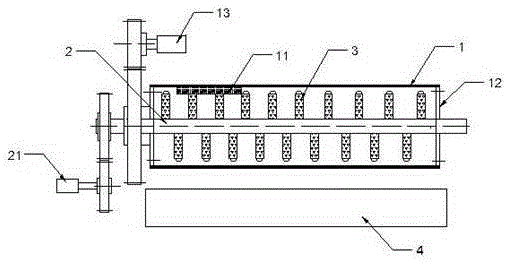

Biomass straw smashing and forming all-in-one machine

InactiveCN103495484ABig hitImprove crushing efficiencyGranulation by pressingGrain treatmentsWork cycleAir blower

The invention provides a biomass straw smashing and forming all-in-one machine, and relates to a straw smashing and forming device. The biomass straw smashing and forming all-in-one machine solves the problems that in an existing straw forming fuel production process, the straw smashing procedure and the compressing and compacting forming procedure are independently completed through a smashing device and a squeezing forming device respectively, the power consumption is high, the logistics cost is high, and the working cycle is long. The vertical smashing device and the squeezing forming device are arranged on a walking plate in parallel from front to back, walking wheels are arranged below the walking plate, a blade is arranged at the bottom of a feed port of the vertical smashing device, a main shaft of the smashing machine is sleeved with a sleeve, hammer carrier plates are arranged on the sleeve from top to bottom, a hammer set is arranged between every two adjacent hammer carrier plates in an annular mode, hammers of each hammer set are evenly arranged in the vertical direction, each hammer is of a multi-tooth-edge rectangular structure, an air blower is arranged at the bottom of a machine shell and communicate with a material storage hopper, and the material storage hopper is communicated with an inlet of the squeezing forming device through an air duct. The biomass straw smashing and forming all-in-one machine is used for smashing and forming biomass straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

