Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Glassy matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix. A primer composition is also provided and is a mixture of an epoxy, an alkoxy-functionalized siloxane and a silane capable of compatabilizing the epoxy and the alkoxy-functionalized siloxane; a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane.

Owner:MICROPHASE COATINGS

Antifouling coating composition

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix.

Owner:MICROPHASE COATINGS

Antifouling coating composition

InactiveUS6476095B2Antifouling/underwater paintsSynthetic resin layered productsEpoxyPolymer science

The antifouling composition of the present invention includes a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane to provide an interpenetrating polymer network of glass and silicone and at least two materials capable of microphase separation, at least one of which is graftable to the glassy matrix. A primer composition is also provided and is a mixture of an epoxy, an alkoxy-functionalized siloxane and a silane capable of compatabilizing the epoxy and the alkoxy-functionalized siloxane; a glassy matrix formed by crosslinking a mixture of a silanol-terminated silicone and an alkoxy-functionalized siloxane.

Owner:MICROPHASE COATINGS

Antifouling coating composition

Owner:MICROPHASE COATINGS

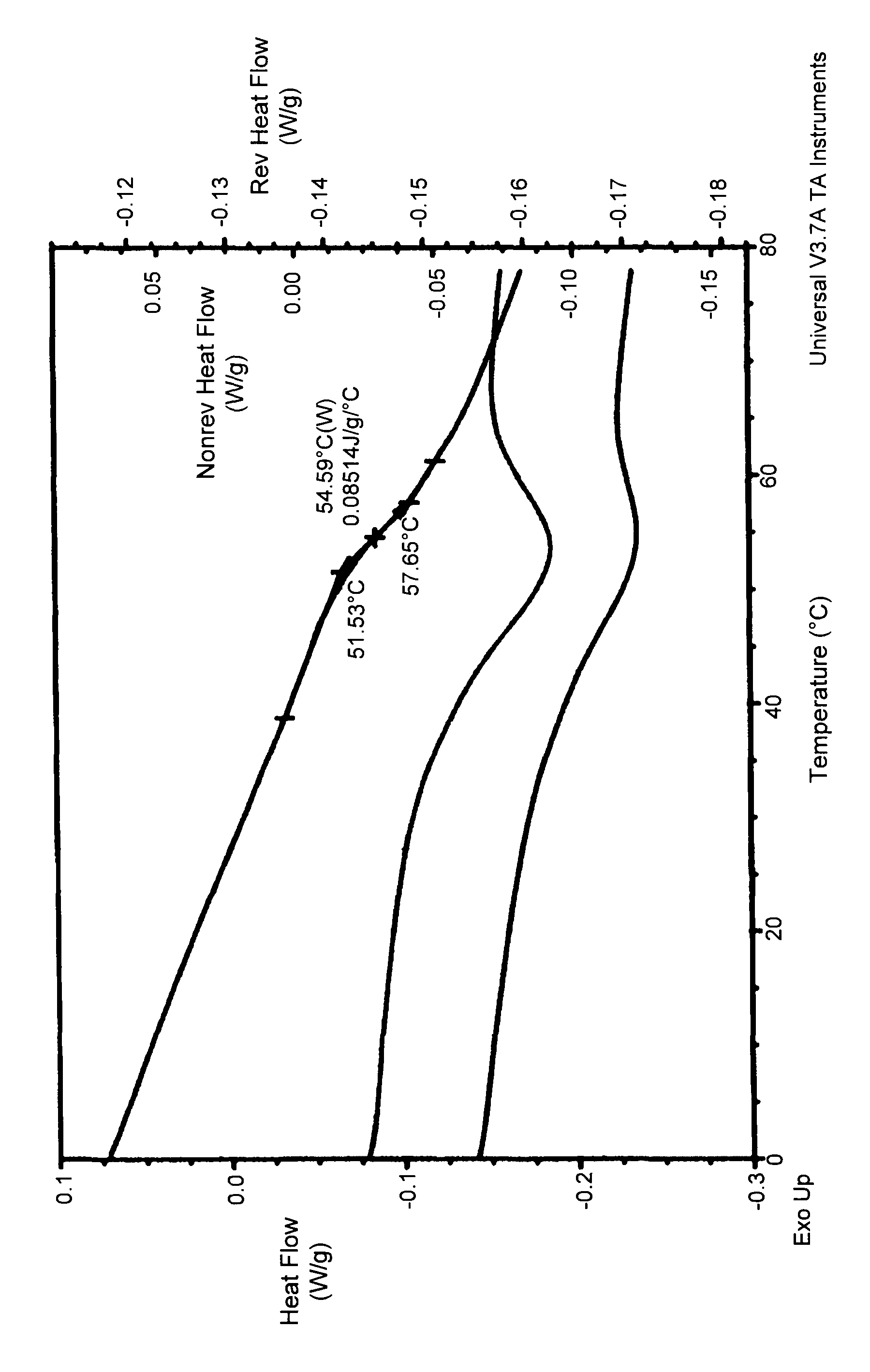

Stable glassy state powder formulations

InactiveUS20030215512A1Good dispersionGood dispersibilityPowder deliveryPeptide/protein ingredientsSolventMoisture barrier

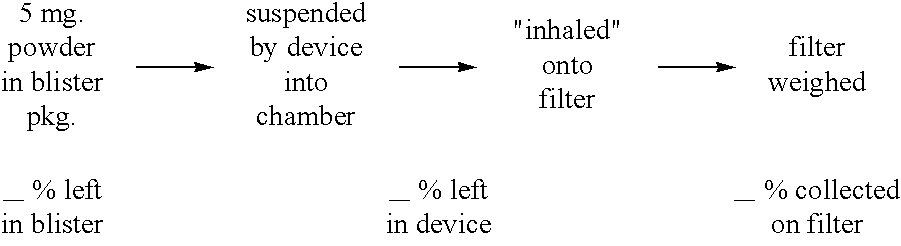

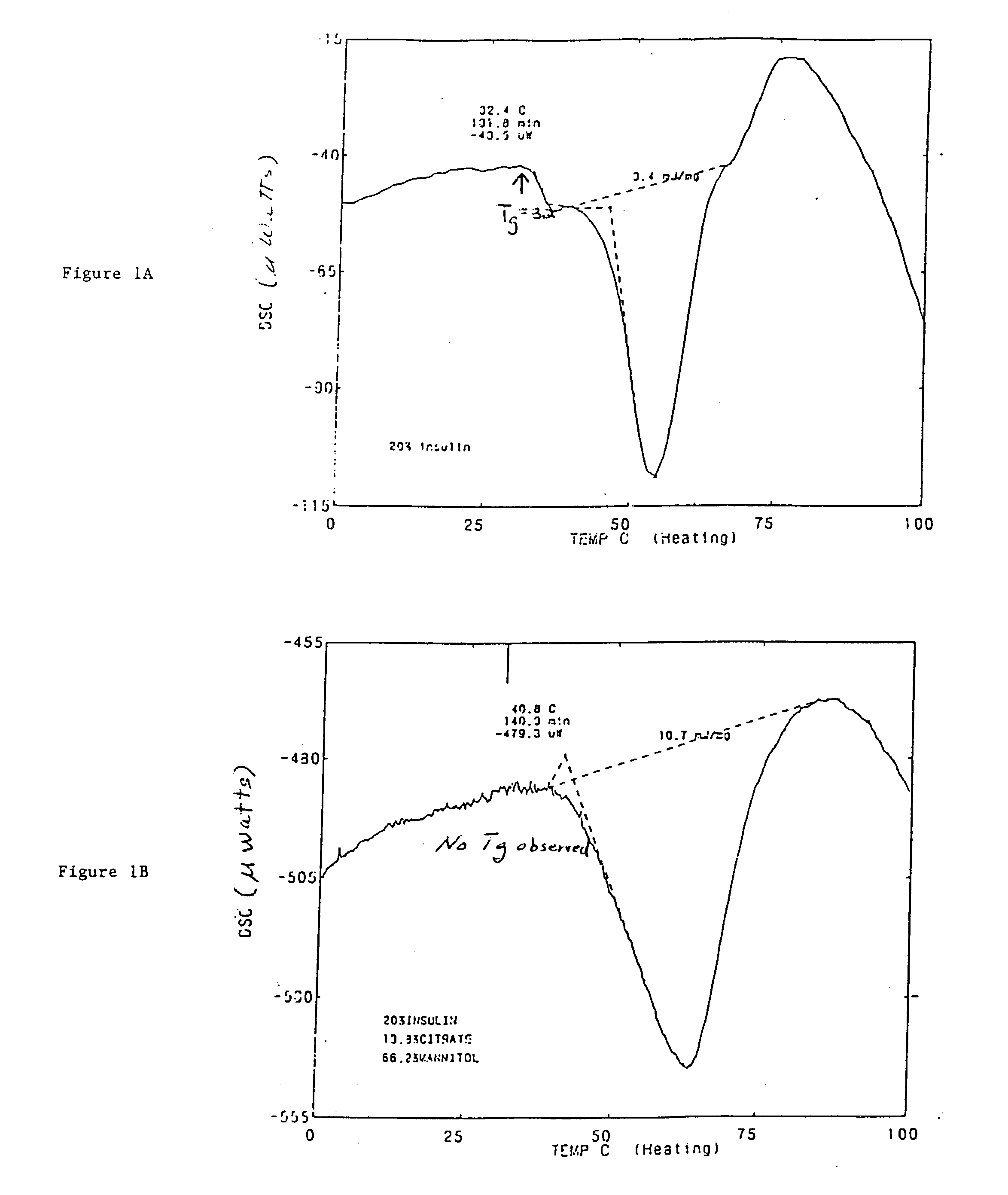

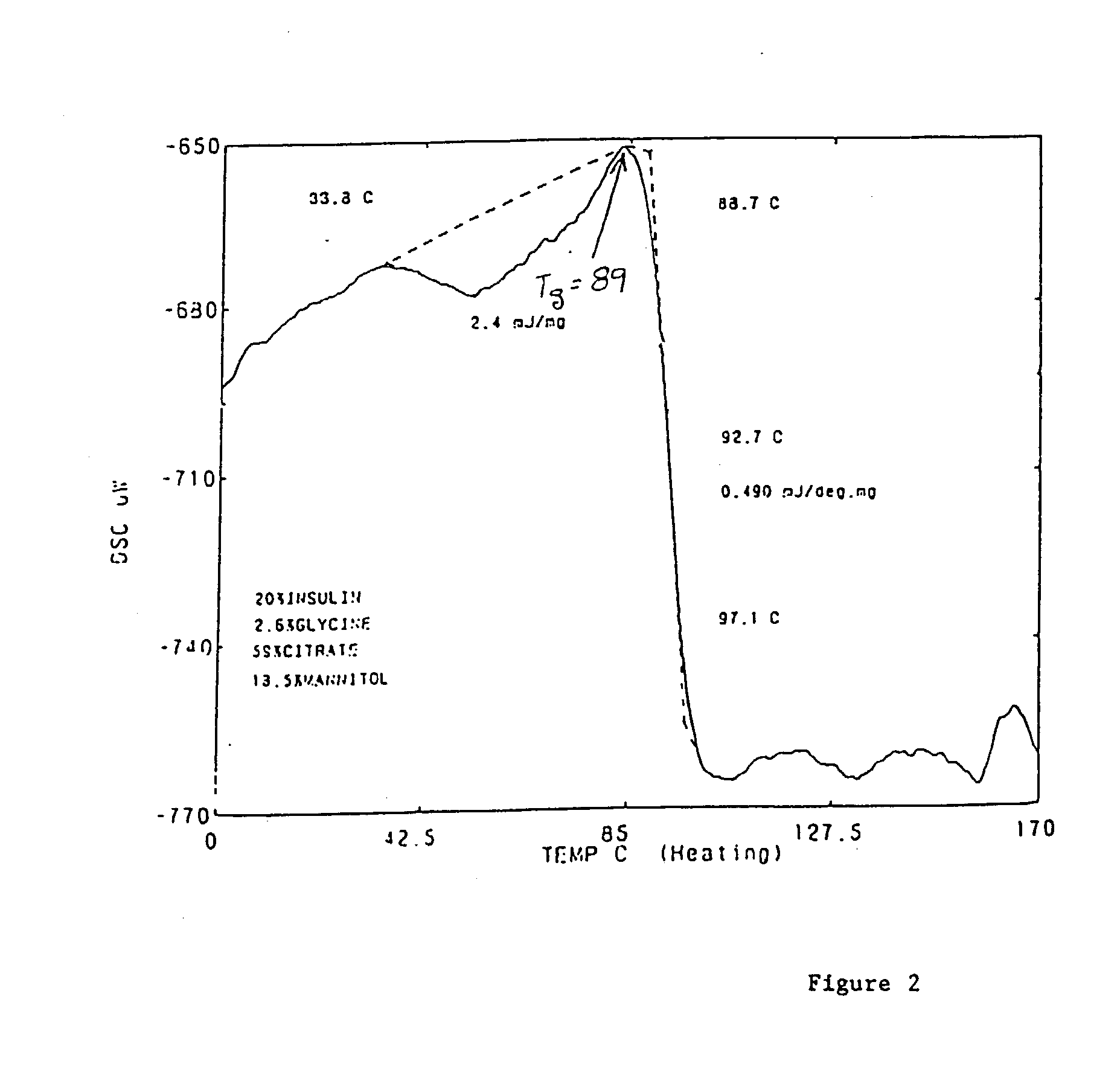

A powdered, dispersible composition having stable dispersibility over time is provided. The composition exhibits a characteristic glass transition temperature (Tg) and a recommended storage temperature (Ts), wherein the difference between Tg and Ts is at least about 10° C. (i.e. Tg-Ts is greater than 10° C.). The composition comprises a mixture of a pharmaceutically-acceptable glassy matrix and at least one pharmacologically active material within the glassy matrix. It may be further mixed with a powdered, pharmaceutically-acceptable carrier. It is particularly valuable in unit dosage form having a moisture barrier, in combination with appropriate labelling instructions. A process for producing a powdered dispersible composition is also provided, wherein the process comprises removing the solvent from a solution comprising a solvent, a glass former and a pharmacologically active material under conditions sufficient to form a glassy matrix having the pharmacologically active material within the matrix.

