Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Yield loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

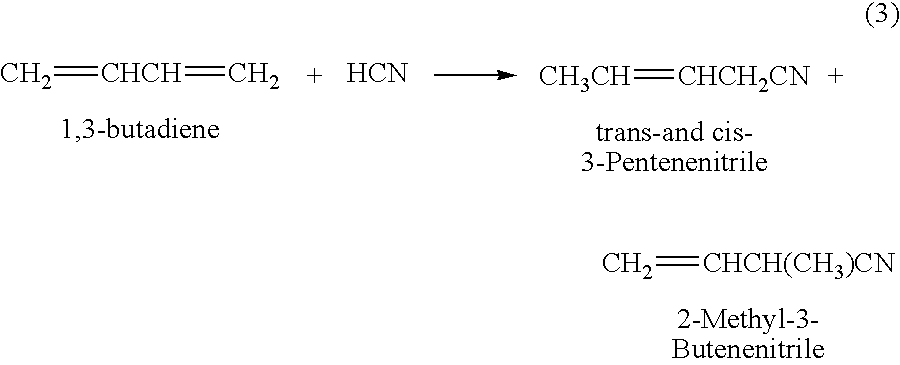

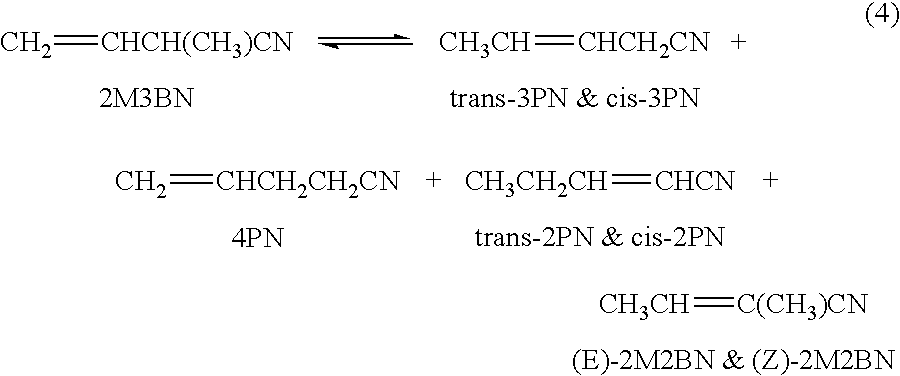

Hydrocyanation process with reduced yield losses

ActiveUS20080015381A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionNitriteHydrogen

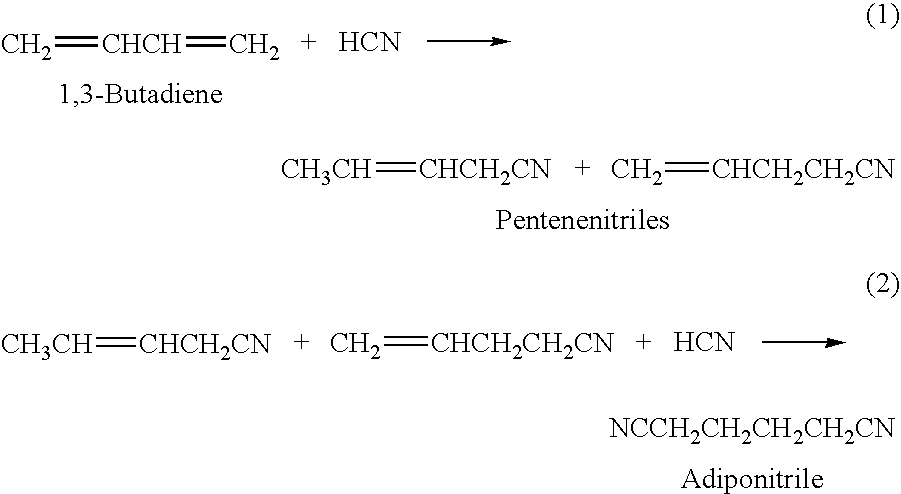

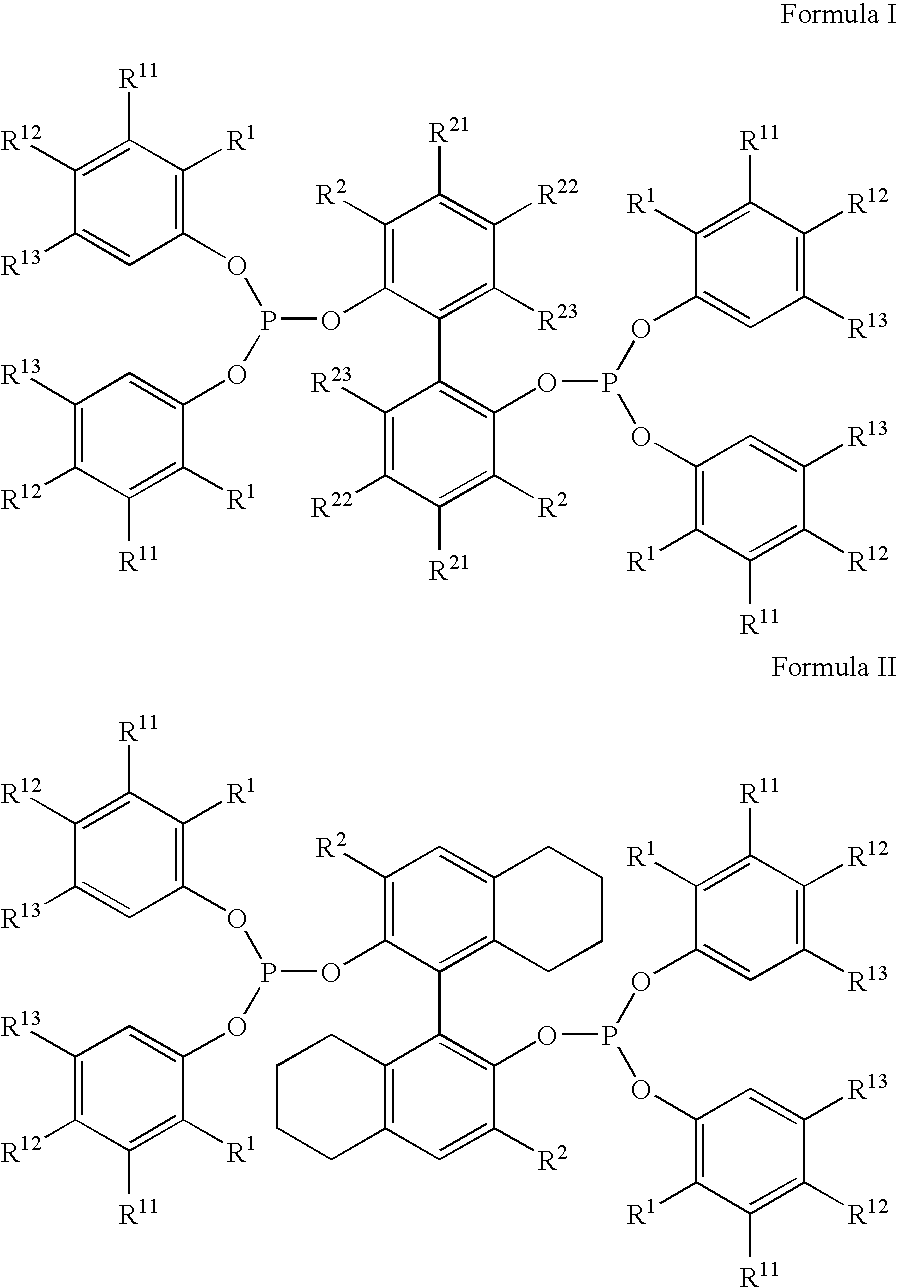

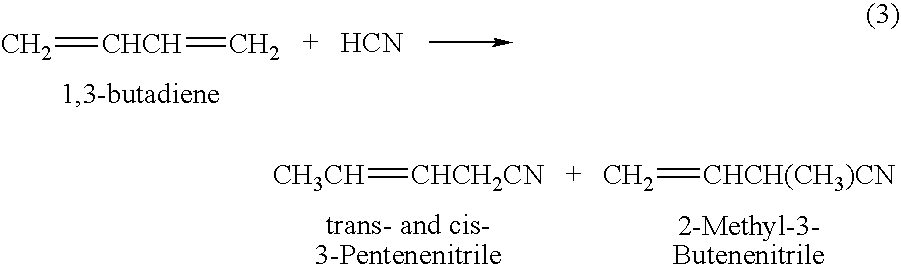

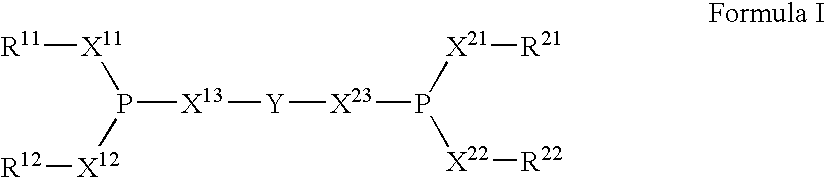

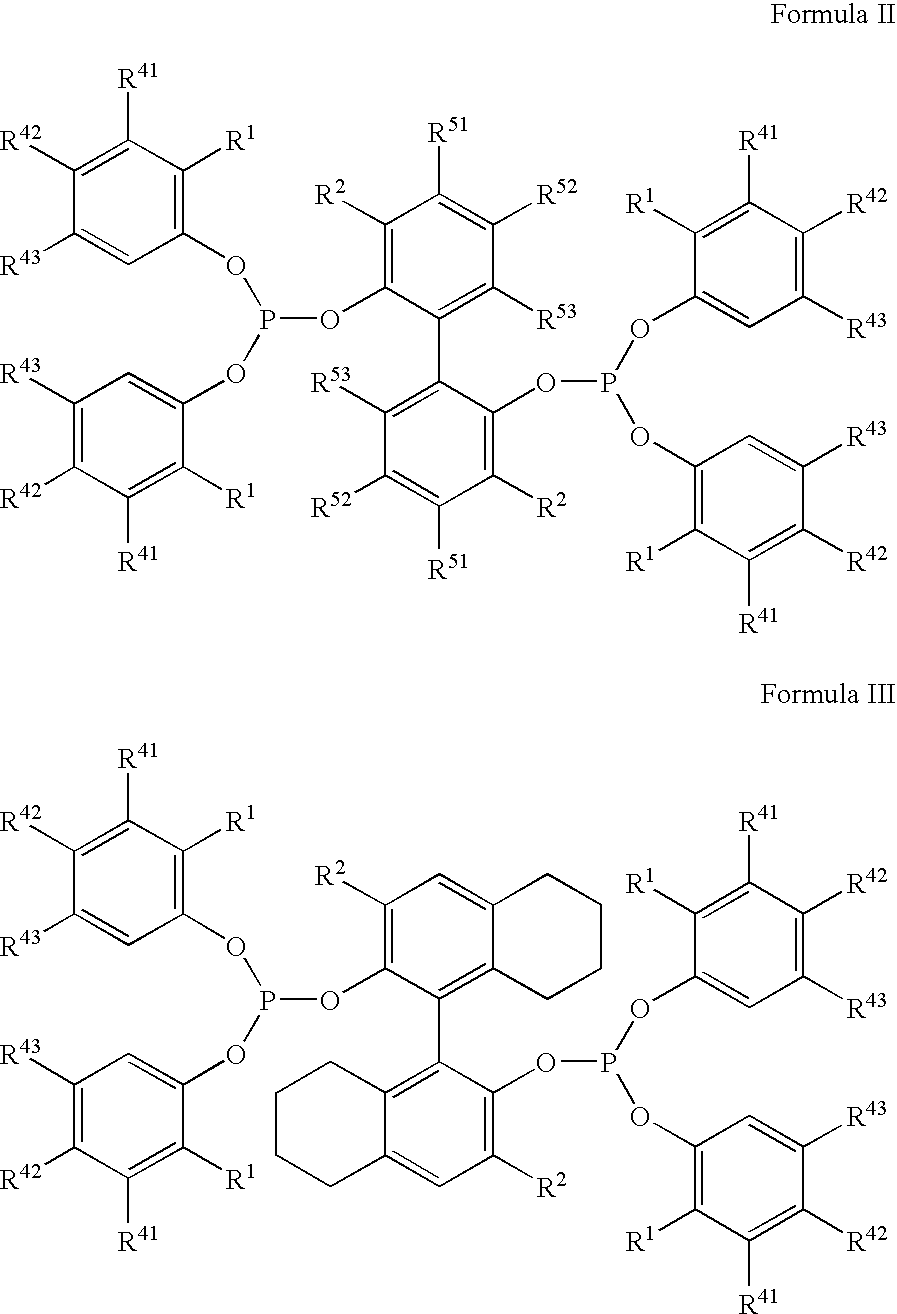

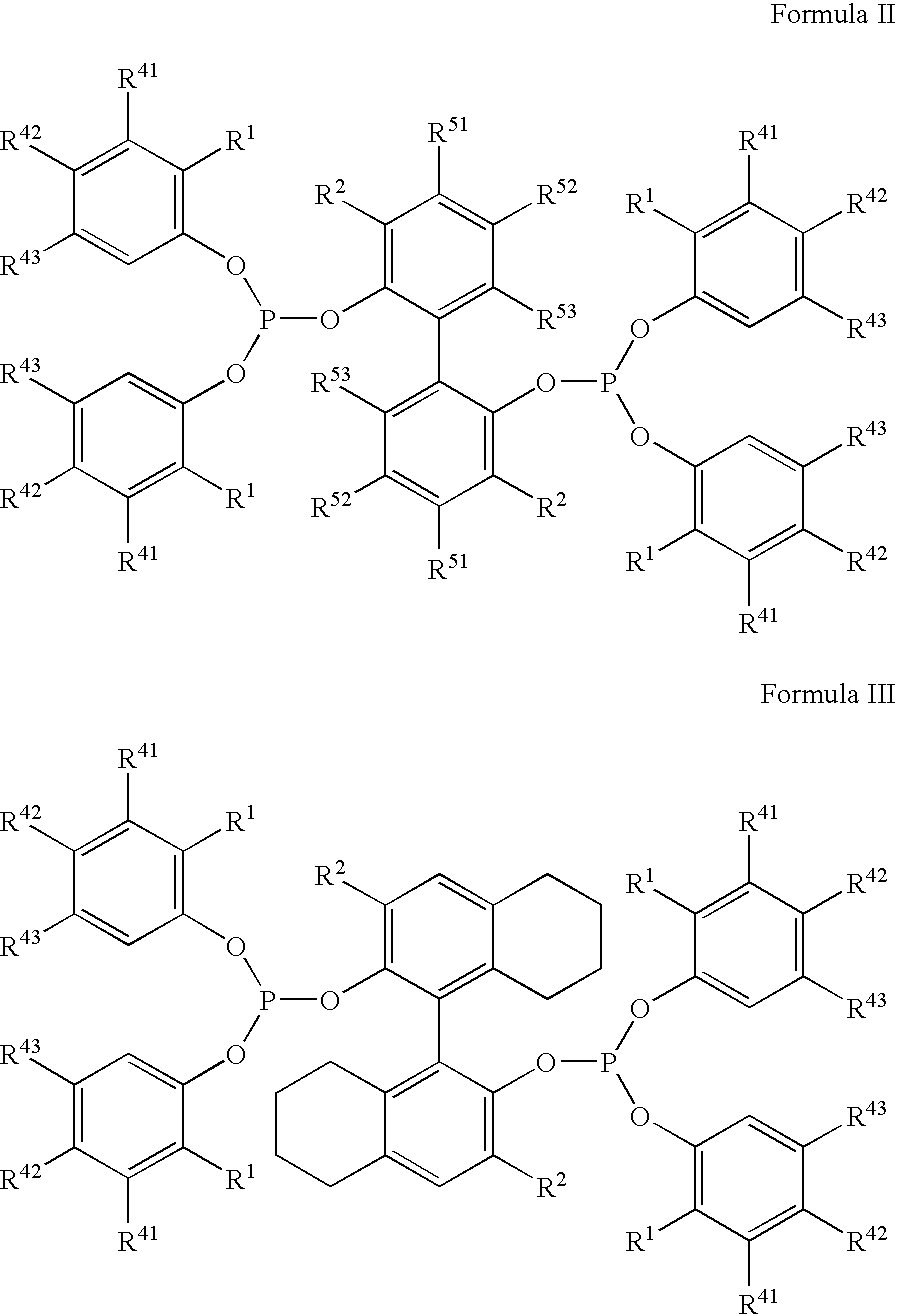

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitrites, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed)(molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one bidentate phosphite ligand; andwherein the bidentate phosphite ligand is selected from a member of the group represented by Formulas I and 11 as described herein.

Owner:INV NYLON CHEM AMERICAS LLC

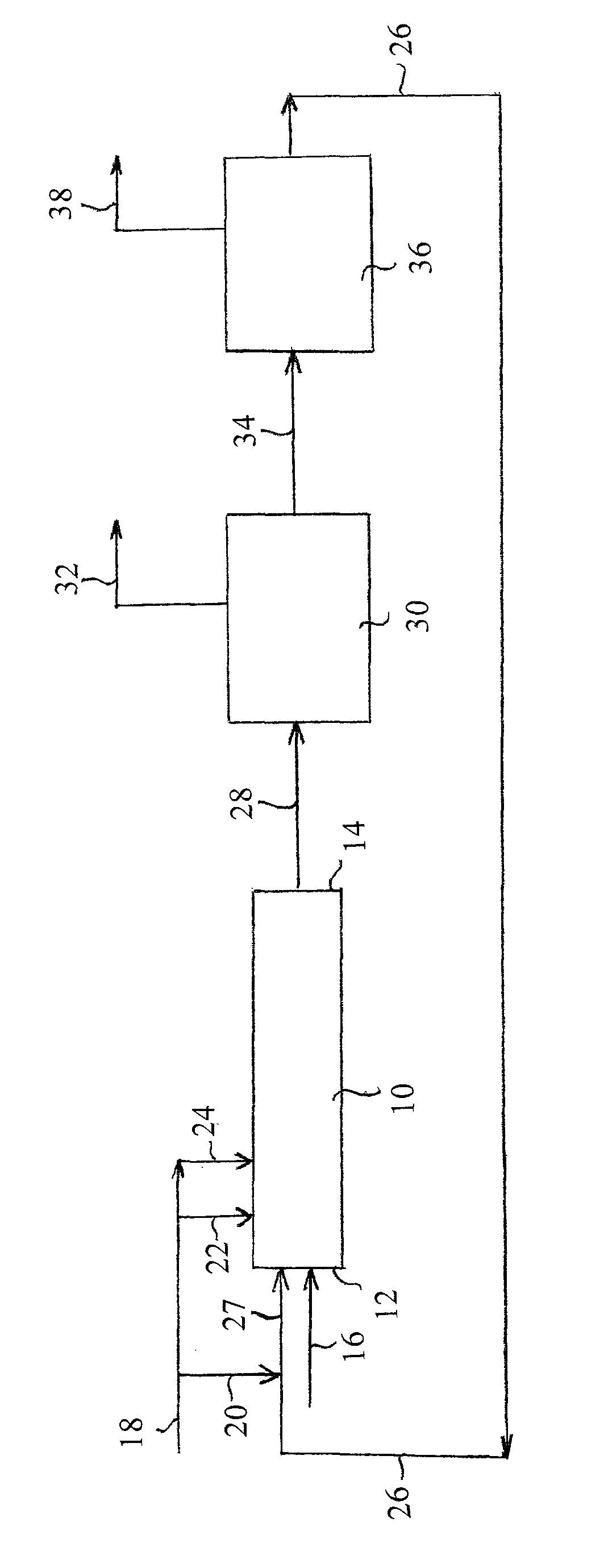

Apparatus and method for preparing microparticles

InactiveUS6331317B1Yield lossEasy to zoom inPowder deliveryOrganic active ingredientsEmulsionMicroparticle

