Calcium carbide slag powder and application thereof

A technology of calcium carbide slag powder and calcium carbide, which is applied in the field of solidified materials, can solve the problems of difficult promotion and high cost, and achieve the effects of accelerating reaction speed, reducing production power consumption, and reducing reaction heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Carbide slag powder solidification material is that the following raw materials are mixed in proportion and obtained by granulation, all in parts by weight:

[0033] Calcium carbide slag powder, containing 72% CaO and 20% C, 100 parts

[0034] Dry powder industrial adhesive 15 parts

[0035] The above-mentioned dry powder industrial binder is a combination of lime and starch in a weight ratio of 2:1.

[0036] During the granulation process of slag powder solidified material, it is absolutely forbidden to add aqueous solution. Carbide slag powder is mixed with dry powder industrial additives, sent to the feed port of dry powder granulator by conveyor, and granulated after extrusion.

Embodiment 2

[0037] Embodiment 2: Carbide slag powder solidification material is that following raw materials are mixed in proportion, and granulation obtains, and all are parts by weight:

[0038] Calcium carbide slag powder, containing 60% CaO and 15% C, 100 parts

[0039] Dry powder industrial adhesive 10 parts

[0040] The above-mentioned dry powder industrial binder is a combination of lime and starch in a weight ratio of 2:1.

Embodiment 3

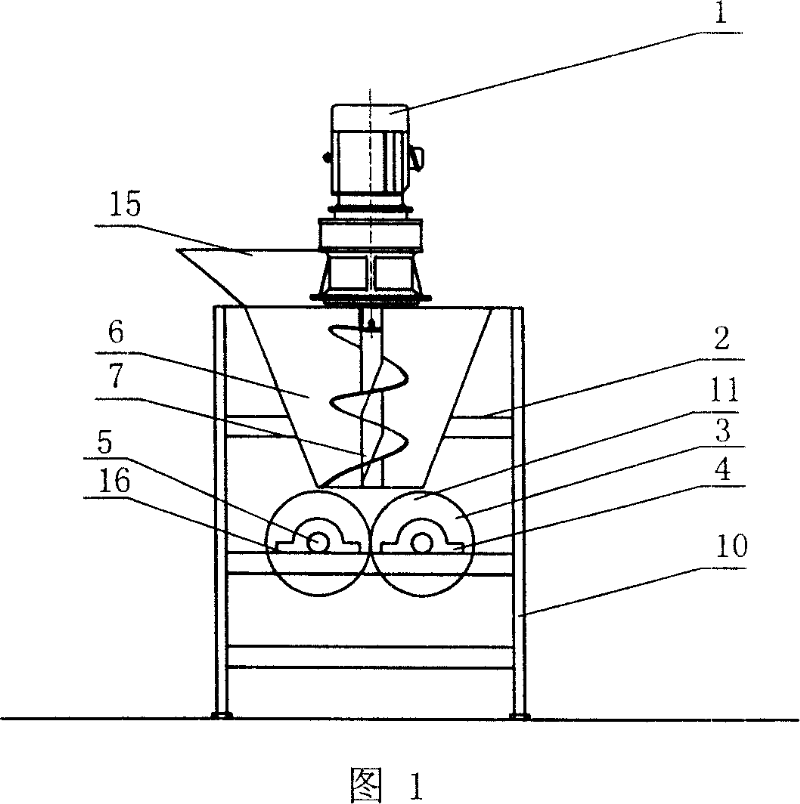

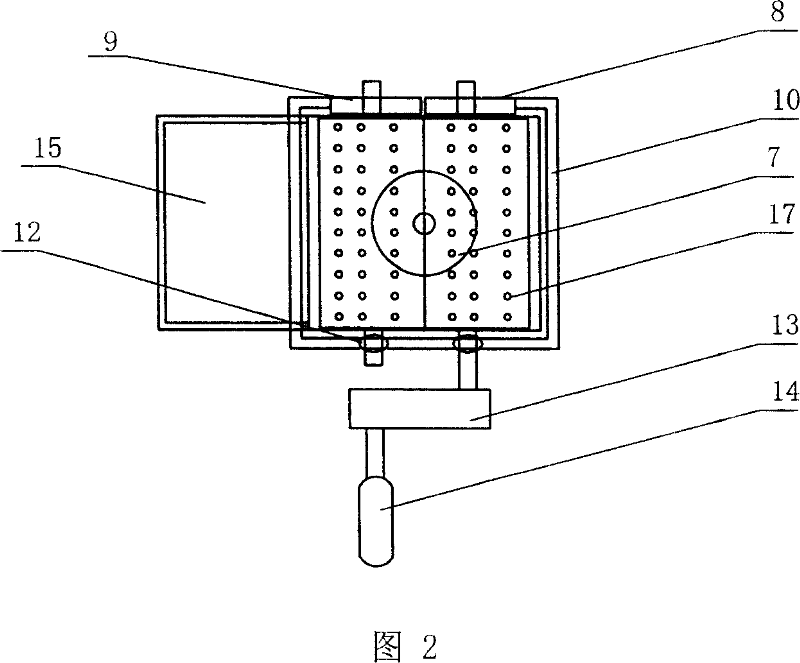

[0041] Embodiment 3: dry material solidification granulator, the structure is shown in Figure 1 and Figure 2.

[0042] Including motor 14, gearbox 13, two extrusion rollers 3, 11, screw device 7, motor 14 and gearbox 13 drive two oppositely rotating extrusion rollers 3, 11. In order to increase the strength of extrusion, a downward-rotating screw device 7 is installed in the middle of the feeding hopper 6 above the two extrusion rollers. The screw device is driven by the direct-coupled motor reducer 1 to push the powder into the Between the two extrusion rollers 3, 11, the extruded pellets have more strength and hardness, which can meet the requirements of extruding the pellets into granules without adding water. Described extruding roll is the round roll that has pit 17 on the surface. A feed opening 15 is provided on the upper side of the feed hopper 6 . The two linkage gears 8 and 9 are mounted on two bearings 5 and 12 respectively, the linkage gear 8 that is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com