Owner:NOVARTIS FARMA

Corrosion inhibiting ceramic coating and method of application

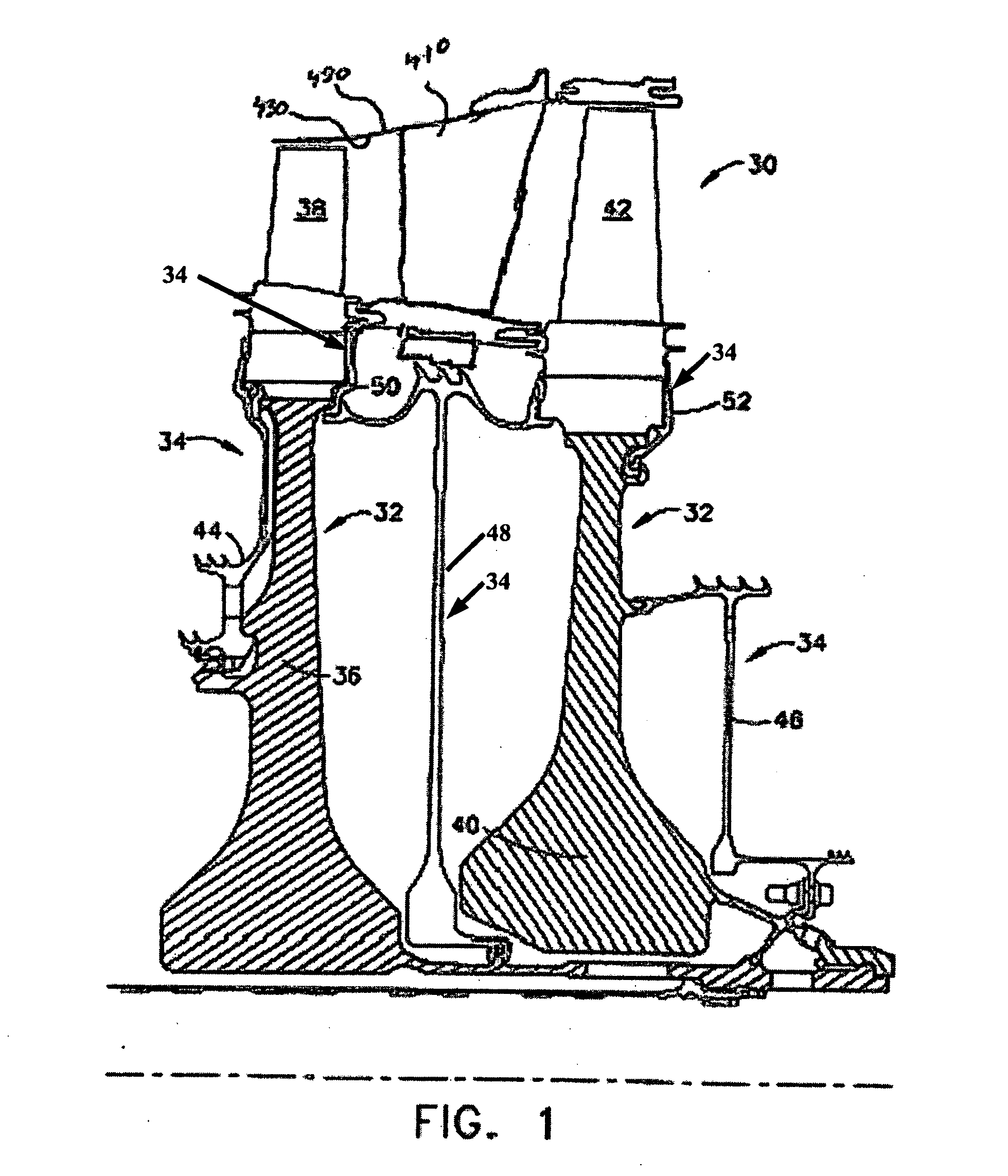

InactiveUS20070128447A1Reduce thermal stressCarefully controlledPretreated surfacesEfficient propulsion technologiesCeramic coatingTurbine blade

A corrosion resistant coating for engine components such as turbine disks, turbine seal elements and turbine shafts. This coating may also find application to other turbine components that are subjected to high temperatures and corrosive environments, such as turbine components located within or on the boundary of the gas fluid flow path, including for example turbine blades, turbine vanes, liners and exhaust flaps. The corrosion resistant coating of the present invention in service on a gas turbine component includes a glassy ceramic matrix wherein the glassy matrix is silica-based and particles selected from the group consisting of refractory oxide particles, MCrAlX particles and combinations of these particles, substantially uniformly distributed within the matrix. The refractory oxide and / or the MCrAlX provides the coating with corrosion resistance. Importantly the coating of the present invention has a coefficient of thermal expansion (CTE) greater than alumina. The CTE of the coating is sufficiently close to the substrate material, that is, the component to which it is applied, such that the coating does not spall after frequent engine cycling at elevated temperature

Owner:GENERAL ELECTRIC CO

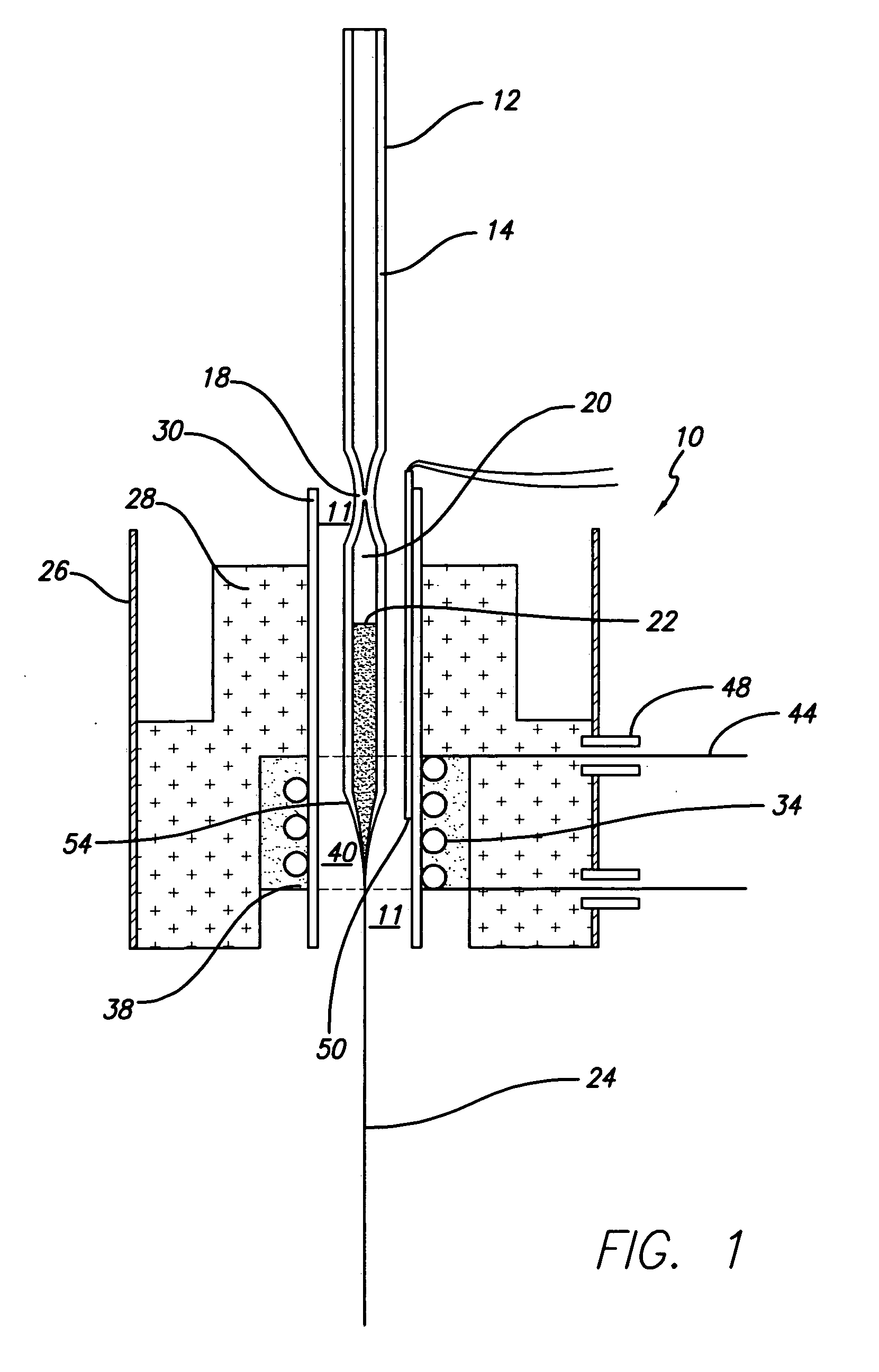

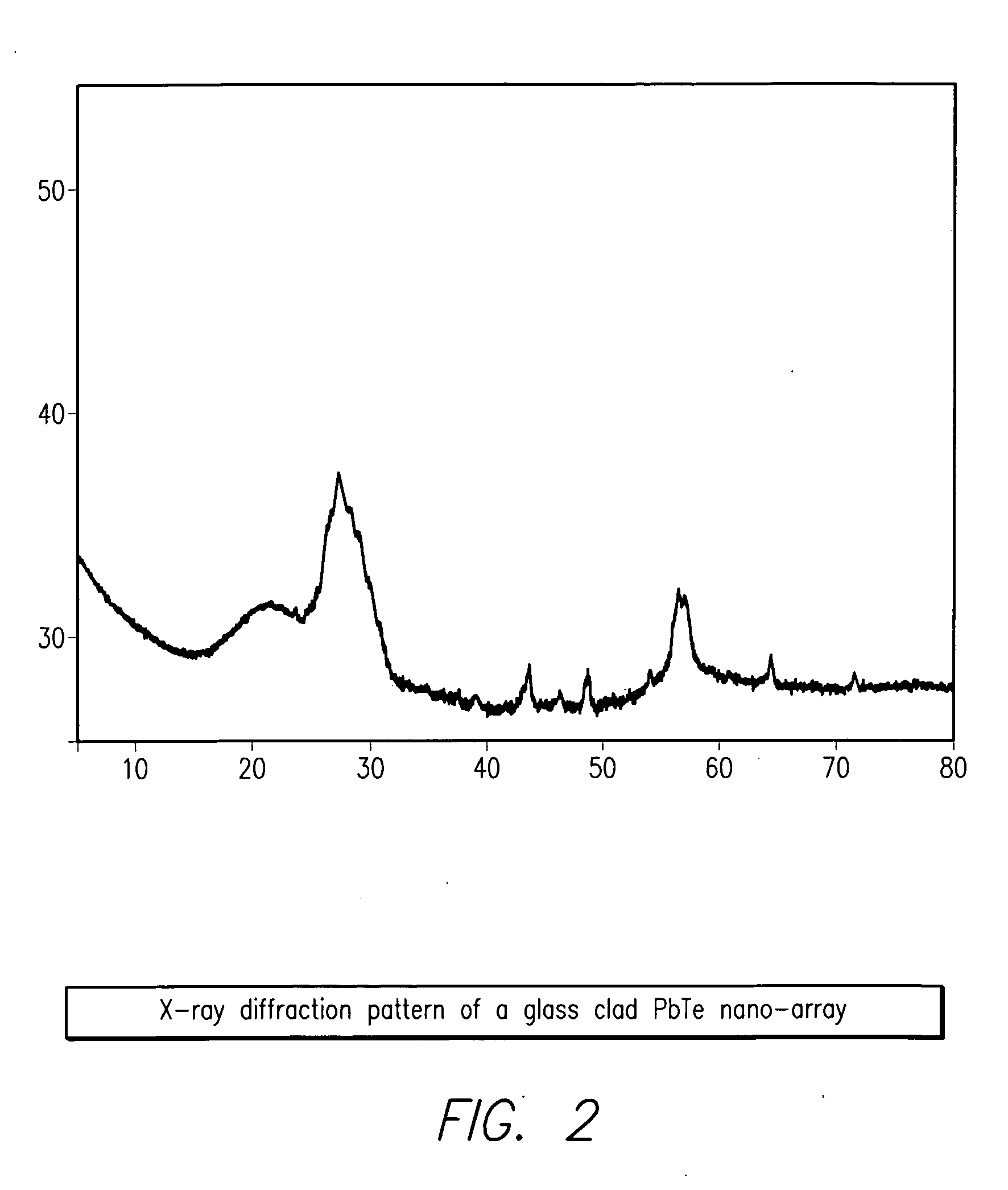

High density nanowire arrays in glassy matrix

InactiveUS20070131269A1Cost-effectivelySmall footprintThermoelectric device detailsThermoelectric device junction materialsThermoelectric materialsFiber

The present invention provides high density nanowire arrays in a glassy matrix comprising one or more thermoelectric fibers embedded in an electrically insulating material such that the thermoelectric material exhibits quantum confinement. According to the preferred embodiment of the invention, the thermoelectric material comprises PbTe and the glassy matrix comprises an electrically insulating material comprising a binary, ternary or higher component glass such as pyrex, borosilcate, aluminosilicate, quartz. The glass may also be formed from multiple constituents but not limited to lead oxide, tellurium dioxide and silicon dioxide, alumina, calcium oxide etc.