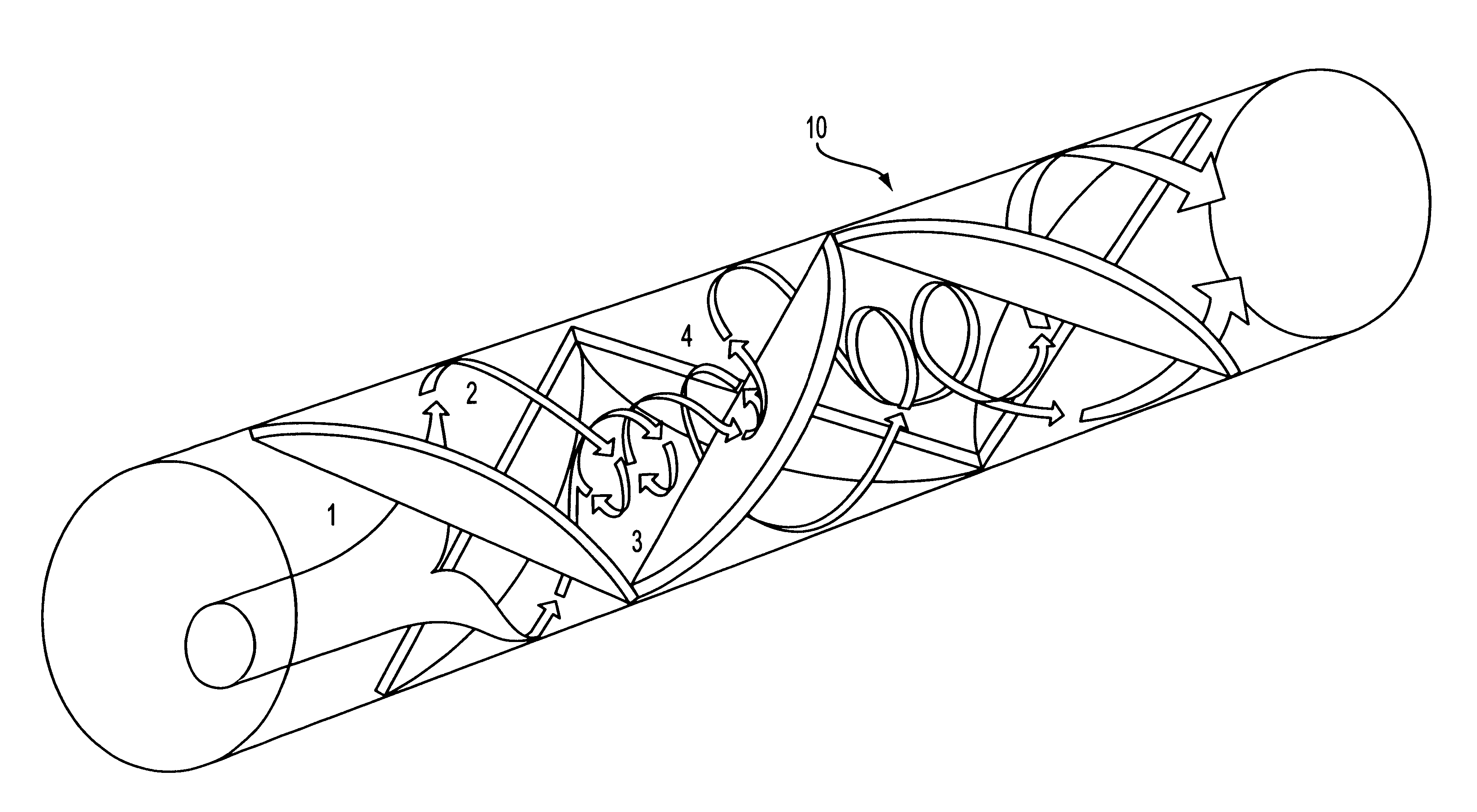

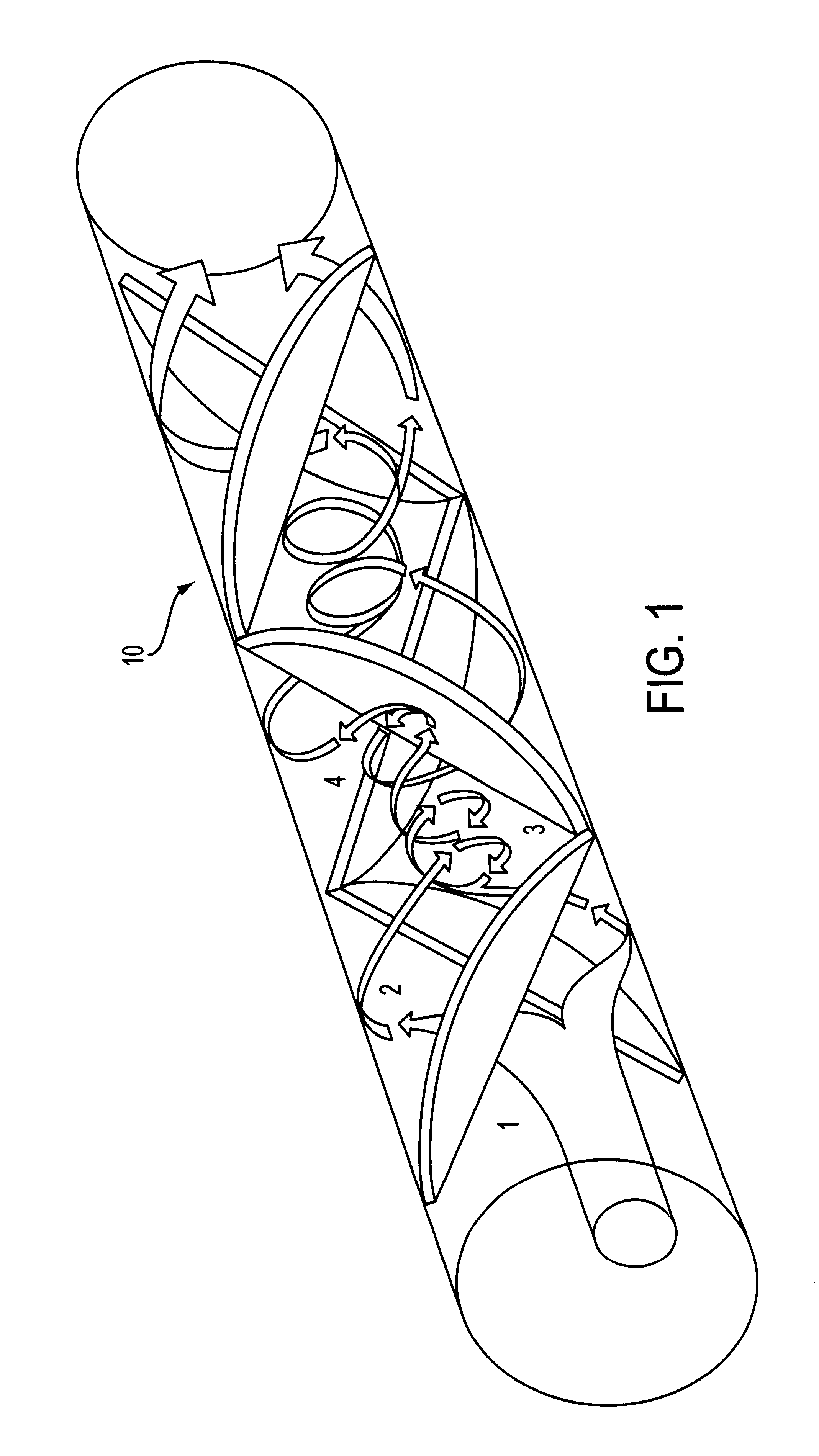

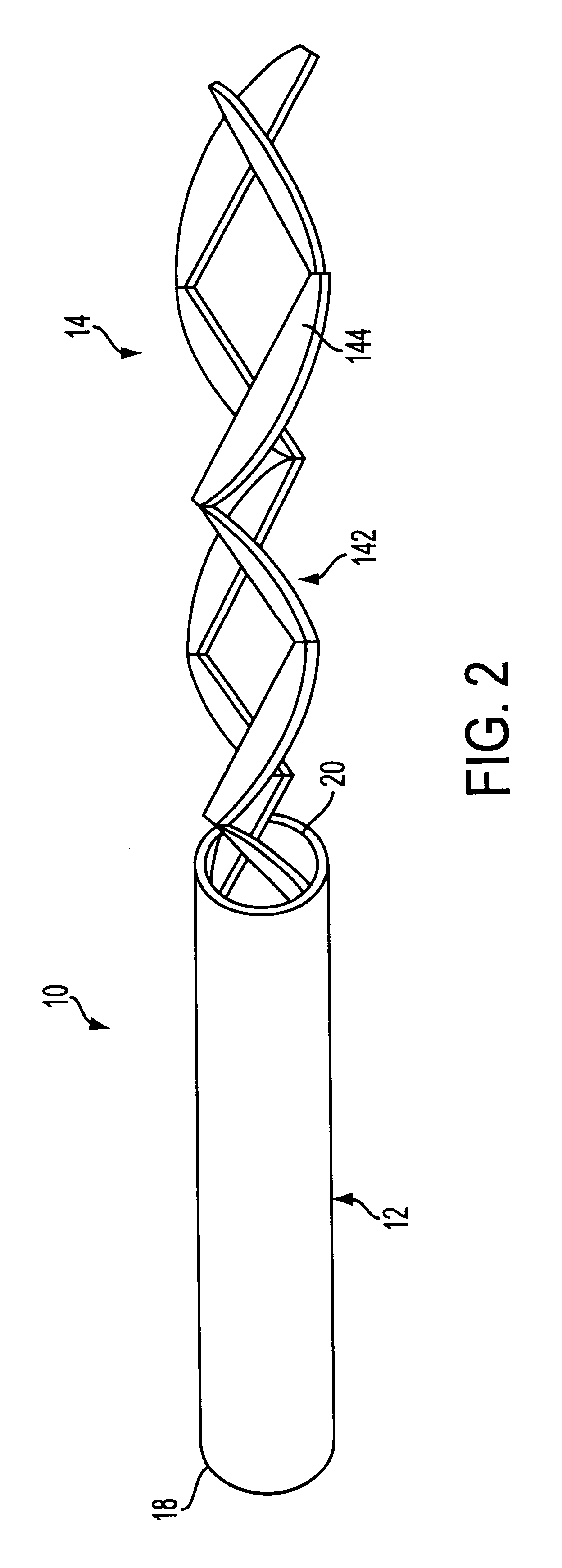

Apparatus and method for preparing microparticles. An emulsion is formed by combining two phases in a static mixing assembly. The static mixing assembly preferably includes a preblending static mixer and a manifold. The emulsion flows out of the static mixing assembly into a quench liquid whereby droplets of the emulsion form microparticles. The residence time of the emulsion in the static mixing assembly is controlled to obtain a predetermined particle size distribution of the resulting microparticles.

Owner:ALKERMES INC

Hydrocyanation process with reduced yield losses

ActiveUS20080015382A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionHydrogenPhosphite ester

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitriles having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitriles, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitriles, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed) / (molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one multidentate phosphorus-containing ligand;wherein the multidentate phosphorus-containing ligand is selected from the group consisting of a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members; andwherein the multidentate phosphorus-containing ligand gives acceptable results according to at least one protocol of the 2-Pentenenitrile Hydrocyanation Test Method.

Owner:INV NYLON CHEM AMERICAS LLC

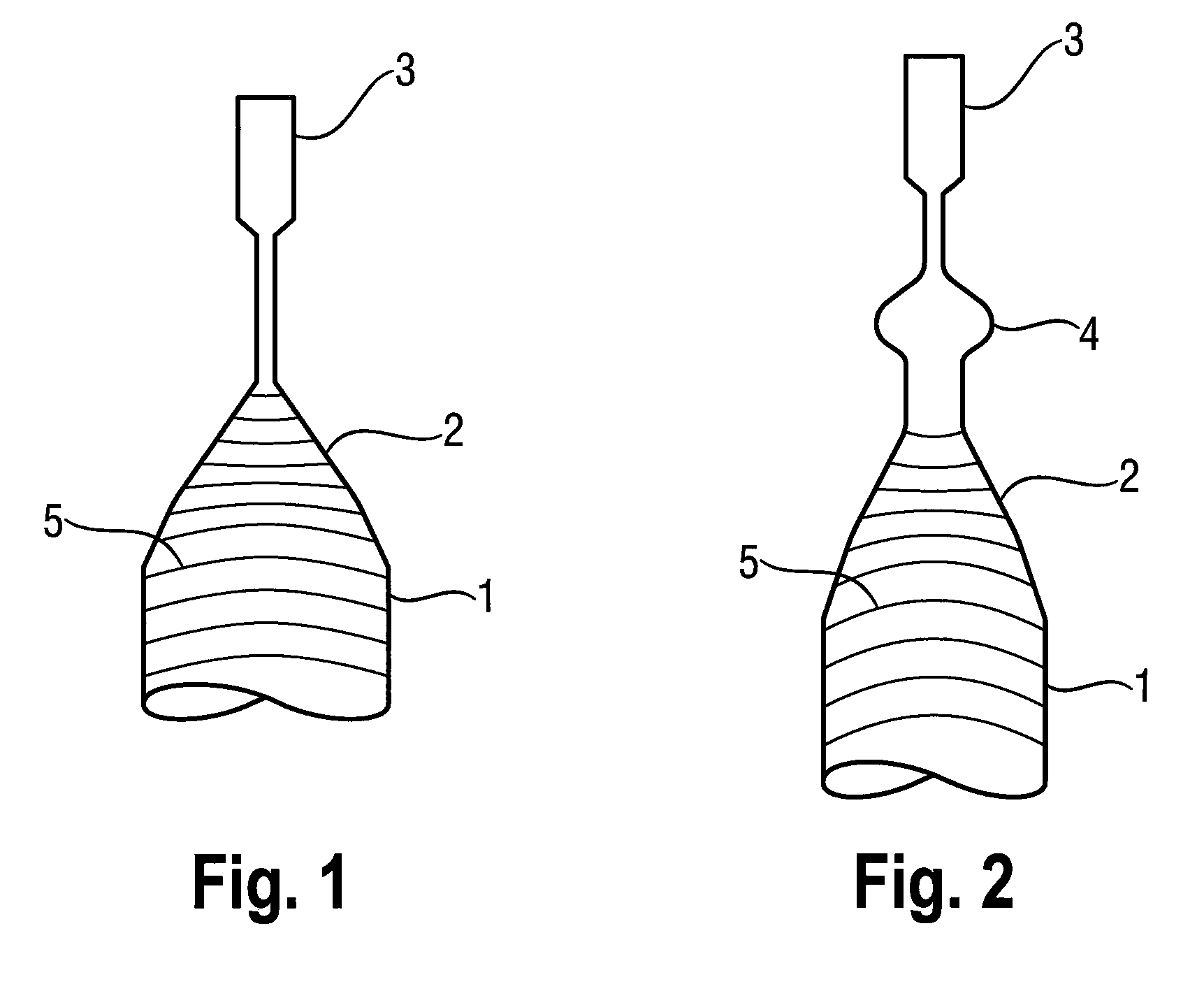

Fiber optic collimator system, fiber optic collimator array, and manufacturing method of the fiber optic collimator system and fiber optic collimator array system

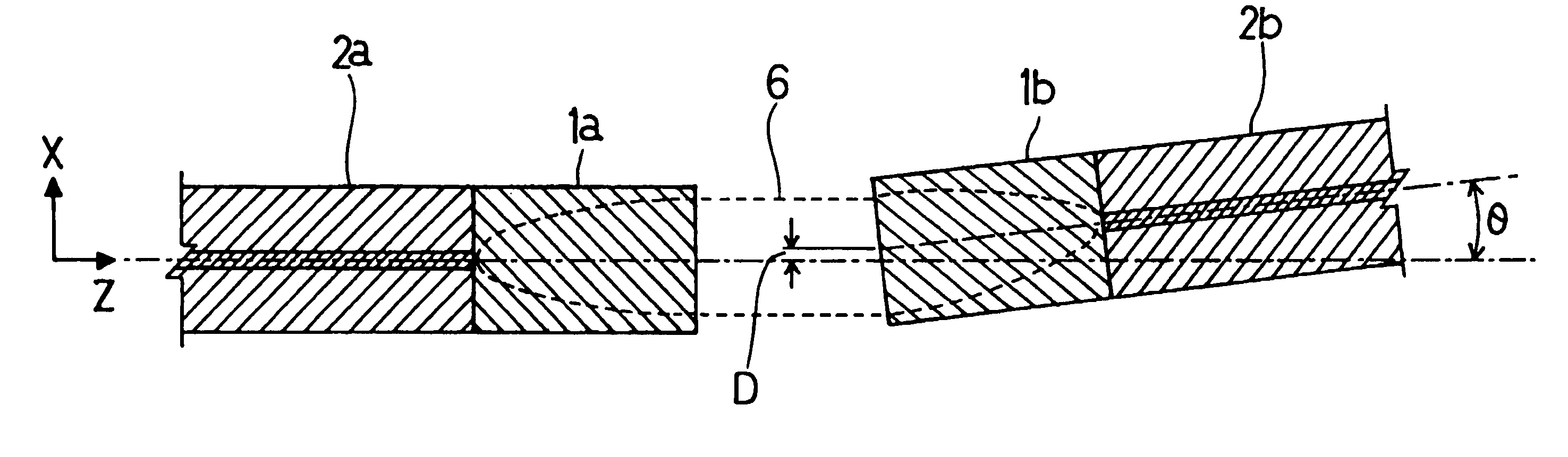

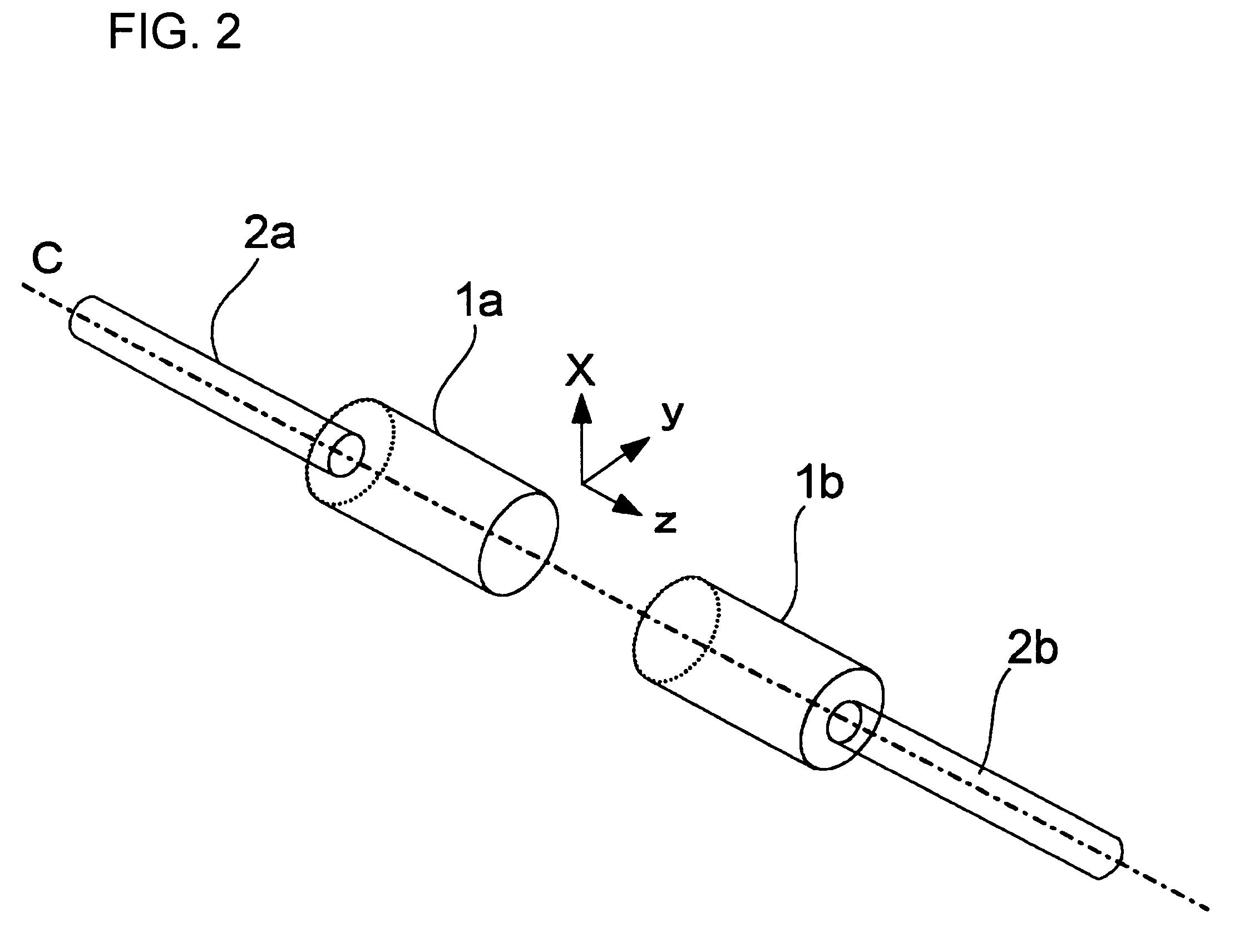

ActiveUS7357005B2Efficient manufacturingEasy to produceGlass making apparatusCoupling light guidesCoupling lossFiber

A fiber optic collimator system, a fiber optic collimator array, and a fiber optic collimator array system, which can reduce difficulty in an alignment process, minimize a coupling loss, and prevent the optical characteristics from deteriorating. An optical fiber is fused to one end of a GRIN lens made of quartz glass containing one or more selected from Sb2O3, Ta2O5, TiO2 and ZrO2 as a refractive index regulating substance, to form an optical fiber with a GRIN lens. Since an adhesive is not used, the core alignment of the GRIN lens and the optical fiber can be facilitated by a self alignment effect without deteriorating the optical characteristics. Moreover, the coupling loss is remarkably reduced by appropriately setting a refractive index distribution constant g of the GRIN lens. By fabricating the fiber optic collimator system, the fiber optic collimator array, the fiber optic collimator array system using the optical fiber with a GRIN lens can reduce the difficulty in the core alignment process, minimize the coupling loss, and prevent the optical characteristics from deteriorating.