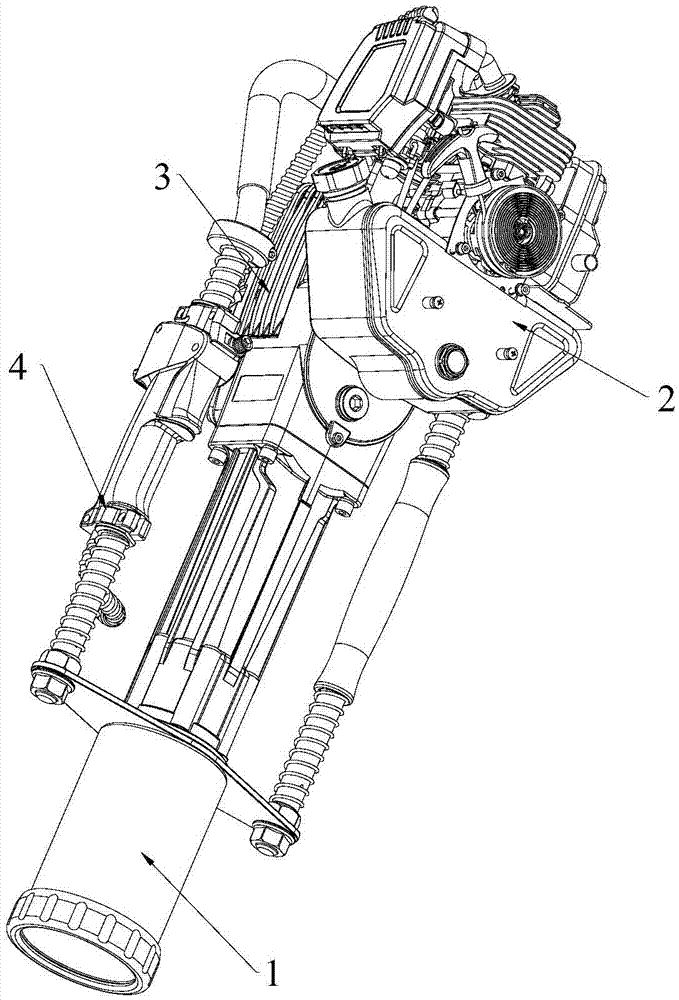

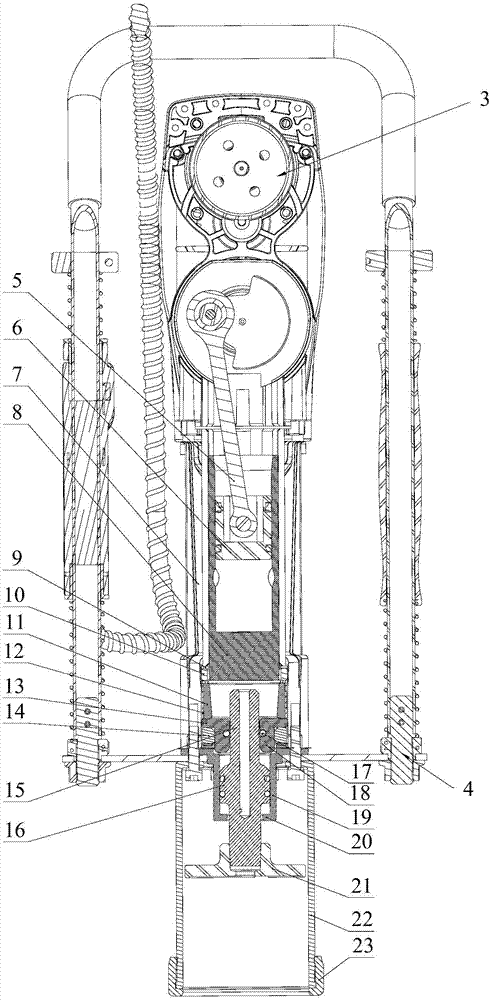

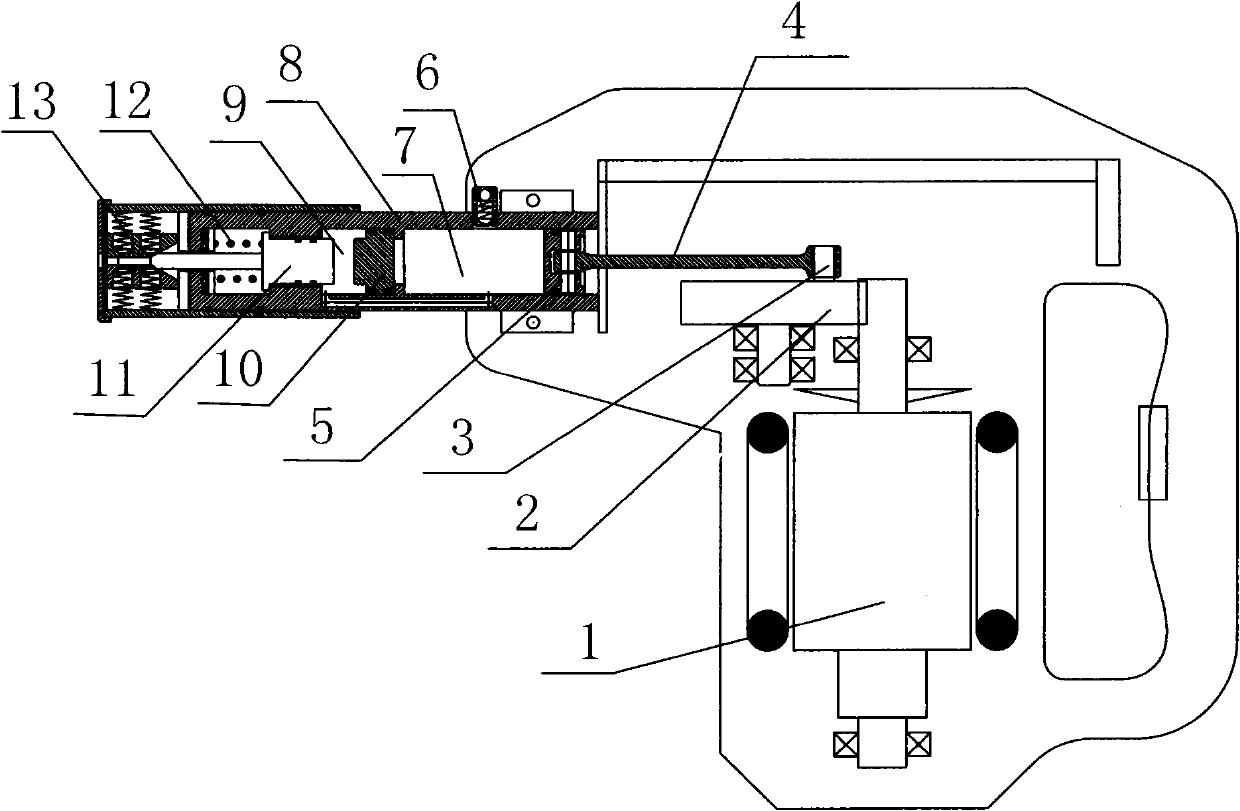

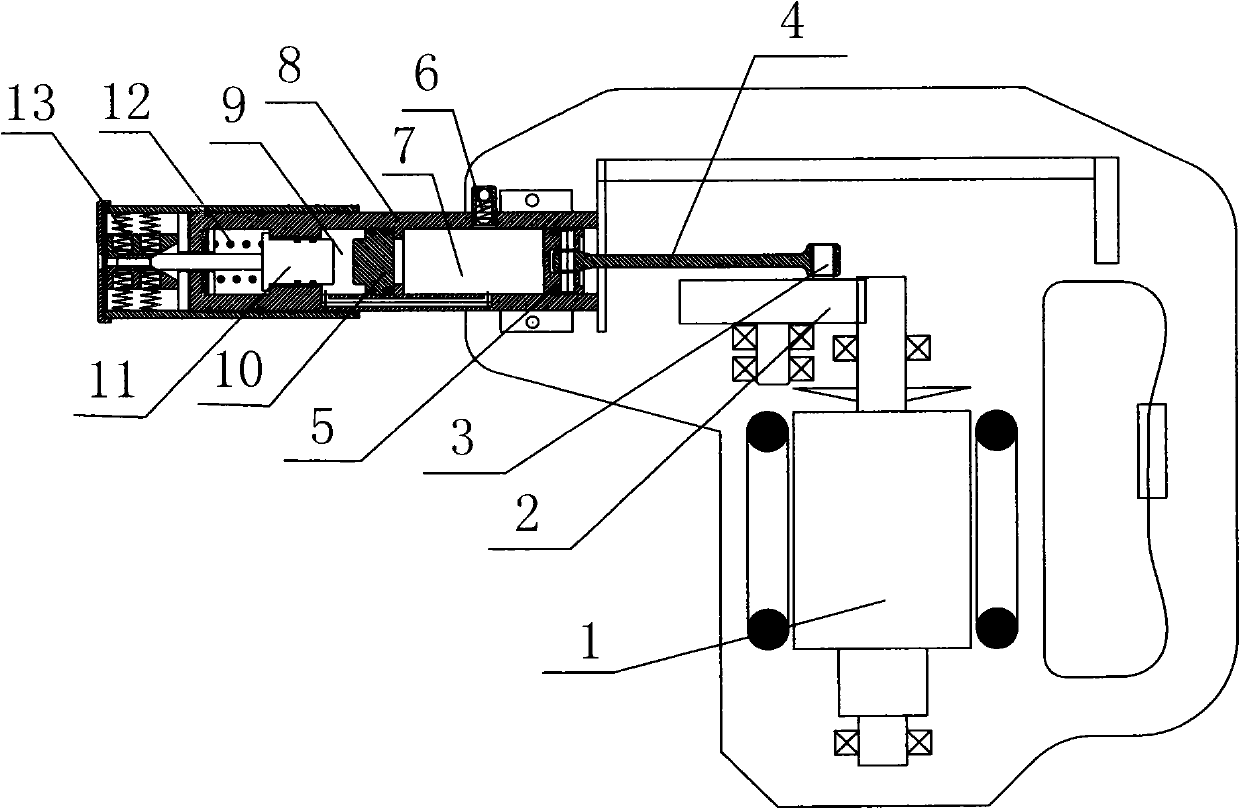

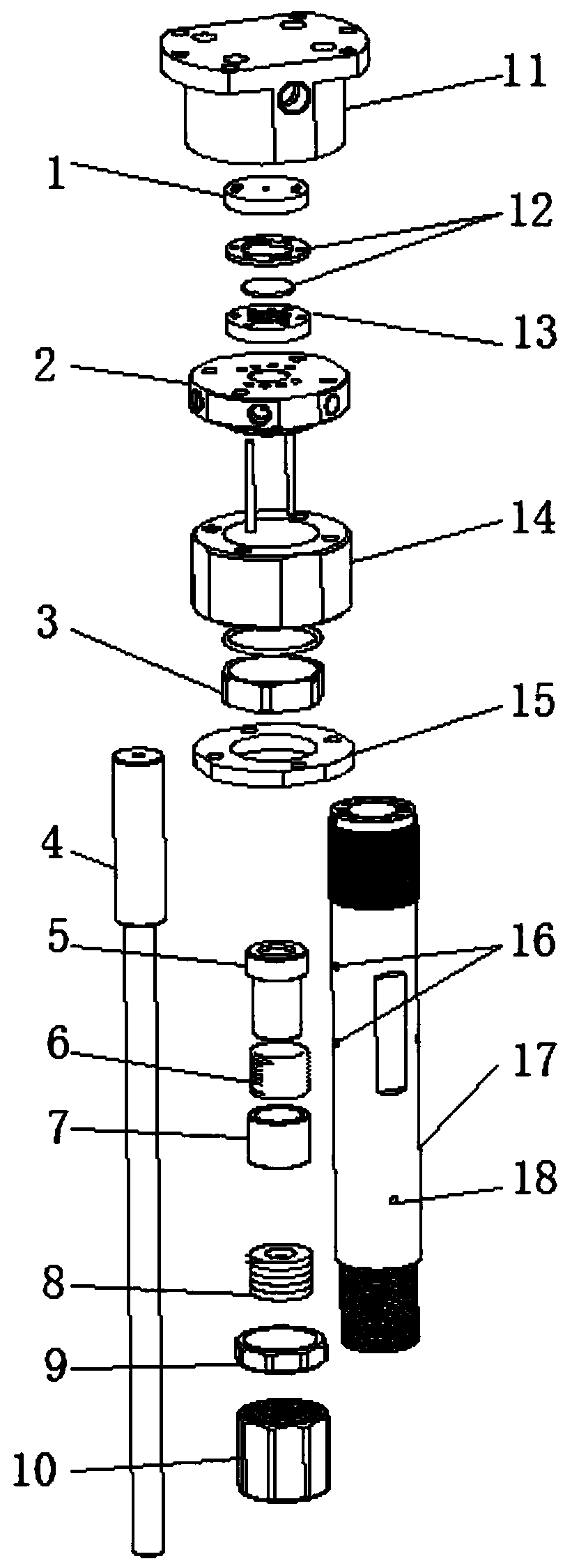

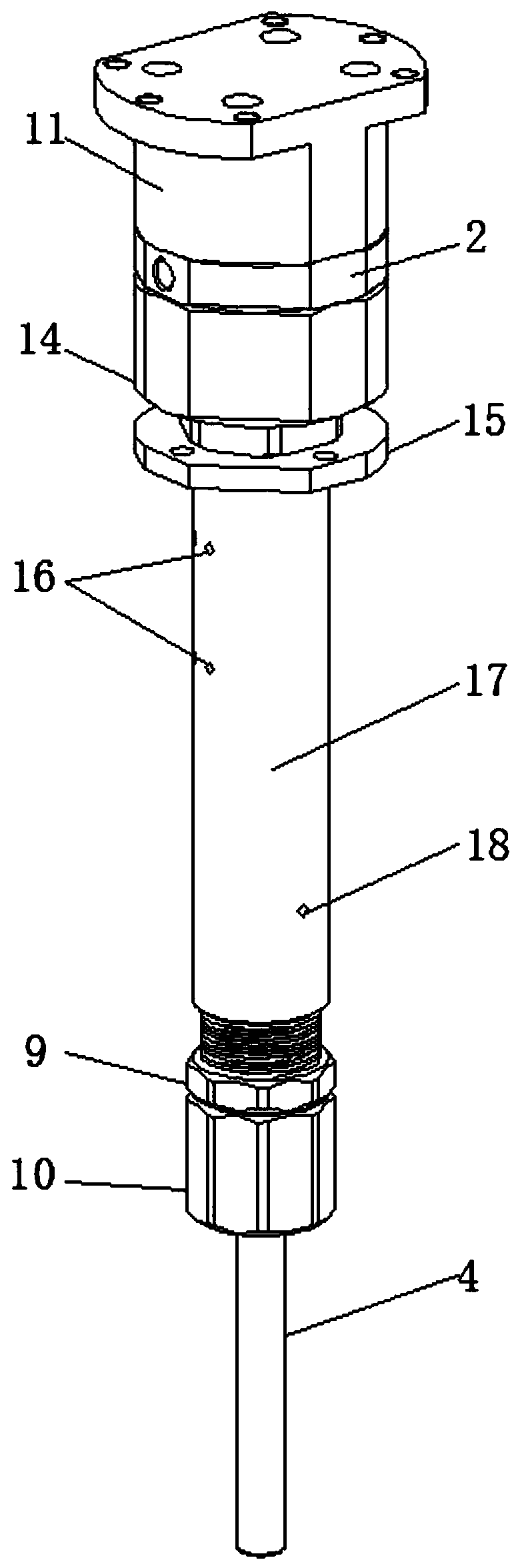

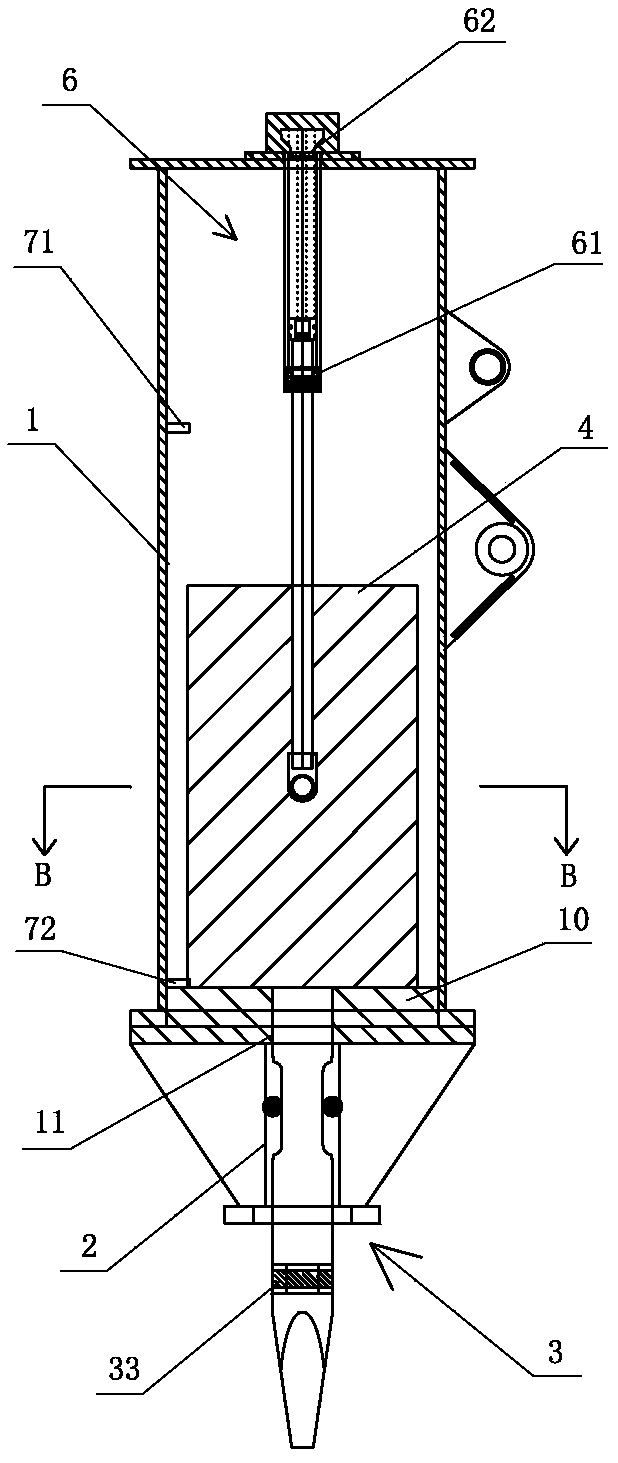

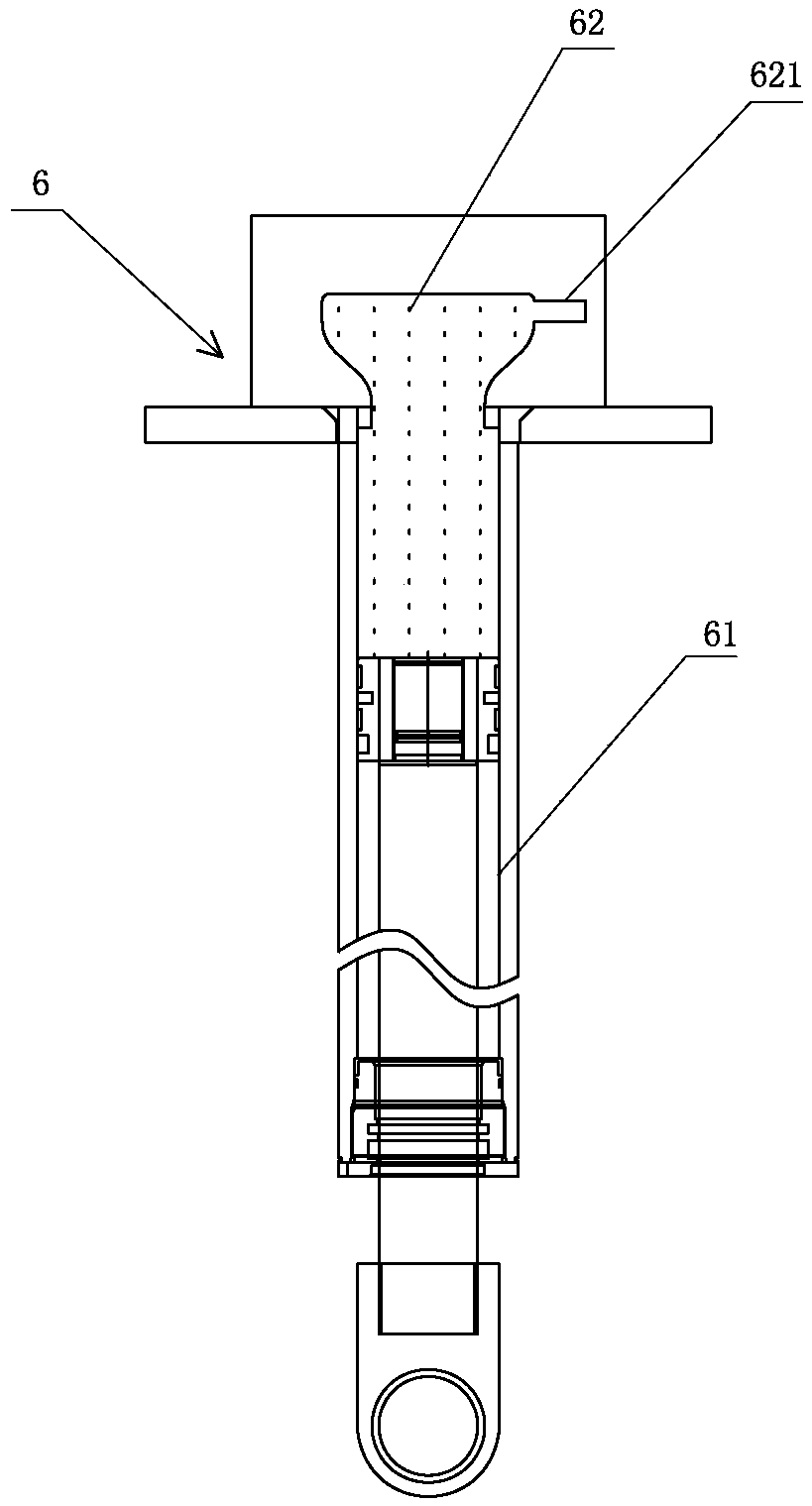

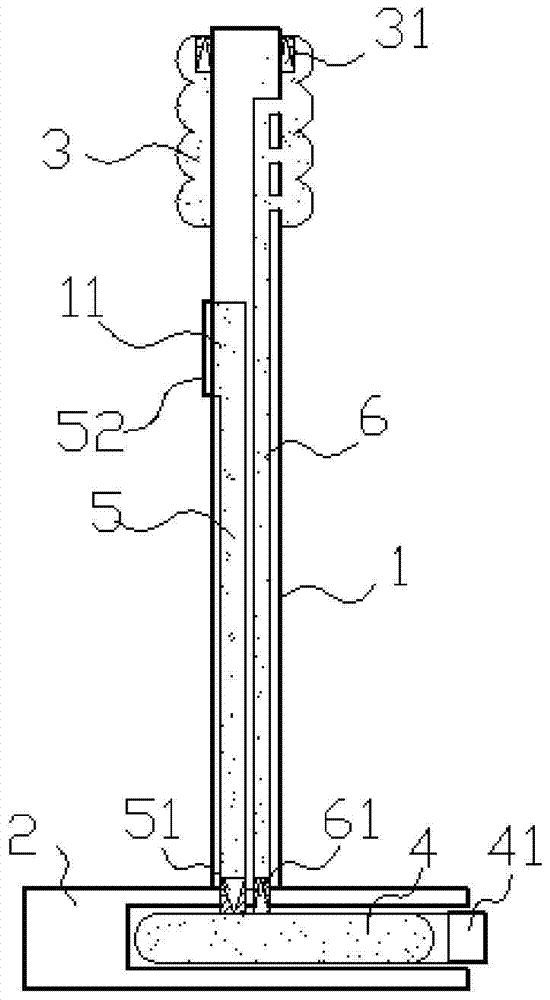

Piling mechanism of piling machine and piling machine

The invention discloses a piling mechanism of a piling machine. The piling mechanism of the piling machine comprises a barrel, an impact cylinder, an impact piston, an impactor guide sleeve, a wood pile guide sleeve, an impactor and an inner pile head; the impact cylinder is arranged in the barrel in a sliding mode, one end of the impact cylinder is closed, and other end of the impact cylinder is opened; the impact piston is arranged in the impact cylinder in a sliding mode and linked with a transmission mechanism; the wood pile guide sleeve is fixed relative to the barrel, the impactor is installed on the impactor guide sleeve in a sliding mode, one end of the impactor penetrates out of the impactor guide sleeve and extends to the impact cylinder, and other other end of the impactor penetrates out of the impactor guide sleeve and is located in the wood pile guide sleeve; the inner pile head is fixed relative to the end, located in the wood pile guide sleeve, of the impactor. According to the piling mechanism of the piling machine, one end of the impact cylinder is opened, the other end of the impact cylinder is closed, the impactor is impacted through the impact cylinder arranged in the barrel in a sliding mode, and only the portion, between the impact piston and the inner side wall of the impact cylinder, in the impact cylinder needs to be sealed; compared with an exiting structure, the reliability is good, and the strike force is larger.

Owner:ZHEJIANG JIAHONG TOOL MFG CO LTD

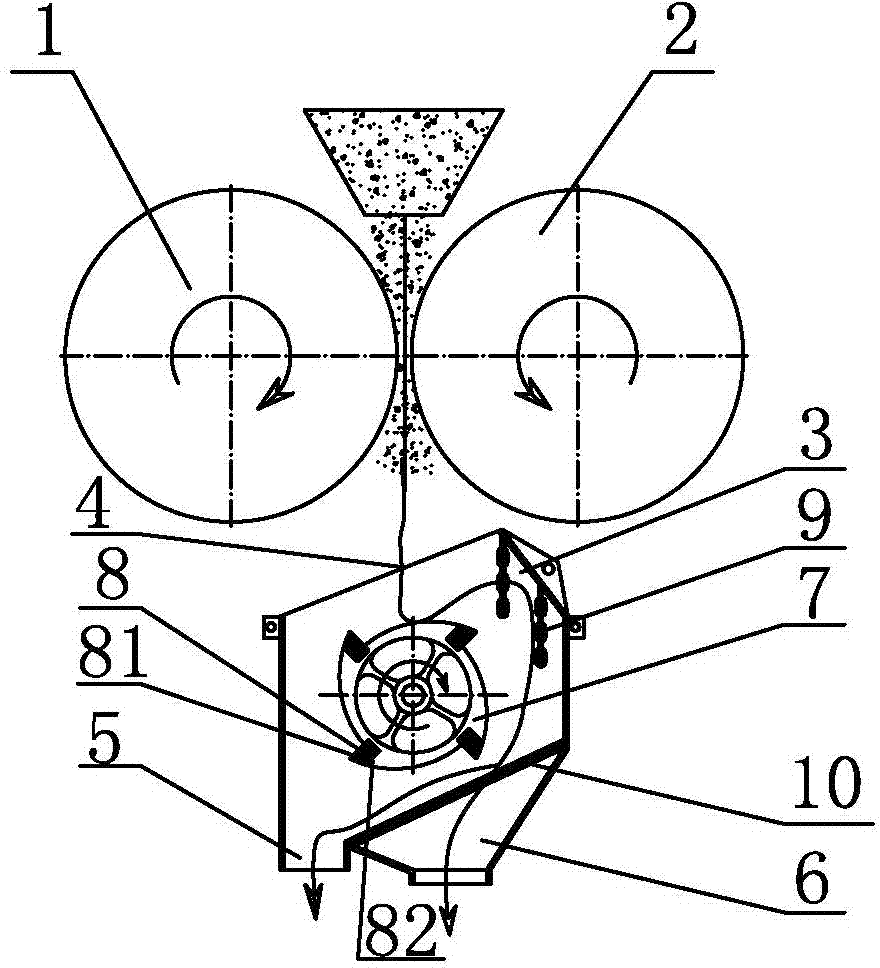

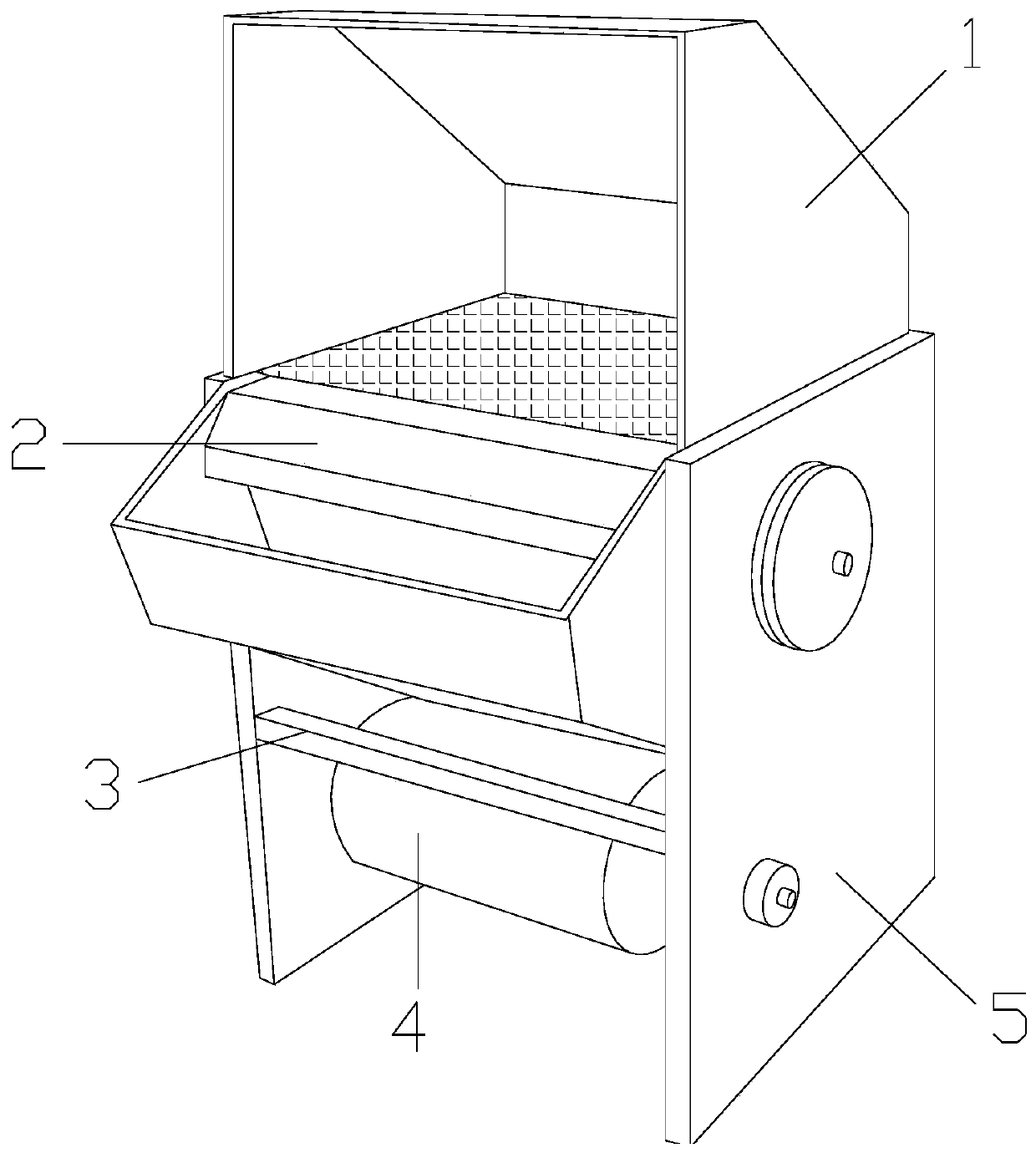

Dispersing device for roller press

The invention relates to a dispersing device for a roller press, which comprises a shell of which one side is provided with a feed inlet and the opposite side is provided with a coarse material outlet and a fine material outlet. A rotating wheel of which a wheel shaft is perpendicular to the feeding direction is arranged in the shell; the peripheral surface of the rotating wheel is peripherally and uniformly provided with a wear-resistant striking plate; the striking end face of the wear-resistant striking plate is arranged towards the feeding direction of materials; and the shell facing the striking end face of the wear-resistant striking plate is provided with a wear-resistant chain for receiving the materials struck and thrown up by the wear-resistant striking plate and carrying out impact on the materials again. A material cake squeezed by a fixed roller and a movable roller is dispersed by an impact force generated by high-speed rotation of the wear-resistant striking plate; the dispersed small material cake blocks crash into the wear-resistant chain at a high speed after being struck and thrown up; the wear-resistant chain impacts and finely crushes the small material cake blocks into material particles; and high-speed impact for twice enables the materials to be smashed into finer particles. The device can be far away from the movable roller and the fixed roller; and when the device is at a long distance with the movable roller and the fixed roller, the speed that the materials arrive at the wear-resistant striking plate is higher, the striking force is larger and the materials are more sufficiently smashed.

Owner:JIANGSU PENGFEI GROUP

Cyperus esculentus harvest threshing, separating and cleaning system

PendingCN112056097AEasy to separateImprove liquidityThreshersAgricultural scienceAgricultural engineering

The invention discloses a cyperus esculentus harvest threshing, separating and cleaning system, and belongs to the technical field of agricultural machinery. The system comprises a frame, a threshingcylinder, a straw shaker, a cleaning fan and a transverse conveyor, the threshing cylinder is arranged at the end of one side of the frame through bolts, and the threshing cylinder comprises a threshing shaft component, an upper cover arc plate and a lower screen arc plate. The upper cover arc plate and the lower screen arc plate are fixedly connected through bolts to form a cylindrical structure,a feeding port is formed at one end, a discharging port is formed at the other end, and the threshing shaft component is arranged in the cylindrical structure. The whole set of threshing and cleaningsystem has good separability, liquidity and multiple cleaning functions through working components such as the tangential flow type threshing cylinder, a double-layer multi-stage four-box type strawshaker separation device, the cleaning fan and the transverse conveyor with the soil leakage function; and faults and problems such as winding of rhizomes, blocking of a screen and incomplete separation can be effectively prevented.

