Gas combustion type driving tool

A technology for driving tools and gases, applied in nailing tools, manufacturing tools, etc., can solve the problems of reduced combustion energy, reduced combustion chamber volume, difficult ignition, etc., and achieves the effect of increasing striking force and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, typical embodiments of the present invention will be described with reference to the drawings.

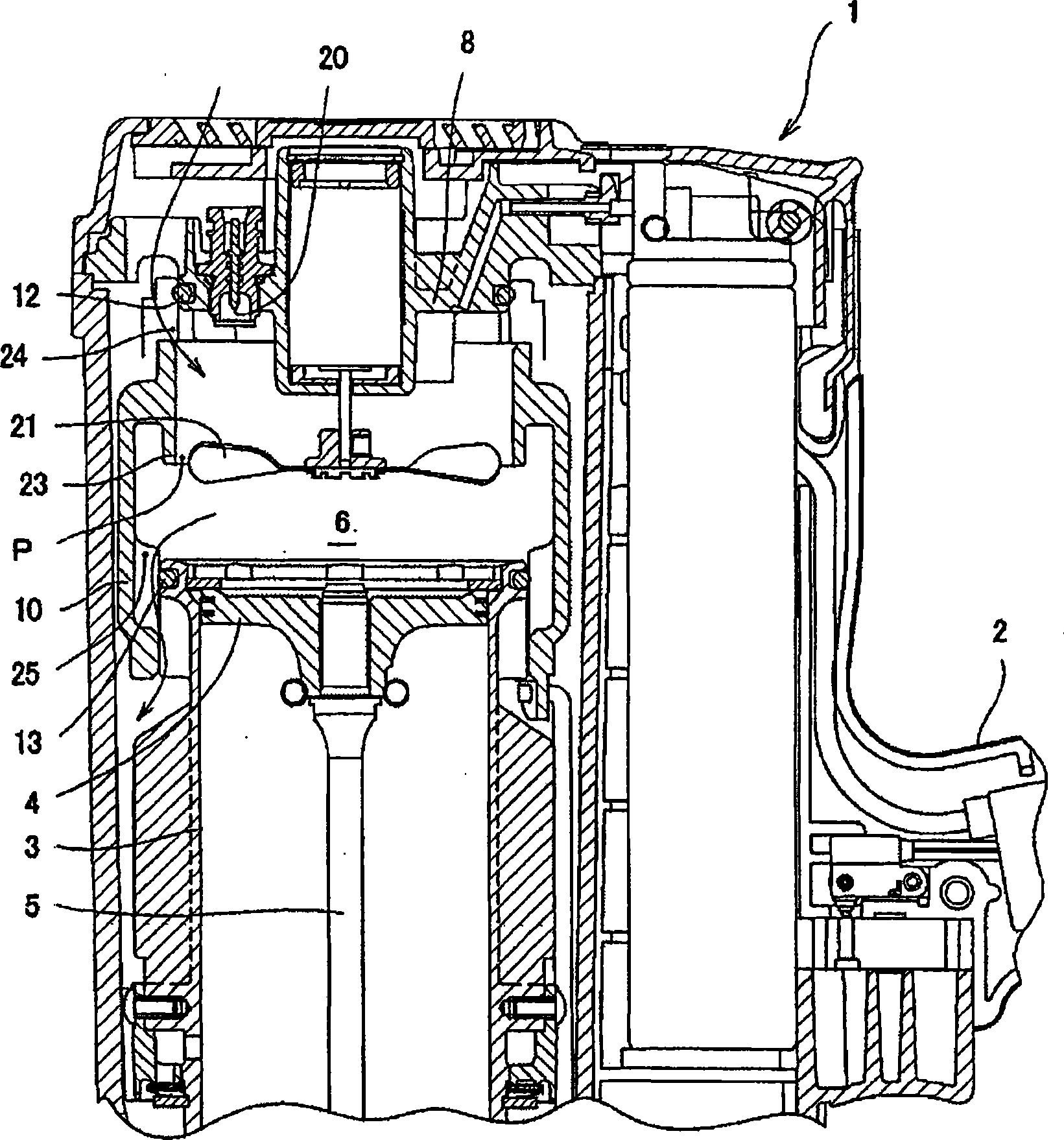

[0034] figure 1 and figure 2 In , reference numeral 1 denotes a tool body of a gas combustion driving tool (nail driver). The tool main body 1 is connected with a handle 2 and a staple cartridge (not shown), and is provided with a striking piston-cylinder mechanism inside. Below the tool main body 1, a head (not shown) for driving nails is provided.