Owner:ZT3 TECH INC

Melt extrusion encapsulation of flavors and other encapsulates in a carrier containing spices and herbs

Active encapsulation compositions which are stable in the glassy state at ambient temperatures are prepared by melt extrusion of a ternary carrier blend comprising of 1) a food polymer, 2) a spice or herb, and 3) a low molecular weight sugar or polyol. Such glassy matrices are useful for the encapsulation of encapsulates, in particular, flavors and medications.

Owner:MCCORMICK & CO INC

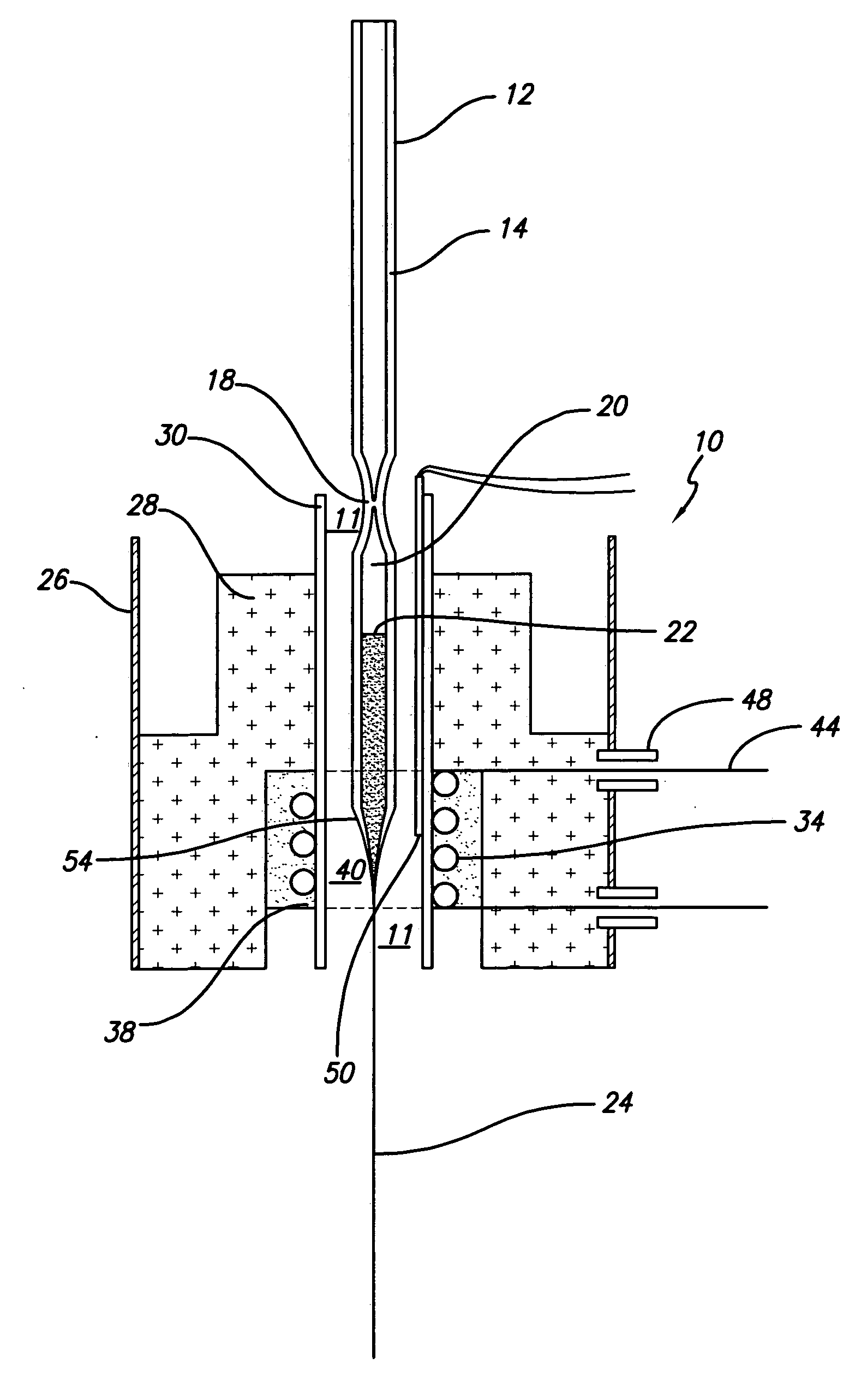

Methods of drawing high density nanowire arrays in a glassy matrix

InactiveUS20070131266A1Reduce variationExpand the populationGlass making apparatusThermoelectric device with peltier/seeback effectThermoelectric materialsFiber

The present invention provides a method of drawing a thermoelectrically active material in a glass cladding, comprising sealing off one end of a glass tube such that the tube has an open end and a closed end, introducing the thermoelectrically active material inside the glass tube and evacuating the tube by attaching the open end to a vacuum pump, heating a portion of the glass tube such that the glass partially melts and collapses under the vacuum such that the partially melted glass tube provides an ampoule containing the thermoelectric material to be used in a first drawing operation, introducing the ampoule containing the thermoelectric material into a heating device, increasing the temperature within the heating device such that the glass tube melts just enough for it to be drawn and drawing fibers of glass clad thermoelectrically active material. The invention further provides a method for bunching together such fibers and re-drawing them one or more times to produce arrays of thermoelectric nanowires clad in glass.

Owner:ZT3 TECH INC

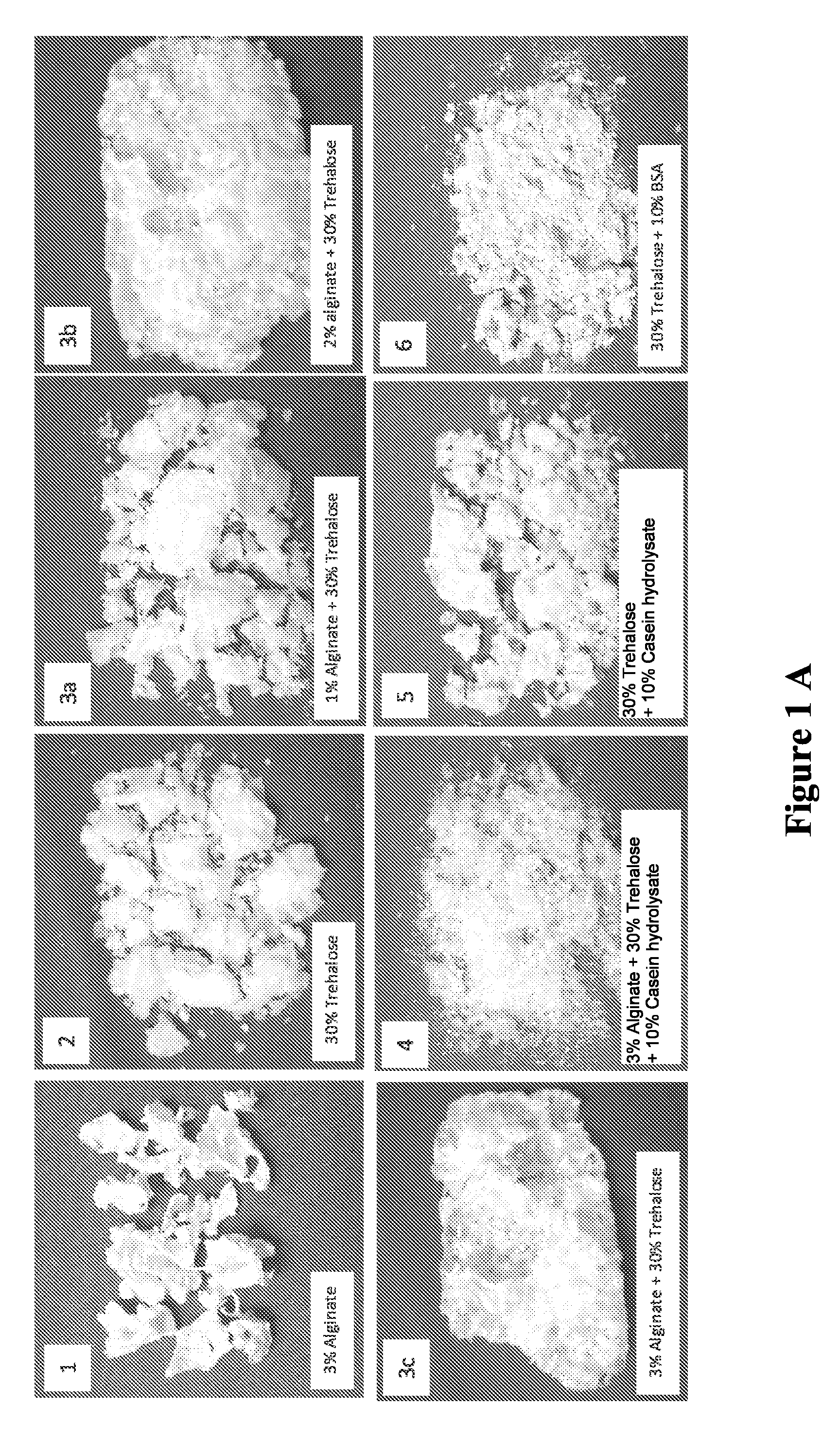

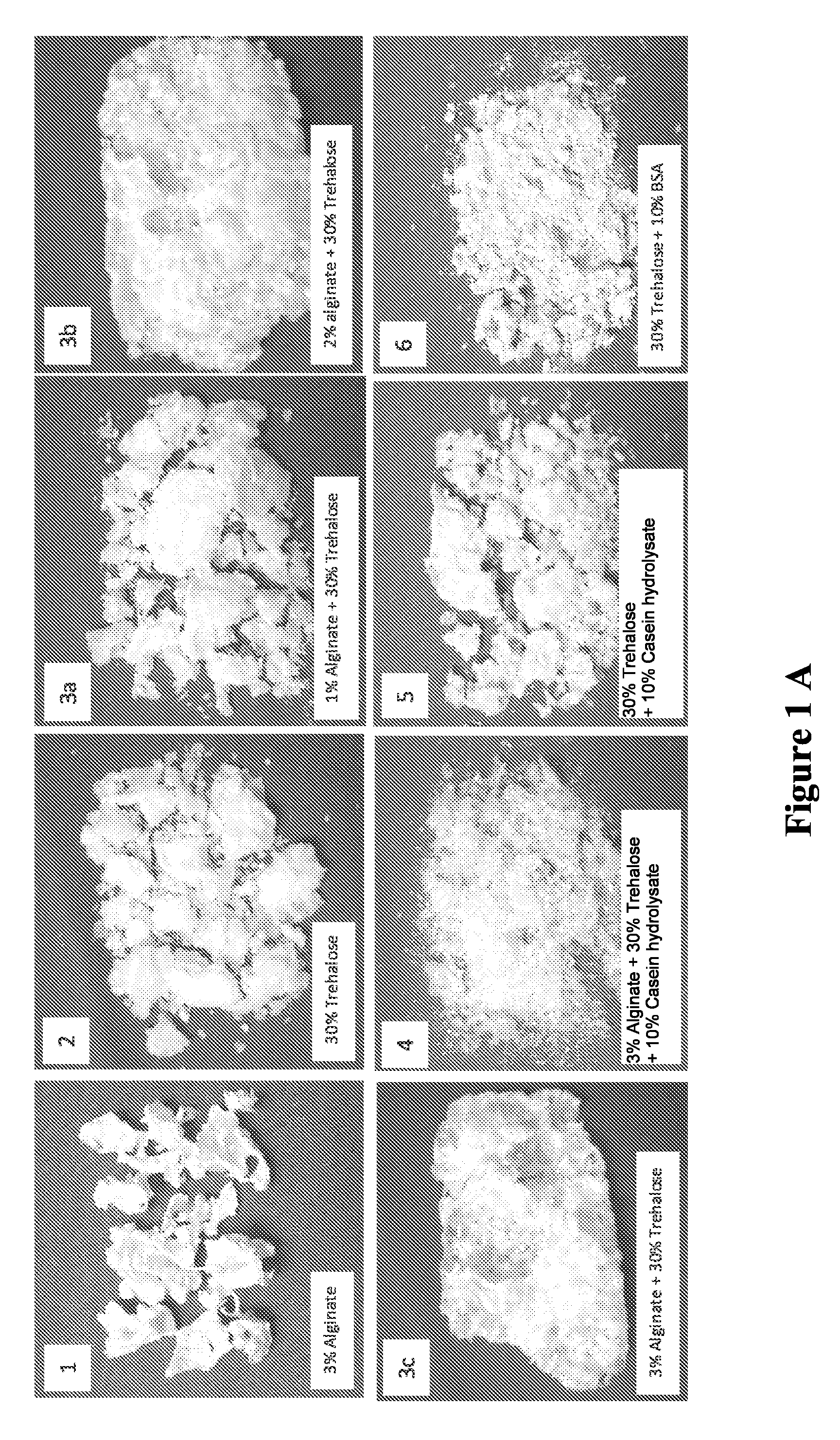

Dry glassy composition comprising a bioactive material

ActiveUS20120322663A1Improve stabilityLower water activityBiocidePeptide/protein ingredientsBiologyGlassy matrix

