Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about How to "Resistance to cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

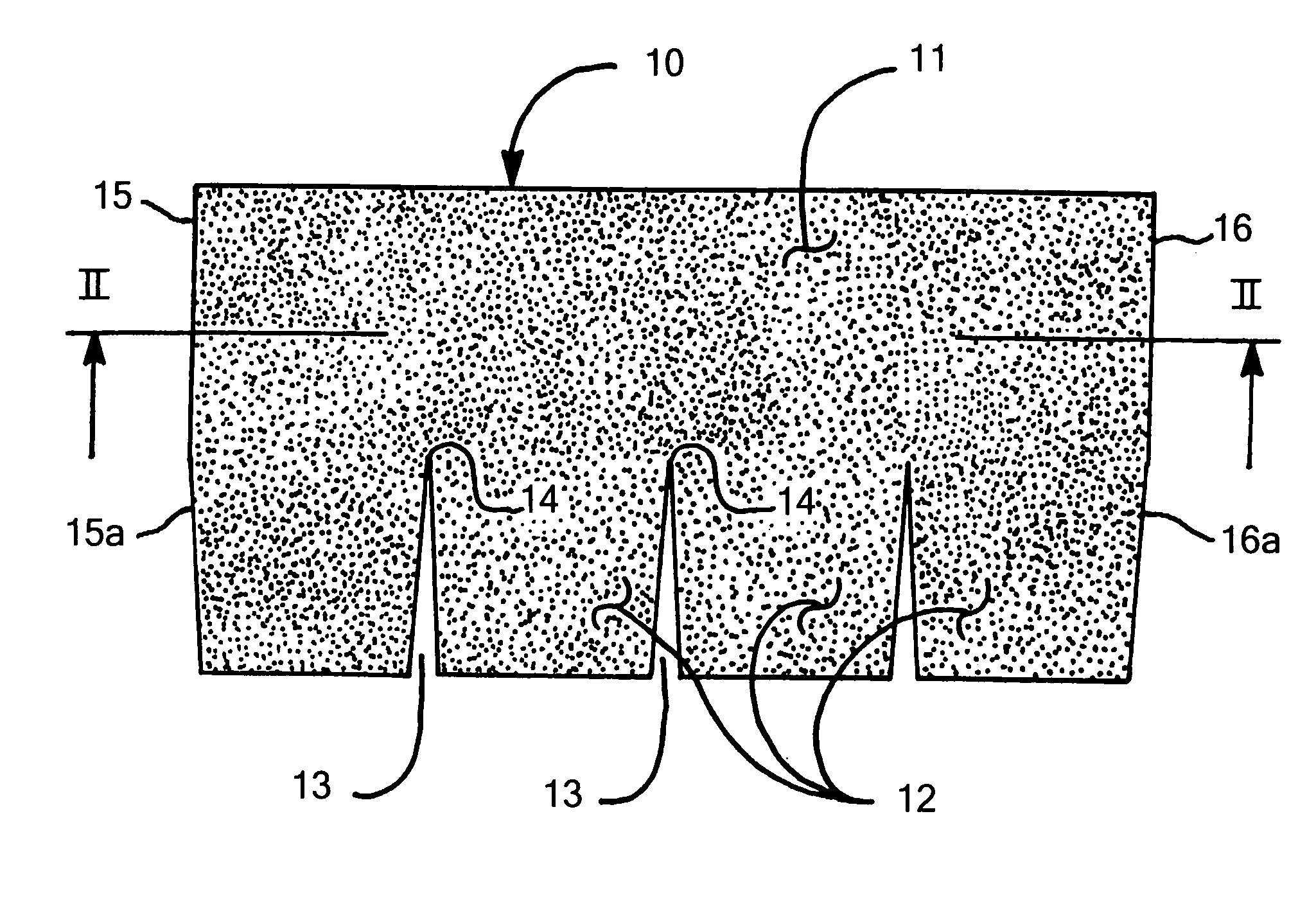

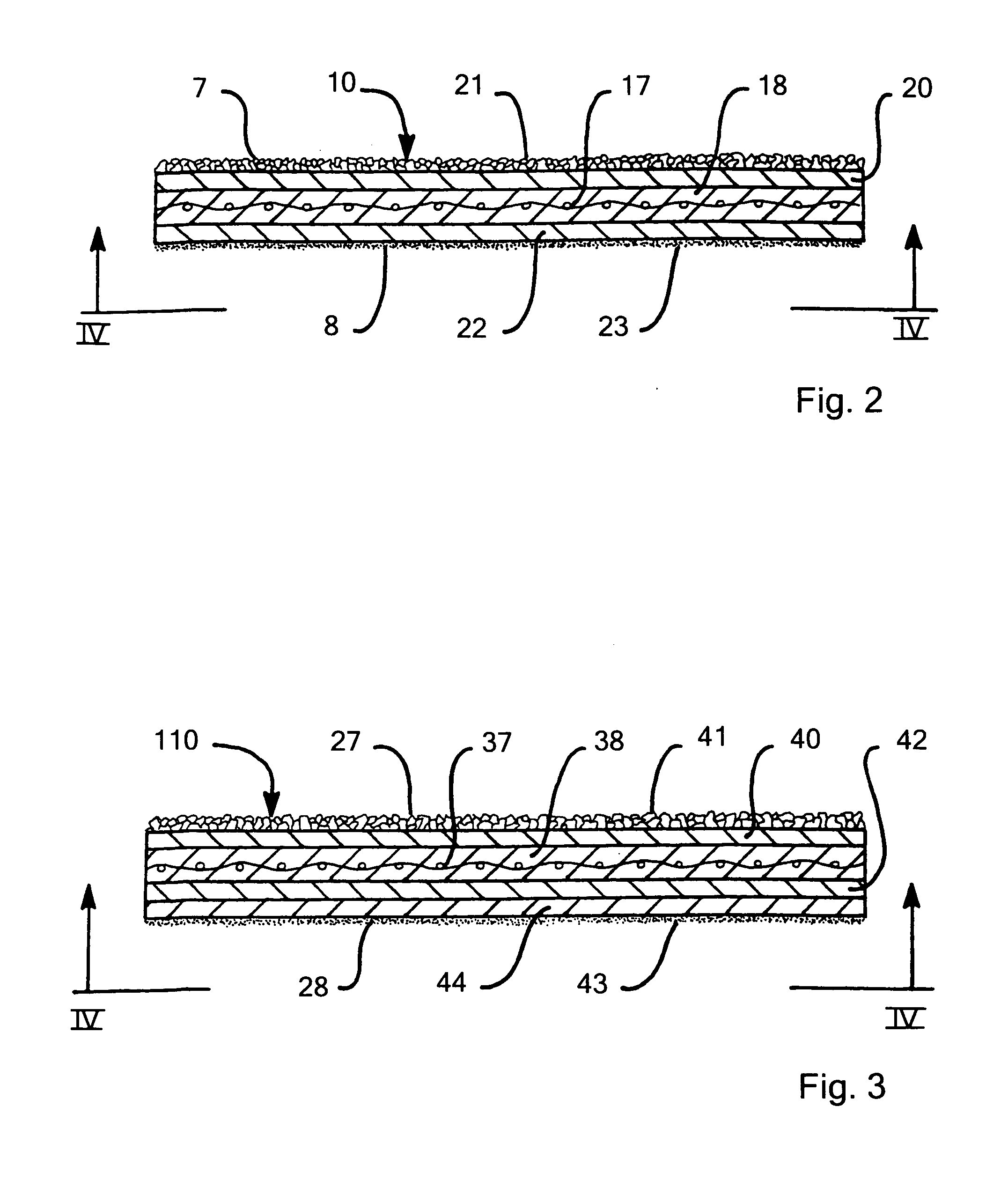

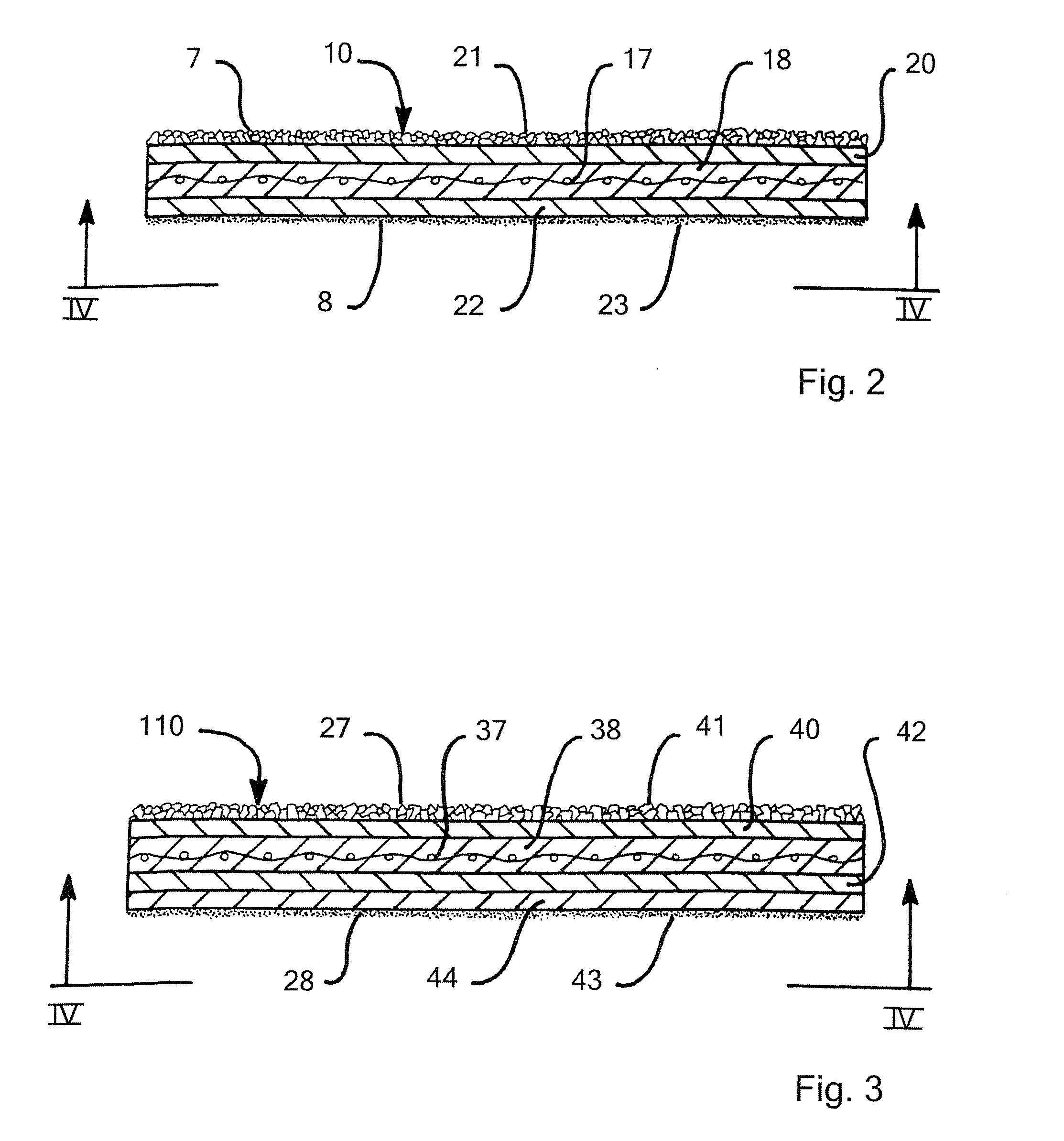

Impact resistant shingle

InactiveUS20050204675A1Resistance to crackingDissipate energyRoof covering using tiles/slatesConstructions elementsCrack resistanceShingles

An impact resistant shingle is provided, wherein the base mat is impregnated with an asphaltic material, with an asphaltic material on the upper surface of the shingle, and wherein another asphaltic material is disposed on the rear surface of the shingle, which other asphaltic material is softer with greater elongation than the asphaltic material used elsewhere in the shingle, such that crack resistance is afforded because energy from impact on the shingle is dissipated.

Owner:CERTAINTEED CORP

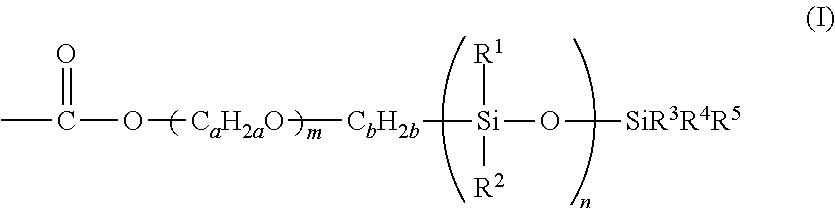

Encapsulating composition for LED

InactiveUS20060081864A1Convenient lightingHigh transparencyCoatingsSemiconductor devicesHigh intensitySilicon

An organopolysiloxane composition which cures to a resinous solid has high strength, transparency, and resistance to thermal- and photo-degradation, and is especially suited for encapsulating LEDs. The composition contains specific addition curable organopolysiloxanes having D, T, and Q units, and a proportion of silicon-bonded aromatic groups.

Owner:WACKER CHEM GMBH

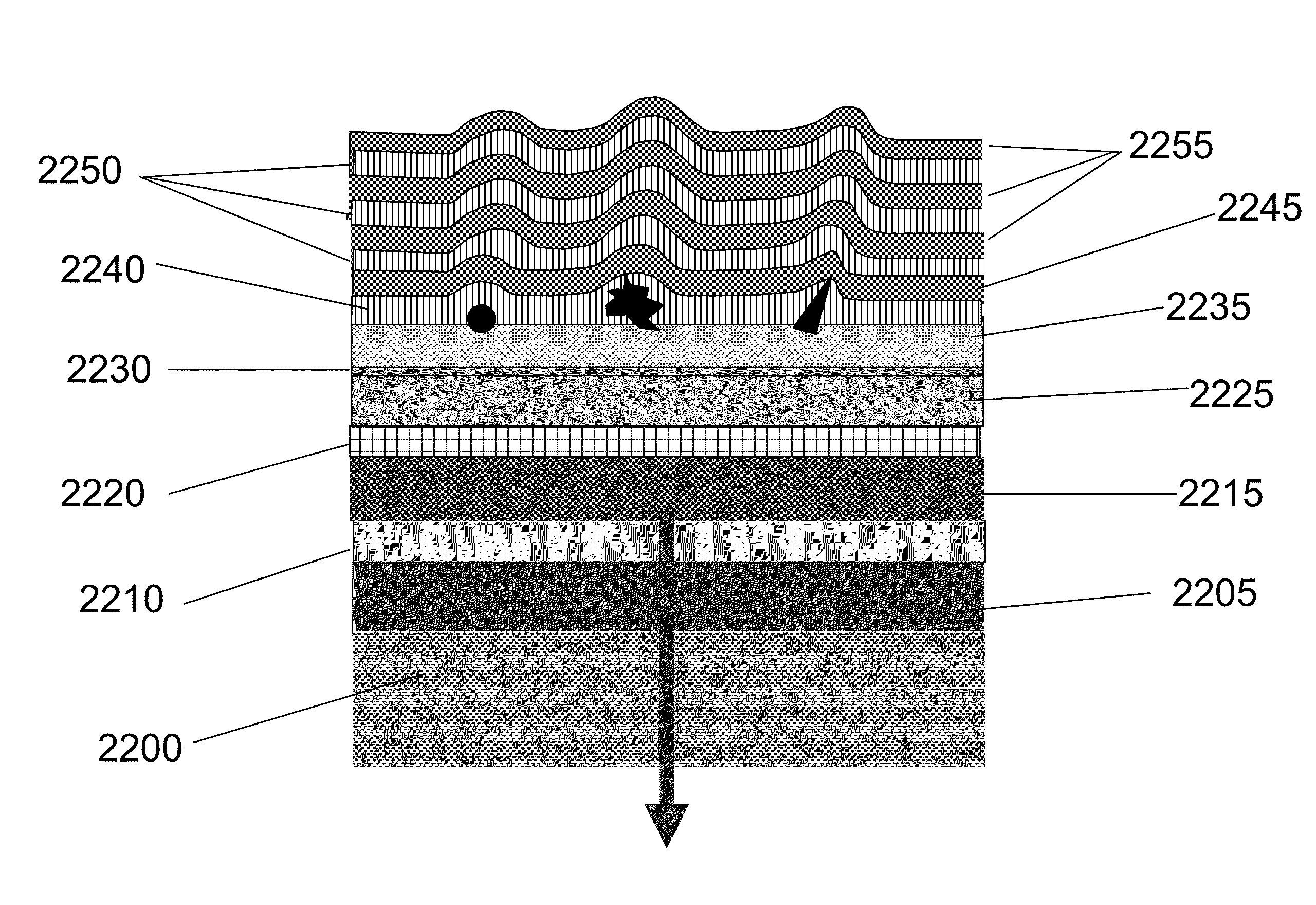

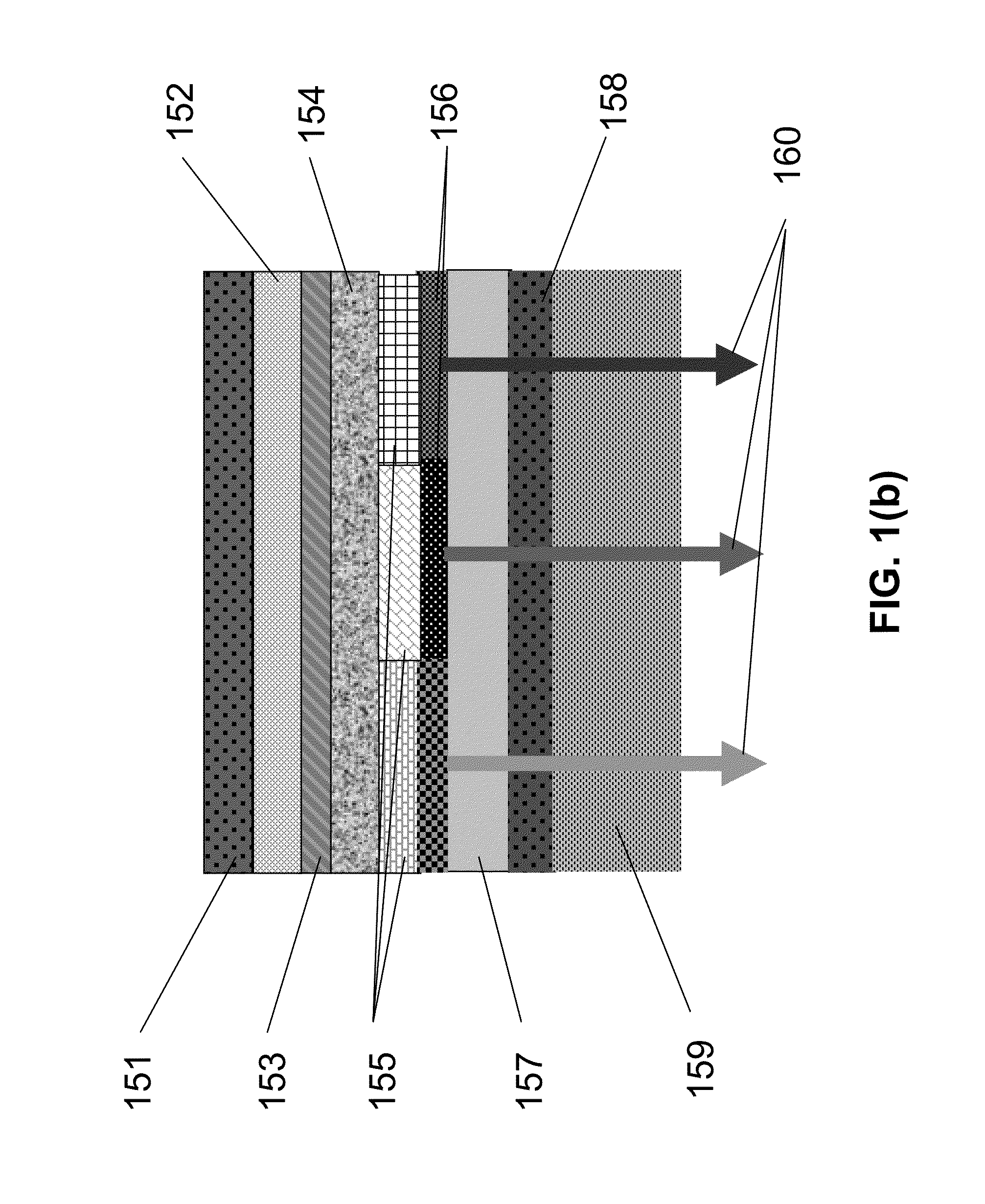

Method for deposition of high-performance coatings and encapsulated electronic devices

ActiveUS20130334511A1Without crackingWithout peelingSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporEffect light

A method is disclosed for forming leak-free coatings on polymeric or other surfaces that provide optical functions or protect underlying layers from exposure to oxygen and water vapor and do not crack or peel in outdoor environments. This method may include both cleaning and surface modification steps preceding coating. The combined method greatly reduces defects in any barrier layer and provides weatherability of coatings. Specific commercial applications that benefit from this include manufacturing of photovoltaic devices or organic light emitting diode devices (OLED) including lighting and displays.

Owner:AIXTRON AG

Methods and compositions for coating pipe

InactiveUS20040191439A1Improve stabilityHigh strengthSolid waste managementPretreated surfacesUltimate tensile strengthMechanical property

The present invention includes cement compositions and methods for using such cement compositions to coat pipe surfaces, particularly usefull for providing protection from hostile conditions that may otherwise lead to corrosion of the pipe surface. These cement compositions have improved mechanical properties including tensile strength, elasticity, and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

