Amorphous alloy surface treatment process

An amorphous alloy and surface treatment technology, which is applied in the field of amorphous alloy manufacturing, can solve the problems that affect the preparation accuracy and use effect of the workpiece, the large deformation of the workpiece, and the large roughness, etc., to achieve the elimination of defects and micro cracks, the impact force is small, Good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

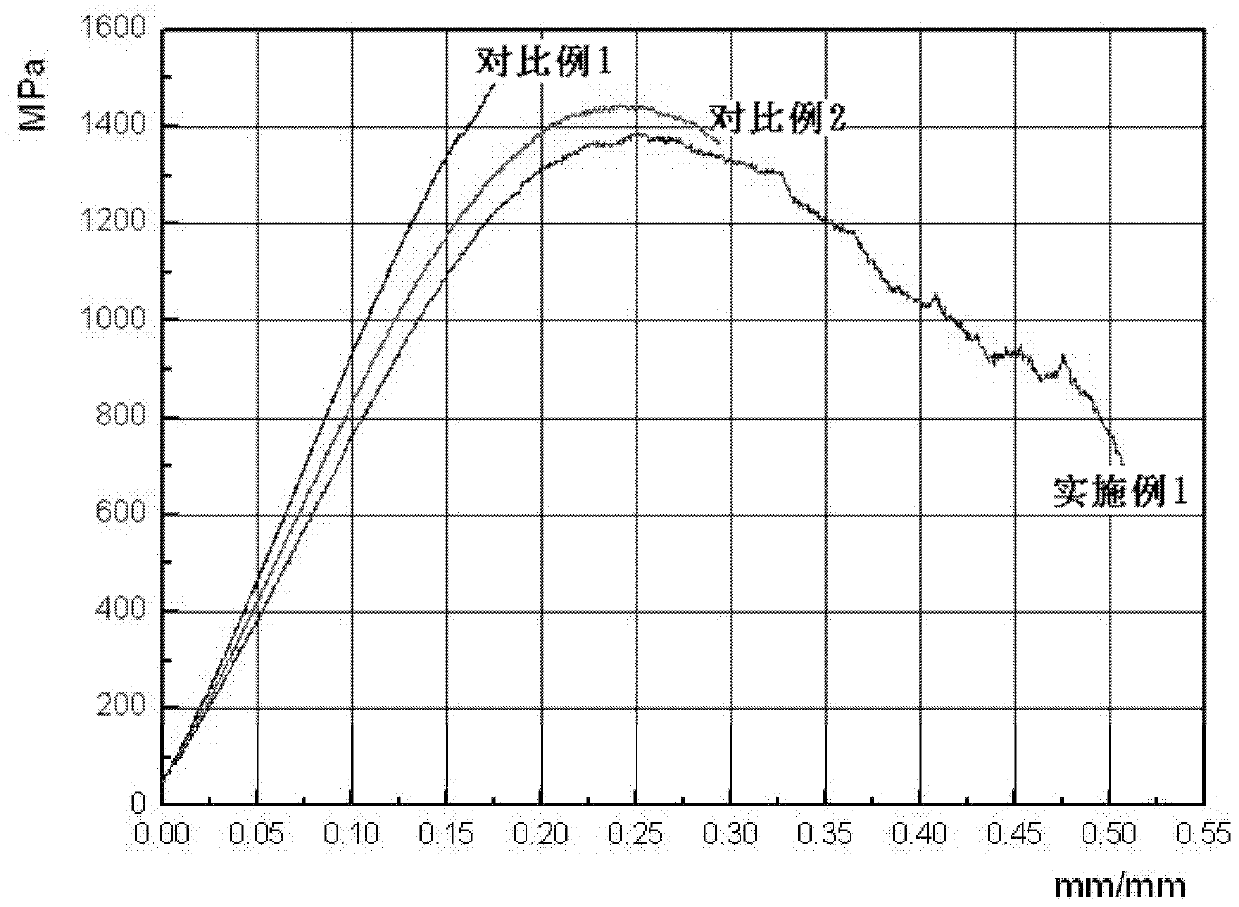

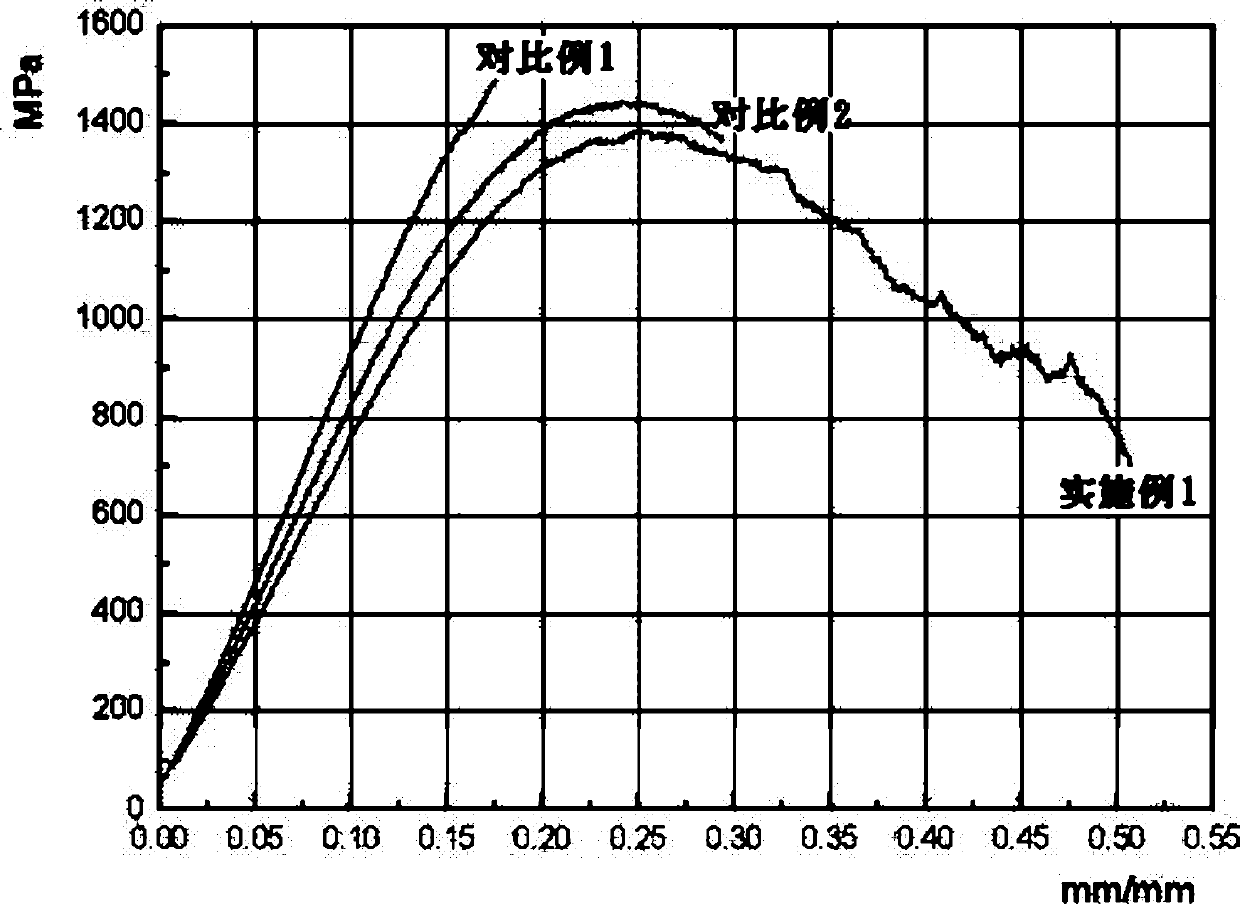

Examples

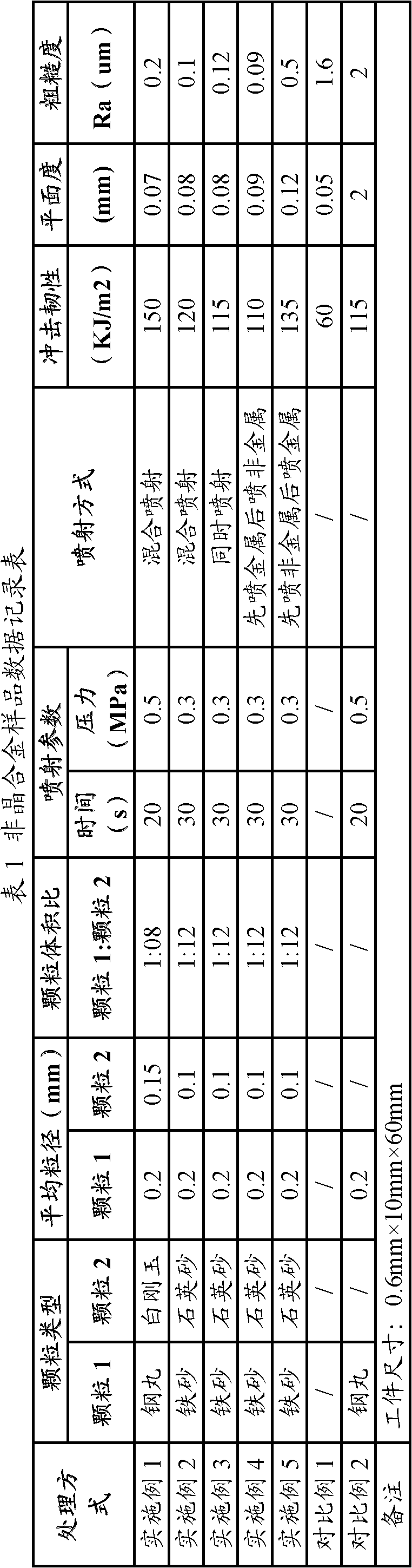

Embodiment 1

[0023] will be composed of Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy is melted and cast into a metal mold by die-casting equipment to obtain an amorphous alloy blank with a size of 0.6mm×10mm×60mm.

[0024] Fully mix steel shot particles with an average particle size of 0.2mm and white corundum particles with an average particle size of 0.15mm and add them to an automatic sandblasting machine. Under the condition of 0.5MPa, spray the amorphous alloy blank for 20s to obtain sample.

Embodiment 2

[0026] will be composed of Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy is melted and cast into a metal mold by die-casting equipment to obtain an amorphous alloy blank with a size of 0.6mm×10mm×60mm.

[0027] Fully mix iron sand particles with an average particle size of 0.2mm and quartz sand particles with an average particle size of 0.1mm and add them to an automatic sandblasting machine. Under the condition of 0.3MPa, spray the amorphous alloy blank for 30s to obtain a spray sample .

Embodiment 3

[0029] will be composed of Zr 52 Al 10 Cu 30 Ni 7 The amorphous alloy is melted and cast into a metal mold by die-casting equipment to obtain an amorphous alloy blank with a size of 0.6mm×10mm×60mm.

[0030] Iron sand particles with an average particle size of 0.2 mm and quartz sand with an average particle size of 0.1 mm were added to different injection chambers of the automatic sandblasting machine. Under the condition of 0.3 MPa, the iron sand particles and quartz sand particles simultaneously The blank was sprayed for 30s to obtain spray samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com