Flame-retardant polyamide compositions and use thereof

A kind of polyamide composition, flame retardant technology, applied in the field of molded parts, flame retardant polyamide composition, can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

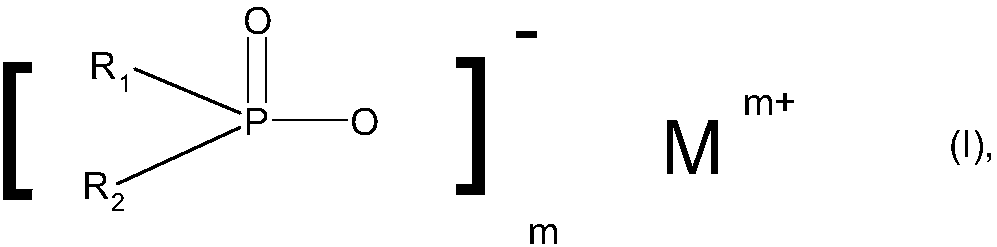

[0203] Aluminum salt of diethylphosphinic acid comprising 0.9 mol% of aluminum ethylbutylphosphinate and 0.5 mol% of aluminum ethylphosphonate, prepared according to example 3 of US 7,420,007B2

[0204] Flame retardant FM 2 (components C, D and E):

Embodiment 4

[0205] Aluminum salt of diethylphosphinic acid, comprising 2.7 mol % aluminum ethylbutylphosphinate and 0.8 mol % aluminum ethylphosphonate, prepared according to Example 4 of US 7,420,007 B2

[0206] Flame retardant FM 3 (components C, D and E):

[0207] Aluminum salt of diethylphosphinic acid, comprising 0.5 mol% of aluminum ethylbutylphosphinate and 0.05 mol% of aluminum ethylphosphonate, prepared according to the method of US 7,420,007B2

[0208] Flame retardant FM 4 (components C, D and E):

[0209] Aluminum salt of diethylphosphinic acid, comprising 10 mol% of aluminum ethylbutylphosphinate and 5 mol% of aluminum ethylphosphinate, prepared according to the method of US 7,420,007B2

[0210] Flame retardant FM 5 (component C):

[0211] Aluminum salt of diethylphosphinic acid, prepared analogously to Example 1 of DE 196 07 635 A1

[0212] Flame retardant FM 6 (components C and E):

[0213] Aluminum salt of diethylphosphinic acid, containing 8.8 mol % of aluminum ethylph...

Embodiment 1

[0215] Aluminum salt of phosphonic acid, prepared according to Example 1 of DE 10 2011 120 216 A1

[0216] Flame retardant FM 8 (component F):

[0217] Melamine polyphosphate, prepared according to the examples of WO 2000 / 002869A1

[0218] Flame retardant FM 9 (not according to the invention):

[0219] Melamine polyphosphate with an average degree of condensation of 18, prepared analogously to WO 2000 / 002869A1

[0220] Antioxidant (Component G)

[0221] N,N'-bis[3-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionyl]-hexamethylenediamine ( 1098, BASF)

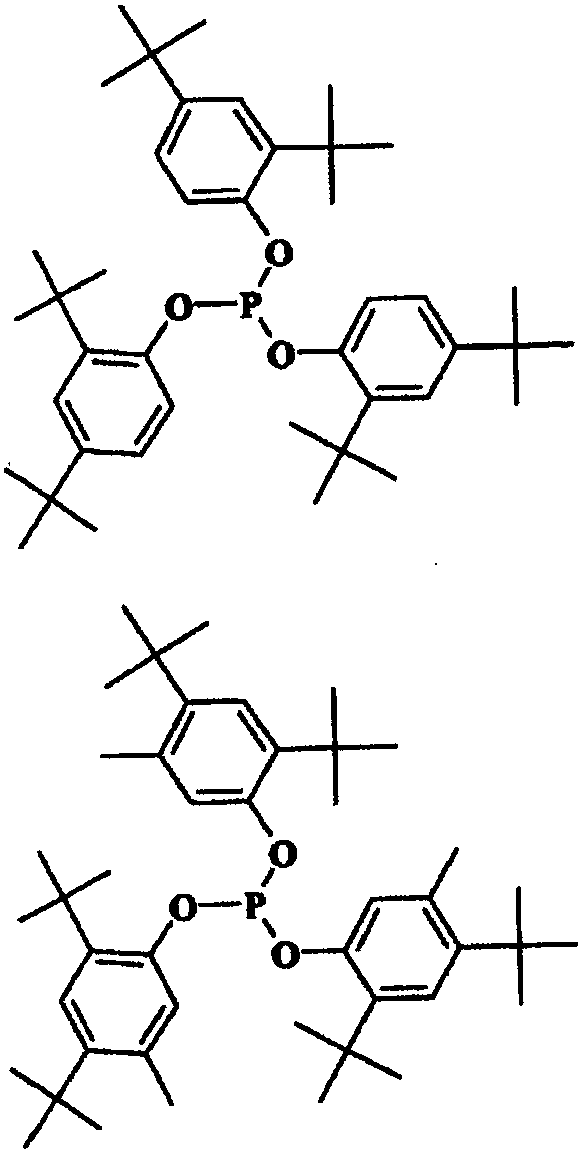

[0222] Costabilizer H 1 (Component H)