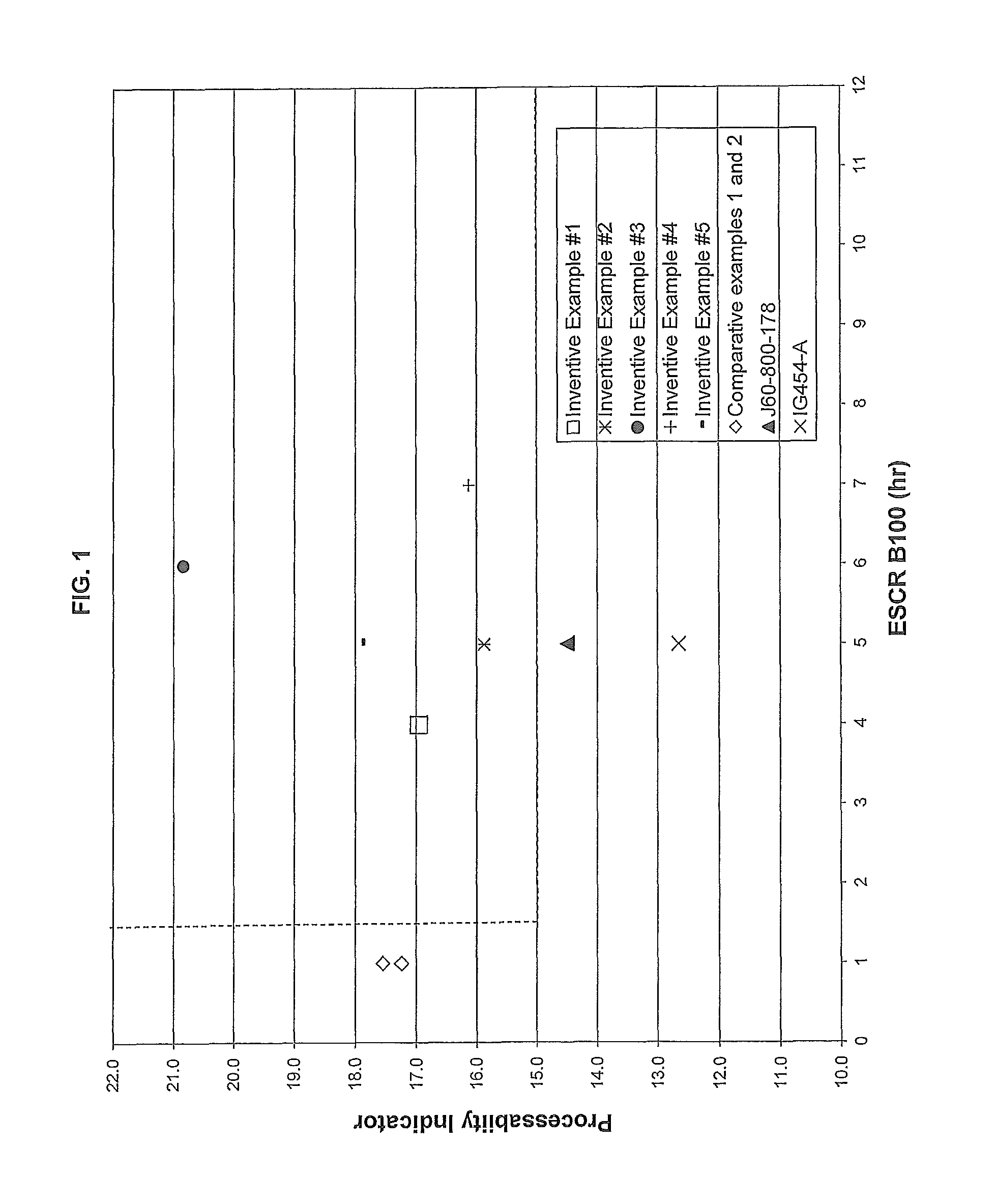

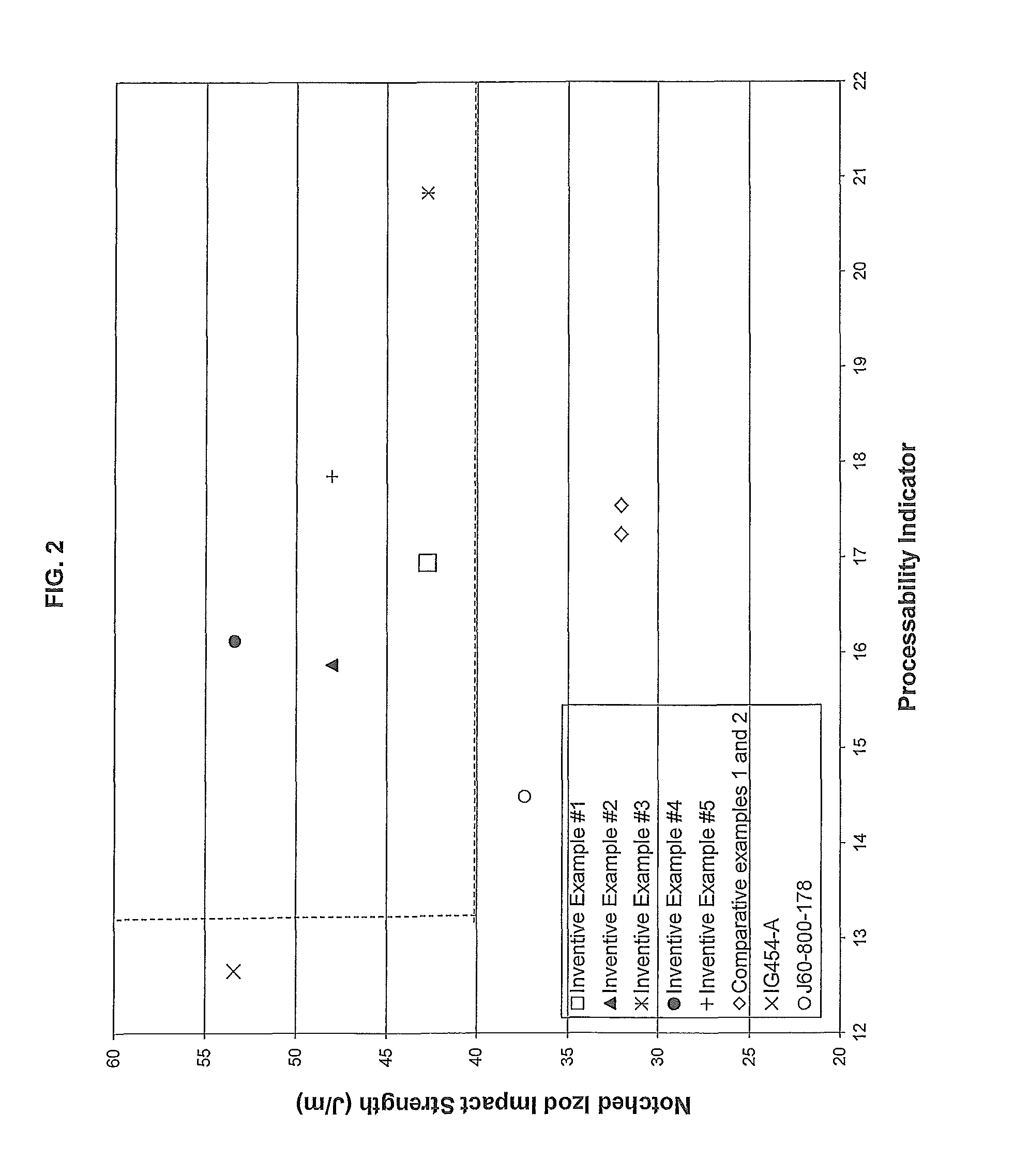

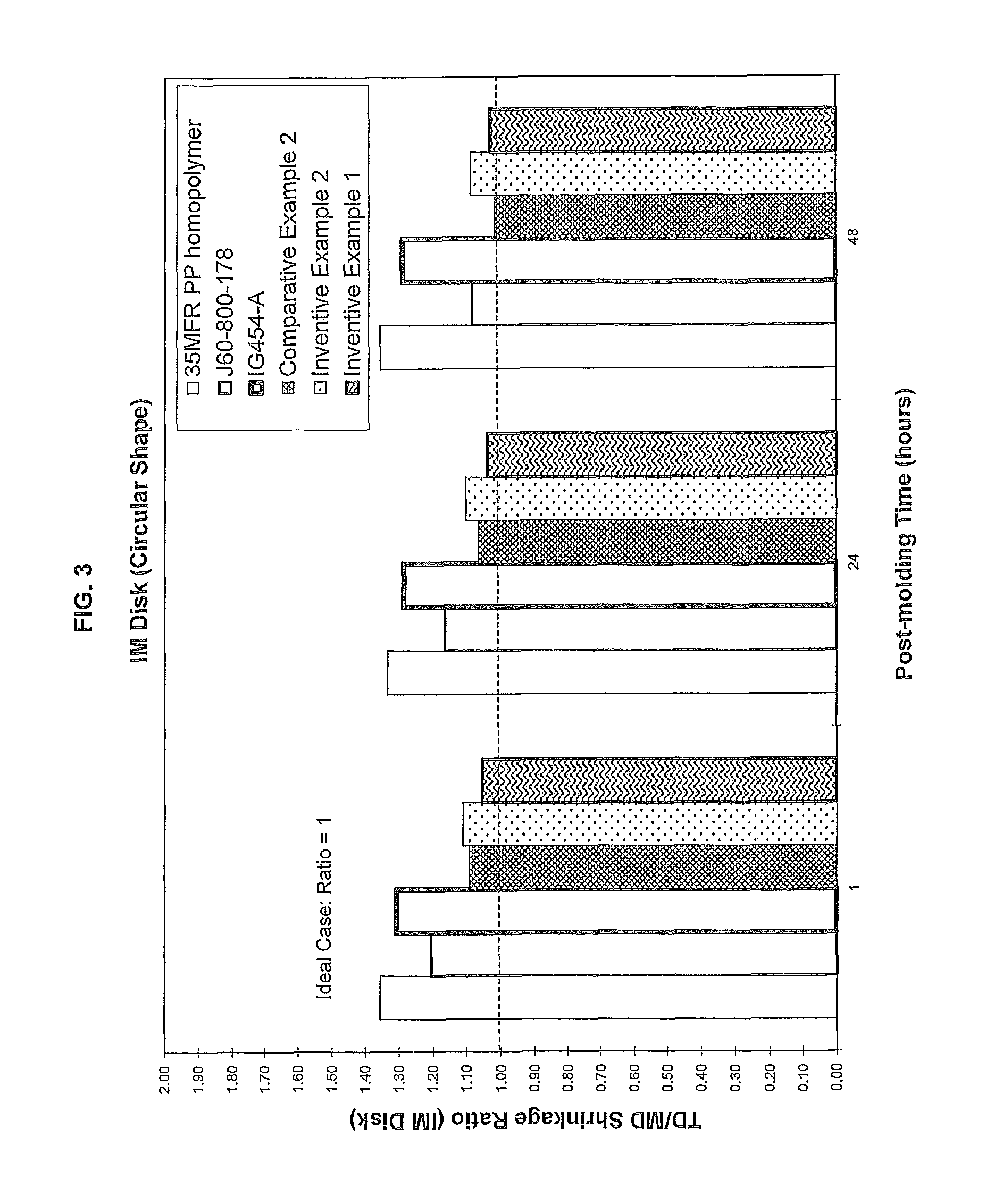

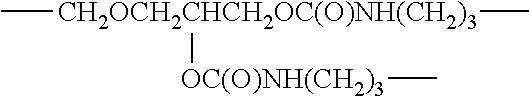

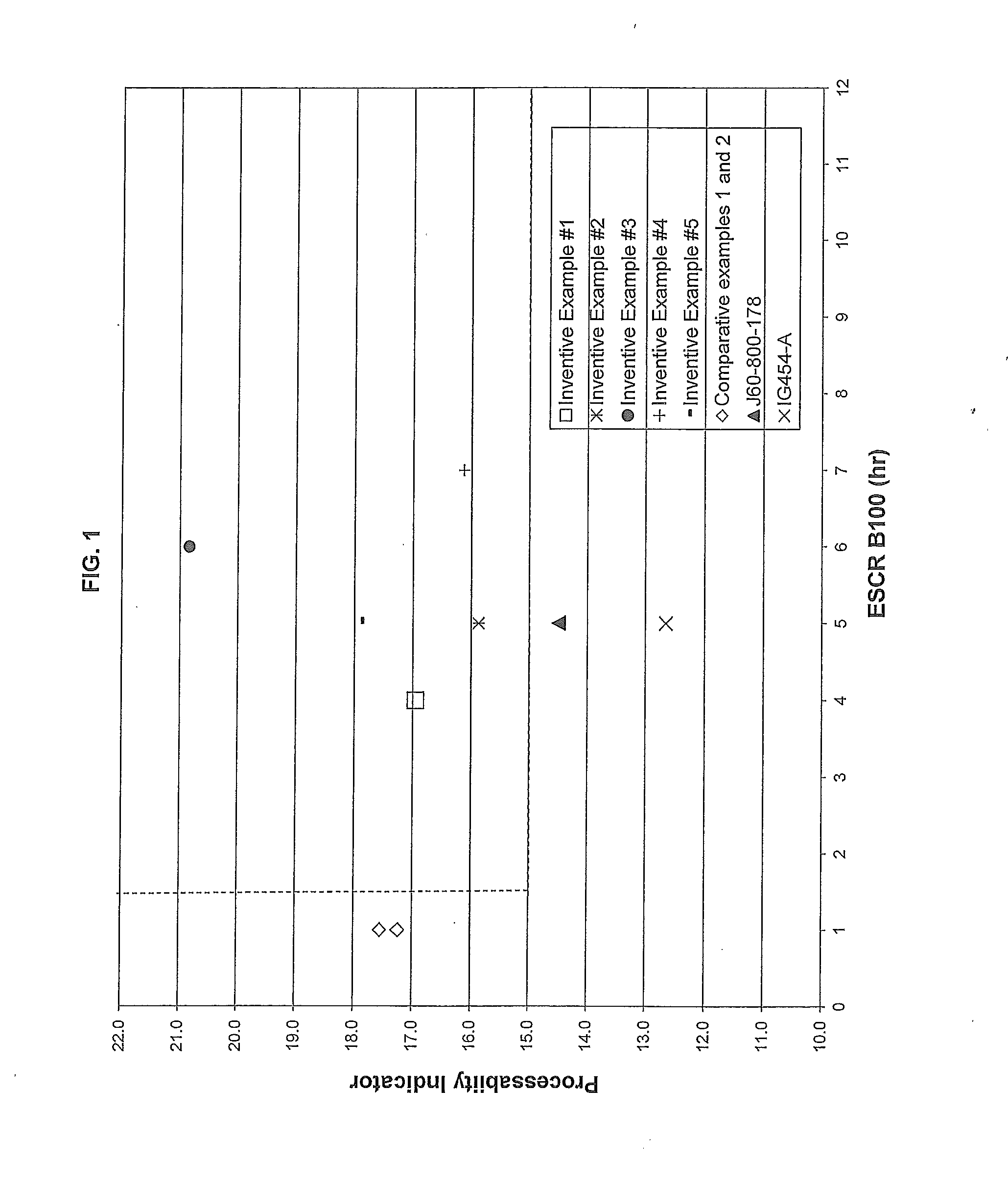

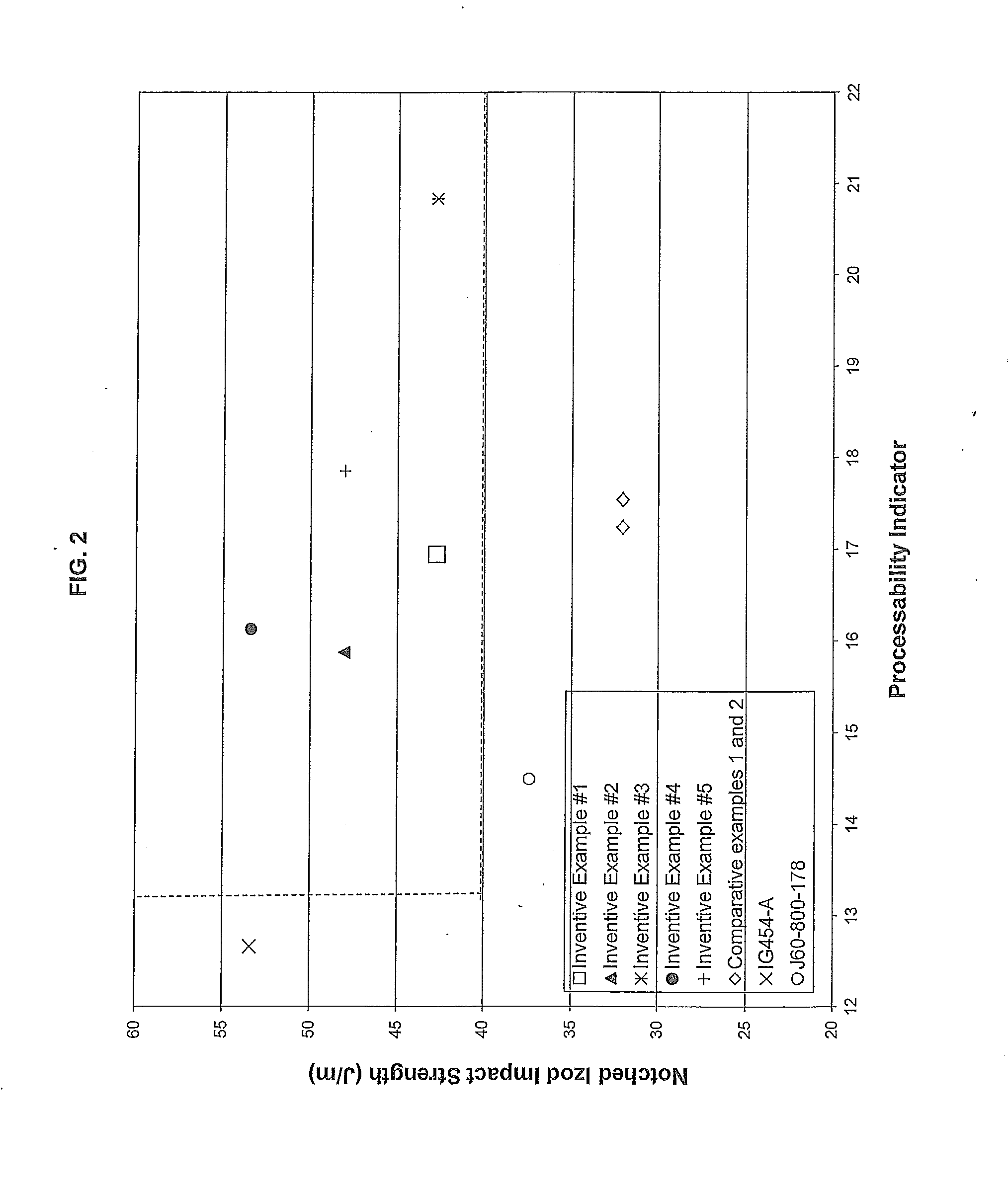

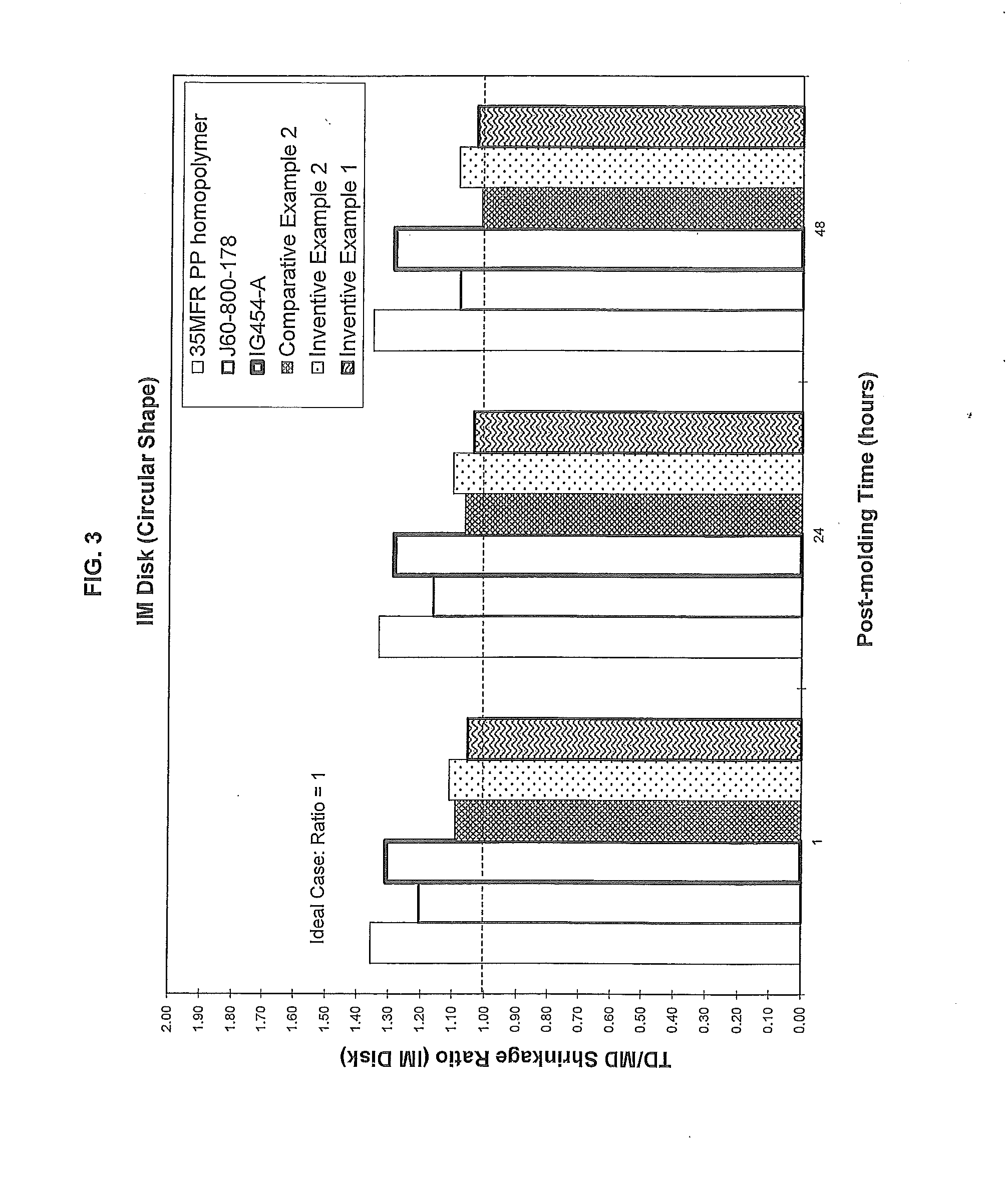

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

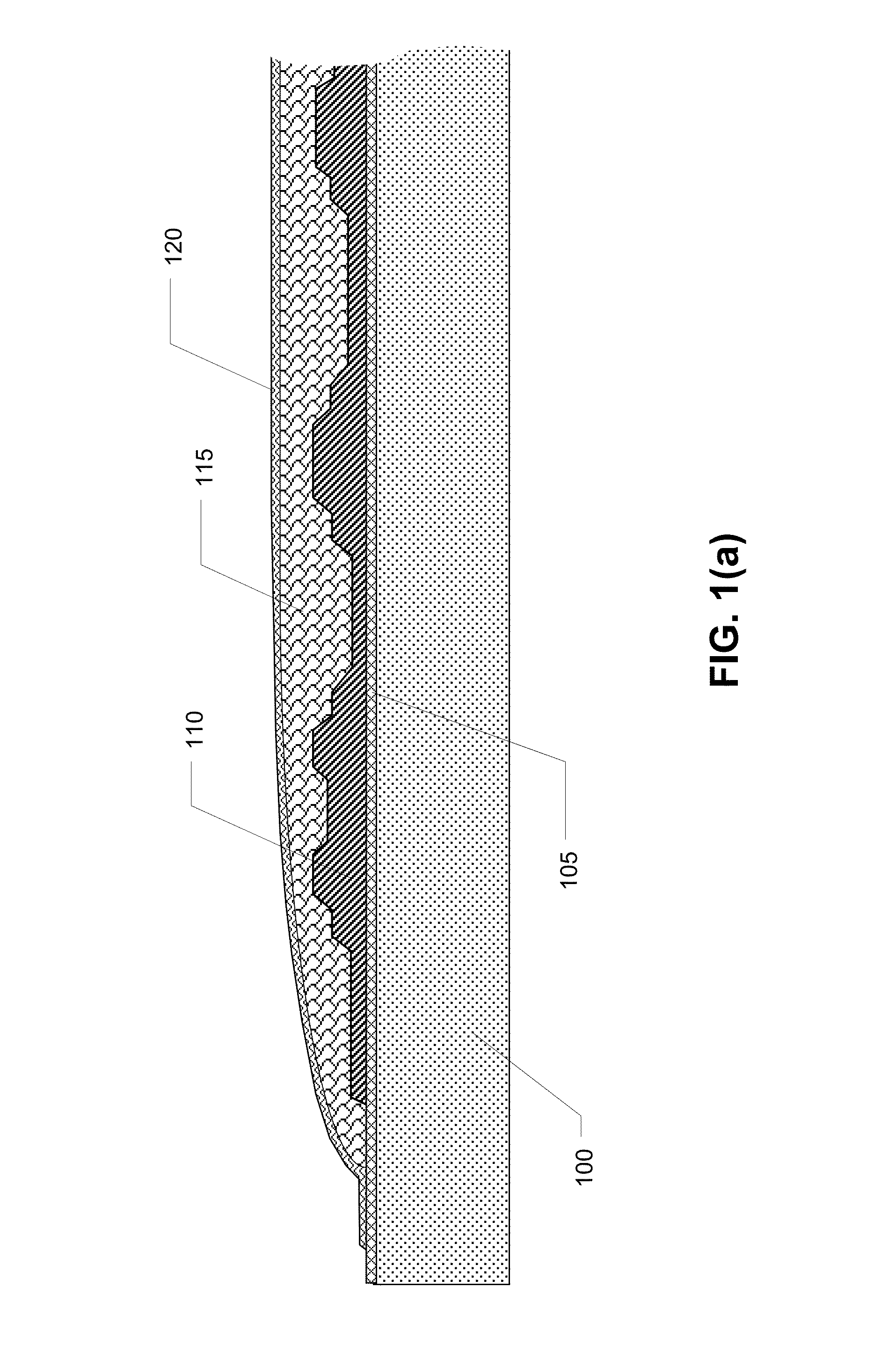

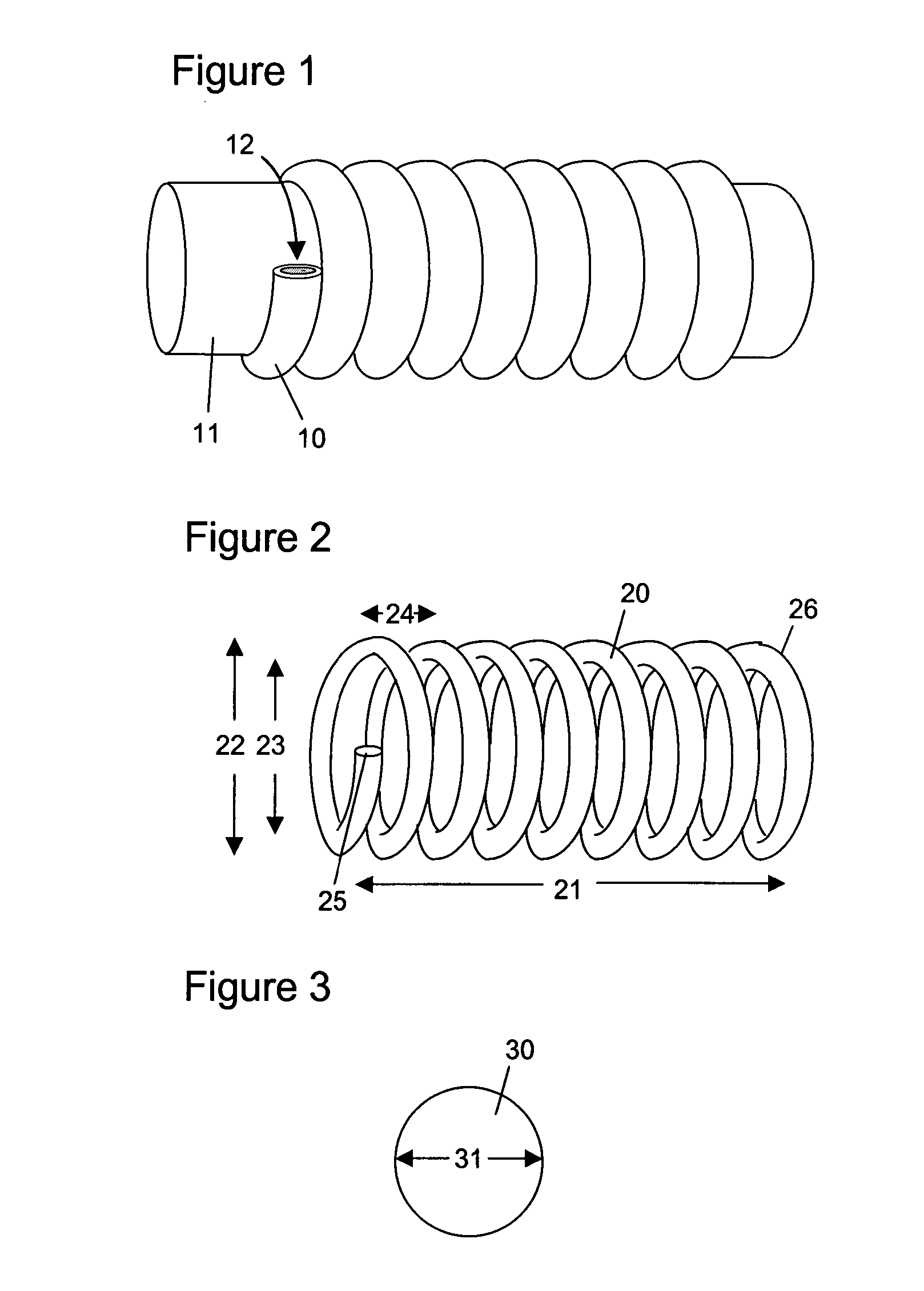

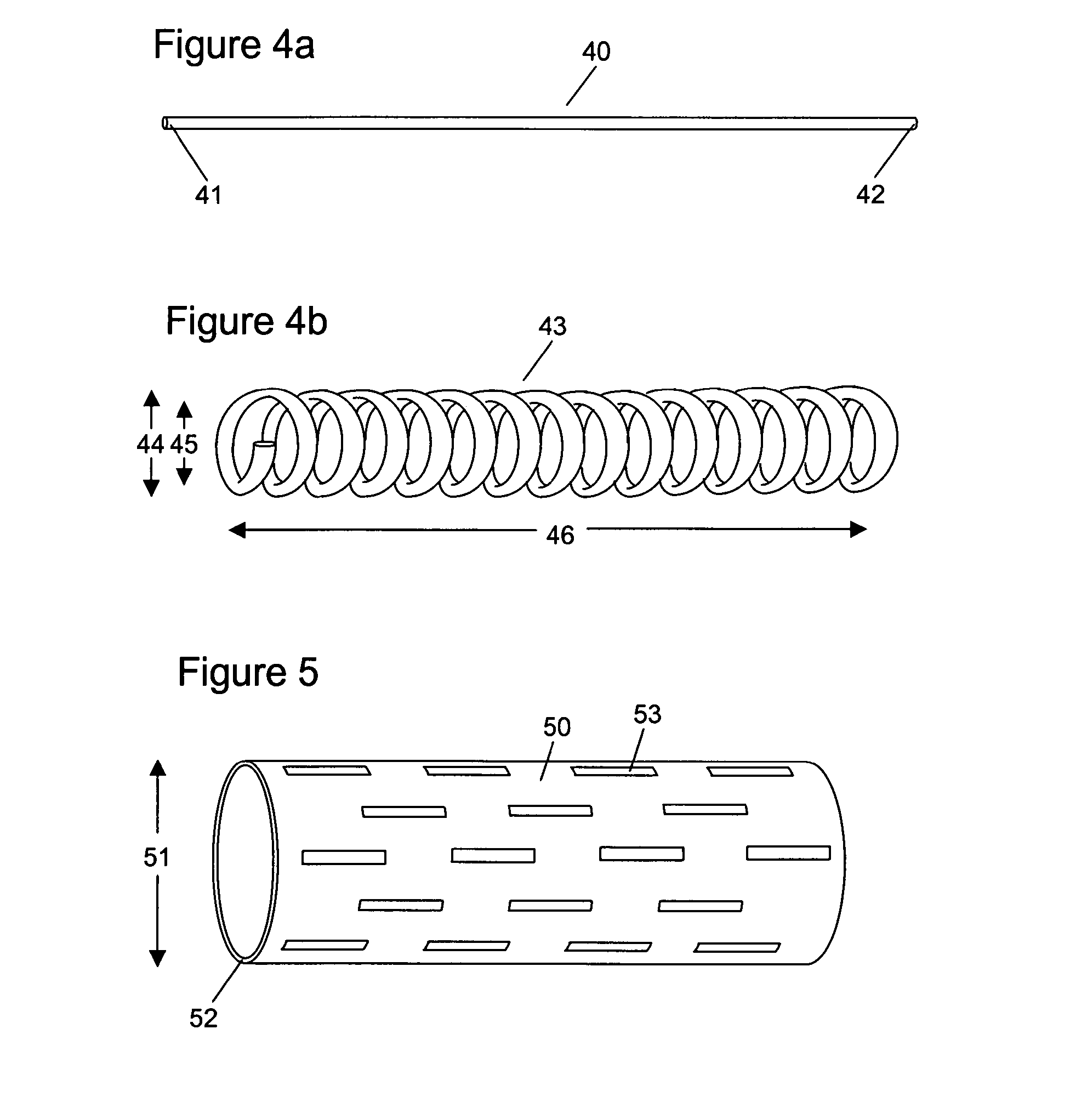

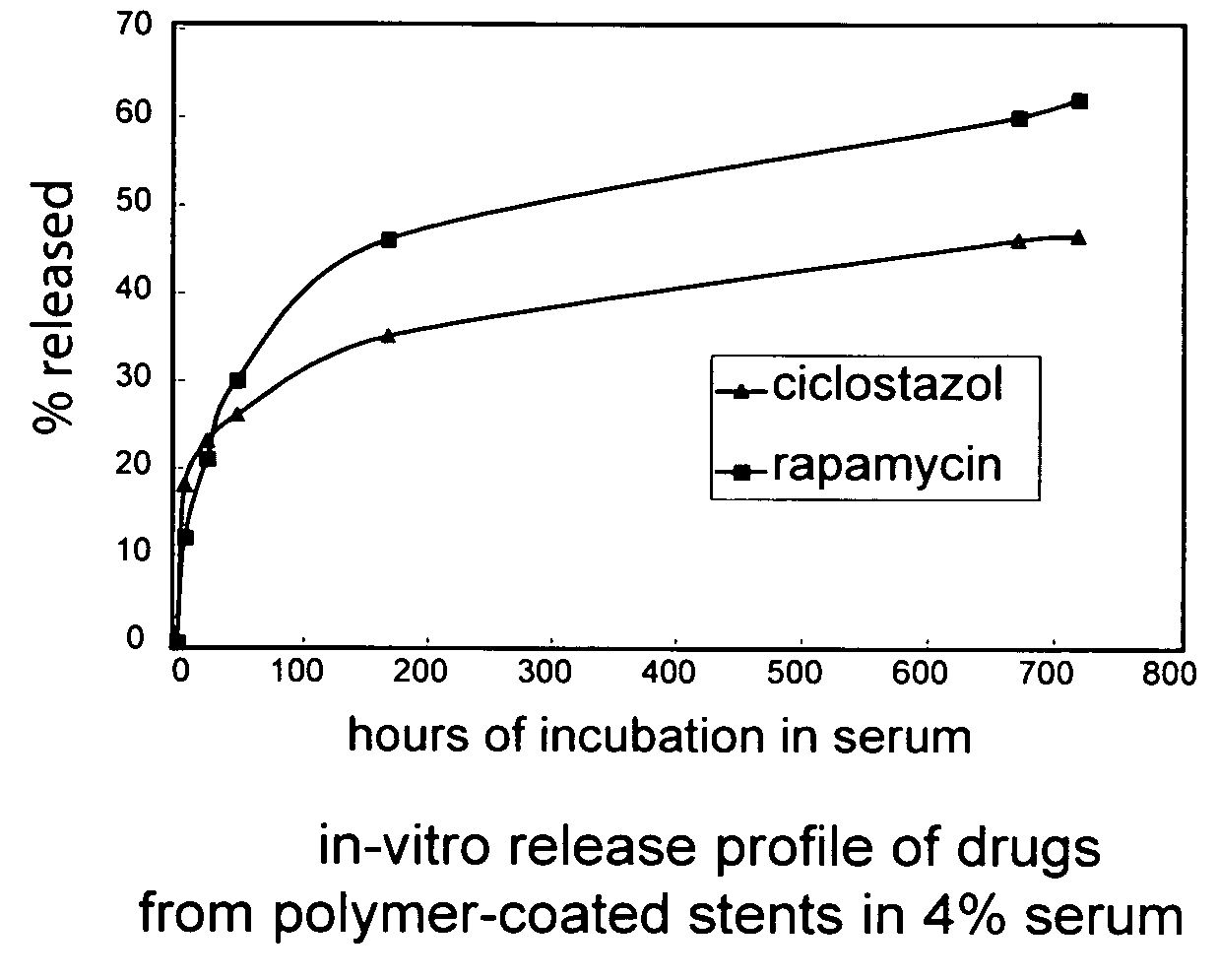

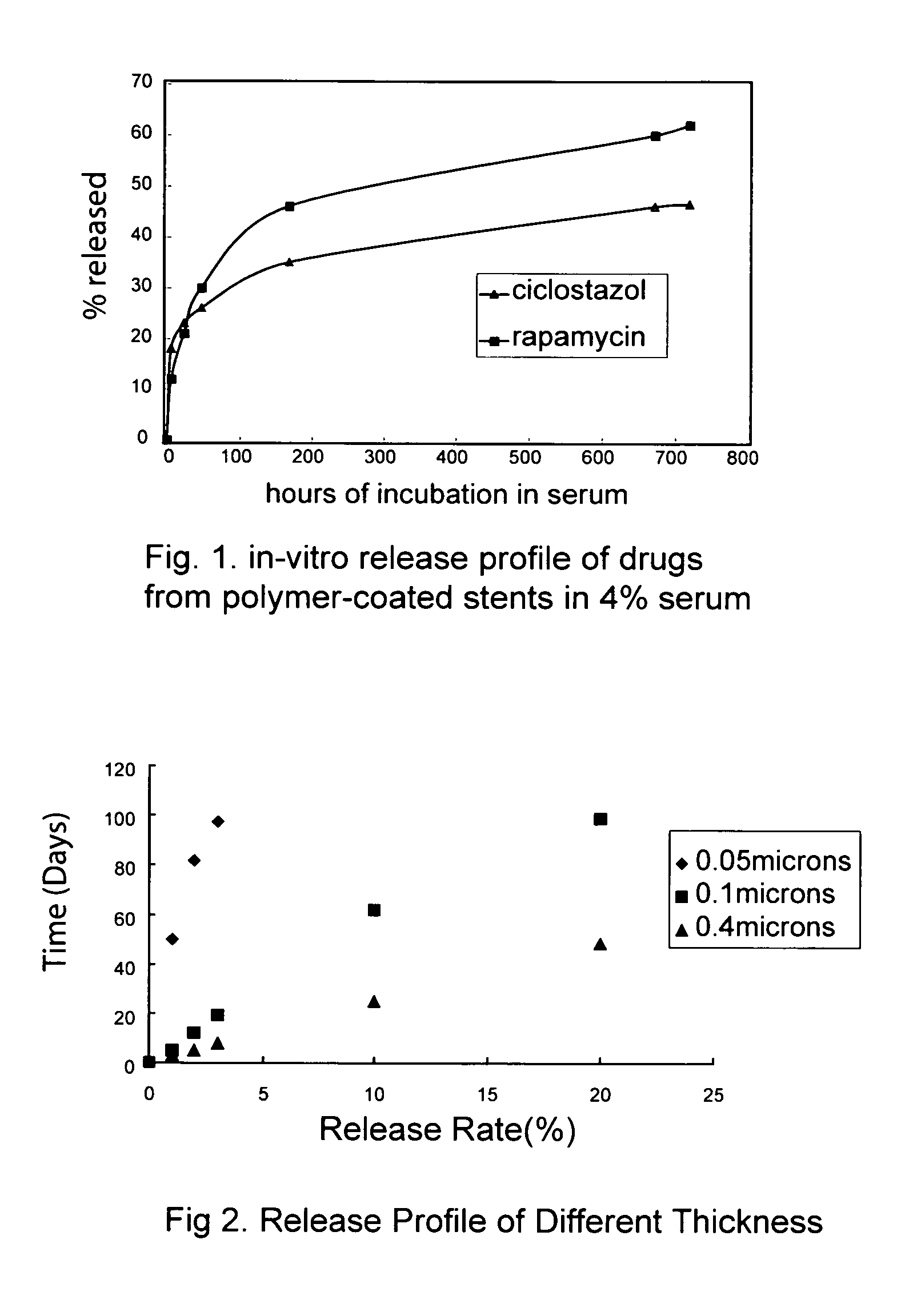

Drug-eluting stent with multi-layer coatings

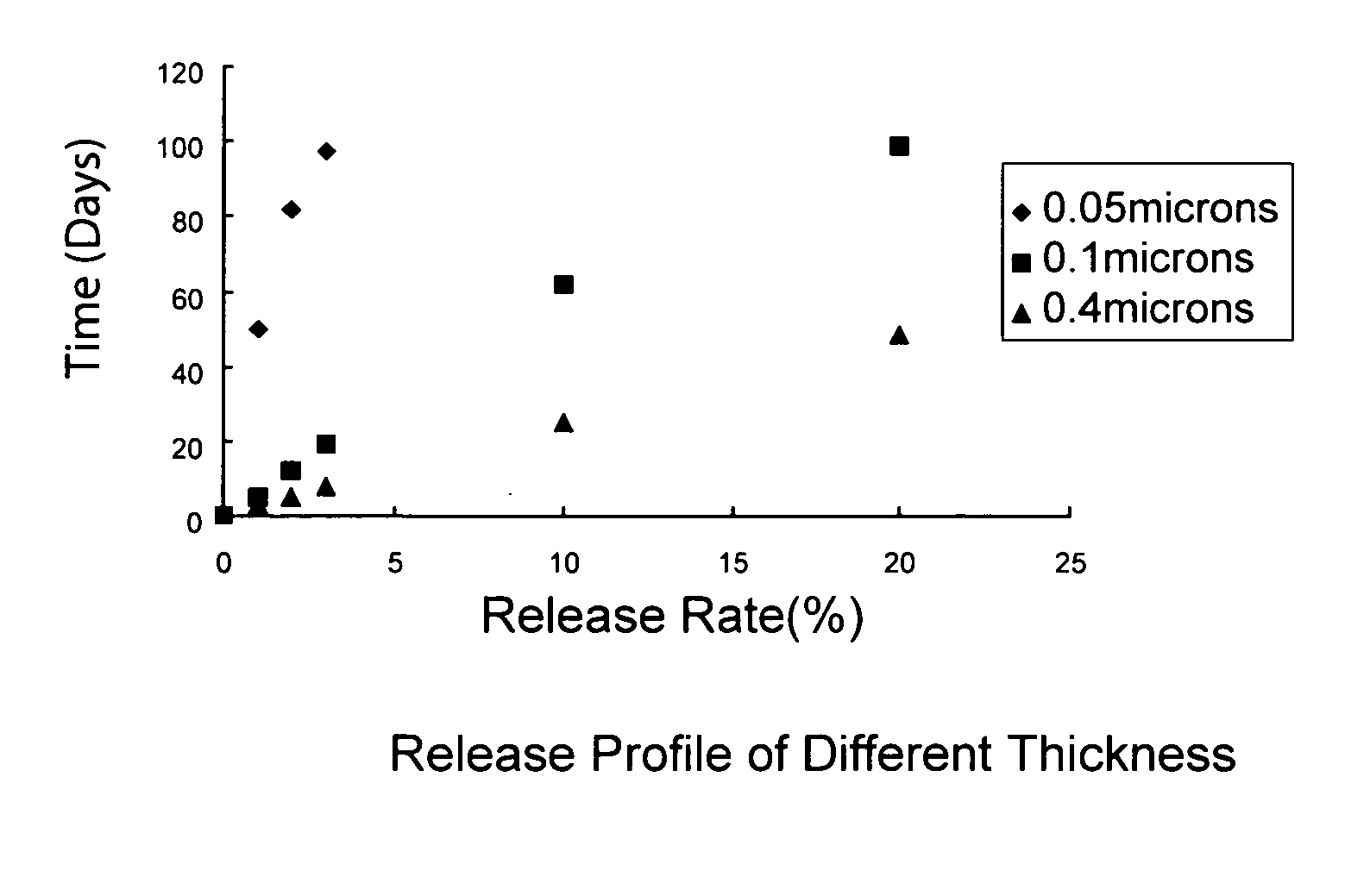

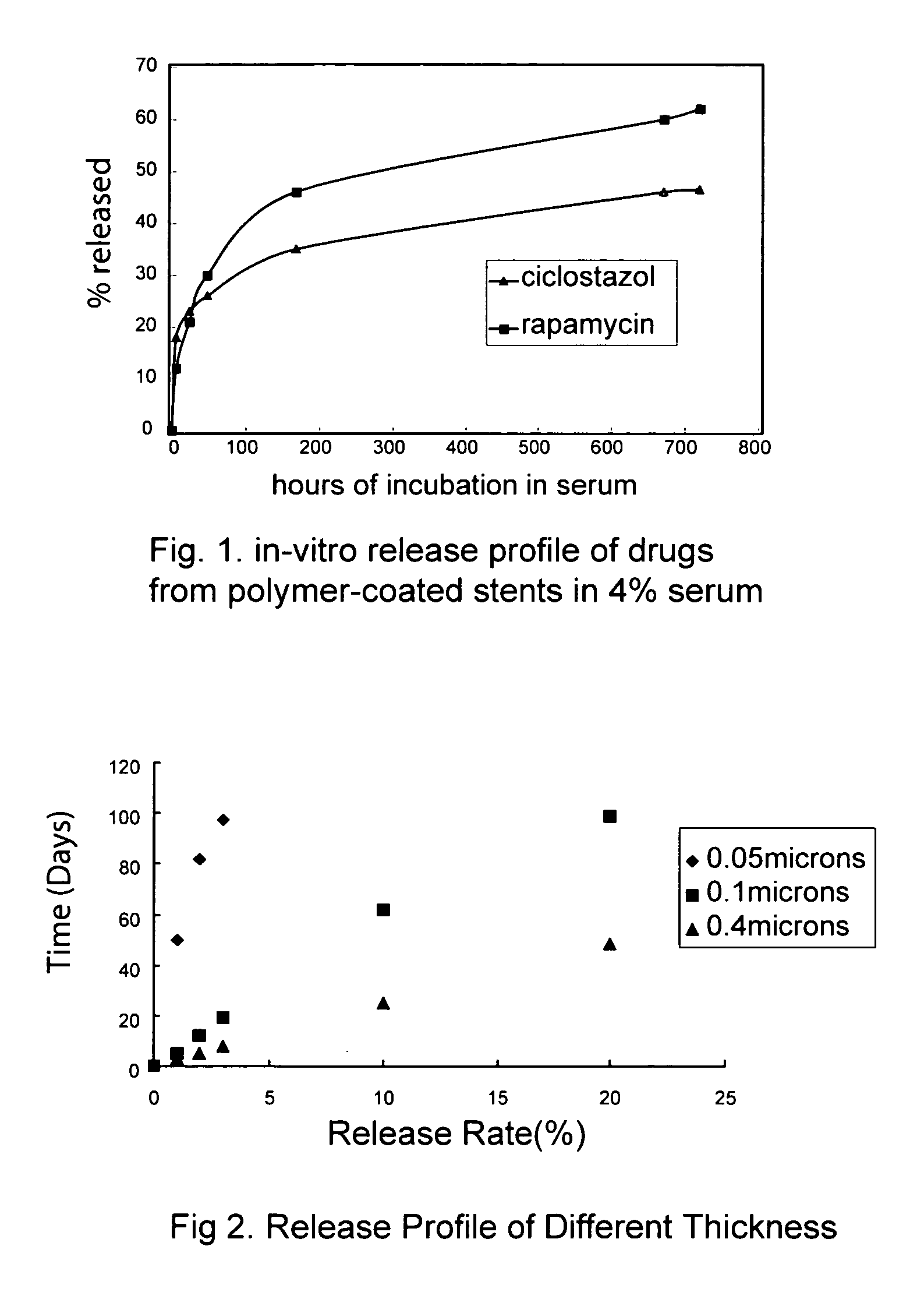

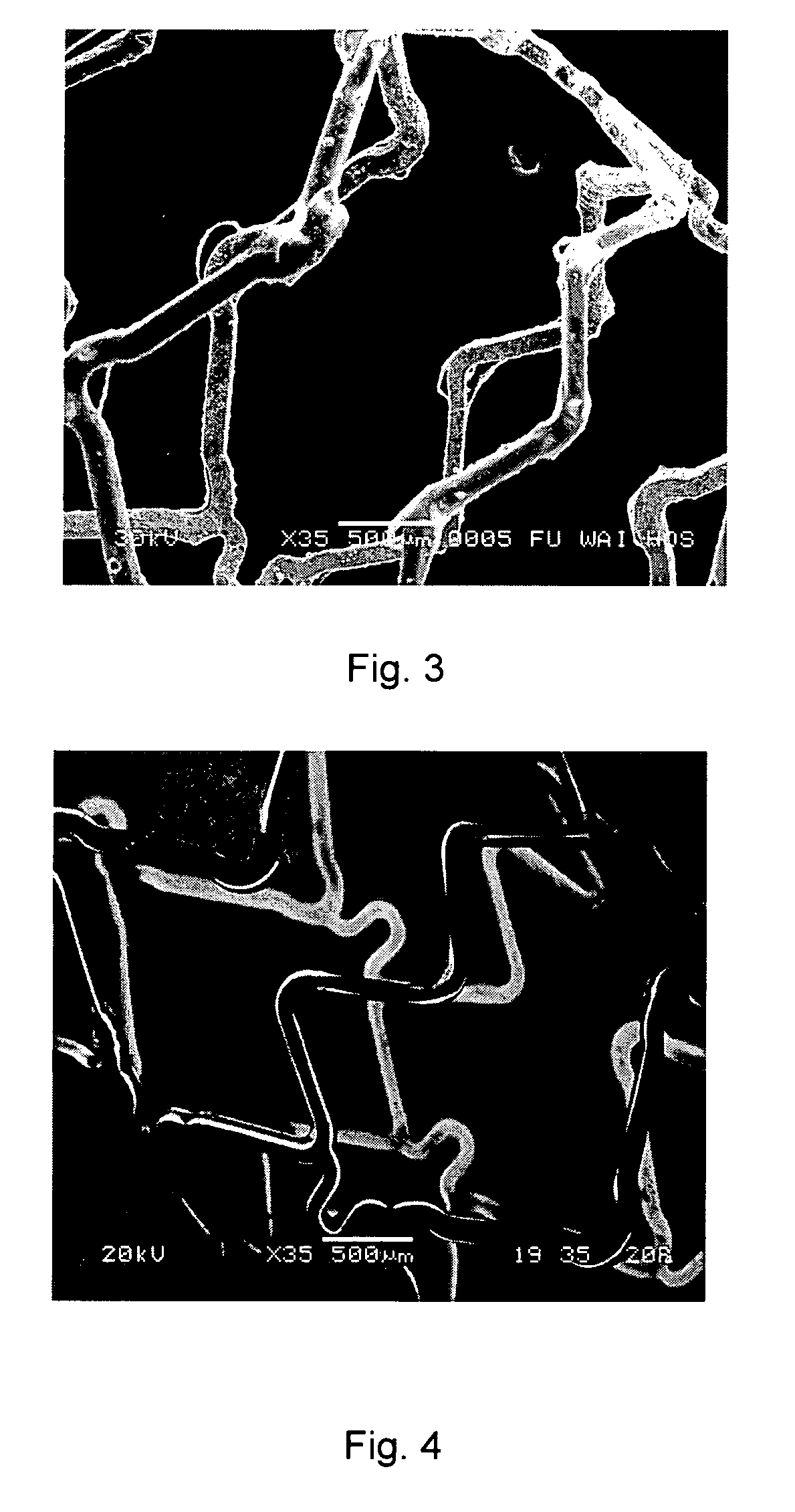

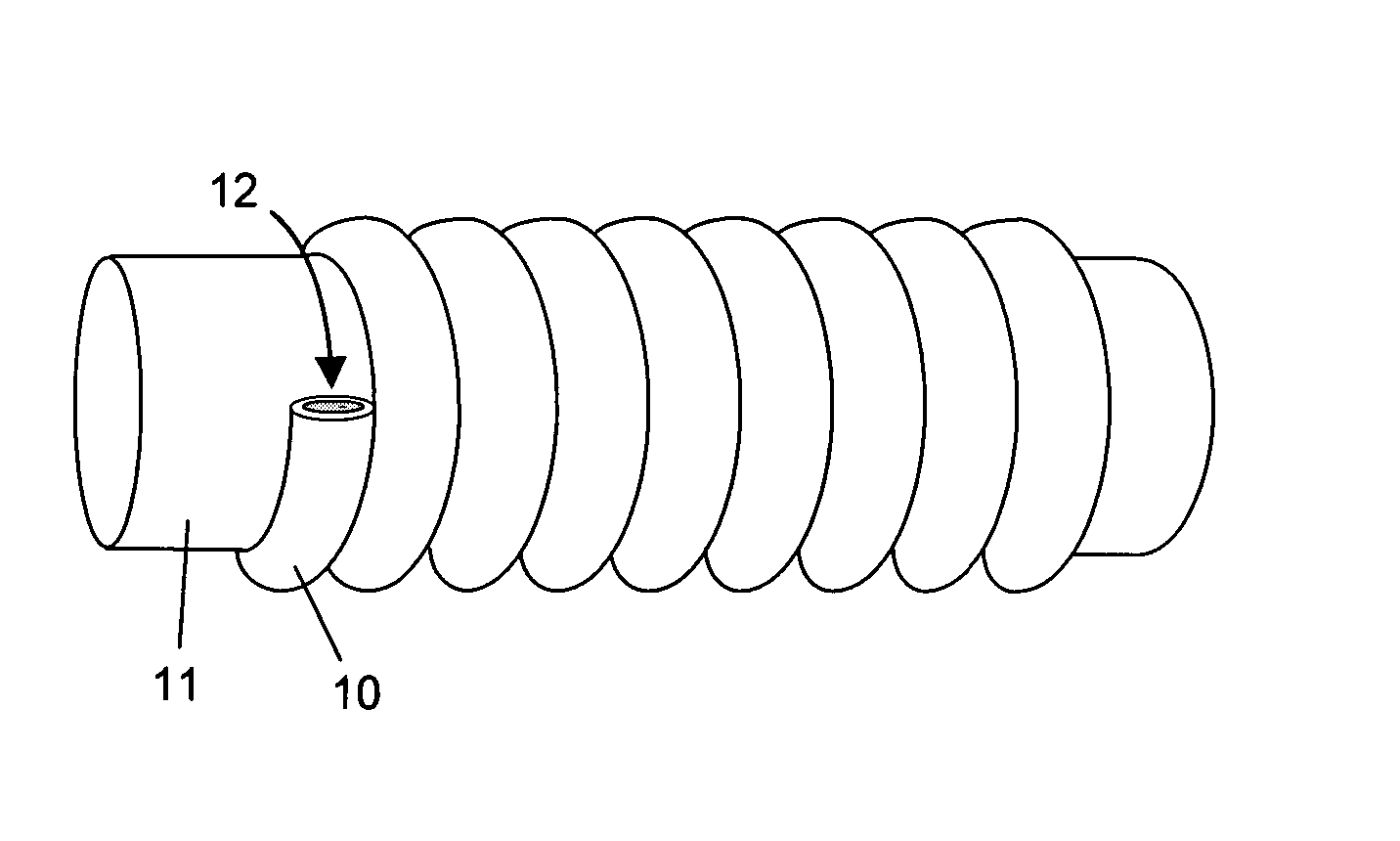

InactiveUS20050033414A1Resistance to crackingAvoid complicationsPeptide/protein ingredientsGenetic material ingredientsControlled releaseInsertion stent

The invention relates to a drug eluting stent and a method for making the stent. The stent comprises a stent body and coats covering on the stent body, it is characterized in that: 2-4 coats are provided on the surface of the stent body, wherein at least two coats are drug coats. The drug coats comprise 0.5-99% polymer by weight, 0-10% additive by weight and 0.5-99% active ingredient by weight. A primer layer is provided between the drug coats and the stent body. A compact control-releasing layer is also coated on the surface of the drug coats.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Hydrophilic shape memory insertable medical articles

InactiveUS20080039931A1Increase elasticityResistant to detrimental fracturingPowder deliveryStentsPolymer scienceHydrophilic polymers

Insertable medical articles with a shape memory property having a body member formed of crosslinked hydrophilic polymers are described.

