Polyamide composition and preparation method and application thereof

A polyamide composition and polyamide technology, applied in the field of polyamide composition, can solve problems such as easy color difference, failure to meet requirements, easy moisture absorption, etc., achieve the effect of reducing color change and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

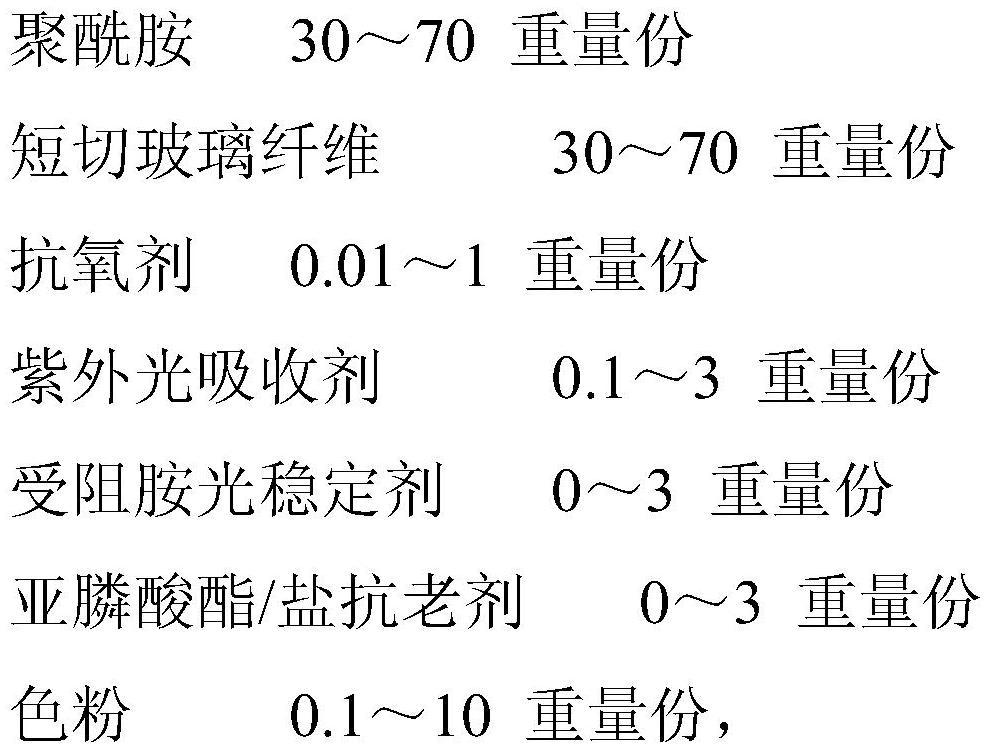

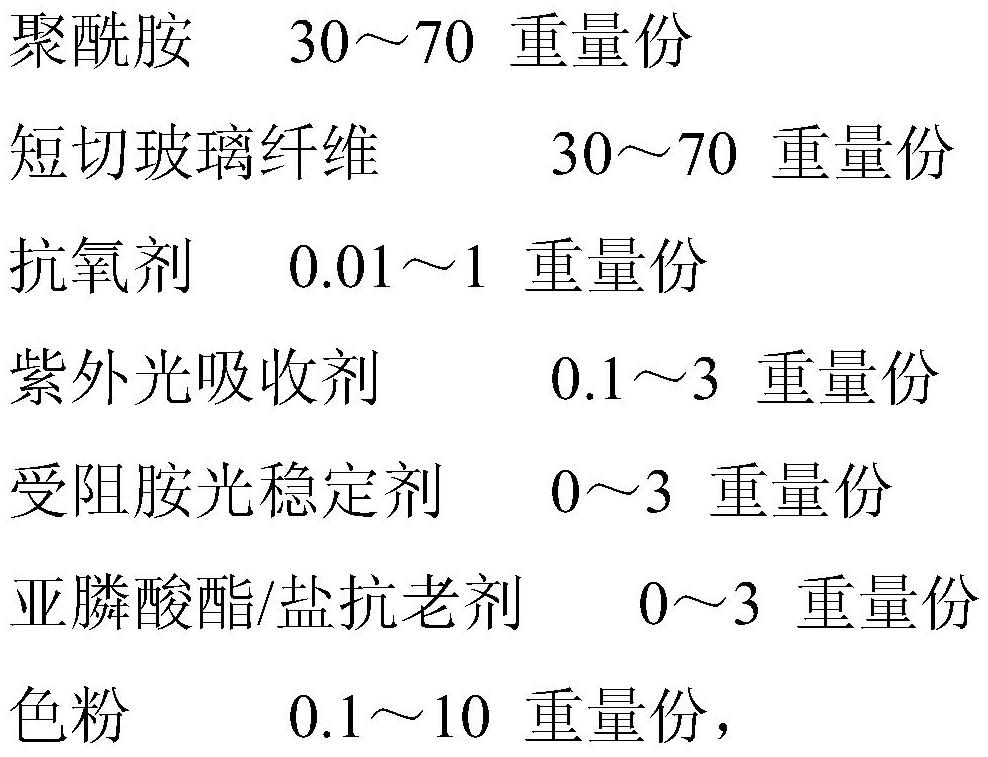

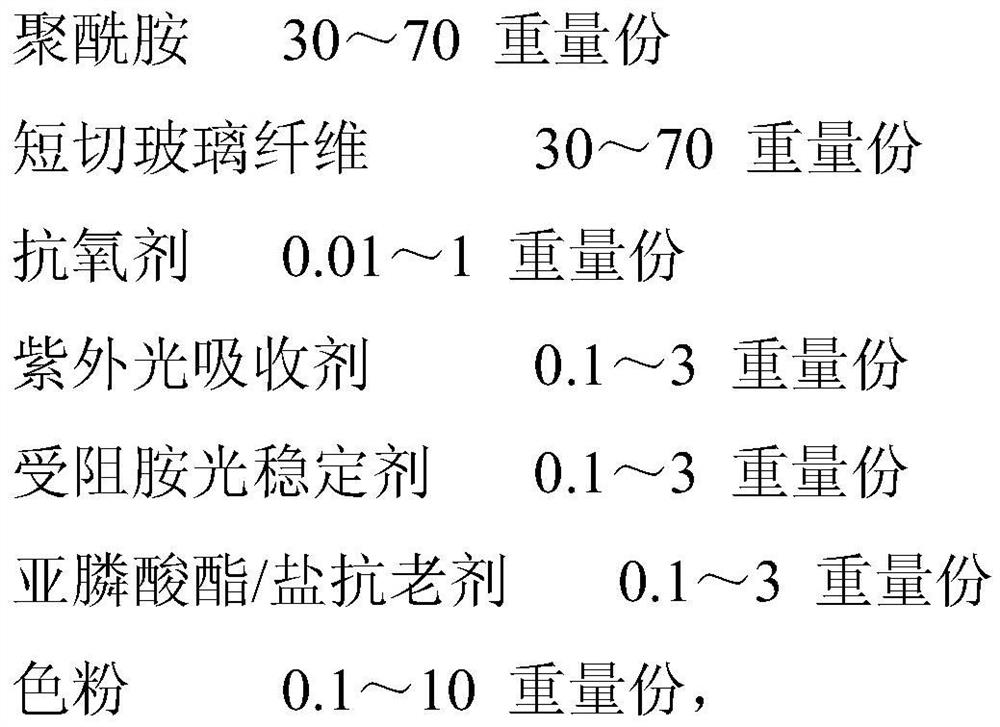

Method used

Image

Examples

preparation example Construction

[0065] According to one aspect of the present invention, a kind of preparation method of polyamide composition is provided, and this method can be used for preparing the polyamide composition as described in this application, and this method comprises the steps:

[0066] Step 1, preparing raw materials: prepare each raw material according to the aforementioned components and parts by weight;

[0067] Step 2, mixing and extruding: mixing and extruding the prepared raw materials.

[0068] According to one aspect of the present invention, polyamide, and other components such as antioxidant, UV absorber, hindered amine light stabilizer, phosphonite / salt antiaging agent, toner Mix and stir evenly, and then add to the extruder (for example, twin-screw extruder); out, cooled, drawn and pelletized to obtain the polyamide composition of the present invention.

