Air pressure type screw nail infiltrating device

An air pressure and driver technology, which is applied in nailing tools, nailing staple tools, motor tools, etc., can solve the problems of increasing the number of parts and the overall height of the tool, reducing the number of parts, easy operation, Get the right depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

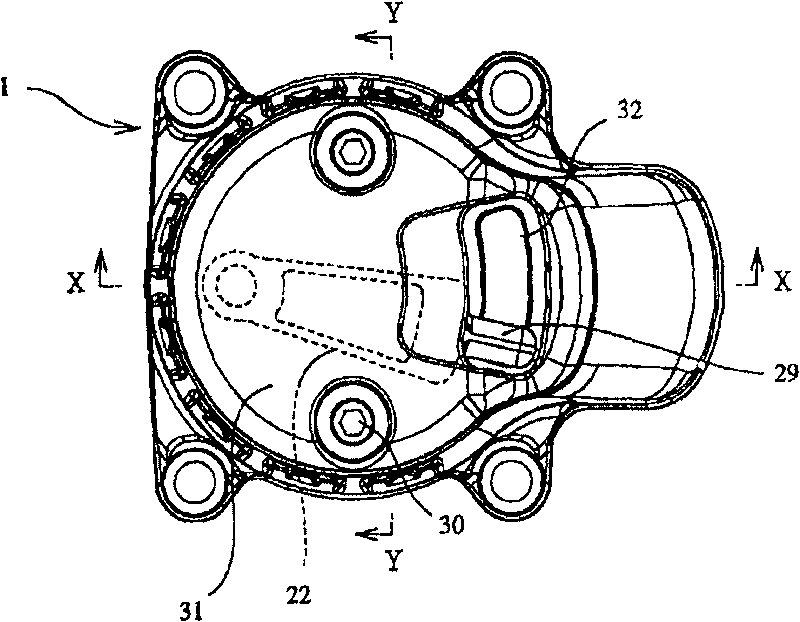

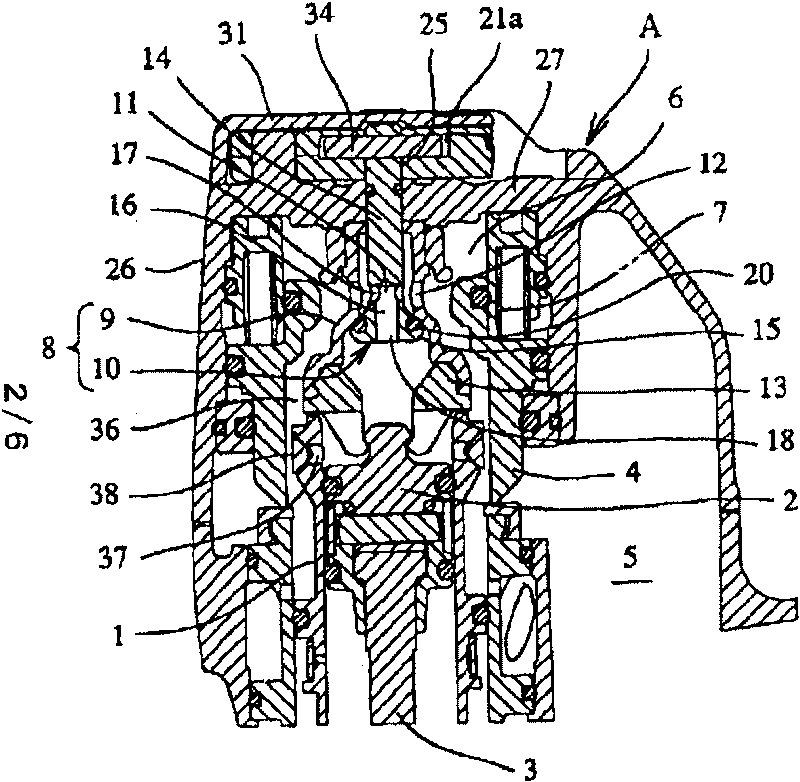

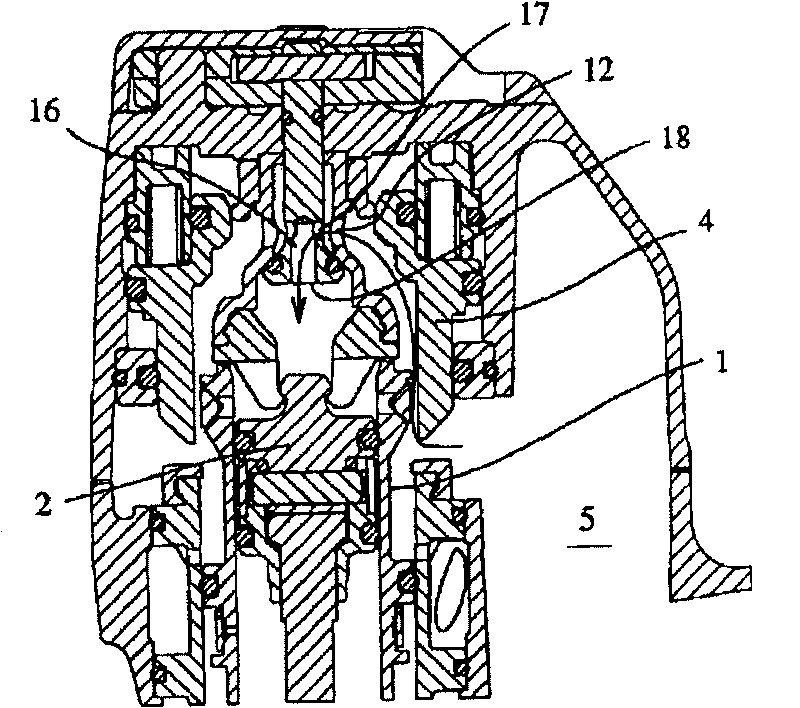

[0044] figure 1 Indicates the upper surface of the screwdriver, Figure 2A and Figure 2B means along figure 1Cross-sectional view of the X-X line. This screw driver has a striking mechanism and a screw tightening mechanism inside the tool body A. As shown in FIG. The percussion mechanism includes a percussion cylinder 1, a percussion piston 2 freely slidably arranged in the percussion cylinder 1, and a screwdriver head 3 integrated with the percussion piston 2, and the main valve 4 is opened by pulling the unillustrated trigger. Action: supply compressed air from the air chamber (connected to the air supply source) 5 storing compressed air to the percussion cylinder 1 to make the screwdriver bit 3 perform the driving action. In addition, a screw tightening mechanism (not shown) drives the screwdriver bit 3 to tighten the screws by power such as an air motor. That is, almost at the same time when the striking mechanism starts to operate, the screw tightening mechanism ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com