Owner:TOYO SEIKAN GRP HLDG LTD

Semiconductor package structure and method for fabricating the same

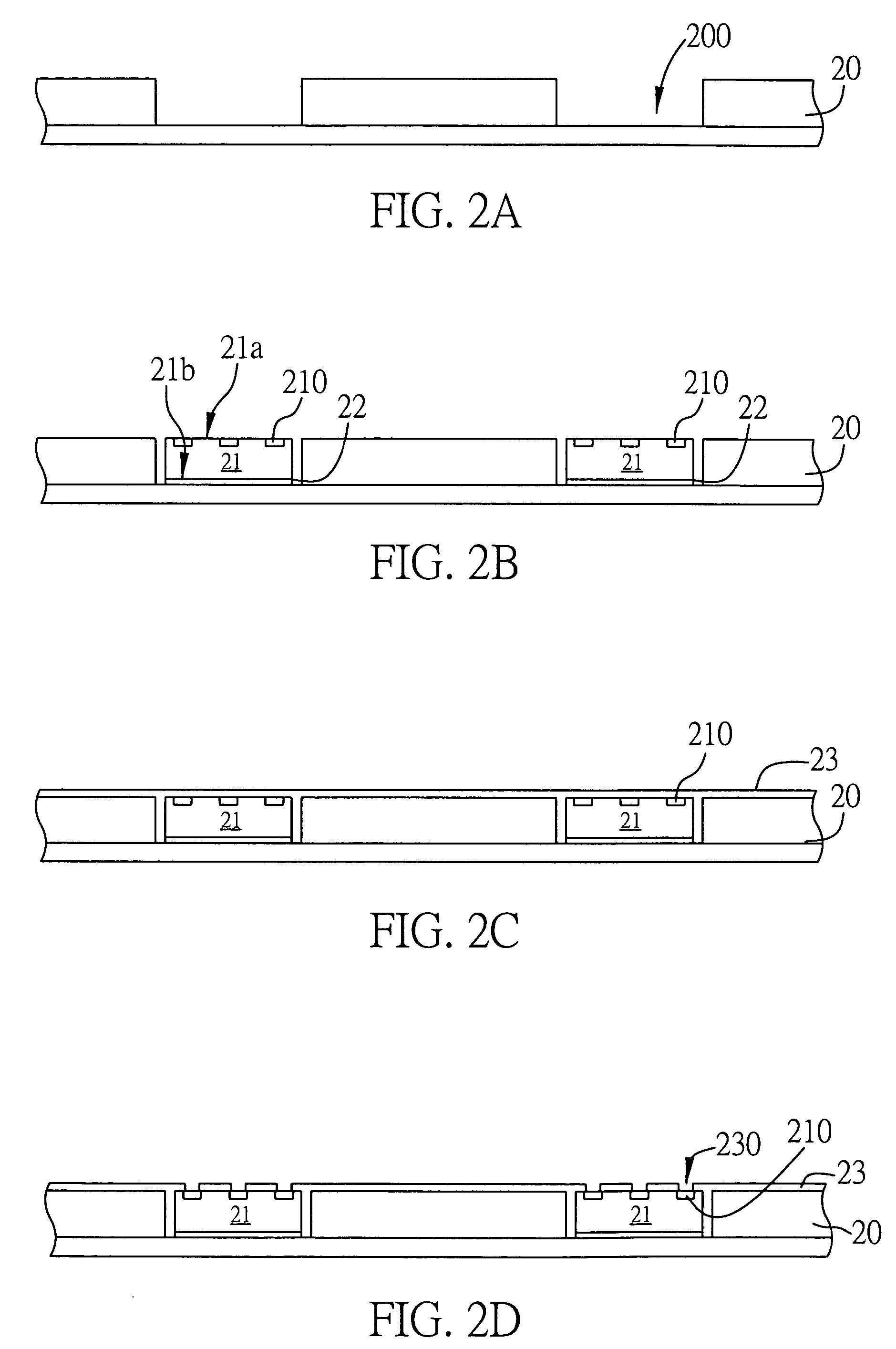

InactiveUS20060125080A1Avoid lostFabrication cost is increasedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package structure and a method for fabricating the same are proposed. A carrier having at least one cavity is provided. At least one semiconductor chip having electrode pads is mounted in the cavity. A dielectric layer is applied on the carrier and the chip, and has vias for exposing the electrode pads of the chip. A circuit layer and conductive structures are formed on the dielectric layer and in the vias, wherein the conductive structures are electrically connected to the electrode pads of the chip. A conductive adhesive layer having conductive adhesive posts and a circuit board having conductive pads thereon are provided. The circuit board is mounted on the carrier via the conductive adhesive layer. The conductive pads of the circuit board are electrically connected to the circuit layer by the conductive adhesive posts and are further electrically connected to the electrode pads of the chip.

Owner:PHOENIX PRECISION TECH CORP

Liquid crystal display

InactiveUS20140168575A1Reduce manufacturing costYield lossNon-linear opticsLiquid-crystal displayFluorescence

A liquid crystal display is described, which includes a backlight module and a liquid crystal display panel. The backlight module includes a light guide plate and a plurality of blue light-emitting diodes adjacent to the light guide plate. The liquid crystal display panel is disposed above the backlight module. The liquid crystal display panel includes a first transparent substrate, a first electrode, a liquid crystal layer, a phosphor powder layer, a color filter, a second electrode and a second transparent substrate stacked above the light guide plate in sequence. The phosphor powder layer includes a plurality of green phosphor powder regions and red phosphor powder regions. The color filter is adjacent to the phosphor powder layer. The color filter includes a plurality of green color filter regions and red color filter regions respectively and correspondingly located, on the green phosphor powder regions and the red phosphor powder regions.

Owner:RADIANT OPTO ELECTRONICS

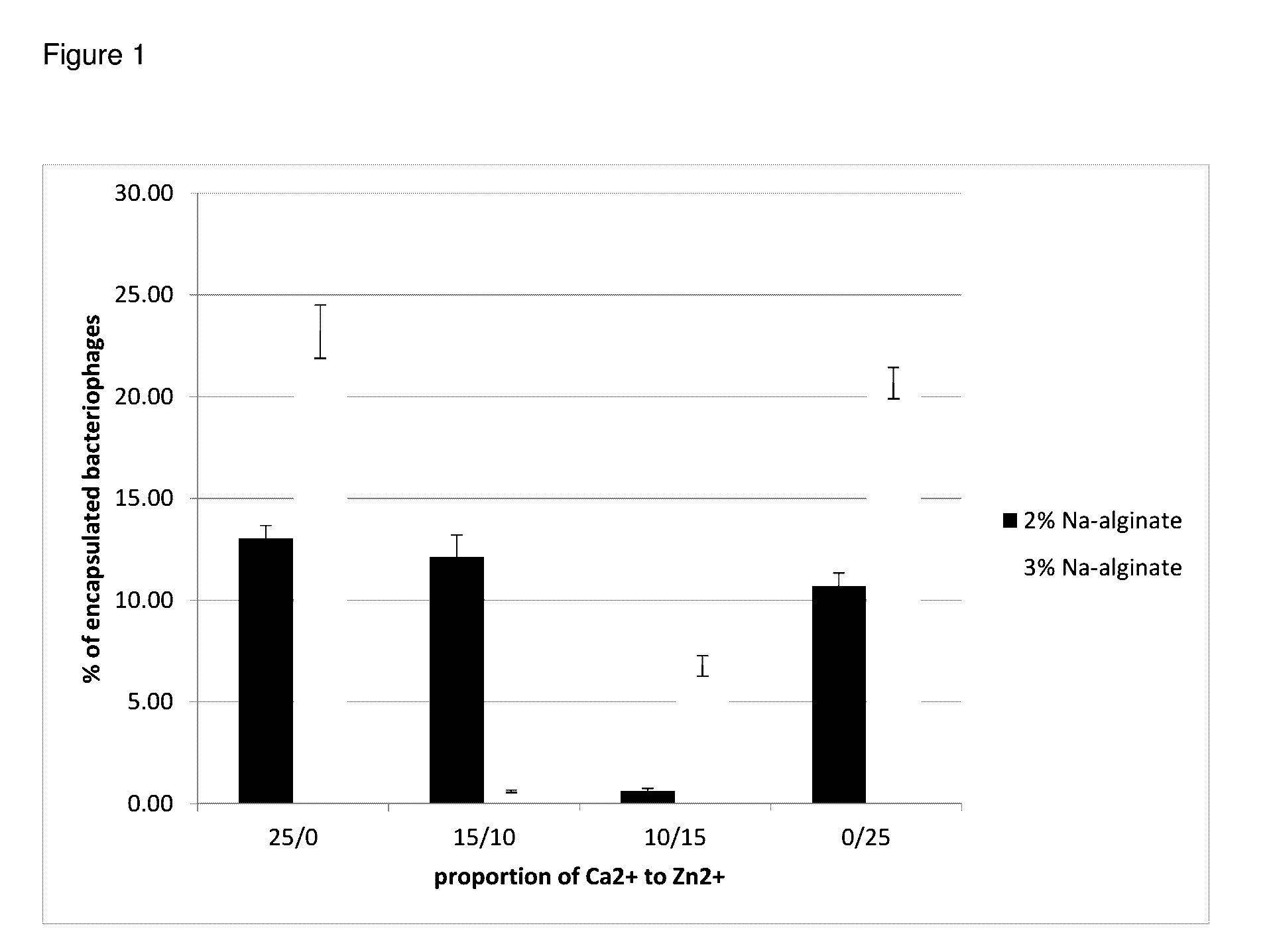

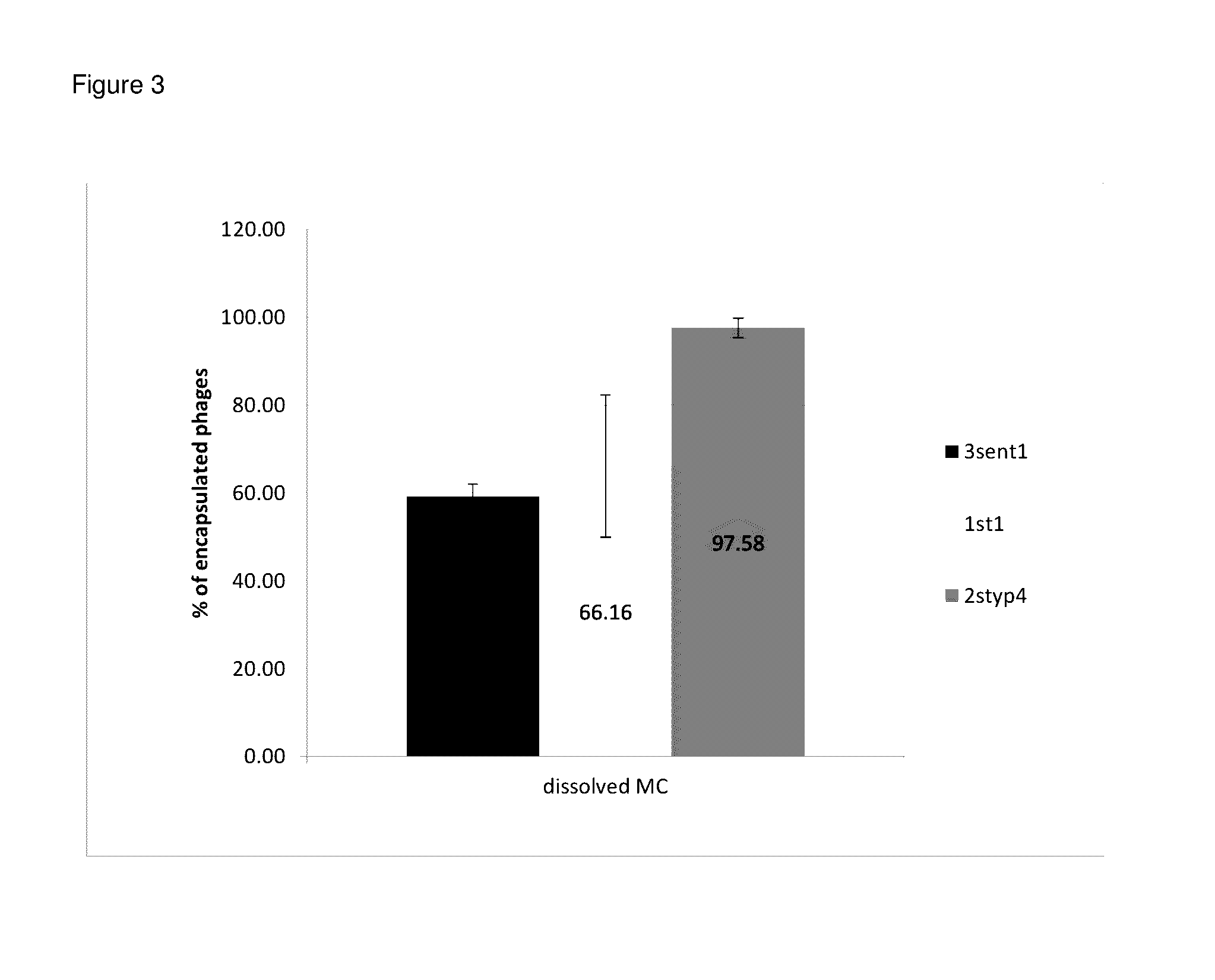

Methods for encapsulation and microcapsules produced thereby

ActiveUS20160279070A1Small average pore sizeMaintain integrityAntibacterial agentsPharmaceutical non-active ingredientsDissolutionSURFACTANT BLEND

The invention relates to methods for encapsulating a material comprising the steps of: (a) providing an aqueous solution or suspension of the material that is to be encapsulated, (b) warming the aqueous solution or suspension to a temperature that is sufficient to enable dissolution of a first biocompatible polymer in the aqueous solution or suspension without adversely affecting the properties of the material to be encapsulated, (c) dissolving the first biocompatible polymer in the aqueous solution or suspension, (d) de-aerating the solution or suspension obtained in step (c), (e) emulsifying the solution or suspension obtained in (d) in a biocompatible oil comprising a surfactant to create microdroplets, and (f) hardening the microdroplets by dropwise addition of an aqueous solution comprising Zn2+ ions and a second biocompatible polymer to form microcapsules; the invention further relates to microcapsules obtained by methods of the invention and their uses.

Owner:PROTEON PHARMA

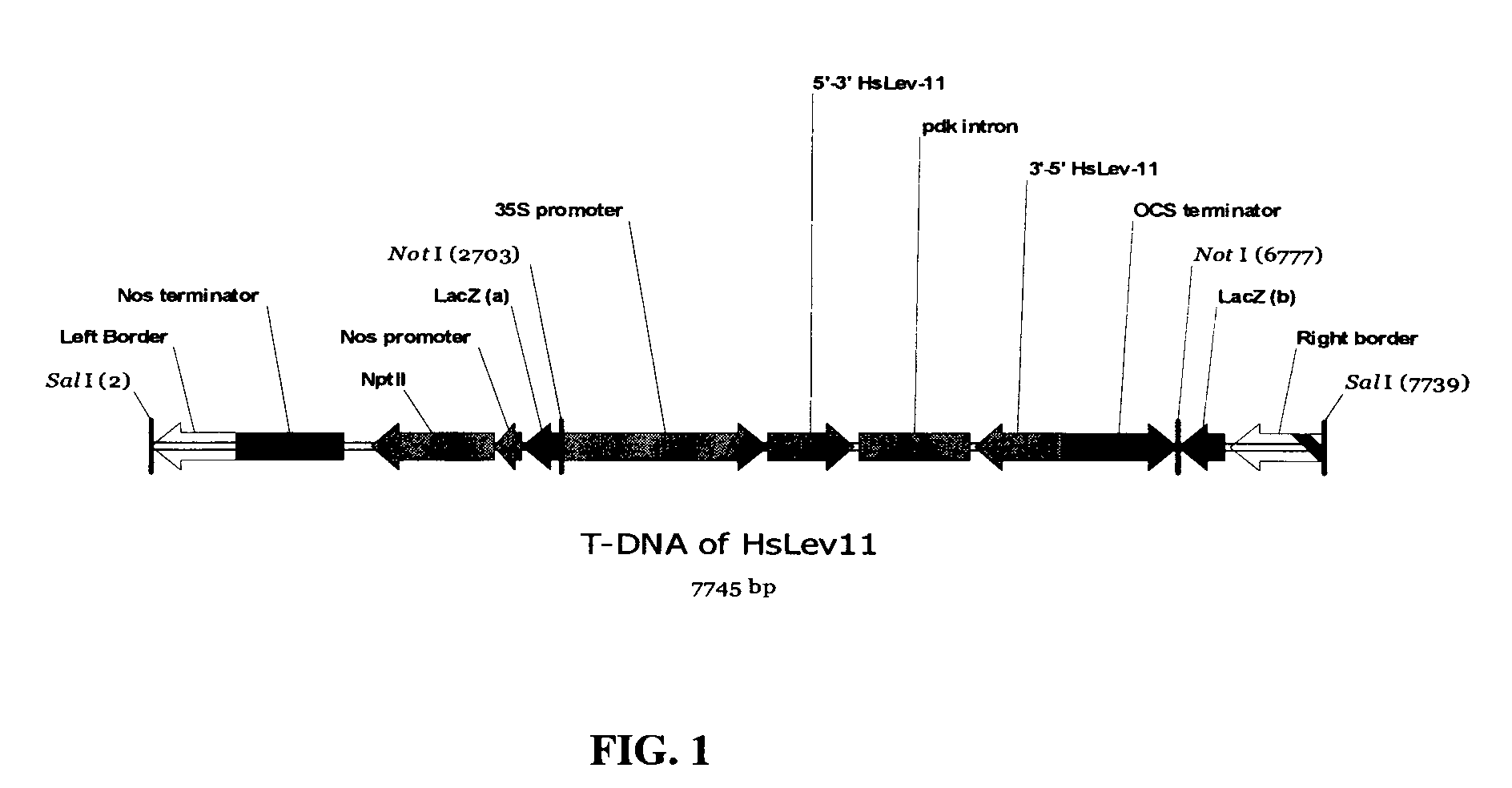

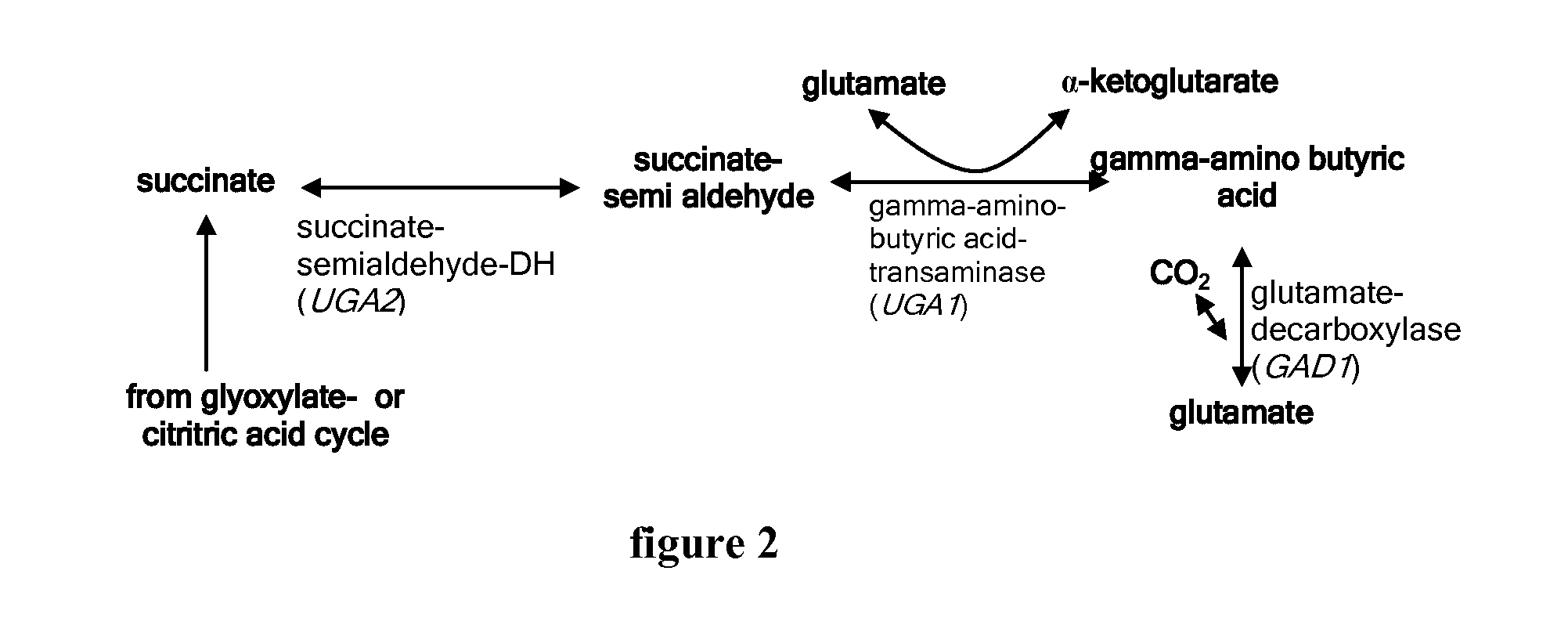

Target genes for control of plant parasitic nematodes and use of same

The invention relates to identifying and evaluating target coding and non-coding sequences for control of plant parasitic nematodes by inhibiting one or more biological functions, and their use. The invention provides methods and compositions for identification of such sequences and for the control of a plant-parasitic nematode population. By feeding one or more recombinant double stranded RNA molecules provided by the invention to the nematode, a reduction in disease may be obtained through suppression of nematode gene expression. The invention is also directed to methods for making transgenic plants that express the double stranded RNA molecules, and the plant cells and plants obtained thereby.

