Rolling brush of dust collector

A vacuum cleaner and rolling brush technology, applied in the direction of the suction nozzle, can solve the problems of reducing the cleaning effect of the rolling brush and difficult cleaning, and achieve the effects of reducing the cost of use, smooth cleaning process, and increasing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by specific embodiment:

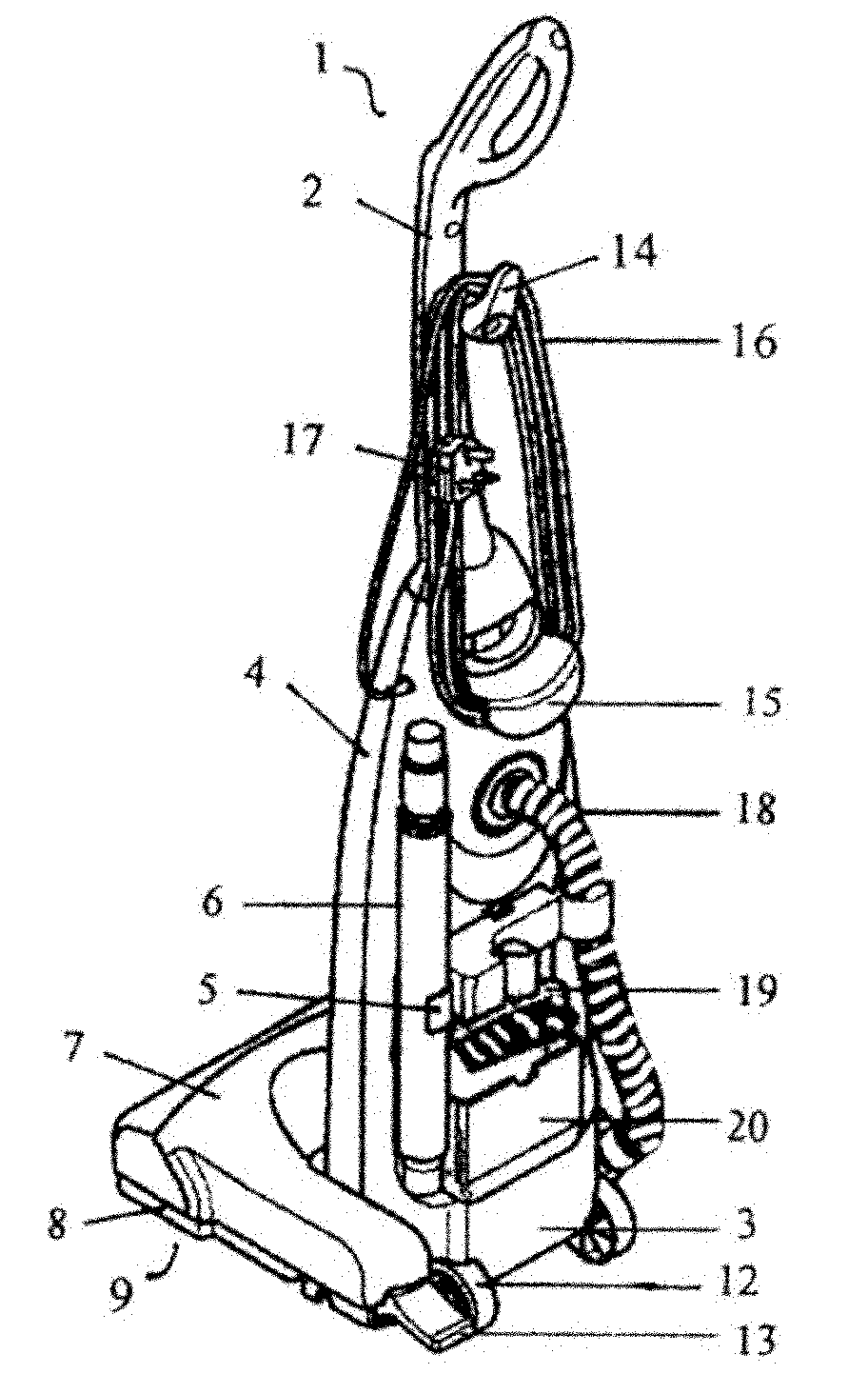

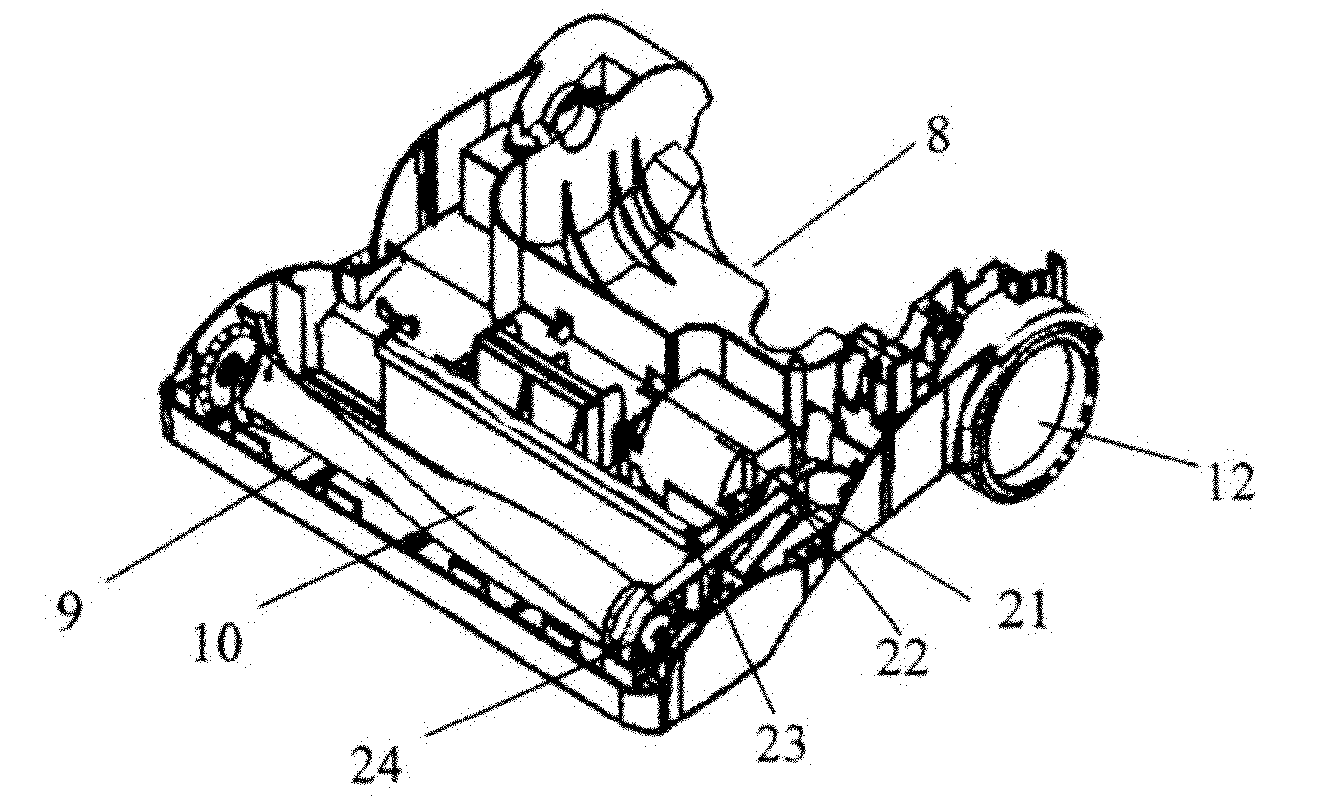

