High-strength zeolite bead molding and method for producing the same

A manufacturing method and a technology for a shaped body, which are applied in separation methods, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problems of high shaped body, inability to use Freon desiccant, and inability to obtain sphericity, etc. Excellent effect of strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 40 parts by weight of kaolin clay was mixed with 100 parts by weight of zeolite (K ion-exchanged A-type zeolite), and then 50 parts by weight of water was mixed with 100 parts by weight of the total of zeolite and kaolin clay, and tumbling granulation was performed, and sieving was used. A preform of 1.7 mmφ was obtained. The water content (in terms of loss on ignition when calcined at 900° C.) of the molded preform was 36 parts by weight. With respect to 100 parts by weight of the solid content of the preform, add 3 parts by weight of kaolin clay from a different production area from that used in the molding of the molded body, adjust the water content of the molded body to 37 parts by weight with a sprayer, and continue A 70-minute rolling mill was performed. Thereafter, it was dried and fired at 680° C. for 5 hours.

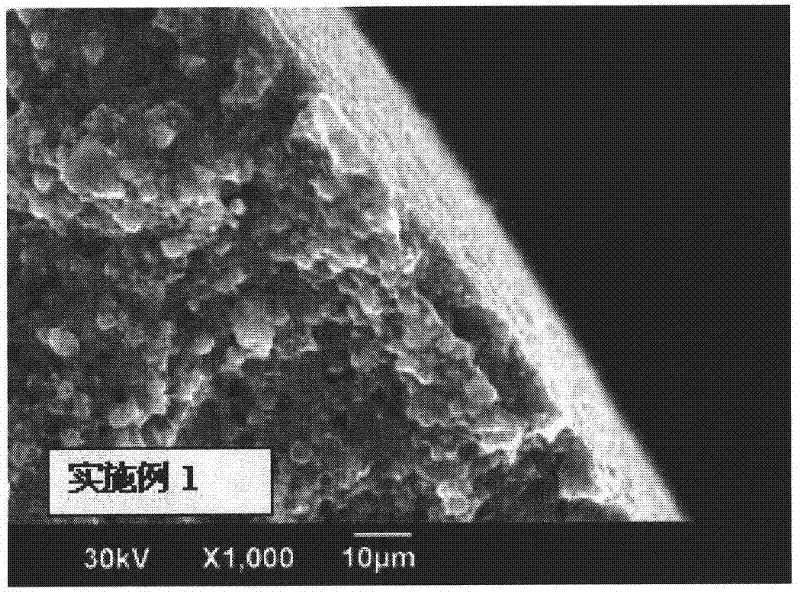

[0072] The characteristics of the obtained bead molded body are shown in Table 1, and the cross-section (surface) of the shaped body after sizing is ...

Embodiment 2

[0074] The same process as in Example 1 was performed except that kaolin clay from the same production area was used in molding and tumbling sizing, and that the binder added during tumbling sizing was 0.1 parts by weight.

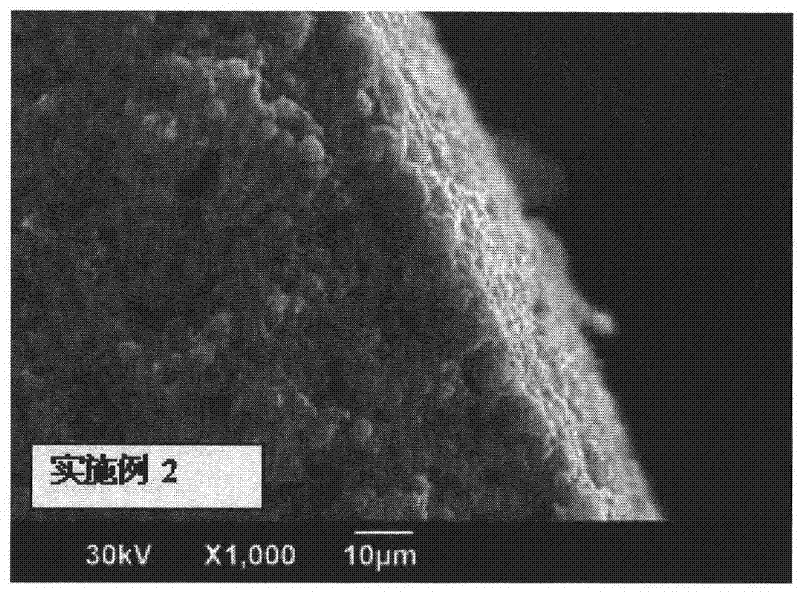

[0075] The characteristics of the obtained bead molded body are shown in Table 1, and the cross-section (surface) of the shaped body after sizing is shown in Table 1. figure 2 . Confirm that a protective film is formed on the surface of the molded article.

Embodiment 3

[0077] 43 parts by weight of kaolin clay was mixed with 100 parts by weight of zeolite (K ion-exchanged A-type zeolite), and then 55 parts by weight of water was mixed with 100 parts by weight of the total of zeolite and kaolin clay, and formed by tumbling granulation and sieving A preform of 1.7 mmφ was obtained. The water content (in terms of loss on ignition when calcined at 900° C.) of the molded preform was 38 parts by weight. With respect to 100 parts by weight of the solid content of the preform, add 3 parts by weight of kaolin clay from the same origin as that used in the molding of the molded product, adjust the water content of the molded product to 39 parts by weight with a sprayer, and continue 70 minutes of rolling whole grains. Thereafter, it was dried and fired at 680° C. for 5 hours.

[0078] Table 1 shows the characteristics of the obtained bead molded body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com