Method for producing raw material powder for rare earth sintered magnet, method for producing rare earth sintered magnet, granule and sintered article

一种烧结磁体、制造方法的技术,应用在电感/变压器/磁铁制造、磁性材料、磁性物体等方向,能够解决不能获得成形体尺寸精度、颗粒产额降低、耗费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0147] The raw material alloy is produced by the strip continuous casting method, and its composition is: 26.5wt% Nd-5.9wt% Dy-0.25wt% Al-0.5wt% Co-0.07wt% Cu-1.0wt% B-balance Fe .

[0148] Next, a hydrogen pulverization treatment is performed, that is, the raw material alloy is allowed to absorb hydrogen at room temperature, and then dehydrogenated in an Ar atmosphere at 600° C. for 1 hour.

[0149] The alloy subjected to the hydrogen pulverization treatment is mixed with 0.05 to 0.1% of a lubricant that contributes to improvement of pulverization and orientation during molding. The mixing of the lubricant may be performed for about 5 to 30 minutes using, for example, a Nauta mixer. Then, a finely pulverized powder having an average particle diameter of 5.0 μm was obtained using a jet mill.

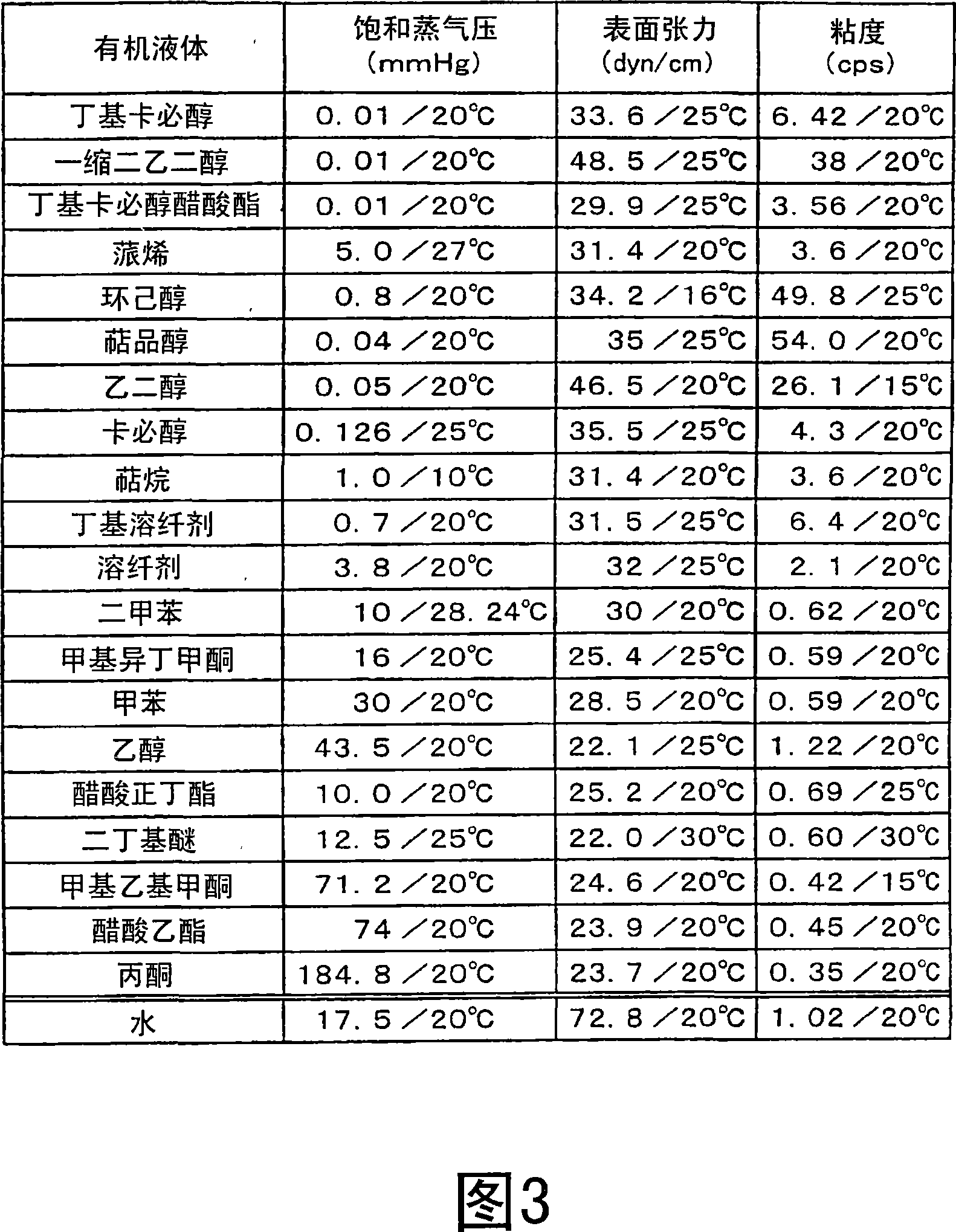

[0150]To the above finely pulverized powder, various organic liquids shown in FIG. 4 were added in the amounts shown in FIG. 4, and then sufficiently kneaded with a mortar. Pellets we...

Embodiment 7

[0153] SEM photographs of the molded articles of Example 7 and Comparative Example 1 are shown in FIG. 6 . 6( a ) is an SEM photograph of the molded body of Example 7, and FIG. 6( b ) is a SEM photograph of the molded body of Comparative Example 1. FIG. As shown in Figure 6(a), the molded body formed by granulating particles using an organic liquid has voids compared to the molded body formed by not granulating finely pulverized powder (see Figure 6(b)). Fewer, denser shaped bodies.

[0154] The obtained molded body was heated up to 1080° C. in vacuum or in an Ar atmosphere, and held for 4 hours to perform sintering. Next, the obtained sintered body was subjected to two-stage aging treatment at 800° C.×1 hour and 560° C.×1 hour (both in an Ar atmosphere).

[0155] The measurement results of the magnetic properties of the obtained sintered body are shown in FIG. 4 . In addition, Fig. 4 also shows the magnetic properties of the sintered magnet of Comparative Example 1 and the...

no. 2 Embodiment

[0160] To the finely pulverized powder produced in the same manner as in the first example, 6 wt% of various organic liquids shown in FIG. 9 were added, and then granules were produced in the same manner as in the first example. For the obtained pellets, the angle of repose was measured in the same manner as in the first example. The results are shown together in FIG. 9 . In addition, FIG. 9 also shows the angle of repose of the finely pulverized powder before granulation. The particles obtained above were exposed for 20 to 300 minutes in a reduced-pressure atmosphere (room temperature) having a vacuum degree shown in FIG. 9 .

[0161] The obtained pellets were molded in a magnetic field in the same manner as in the first example to obtain a molded body.

[0162] The obtained compact was subjected to sintering and two-stage aging treatment under the same conditions as in the first example.

[0163] The measurement results of the magnetic properties of the obtained sintered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com