Owner:JILIN ACAD OF AGRI MACHINERY

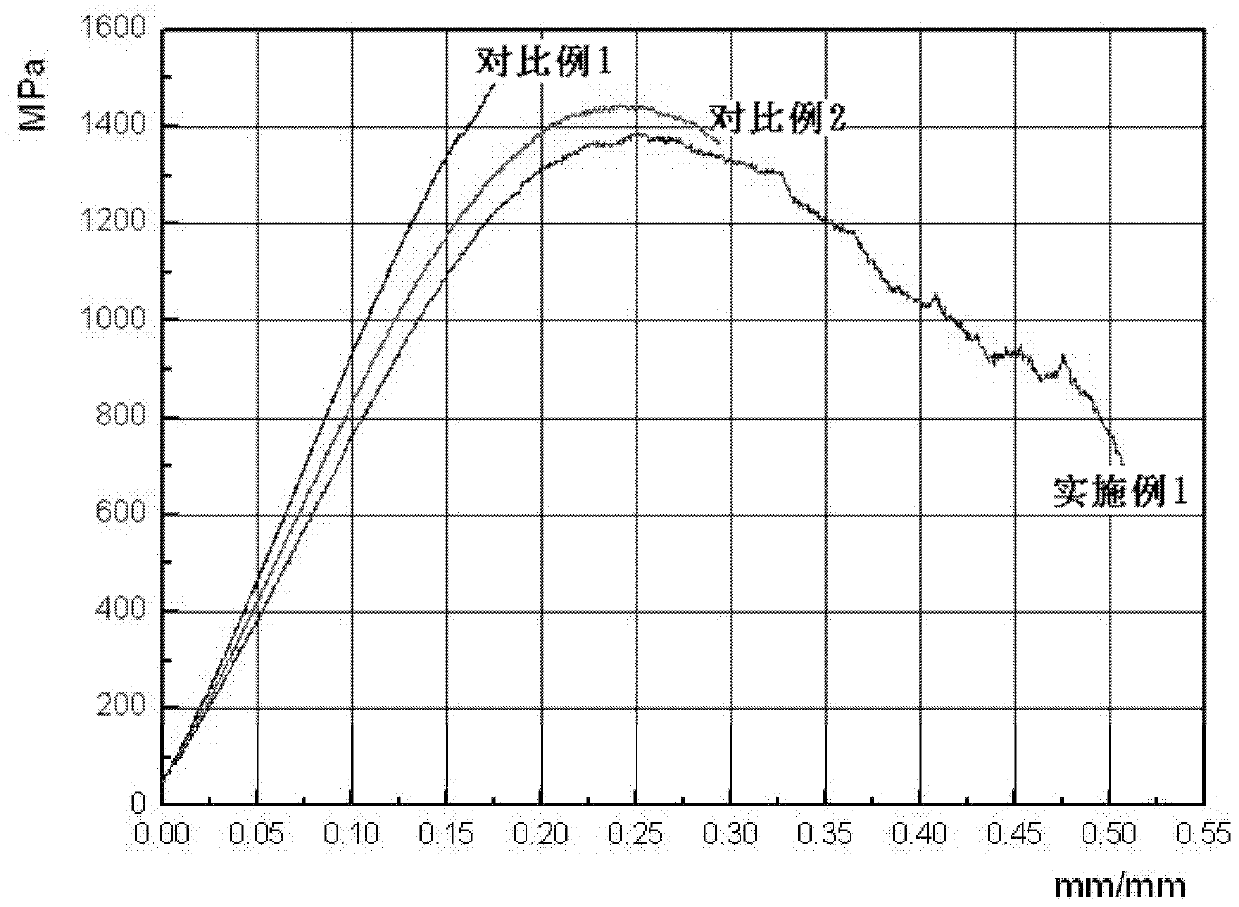

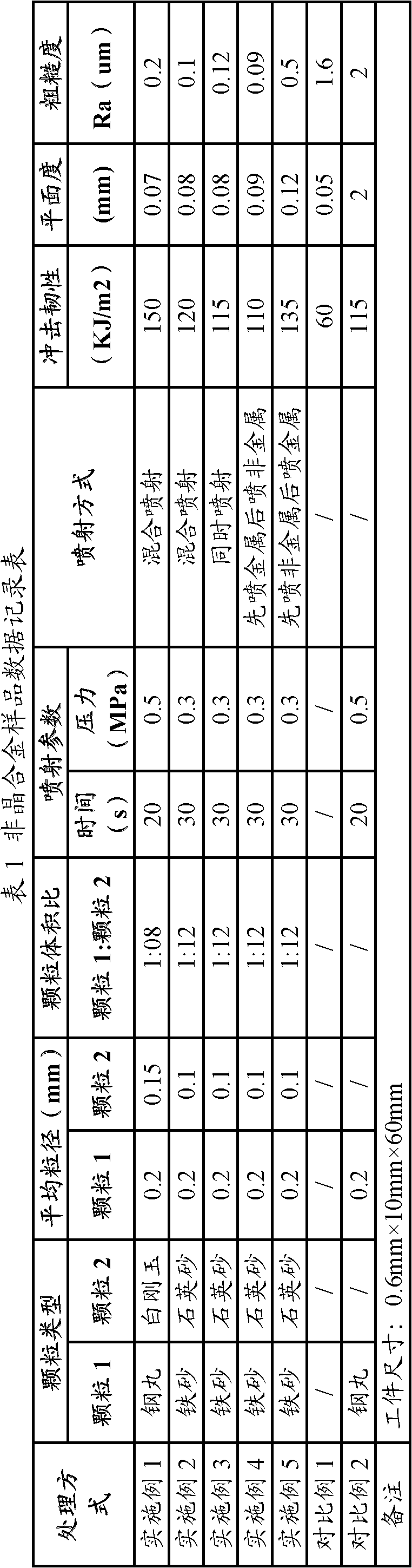

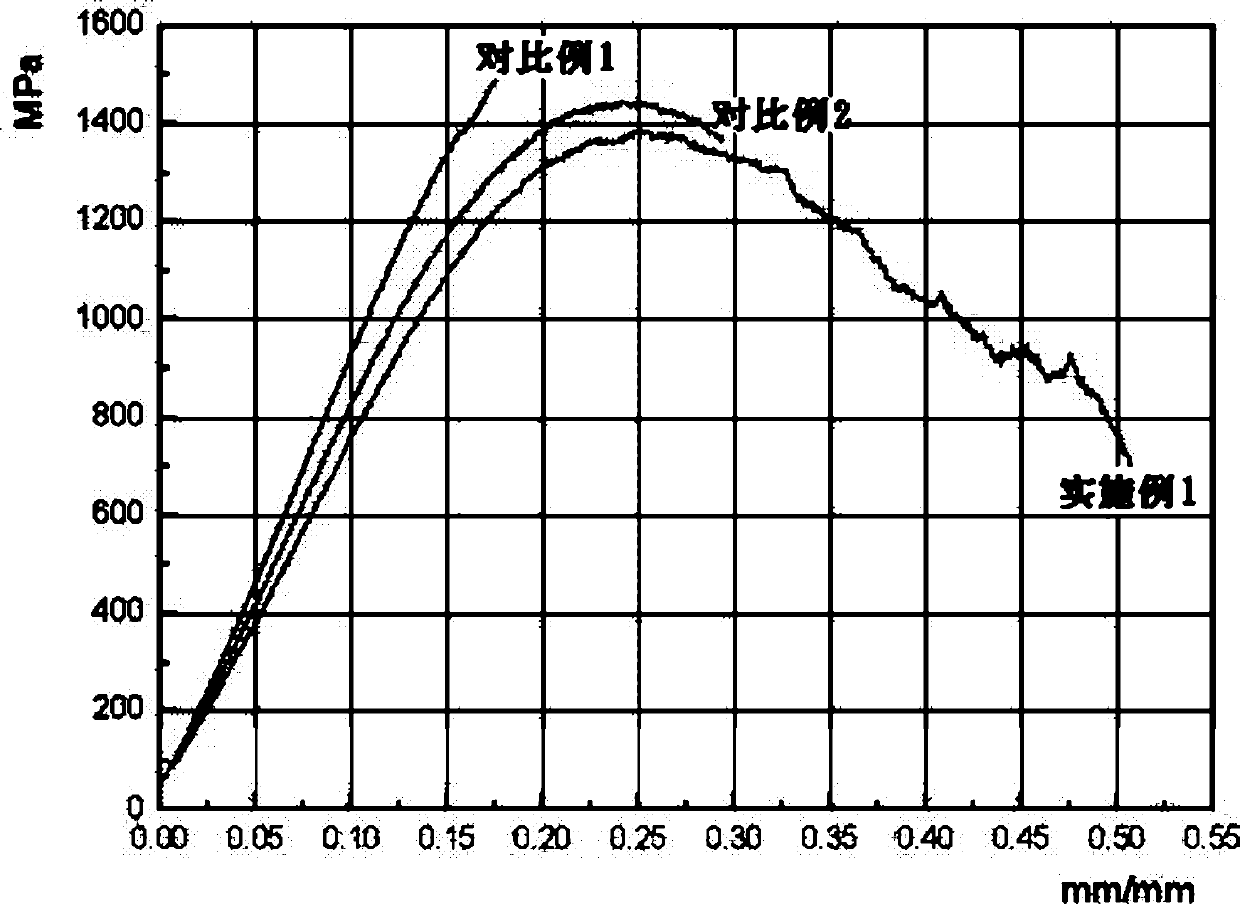

Amorphous alloy surface treatment process

The invention discloses an amorphous alloy surface treatment process, which comprises the step of adopting metal particles and nonmetal particles to perform injection treatment on the surface of an amorphous alloy, wherein the metal particles are one or more of steel shots, iron shots, steel sand and iron sand; and the nonmetal particles are one or more of slot materials and sand materials of ceramics and glass. By the amorphous alloy surface treatment process in the invention, the plastic deformation capability and impact toughness of the amorphous alloy can be improved, the surface roughness of the amorphous alloy can be improved, and the workpiece deformation problem in the injection treatment process of the prior art is solved, thereby making applications of amorphous alloys in high-strength precious workpieces and workpieces with high appearance requirements possible.

Owner:BYD CO LTD

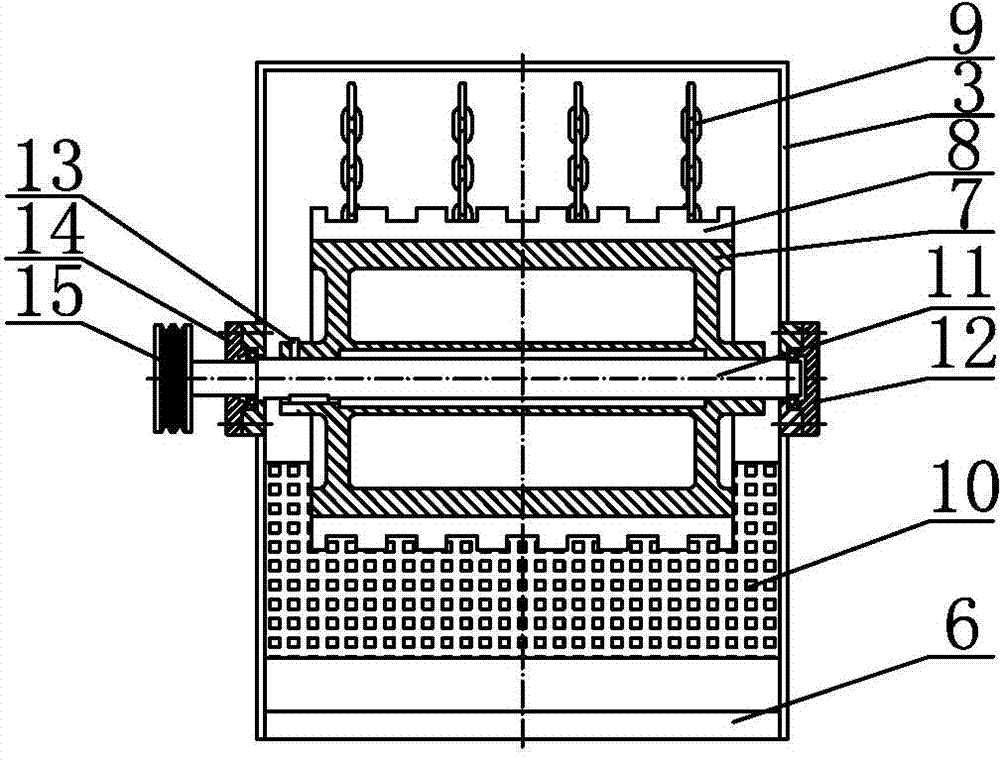

Aftertreatment surface fiber opener with superhigh performance

InactiveCN102877241ABig hitEven by forceTextile treatment with treating outlet contectSpray nozzleSingle hole

The invention discloses an aftertreatment surface fiber opener with a superhigh performance. Two spray nozzle seats parallel to each other are mounted in the machine body of the surface fiber opener; a plurality of single-hole linear spray nozzles are arranged on the spray nozzle seats; the diameters of spray nozzle holes in the single-hole linear spray nozzles are not larger than 0.2 mm; the distance between the adjacent single-hole linear spray nozzle holes is not larger than 0.2 mm; and fiber-opening treatment is carried out on electronic glassfiber cloth by high-pressure linear water sprayed from the spray nozzle holes. Compared with the prior art, the fiber-opening treatment is carried out on electronic glassfiber cloth by high-pressure linear water sprayed from the spray nozzle holes, so that the beating force on the electronic glassfiber cloth is increased, and the uniform stress of a cloth cover is ensured; meanwhile, the stacking of water sprayed from a part between the adjacent spray nozzles is avoided, the looseness degree of the glassfiber in the electronic glassfiber cloth is ensured, the air permeability of the electronic glassfiber cloth is reduced, the back of the electronic glassfiber cloth of the machine body is not shielded by a roller, linear high-pressure water can penetrate through the cloth cover directly, the penetration of the high-pressure water from the cloth cover is effectively ensured, and the fiber opening effect is good.