Owner:SURMODIES

Drug-eluting stent

InactiveUS20050043788A1Resistance to crackingAvoid complicationsPeptide/protein ingredientsGenetic material ingredientsControl releaseInsertion stent

The invention relates to a drug eluting stent and a method for making the stent. The stent comprises a stent body and coats covering on the stent body, it is characterized in that: 2-4 coats are provided on the surface of the stent body, wherein at least two coats are drug coats. The drug coats comprise 0.5-99% polymer by weight, 0-10% additive by weight and 0.5-99% active ingredient by weight. A primer layer is provided between the drug coats and the stent body. A compact control-releasing layer is also coated on the surface of the drug coats.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

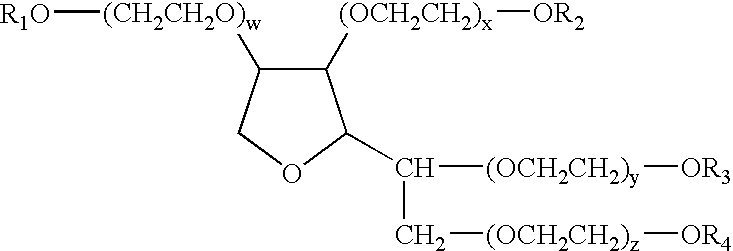

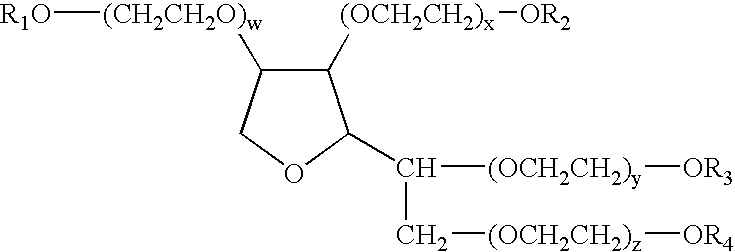

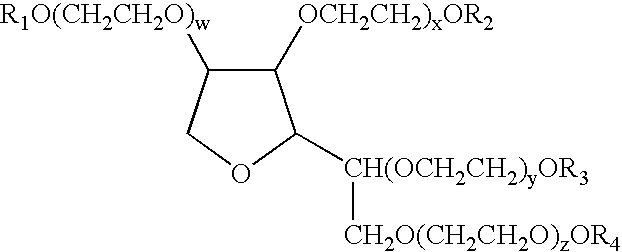

Detergent particle

InactiveUS20030017959A1Resistance to crackingResistant to and fragmentationOrganic detergent compounding agentsNon-surface-active detergent compositionsParticulatesWater dispersible

The present invention relates to a water-soluble and / or water-dispersible particle comprising an active ingredient uniformly dispersed, preferably an enzyme, in a matrix comprising from 20-95% by weight of the particle of polyvinyl alcohol of a molecular weight of 10-30K daltons. The present invention further relates to a process to obtain a particle, to a detergent composition comprising the particle and to the use of particle to minimize, reduce or prevent the generation of dust while providing excellent cleaning on enzyme sensitive stains and soils and on particulate stains, improved thermostability and fabric softness performance.

Owner:THE PROCTER & GAMBLE COMPANY

Non-crystalline saliva-soluble coatings for elastomeric monofilament dental tapes

InactiveUS20050226820A1Substantivity of coatings onto flexible surfacesResistance to crackingCosmetic preparationsToilet preparationsMedicineControl substances

Owner:WHITEHILL ORAL TECH

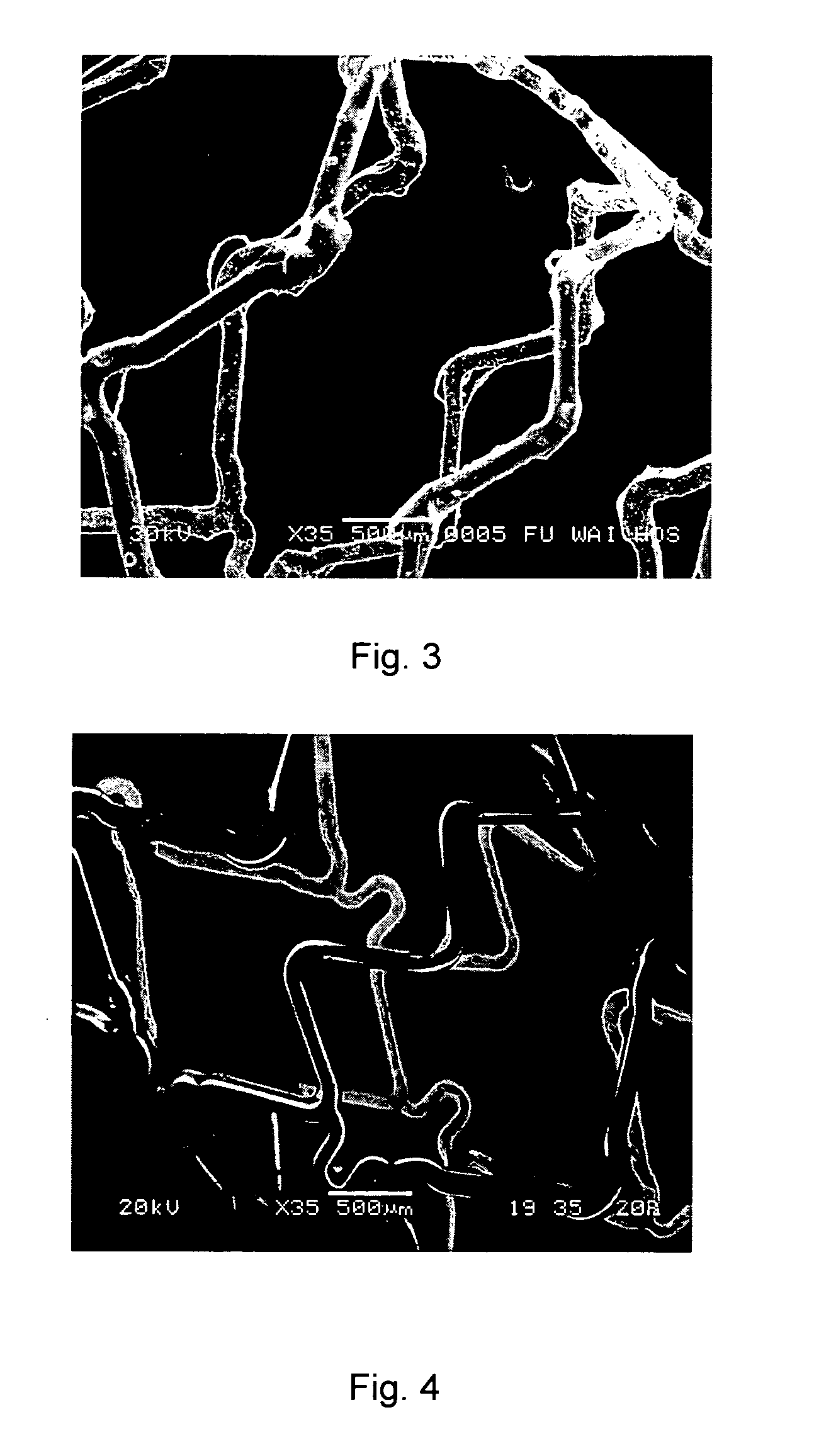

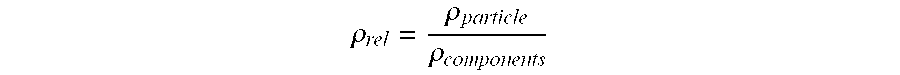

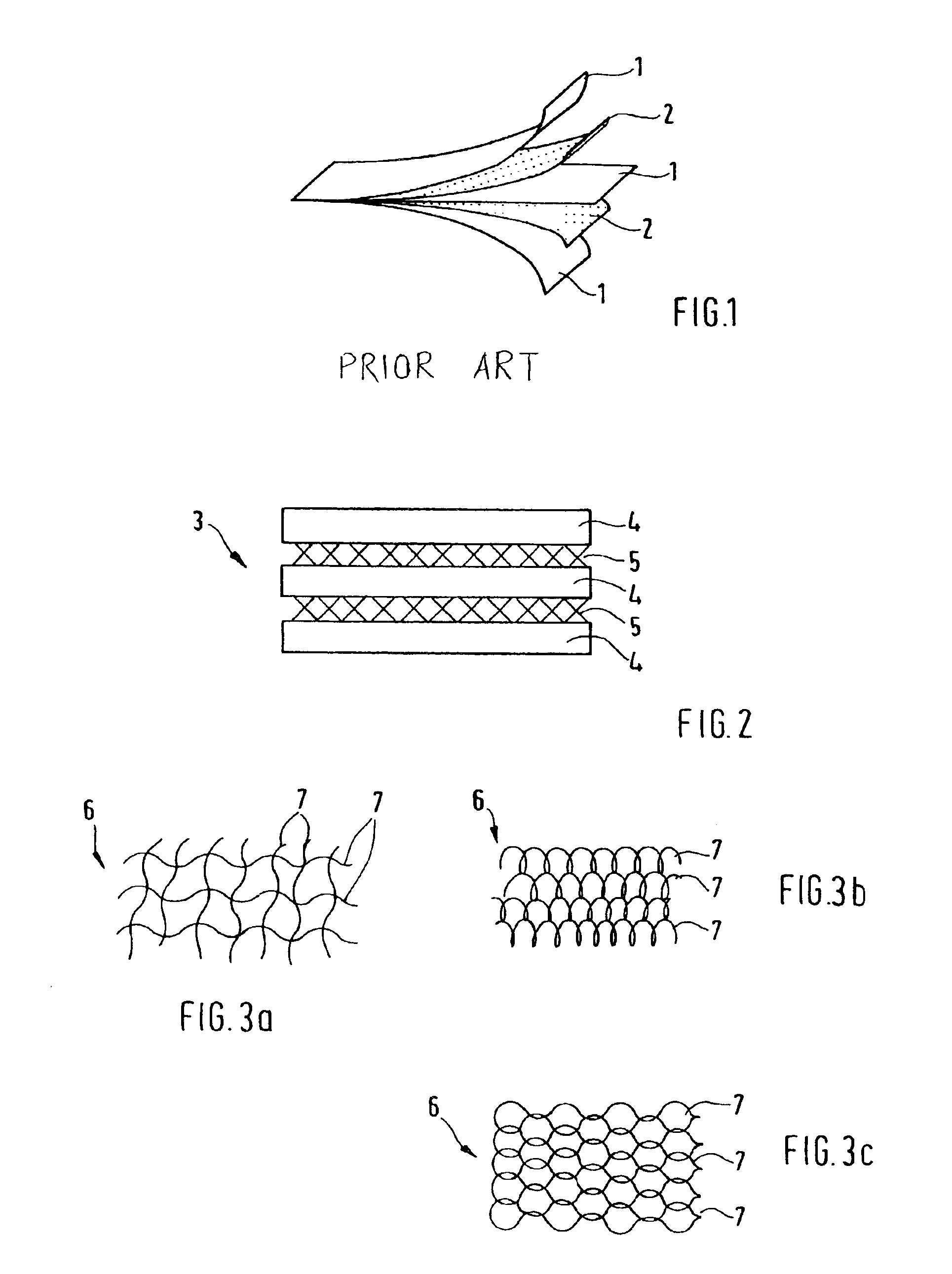

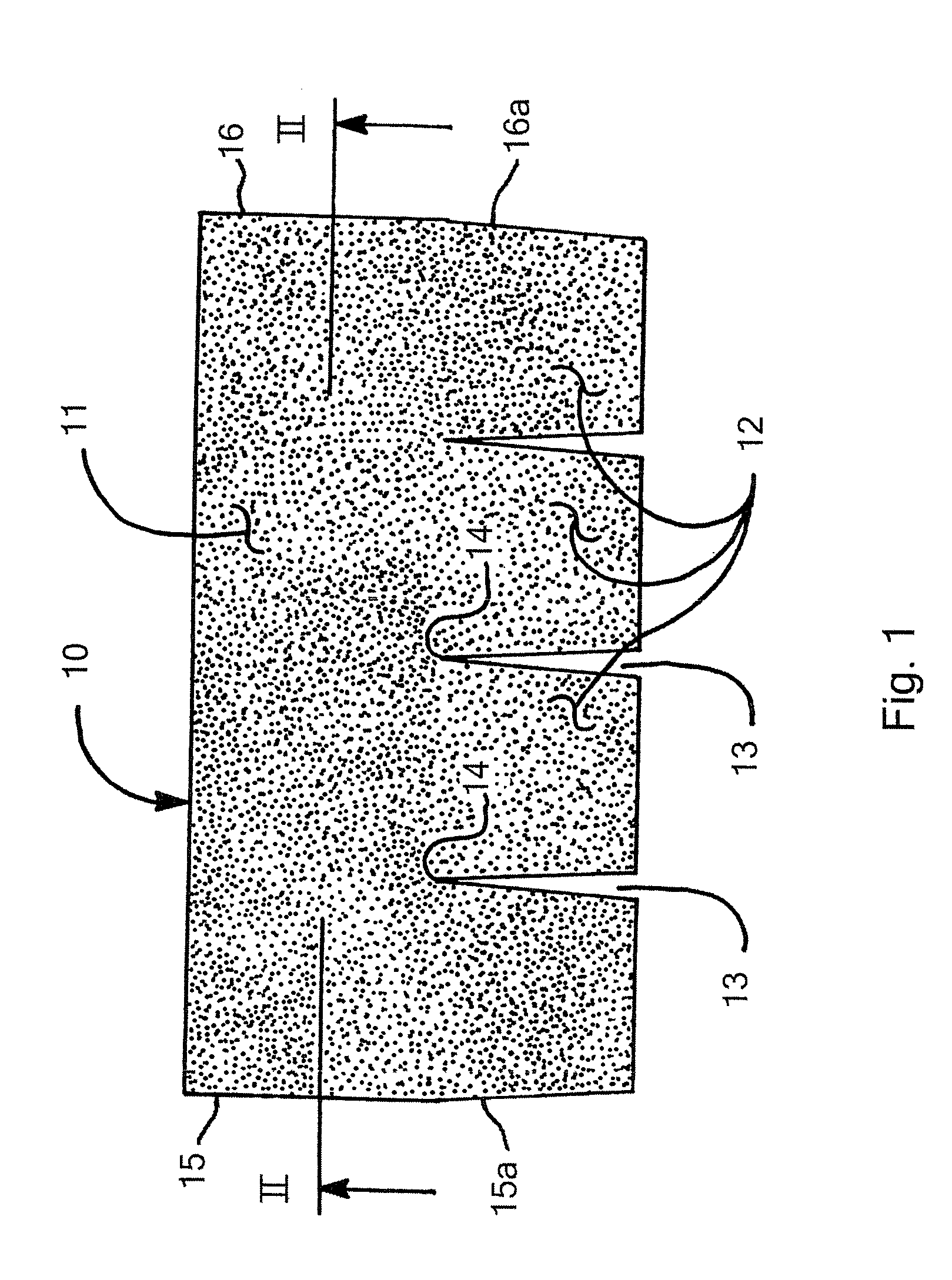

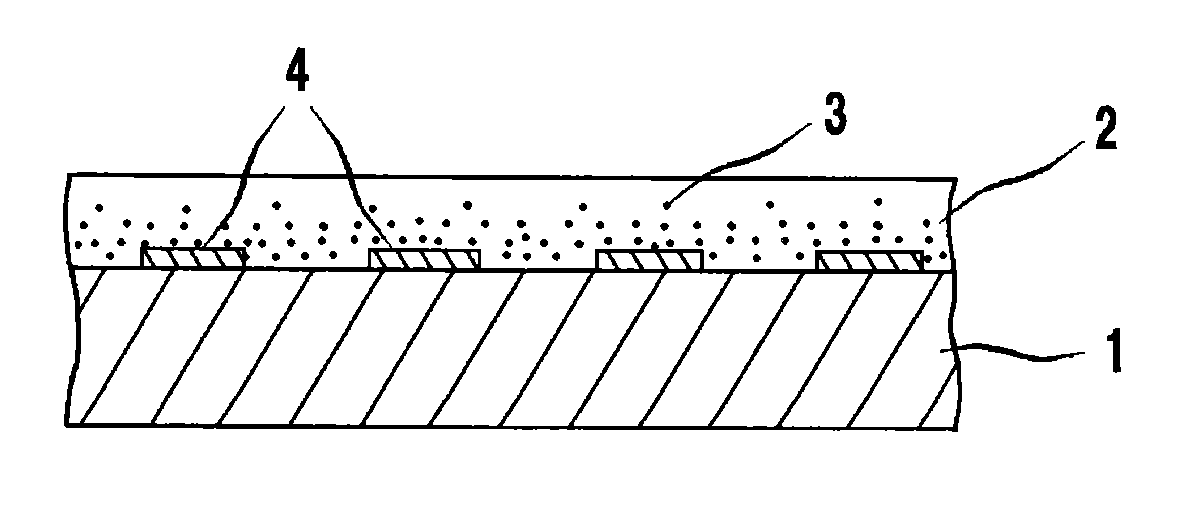

Metal fiber-reinforced composite material as well as a method for its production

InactiveUS6861156B2Simple procedureEasy to useArmour platesThin material handlingMetal fiberMetallic materials

A metal fiber-reinforced composite material can be produced by providing metal layers and reinforcing layers disposed alternately into a sandwich structure, the reinforcing layers containing fibers of a high-strength metallic material, which are disposed in the form of a loose structure between the metal layers, in order to create a material excess of fibers in the reinforcing layers, the sandwich structure being bonded by a thermomechanical process in such a manner, that the fibers are lengthened because of the excess of material, the sandwich structure being bonded.