[0223] Tris(2,4-di-tert-butylphenyl)phosphite ( 168, BASF)

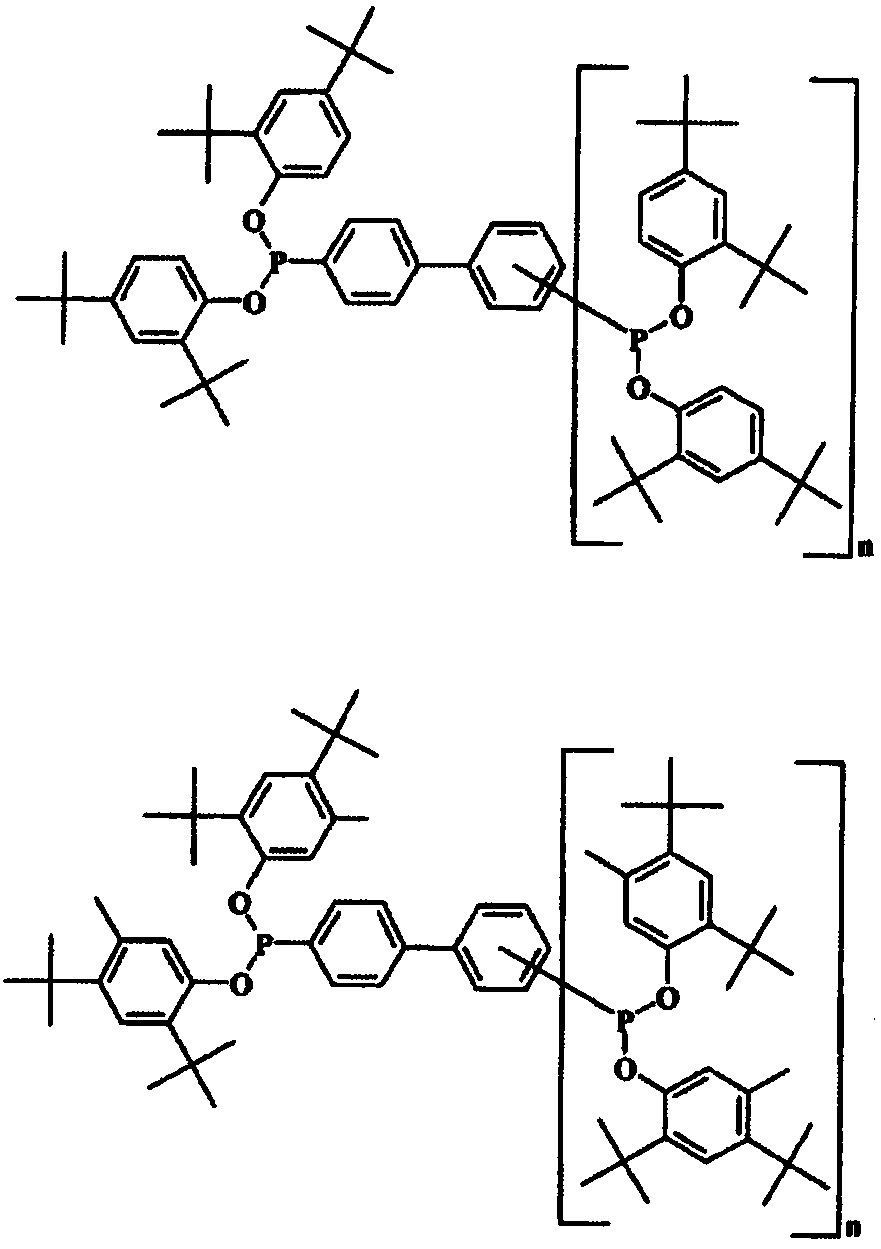

[0224] Costabilizer H2 (Component H)

[0225] Tetrakis(2,4-di-tert-butylphenyl)-[1,1-biphenyl]-4,4'-diylbisphosphonite ( P-EPQ, Clariant)

[0226] 2. Preparation, processing and testing of flame retardant polyamide molding compound

[0227] The flame retardant component was mixed with the antioxidant and with the co-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com