Owner:NEMGENIX

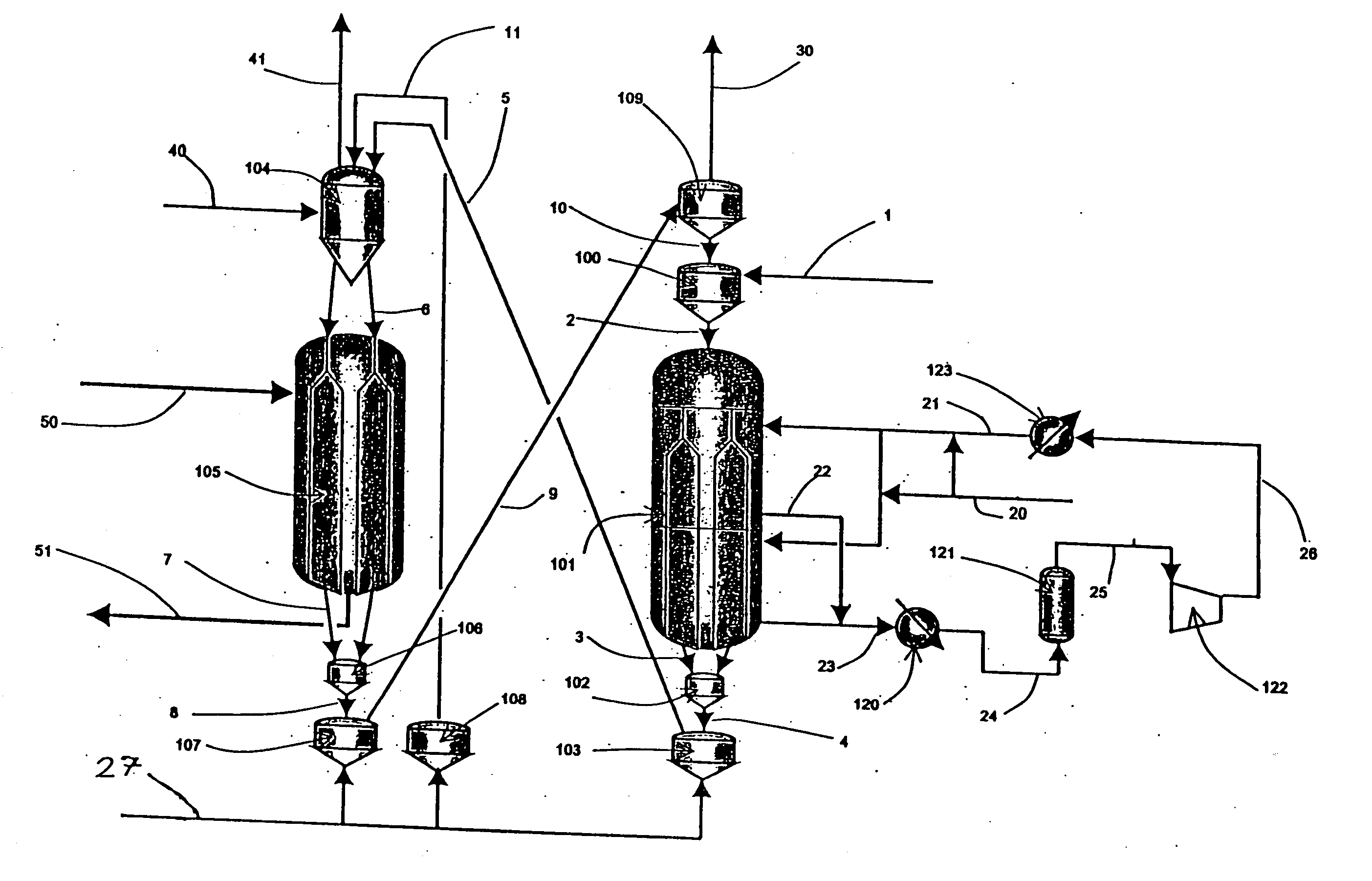

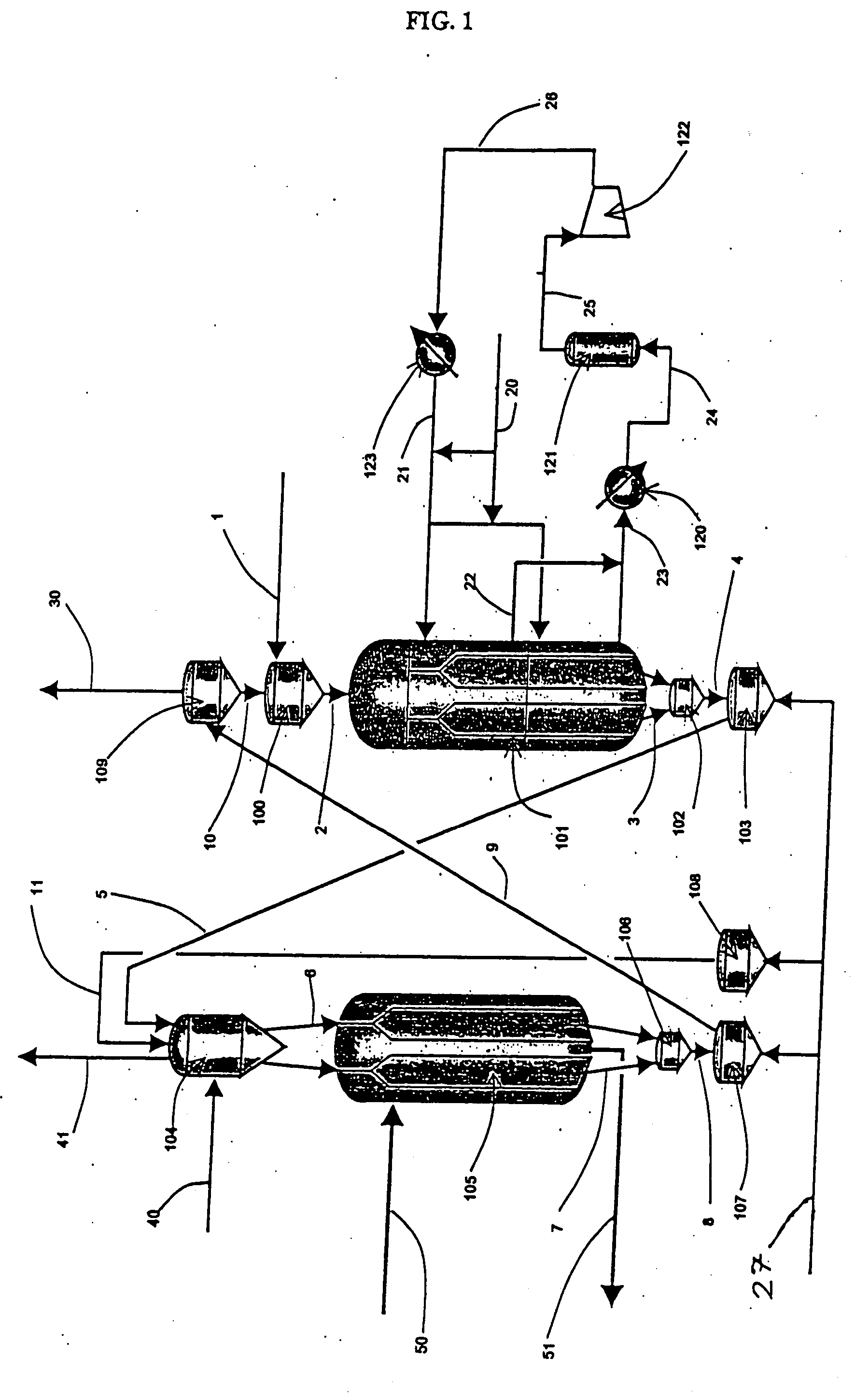

Moving bed process for producing propylene, recycling a fraction of used catalyst

InactiveUS20060063957A1Reduce catalytic activity gradientReduced activityThermal non-catalytic crackingCatalytic crackingCatalyst regenerationMoving bed

The invention concerns a process for producing propylene from a steam cracking and / or catalytic cracking light olefinic cut, said process comprising a moving bed catalytic cracking step with a catalyst regeneration loop. The process recycles a portion of the used catalyst to the inlet of the moving bed reactor. The conversion is high using the process of the invention, with a good yield and good propylene selectivity.

Owner:INST FR DU PETROLE

Sertraline hydrochloride form II and methods for the preparation thereof

InactiveUS20050032906A1Yield lossHigh yieldBiocideOrganic active ingredientsMethyl groupPhenyl group

This invention relates to a method for the preparation of sertraline hydrochloride, (1S-cis)-4-(3,4-dichlorophenyl)-1,2,3,4-tetrahydro-N-methyl-1-naphtalenamine hydrochloride, in its crystalline form II.