The present invention relates to formulations and methods for stabilizing and protecting of biologic materials during harsh storing and use conditions, wherein the formulations relate to embedded bioactive materials and biologics, including live bacteria, in a protective glassy matrix.

Owner:ADVANCED BIONUTRITION CORP

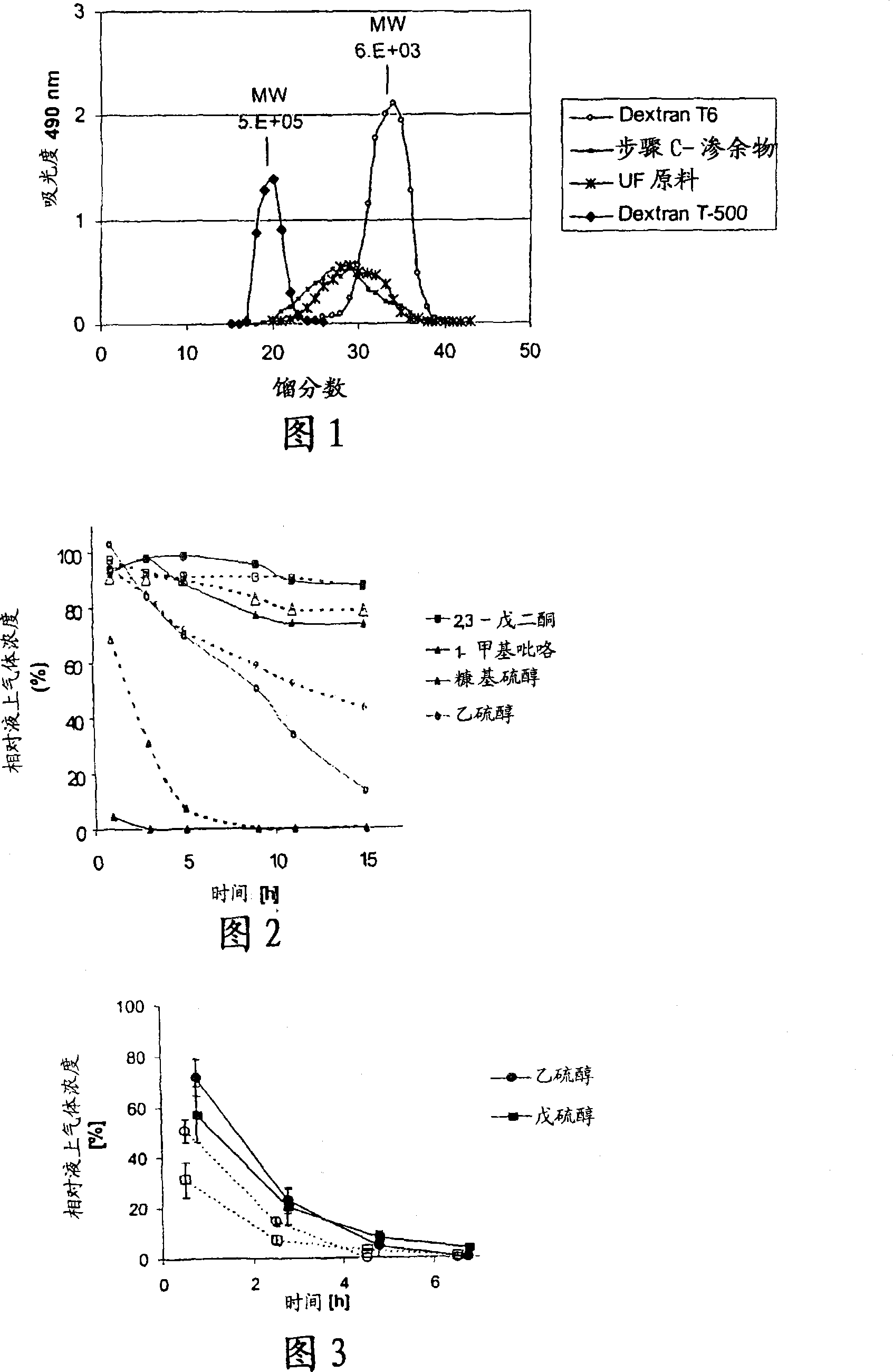

Polysaccharide Microparticles Containing Biological Agents: Their Preparation and Applications