[0069] According to one aspect of the present invention, the extrusion temperature is 260-330 degrees Celsius, for example, ...

Embodiment 1

[0084] The natural color anti-ultraviolet aging polyamide composition of the present embodiment is composed of the following components by weight: 33.4 parts of polyamide PA612, 11.2 parts of polyamide PA6I / 6T, 55 parts of chopped glass fibers, and 0.25 parts of hindered phenols Antioxidant 1010, 0.15 parts of phosphite antioxidant 168, 1.5 parts of UV absorber 2-(2H-benzotriazole-2)-4,6-bis(1-methyl-1-phenyl Ethyl)-phenol, 0.3 parts of hindered amine light stabilizer N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-N,N'-dialdehyde hexamethylenediamine .

[0085] The preparation method of the natural color UV aging resistant polyamide composition of this Example 1 is the same as that of Comparative Example 1.

Embodiment 2

[0087] The natural color anti-ultraviolet aging polyamide composition of the present embodiment is composed of the following components by weight: 33.4 parts of polyamide PA612, 11.2 parts of polyamide PA6I / 6T, 55 parts of chopped glass fibers, and 0.25 parts of hindered phenols Antioxidant 1010, 0.15 parts of phosphite antioxidant 168, 1.5 parts of UV absorber 2-(2H-benzotriazole-2)-4,6-bis(1-methyl-1-phenyl Ethyl)-phenol, 0.3 parts of anti-aging agent sodium phenylphosphinate.

[0088] The preparation method of the natural color UV-resistant polyamide composition of Example 2 is the same as that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com