Owner:建滔(清远)电子材料有限公司

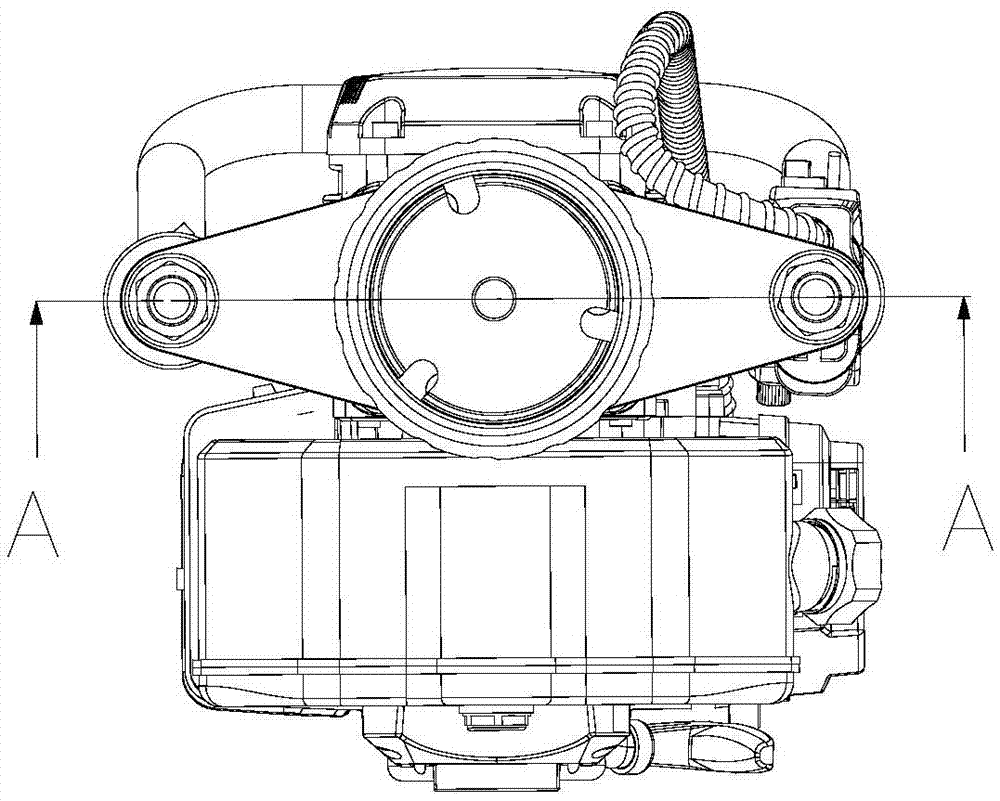

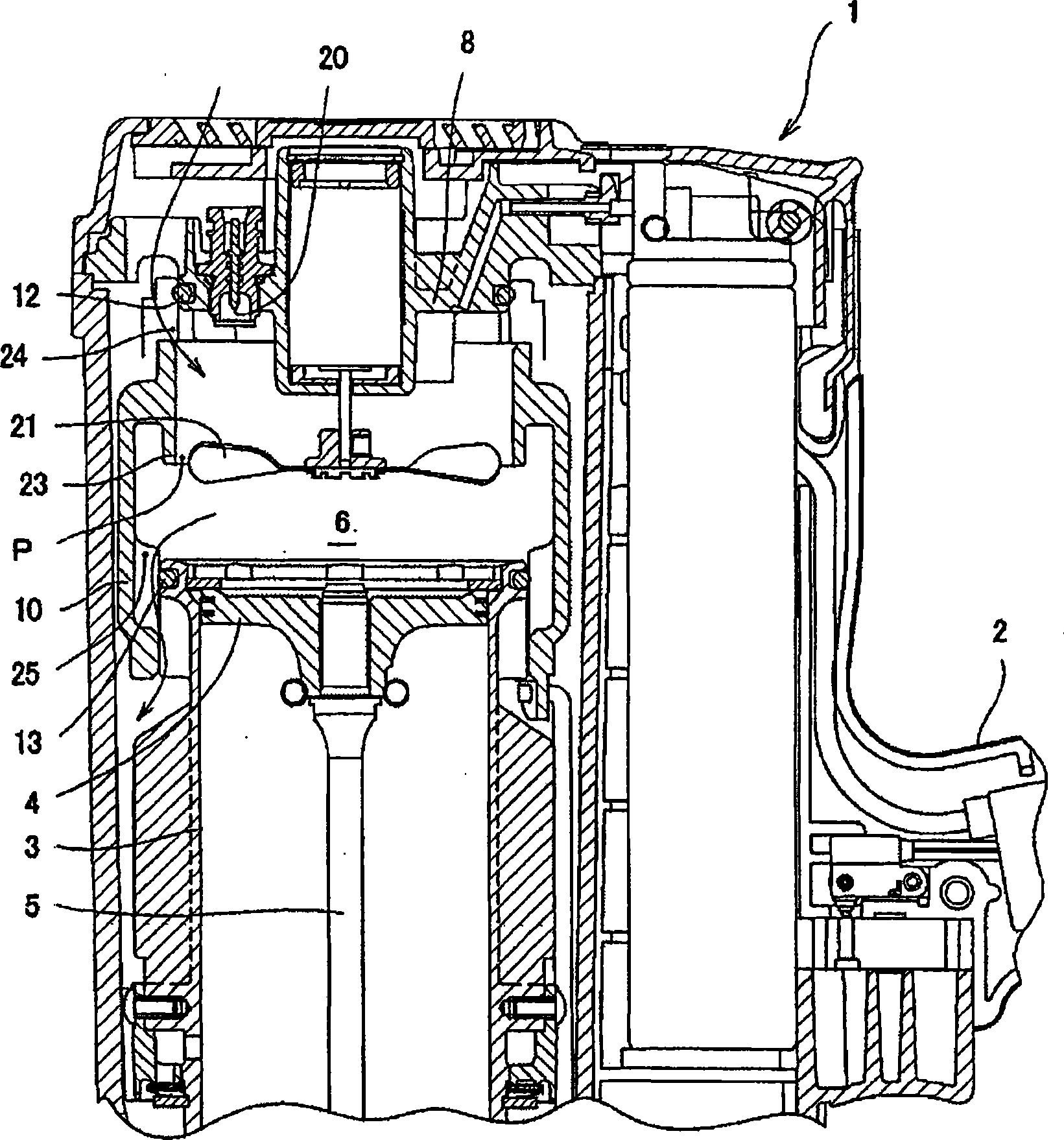

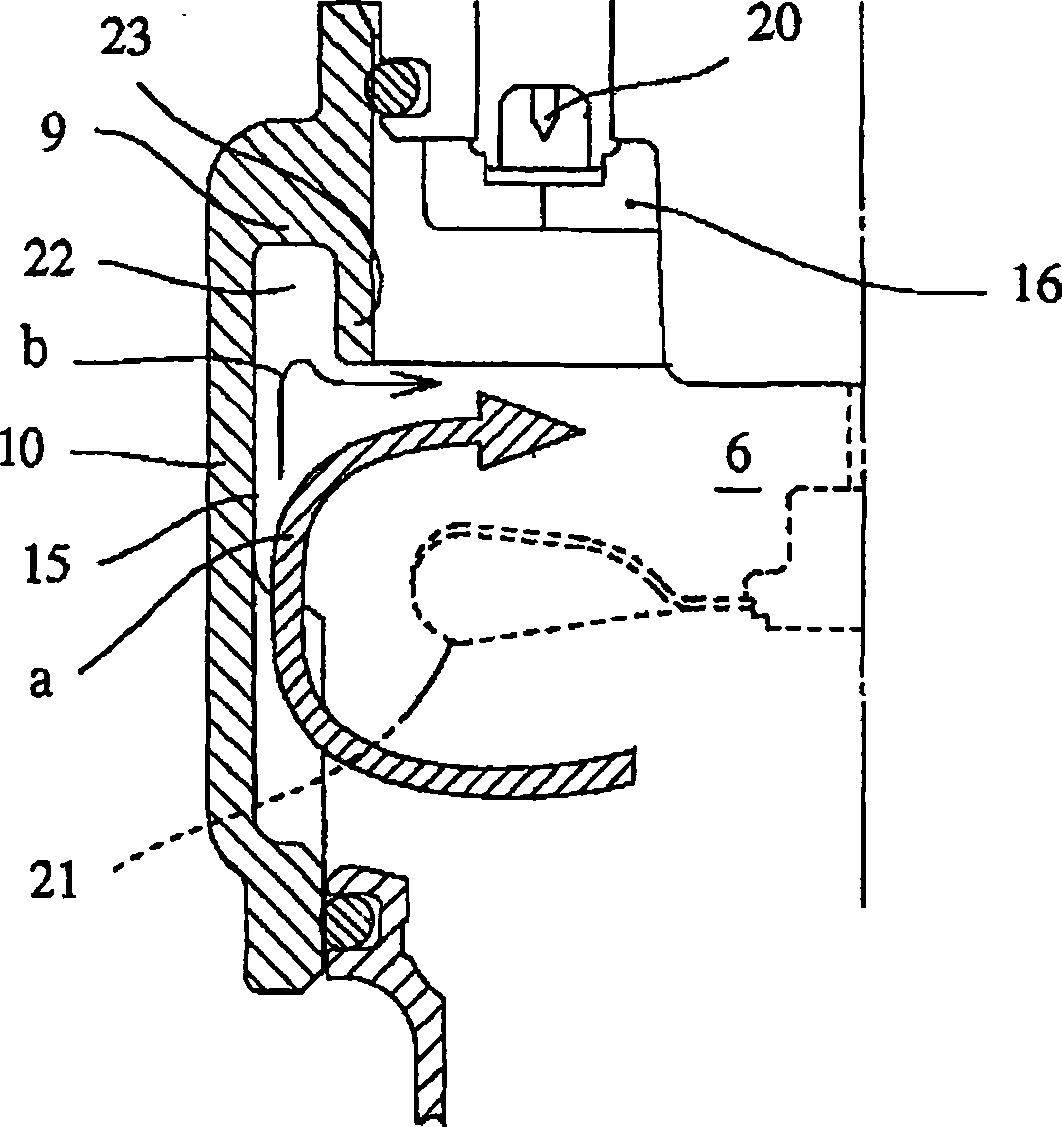

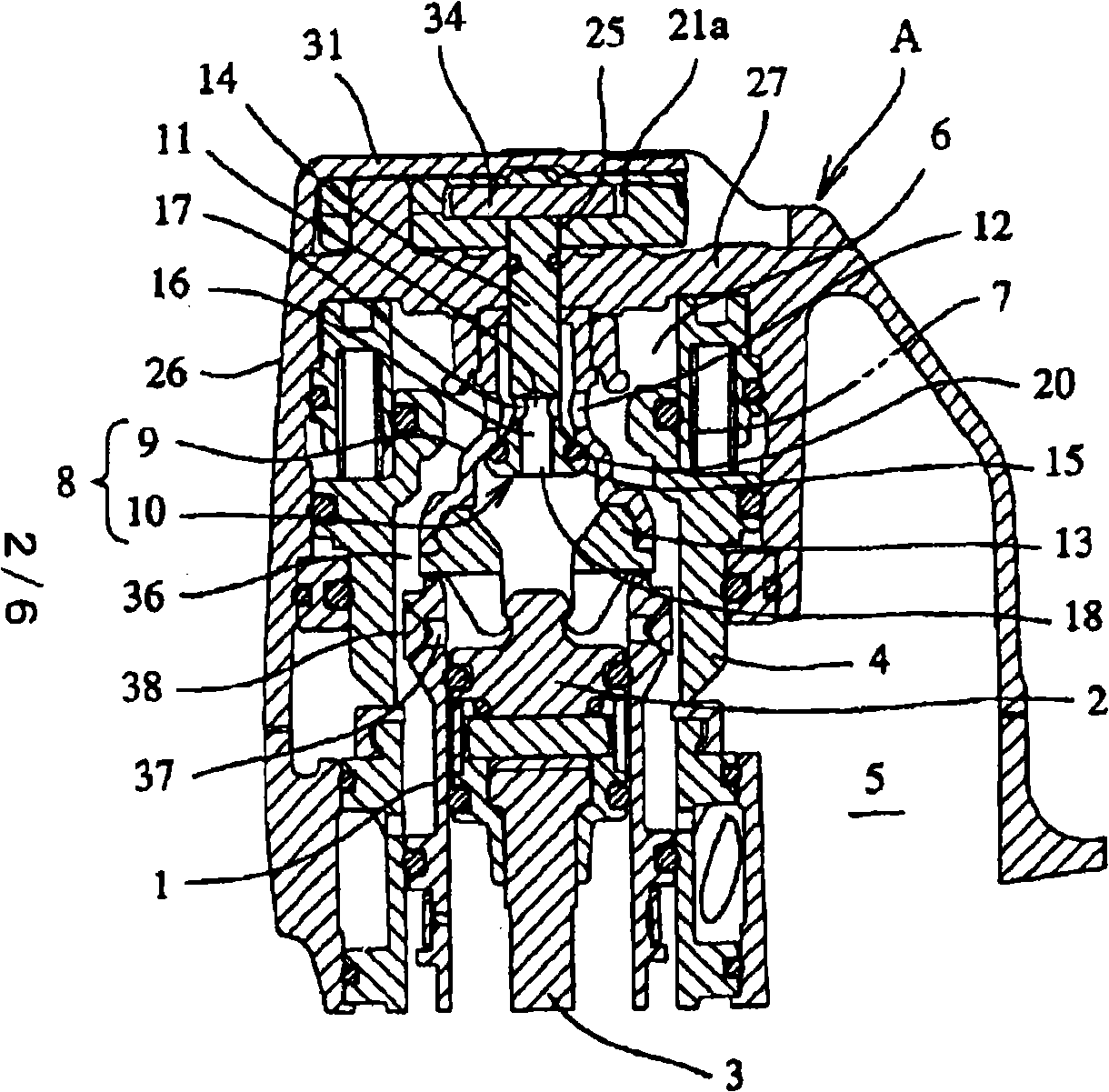

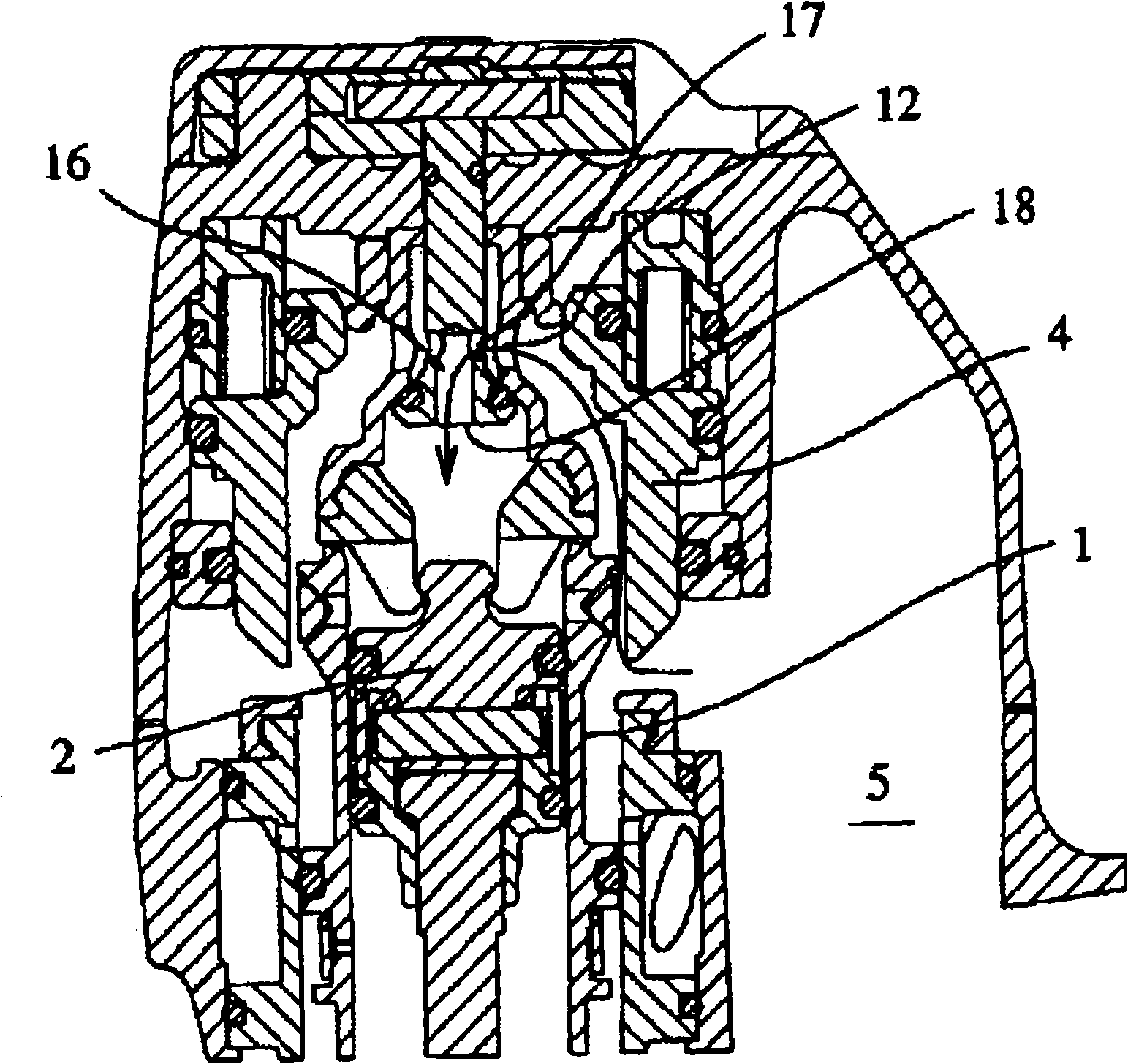

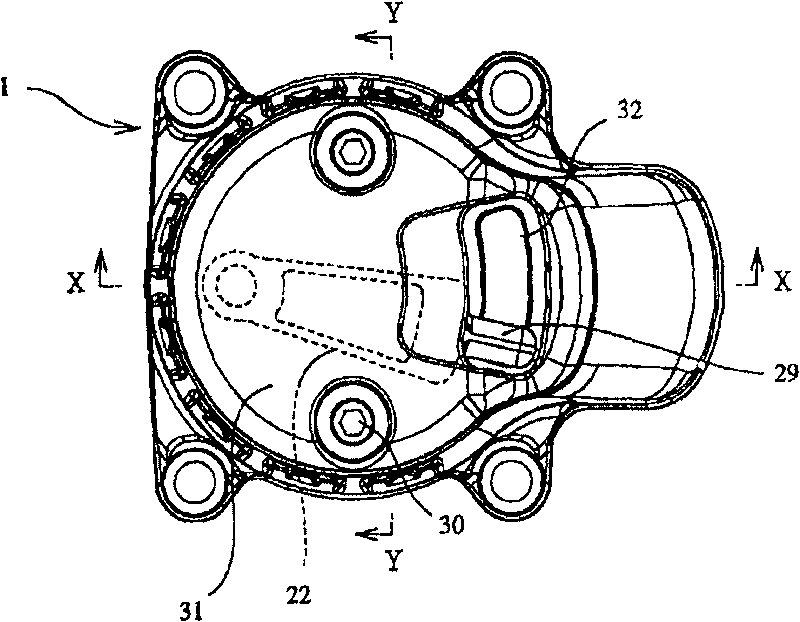

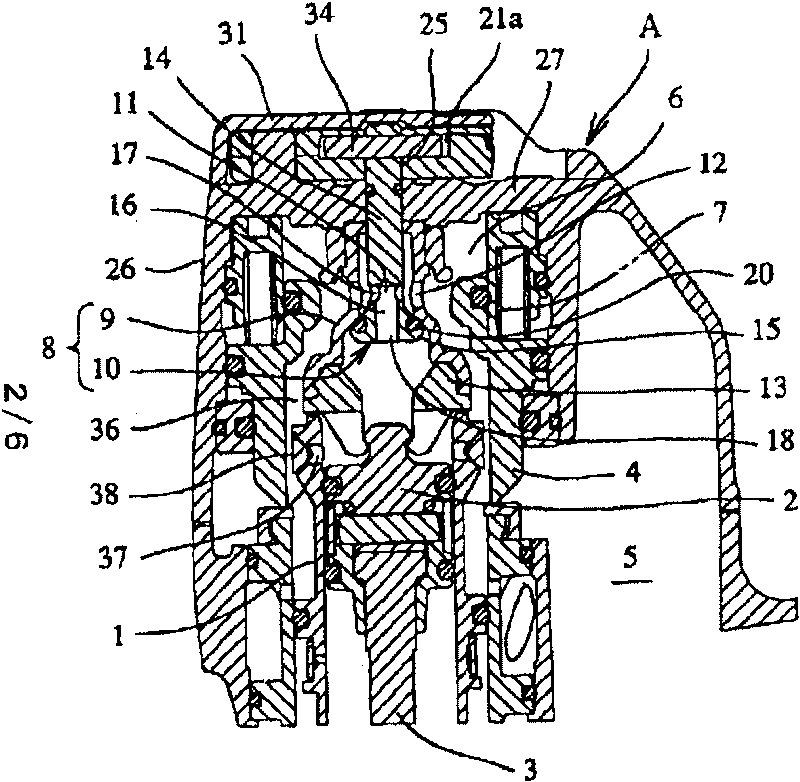

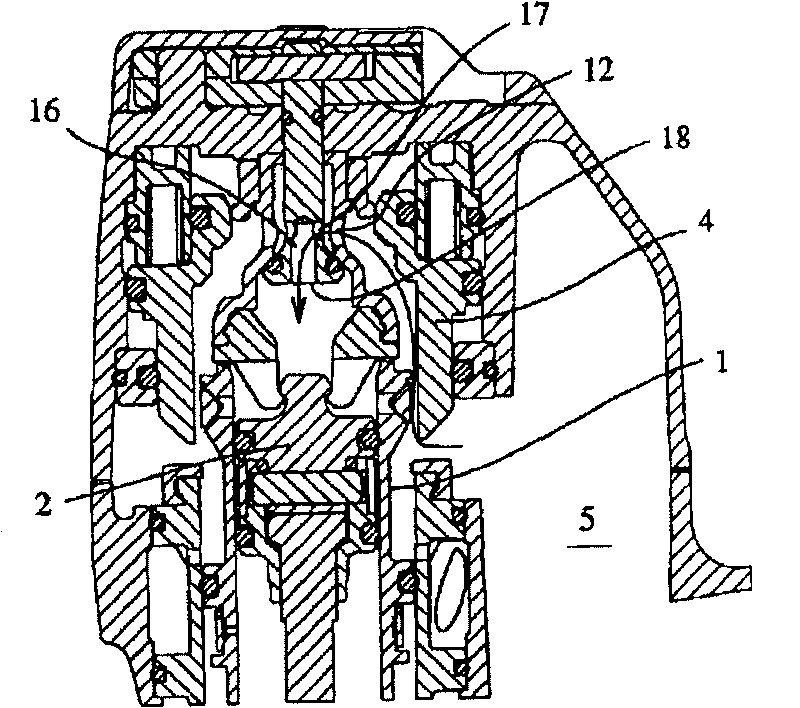

Gas combustion type driving tool

InactiveCN101400483AReduce flow rateReliable ignitionNailing toolsCurrent velocityCombustion chamber

An enclosed combustion chamber (6) is formed by moving a movable sleeve (10) provided at a hammering cylinder (3) up and down thereby butting the movable sleeve (10) against a cylinder head (8) above the hammering cylinder (3). Flammable gas and air are stirred in the combustion chamber (6) by means of a rotary fan (21) to produce mixture gas which is then ignited by means of an ignition plug (20) and combusted explosively. High pressure combustion gas acts on a hammering piston (4) to drive the piston impulsively, and a driver (5) coupled to the lower surface of the hammering piston (4) hammers out a stud. The upper wall surface on the outside of the combustion chamber (6) is located remotely from the ignition plug (20) in order to decrease the current velocity of the mixture gas passing trough the upper wall surface sufficiently enough to cause no trouble in ignition when the gas reaches the ignition plug (20). A groove (22) opening to the combustion chamber (6) is formed in the upper wall surface.

Owner:MAX CO LTD

Automatic nail hammer

InactiveCN101947765AAddressing shortcomings that require extra effortImprove binding efficiencyDispensing apparatusNailing toolsInlet valvePiston

The invention discloses an automatic nail hammer, comprising a driving mechanism for providing driving power, a transmission mechanism, and a pneumatic mechanism (8), wherein the transmission mechanism comprises a gear set and a link mechanism connected with an actuating device; and the pneumatic mechanism (8) comprises a first cavity (9) and a second cavity (7), a collision block (10) arranged in the first cavity (9) and used for separating the first cavity (9) and the second cavity (7), a piston (5) and a one-way gas inlet valve (6) arranged in the second cavity (7), the collision block (10) can slide along the axis of the first cavity (9) in the first cavity (9), the piston (5) is connected with the link mechanism, and the first cavity (9) is connected with an airflow channel. The invention solves the defects in the prior art, and provides an automatic nail hammer with high efficiency and capacity of automatically beating nails.

Owner:苏州卓识商务咨询有限公司

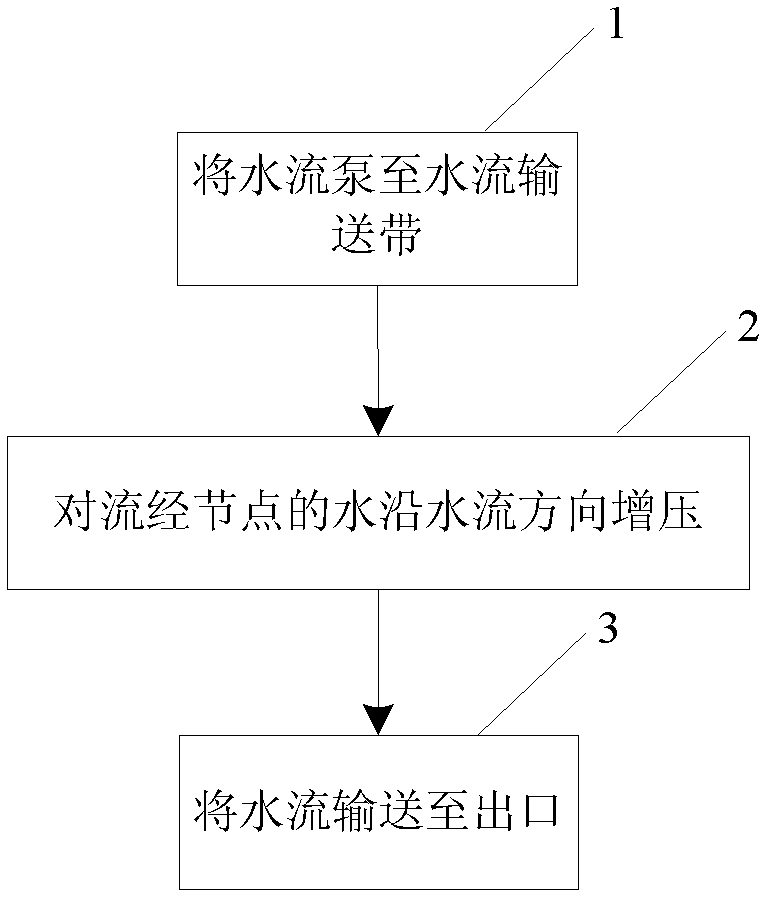

Water band pressurizing device and method and fire fighting apparatus

InactiveCN102430220ADoes not significantly increase spaceIncrease the striking powerFire rescuePipe-jointsWater flowEngineering

The invention provides a water band pressurizing device, a water band pressurizing method and a fire fighting apparatus. The water band pressurizing device comprises a water flow conveying belt consisting of a plurality of sections of water bands which are mutually communicated, wherein an axial-flow electric pump is arranged at a node between every two adjacent sections of water bands; the axial center of a blade of the axial-flow electric pump is parallel to the water flow direction in the water bands; and the axial-flow electric pump is used for pressurizing water flowing through the node along a water flow direction. After sequentially flowing through the node, the water flow is pressurized in a way of relay, so the problem that it is difficult to delivery water to a high floor during fire fighting is solved. The water band pressurizing device has the advantages of high fire-fighting efficiency, flexible operation, compact structure and the like.

Owner:SANY HEAVY IND CO LTD (CN)

Clutch type screw press

The clutch type screw press includes a frame, a sliding block, a flywheel and a motor. On the frame, there are screw in the center, brake and sliding block connected to the lower part of the screw, flywheel and clutch, comprising a power disc and a friction wheel train, connected to the upper part of the screw, compressed air driven cylinder connected to the clutch, pressing board around the lower part of the friction wheel train, guide post with spring and with upper end fixed to the flywheel and lower end connected movably to the pressing board, and operating block around the pressing board and connected to the cylinder. The clutch type screw press has compressed air as operating power of the clutch, less pressure releasing links, fast pressure release, simple structure, great impact force and other advantages, and may be used in pressure formation of metal material in different industry.