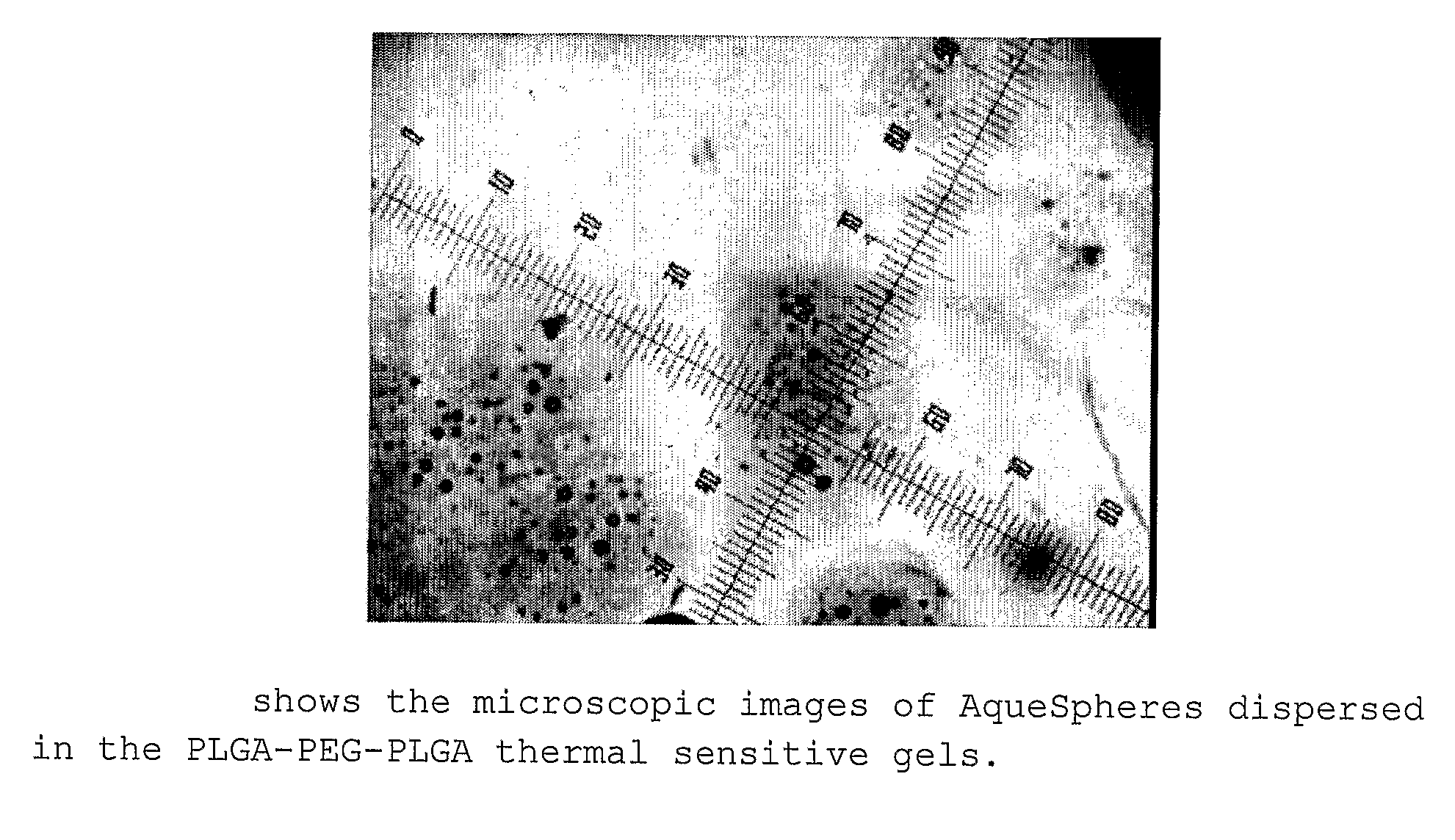

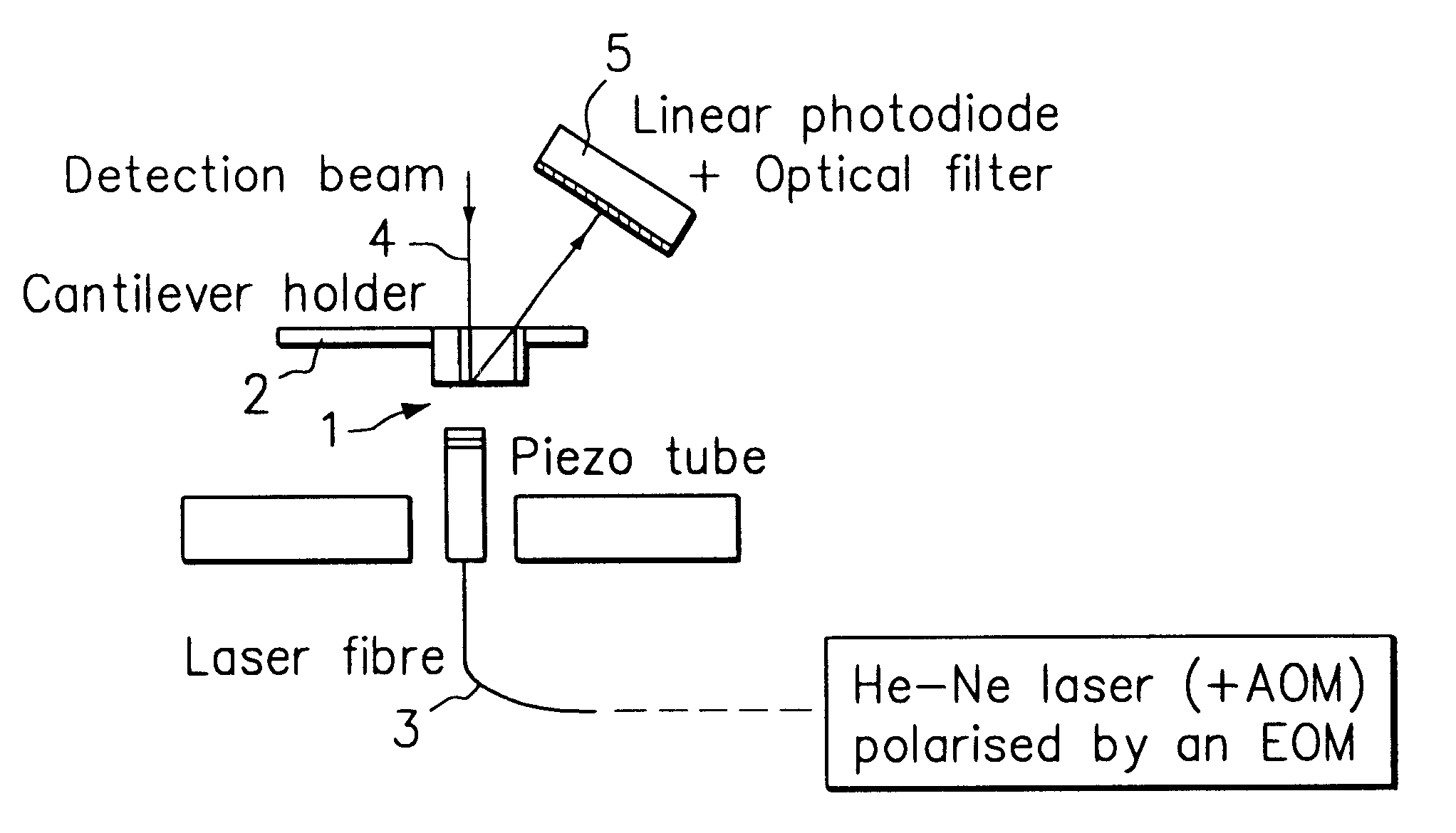

A method of preparing polysaccharide glassy microparticles which are less than 10 μum in diameter and contain structurally delicate agents, such as proteins, peptides, gene materials, vaccines, antibodies, viruses and liposomes using low-temperature aqueous-aqueous emulsification (free of polyelectrolytes) and freezing-induced phase separation. When delicate agents are added to a polysaccharide-PEG two phase system followed by homogenization (or other shear adding process), the agents partition into the polysaccharide dispersed phase preferentially. These processes help to avoid aggregation of proteins caused by interaction with charged polyelectrolytes used for stabilizing the polysaccharide dispersed phase in our previously reported aqueous-aqueous emulsion. When this system is frozen and lyophilized, glassy particles less than 10 μm in diameter containing delicate agents can be formed. These fine polysaccharide particles protect proteins within their hydrophilic glassy matrix, and can therefore be easily suspended in hydrophobic polymer solutions and formulated to various forms of sustained release devices such microsphere, sheets, fibers, coating layers, and scaffolds. The particles can also be dispersed in hydrophilic gels to improve releasing kinetics and to deliver vaccines and antibodies for immune therapy.

Owner:BIODVERY PHARMATECH LTD

Extrusion encapsulation of actives at an increased load, using surface active plant

ActiveUS20130243851A1Improve the level ofIncrease the maximum loadConfectionerySweetmeatsFlavorLoad following power plant

A glassy extrusion encapsulation composition and a method of making the composition are provided. The encapsulation composition comprises an encapsulate encapsulated in a glassy matrix comprising 0.5 to 12% by weight, based on the total weight of the glassy matrix, of at least one surface active plant extract, and 88 to 99.5% of at least one carbohydrate. The addition of a surface active plant extract to a carbohydrate matrix markedly increases the load of an encapsulate in the encapsulation composition. Such glassy matrices are useful for encapsulation of encapsulates, for example, flavors and medications. A food composition containing the encapsulation composition is also provided.

Owner:MCCORMICK & CO INC

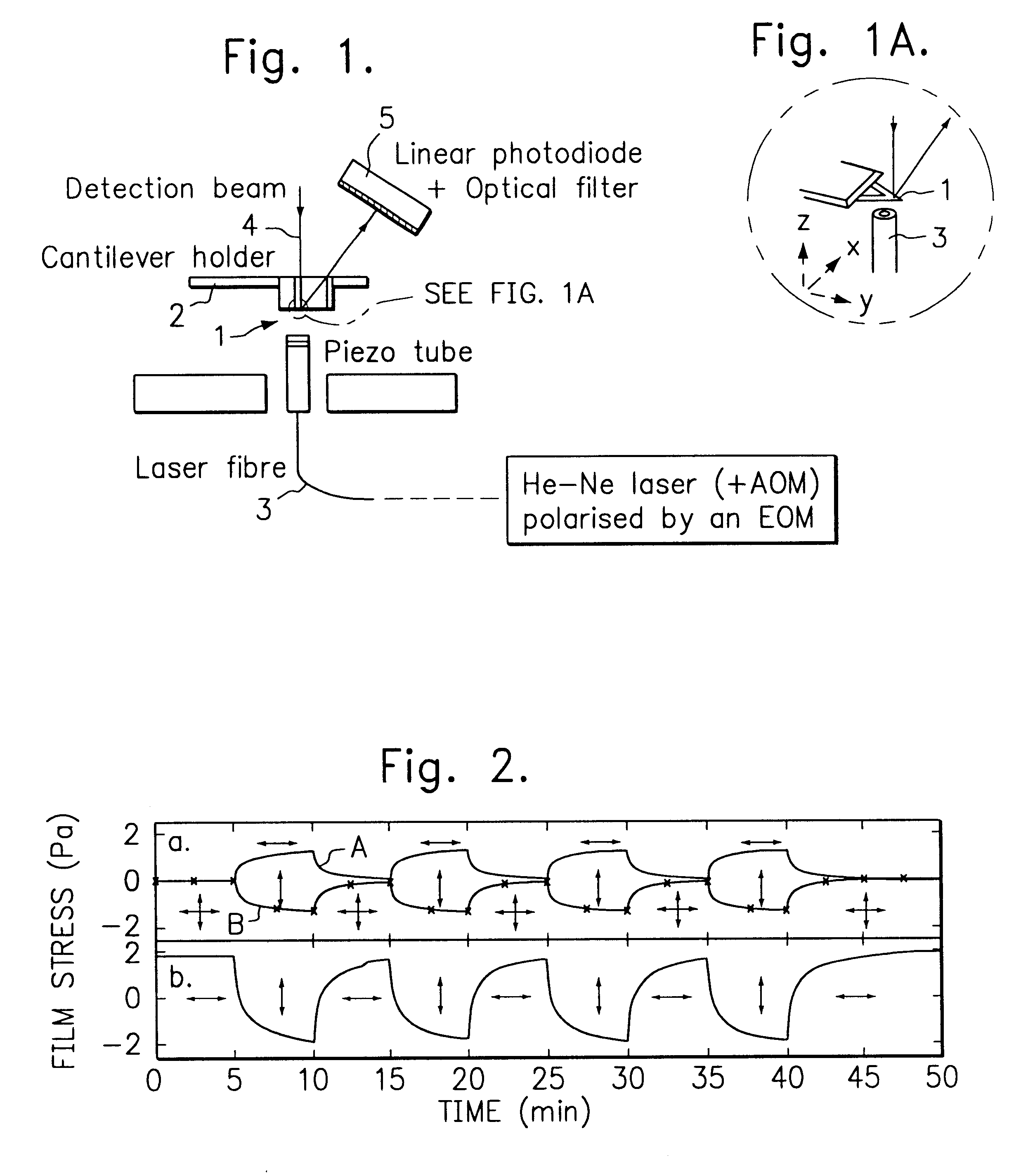

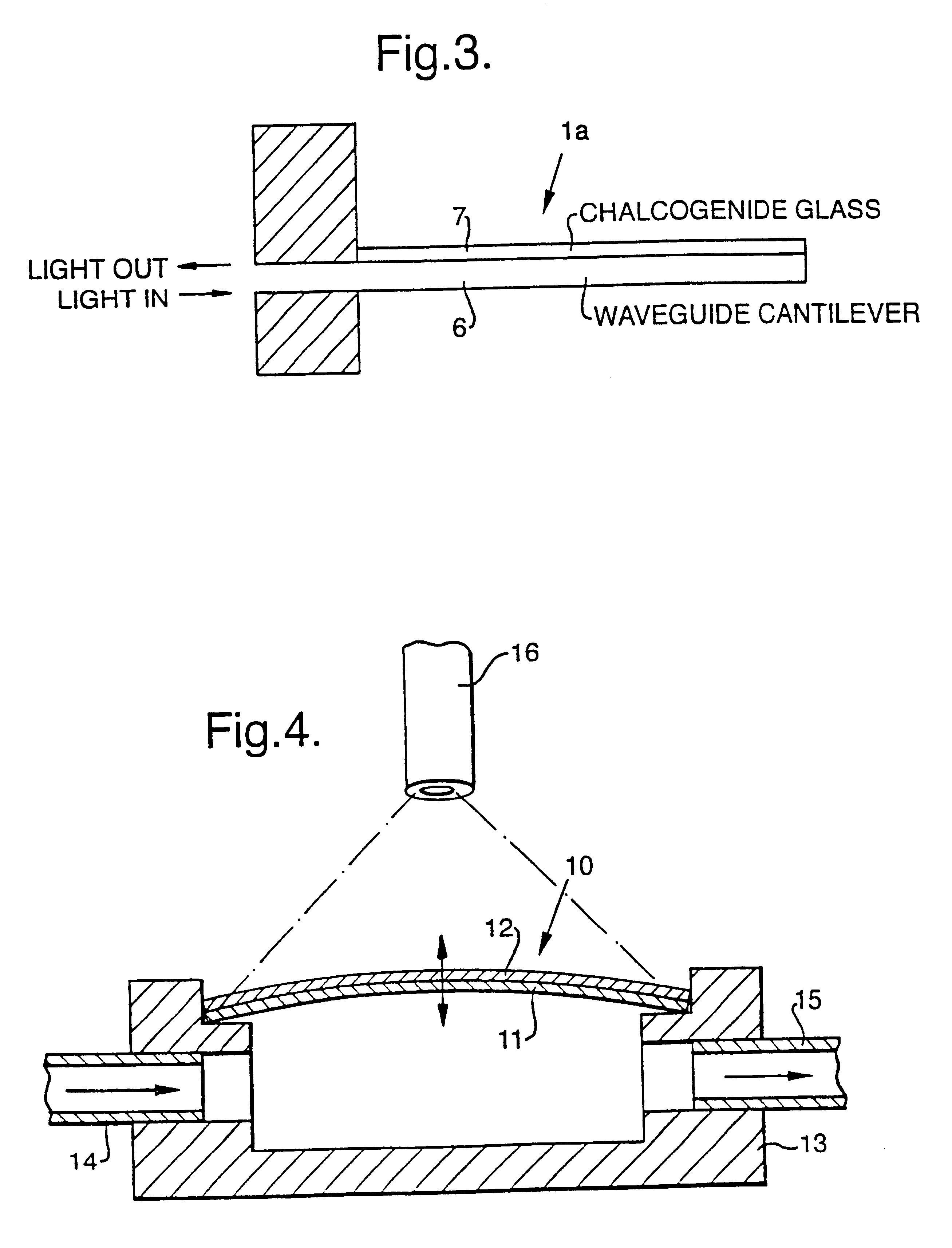

Opto-mechanical device

InactiveUS6392777B1Optimise its sensitivityLess rigidMicromanipulatorFlexible member pumpsChalcogenide glassSemiconductor

An opto-mechanical device is constituted by an optically responsive actuating member in which a mechanical strain occurs in response to changes in its illumination. The actuating member is preferably at least partly formed from a semiconducting glassy matrix such as a chalcogenide glass. Preferably the opto-mechanical device illuminates the actuating member with light which is preferably plane polarized. Preferably it also varies the polarization angle of the plane polarized light to cause a change in the strain generated in the actuating member.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD

