Sound adsorption microsphere material and preparation method thereof

A technology of microspheres and wet materials, applied in the field of loudspeakers, to achieve the effects of long service life, good anti-aging ability, and good acoustic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

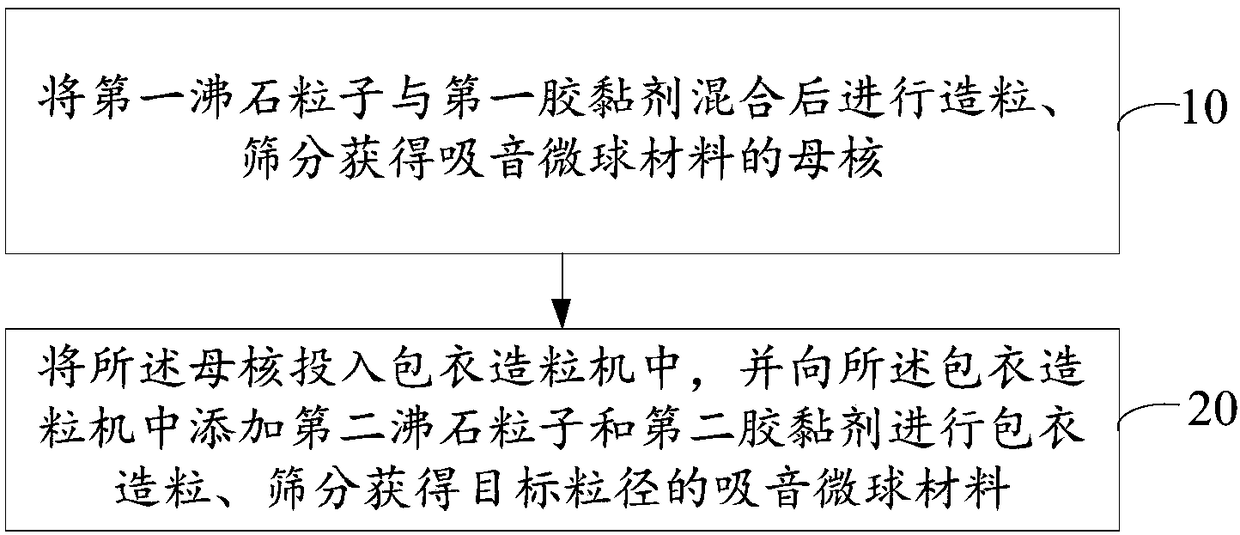

[0024] see figure 1 , figure 1 It is a schematic flow chart of a method for preparing a sound-absorbing microsphere material provided by an embodiment of the present invention, as figure 1 As shown, the method 100 includes:

[0025] Step 10, mixing the first zeolite particles with the first adhesive, granulating and sieving to obtain the core of the sound-absorbing microsphere material.

[0026] Wherein, the first zeolite particles can be zeolite particles with one or more of the following structures: FER zeolite, MFI zeolite, MEL zeolite, CHA zeolite, IHW zeolite, IWV zeolite, ITE zeolite, UTL zeolite, VET zeolite, MTW zeolite Or FAU zeolite. Preferably, the silicon-aluminum ratio of the zeolite particle raw material is greater than 200, and a higher silicon-aluminum ratio can increase the hydrophobicity of the zeolite particle, reduce the hygroscopicity of the sound-absorbing microsphere material, and thus increase its aging resistance.

[0027] The zeolite raw material ...