Owner:RECORDATI IND CHEM E FARM SPA

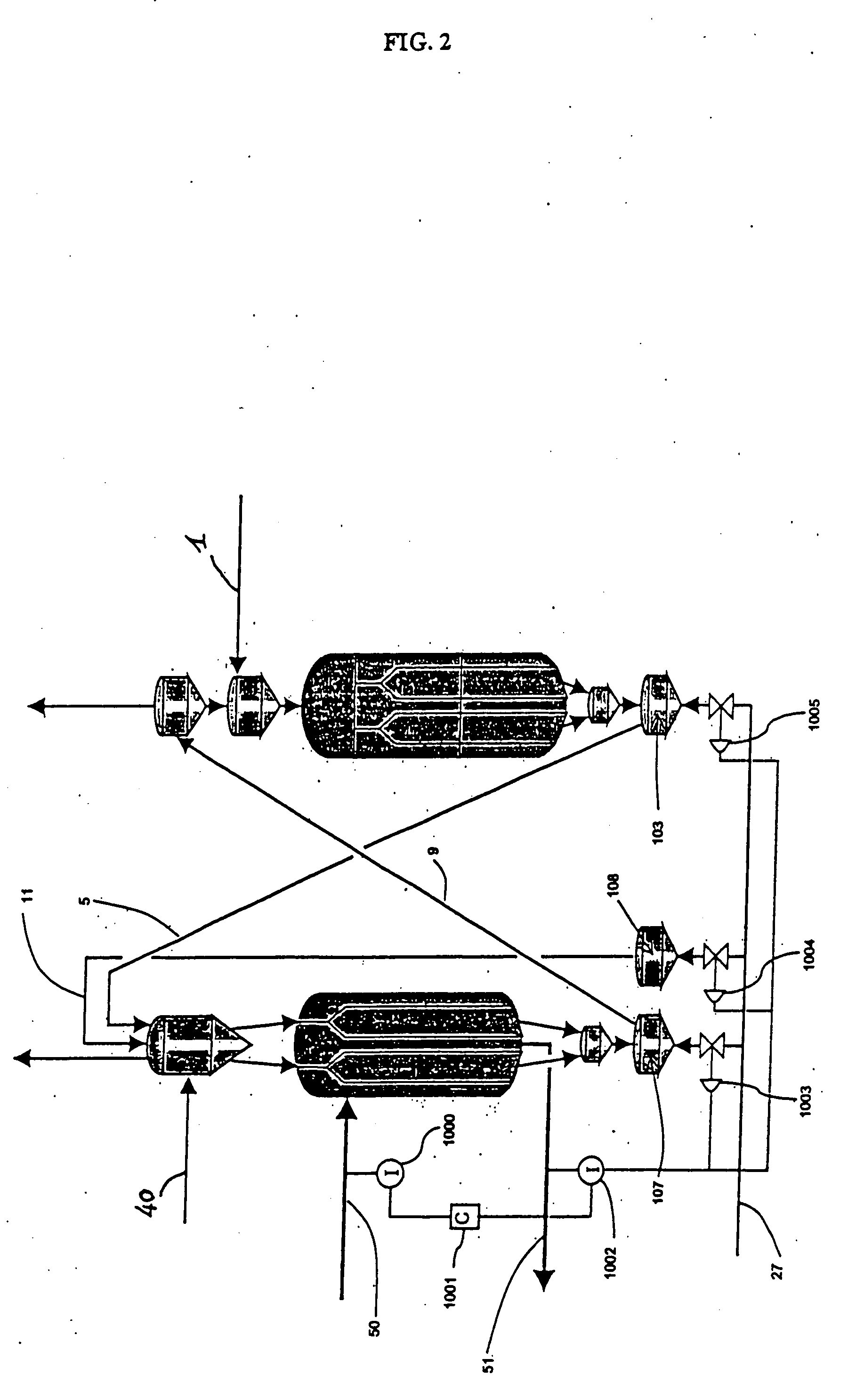

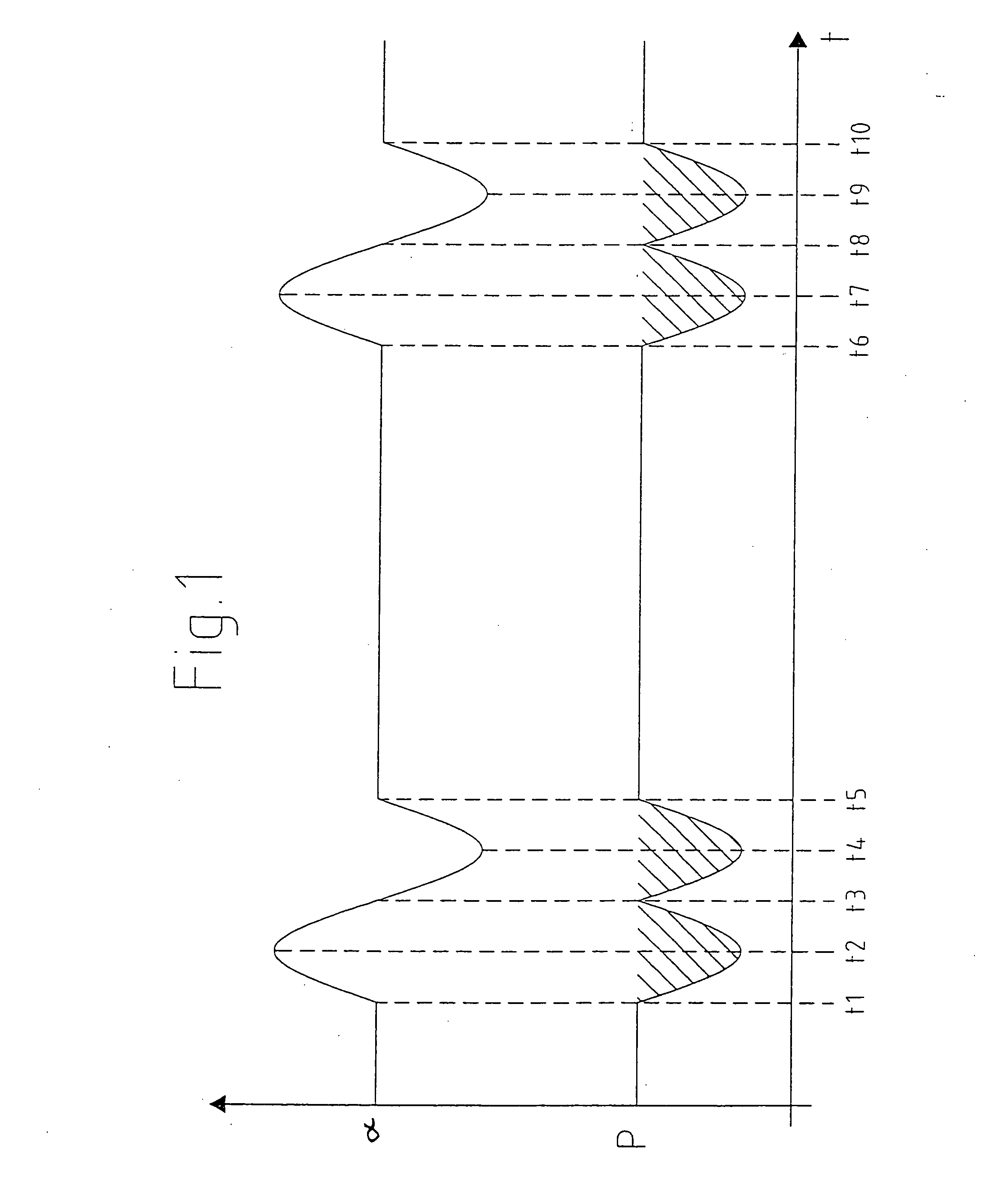

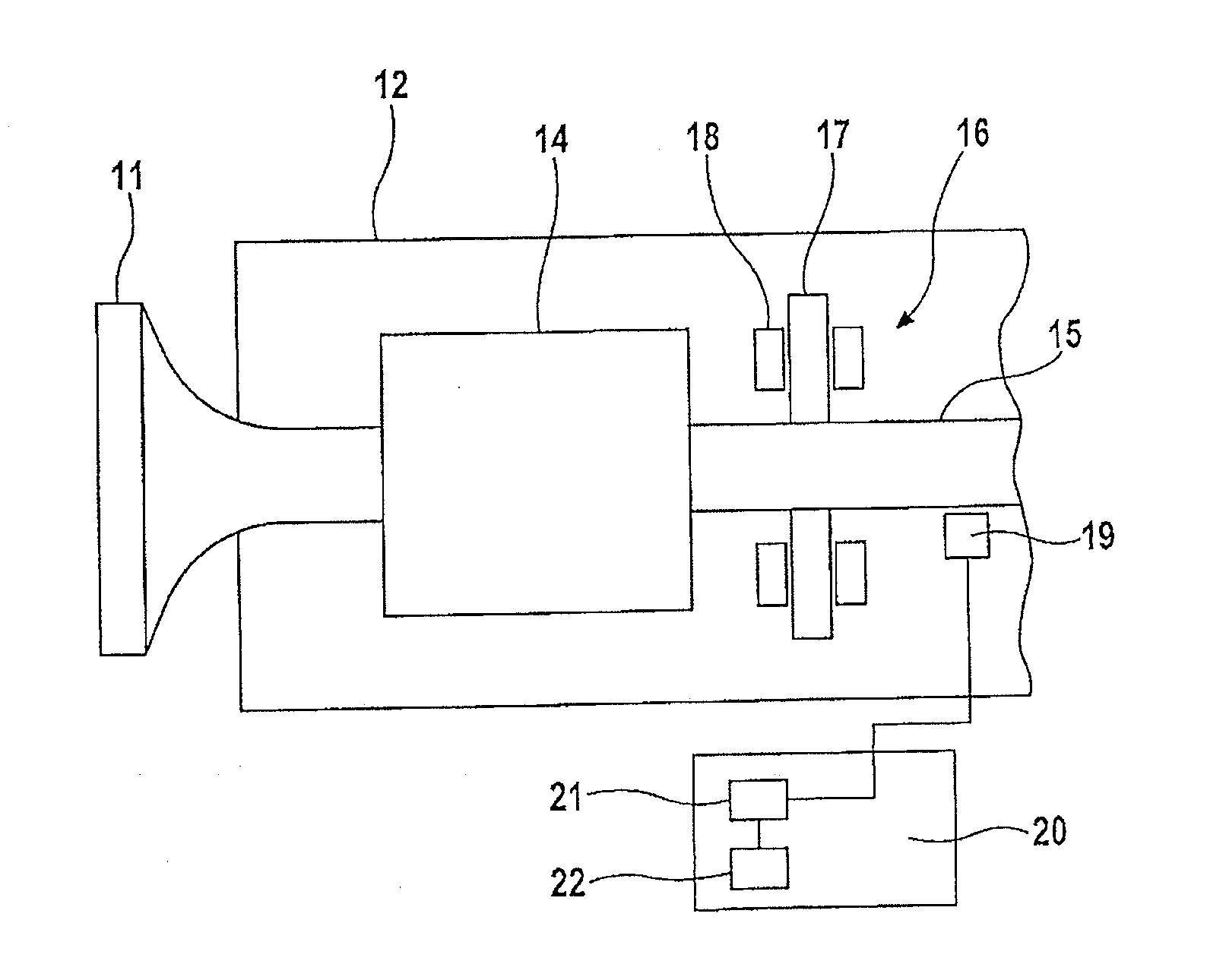

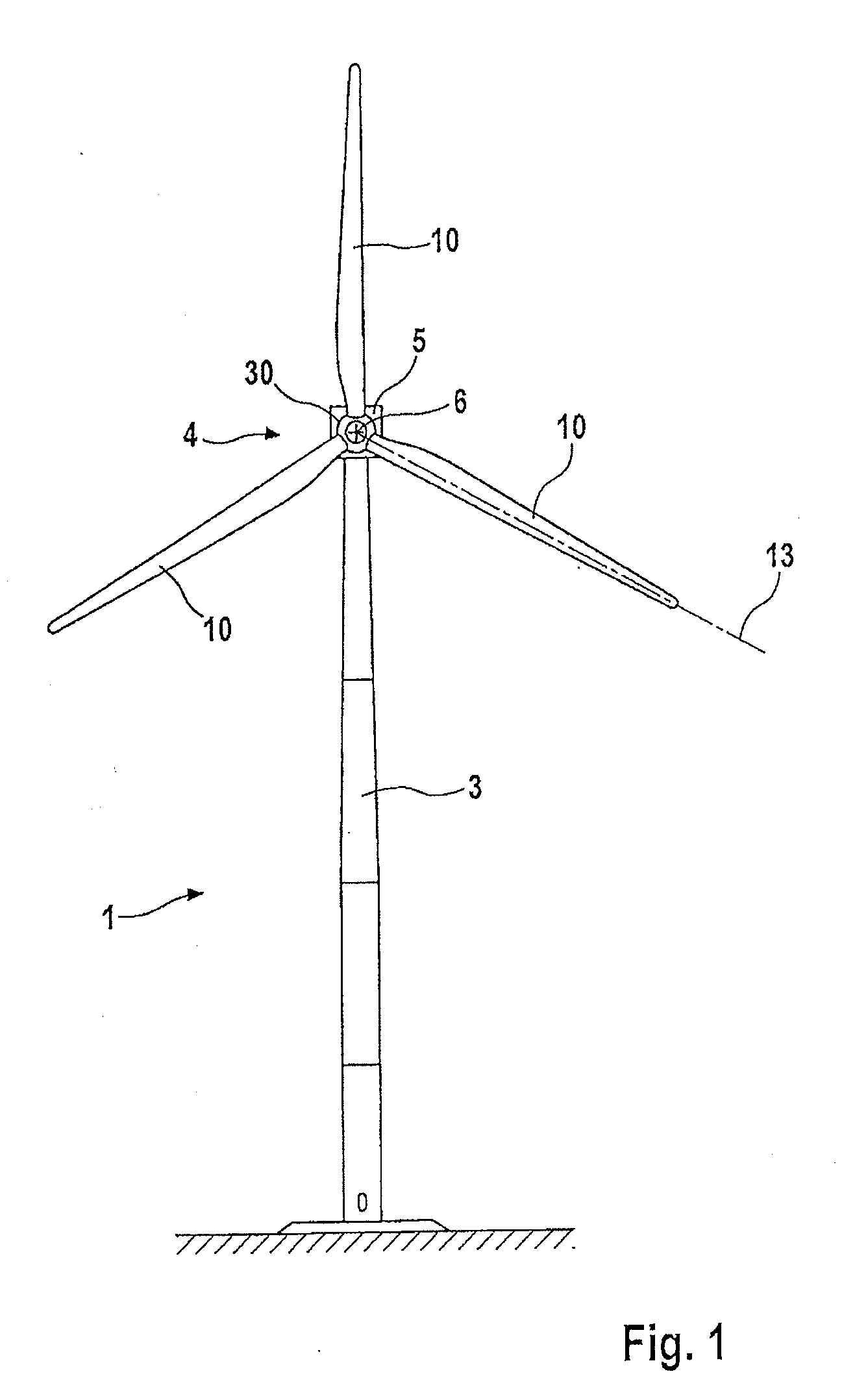

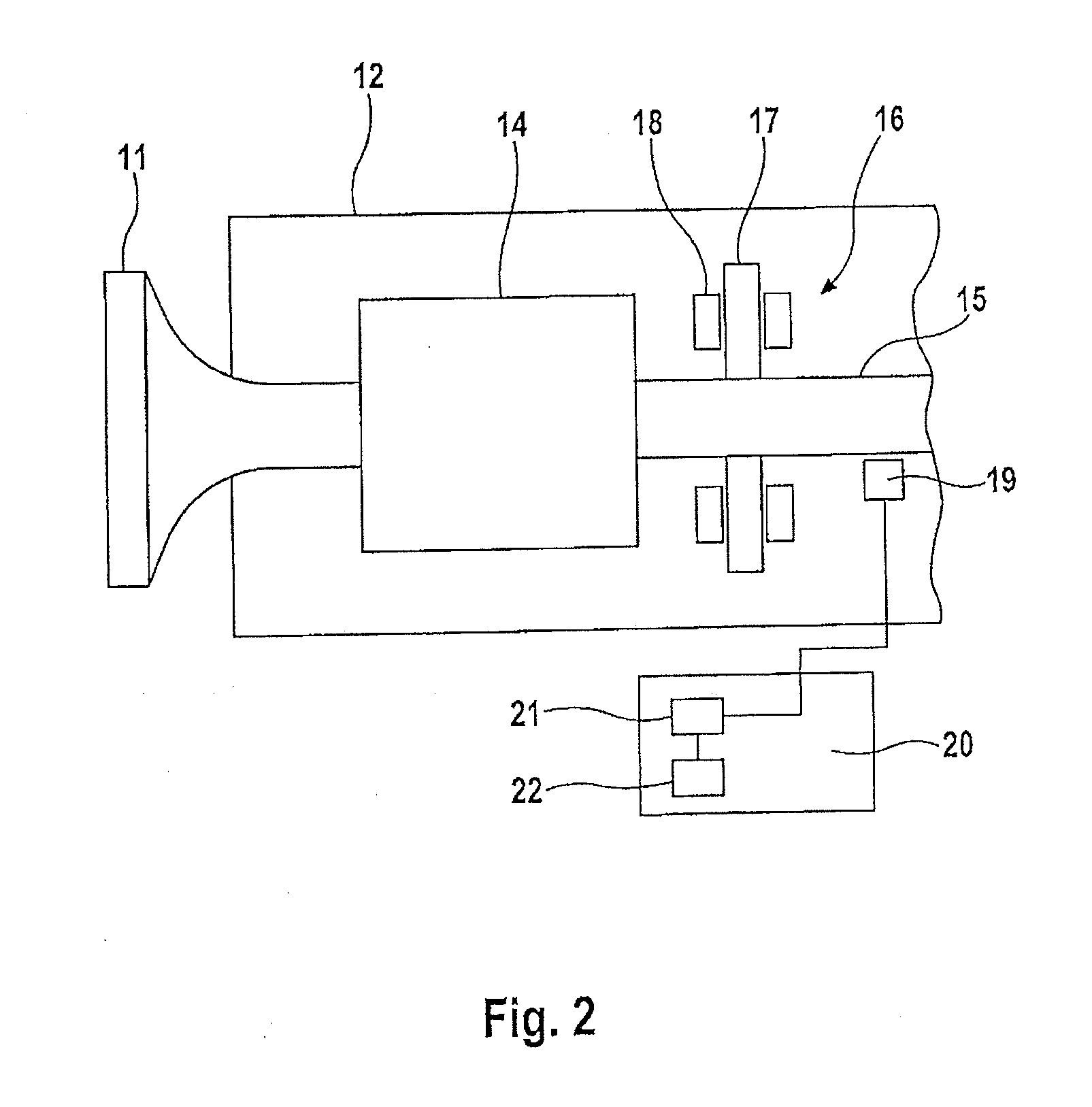

Method for controlling a wind turbine

A method is provided for controlling a wind turbine, and a wind turbine is provided with a control device for controlling a wind turbine. A method and a wind turbine are developed so that losses of yield, particularly as a result of variations in the conversion of the kinetic energy of the wind into electrical energy, e.g., in the rotor, drive train and generator, are minimized as far as possible. A method is provided for controlling a wind turbine, wherein at least one operational setting is varied within predefined limits.

Owner:WOBBEN ALOYS

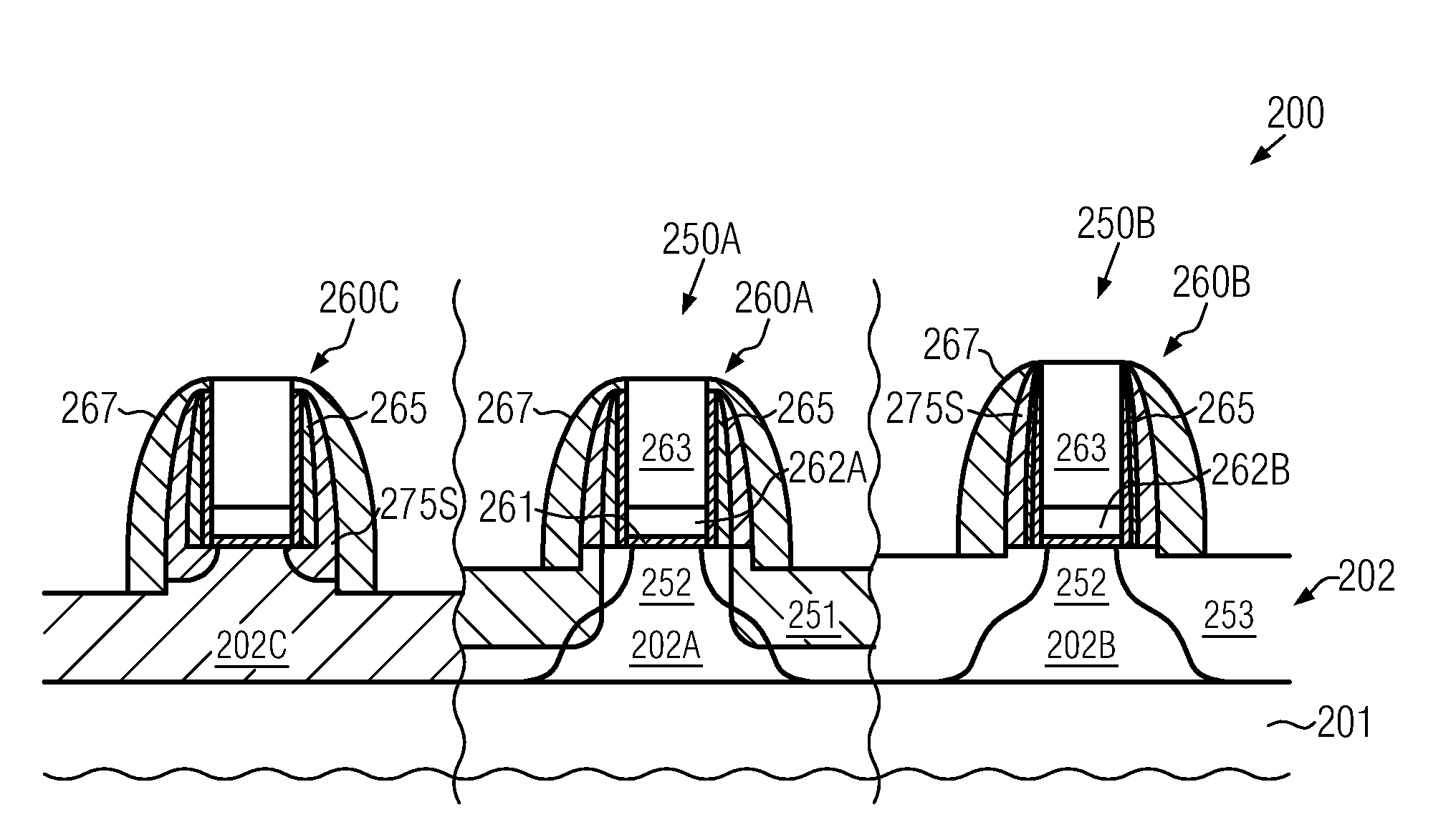

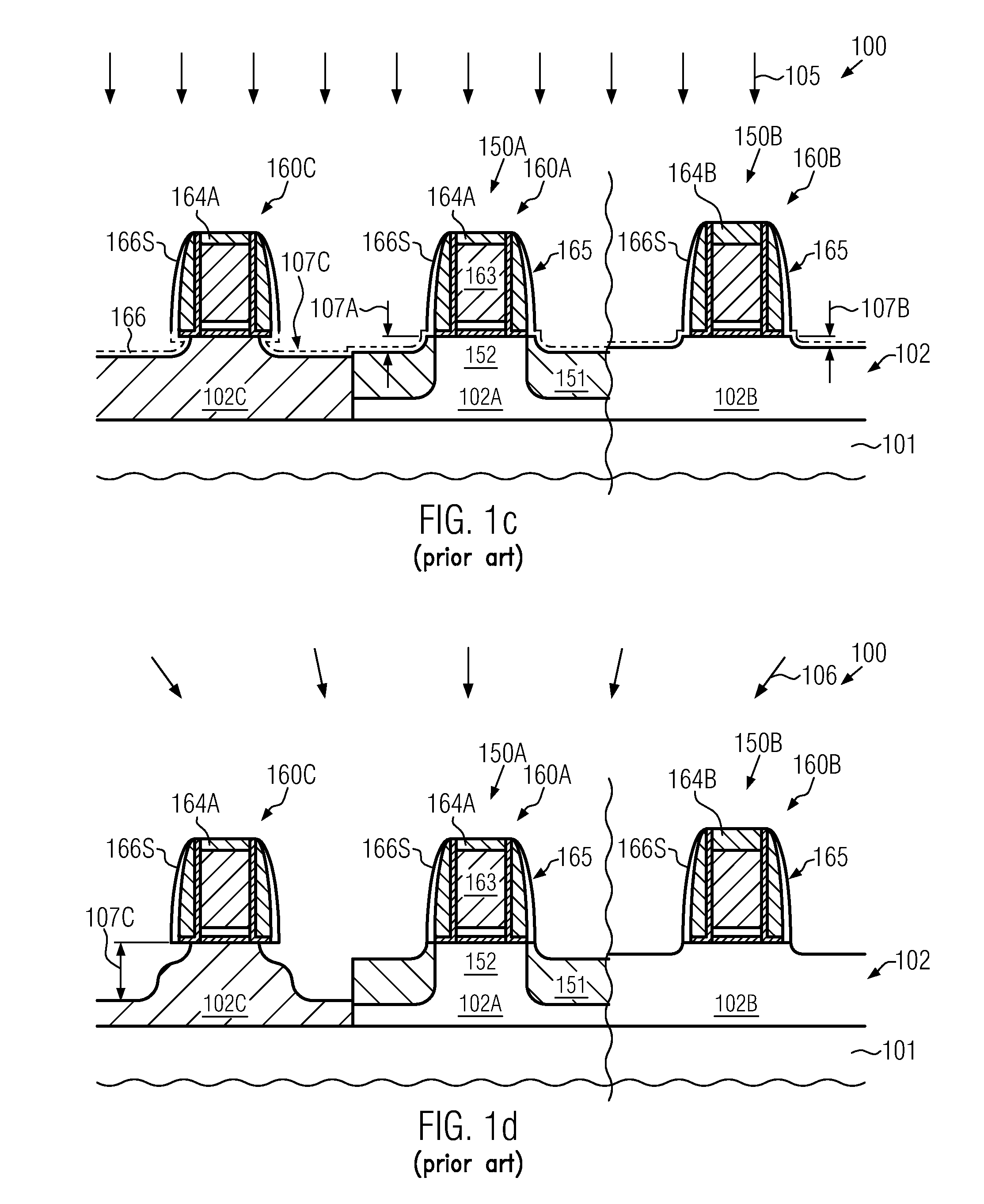

High-K Metal Gate Electrode Structures Formed by Cap Layer Removal Without Sacrificial Spacer

ActiveUS20120161243A1Easy to packReduce saggingTransistorSemiconductor/solid-state device manufacturingDielectricSemiconductor materials

In sophisticated semiconductor devices, high-k metal gate electrode structures may be formed in an early manufacturing stage with superior integrity of sensitive gate materials by providing an additional liner material after the selective deposition of a strain-inducing semiconductor material in selected active regions. Moreover, the dielectric cap materials of the gate electrode structures may be removed on the basis of a process flow that significantly reduces the degree of material erosion in isolation regions and active regions by avoiding the patterning and removal of any sacrificial oxide spacers.

Owner:TAIWAN SEMICON MFG CO LTD

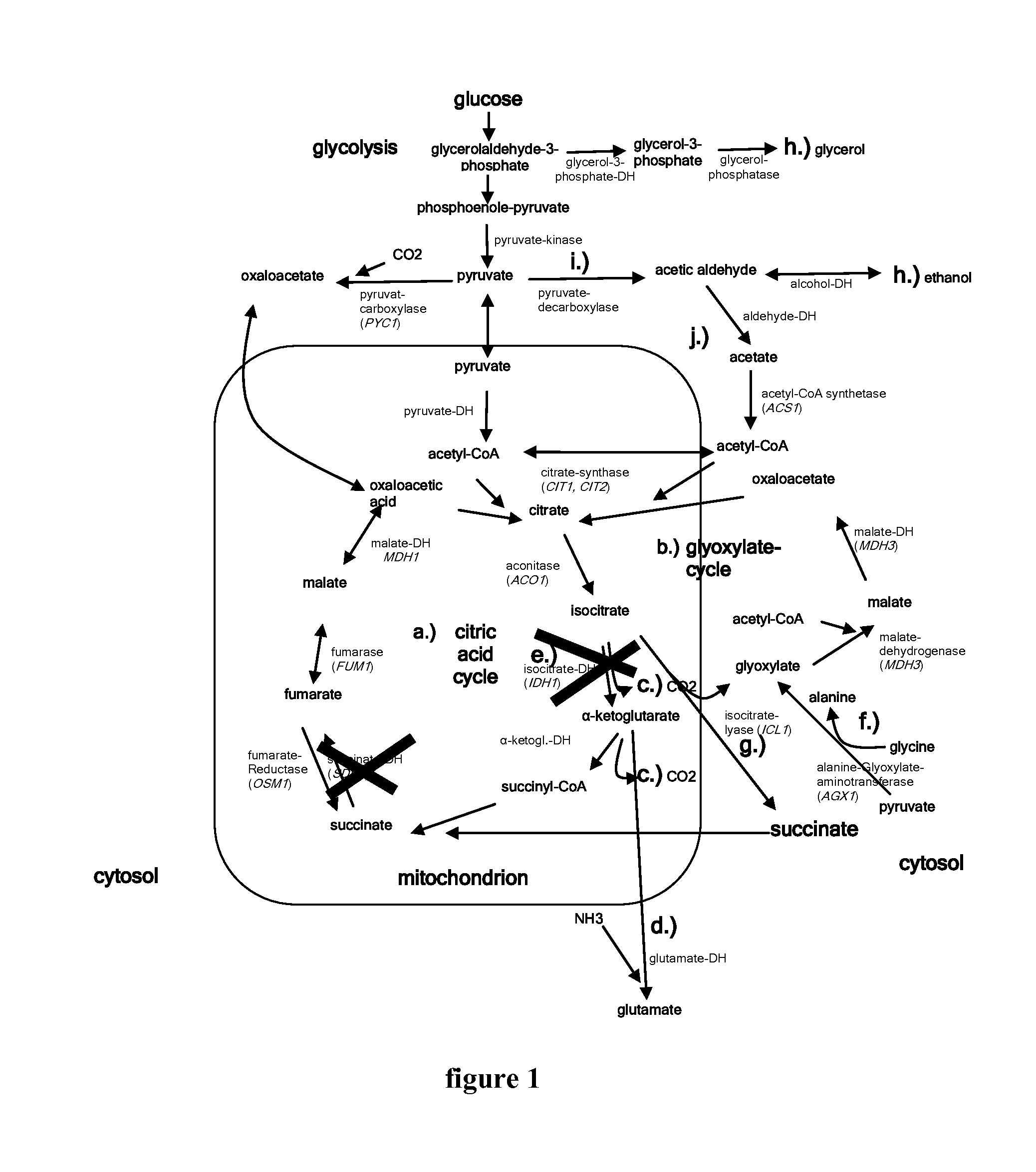

Microorganism for producing succinic acid

InactiveUS20110300595A1Efficient productionAvoid and reduce yield lossFungiOxidoreductasesMicroorganismIDH1

The invention relates to an isolated, genetically modified microorganism, wherein compared to the wild type a) the idh1 and idp1 genes have been deleted or inactivated, and / or b) the sdh2 and sdh1 genes have been deleted or inactivated, and / or c) the PDC2 gene has been deleted or inactivated or is under the control of a promoter which can be suppressed or induced by exposure of the microorganism using an inductor substance, and / or d) one or more genes from the group consisting of ICL1, MLS1, ACS1 and MDH3 has been replaced or supplemented by a corresponding foreign gene or corresponding foreign genes from Crabtree-negative organisms, and to the uses thereof.