Owner:AIRBUS OPERATIONS GMBH

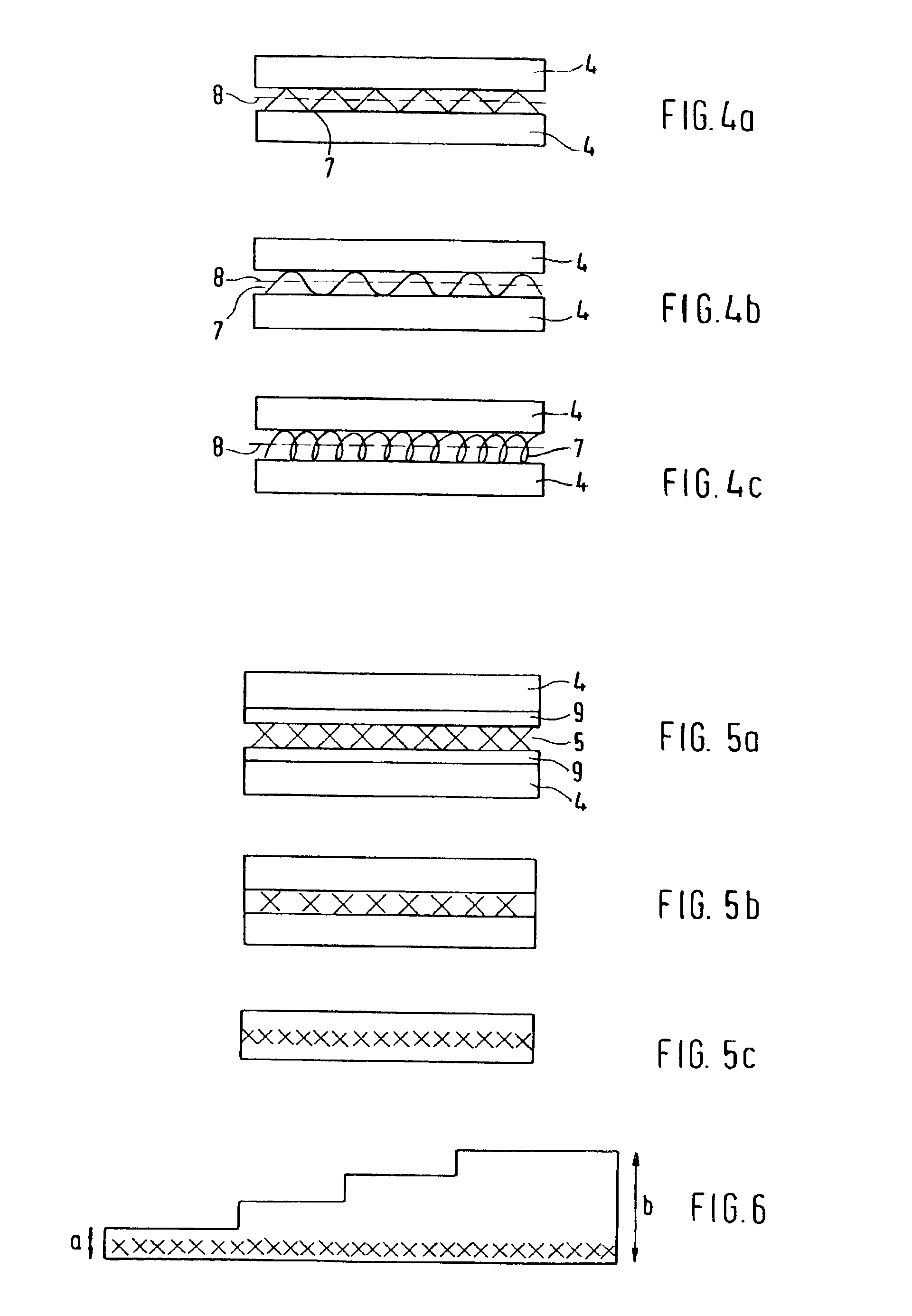

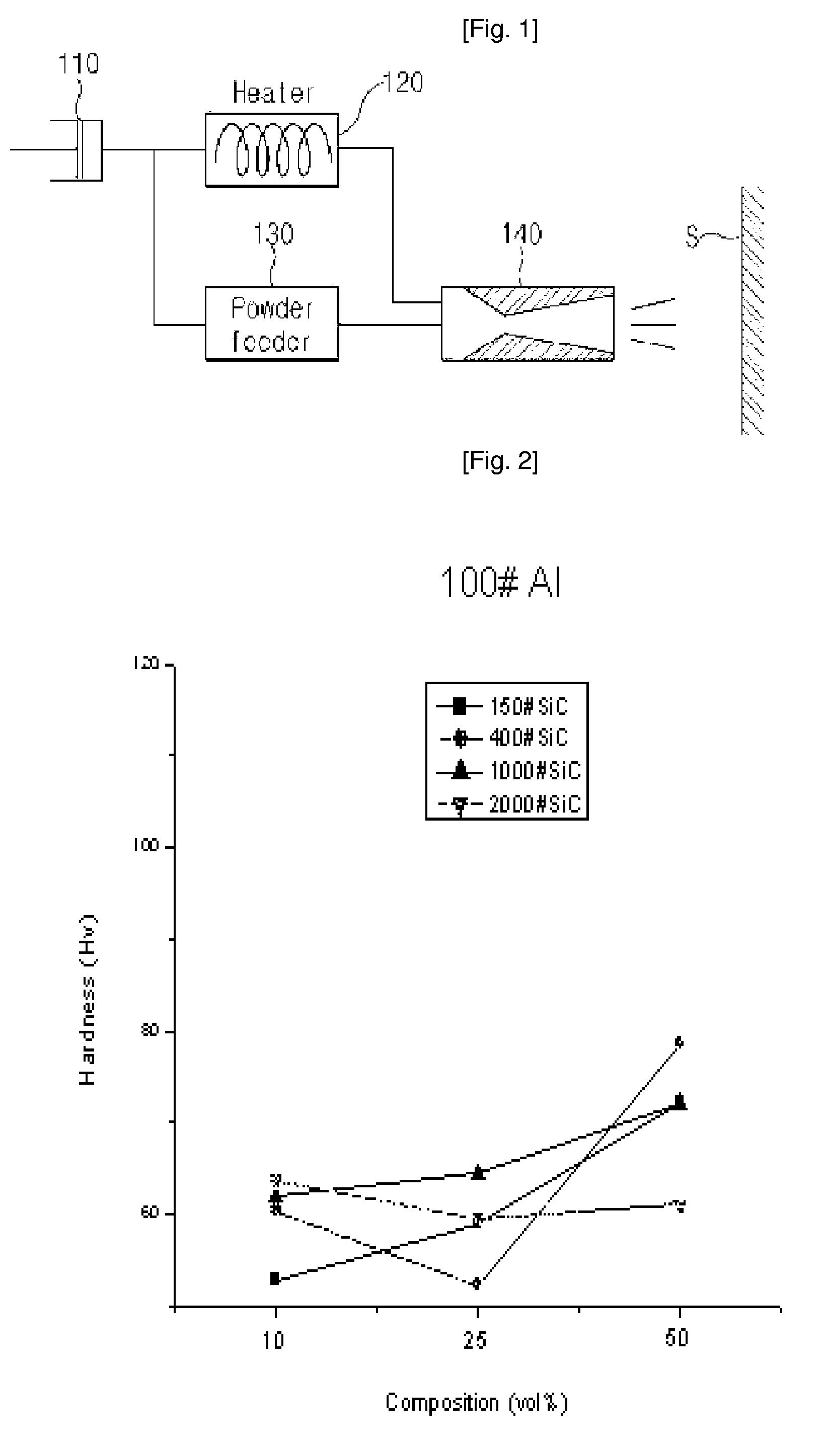

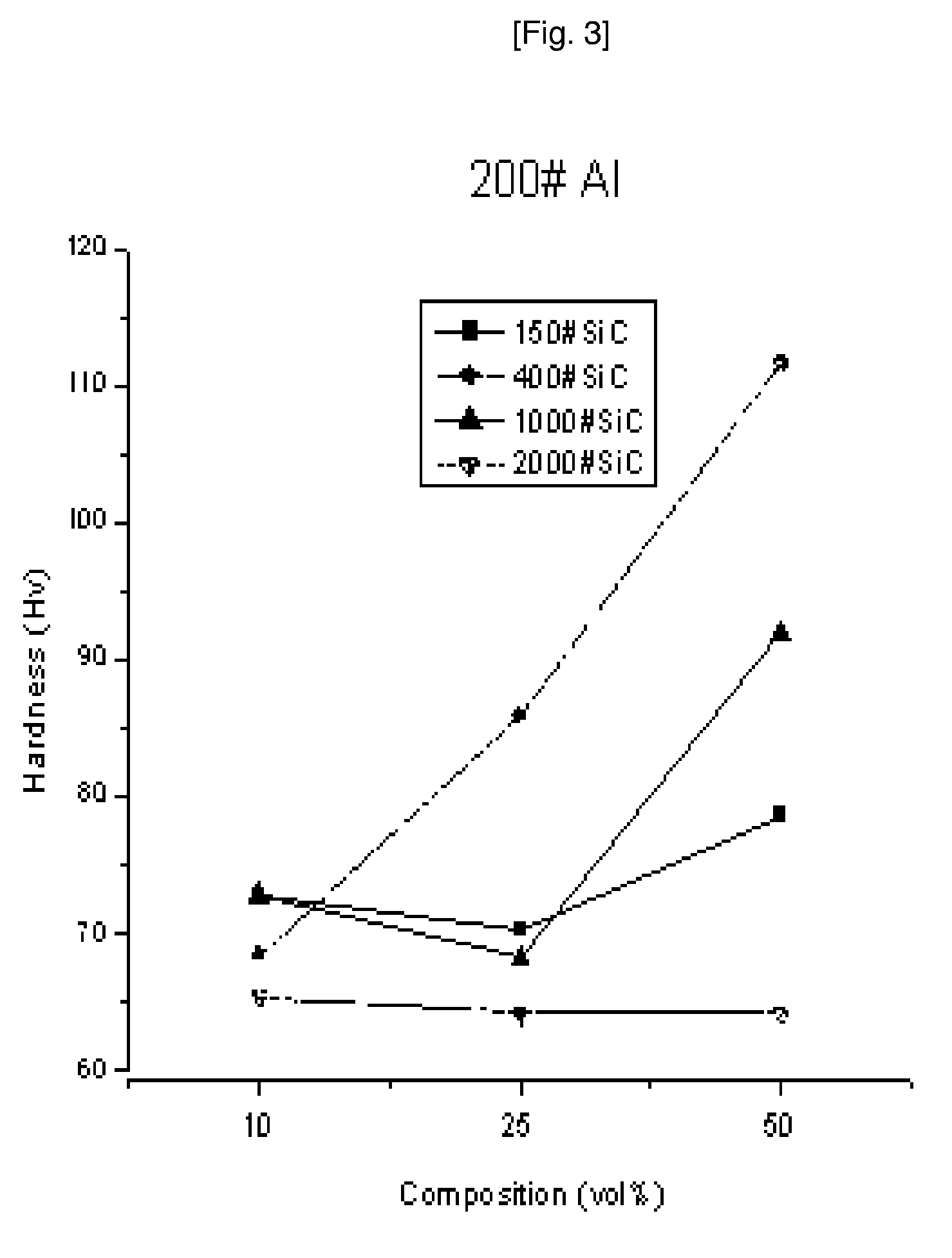

Method of Preparing Wear-Resistant Coating Layer Comprising Metal Matrix Composite and Coating Layer Prepared Thereby

ActiveUS20080220234A1Excellent resistance against fatigue crackImproves wear resistance property propertyMolten spray coatingSynthetic resin layered productsMolten stateWear resistant

The invention provides a method of preparing a wear-resistant coating layer comprising metal matrix composite and a coating layer prepared by using the same and more particularly, it provides a method of preparing a wear-resistant coating layer comprising metal matrix composite, which comprises the steps of providing a base material, preparing a mixture powder comprising a metal, alloy or mixture particle thereof having an average diameter of 50 to 100 um and a ceramic or mixture particle thereof having an average diameter of 25 to 50 um in a ratio of 1:1 to 3:1 by volume, injecting the mixture powder into a spray nozzle for coating, and coating the mixture powder on the surface of the base material by accelerating the mixture powder in the state of non-fusion at a rate of 300 to 1,200 m / s by the flow of transportation gas flowing in the nozzle and a coating layer prepared by using the same whereby the coating layer with high wear resistance and excellent resistance against fatigue crack on the surface of the base material without causing damages such as heat strain to the base material during the formation of the coating layer can be provided.

Owner:SKC SOLMICS

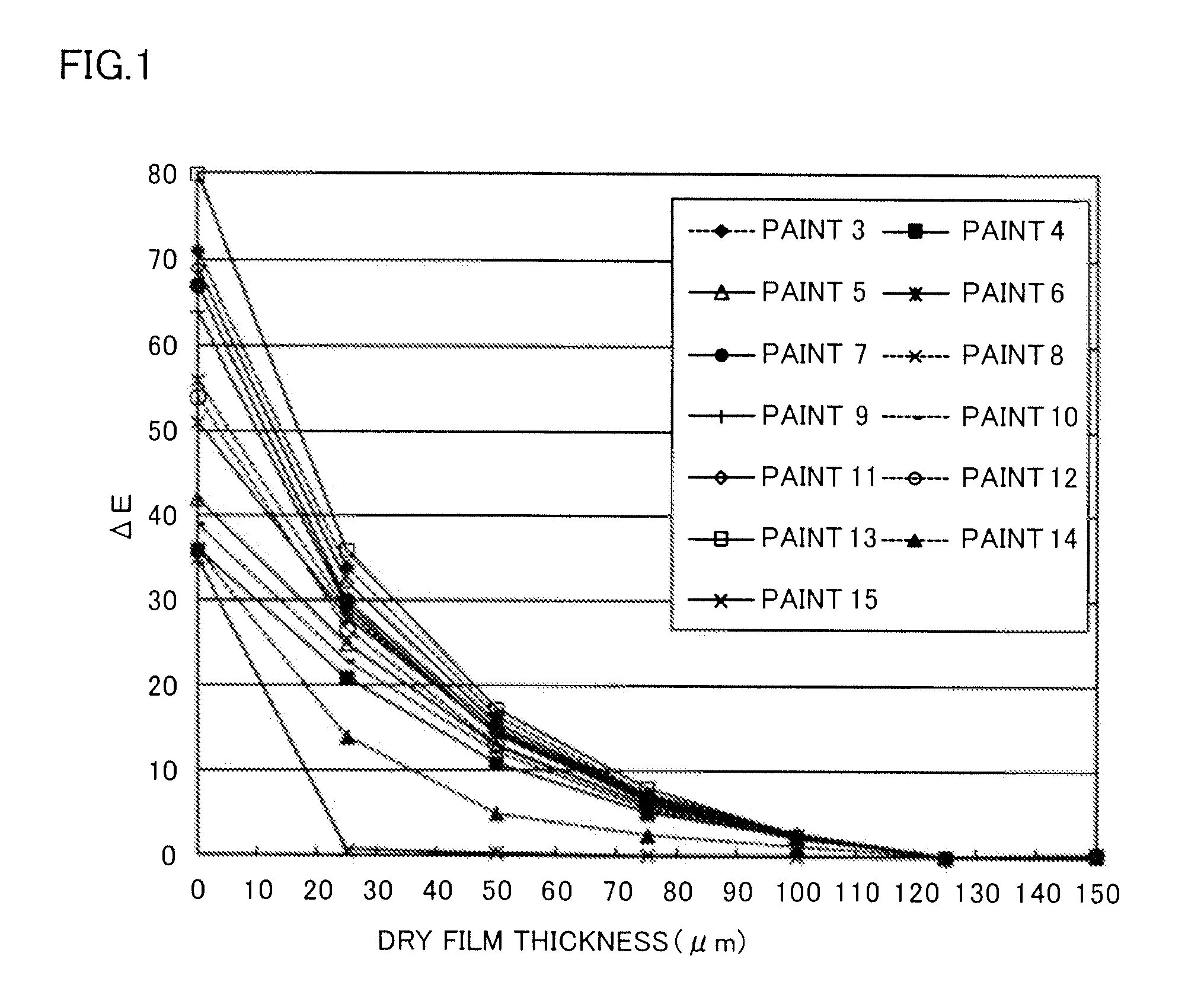

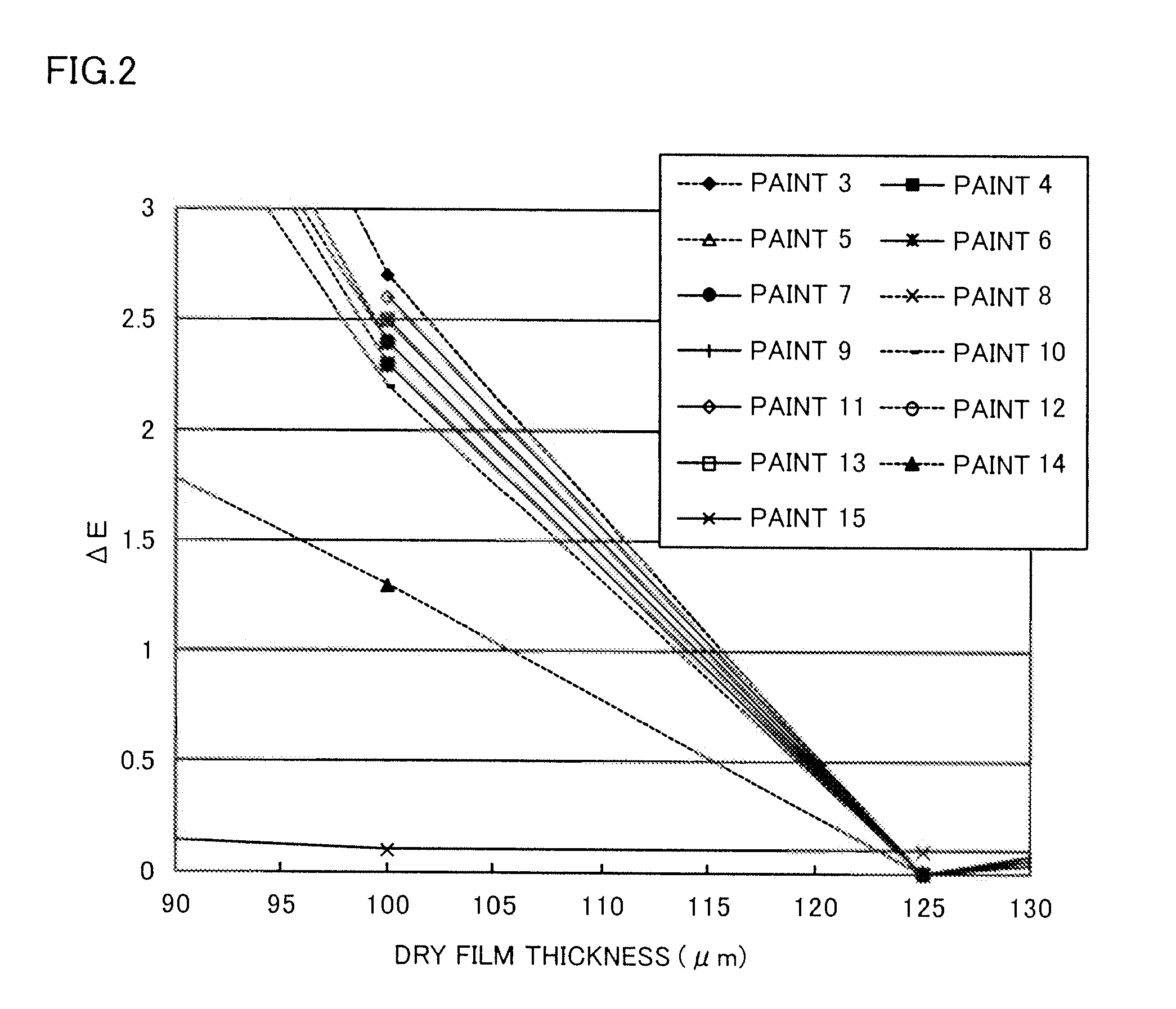

Method of forming antifouling coating film

ActiveUS20120294825A1Paint be saveResistant to crackAntifouling/underwater paintsPaints with biocidesColor differencePolymer chemistry

Provided is a method of forming an antifouling coating film including the steps of [1] preparing a colored antifouling paint containing a prescribed Si-containing hydrolyzable resin and a color pigment such that a coating film having a target dry film thickness T completely hides a surface of an object to be coated, the colored antifouling paint has a color difference ΔE1 between the coating film having the thickness T and a coating film having a dry film thickness of 0.8 T, at least 2.0, and preferably the colored antifouling paint has a color difference ΔE2 between the coating film having the thickness T and a coating film having a dry film thickness of 1.2 T, less than 1, and [2] coating a surface of the object with the colored antifouling paint until the surface of the object is completely hidden by the coating film formed from the colored antifouling paint.

Owner:NIPPON PAINT MARINE COATINGS

Shield material

InactiveUS20060251203A1Improve the immunityHigh densityElectrode and associated part arrangementsDischarge tube/lamp detailsPolyesterCarbon fibers

Disclosed is a fire-resistant lead-free shield material having high shielding ability against nuclear or electromagnetic radiation, and excellent bending workability and handling performance. The shield material comprises a composite material consisting of an organic material and a metal or metal compound having a nuclear or electromagnetic radiation-shielding ability. The composite material is formed into a given shape, such as a plate shape, and wrapped with a cloth-like sheet formed of glass fibers, metal fibers or carbon fibers. Alternatively, the shield material comprises a shielding element consisting of an elastic polymeric organic compound and a particle having a nuclear or electromagnetic radiation-shielding ability, such a heavy metal or ferrite. The shield material also includes either one of a film made of polyethylene, nylon, polyester or metal, a wire mesh formed of nylon fiber or metal fiber, and a plate- or rod-shaped member having a surface formed with a protrusion, which is compression-bonded onto or in the vicinity of a surface of the shielding element, or inside the shielding element.

Owner:NIPPON TUNGSTEN CORP

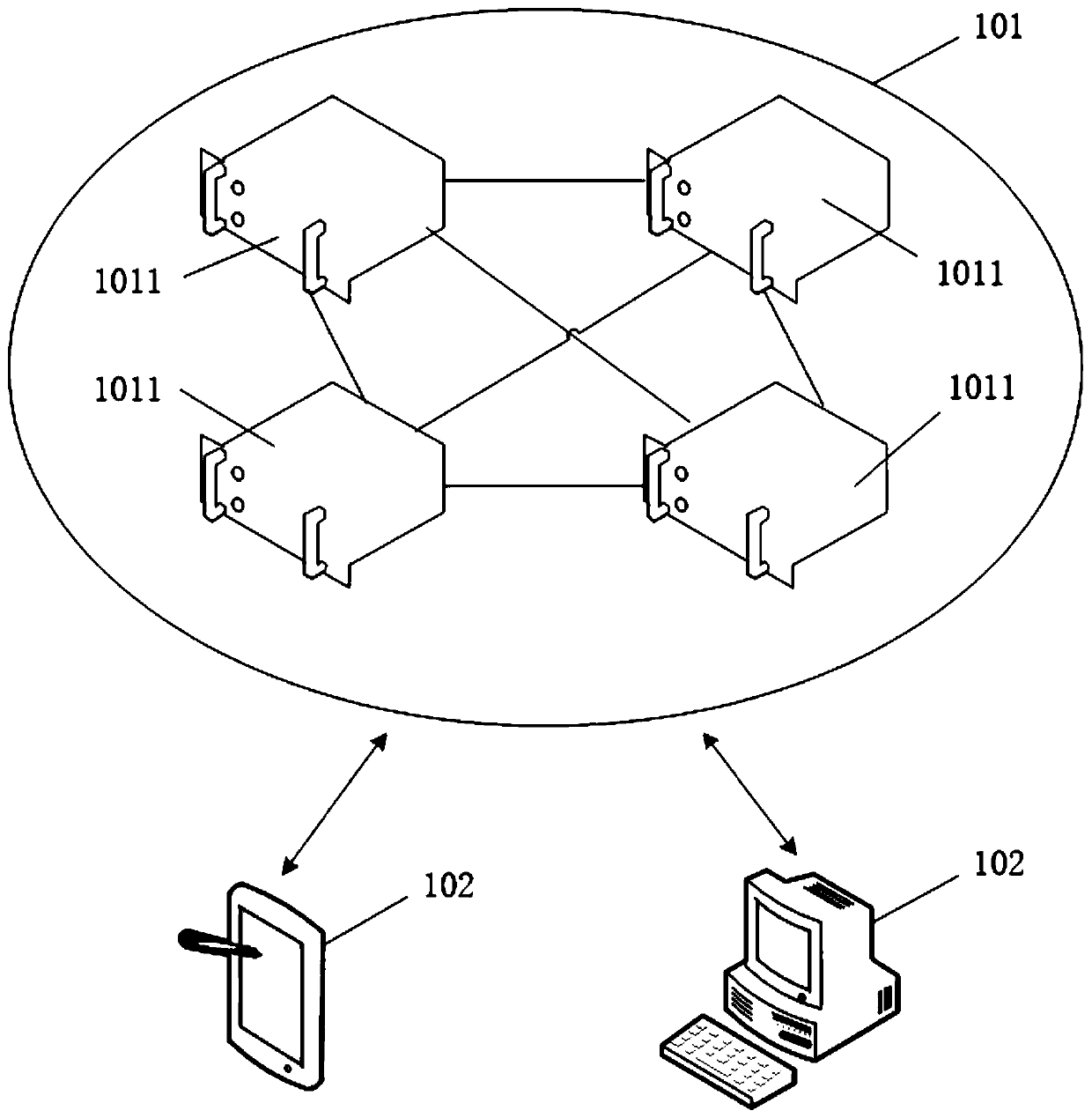

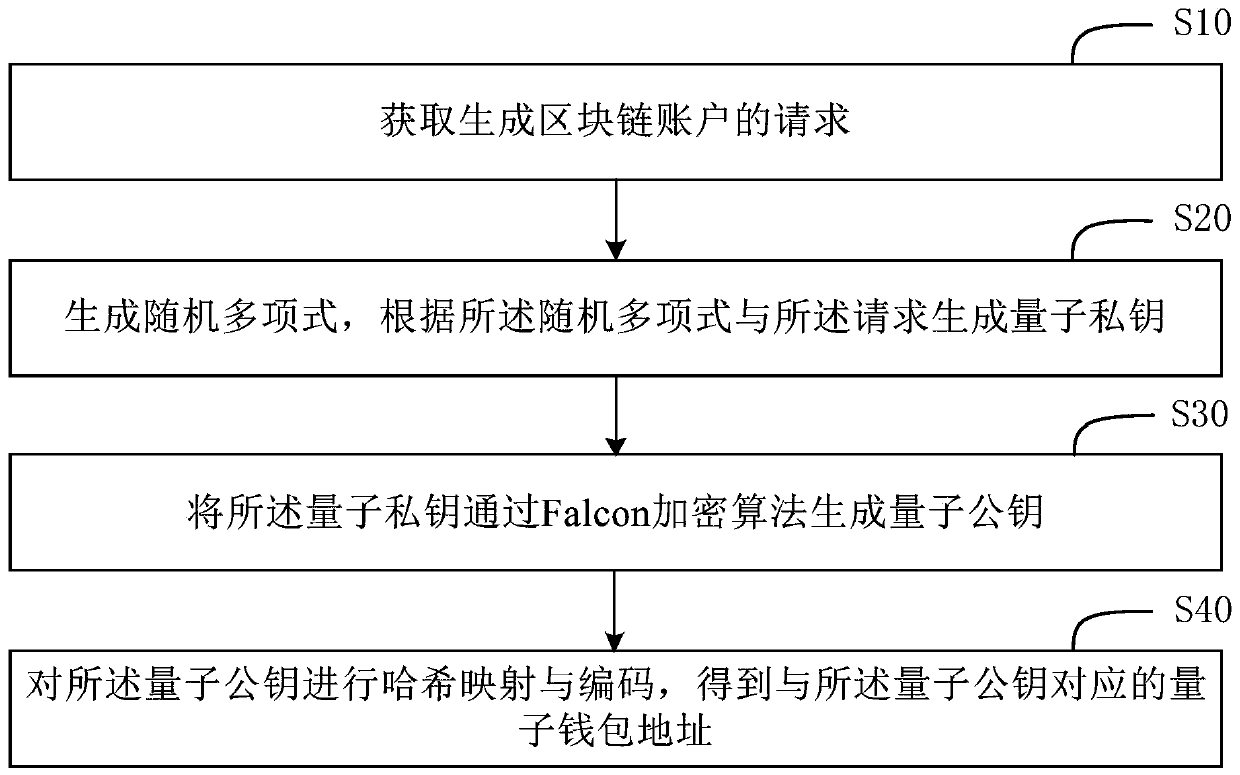

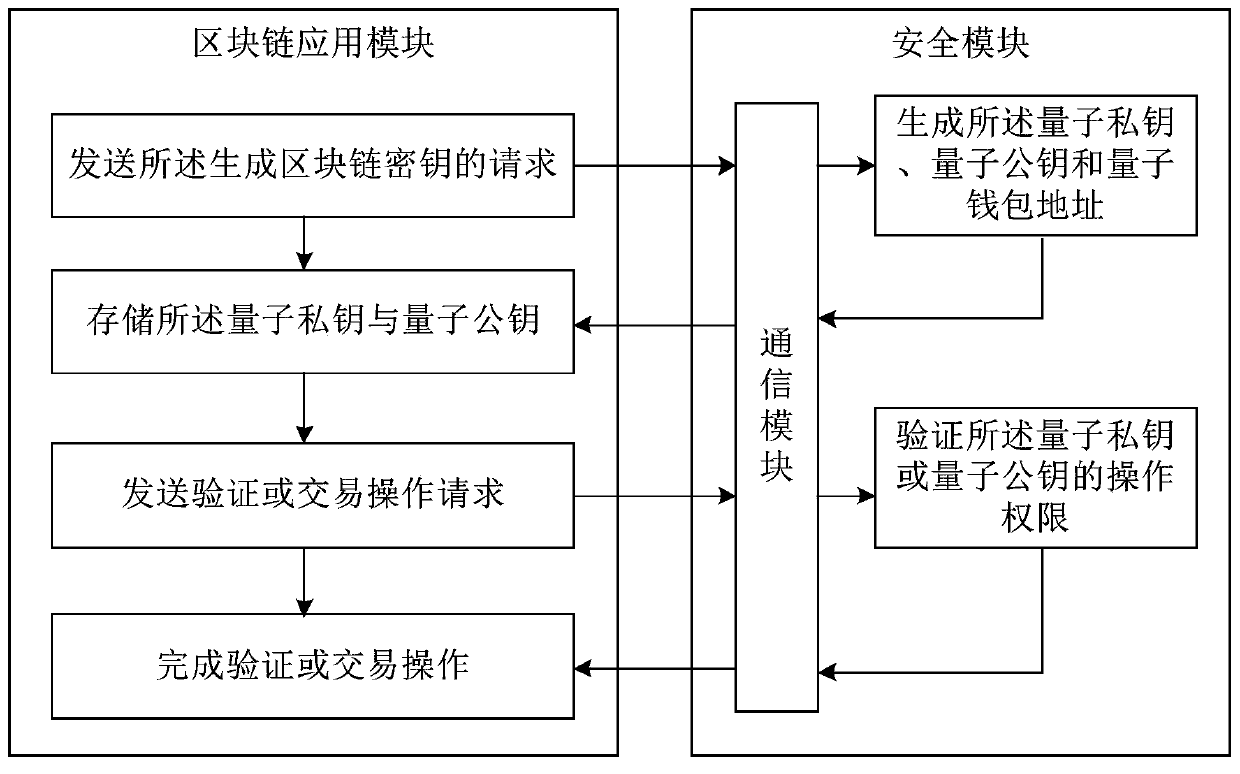

Blockchain account processing method and apparatus, and storage medium

ActiveCN109716375AImprove securityResistance to crackingKey distribution for secure communicationPublic key for secure communicationPasswordSecurity level

The invention provides a blockchain account processing method and apparatus, and a storage medium. The blockchain account processing method comprises the steps of obtaining a request for generating ablockchain account; generating a random polynomial, and generating a quantum private key according to the random polynomial and the request; generating a quantum public key from the quantum private key through a Falcon encryption algorithm; and performing Hash mapping and coding on the quantum public key to obtain a quantum wallet address corresponding to the quantum public key. The quantum publickey is generated through the Falcon encryption algorithm, the security level of the block chain account is improved, and cracking of an existing block chain account system by a quantum computer can be resisted; Compared with an existing secret key formed by a student with a later quantum password, the quantum private key and the quantum public key generated by the method are smaller in storage space and faster in signature and verification speed, and the operation burden caused to the block chain server is also reduced.

