Technology and equipment for continuously producing 3-(methyl hydroxyl phosphonyl) propionaldehyde

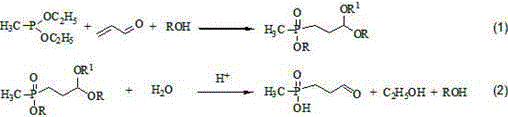

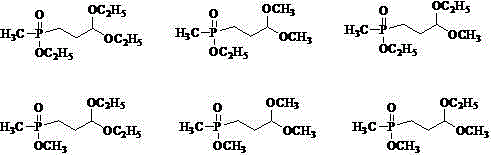

A technology of methyl hydroxy phosphono and diethyl methyl phosphonite is applied in the field of continuous production of 3-propionaldehyde, and can solve the problems of unsuitability for large-scale industrial production, unstable product quality and high labor intensity, Achieve the effect of low production cost, high degree of automation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

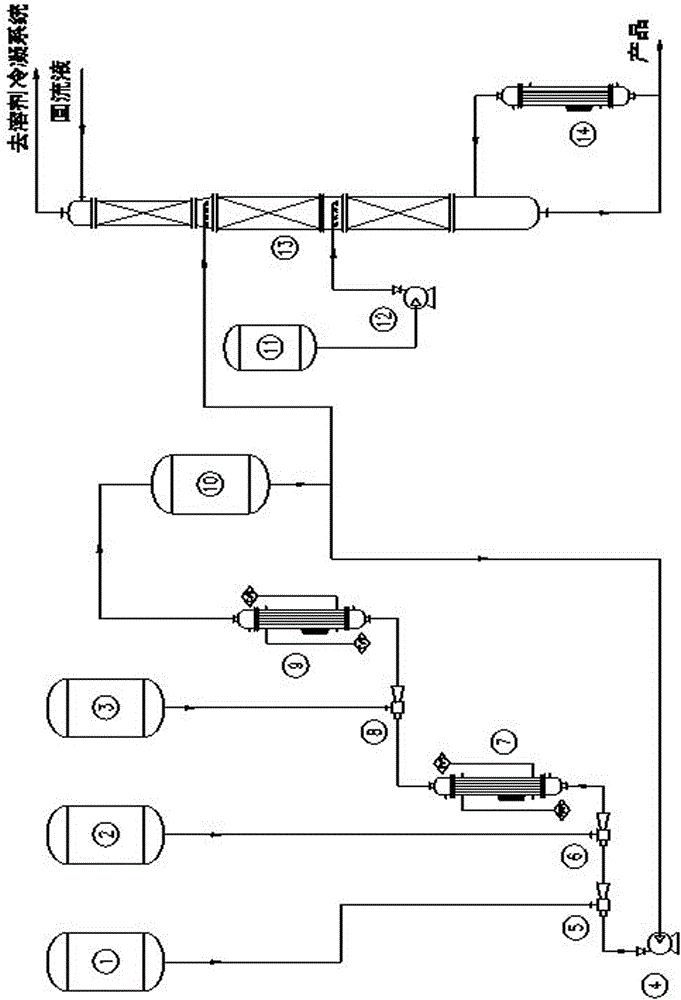

[0030] Such as figure 1As shown, the equipment for continuous production of 3-(methylhydroxyphosphono) propionaldehyde includes acrolein metering tank 1, alkyl alcohol metering tank 2, diethyl methylphosphonite metering tank 3, the first circulation pipe type Reactor 7, second circulating tubular reactor 9, intermediate storage tank 10, dilute acid solution metering tank 11 and reaction tower 13; the acrolein metering tank 1, alkyl alcohol metering tank 2 and methylphosphonous acid The discharge port of the diethyl ester metering tank 3 is connected with the feed ports of the first to the third jet mixer 5, 6, 8 respectively, and the first jet mixer 5 and the second jet mixer 6 are connected in series The feed port of the first circulating tubular reactor 7, the discharge port of the first circulating tubular reactor 7 connects the charging port of the second circulating tubular reactor 9 through the 3rd jet mixer 8, the second circulation The discharge port of the tubular re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com