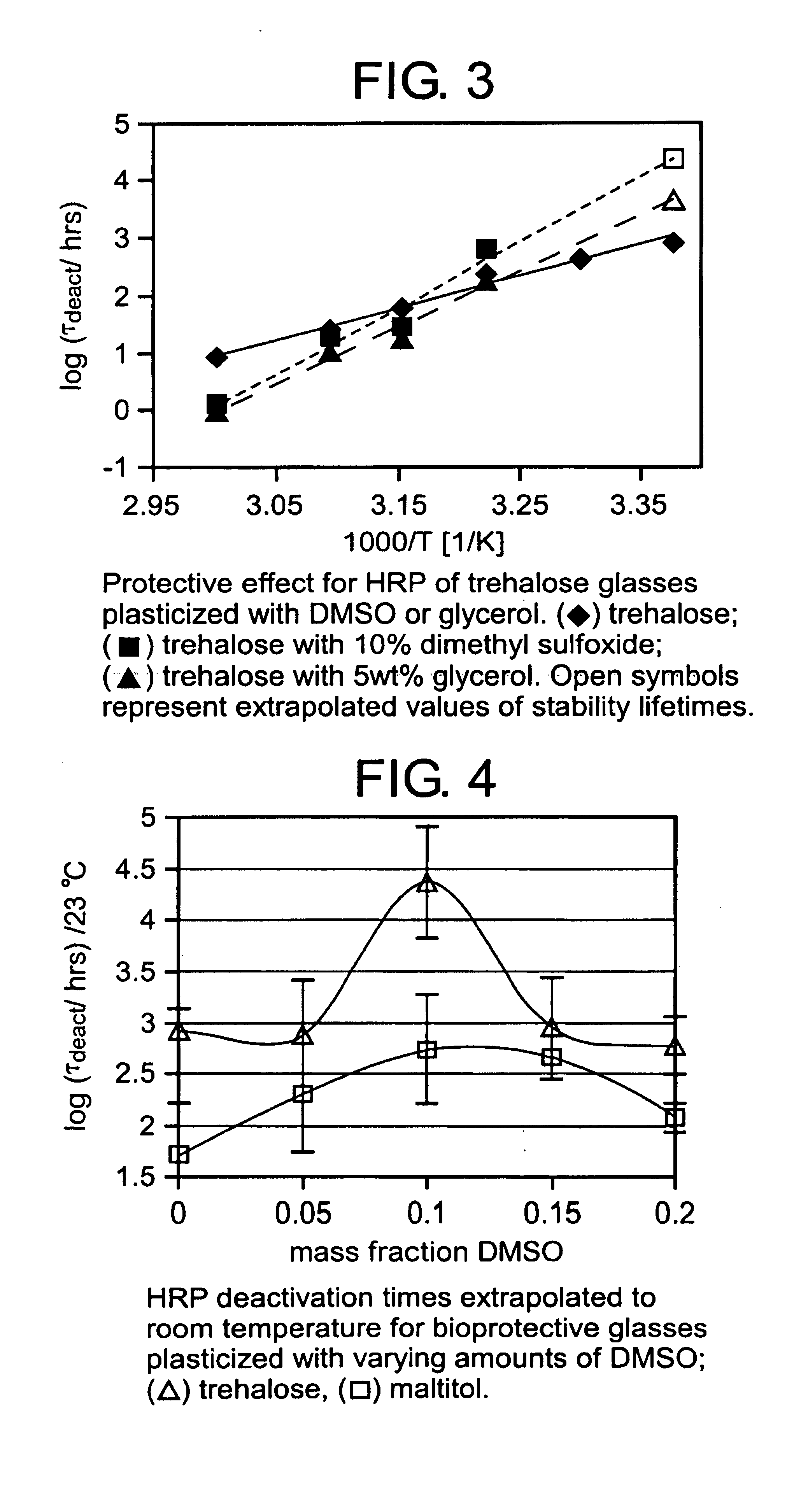

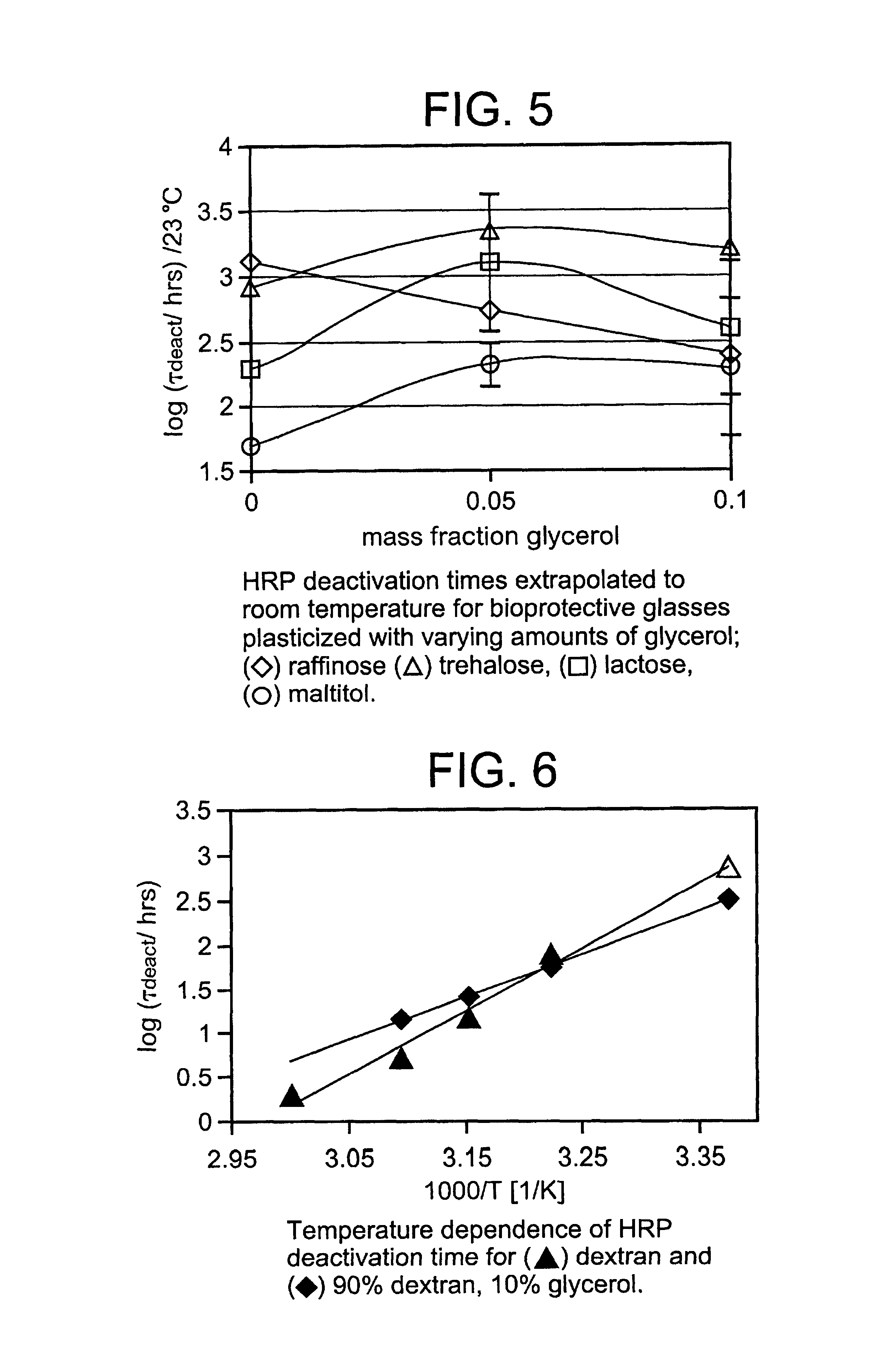

Plasticized hydrophilic glasses for improved stabilization of biological agents

InactiveUS7101693B2Slow dynamicReducing lengthscaleBiocidePowder deliveryBiological materialsGlass transition

The stabilization of biomaterials such as proteins in a nominally dry, hydrophilic glassy matrix is vastly improved by the addition of an appropriate amount of a small-molecule pasticizer such as a glycol or DMSO to the formulation, while maintaining a glass transition temperature (Tg) that is above the storage temperature. By plasticizing the glasses, their ability to preserve proteins is improved by as much as 100 times over the unplasticized glass at room temperature. The plasticizer confers the greatest beneficial effect when it is dynamically coupled into the bulk glass, and this coupling occurs over a fairly narrow range of plasticizer concentration. Methods are described in which a small-molecule plasticizer can be incorporated into a glass made of much larger molecules (e.g. a polymeric glass), with desired dynamic coupling, via a molecule that is believed to act as a dynamic linker. Protein preservation data was obtained from two enzymes, horseradish peroxidase (HRP) and alcohol dehydrogenase (ADH).

Owner:BRIGHAM YOUNG UNIV

Encapsulated Active Ingredients, Methods of Preparation and Their Use

InactiveUS20080206325A1Improve stabilityEffective oxygen barrierGranular deliveryFood shapingAdditive ingredientHydrolysate

The present invention relates to particles that include an active ingredient that is encapsulated first by coacervation, and then by a glassy matrix. The glassy matrix includes 3-50 wt % of a hydrophobically modified starch, and 50-97 wt % of a starch hydrolysate. The particles are useful for encapsulating active ingredients intended for oral ingestion and may be added to food products.

Owner:FIRMENICH SA

Dry glassy composition comprising a bioactive material

ActiveUS8834951B2Avoiding boiling and excessive foamingEfficient primary dryingPowder deliveryBiocideProtection sexBiology

The present invention relates to formulations and methods for stabilizing and protecting of biologic materials during harsh storing and use conditions, wherein the formulations relate to embedded bioactive materials and biologics, including live bacteria, in a protective glassy matrix.

Owner:ADVANCED BIONUTRITION CORP

Strain tolerant corrosion protecting coating and tape method of application

InactiveUS20090098394A1Provide corrosion resistanceCorrosion resistanceOther chemical processesBlade accessoriesThermal expansionSilicon dioxide

A corrosion resistant tape coating for gas turbine engine includes a glassy ceramic matrix wherein the glassy matrix is silica-based, and includes corrosion resistant particles selected from refractory particles and non-refractory MCrAlX particles, and combinations thereof. The corrosion resistant particles are substantially uniformly distributed within the matrix, and provide the coating with corrosion resistance. Importantly the coating of the present invention has a coefficient of thermal expansion (CTE) greater than that of alumina at engine operating temperatures. The CTE of the coating is sufficiently close to the substrate material such that the coating does not spall after frequent engine cycling at temperatures above 1200° F.

Owner:GENERAL ELECTRIC CO

Encapsulated active ingredients, methods of preparation and their use

InactiveCN101252845AExtended shelf lifeImprove thermal stabilityGranular deliveryFood shapingAdditive ingredientHydrolysate

The present invention relates to particles that include an active ingredient that is encapsulated first by coacervation, and then by a glassy matrix. The glassy matrix includes 3-50 wt % of a hydrophobically modified starch, and 50-97 wt % of a starch hydrolysate. The particles are useful for encapsulating active ingredients intended for oral ingestion and may be added to food products.

Owner:FIRMENICH SA

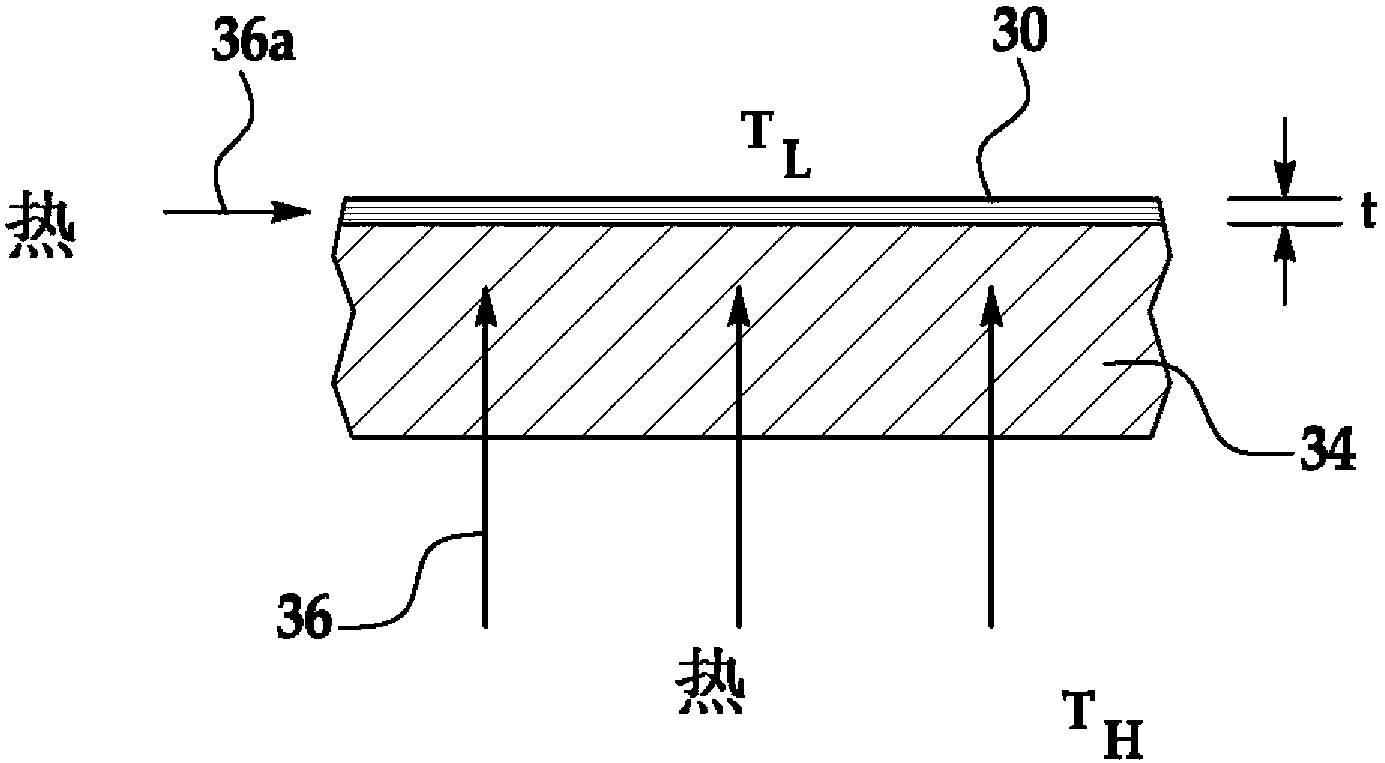

Thermal barrier composition

The thermal barrier composition of the present invention provides a glassy matrix comprising an alkoxy-functionalized siloxane and a functionally-terminated silane or siloxane, polymethylsilsesquioxane dissolved in a crosslinking agent, and optionally a filler and / or hollow glass microspheres.