Owner:ORGANOBALANCE GMBH

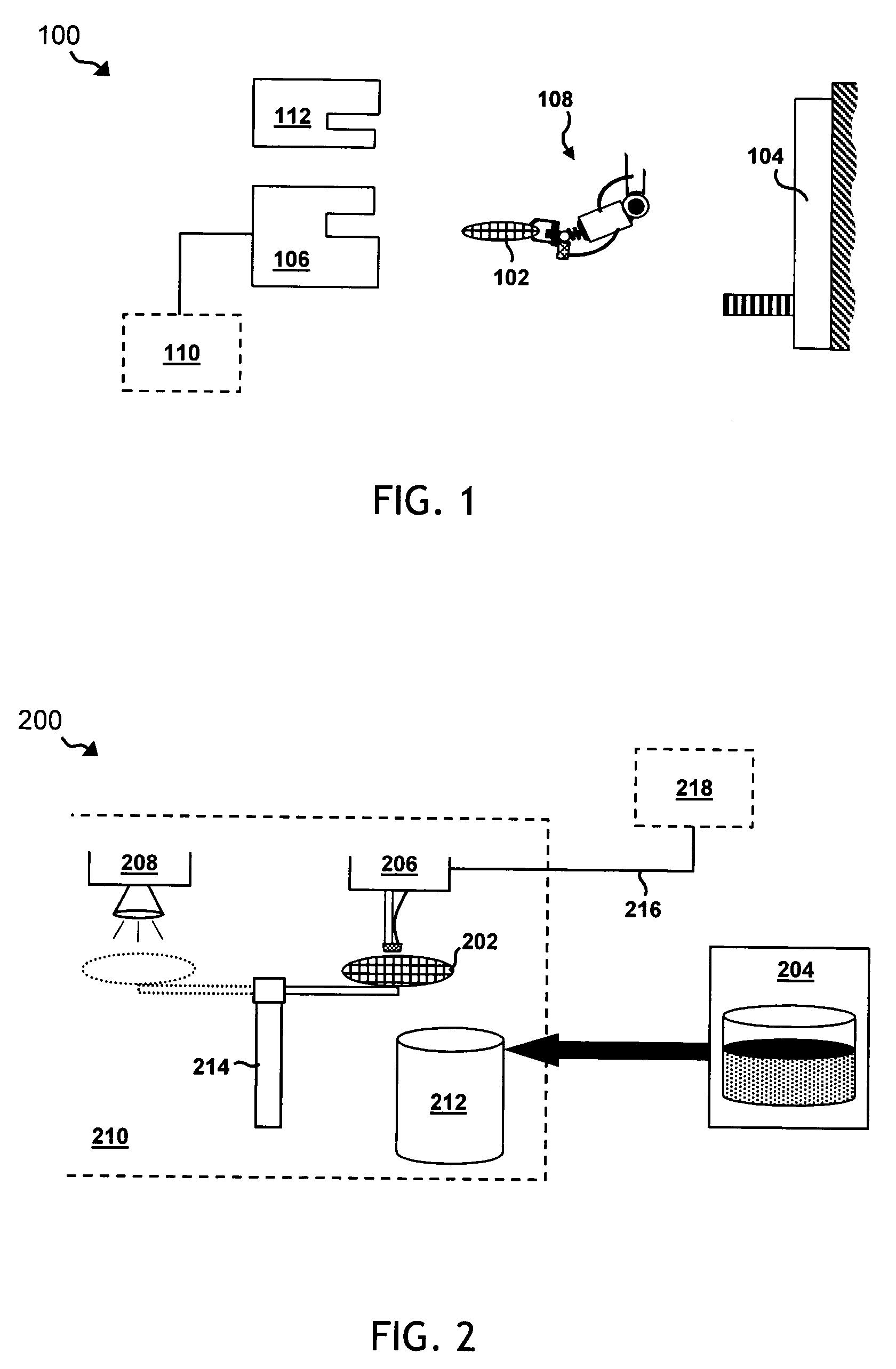

System for remediating cross contamination in semiconductor manufacturing processes

ActiveUS7200498B2Easy and efficient and cost-effectiveProcesses—efficiently streamlining cross-contamination testingSemiconductor/solid-state device testing/measurementMaterial analysis by electric/magnetic meansCopper contaminationEngineering

The present invention defines a system (100) for detecting copper contamination within a semiconductor manufacturing process. According to the present invention, a semiconductor wafer (102) is transferred (108) from a semiconductor manufacturing component (104), which may have exposed the wafer to copper contamination, to a measurement system (106). The measurement system measures an electrical value at a plurality of locations along a surface of the wafer, prior to and after exposure of the surface to an activation system (112). The activation system is provided to cause any copper contamination along the surface to form a precipitate thereon. An analysis component (110) is provided to receive electrical value and location information from the measurement system and to identify, from the measurements, the presence and location of copper contamination along the semiconductor wafer surface.

Owner:TEXAS INSTR INC

System for remediating cross contamination in semiconductor manufacturing processes

ActiveUS20050274805A1Easy and efficient and cost-effectiveProcesses—efficiently streamlining cross-contamination testingSemiconductor/solid-state device testing/measurementTransmission systemsCopper contaminationEngineering

The present invention defines a system (100) for detecting copper contamination within a semiconductor manufacturing process. According to the present invention, a semiconductor wafer (102) is transferred (108) from a semiconductor manufacturing component (104), which may have exposed the wafer to copper contamination, to a measurement system (106). The measurement system measures an electrical value at a plurality of locations along a surface of the wafer, prior to and after exposure of the surface to an activation system (112). The activation system is provided to cause any copper contamination along the surface to form a precipitate thereon. An analysis component (110) is provided to receive electrical value and location information from the measurement system and to identify, from the measurements, the presence and location of copper contamination along the semiconductor wafer surface.

Owner:TEXAS INSTR INC

Hydrocyanation process with reduced yield losses

ActiveUS7709674B2Yield lossInvestment exemptionOrganic compound preparationPreparation by hydrogen cyanide additionPhosphonitePhosphine

A hydrocyanation process produces adiponitrile and other dinitriles having six carbon atoms. The process involves forming a reaction mixture in the presence of at least one Lewis acid. The reaction mixture includes ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor compositions. The reaction mixture is continuously fed while controlling the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites. In the reaction product mixture, including adiponitrile, the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles from about 0.2 / 1 to about 10 / 1. Included in the catalyst precursor composition is a zero-valent nickel and at least one multidentate phosphorus-containing ligand. The multidentate phosphorus-containing ligand may be a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members.

Owner:INV NYLON CHEM AMERICAS LLC

Moving bed process for producing propylene, recycling a fraction of used catalyst

InactiveUS7566811B2Reduce catalytic activity gradientReduced activityThermal non-catalytic crackingCatalytic crackingMoving bedOrganic chemistry

Owner:INST FR DU PETROLE

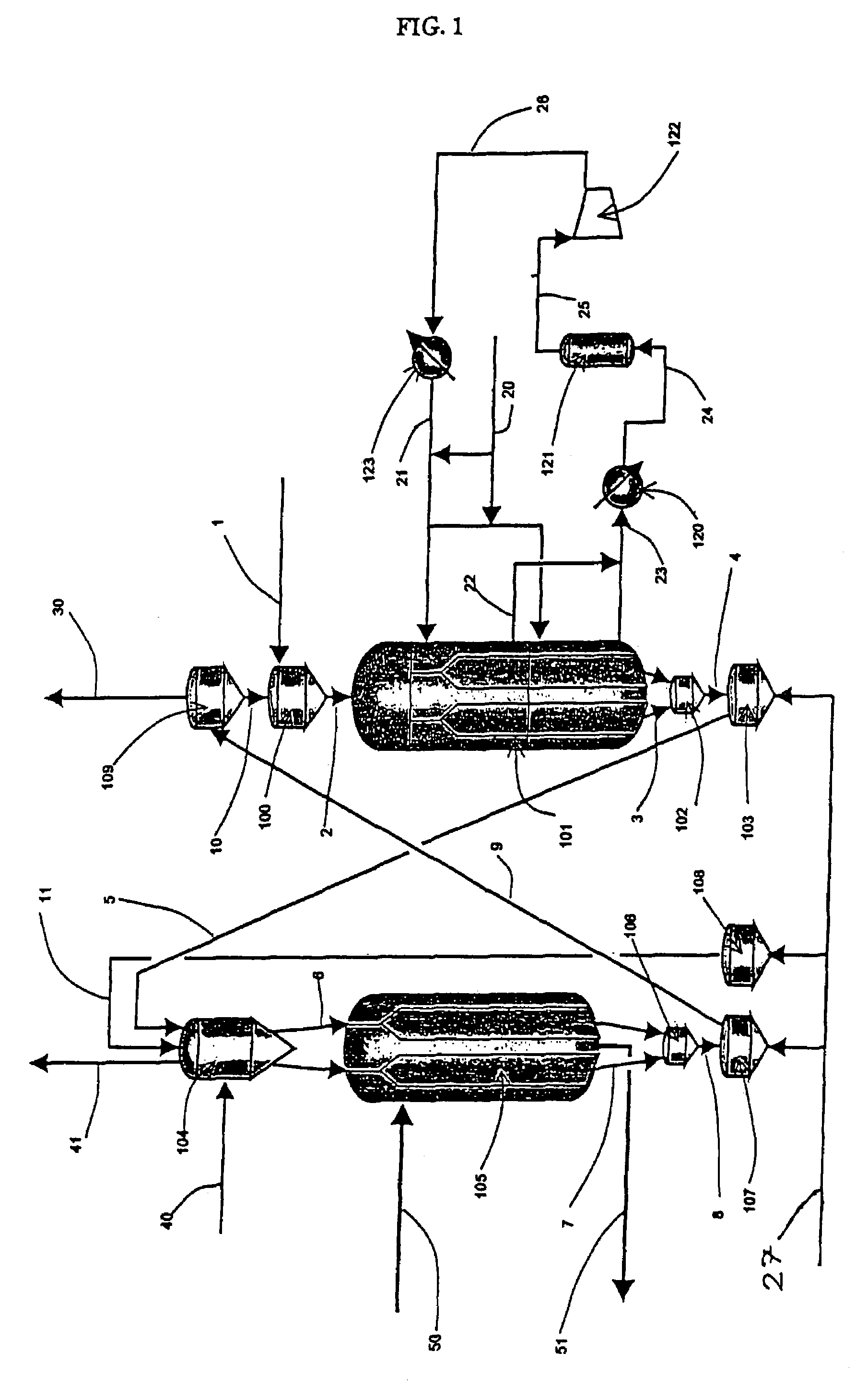

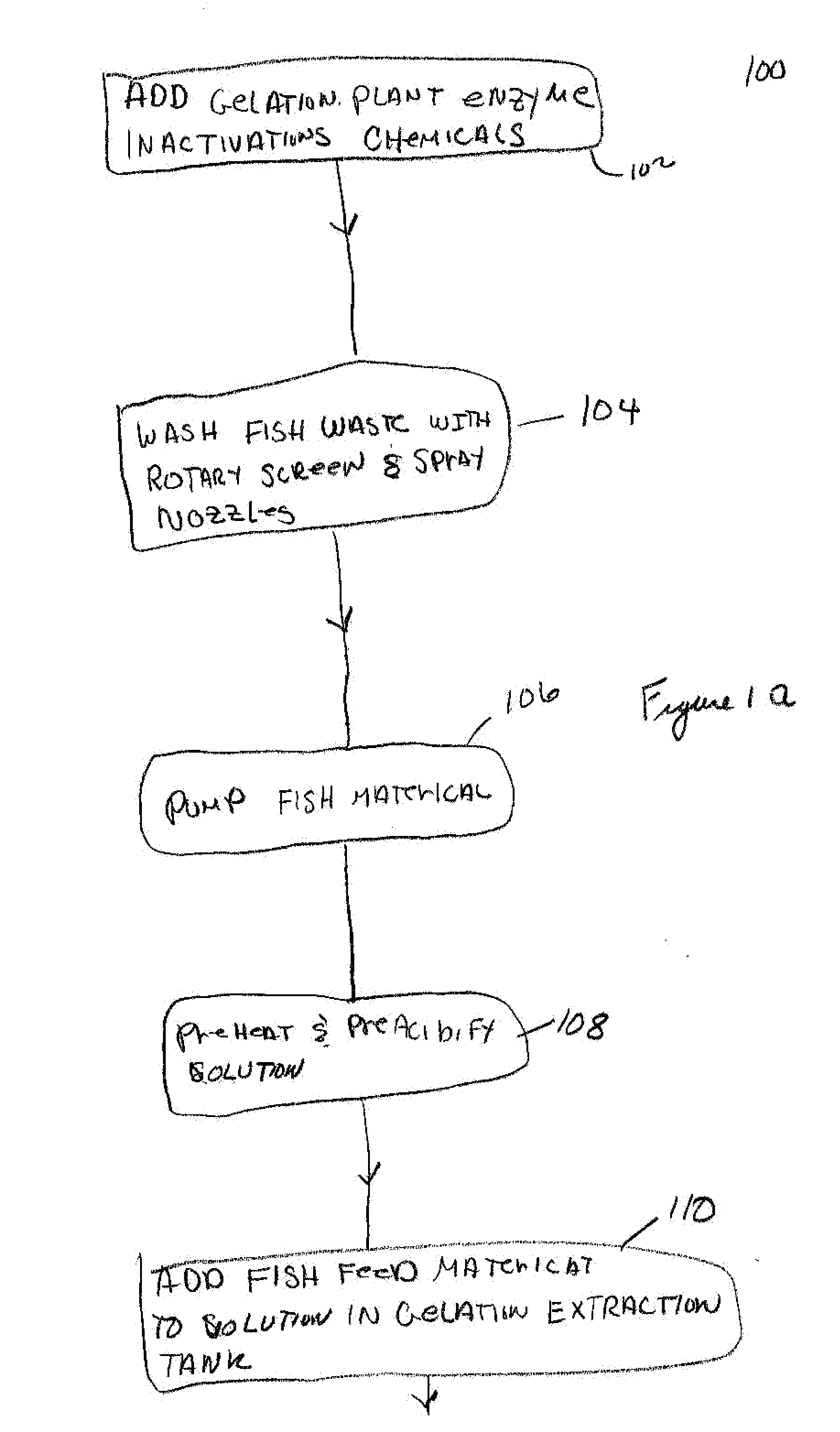

Gelatin Production System

InactiveUS20080175976A1Yield lossReduced period of timeProtein composition from fishFood preparationChemistryRemove blood

Process for the preparation of gelatin from fish parts includes the steps of washing the fish parts with an aqueous solution of a calcium hydroxide hydrate and ice to remove blood from the fish parts, treating the washed skins with an acid, and extracting gelatin from the fish skins at a temperature approximately between 100 Fahrenheit to 170 Fahrenheit and at an acidic pH approximately between pH 1.5 to pH 5.5.

Owner:BERNEGGER PETER M +1

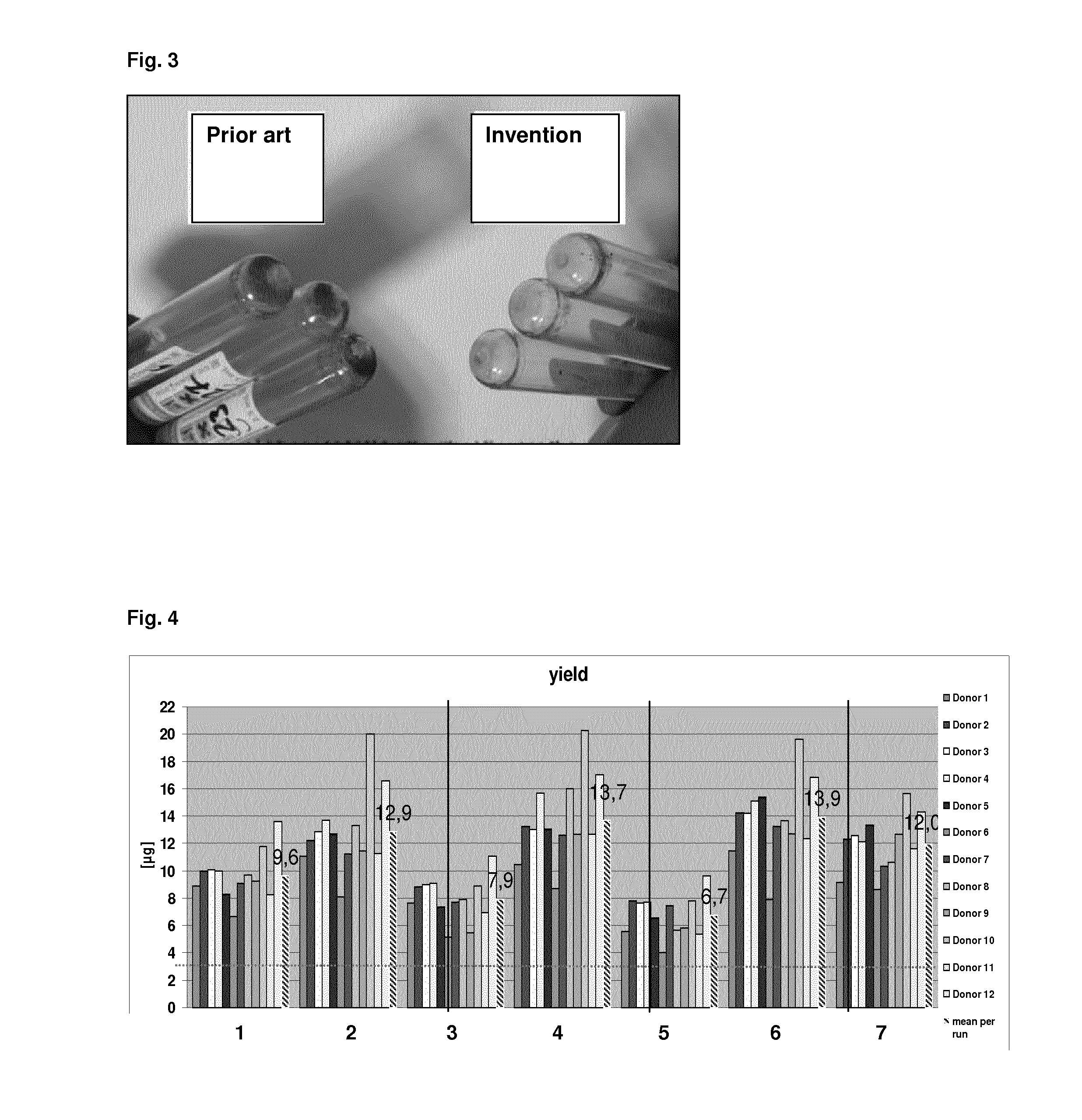

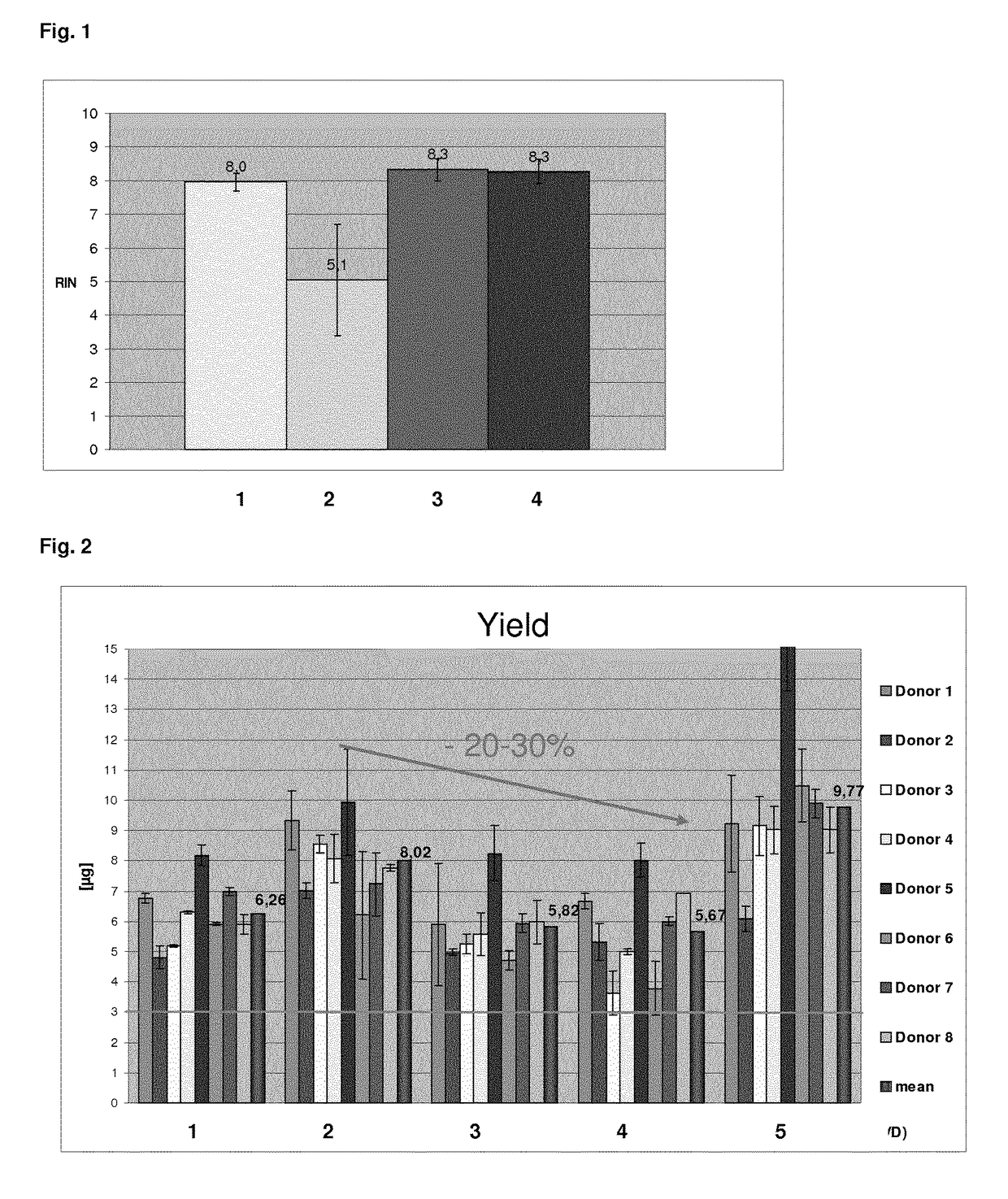

Method for isolating nucleic acids

ActiveUS20140199689A1Avoid less flexibilityQuality improvementMicrobiological testing/measurementDNA preparationCationic detergentChaotropic agent

The present invention pertains to a method for isolating nucleic acids from a sample, preferably a blood sample, comprising the following steps: a) obtaining a sample which has been stabilised by the use of at least one cationic detergent, wherein the cationic detergent has formed complexes with the nucleic acids; b) obtaining the complexes optionally together with other sample components from the stabilised sample, wherein said complexes comprise the nucleic acids to be isolated; c) resuspending the complexes and optionally adding one or more additives before, during and / or after resuspension, thereby obtaining a resuspended sample comprising at least: i) the nucleic acid to be isolated; ii) at least one chaotropic agent; and iii) at least one chelating agent; and d) isolating nucleic acids from the resuspended sample. It was found that adding a chelating agent during resuspension considerably increases the nucleic acid yield as the formation of precipitates which irreversibly adhere to the container wall is considerably reduced.