Owner:BCM SOCIAL CORP +1

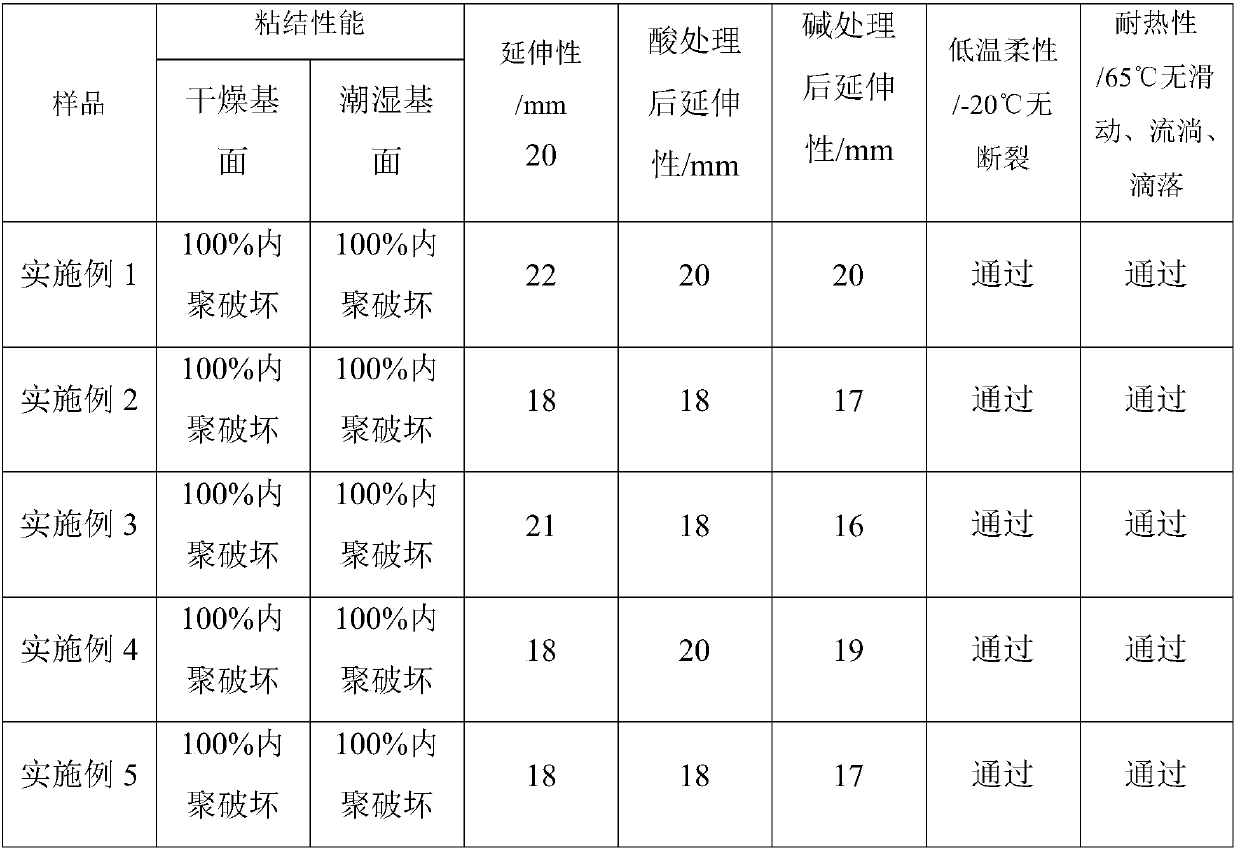

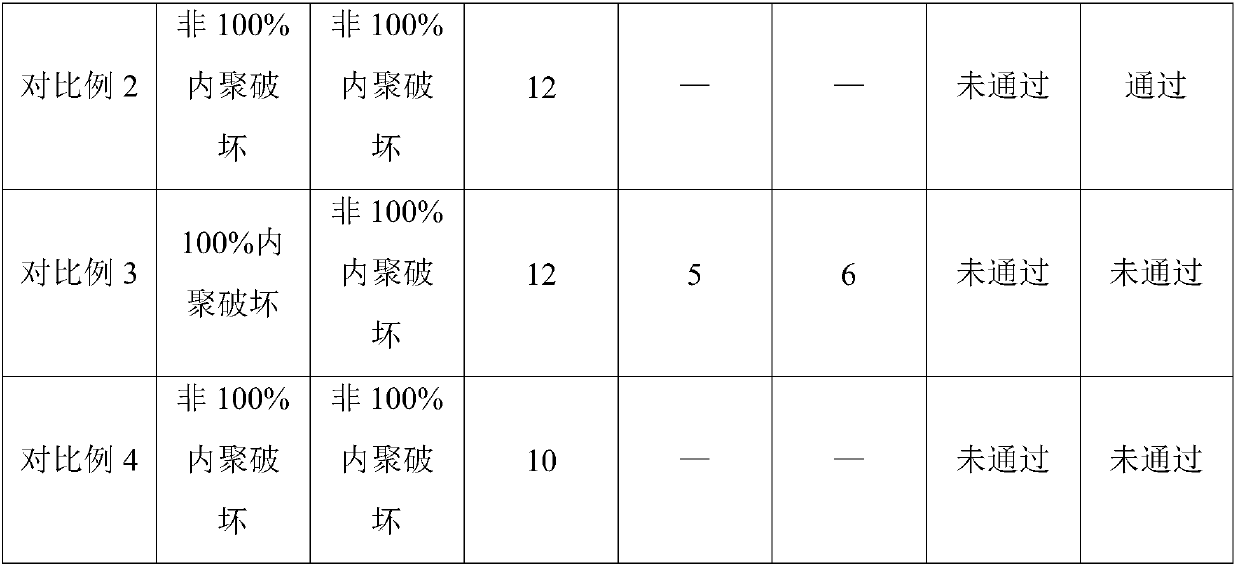

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Fluoropolymer and composition thereof

InactiveUS20060088680A1Stress crackingGood moldabilitySynthetic resin layered productsThin material handlingPolymer scienceOligomer

The present invention provides a fluoropolymer capable of giving fluorine-containing molded materials and laminates excellent in moldability, productivity, interlaminar bonding and stress cracking resistance, in particular stress cracking resistance upon contacting with various liquid chemicals, without impairing such characteristics intrinsic in fluororesins as chemical resistance, solvent resistance, weathering resistance, antifouling properties, liquid chemical impermeability and nonstickiness. The present invention provides a fluoropolymer which is an oligomer-containing or oligomer-free fluoropolymer, wherein said oligomer has a molecular weight not higher than 10,000 and amounts to not more than 0.05% by mass relative to the fluoropolymer.

Owner:DAIKIN IND LTD

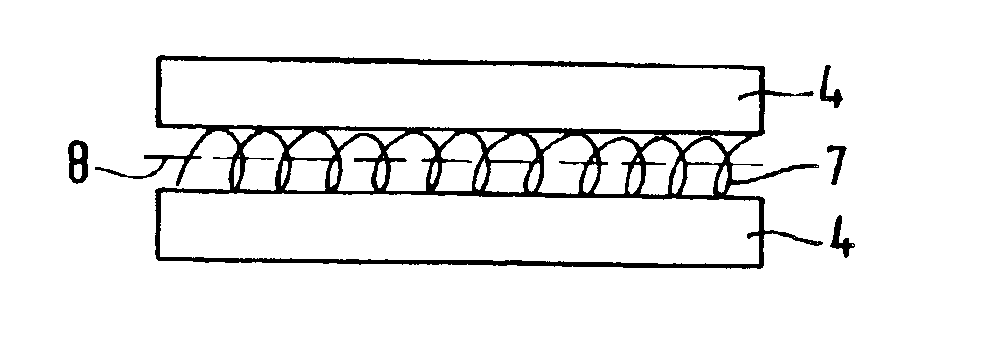

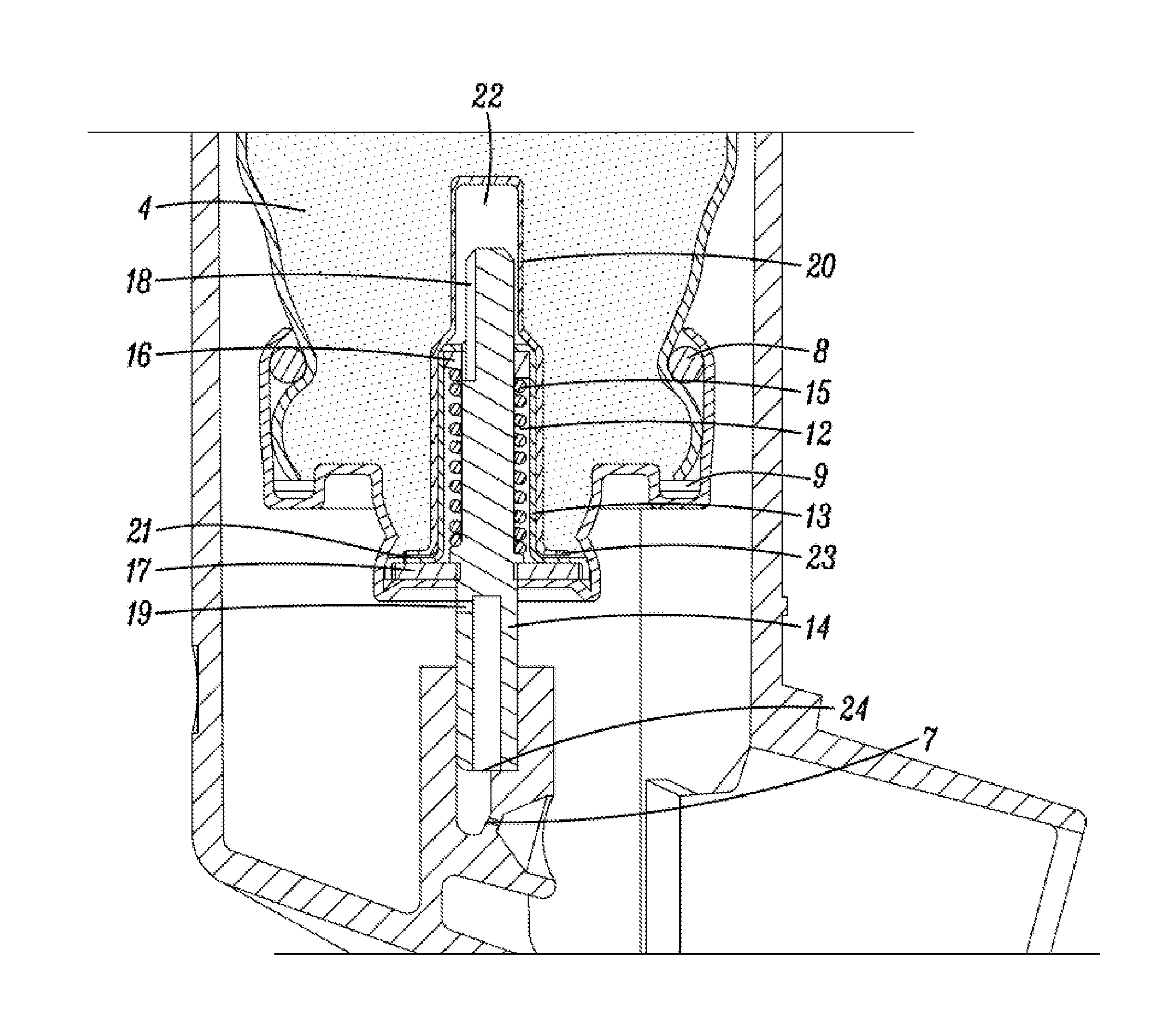

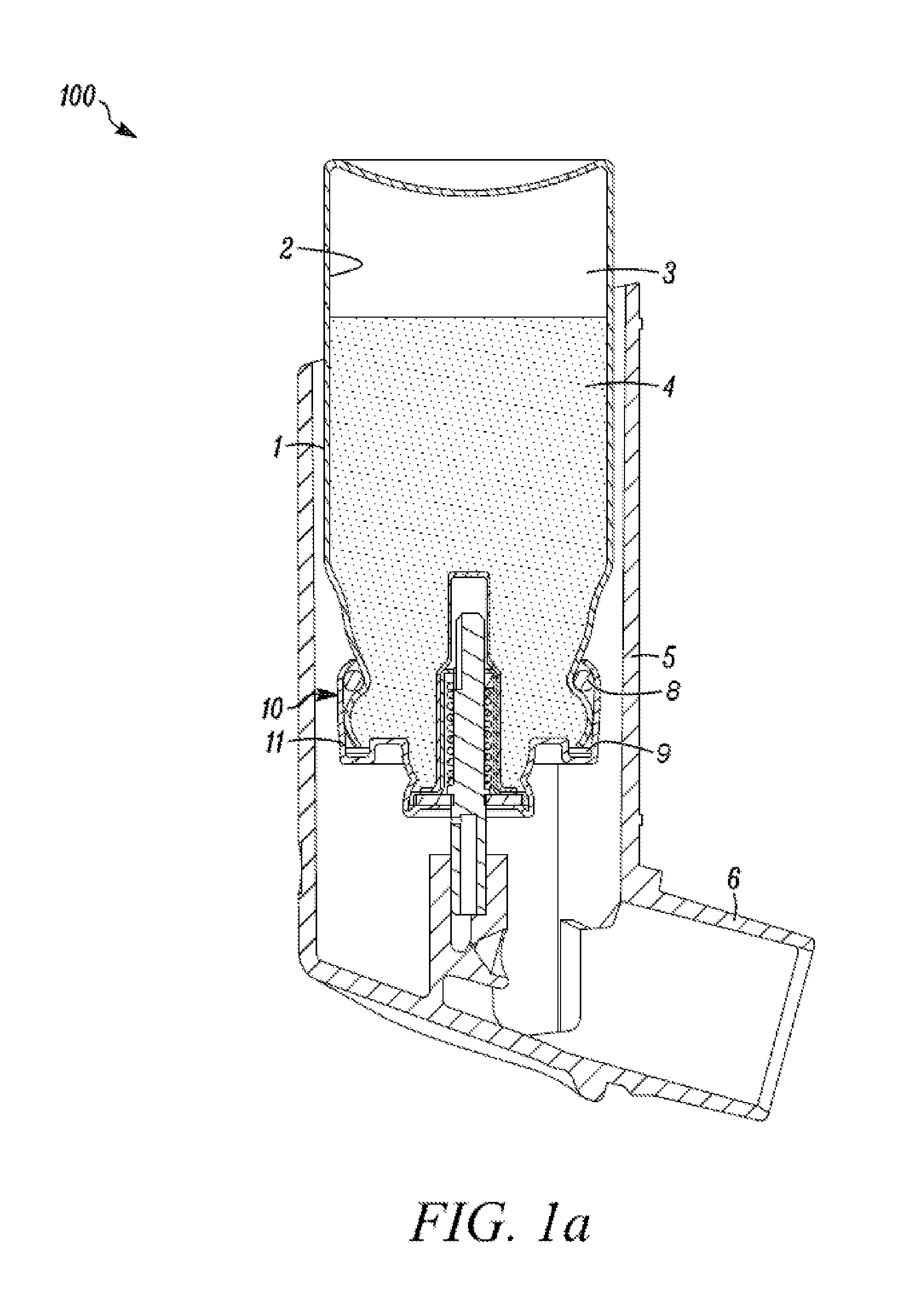

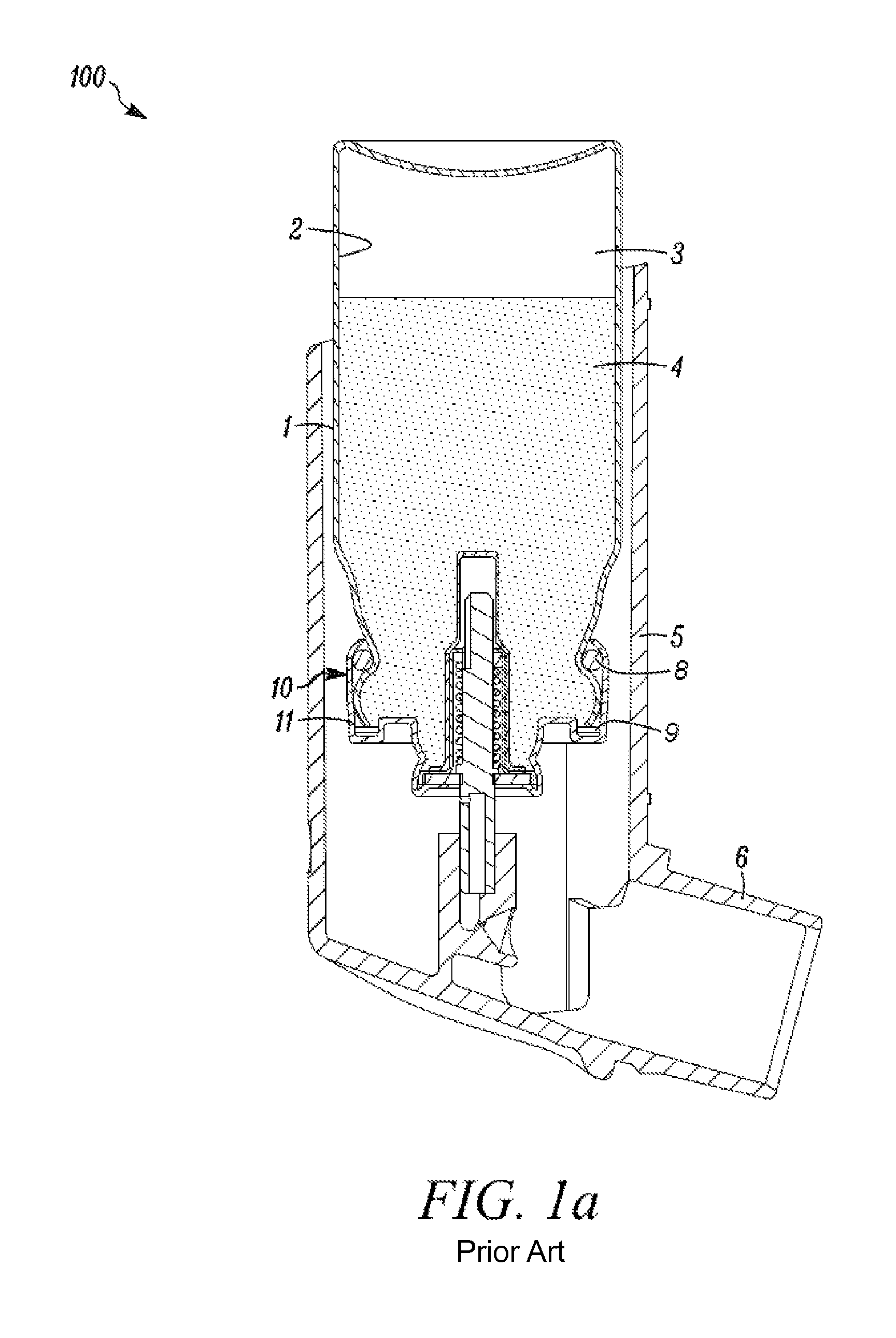

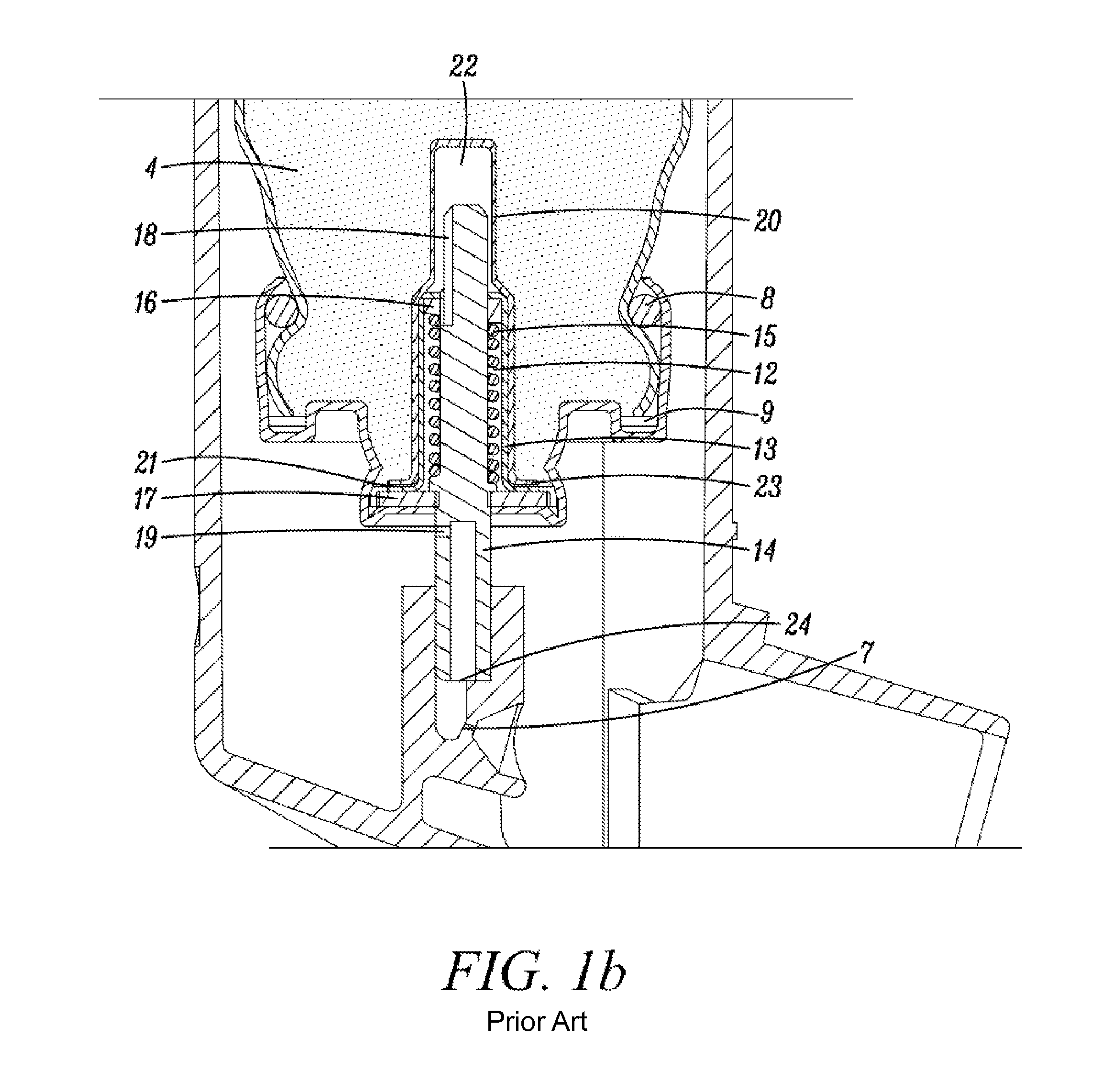

Medicinal inhalation device

InactiveUS20120103330A1Marked flexibilityAdvantageously low surface energyRespiratorsPharmaceutical containersHydrogenMedicine

