Optical film, method for producing same, polarizing plate using same and liquid crystal display device

A manufacturing method and technology of optical film, applied in the field of optical film, capable of solving problems such as film breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

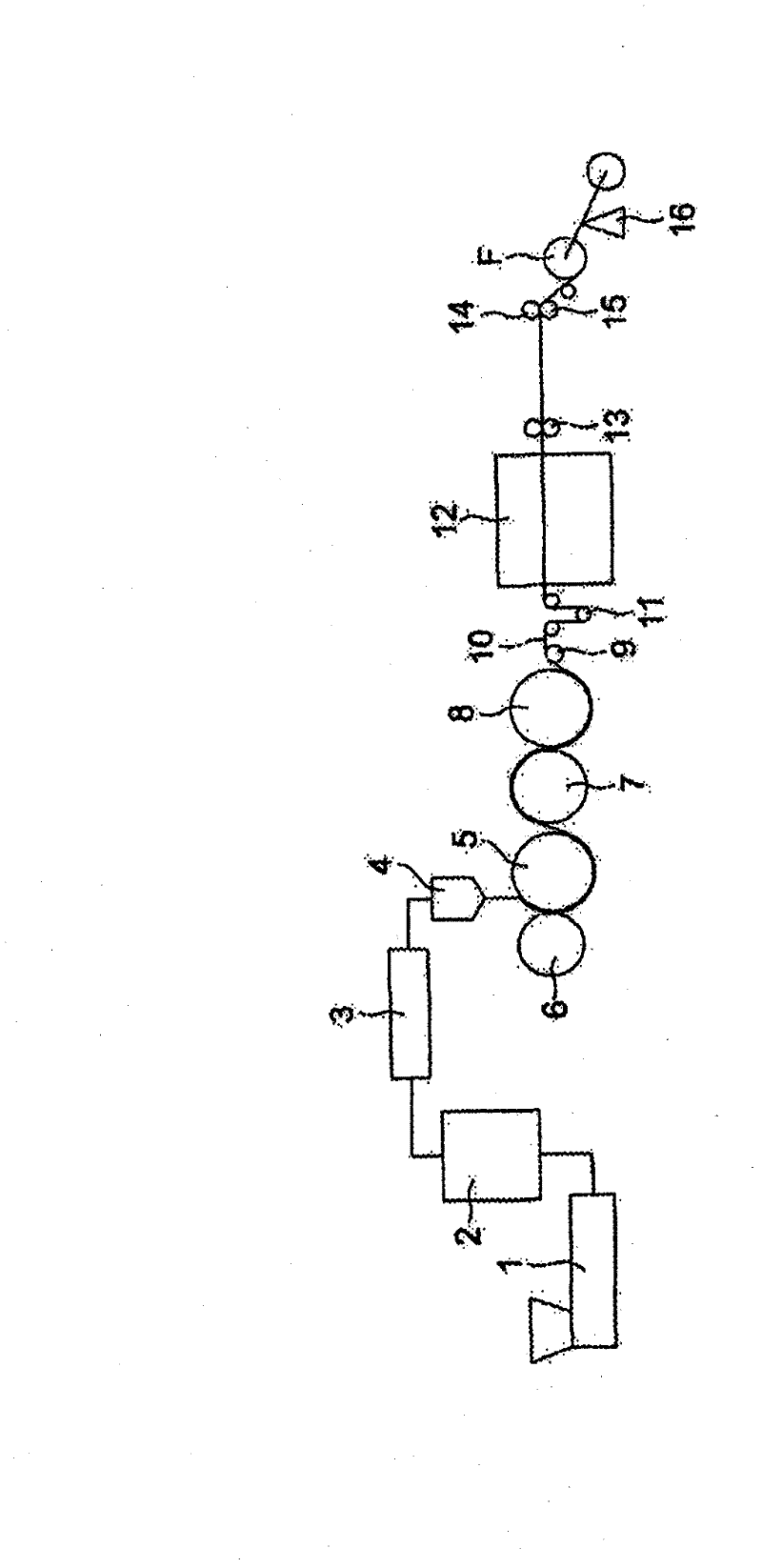

Method used

Image

Examples

Embodiment 1

[0349] [Preparation of acrylic resin]

[0350] As the acrylic resin used in the present invention, the following commercially available acrylic resins were used.

[0351] Daiyanaichiru BR83 (manufactured by Mitsubishi Rayon Co., Ltd.) Mw40000

[0352] Dayanaichiru BR85 (manufactured by Mitsubishi Rayon Co., Ltd.) Mw280000

[0353] Acrypet VH-4 (manufactured by Mitsubishi Rayon Co., Ltd.) Mw140000

[0354] Acrypetus V (manufactured by Mitsubishi Rayon Co., Ltd.) Mw105000

[0355] The ratio of the MMA unit in the molecule in the acrylic resin used in the present invention is 90% by mass or more and 99% by mass or less.

[0356] [Preparation of acrylic particles]

[0357]

[0358] In a reactor with an internal volume of 60 liters and a reflux condenser, 38.2 liters of ion-exchanged water and 111.6 g of sodium dioctyl sulfosuccinate were put in, stirred at a rotation speed of 250 rpm, and the temperature was raised to 75 ° C under a nitrogen atmosphere at the same time, Mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com