Owner:MICROPHASE COATINGS

Melt extrusion encapsulation of flavors and other encapsulates in a carrier containing spices and herbs

Active encapsulation compositions which are stable in the glassy state at ambient temperatures are prepared by melt extrusion of a ternary carrier blend comprising of 1) a food polymer, 2) a spice or herb, and 3) a low molecular weight sugar or polyol. Such glassy matrices are useful for the encapsulation of encapsulates, in particular, flavors and medications.

Owner:MCCORMICK & CO INC

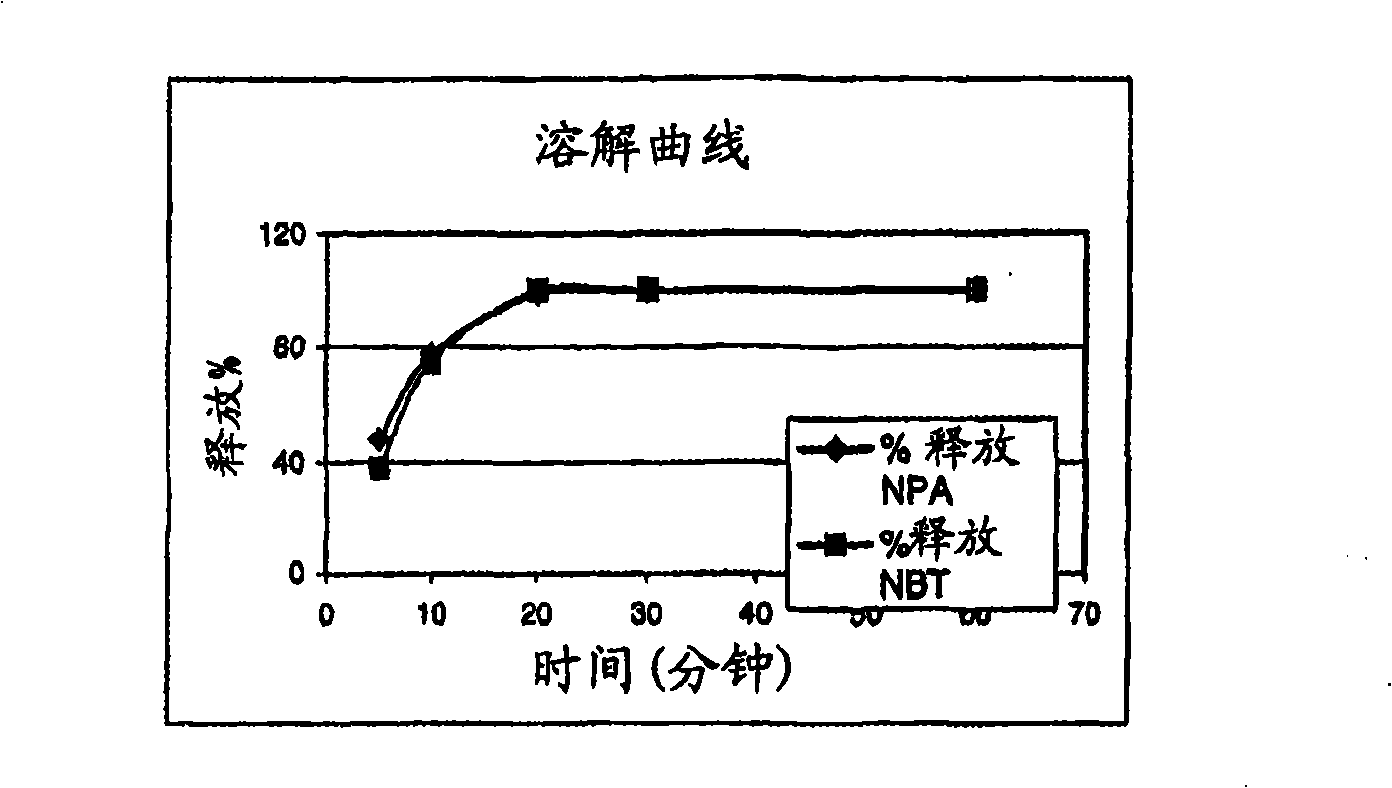

Method for preparing nicotine containing oral dosage form

InactiveCN101301275AReduce usageReduce nicotine addictionOrganic active ingredientsPowder deliveryOral medicationGlassy matrix

The present invention relates to a preparing method of oral dosage forms including nicotine, specifically to glassy matrix solid oral dosage forms useful for transmucosal oral administration of a nicotine active.

Owner:SMITHKLINE BECKMAN CORP

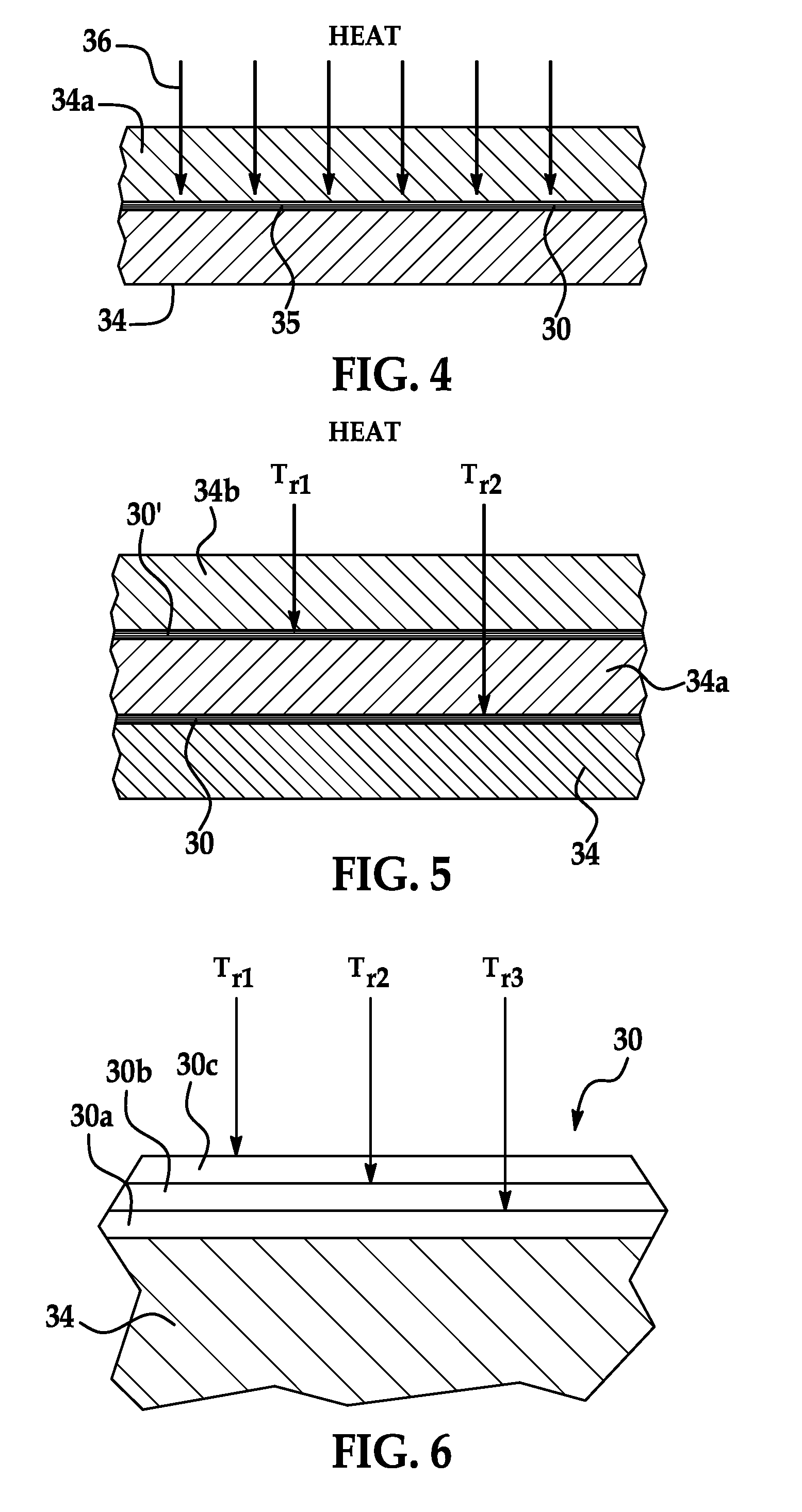

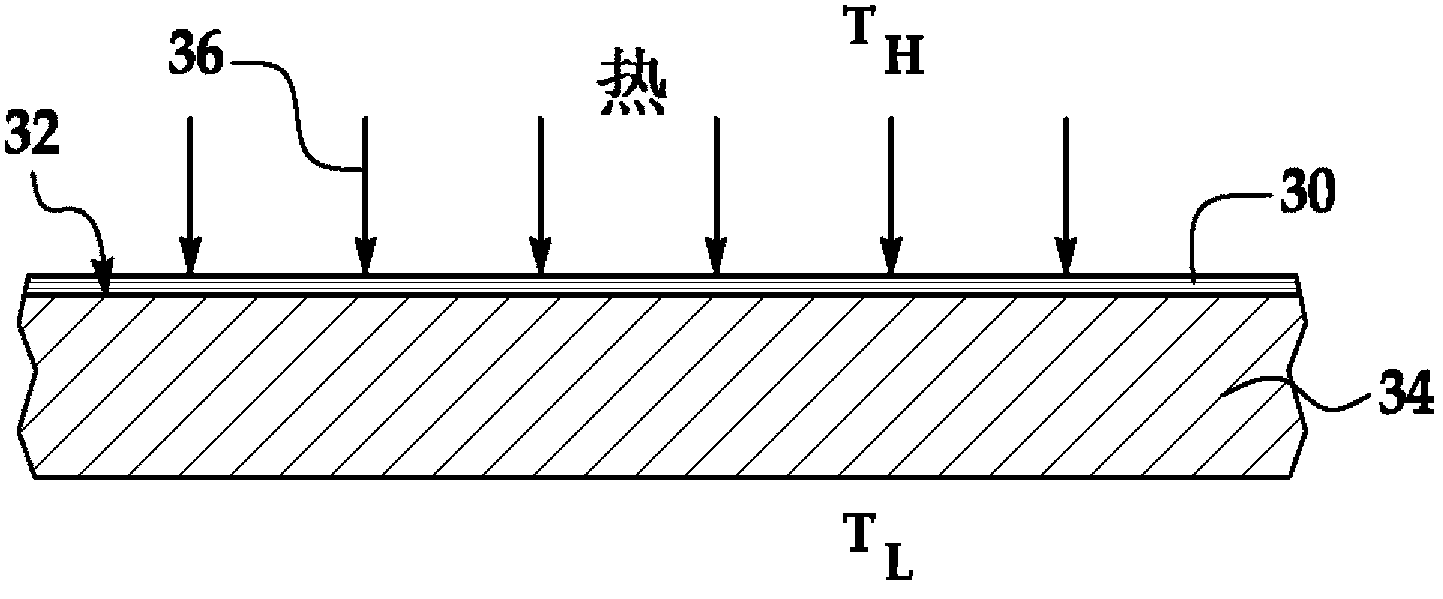

Nano-coating thermal barrier and method for making the same

InactiveUS20110297358A1Light weightInexpensively appliedThermal insulationRadiation applicationsGlassy matrixMetal

A coating is adapted to be applied to a substrate for managing the flow of heat traveling through the substrate. The coating comprises an array of metal nano-particles held in a glassy matrix.

Owner:THE BOEING CO

Thermal barrier composition

InactiveUS20060110612A1Improve adhesionFireproof paintsPigmenting treatmentPolymer scienceMicrosphere

The thermal barrier composition of the present invention provides a glassy matrix comprising an alkoxy-functionalized siloxane and a functionally-terminated silane or siloxane, polymethylsilsesquioxane dissolved in a crosslinking agent, and optionally a filler and / or hollow glass microspheres.

Owner:MICROPHASE COATINGS

High density nanowire arrays in glassy matrix

InactiveCN101326650AThermoelectric device manufacture/treatmentThermoelectric device detailsFiberThermoelectric materials

Owner:ZT3 TECH INC

Nicotine-containing oral dosage form

The present invention is directed to glassy matrix solid oral dosage forms useful for transmucosal oral administration of a nicotine active.