Owner:3M INNOVATIVE PROPERTIES CO

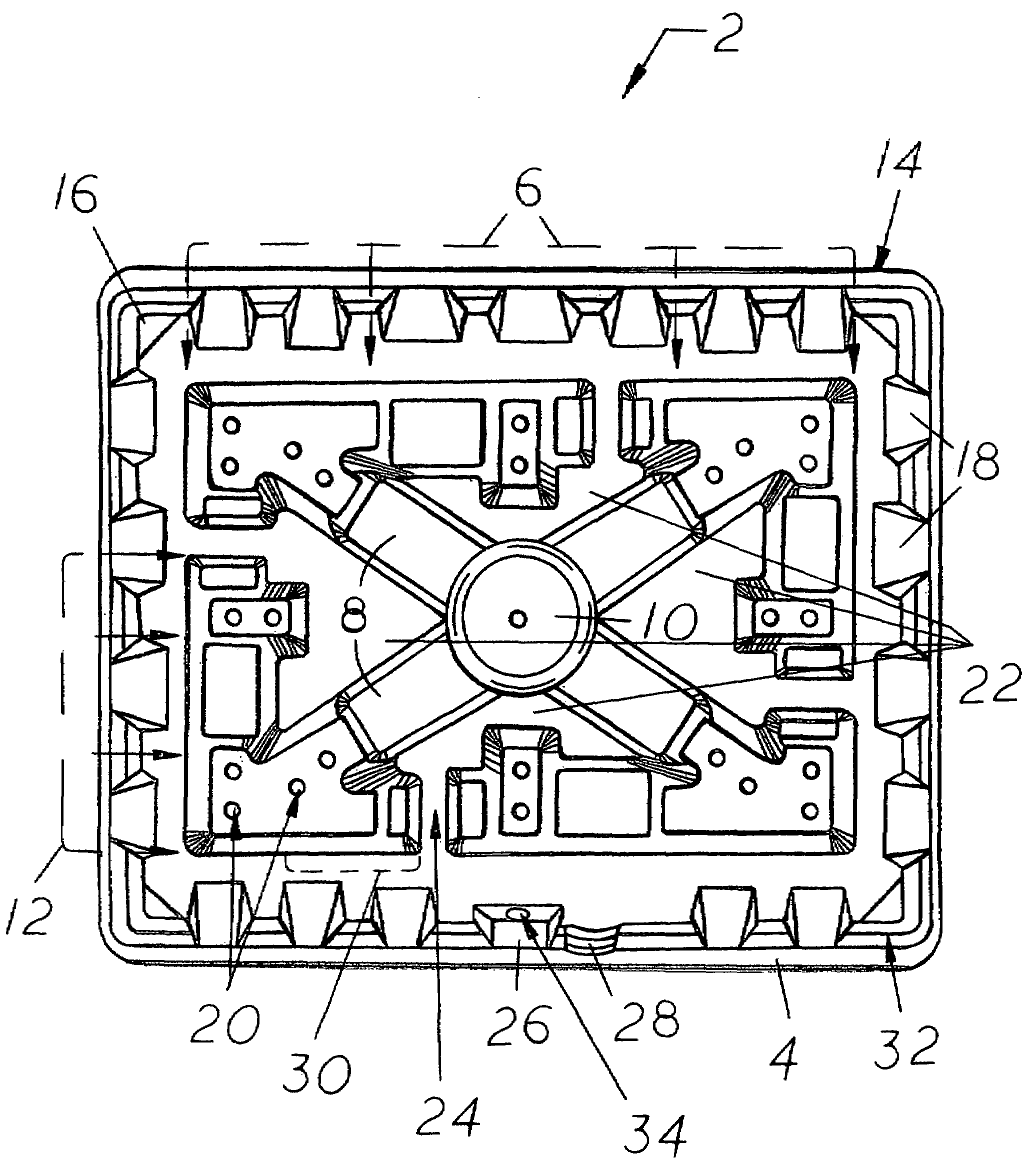

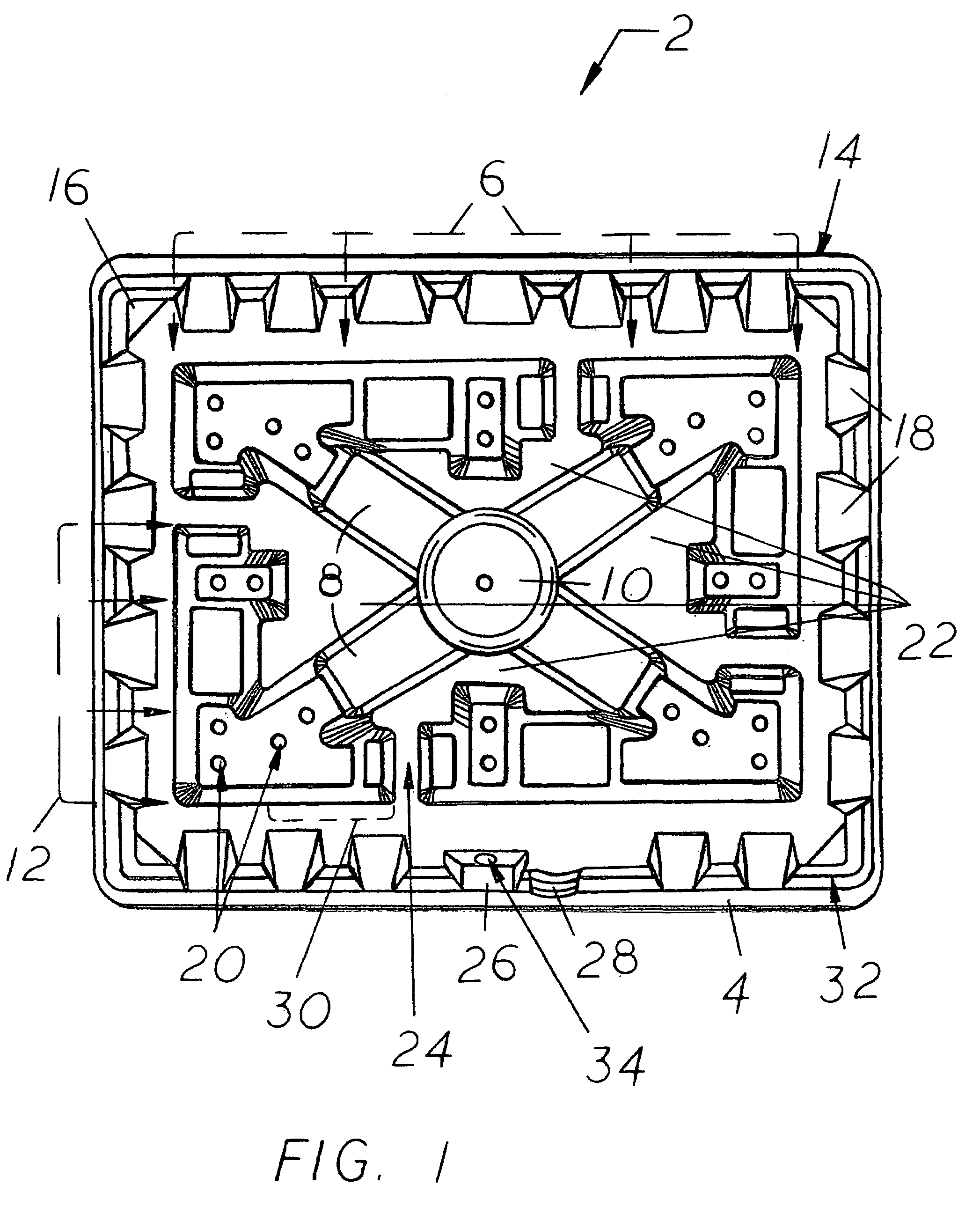

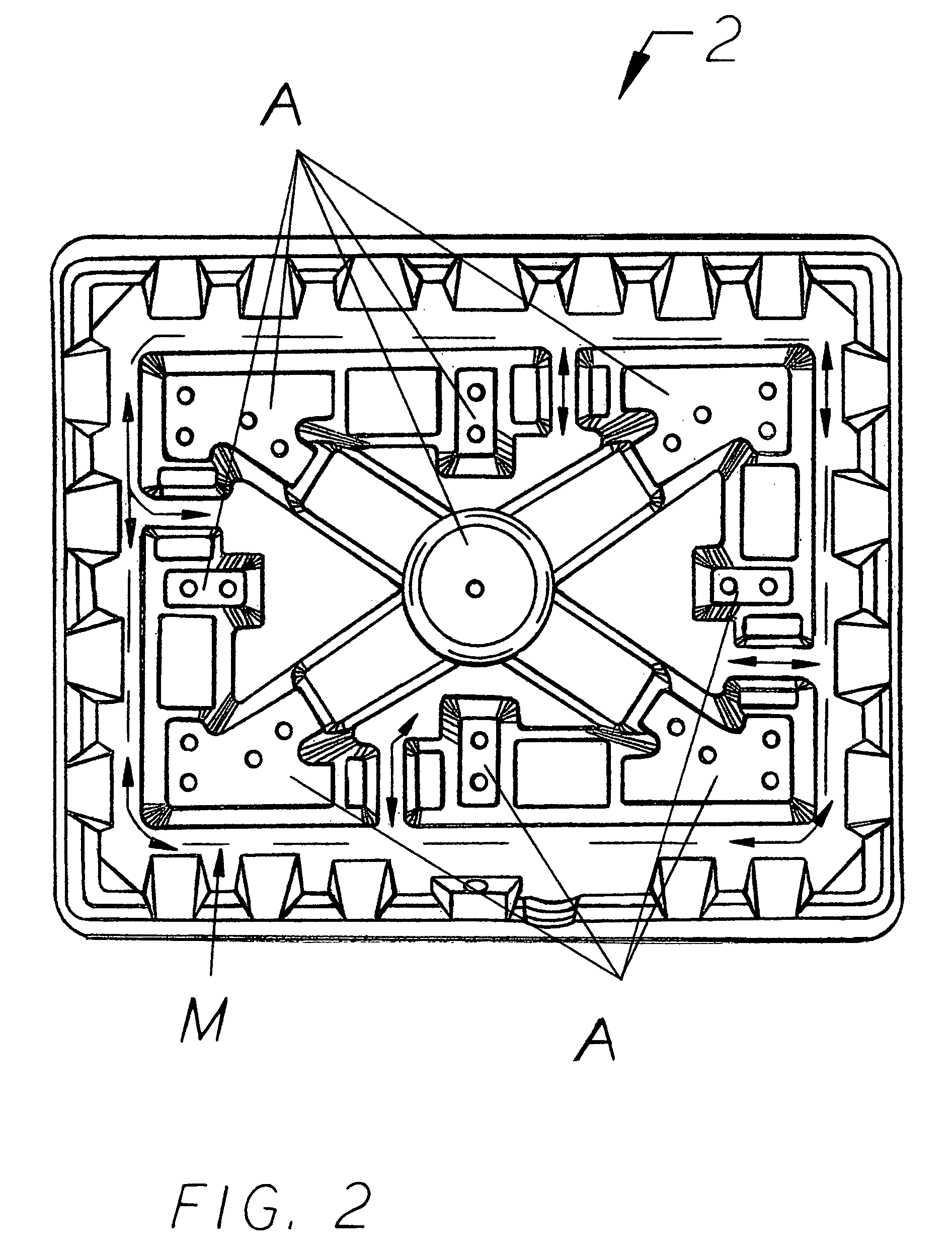

Fluid collection and drain pan with integrated strength-enhancing structure

InactiveUS7637387B1Cutting costsResisting permanent deformationInternal framesBoxesBlood collectionEngineering

A one-size-fits-all pan configured for supporting a fluid-producing unit. It has a perimeter wall spaced apart from a raised central structure to provide a moat-like area for flow of collected fluid toward a wall-mounted shut-off switch. When a desired maximum amount of fluid collection is exceeded, an electrical signal is sent to stop fluid production. The raised central structure comprises a hub with radially-extending ribs that each widens into a bent distal end having non-uniform height and width dimensions, and top indentations for receipt of vibration isolators that support the fluid-producing unit at a height above that of the perimeter wall. The non-raised areas around the ribs are all connected to the moat-like area to facilitate even fluid distribution within the pan. The pan further has an up-turned perimeter lip, staggered gussets, and angled corners for added strength, and may optionally have a nesting configuration for compact storage and transport.

Owner:RECTORSEAL LLC

Thermal degradation and crack resistant functionally graded cemented tungsten carbide and polycrystalline diamond

InactiveUS20090226688A1Improve thermal conductivityDissipate frictional heatLamination ancillary operationsSynthetic resin layered productsPolycrystalline diamondHardness

A WC—Co material or polycrystalline diamond-Co material that has a gradient in the grain size of the particles. Specifically, the material may have a top layer that has coarse grains that is designed to dissipate the heat caused by friction (and thus prevent thermal cracking). The material will then have a bulk substrate that is made up of finer grains and provide adequate hardness for the material. The top layer is positioned on top of the bulk substrate.

Owner:UNIV OF UTAH RES FOUND

Impact Resistant Shingle

InactiveUS20100098912A1Resistance to crackingDissipate energyRoof covering using tiles/slatesTraffic signalsCrack resistanceShingles

An impact resistant shingle is provided, wherein the base mat is impregnated with an asphaltic material, with an asphaltic material on the upper surface of the shingle, and wherein another asphaltic material is disposed on the rear surface of the shingle, which other asphaltic material is softer with greater elongation than the asphaltic material used elsewhere in the shingle, such that crack resistance is afforded because energy from impact on the shingle is dissipated.

Owner:CERTAINTEED CORP

Diamond single crystal, method for producing the same, and single crystal diamond tool

ActiveUS20150176155A1High hardnessEasy to processPolycrystalline material growthLayered productsGas phaseTransmittance

A method for producing a diamond single crystal includes implanting an ion other than carbon into a surface of a diamond single crystal seed substrate and thereby decreasing the transmittance of light having a wavelength of 800 nm, the surface having an off-angle of 7 degrees or less with respect to a {100} plane, and homoepitaxially growing a diamond single crystal on the ion-implanted surface of the seed substrate using a chemical vapor synthesis under synthesis conditions where the ratio NC / NH of the number of carbon-containing molecules NC to the number of hydrogen molecules NH in a gas phase is 10% or more and 40% or less, the ratio NN / NC of the number of nitrogen molecules NN to the number of carbon-containing molecules NC in the gas phase is 0.1% or more and 10% or less, and the seed substrate temperature T is 850° C. or more and less than 1000° C.

Owner:SUMITOMO ELECTRIC IND LTD

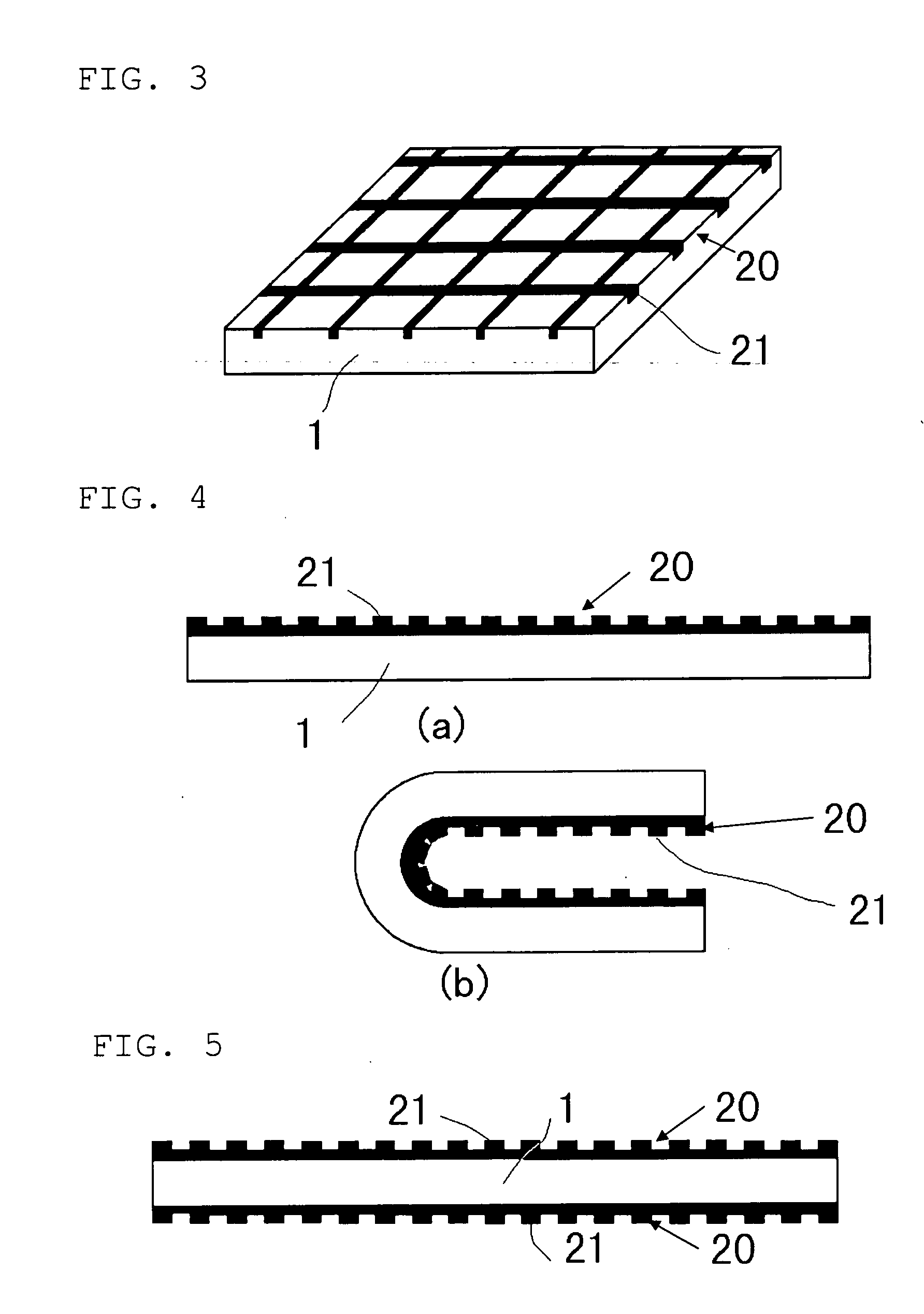

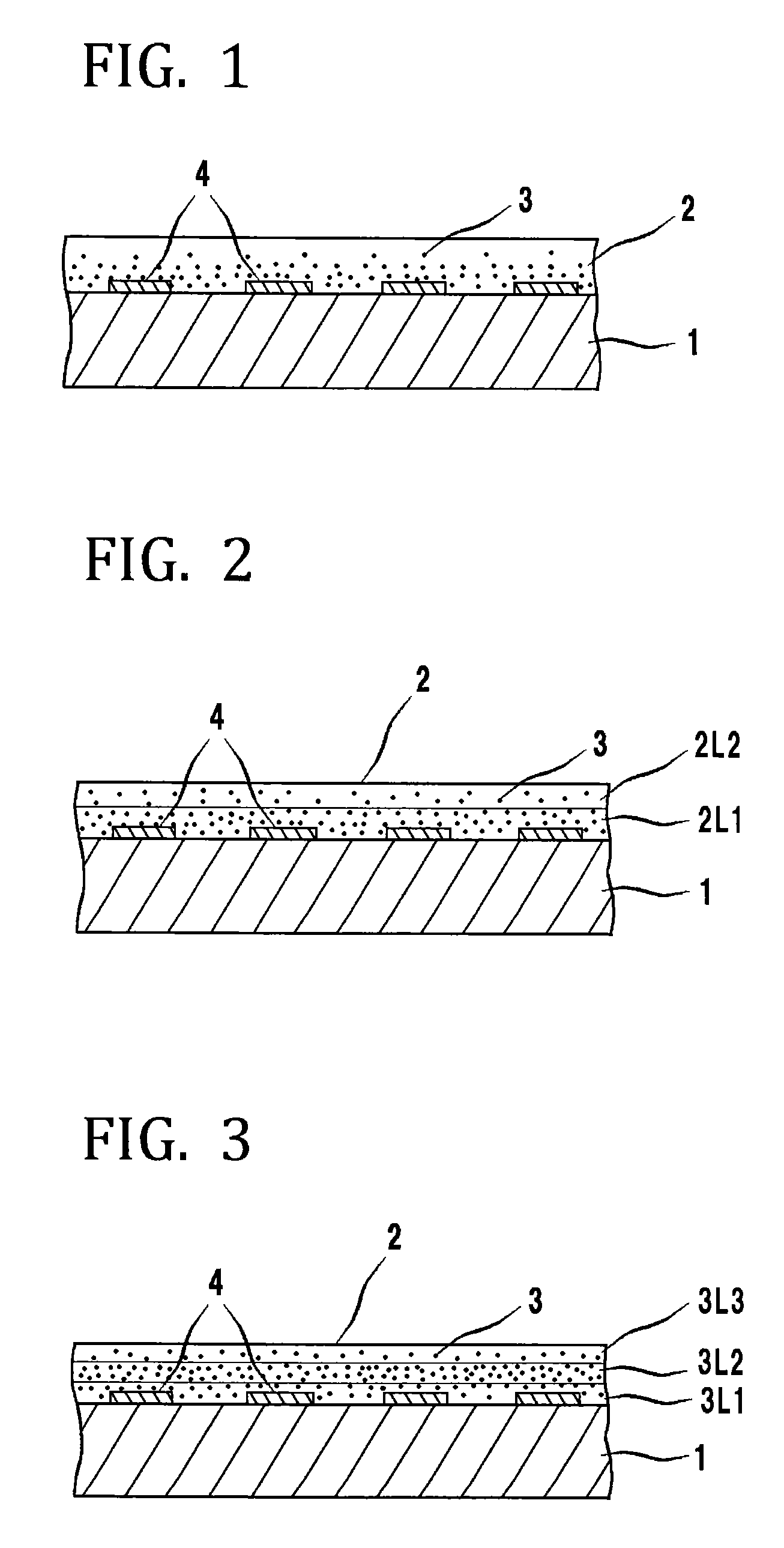

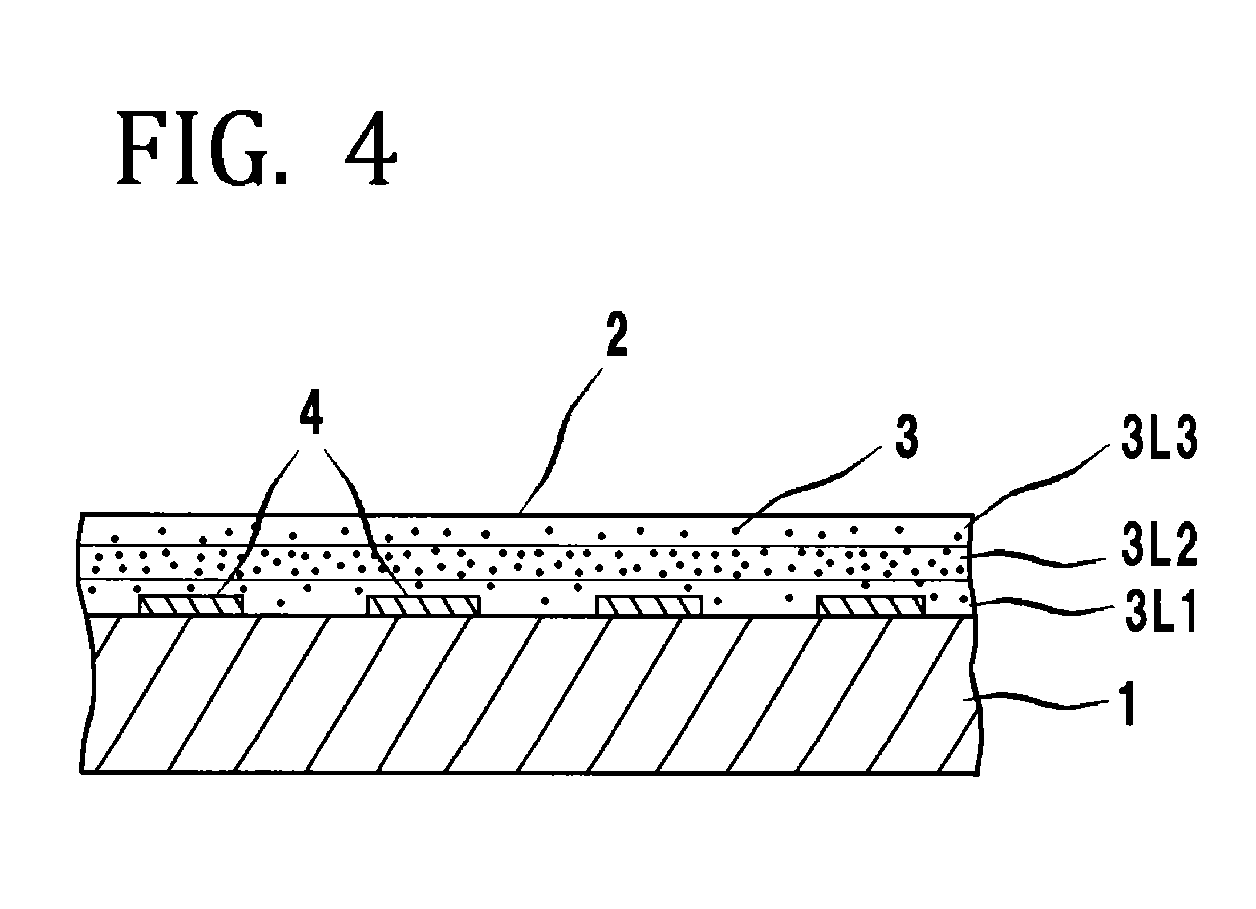

Layered structure and photosensitive dry film to be used therefor

InactiveUS20120301825A1Improve adhesionImprove reliabilityPhotosensitive materialsPrinted circuit aspectsResistInsulation layer

In a layered structure having at least a substrate and a photosensitive resin layer or cured film layer formed on the substrate and containing an inorganic filler, the content of the inorganic filler in the photosensitive resin layer or cured film layer is lower in a surface layer region away from the substrate than in other region, so that a linear thermal expansion coefficient of the layer as a whole is maintained as low as possible. Preferably, the photosensitive resin layer or cured film layer comprises at least two layers having different inorganic filler contents, wherein the inorganic filler content in the layer on the surface side away from the substrate is lower than the inorganic filler content in the other layer. A photosensitive dry film containing the photosensitive resin layer is suitable for use as a solder resist or an interlayer resin insulation layer of a printed wiring board.

