Piling mechanism of piling machine and piling machine

A technology of pile driver and transmission mechanism, which is applied in the direction of sheet pile wall, foundation structure engineering, building type, etc. It can solve the problems of poor reliability of striking force and achieve the effect of high striking force and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with each accompanying drawing, the present invention is described in detail.

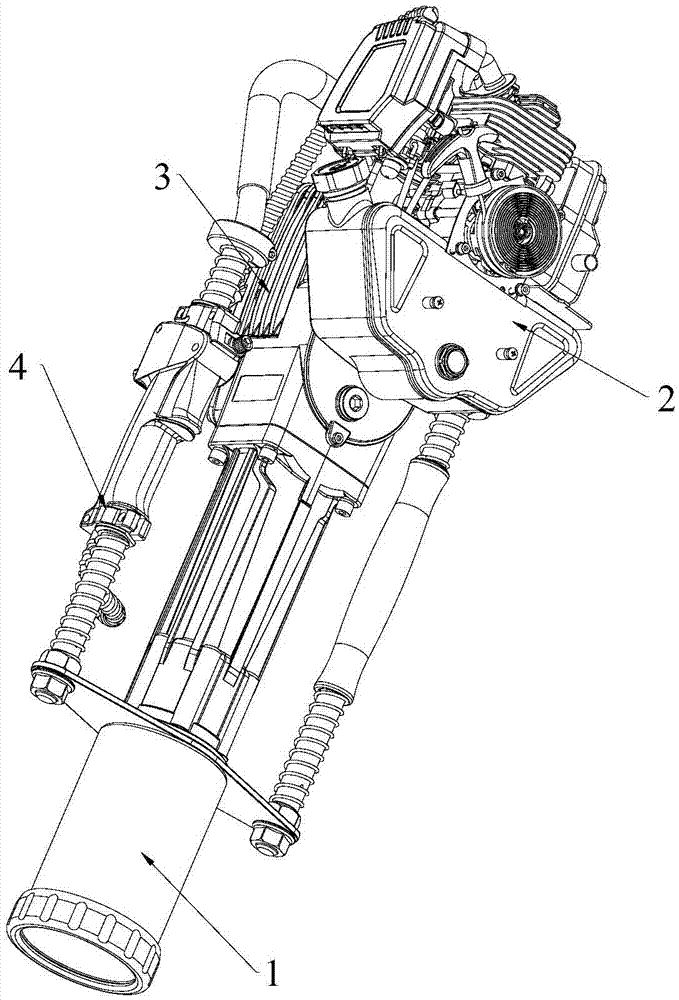

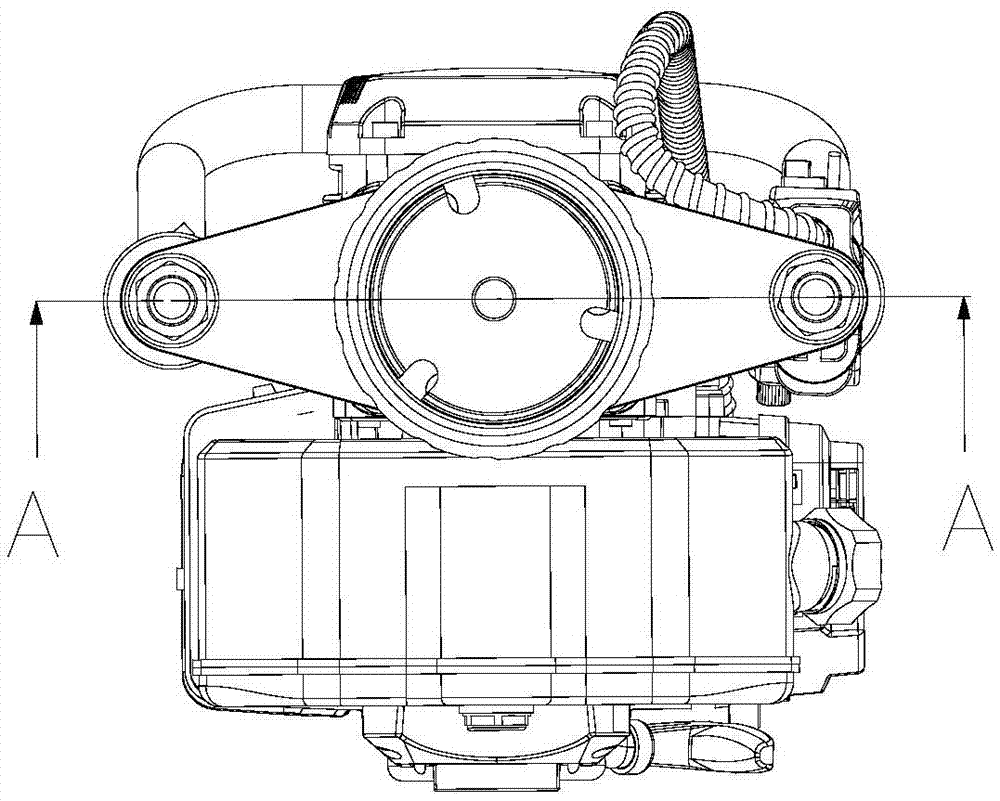

[0039] Such as Figure 1~4 As shown, a pile driver includes a gasoline engine 2, a transmission mechanism 3 and a piling mechanism 1. The gasoline engine 2 is used to drive the transmission mechanism 3 to work, and the transmission mechanism 3 cooperates with the piling mechanism 1 to drive the piling mechanism to work.

[0040] In this embodiment, the pile driver also includes a damping mechanism 4 that cooperates with the pile driver.

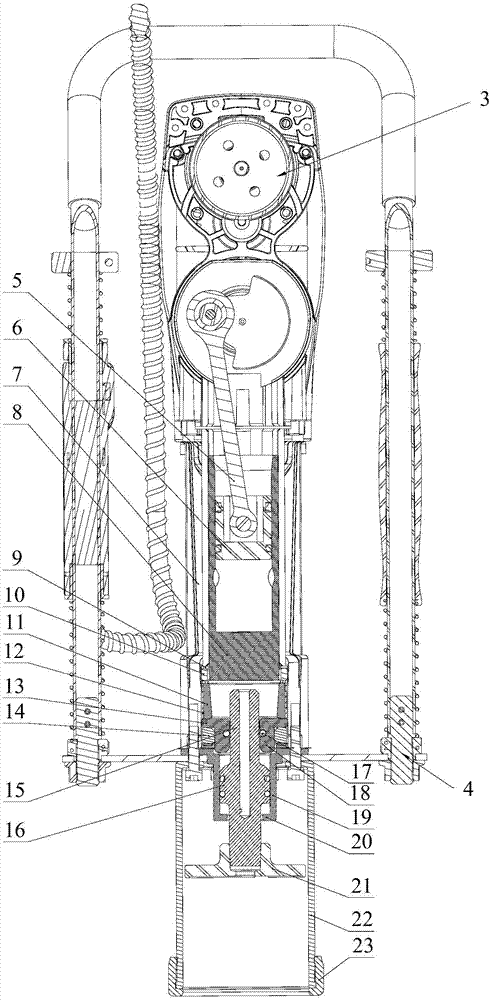

[0041] Such as image 3 with 4 Shown, the piling mechanism of the present embodiment comprises:

[0042] Cylinder 7;

[0043] The impact cylinder 8 is slidingly arranged in the cylinder body 7, one end of the impact cylinder is closed, and the other end is open;

[0044] The impact piston 6 is slidingly arranged in the impact cylinder, and the impact piston is linked with the transmission mechanism 3 through the connecting rod 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com