Owner:韩宝林

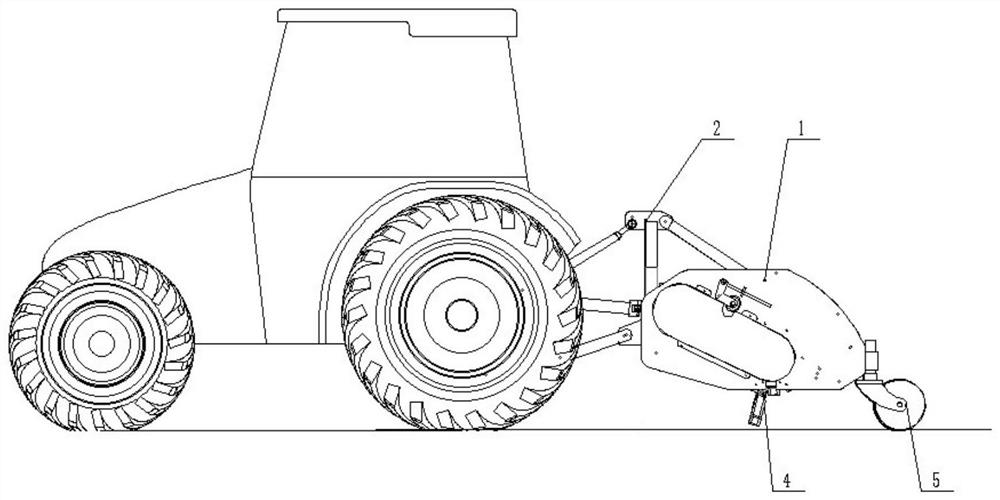

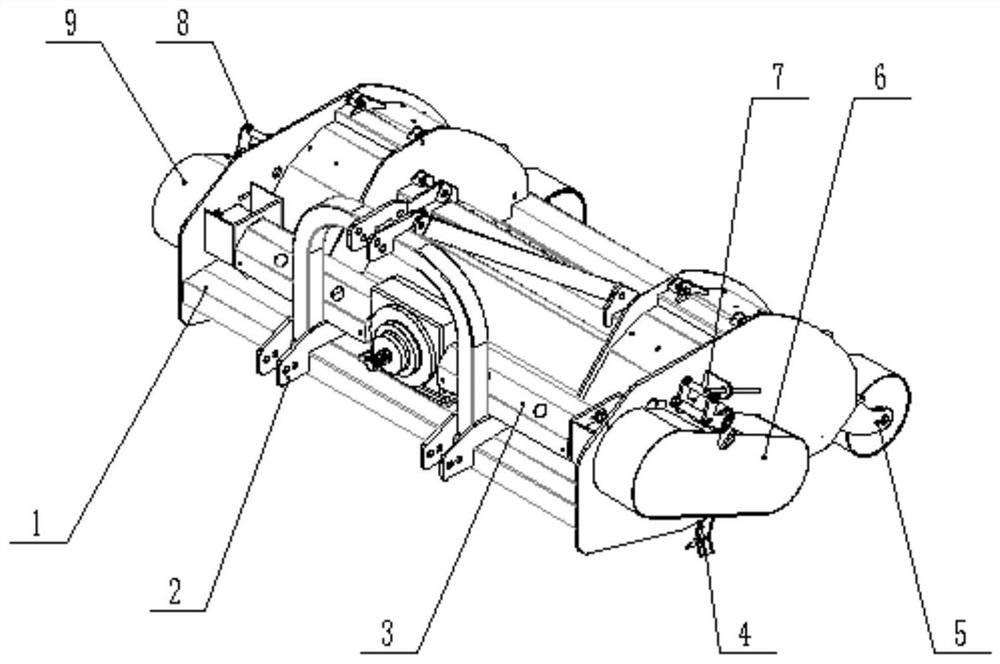

Variable-shaft-diameter ridge-imitating cassava stem smashing and returning machine

PendingCN113366966ACapable of cuttingHas the ability to pick upAgricultural machinesMowersStructural engineeringManihot esculenta

The invention relates to a variable-shaft-diameter ridge-imitating cassava stem smashing and returning machine which comprises a machine frame, a three-point suspension mechanism, a transmission device, a smashing and returning device and two land wheels, wherein the machine frame is installed behind a tractor through the three-point suspension mechanism, and an output shaft outputting power behind the tractor provides power for a transmission system. The smashing and returning device comprises a variable-shaft-diameter smashing cutter shaft, a smashing cutter holder, a first bearing seat support, a second bearing seat support and a profiling smashing cavity; and the variable-shaft-diameter smashing cutter shaft comprises a middle small-shaft-diameter cutter shaft and large-shaft-diameter cutter shafts at the two ends. A variable-shaft-diameter ridge-imitating structure is adopted, the problems that many cassava stems remain in furrows and smashing is not thorough are solved, the service life of a cutter set is effectively prolonged, the hitting force of the furrows is increased, the whole machine structure is simplified, energy consumption is reduced, the operation stability and safety are improved, waste cassava stems are effectively prevented from sprouting again, the cassava harvesting cost and harvesting efficiency are reduced, and smashing capacity and working efficiency are improved.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI +1

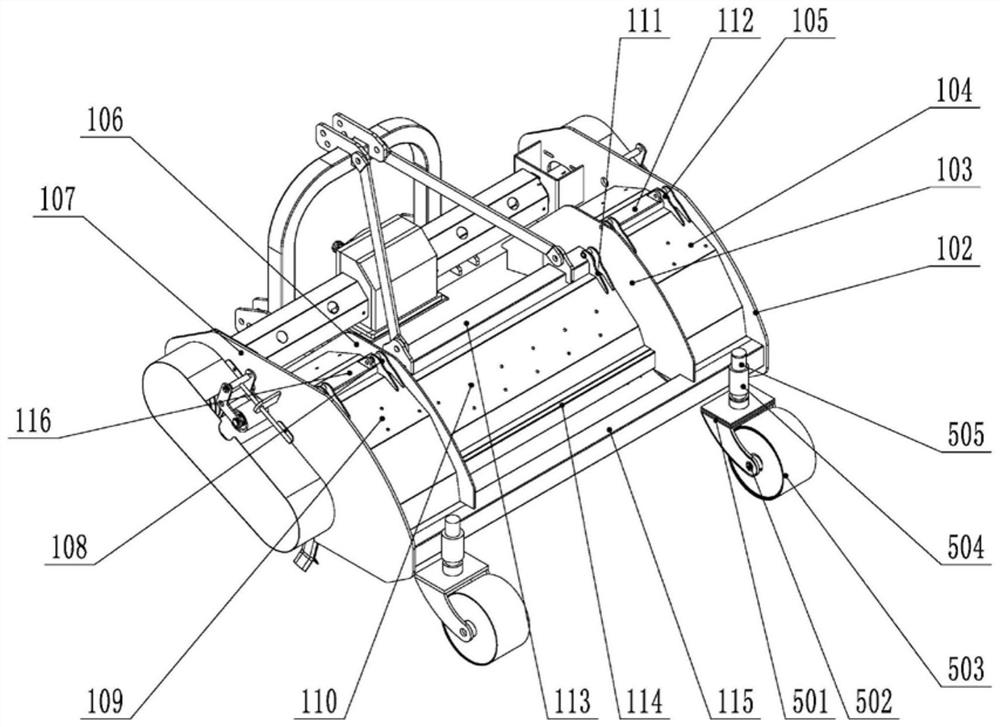

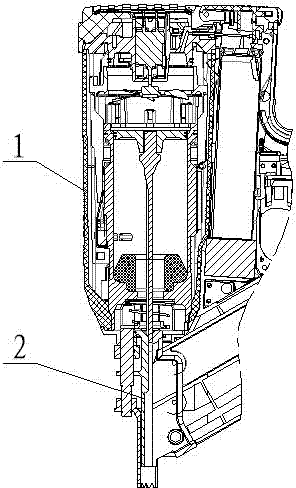

Energy-saving electric massage gun

PendingCN112190459ACompact designReduce volumeVibration massagePhysical medicine and rehabilitationMassage

The invention provides an energy-saving electric massage gun. The massage gun comprises a shell and a massage head; the shell comprises a machine body and a handle; a fixing mechanism and a moving mechanism are installed inside the machine body; the fixing mechanism comprises a coil; the moving mechanism comprises a magnet; a travel switch for detecting the positions of the fixing mechanism and the moving mechanism is further installed between the fixing mechanism and the moving mechanism; and the massage head is connected with the moving mechanism; the massage gun further comprises a main control board and a power supply; the power supply, the coil, and the travel switch are electrically connected with the main control board; and the massage head moving mechanism is pressed to move towards the fixing mechanism to trigger the travel switch, the coil is powered on, and the moving mechanism pushes the massage head out. The energy-saving electric massage gun is driven by electromagnetic force and is compact in structural design, small in overall size and low in noise. During work, the coil is powered on only when the massage head is stretched out, and the coil is not powered on in thewhole process, so that electric energy is saved, and endurance time is long.

Owner:SHENZHEN CHETAIDOU TECH

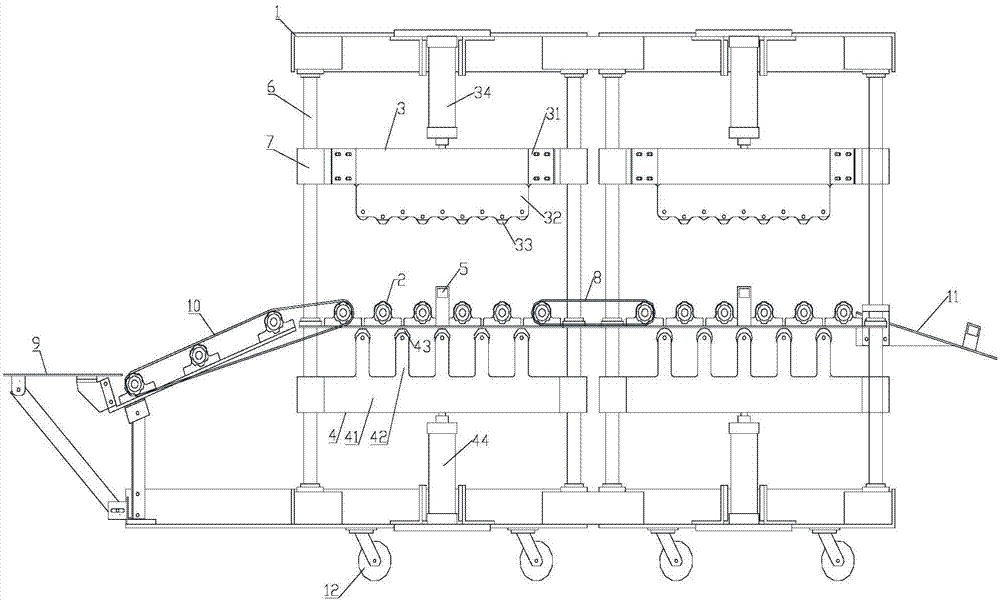

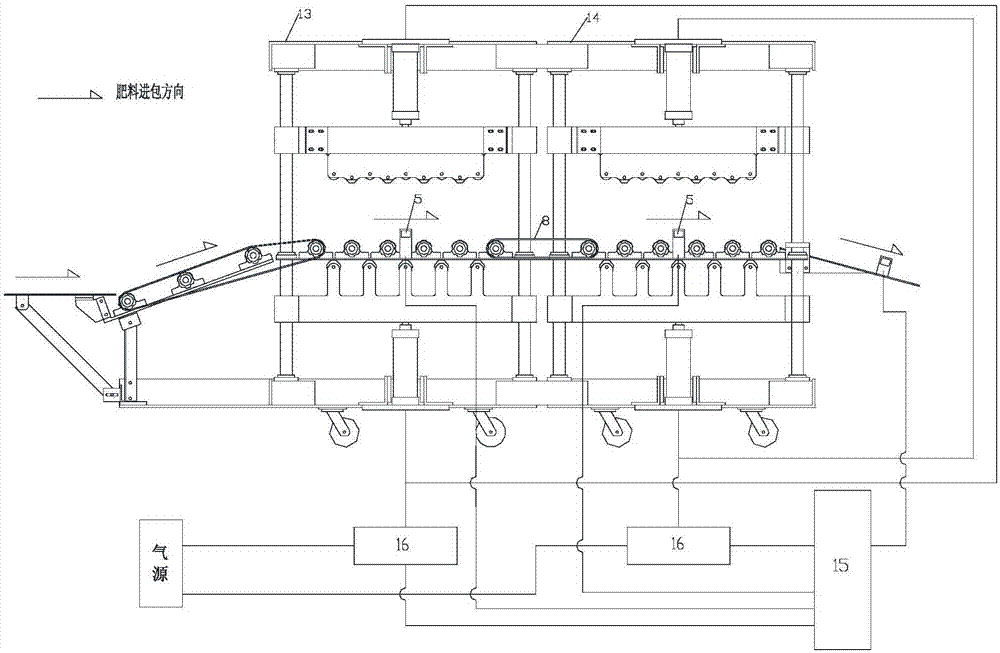

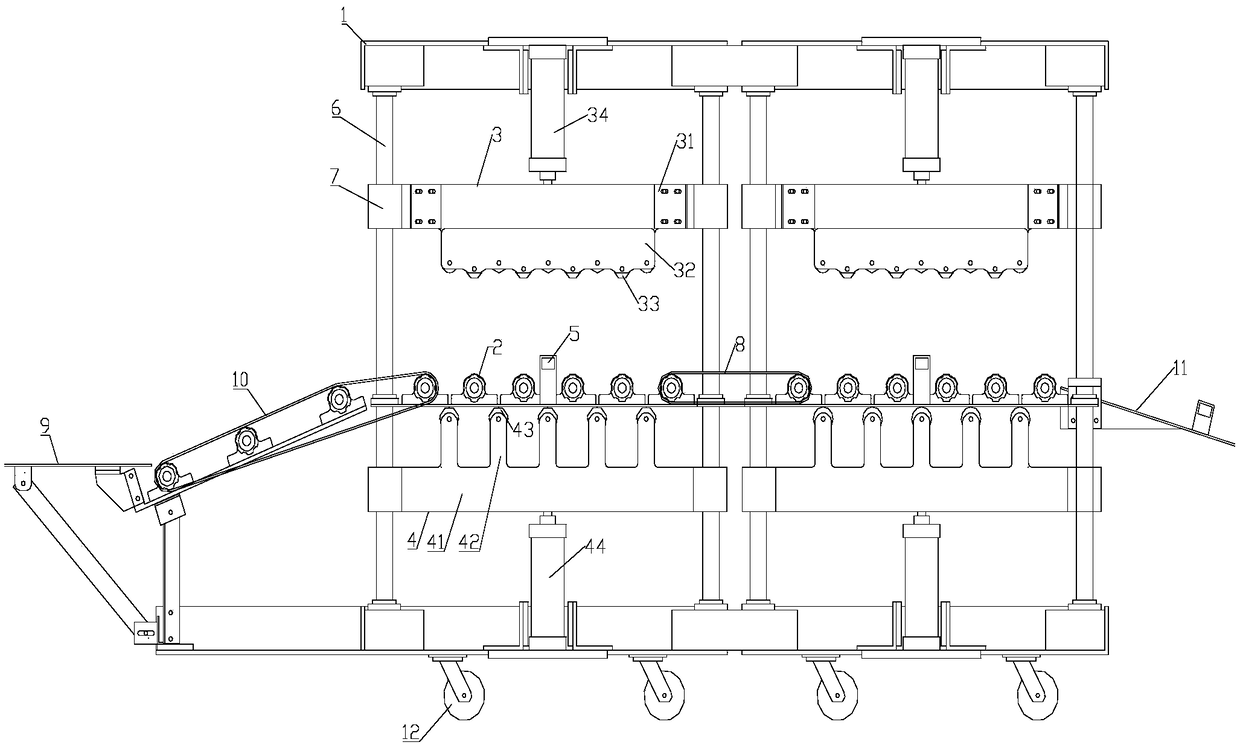

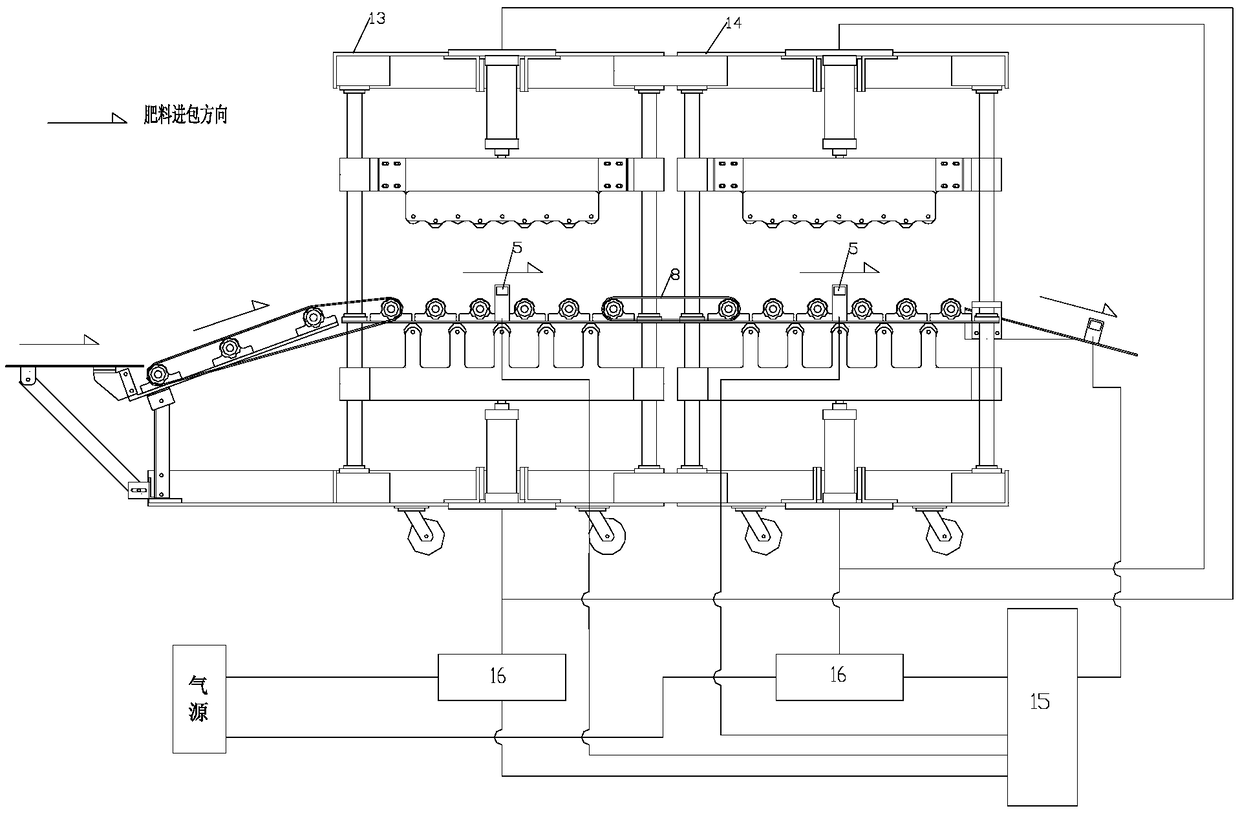

Automatic bale opener

ActiveCN107161735ALoose bale with high efficiencyLoose bag effect is goodLoading/unloadingUltimate tensile strengthMechanical engineering

Owner:王虹

Agricultural water combing and sticking, pushing and crushing-resistance threshing machine

ActiveCN110063144AAvoid sticking to each otherAvoid affecting the effect of hitting riceSeed preservation by dryingThreshersEngineeringRice grain

The invention discloses an agricultural water combing and bonding, pushing and crushing-resistance threshing machine which structurally comprises a baffle, a thresher, a support plate, a driver and amain body, wherein the lower end of the baffle is nested in the main body and fixed by bolts; and the thresher is in transmission connection with the driver. The threshing machine has the benefits that water on rice can be initially treated under the action of a mainboard and is discharged; bonding of leaves and rice grains is avoided; an impact force suffered by the rice is increased under the action of interaction of grain guide holes and extractors; rice grain residue on the rice is avoided; a yield rate of the rice grains is increased; the water on the surfaces of the rice grains can be initially treated under the action of rubbing devices and a main shaft; bonding of the rice grains at the upper part due to the water to influence dropping is avoided; the rice can be intensively driedunder the action of grain controlled at the same time; extrusion of the rice grains due to the bonding and agglomeration is avoided; and the product quality of the rice grains is improved.