Owner:QIAGEN GMBH

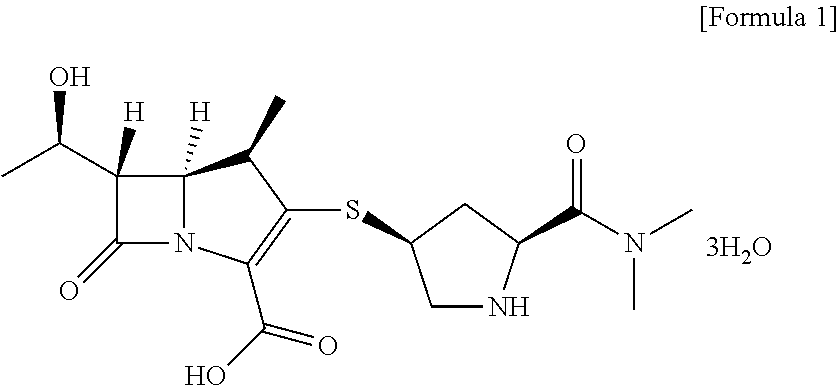

Method for preparing meropenem using zinc powder

ActiveUS20120065392A1Reduce impurityImprove productivityOrganic chemistryCarboxylic acidCombinatorial chemistry

The present invention relates to an improved method for synthesizing meropenem trihydrate [(1R,5S,6S)-2-[((2′S,4′S)-2′-dimethylaminocarbozyl)pyrrolidin-4′-ylthio]-6-[(R)-1-hydroxyethyl]-1-methylcarbapen-2-em-3-carboxylic acid, trihydrate], which is a novel carbapenem antibiotic.

Owner:DAEWOONG BIO +1

Method for reducing the formation of by-product dinitrobenzene in the production of mononitrobenzene

A method for making mononitrobenzene using a plug flow reactor train. Benzene, nitric acid and sulfuric acid are introduced into the reactor and produced mononitrobenzene is removed at an outlet end. All of the benzene and at least part of the sulfuric acid are introduced at the inlet end of the reactor. A first portion of the nitric acid is introduced by a first nitric acid feed into the inlet end and a second portion of the nitric acid is introduced at one or more additional feeds that are spaced between the inlet end and the outlet end. The method results in reduced formation of by-product dinitrobenzene, improving the reaction yield of mononitrobenzene while avoiding the need for a distillation step.

Owner:NORAM INT LTD

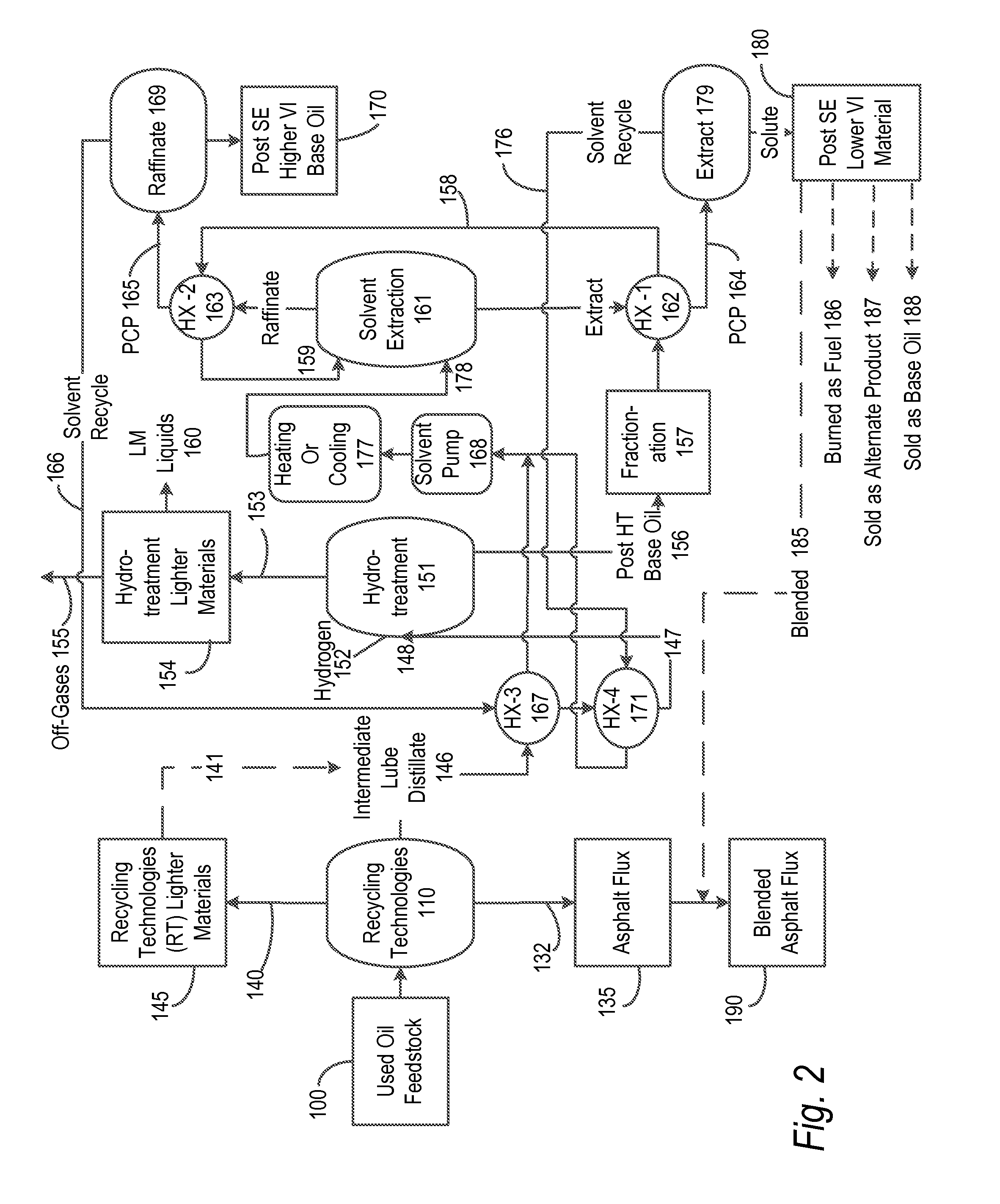

Post hydrotreatment finishing of lubricant distillates

ActiveUS9394495B1Yield lossZero lossTreatment with plural serial refining stagesTreatment with hydrotreatment processesViscosity indexWaste oil

A method wherein either crude oil or a used oil lubricant is processed to produce an intermediate lube distillate which is then hydrotreated to produce a hydrotreated base oil which is then processed by solvent treatment to produce a higher viscosity index base oil (such as Groups II+ and / or III) and a lower viscosity index base oil (such as Groups I and / or II), in each case as compared with the viscosity index of the hydrotreated base oil. In the solvent treatment, one or more solvents are utilized to selectively separate higher viscosity index components from lower viscosity index components found in the hydrotreated base oil, and after the separations have occurred, the solvent is preferably recovered for re-use in the process.

Owner:MURRAY EXTRACTION TECH LLC

Method For Pulling A Silicon Single Crystal

ActiveUS20100316551A1Promote formationYield lossPolycrystalline material growthSiliconCrucibleSilicon

The invention relates to a method for pulling a silicon single crystal from a melt which is contained in a crucible, comprising immersion of a seed crystal into the melt; crystallization of the single crystal on the seed crystal by raising the seed crystal from the melt with a crystal pull speed; widening the diameter of the single crystal to a setpoint diameter in a conical section, comprising control of the crystal pull speed in such a way as to induce a curvature inversion of a growth front of the single crystal in the conical section.

Owner:SILTRONIC AG

Method for braking state monitoring and wind energy installation for carrying out the method

InactiveUS20110238371A1Yield lossFast productionWind motor controlEngine fuctionsEngineeringData memory

A method for determining the state of a braking apparatus of a wind energy installation can include obtaining data relating to load behavior of the braking apparatus, recording a measured value during a time period between a start of a braking process and an end of the braking process, and determining a brake state characteristic value based on the data and the measured value. A wind energy installation for performing the method can include a braking apparatus, a sensor, a control unit configured to instruct the sensor to record a measured value in a time period between a start of a braking process and an end of a braking process, a data memory configured to store data relating to load behavior of the braking apparatus, and a computation module configured to determine a brake state characteristic value based on the data and the measured value.

Owner:SENVION GMBH

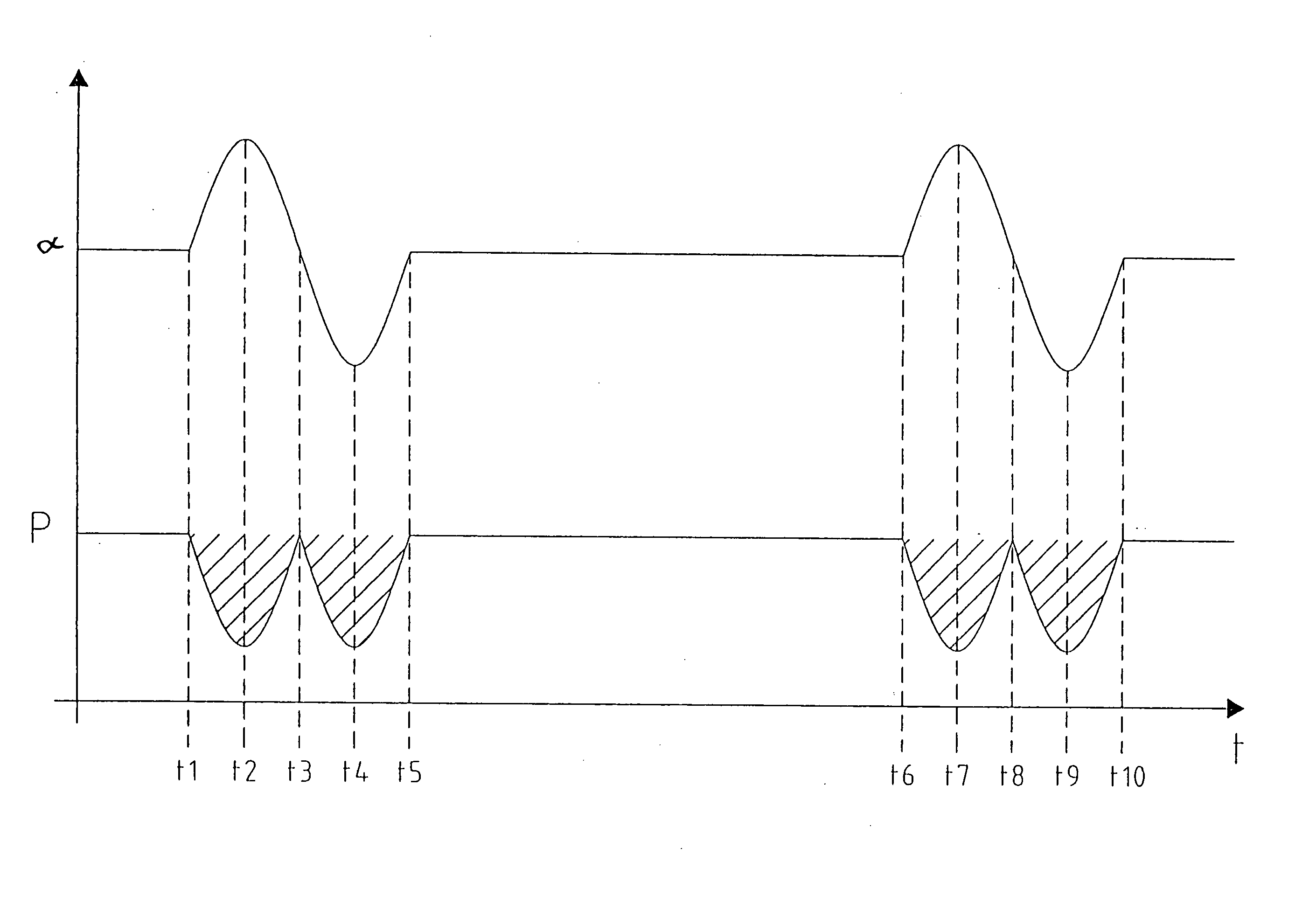

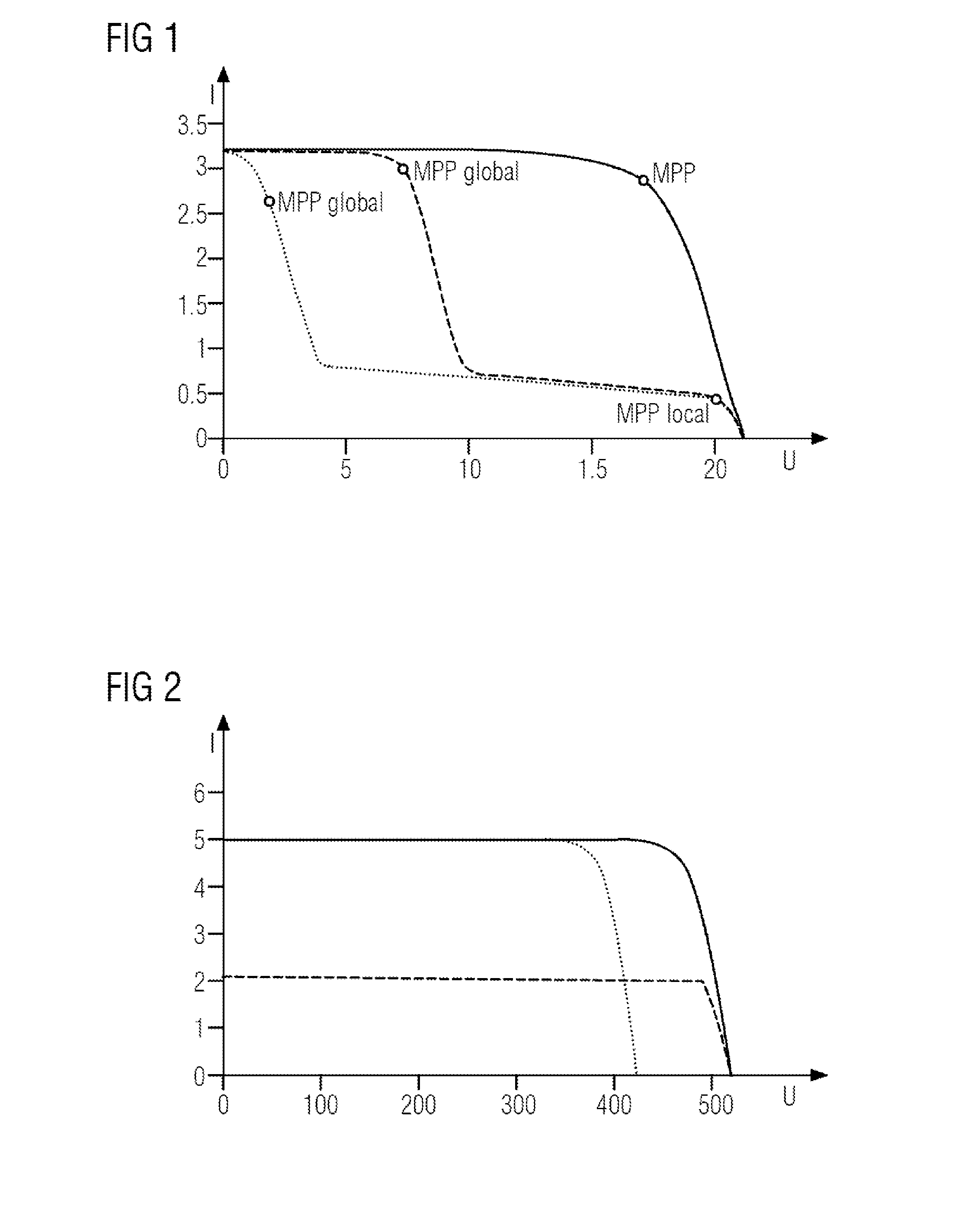

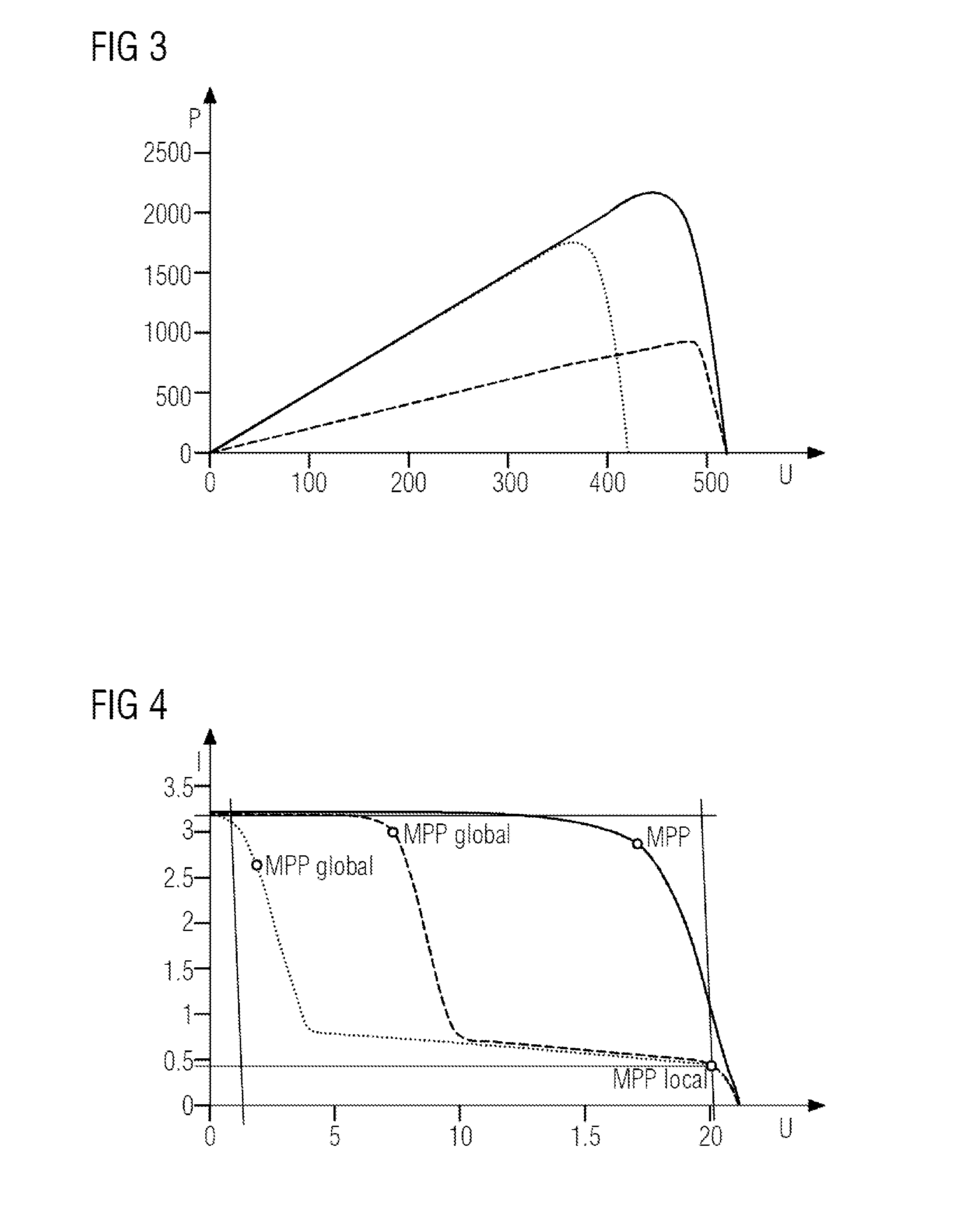

Method for optimizing the yield of a partially shaded photovoltaic array

ActiveUS20140232206A1Good yieldYield lossDc network circuit arrangementsBoards/switchyards circuit arrangementsDc link voltageFrequency changer

A method for optimizing the yield of a photovoltaic array with an inverter is provided. The method includes: a) cyclically measuring a current (Igiv) and a DC link voltage (U) when controlling the inverter by a MPP method (Maximum Power Point) and storing a measured current value, b) lowering the DC link voltage (U) to a value that exceeds by no more than 100% a minimum DC link voltage (Umin) admissible for operation of the inverter, c) measuring a current (Ired) with a reduced DC link voltage and comparing it with a previously stored value at a given time for the current (Igiv), d) if a prescribed threshold for a difference between the two currents (Ired, Igiv) is exceeded, a searching process for a global MPP (Maximum Power Point) is initiated, e) otherwise, operation is continued at a power maximum (MPP) with a last-stored current value for the current (Igiv).

