Automatic bale opener

It is an automatic technology that can be used in transportation and packaging, loading/unloading, etc. It can solve the problems of different manual loosening standards, inconsistent loosening effects, high labor cost and labor intensity, and reduce labor intensity and labor cost. , The effect of loosening the bag is consistent, and the effect of improving the efficiency of feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

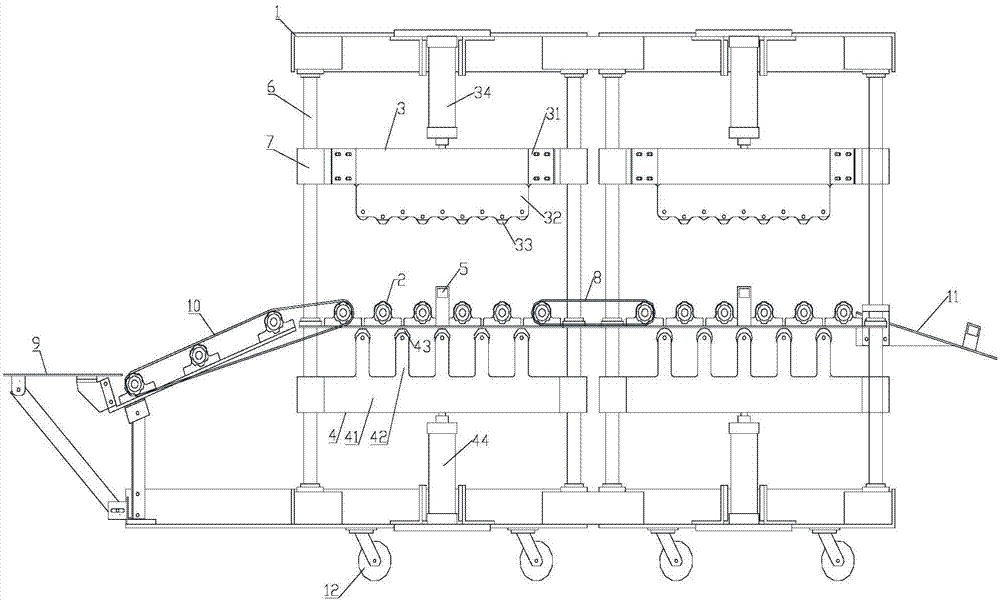

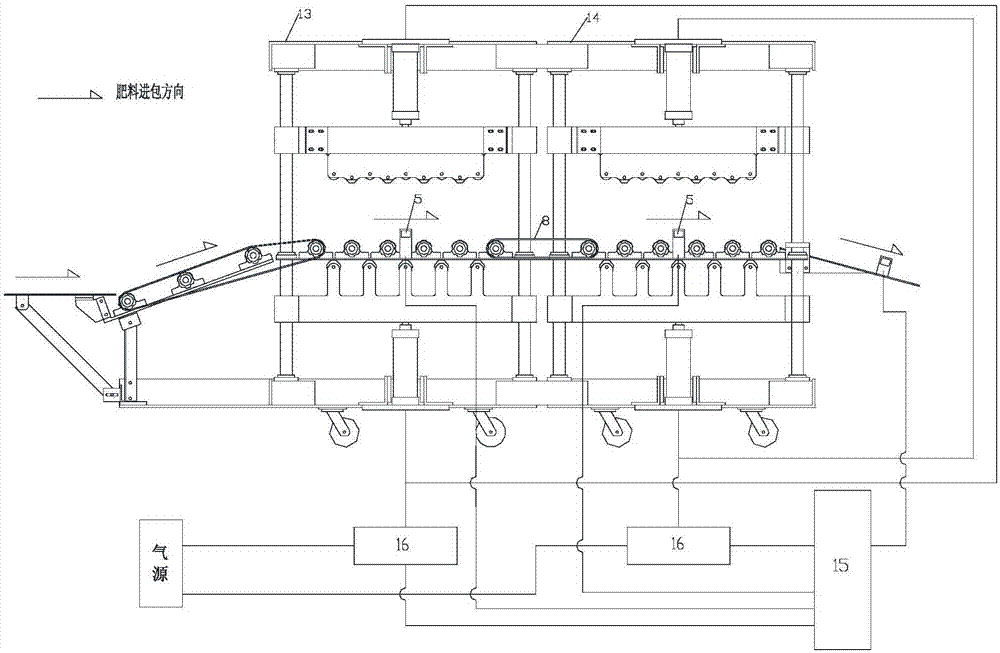

[0042] Such as figure 1 with figure 2 As shown, the present invention provides an automatic bale loosening machine, which includes a plurality of loose bale mechanisms 1 connected by a conveyor belt 8, and any loose bale mechanism 1 includes:

[0043] Transmission device, which includes:

[0044] A plurality of rollers 2 are arranged in parallel at equal intervals in a horizontal plane, and the line connecting the center points of the same end surface of the plurality of rollers 2 is perpendicular to the axis of any roller 2, and the plurality of rollers 2 are driven to rotate by a motor;

[0045] Beating device, which includes:

[0046] The upper striking device, which is arranged directly above the conveying device, includes:

[0047] The upper connecting plate 3 includes an upper frame beam 31 arranged horizontally and a pair of side plates 32 extending downward from both sides of the upper frame beam 31 and arranged vertically;

[0048] A plurality of upper batting rods 33, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com