Owner:黑龙江省牡丹江农垦稻花乡米业有限责任公司

Air pressure type screw nail infiltrating device

ActiveCN101296783AAdjust driving forceAppropriate penetration depthStapling toolsPower driven toolsEngineeringCompressed air

A pneumatic screw driving machine comprises an air chamber for reserving a compressed air, a main valve supplying the compressed air reserved in the air chamber to a hammering cylinder, a driver bit for driving and tightening a screw, a valve housing provided in the main valve, and a valve body so provided as to be capable of vertically movable with respect to the valve housing. A through hole opening to the air chamber is formed in the valve housing; and a lower opening part opening to the hammering cylinder, a side opening part opening to the air chamber through the through hole, and a first air supply passage allowing the lower opening part to communicate with the side opening part are formed in the valve body. When the valve body is moved downward, a second air supply passage allowing the air chamber to communicate with the hammering cylinder through the through hole is formed between the outer peripheral surface of the valve body on the lower side of the side opening part and the inner peripheral surface of the valve housing.

Owner:MAX CO LTD

Safety hammer

ActiveCN103847670AWeight increaseBig hitPoint-like light sourcePedestrian/occupant safety arrangementEngineering

The invention provides a safety hammer, which comprises a hammerhead and a handle, wherein the hammerhead is in the shape of a round sphere; a plurality of thimbles are arranged in the hammerhead; the thimbles are connected with a connecting rod; the connecting rod is arranged in the hammerhead and the handle; a groove is formed in the handle; the groove is provided with a bulge; the bulge is connected with the connecting rod; the connecting rod can be driven to vertically move by the bulge; when the bulge moves towards the hammerhead, the thimbles in the hammerhead can protrude out of the surface of the hammerhead; when the bulge moves far away from the hammerhead, the thimbles can be retracted into the hammerhead. By increasing the weight of the hammerhead, the hitting force of the hammerhead can be more effectively increased, and meanwhile, the thimbles are arranged around the hammerhead, so that the hammerhead can be used for hitting an object from all angles; meanwhile, the hammerhead can be more easily found at night without lamplight.

Owner:DANYANG CITY FEIYUE VEHICLE ACCESSORY

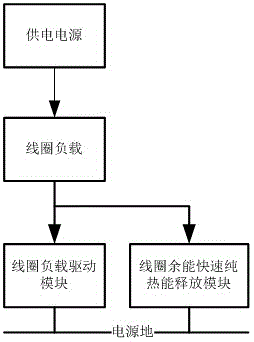

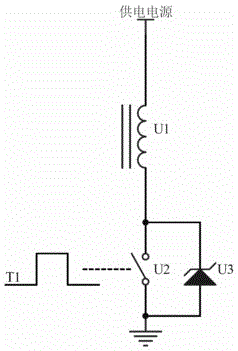

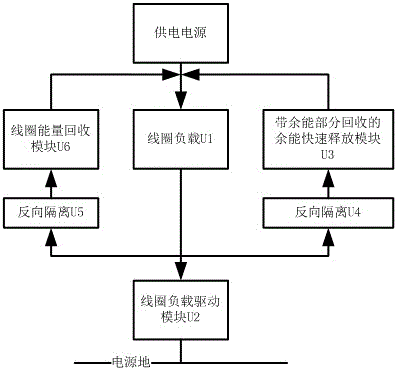

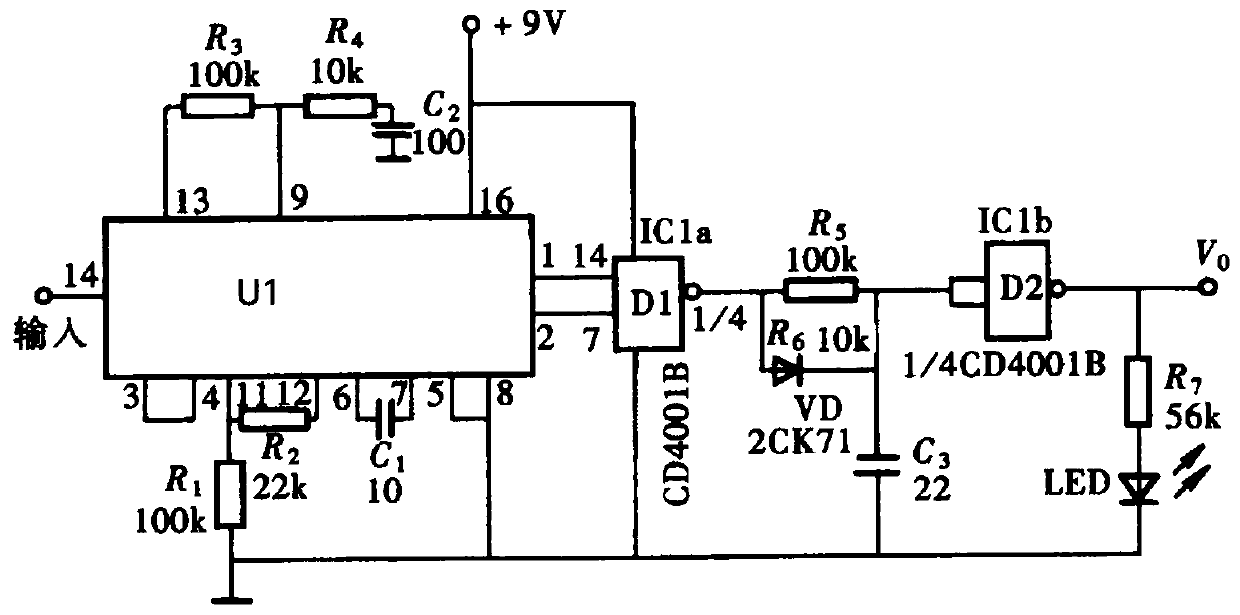

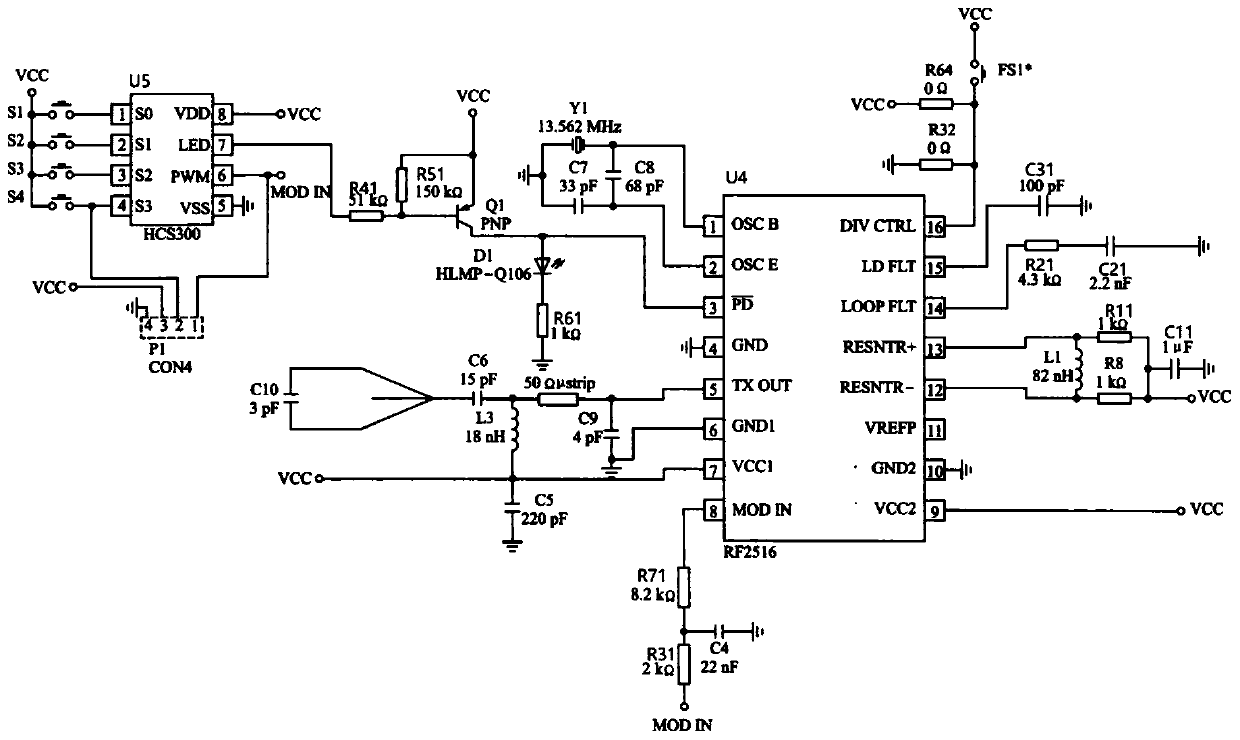

Drive and control circuit for impact force increasing of needle type printing head and control method of drive and control circuit

ActiveCN106004122ABig hitReduce power consumptionOther printing apparatusFast releaseEnergy recovery

The invention relates to a drive and control circuit for impact force increasing of a needle type printing head and a control method of the drive and control circuit. The drive and control circuit comprises a power supply, a coil load module U1, a coil load drive module U2, a complementary energy quick releasing module U3 for recycling a part with complementary energy, a second reverse isolation module U4, a first reverse isolation module U5 and a coil energy recycling module U6; the coil load drive module U2 is further connected with a main sequence circuit T1; the main sequence circuit T1 is used for generating an electromagnetic force to a drive and control coil so as to discharge needles; and the first reverse isolation module U5 and the coil energy recycling module U6 are connected with a sequence circuit T2, and are used for recycling energy. Double sequence drive and control and a new quick energy releasing module are adopted, a function of recycling the complementary energy in a sectional manner is fulfilled, power consumption of a whole printer is greatly reduced, and heating is reduced; and meanwhile, the impact force of the printer is increased, the printing effect is improved, and double functions of saving energy and improving printing effect are fulfilled.

Owner:福建星谷信息科技有限公司

Pneumatic hammer for removing cinder ladle

The invention discloses a pneumatic hammer for removing a cinder ladle, and belongs to the field of pneumatic hammers. The pneumatic hammer for the removing the cinder ladle comprises a cylinder barrel; a pneumatic hammer rod is arranged in the cylinder barrel in a sliding manner; an exhaust block and an air inlet block are sequentially connected to the upper end of the cylinder barrel; the upperend of the cylinder barrel is connected with the exhaust block and the air inlet block through a cylinder barrel connecting block; the pneumatic hammer further comprises an upper diaphragm, a movablediaphragm and a lower diaphragm; the upper diaphragm is fixedly arranged in the air inlet block; an air path a, an air path b and an air path c are arranged on the air inlet block, the upper diaphragm, the movable diaphragm, the lower diaphragm, the exhaust block and the cylinder barrel; the air path a is used for driving the pneumatic hammer rod to move upwards; the air path b is used for drivingthe pneumatic hammer rod to move downwards; and the movable diaphragm moves up and down by opening and closing the air path b. The quick pressure relief and the air path conversion are combined to perform reciprocating hitting, and the pneumatic hammer can quickly hit the cinder ladle, is large in hitting force, can quickly reset, and effectively avoids a sticking phenomenon.

Owner:肇庆谊龙科技有限公司

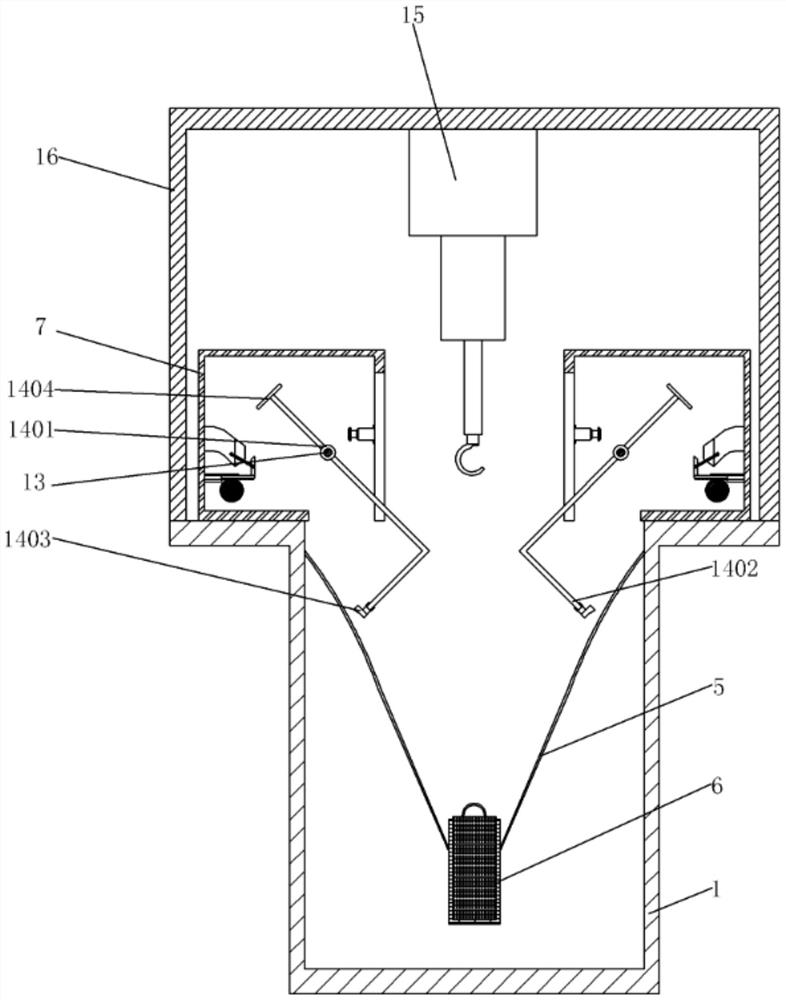

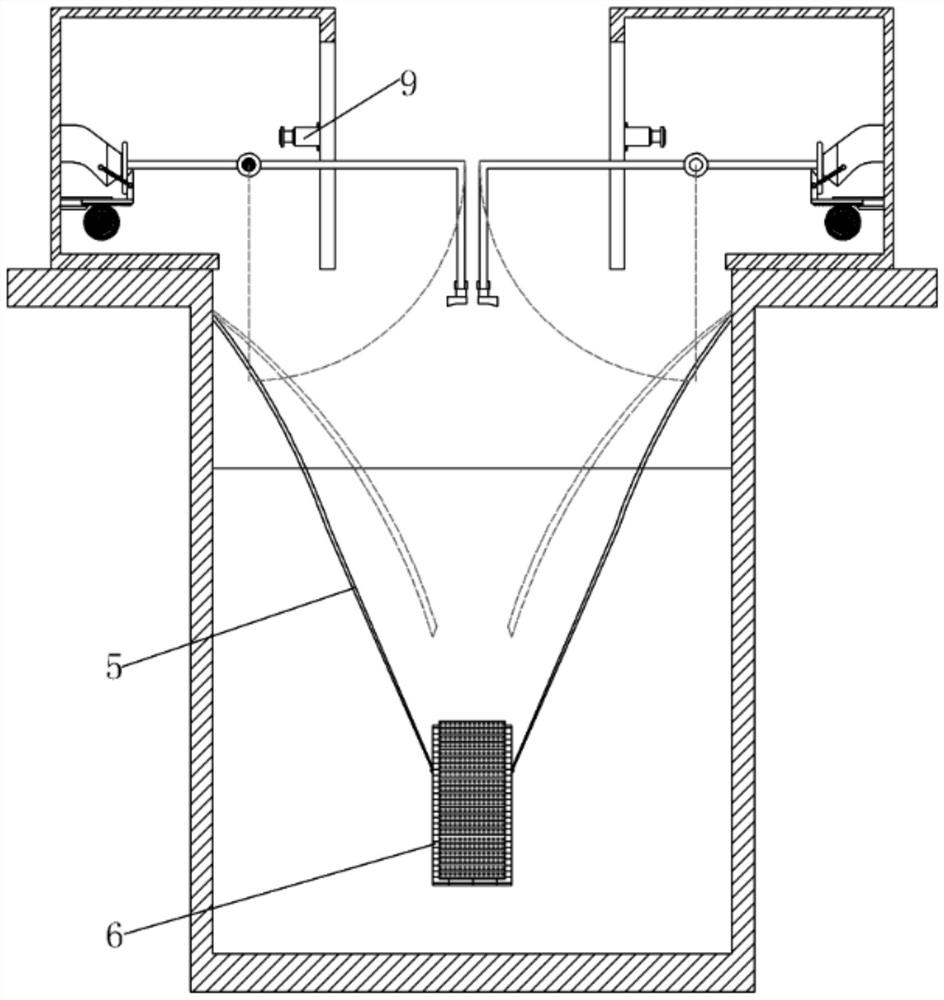

Novel detection equipment for polymer building material

PendingCN114813432AGood damage effectHigh accuracyWeighing by absorbing componentBuilding materialPotential energy

The present invention relates to the technical field of building material quality detection, and discloses a novel polymer building material detection device, which comprises a test pool, the top of the test pool is provided with a support edge table, the support edge table is fixedly provided with a power module, and the power module drives a winding module to rotate and operate, a steel cable is wound on the winding module, the drooping end of the steel cable is fixedly connected to the net cage, a rock wool board to be detected is placed in the net cage in an attached mode, and a fixed shell is further arranged above the supporting edge table. According to the novel detection equipment for the polymer building material, more kinetic energy is converted from power potential energy along with the angle deviation of the steel cable, and the striking force of the driving hammer on the steel cable is larger, so that a sufficient vibration effect can still be generated on a rock wool board although the depth of the rock wool board immersed in water is increased; therefore, the purpose of better destroying the bubbles on the surface of the rock wool board is achieved, and the effect of higher accuracy of the detection result is achieved.

Owner:赵晨 +1

Mountain-cutting heavy punch

InactiveCN108316386ABig hitConvenient crushing workSoil-shifting machines/dredgersNitrogen gasEngineering

The invention discloses a mountain-cutting heavy punch. A through hole is formed in the bottom wall of a barrel body; a guide sleeve is arranged in the through hole in a penetrating mode; a brazing rod is arranged in the guide sleeve in a sleeved mode; a punch body, a slide path, a first oil cylinder and a nitrogen gas chamber are arranged in the barrel body; the upper part of the punch body is connected with a piston rod of the first oil cylinder; a cylinder barrel of the first oil cylinder communicates with a nitrogen gas chamber; the brazing rod comprises a rod body and a rod head; and therod body is connected with the rod head through a pin roll. The mountain-cutting heavy punch has the advantages that: compared with a conventional crushing hammier, dropping speed is extremely high after the punch body is lifted and bears dual action of self-gravity and pushing force of compressed nitrogen gas in the nitrogen gas chamber, hitting force on the brazing rod by the punch body is great, crushing force is increased and crushing efficiency is improved; the rod body of the brazing rod and the rod head of the brazing rod can be freely dismounted, and can be independently replaced afterthe rod head is worn, so that cost is reduced, and working efficiency is improved; and a rake can be used for clearing broken stones or other garbage, so that the integral environment is guaranteed to be beneficial for crushing work. The mountain-cutting heavy punch is clean in operation, is free of waste gas emission, is simple to maintain, and is low in fault rate.

