Cyperus esculentus harvest threshing, separating and cleaning system

A technology of threshing and separation, oily beans, applied in threshing equipment, agriculture, application, etc., can solve the problems of high energy consumption of vibrating screen, no threshing device installed, screen mesh blockage, etc., so as to ensure the balance of moment of inertia and speed up the transition to After the movement speed, the effect of preventing the entanglement of the rhizome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

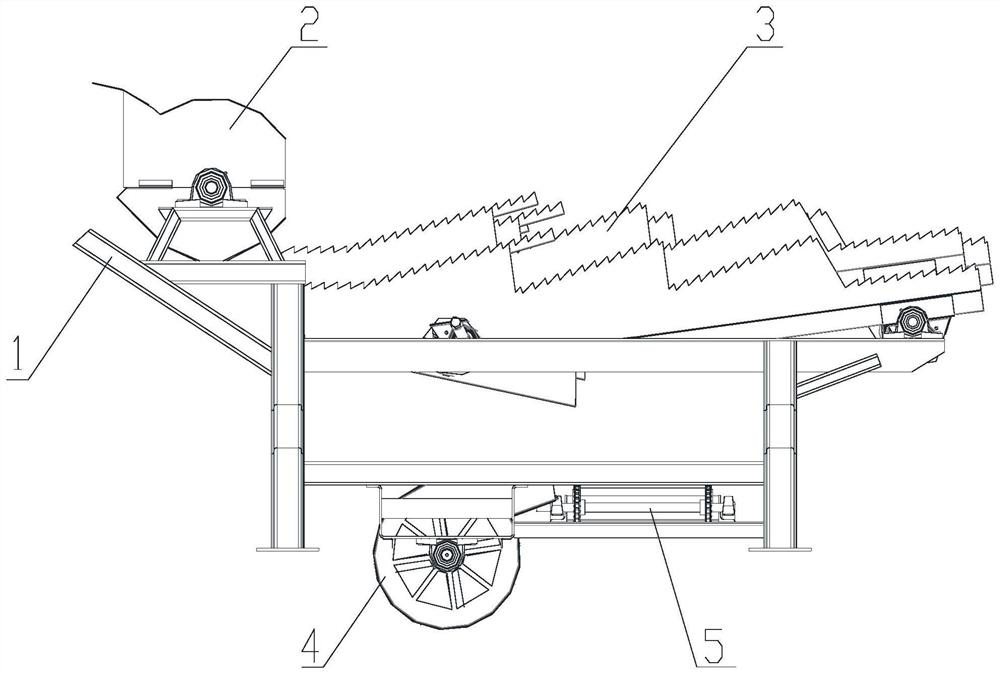

[0041] A system for threshing, separating and cleaning oily bean harvest, such as figure 1 with figure 2 As shown, a frame 1 is included, and the frame 1 is provided with a threshing cylinder 2, a draft device 3, a cleaning fan 4 and a transverse conveyor 5;

[0042] The threshing drum 2 is arranged laterally on the front upper end of the frame 1;

[0043] The document chaser 3 is arranged behind and below the outlet of the threshing cylinder 2;

[0044] The cleaning blower 4 is arranged under the draft chaser 3, and the air outlet is opposite to the groove bottom outlet of the draft chaser 3;

[0045] The transverse conveyor 5 is arranged below the outlet of the grooved bottom of the document chaser 3 .

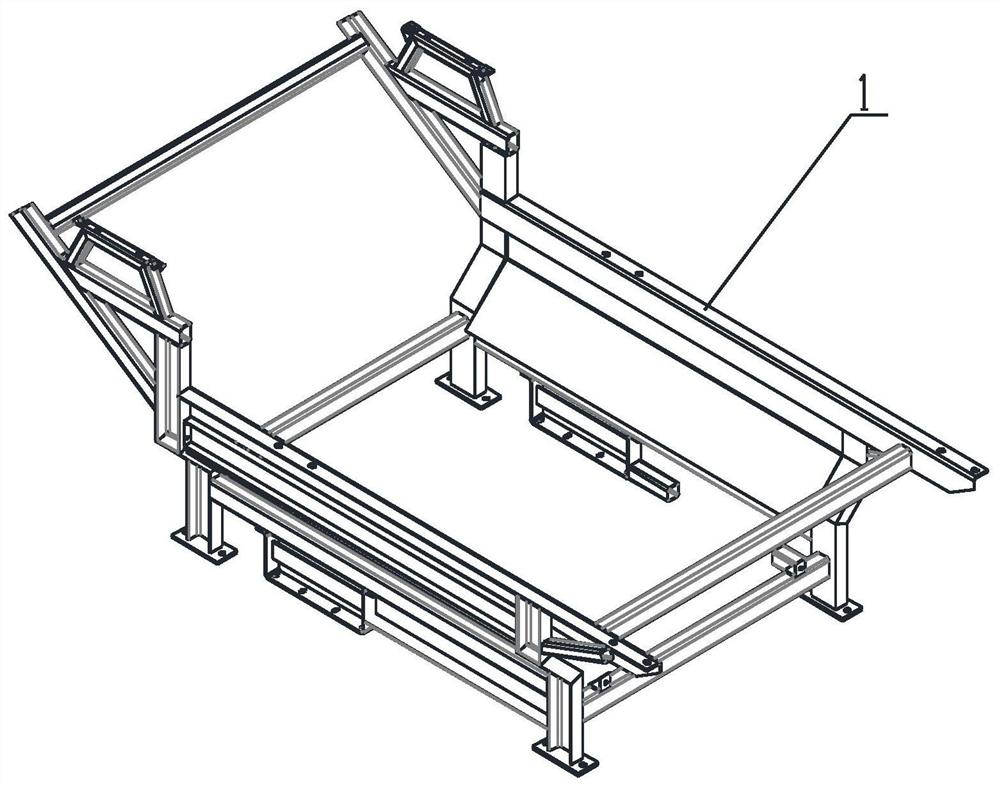

[0046] Such as image 3 Shown is the main mechanism of the frame 1.

[0047] Such as Figure 4 As shown, further, the threshing cylinder 2 includes a threshing shaft assembly 6, and the threshing shaft assembly 6 is sleeved with an upper cover arc plate 7 and a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com