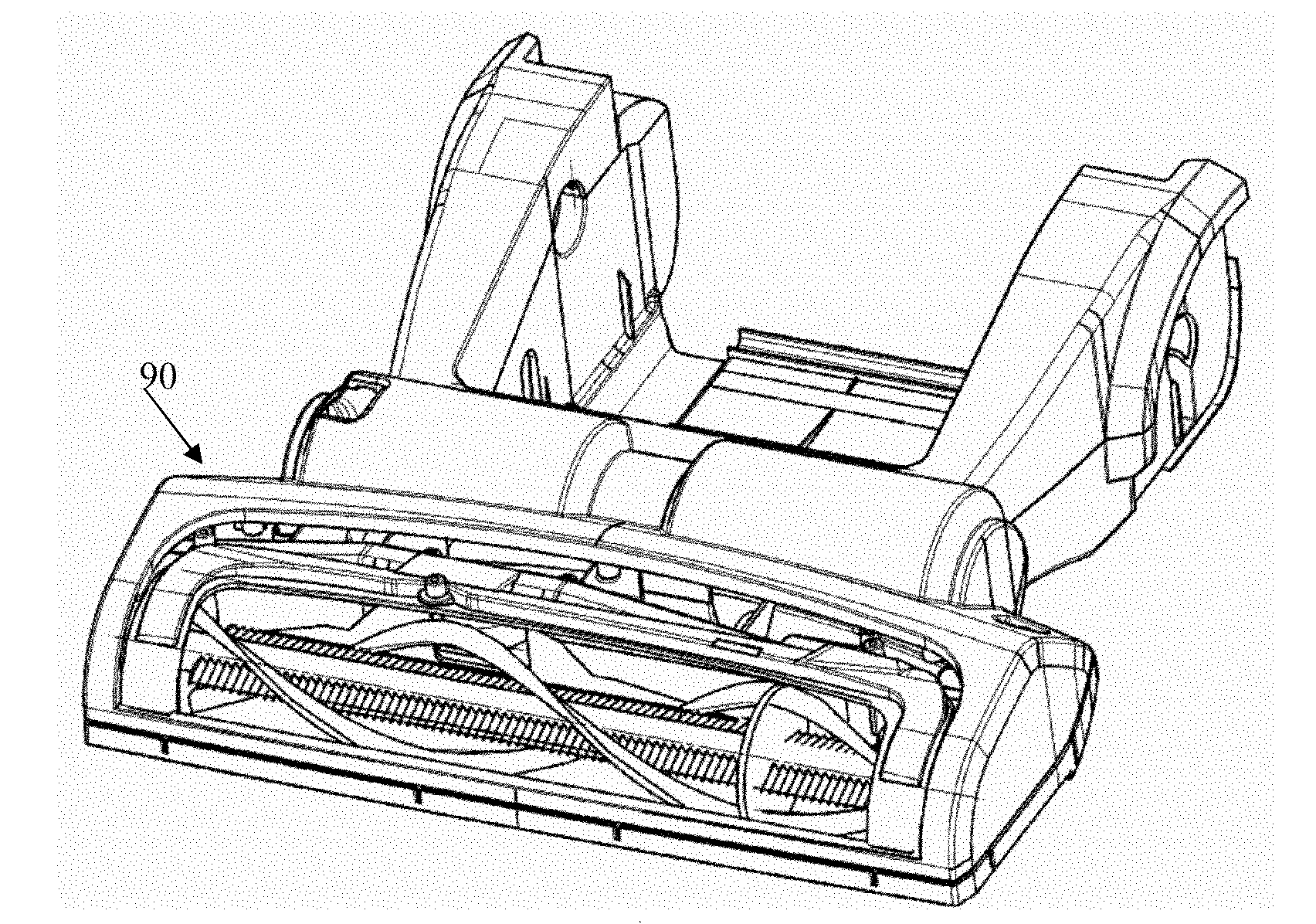

[0027] Such as image 3 , 4 As shown, the brush head 90 is provided with a rotatable roller brush 20, through the drive shaft of the transmission motor fixed on the brush head chassis 28, the power is transmitted to the roller brush 20 by the transmission belt, so that the roller brush 20 rotates, The dust on the work surface is loosened, and the dust is sucked into the dust bag of the vacuum cleaner through the brush head 90.

[0028] Such as Figure 5 , 6 The rolling brush 20 of the present invention includes a roller shaft 21, and a rotating part is formed coaxially with the roller shaft 21 along its axial direction. In the card slot, and the two ends of the roller 21 near the end are rotatably fixed with a baffle 23 and a transmission column 22, wherein the baffle 23 and the transmission column 22 are arranged inside the rotating part to avoid The baffle plate 23 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com