Owner:SMITHKLINE BECKMAN CORP

Nano-coating thermal barrier and method for making the same

Owner:THE BOEING CO

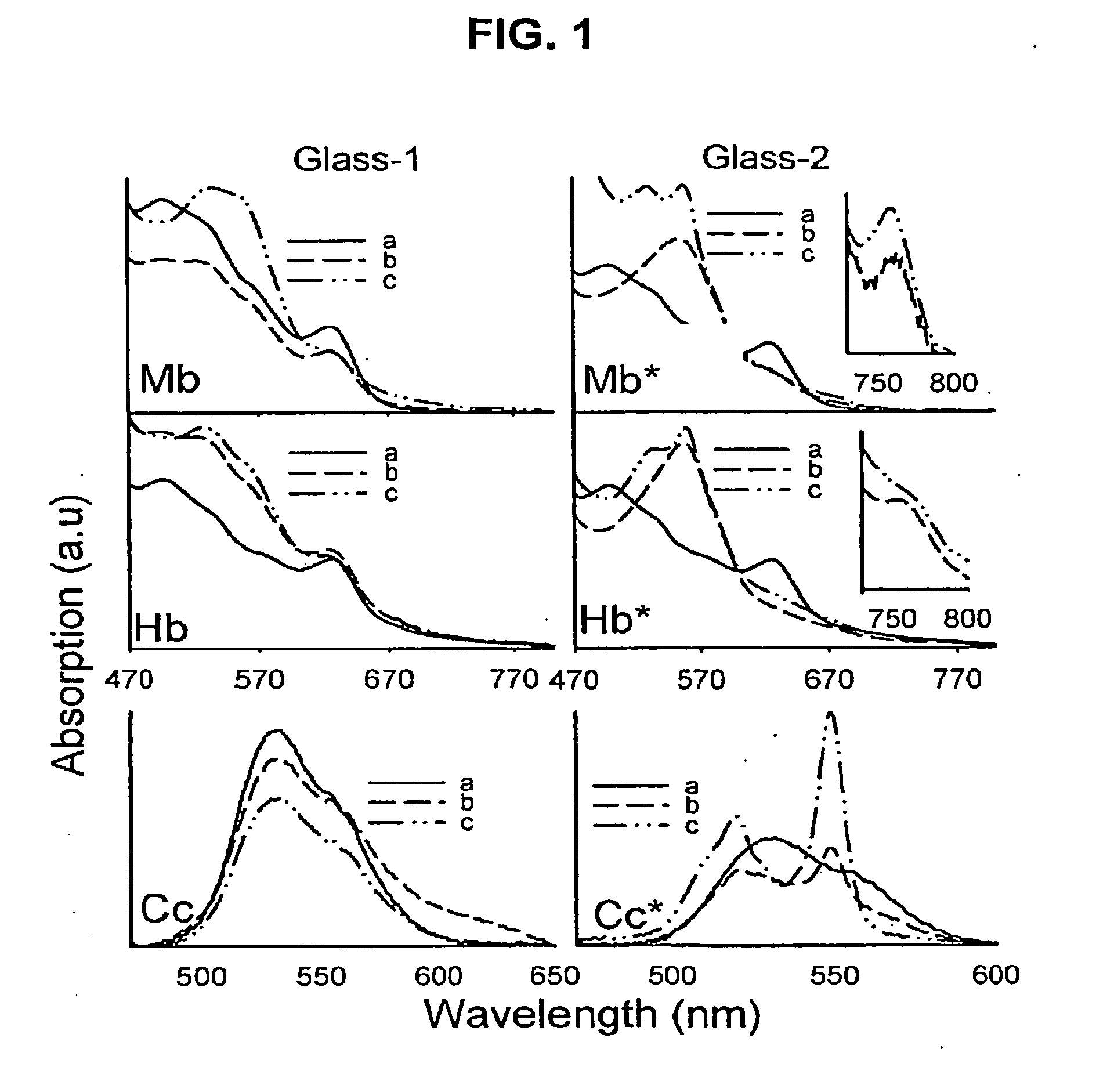

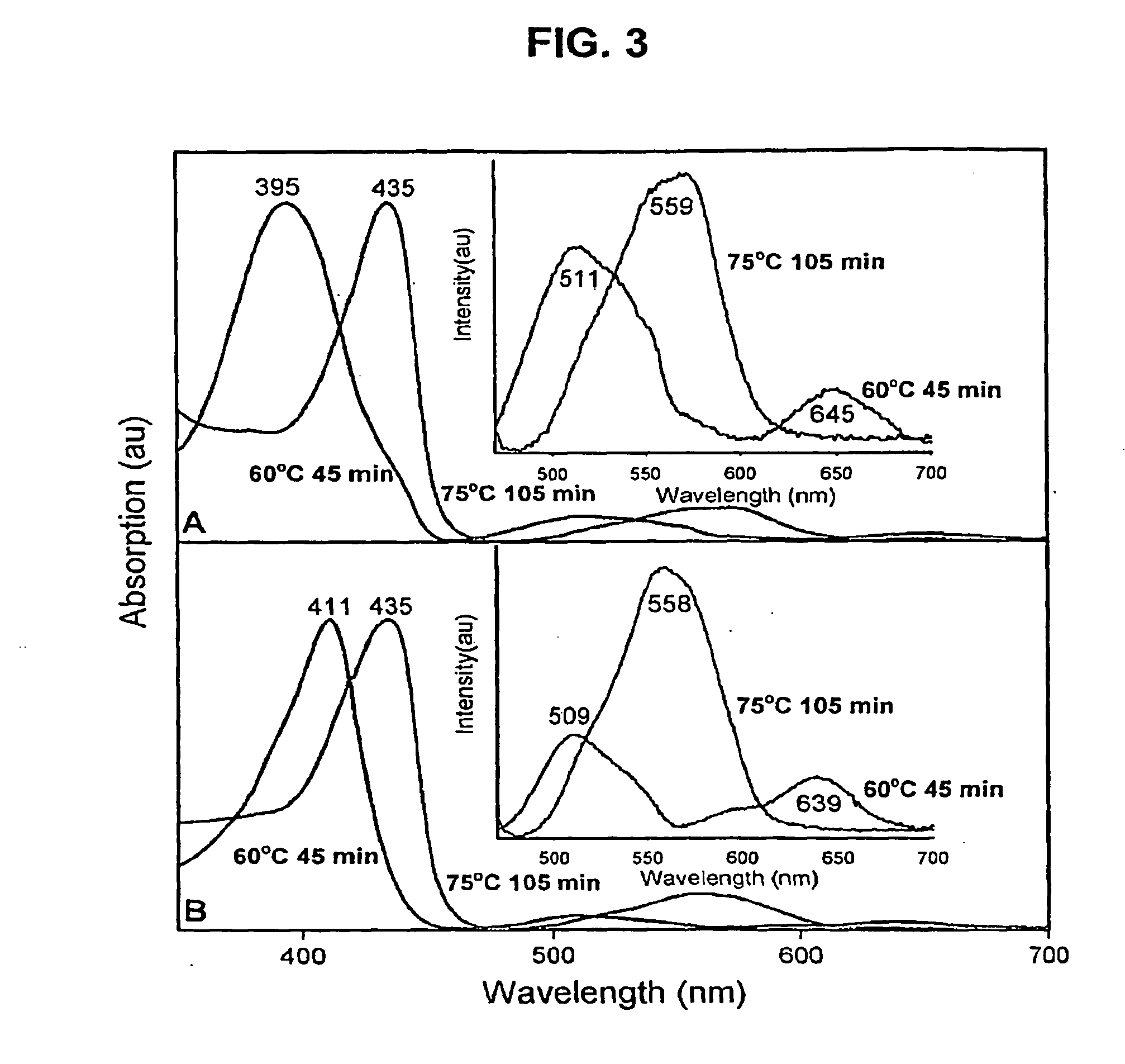

Electron Transfer Through Glassy Matrices

Provided are electron transfer compositions comprising a glassy sugar matrix. Electric batteries, electric circuits, semiconductors, solar cells, thermal detectors, and photo detectors comprising glassy sugar matrices are also provided. Additionally provided are methods of transferring electrons to a redox protein using these compositions.

Owner:FRIEDMAN JOEL M +1

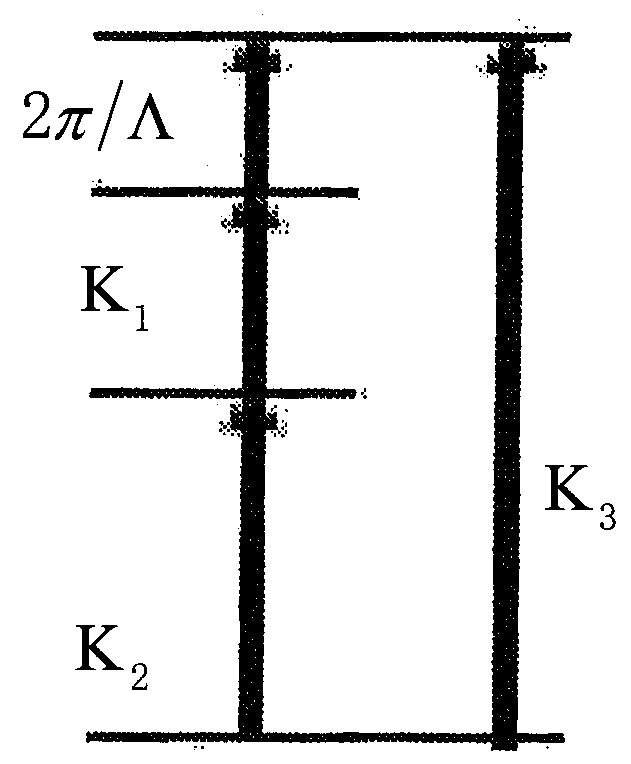

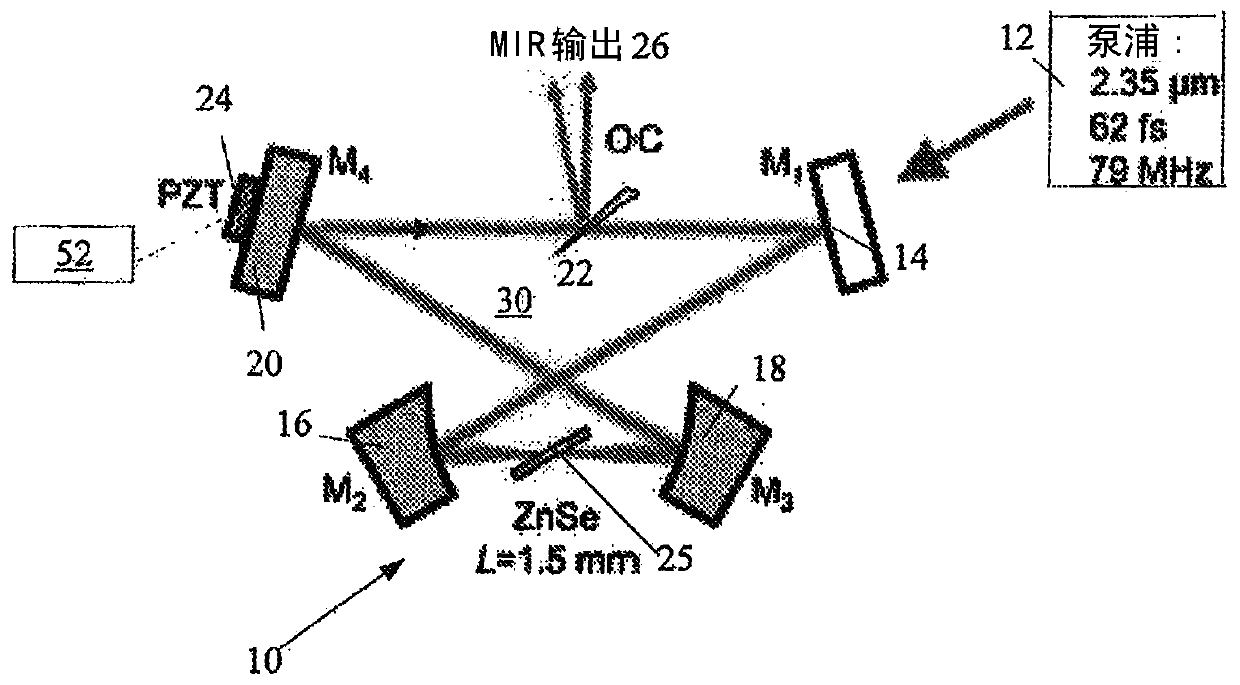

Optical parametric device based on random phase matching in polycrystalline medium

An optical parametric device (OPD), which is selected from an optical parametric oscillator (OPO) or optical parametric generator (OPG), is configured with a nonlinear optical element (NOE) which converts an incoupled pump radiation at first frequency into output signal and idler radiations at one second frequency or different second frequencies, which is / are lower than the first frequency, by utilizing nonlinear interaction via a random quasi-phase matching process (RQPM-NOE). The NOE is made from a nonlinear optical material selected from optical ceramics, polycrystals, micro and nanocrystals, colloids of micro and nanocrystals, and composites of micro and nanocrystals in polymer or glassy matrices. The nonlinear optical material is prepared by modifying a microstructure of the initial sample of the NOE such that an average grain size is of the order of a coherence length of the three-wave interaction which enables the three wave nonlinear interaction with a highest parametric gain achievable via the RQPM process

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Glassy matrices for the stabilization of coffee aroma

A glassy matrix for coffee aroma is provided in which the level of compounds which degrade aroma has been reduced, enabling the production of improved soluble coffee powder.

Owner:NESTEC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com