[0035] In the striking piston-cylinder mechanism, a striking piston 4 is slidably accommodated in a striking cylinder 3 , and a driver 5 is integrally joined below the striking piston 4 .

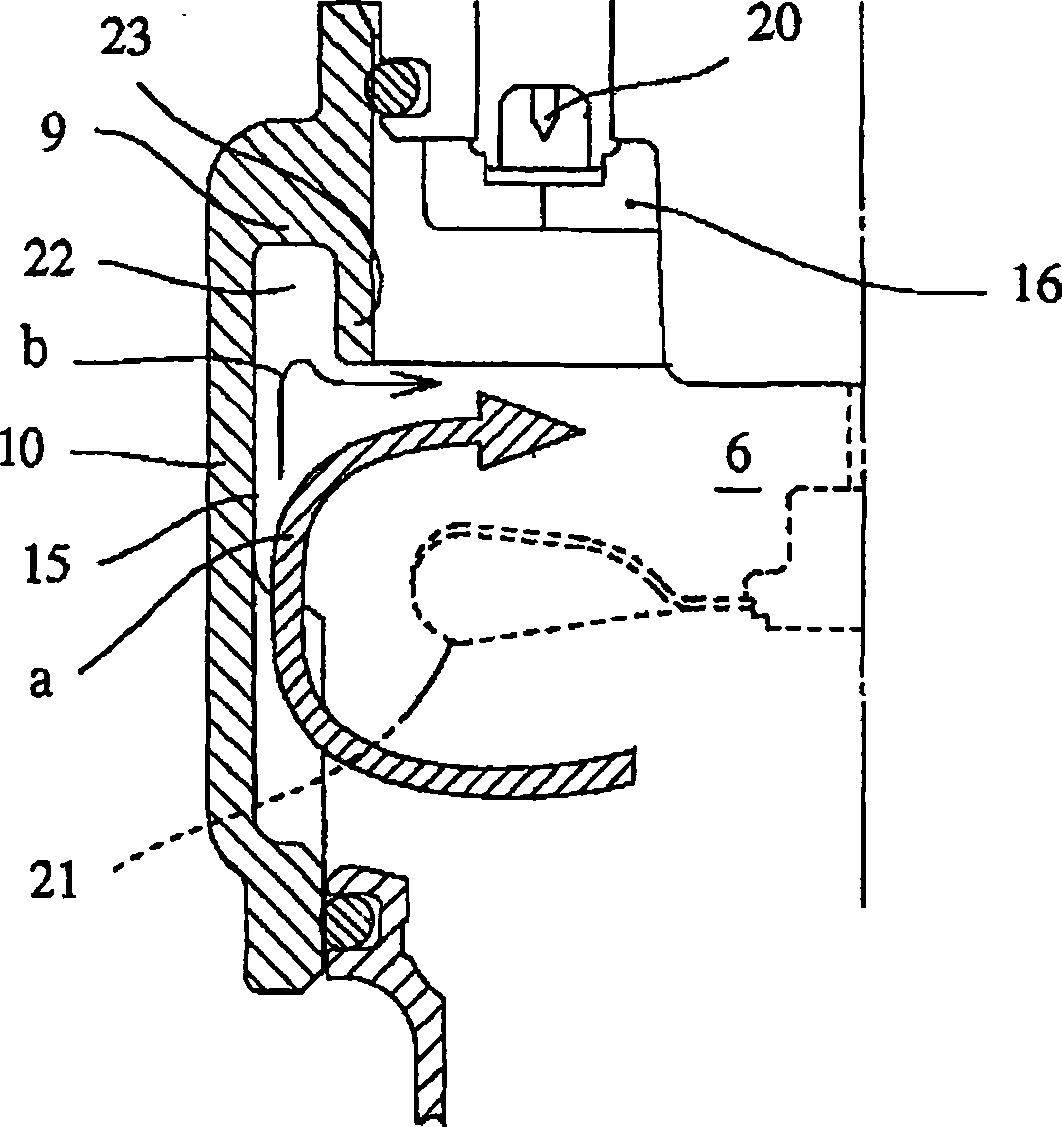

[0036] Next, form the combustion chamber 6 in an openable and closable manner on the top of the striking cylinder 3 . The combustion chamber 6 is formed by the upper end of the above-mentioned striking piston 4 and the movable sleeve 10, wherein the movable sleeve 10 is disposed between the striking cylinder 3 and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com