Owner:TAIYO INK MFG

Medicinal inhalation device

InactiveUS8815325B2Resistance to crackingDesirable surface characteristicPowdered material dispensingPretreated surfacesHydrogenMedicine

Owner:3M INNOVATIVE PROPERTIES CO

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS20140171582A1Isotropic shrinkage ratioShrinkage differentialMixingCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

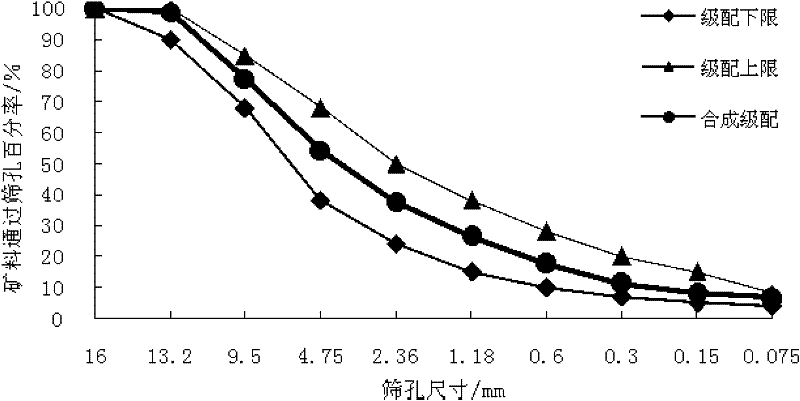

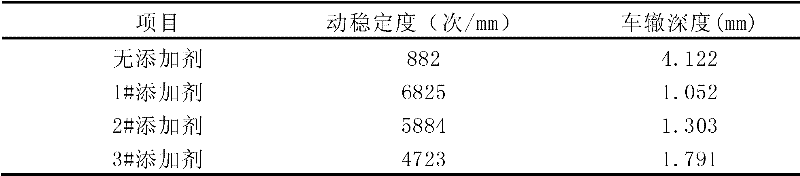

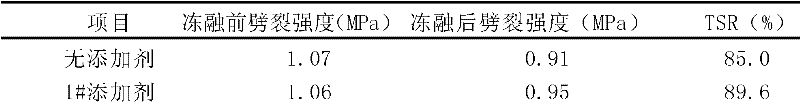

Anti-rutting additive with high modulus and high strength as well as preparation method and applications thereof

The invention relates to an anti-rutting additive with high modulus and high strength for an asphalt mixture as well as a preparation method and applications thereof. The polymer composite additive of the asphalt mixture is formed by mixing crosslinkable polyethylene, random polypropylene, tackifier, styrene-butadiene rubber and fiber, wherein the tackifier is terpene resin. The production method of the anti-rutting additive comprises the following steps: adding the raw materials in a proper processing device so that the raw materials are fully mixed and reacted; and granulating and shaping. The anti-rutting additive has cheap price, and can be used for increasing the road performances of the asphalt mixture such as high temperature stability, low temperature crack resistance and water stability, and prolonging the service life of pavement.

Owner:北京厚德交通科技股份有限公司

Non-crystalline saliva-soluble coatings for elastomeric monofilament dental tapes

InactiveUS6907889B2Substantivity of coatings onto flexible surfacesResistance to crackingCosmetic preparationsGum massageMedicineControl substances

Owner:WHITEHILL ORAL TECH

Sculpting / modeling material composition

InactiveUS6949137B1Easy to useResists chippingStarch adhesivesStarch coatingsCelluloseChemical composition

A sculpting / modeling medium is provided comprised of a nontoxic premixed loose ground cellulose material present in the amount ranging from 10–15% by weight; a vegetable adhesive present in the amount ranging from 75–85% by weight; and water present in the amount of 5–10% by weight. The medium may also include a quantity of food coloring or dyes blended in a proportion such that the color of the medium is due primarily to the dyed color of the cellulose. Also present is a method of making the same.

Owner:ERLING DALE ARTHUR

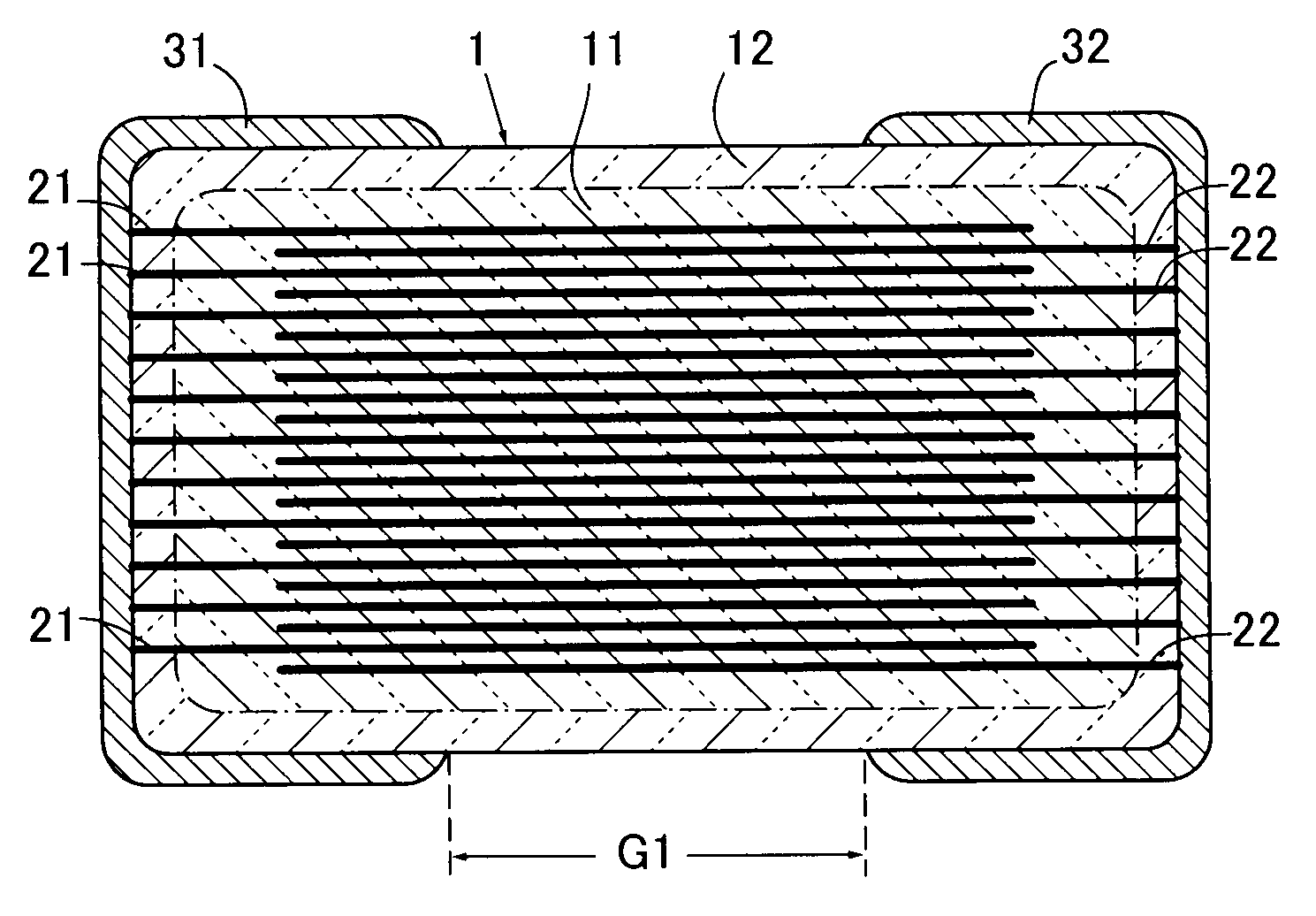

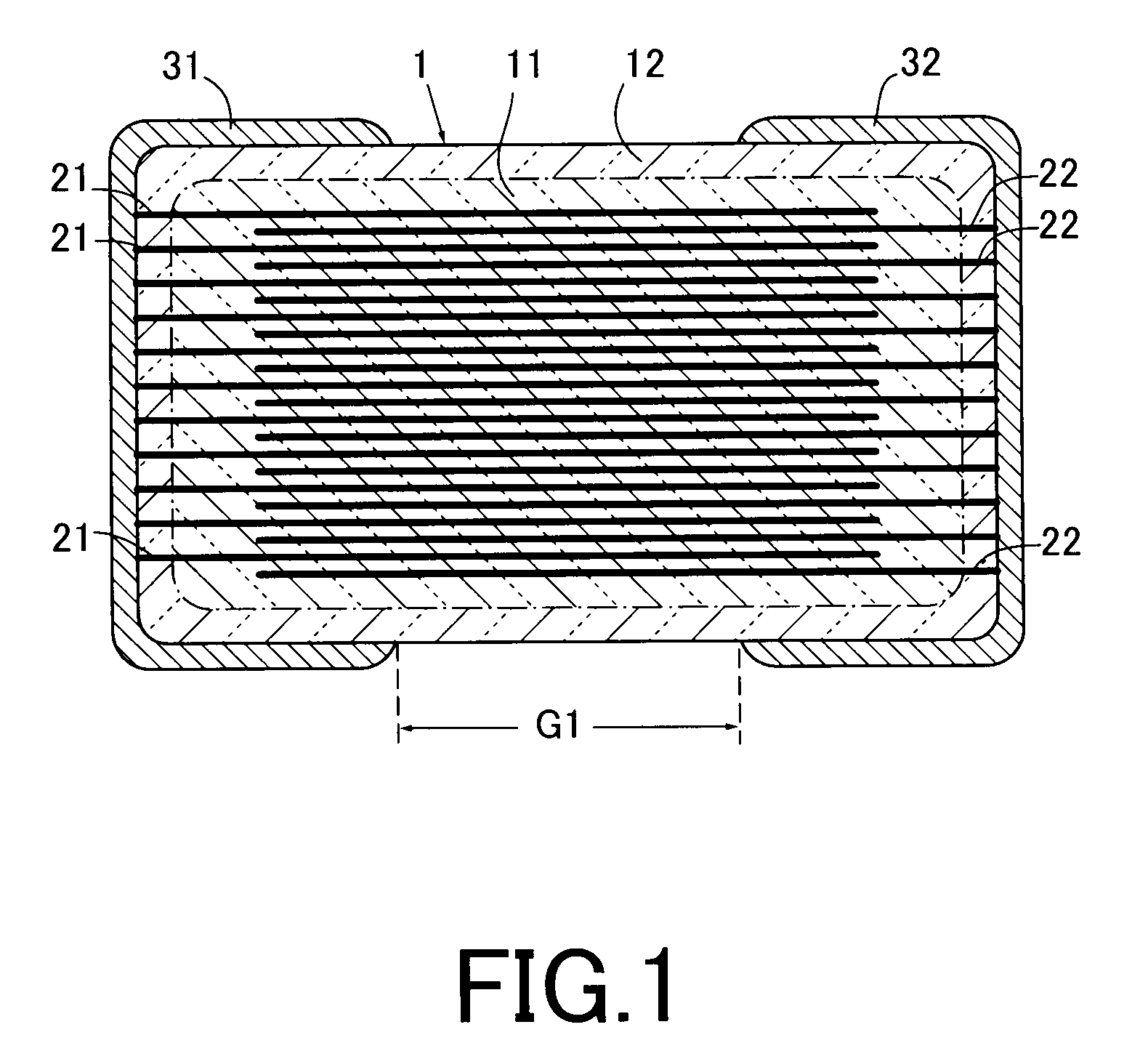

Ceramic electronic component

ActiveUS20090009927A1Increase resistanceSufficiently hardFixed capacitor dielectricStacked capacitorsElectronic componentDiffusion layer

A ceramic electronic component includes a ceramic body and an internal electrode layers disposed within the ceramic body. The ceramic body is covered with a diffusion layer, wherein said diffusion layer is an oxide layer into which at least a part of elements contained in the ceramic body are diffused and is located closer to a surface of the ceramic body than an outermost internal electrode layer.

Owner:TDK CORPARATION

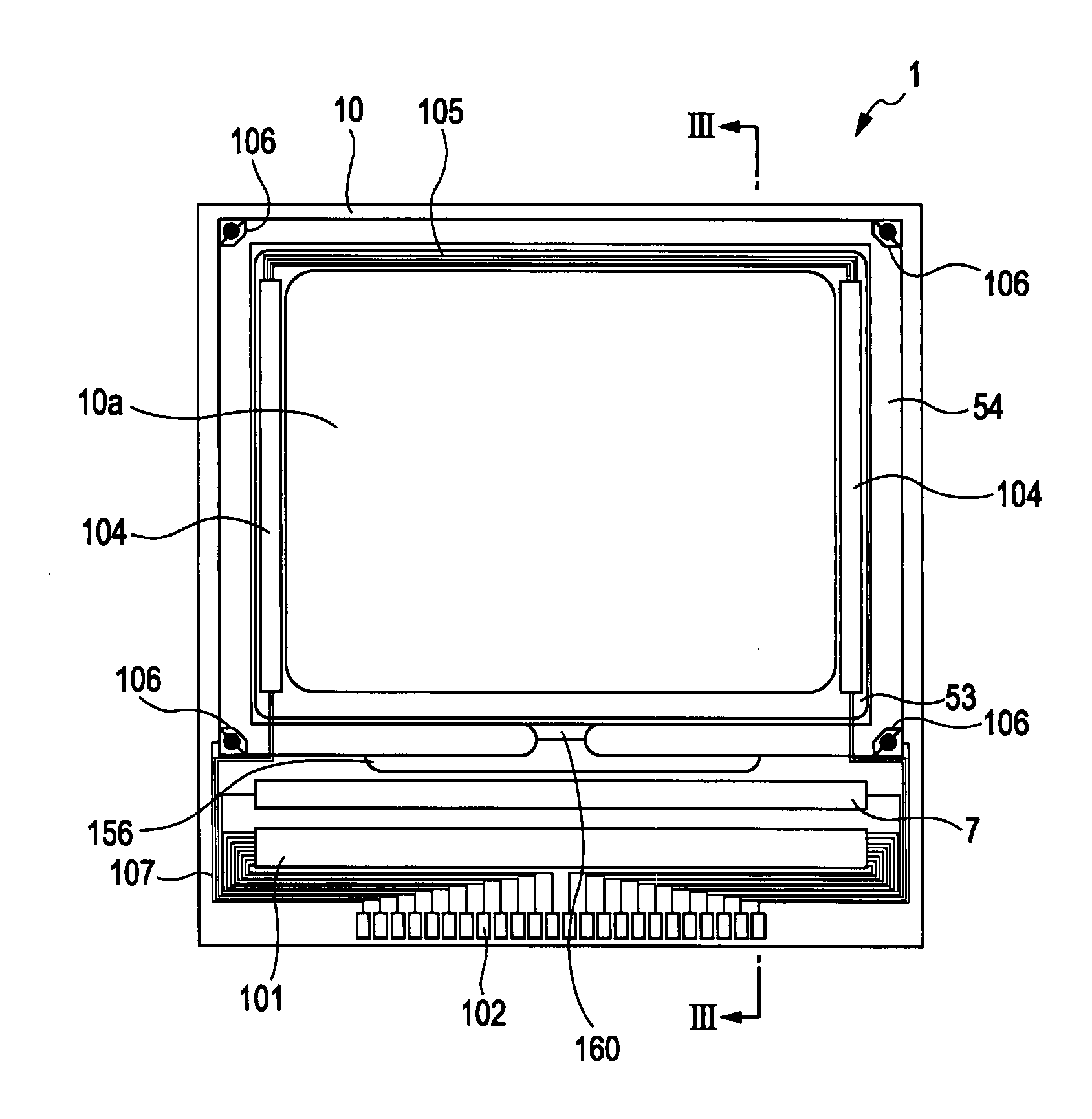

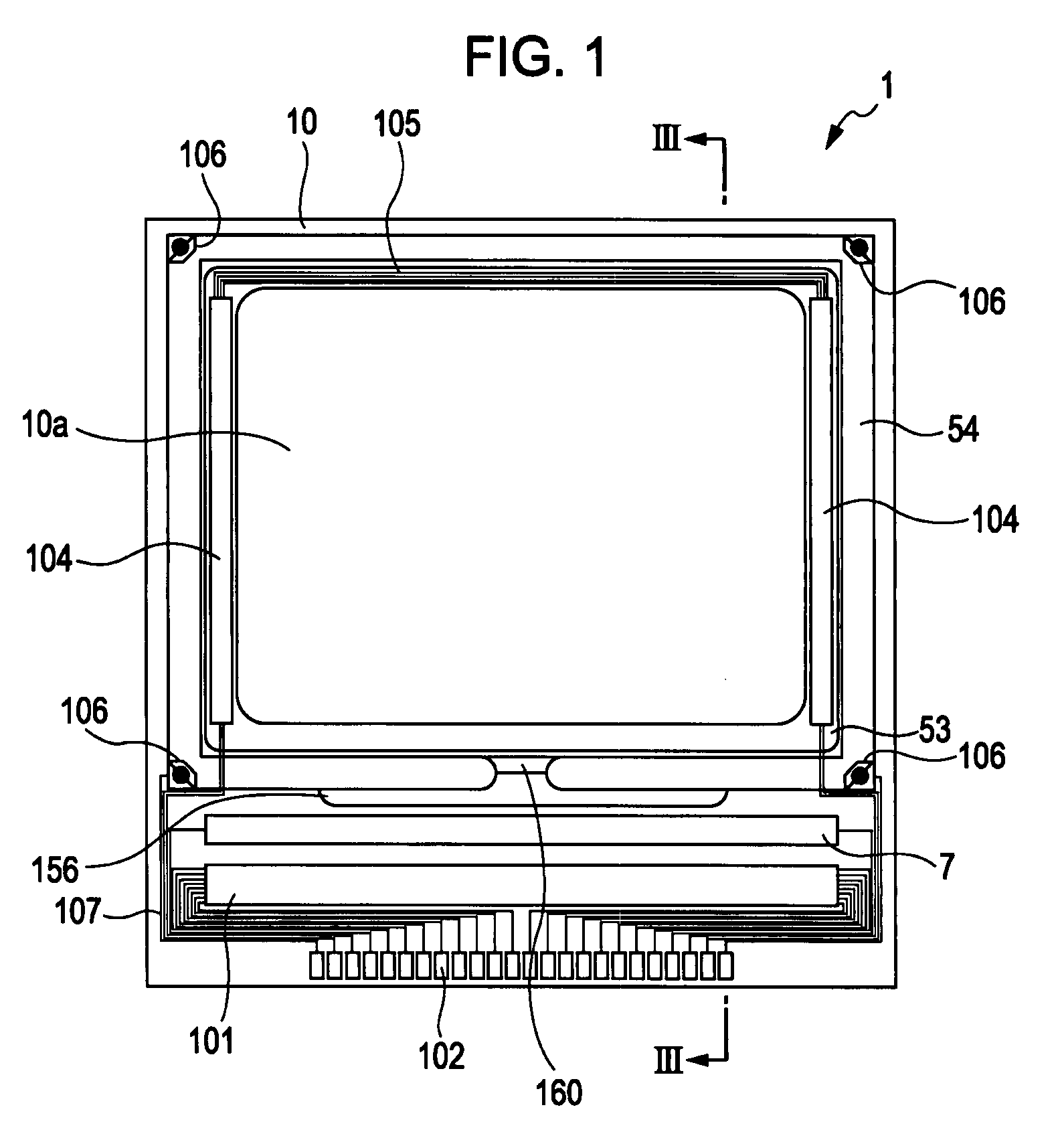

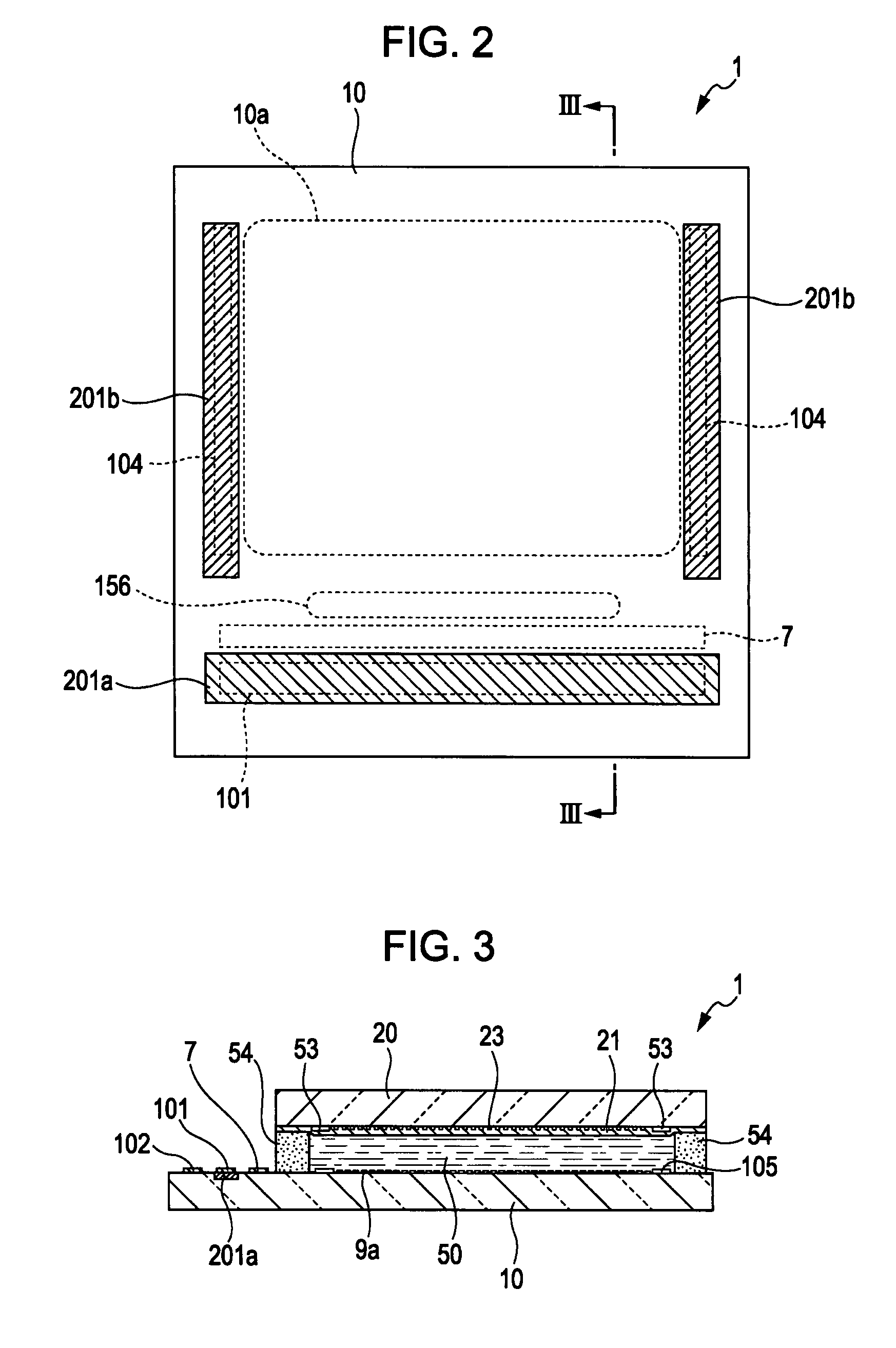

Electro-optical device and electronic apparatus

InactiveUS20080088569A1Reduce harmResistance to crackingStatic indicating devicesNon-linear opticsSample imageImage signal

An electro-optical device includes a scanning-line driving circuit disposed in a peripheral region around the pixel area, and supplies, through scanning lines, a plurality of scanning signals to a plurality of pixel portions in the pixel area. The data-line driving circuit is disposed in the peripheral region, and supplies a plurality of sampling signals to a sampling circuit, which samples image signals and supplies the sampled image signals to data lines. A light-shielding film covers only the scanning-line driving circuit and the data-line driving circuit of a peripheral circuit portion disposed in the peripheral region.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com