Owner:KACO NEW ENERGY GMBH

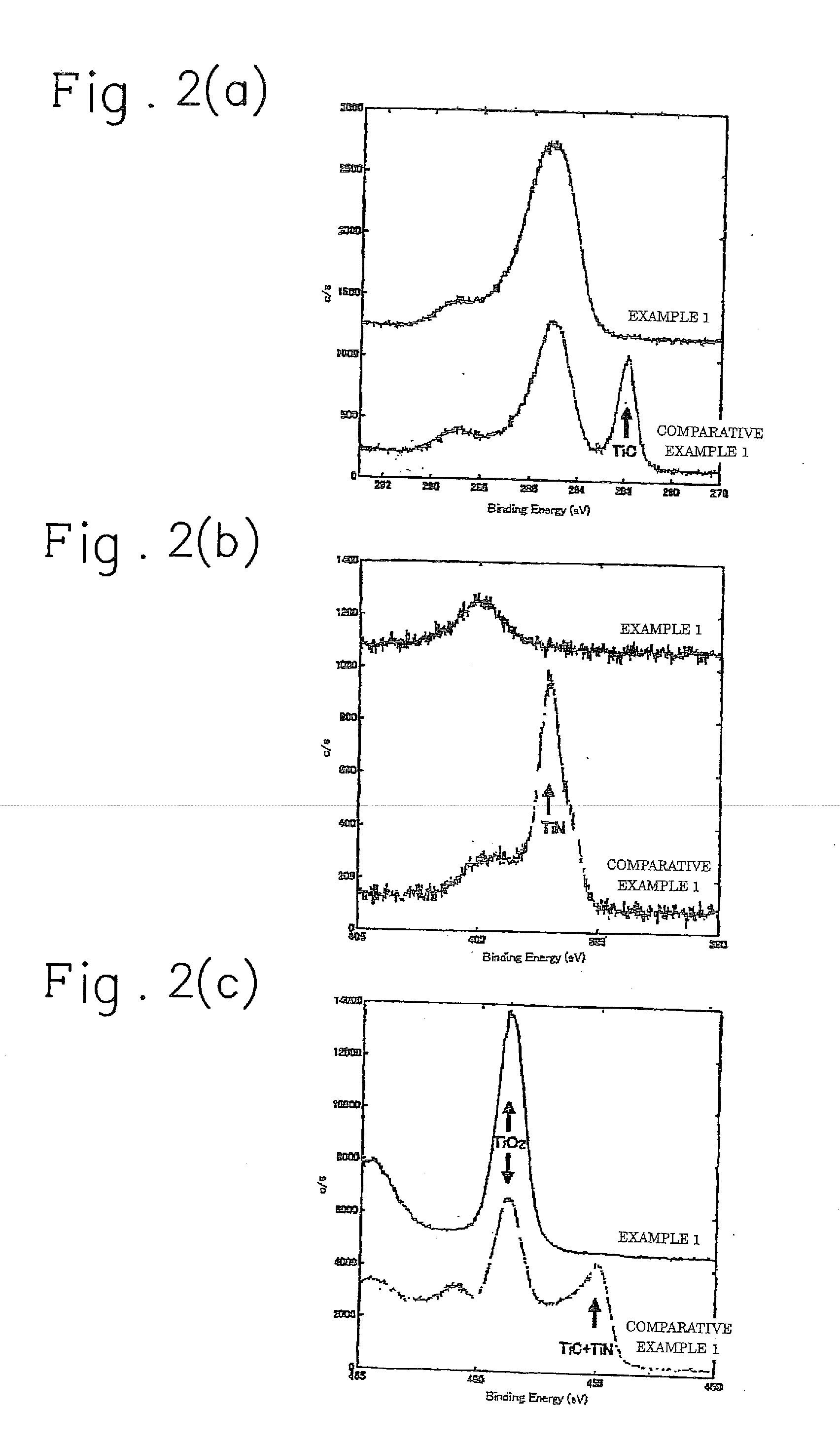

Titanium material and method for producing titanium material

ActiveUS20110244266A1Increase surface lubricityImprove corrosion resistanceElectrolysis componentsSolid state diffusion coatingSurface layerTitanium nitride

Disclosed are a titanium material having excellent surface characteristics and a method for readily producing a titanium material having excellent surface characteristics. More specifically, provided is a titanium material including a surface film having a multilayer structure provided with at least two layers, namely a surface layer and an inner layer in contact with the inner side of the surface layer, wherein the surface layer is formed of titanium oxide with a hardness of 5 GPa to 20 GPa, and the inner layer contains at least one of titanium carbide and titanium nitride.

Owner:NIPPON STEEL CORP

Method for isolating nucleic acids

ActiveUS9695465B2Quality improvementReduce yieldMicrobiological testing/measurementPreparing sample for investigationCationic detergentChemistry

The present invention pertains to a method for isolating nucleic acids from a sample, preferably a blood sample, comprising the following steps: a) obtaining a sample which has been stabilized by the use of at least one cationic detergent, wherein the cationic detergent has formed complexes with the nucleic acids; b) obtaining the complexes optionally together with other sample components from the stabilized sample, wherein said complexes comprise the nucleic acids to be isolated; c) resuspending the complexes and optionally adding one or more additives before, during and / or after resuspension, thereby obtaining a resuspended sample comprising at least: i) the nucleic acid to be isolated; ii) at least one chaotropic agent; and iii) at least one chelating agent; and d) isolating nucleic acids from the resuspended sample. It was found that adding a chelating agent during resuspension considerably increases the nucleic acid yield as the formation of precipitates which irreversibly adhere to the container wall is considerably reduced.

Owner:QIAGEN GMBH

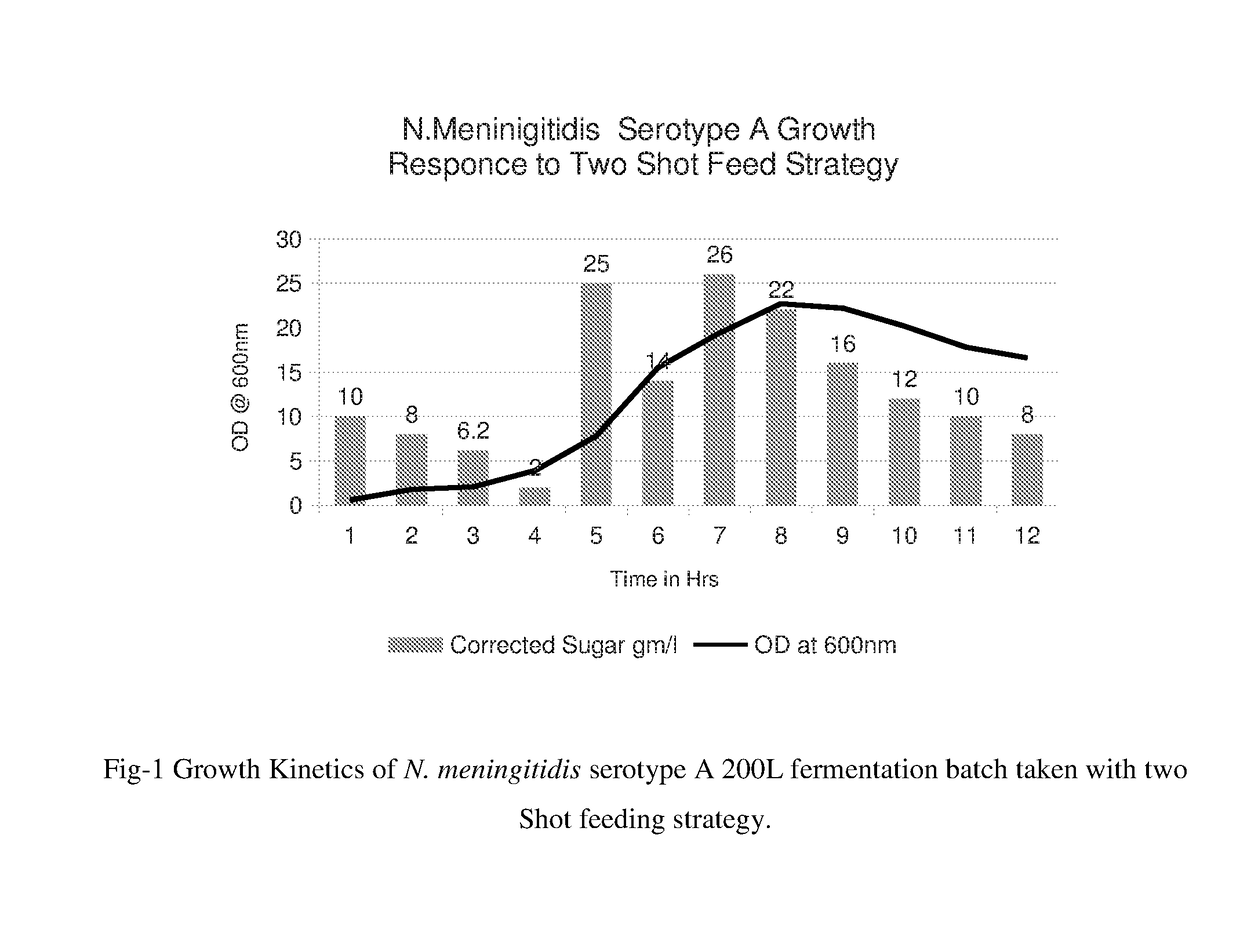

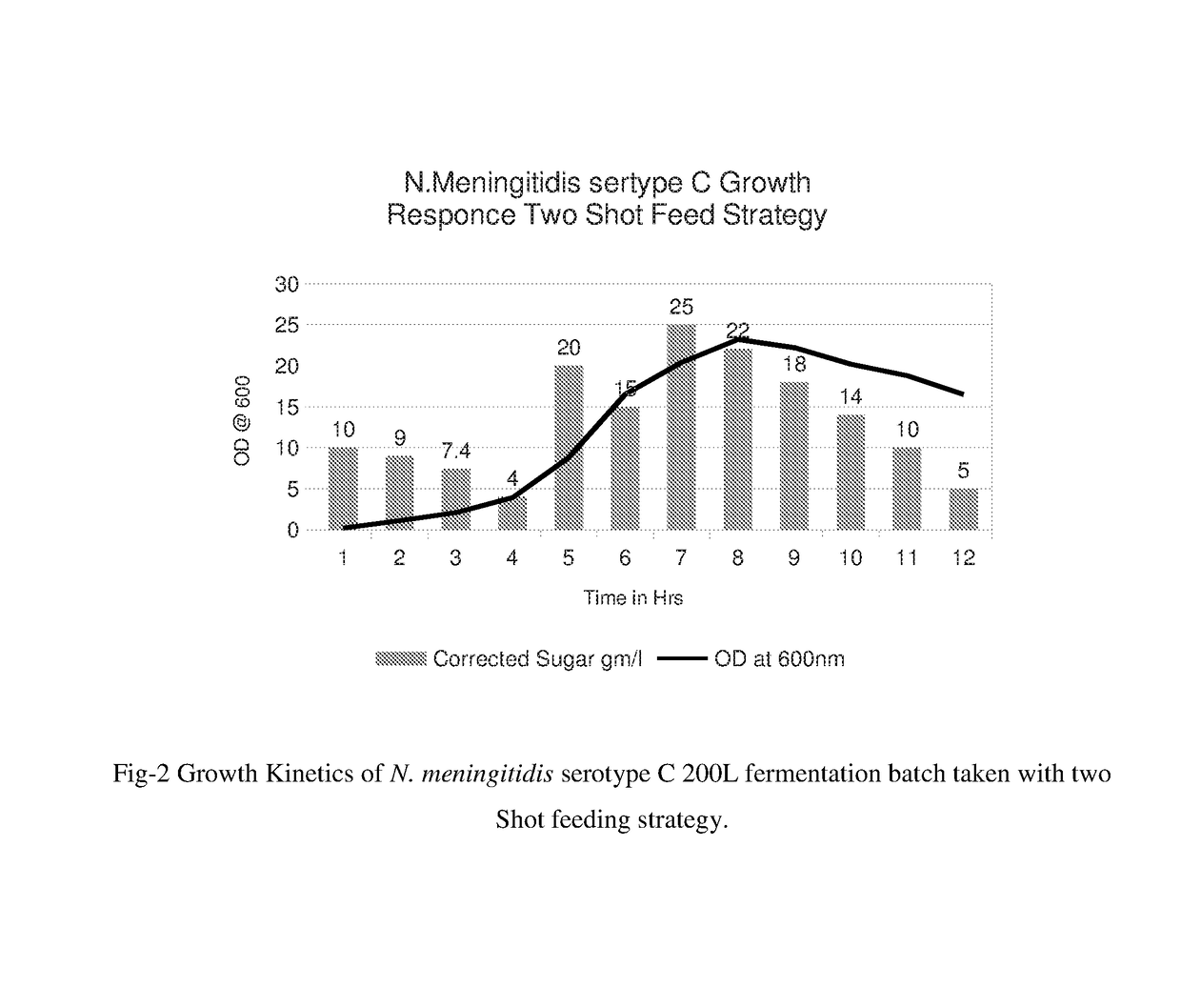

Polysaccharide vaccine formulations and processes for industrial production of bacterial polysaccharides

ActiveUS20180185465A1Highly effectiveCost-effectiveAntibacterial agentsBacterial antigen ingredientsBacteroidesAntigen

The present invention relates to the field of combined vaccine compositions which are effective against all forms of meningococcal diseases as well as typhoid fever. The vaccine formulations comprising antigens from capsular polysaccharides of Neisseria meningitidis A, Neisseria meningitidis C, Neisseria meningitidis Y, Neisseria meningitidis W135, Neisseria meningitidis X, Salmonella typhi Vi capsular polysaccharide (ViPs) or capsular ViPs conjugated to a carrier protein tetanus toxoid (ViPs-TT). This invention is also related to improved methods, especially the use of an improved feed media and an improved method of downstream processing and industrial purification of capsular polysaccharides. The vaccine is free of any animal component or alcohol and is in absolute compliance with respect to the religious sentiments of various ethnic groups. The composition is highly effective and stable, yet cost-effective and affordable, especially for lower-middle income and low-income countries.

Owner:BHARAT BIOTECH INTERNATIONAL

Sertraline hydrochloride form II and methods for the preparation thereof

Owner:RECORDATI CHEM & PHARMA

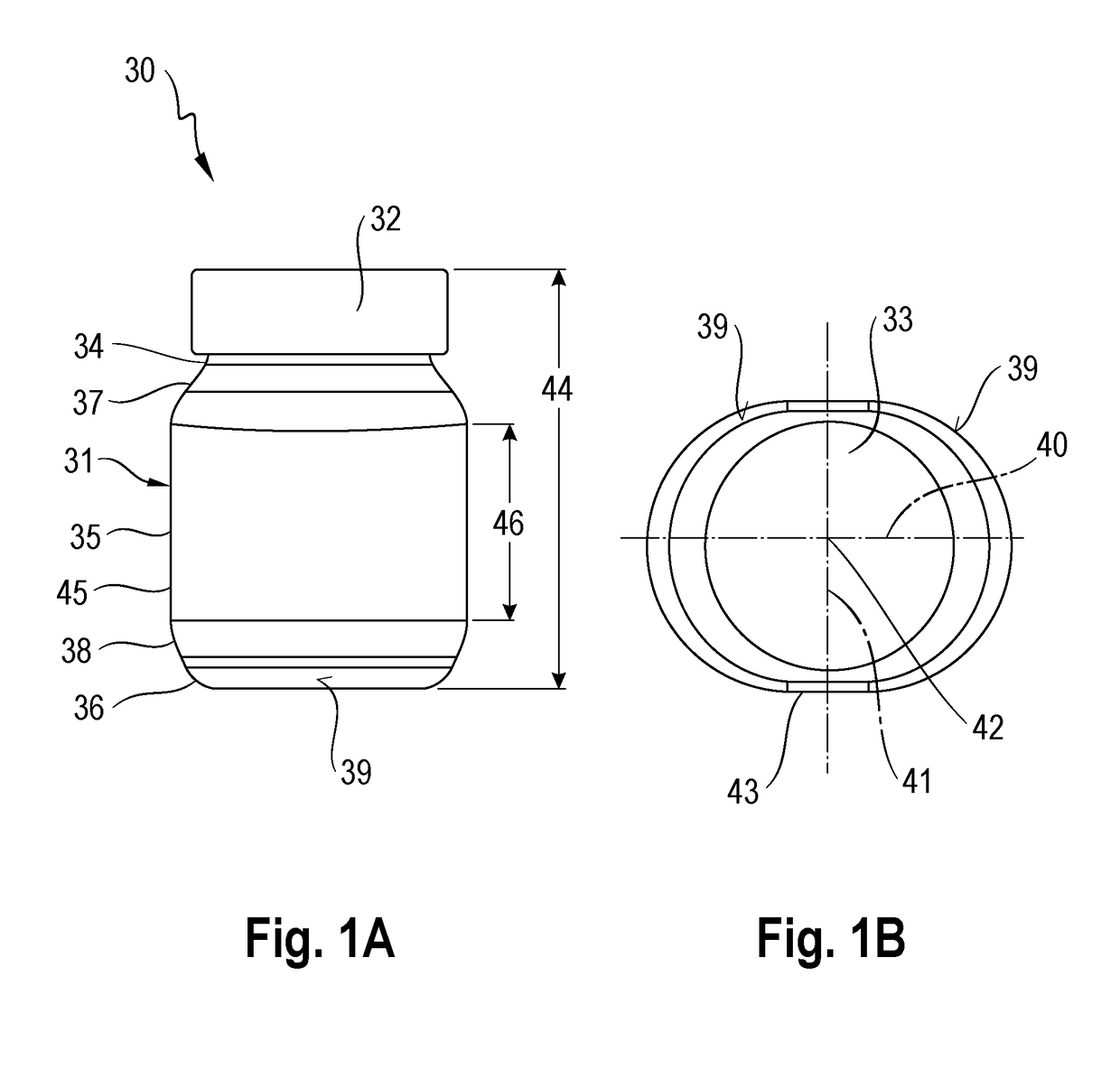

Centrifuge vessel assembly

ActiveUS9868124B2Large capacityIncrease valueRotary centrifugesLaboratory glasswaresMarine engineeringCentrifuge

Owner:THERMO ELECTRONICS LED GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com