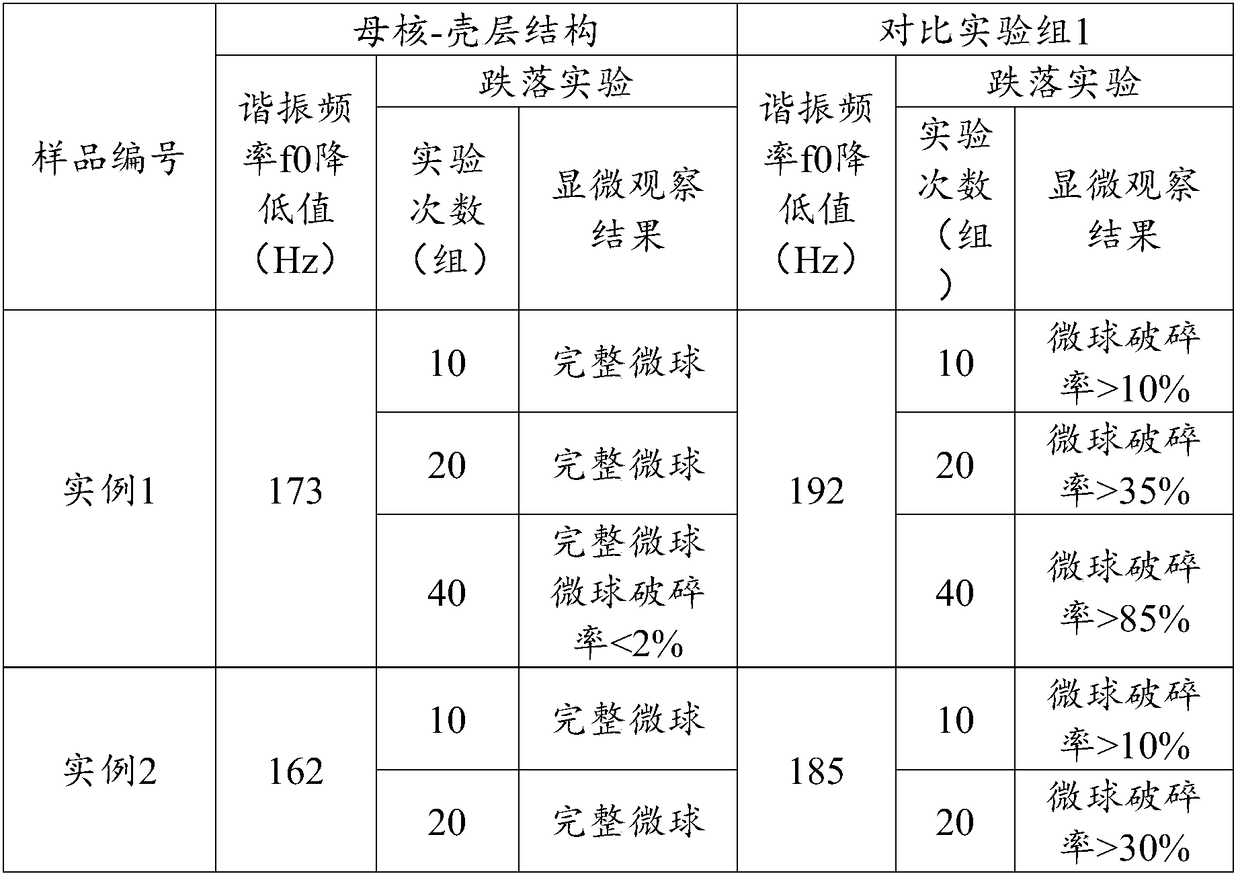

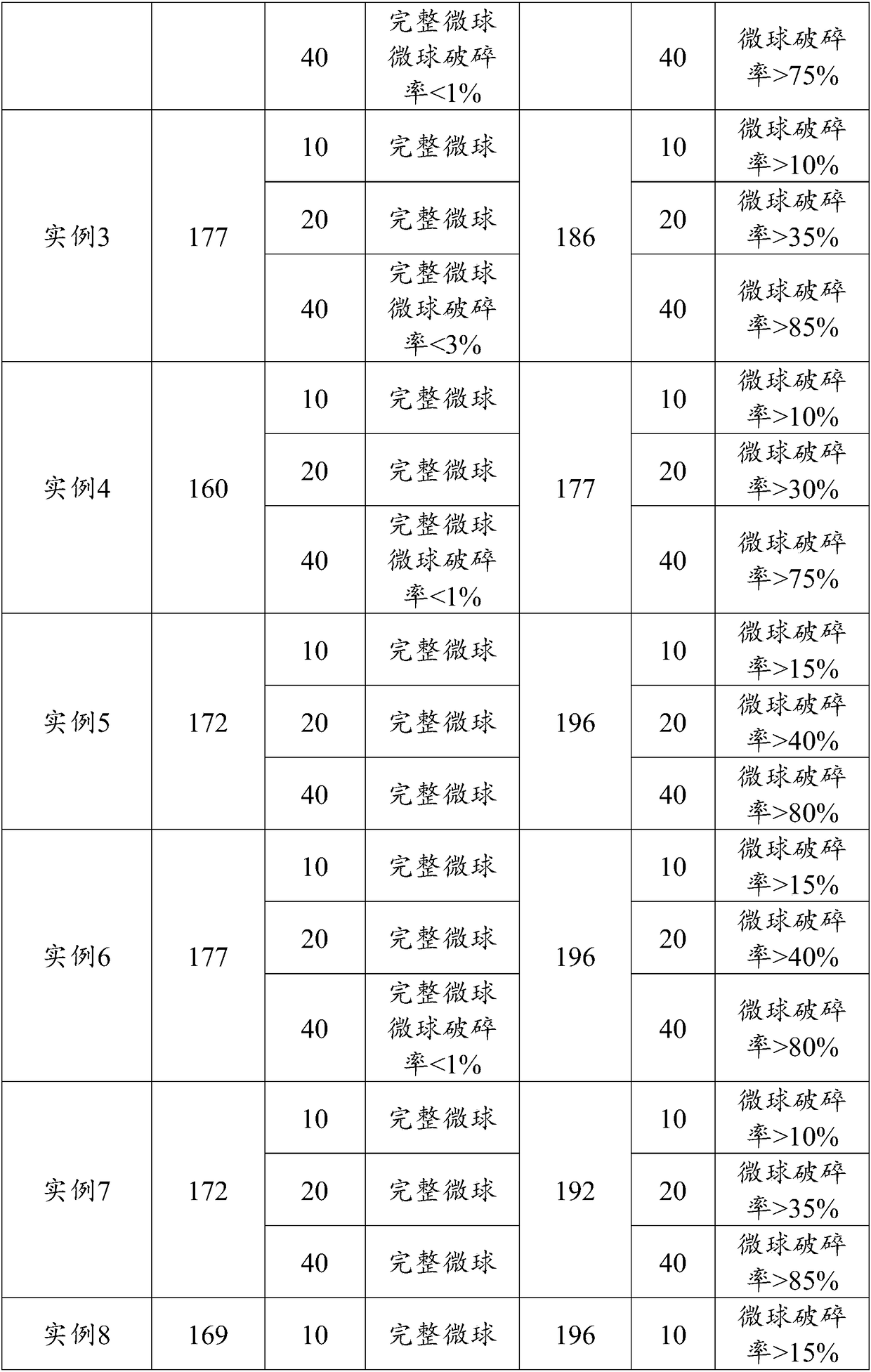

Embodiment 1

[0052] 1) In terms of parts by mass, 100 parts of dry zeolite raw material particles (the zeolite structure is FER, the average pore diameter of micropores is about 0.49nm, and the particle diameter is about 2.5μm), 50 parts of water and 5 parts of silica sol. wet material.

[0053] 2) The above wet material was screened with a 60-mesh screen, and then extruded and spheronized by an extrusion spheronizer, wherein the rotation speed of the spheronizer's turntable was 400r / min and the spheronization time was 5min to obtain a preliminary formed mother core.

[0054] 3) Heat, solidify, and dry the above-mentioned preliminarily formed core in an oven at 120°C for 1.5 hours to obtain a dry core, and then sieve the above-mentioned dry core with a 60-65 mesh screen to obtain a 230-250 μm diameter Sound-absorbing microsphere material core.

[0055] 4) Uniformly mix the zeolite raw material particles with the polystyrene-acrylate emulsion in advance, and mechanically stir at 1000 rpm a...

Embodiment 2

[0059] 1) In terms of parts by mass, 100 parts of dry zeolite raw material particles (the zeolite structure is FER, the average pore diameter of micropores is about 0.49nm, and the particle diameter is about 2.5μm), 50 parts of water and 6 parts of silica sol. wet material.

[0060] 2) Screen the above wet material with a 50-mesh screen, and then use an extrusion spheronizer to extrude and spheronize. The spheronizer rotates at a speed of 400r / min and spheronizes for 5 minutes to obtain a preliminarily formed mother core.

[0061] 3) Heat, solidify, and dry the above-mentioned preliminarily formed core in an oven at 120°C for 1.5 hours to obtain a dry core, and then sieve the above-mentioned dry core with a 50-60 mesh screen to obtain a 250-270 μm diameter Sound-absorbing microsphere material core.

[0062] 4) Uniformly mix the zeolite raw material particles with the polyurethane emulsion in advance, and mechanically stir at 1000 rpm at room temperature to obtain a uniformly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com