Owner:于茂涛

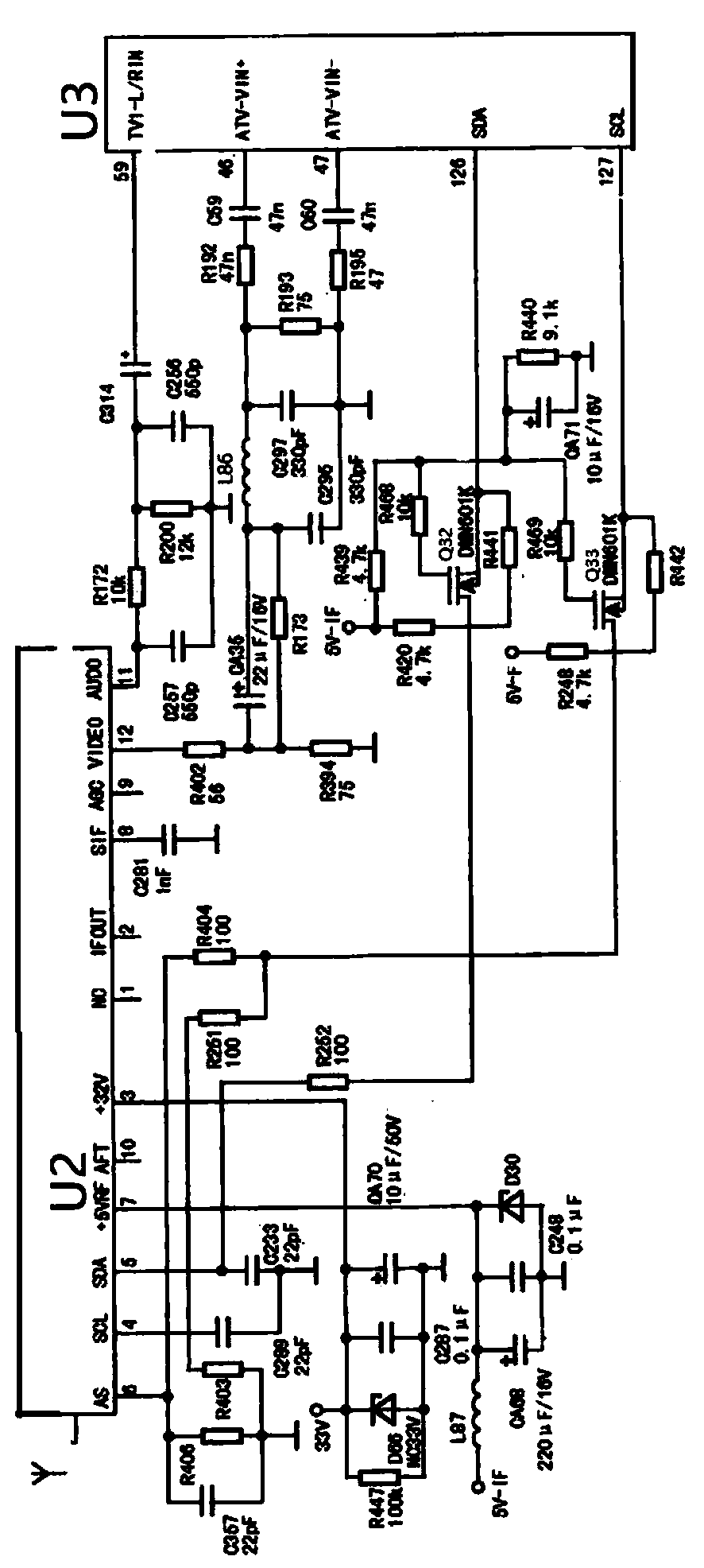

Intelligent anti-unmanned aerial vehicle investigation and suppression system and method

PendingCN111447039AHigh precisionImprove securityProgramme controlComputer controlUncrewed vehicleSignal processing

The invention discloses an intelligent anti-unmanned aerial vehicle investigation and suppression system and method. The method comprises the steps: S1, enabling an investigation module to investigatethe signal frequency characteristics of an unmanned aerial vehicle, and capturing and amplifying the signal frequency characteristics; S2, processing the captured and amplified signal frequency characteristics and comparing the signal frequency characteristics in a database by a signal processing module; and S3, transmitting an interference signal to the successfully compared unmanned aerial vehicle for suppression by a suppression module. According to the investigation and suppression system and method for the intelligent anti-unmanned aerial vehicle, the unmanned aerial vehicle is investigated and detected in real time, the signal frequency characteristics of the unmanned aerial vehicle are captured and amplified, then the signal frequency characteristics are compared to confirm thespecific model of the unmanned aerial vehicle, and finally suppression of different grades is carried out in real time according to different models of the unmanned aerial vehicle.

Owner:浙江瑞通电子科技有限公司

Screen type melon beating machine

InactiveCN105409461ABig hitAvoid Situations That Cannot DeseedSaving energy measuresThreshersNeedle roller bearingPulp and paper industry

The invention relates to agricultural product processing machinery, and discloses a screen type melon beating machine. The screen type melon beating machine comprises a rotating shaft and a drum, wherein a blade rod is arranged on the rotating shaft; through holes are densely formed in the outer peripheral surface of the drum; the rotating shaft is coaxially and rotatably mounted in the drum; the drum is matched with the rotating shaft by a needle bearing; a feeding opening is formed in the drum and is connected with a baffle for closing the feeding opening; the driving end of the rotating shaft is connected with a first motor; the driving end of the drum is connected with a second motor; and a collecting tank for containing melon seeds and chippings in melons is arranged under the drum. Through the rotation of the drum, melon bodies positioned on the bottom of the drum can be taken upwards, and then are beaten by the blade rod, the circumstance that seeds of the parts of the melon bodies cannot be removed is avoided, compared with the prior art, the screen type melon beating machine in the scheme is full and uniform in melon beating, and seed removal missing can be avoided well.

Owner:CHONGQING CITY CHANGSHOU DISTRICT AGRI PROD COMMERCE CIRCULATION ASSOC

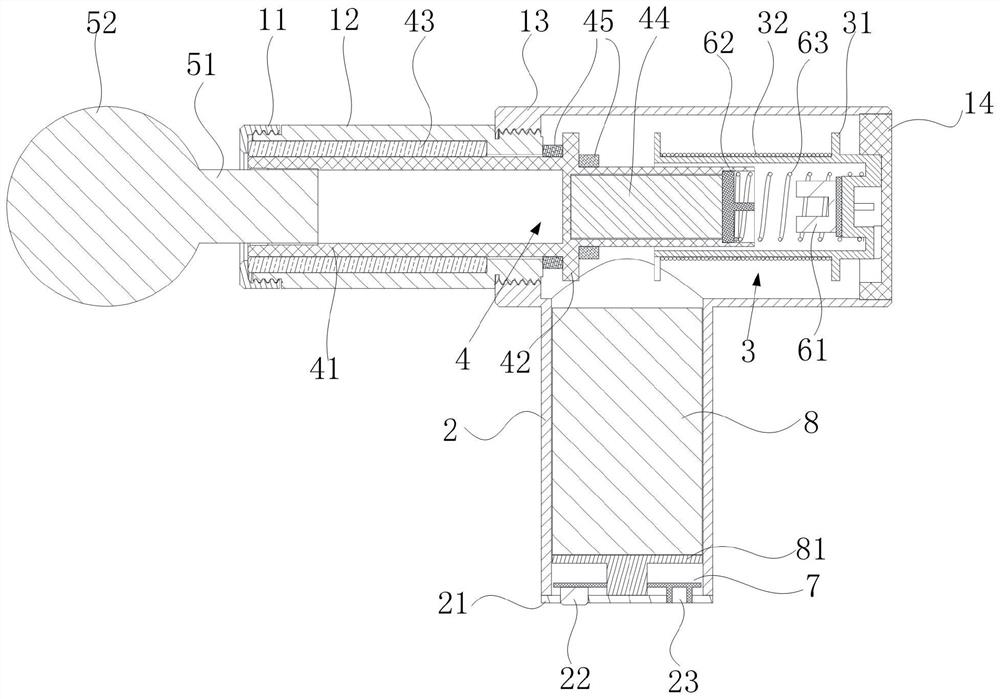

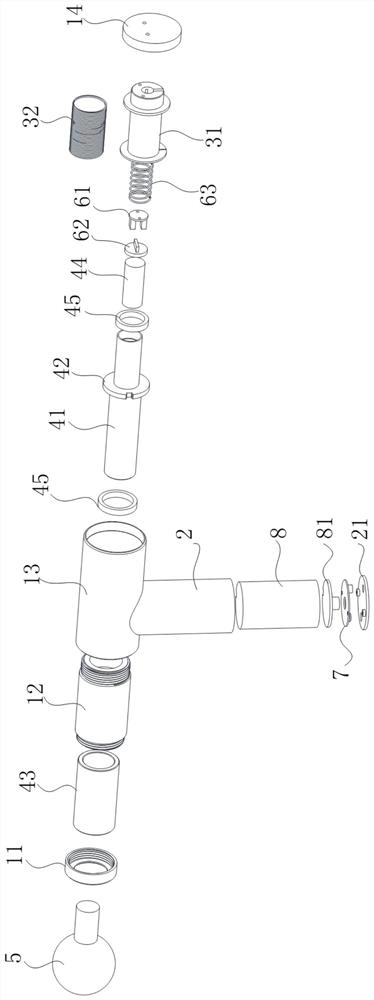

A booster bat

ActiveCN104857682BMake up for lack of explosive powerLight in massRacket sportsMicrochiropteraInlet valve

The present invention relates to a booster goal stick. The booster goal stick mainly includes a club and a mallet; an air bag handle is sheathed on the handle of the club; There is a cylindrical groove, and an elastic airbag is fixedly installed in the groove; an impact block is installed at one end of the elastic airbag, and an exhaust pipe and an air intake pipe are connected next to the elastic airbag A one-way air intake valve and a one-way air extraction valve are respectively installed at the interface where the air intake pipe and the air extraction pipe are communicated with the elastic air bag; A sealed switch is installed at the mouth; the exhaust pipe is connected to the handle of the airbag; the gateball bat has a simple structure and is easy to carry; a high-speed ball can be played with a small force, and at the same time, the grip strength of the palm can be exercised and the hand can be flexibly Meridians.

Owner:廊坊秋睿工程技术有限公司

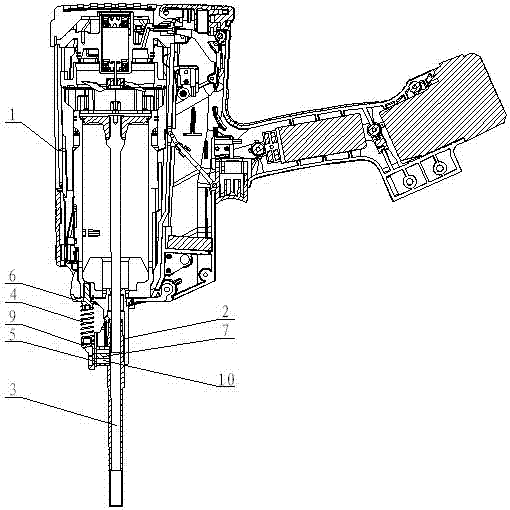

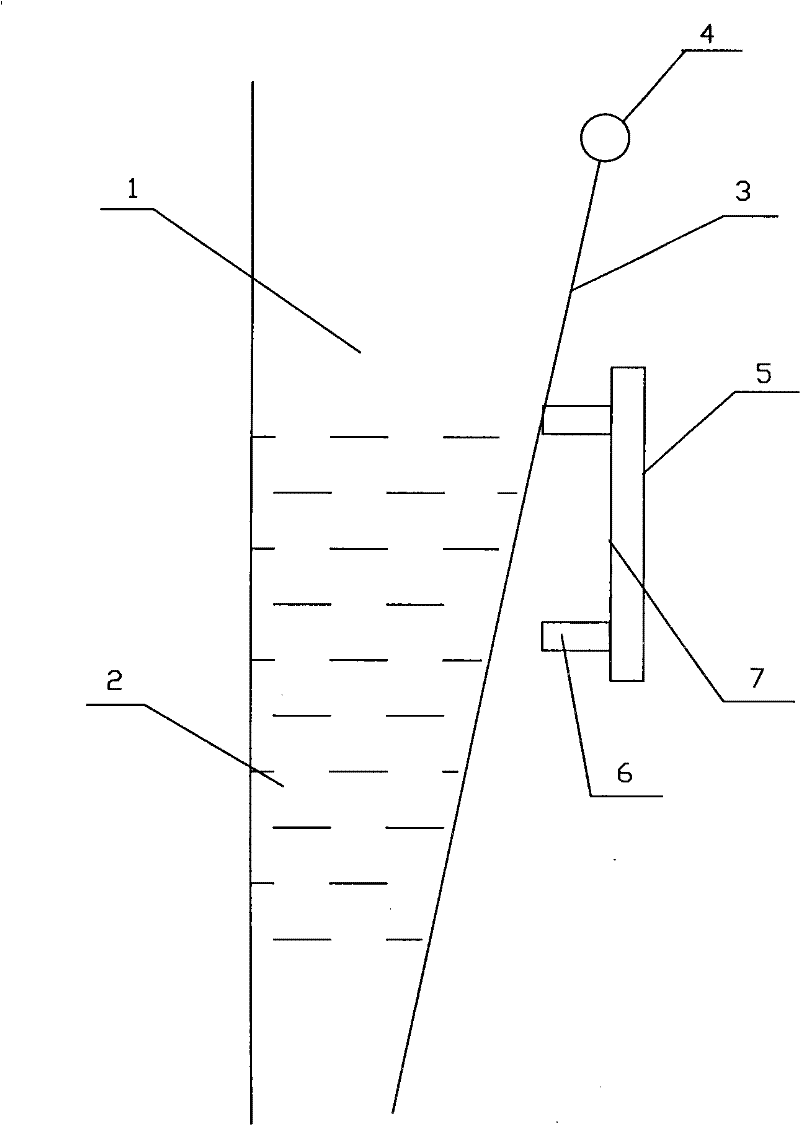

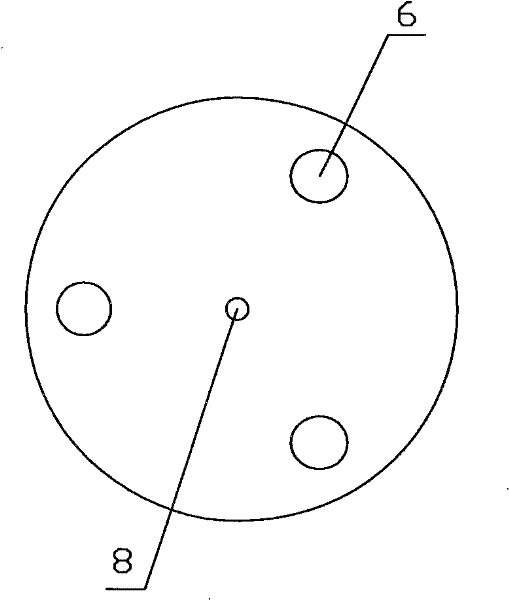

Gas nailing tool

InactiveCN102785218AIngenious structural designEasy to manufacture and installNailing toolsEngineeringGun barrel

The invention discloses a gas nailing tool. The gas nailing tool comprises a shell (1), a gun head (2), a gun barrel (3), a safety support pressure spring (4) and a safety support (5). The gun head (2) is connected with the front end of the shell (1) through a disk (6), the gun head (2) and the gun barrel (3) are split, and the safety support pressure spring (4) and the safety support (5) are both connected to one end of the gun barrel (3) which penetrates into the gun head (2) and is prevented from rotating through a rotation preventing device. The gas nailing tool has the advantages of ingenious structural design and simplicity in manufacturing and mounting, using the gas nailing tool without increasing the length of the shell can not only obtain enough striking force but also realize wider utilization range and low nailing cost, and utilization cost is greatly saved.

Owner:朱益民

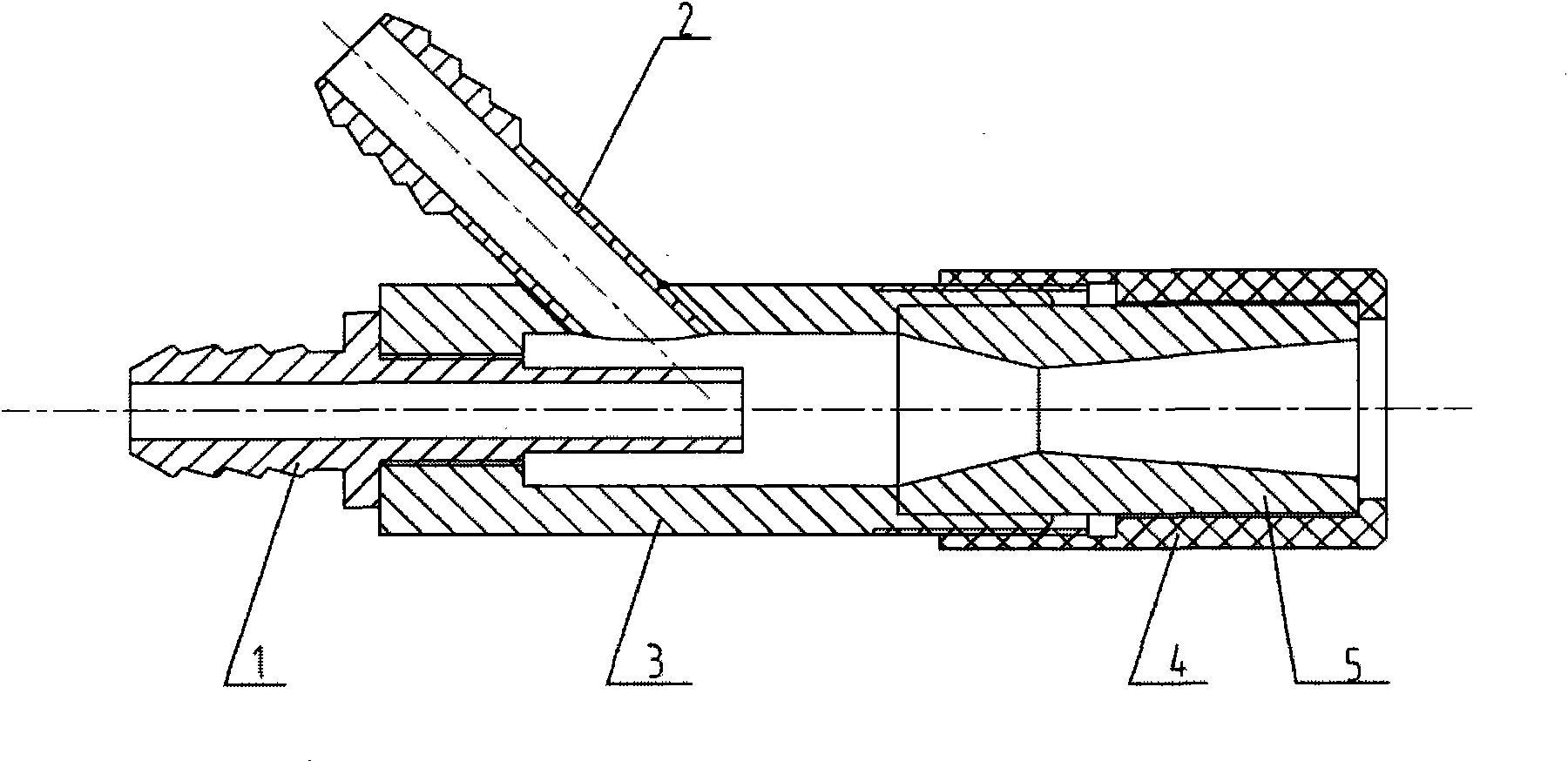

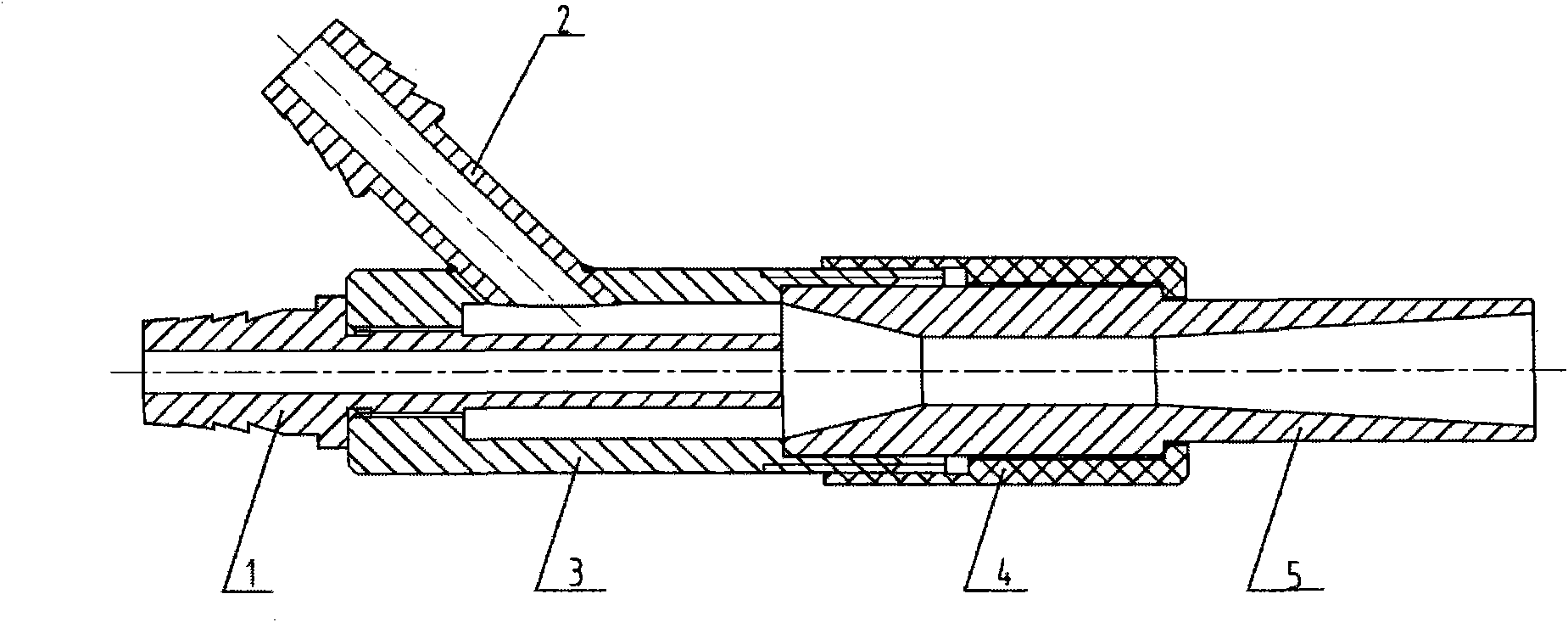

Shot blasting spray gun

The invention provides a shot blasting spray gun, comprising a main body, a mixing chamber arranged in the main body, an air inlet pipe communicated with an opening at the front end of the mixing chamber, a nozzle communicated with the opening at the rear end of the mixing chamber and a shot inlet pipe communicated with the opening on a side wall of the mixing chamber, wherein the mixing chamber is provided with the front end, the rear end and the side wall arranged between the front end and the rear end, the front end, the rear end and the side wall are all provided with openings; and the air inlet pipe is provided with an extension part arranged in the main body, and the extension part of the air inlet pipe extends to a position almost parallel to the initial point of the nozzle in the main body. The extension part of the air inlet pipe in the mixing chamber is almost parallel to the initial point of the nozzle, thus the air inlet pipe is far away from a shot blasting opening and the air inlet pipe can be avoided from being damaged rapidly; and meanwhile, air current can enter into the nozzle in an almost zero-loss way, and the effective blasting dynamic can be improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

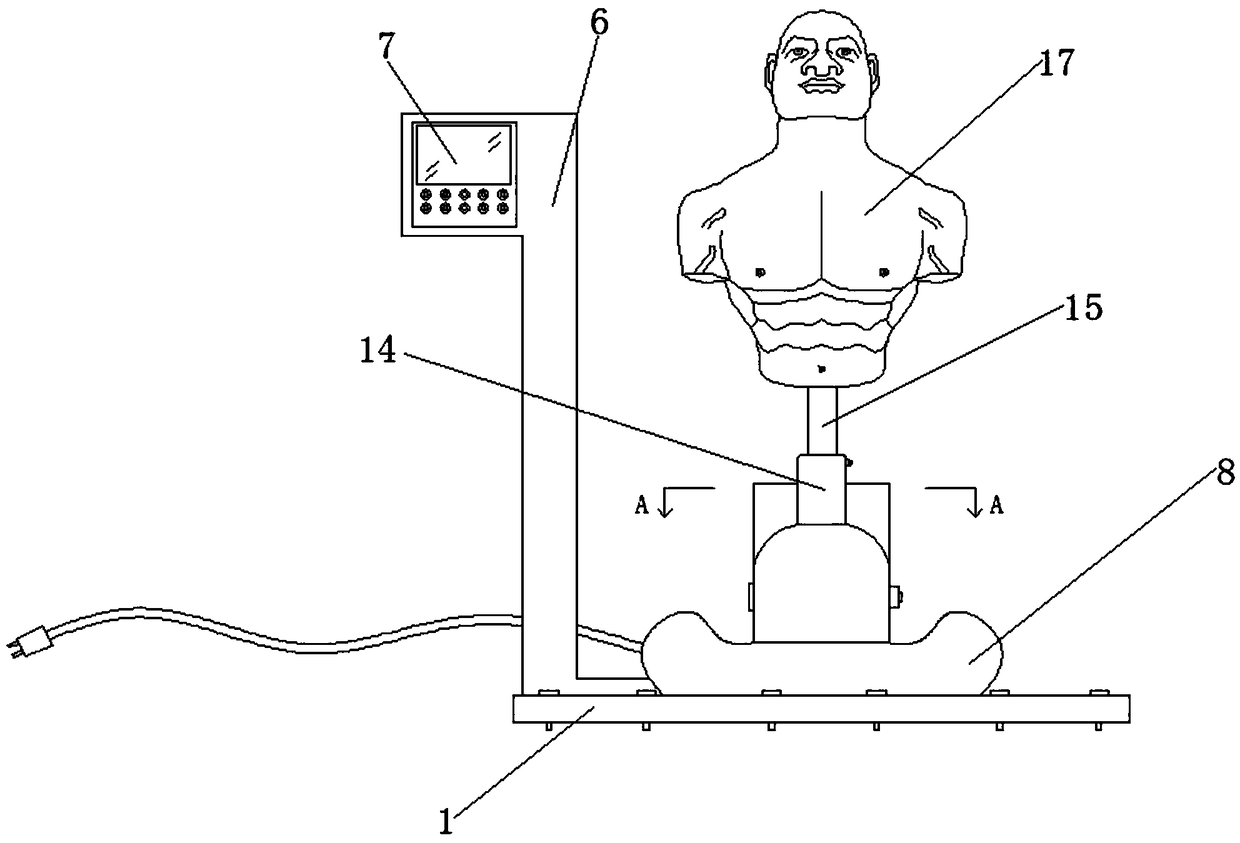

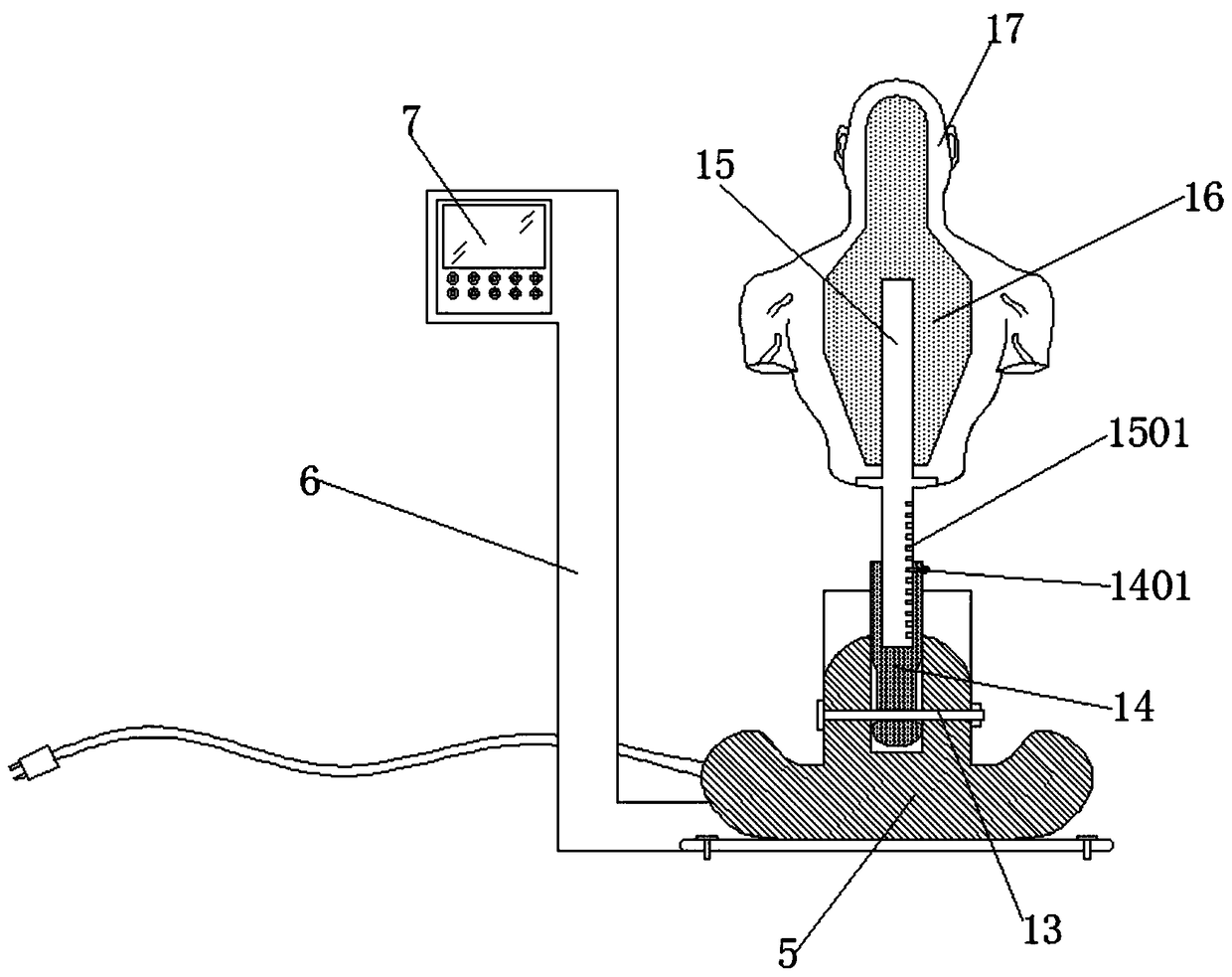

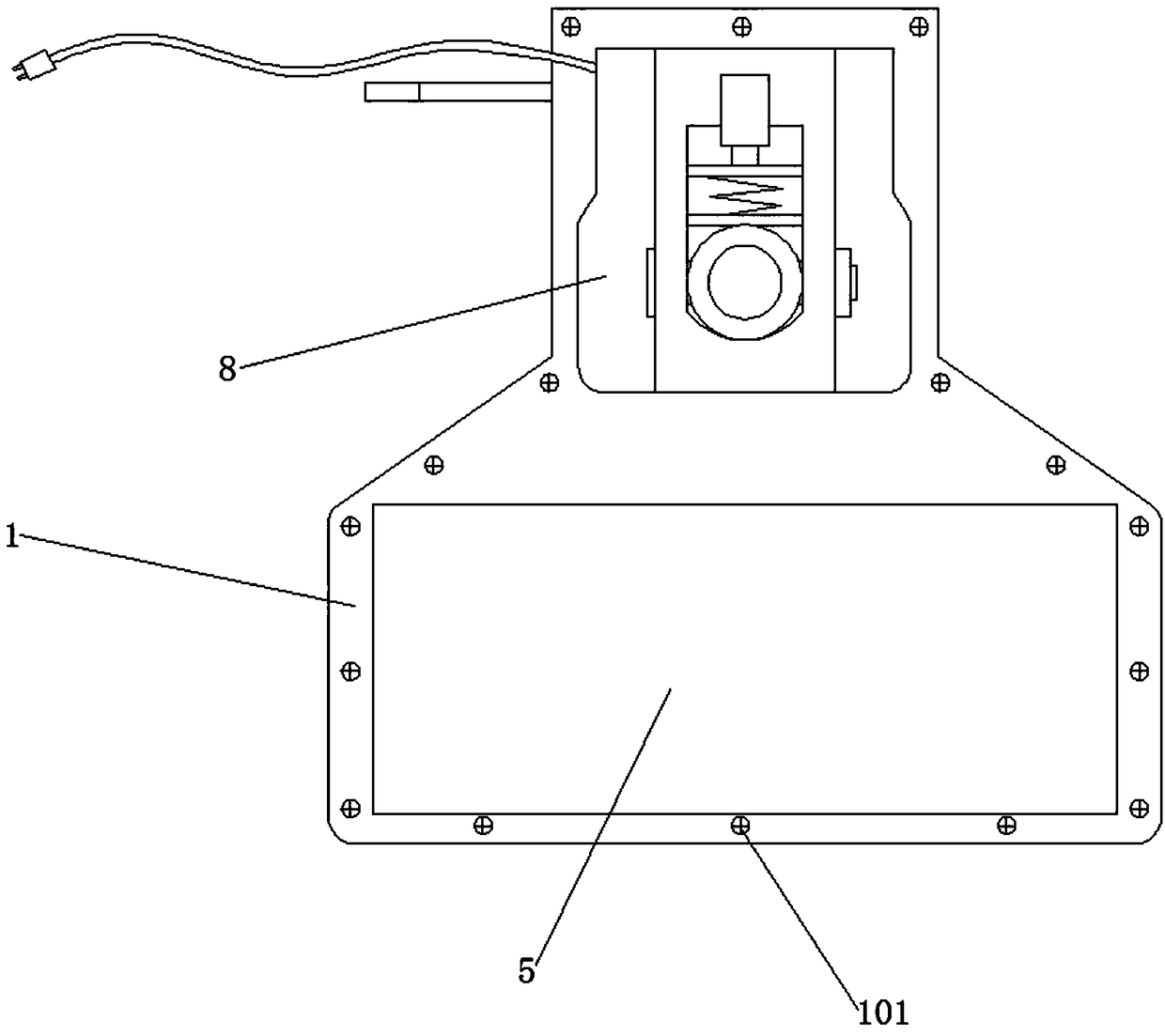

Multi-functional Sanda training sandbag

The invention discloses a multi-functional Sanda training sandbag. The sandbag comprises a base, a sliding groove, a weight sensor, first springs, a bottom board, a support, a weight display device, afixing seat, an electric push rod, a first push board, a second spring, a second push board, a fixing shaft, a rotary sleeve, a telescopic rod, a reinforcing board and a human-shaped sandbag. The multi-functional Sanda training sandbag is ingenious in structure and powerful in function. Firstly, the purpose of adjusting exercise degree is fulfilled according to training degree and the self capability of a person through resistance-type adjusting design. A weight detection mechanism helps a coach gain a better understanding of weight changes of a trainee so that the coach conveniently arrangestargeted training lessons in the later period. The training effect of the trainee is improved. The multi-functional Sanda training sandbag is conducive to promotion and application of Sanda and boxing.

Owner:国武时代国际文化传媒(北京)有限公司

Air pressure type screw nail infiltrating device

ActiveCN101296783BBig hitAdjust penetration depthStapling toolsPower driven toolsPeripheralCompressed air

A pneumatic screw driving machine comprises an air chamber for reserving a compressed air, a main valve supplying the compressed air reserved in the air chamber to a hammering cylinder, a driver bit for driving and tightening a screw, a valve housing provided in the main valve, and a valve body so provided as to be capable of vertically movable with respect to the valve housing. A through hole opening to the air chamber is formed in the valve housing; and a lower opening part opening to the hammering cylinder, a side opening part opening to the air chamber through the through hole, and a firstair supply passage allowing the lower opening part to communicate with the side opening part are formed in the valve body. When the valve body is moved downward, a second air supply passage allowingthe air chamber to communicate with the hammering cylinder through the through hole is formed between the outer peripheral surface of the valve body on the lower side of the side opening part and theinner peripheral surface of the valve housing.

Owner:MAX CO LTD

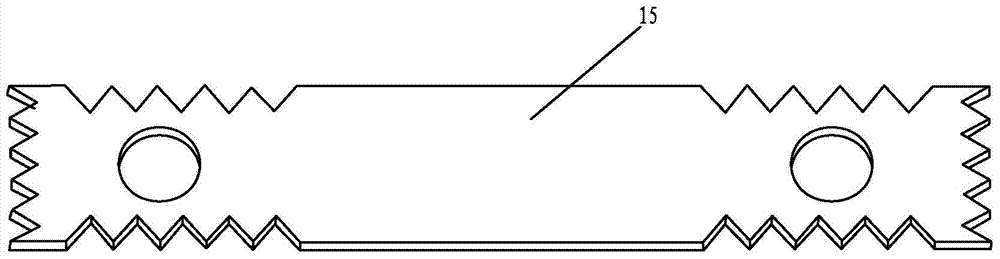

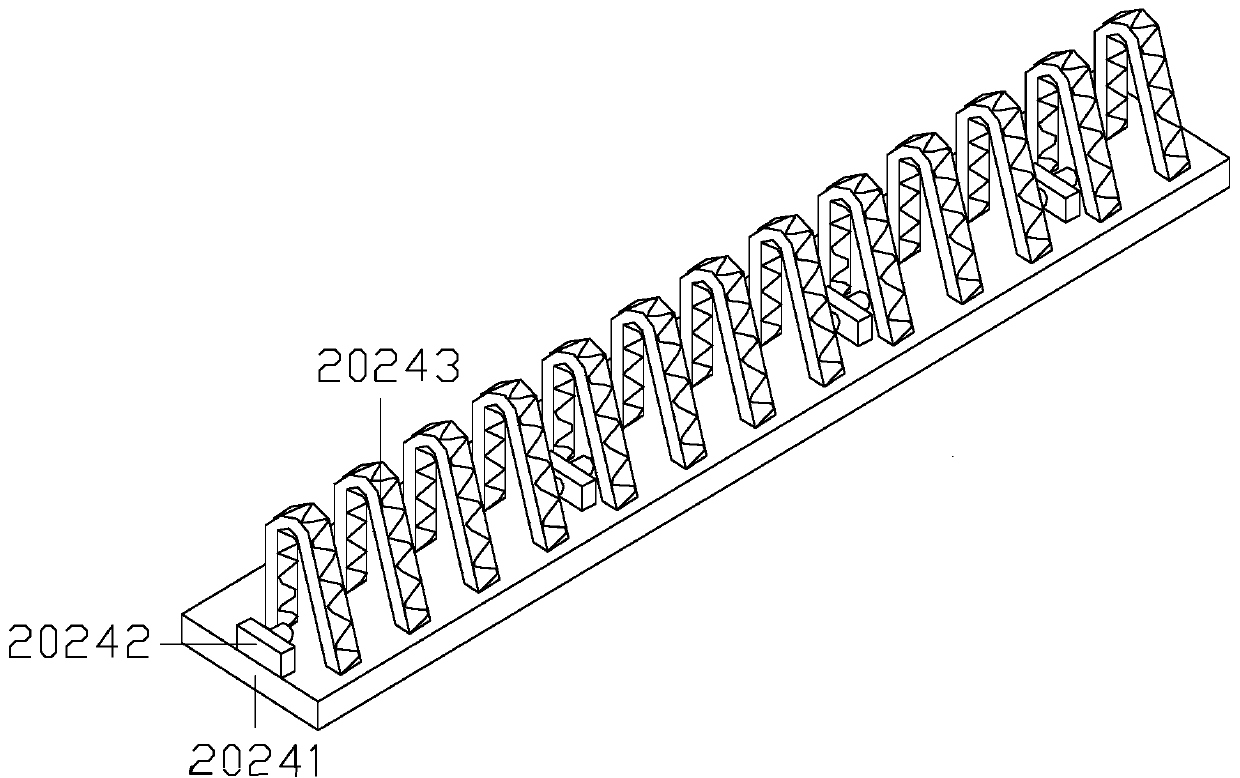

A vibrating plate used in vibrating cotton feeder for hemp fiber spinning

InactiveCN101348955BBig hitReduce gapFibre cleaning/opening machinesEngineeringMechanical engineering

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Automatic Looser

ActiveCN107161735BLoose bale with high efficiencyLoose bag effect is goodLoading/unloadingElectric machineryEngineering

Owner:王虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com