Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Clamping force is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

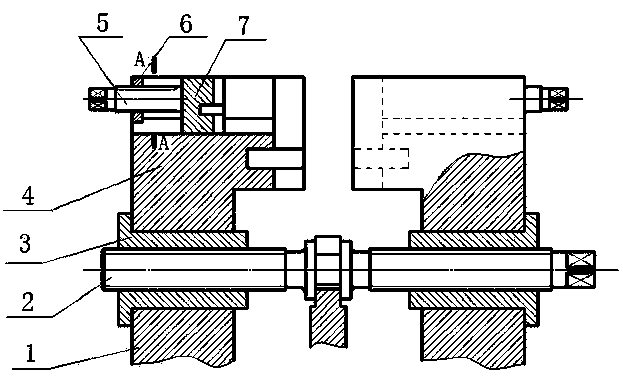

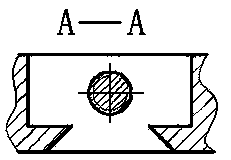

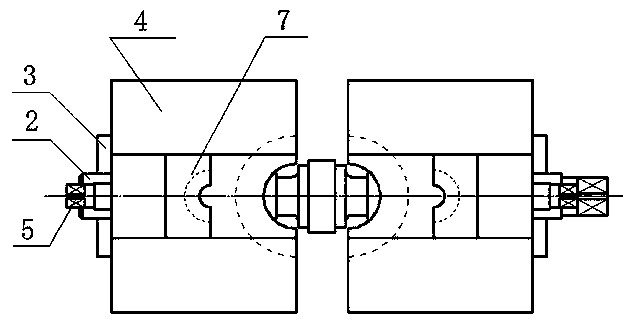

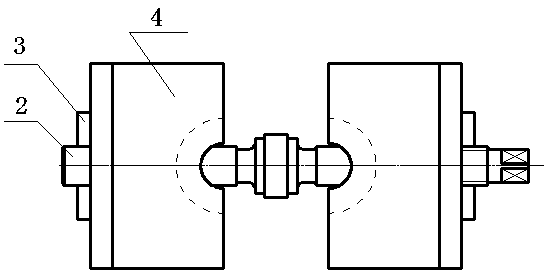

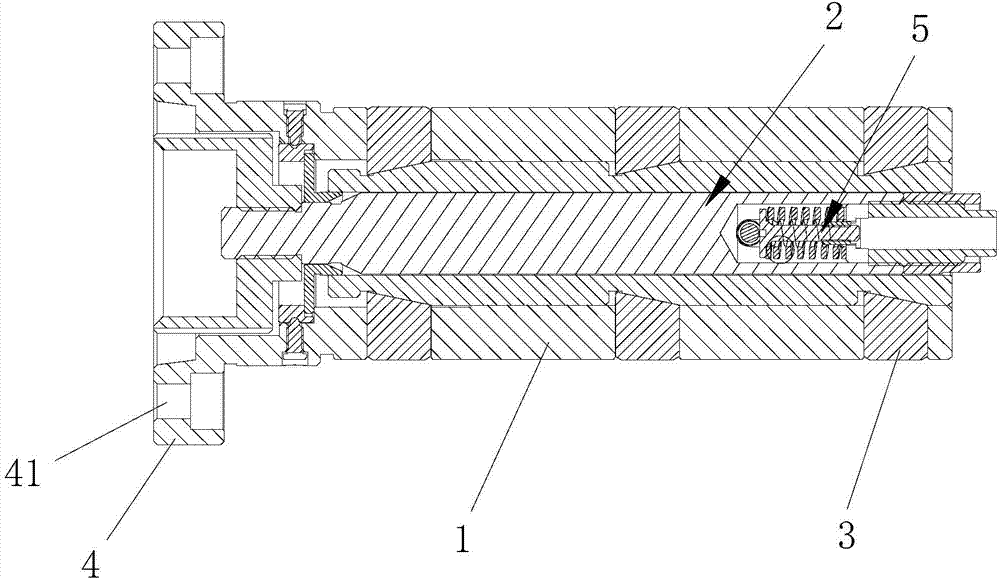

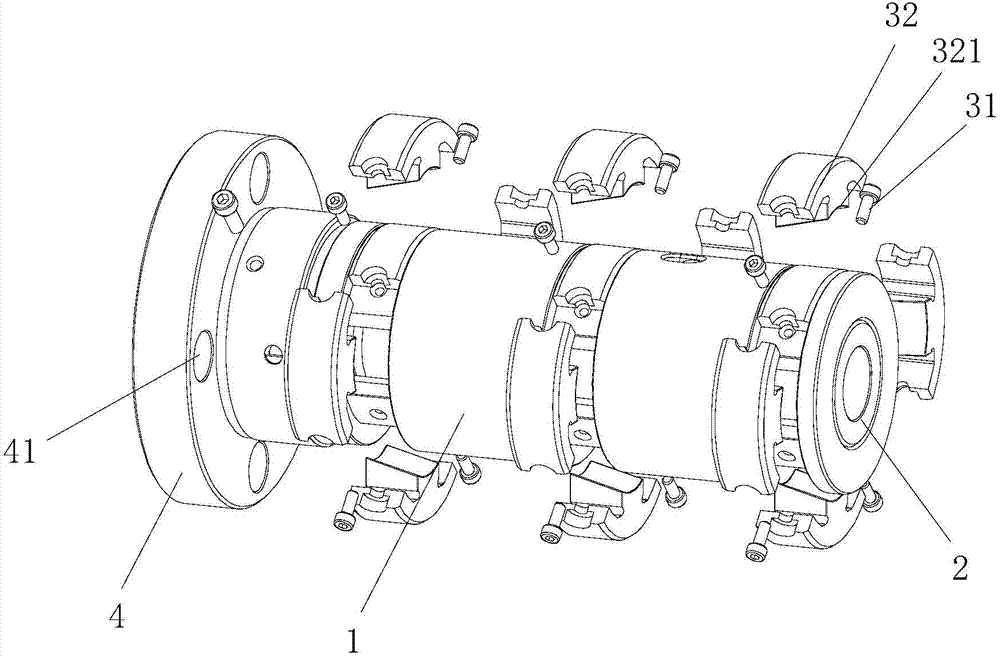

Inward-pushing-type clamping device of three-dimensional corner clamping tube in numerically-controlled tube bending machine

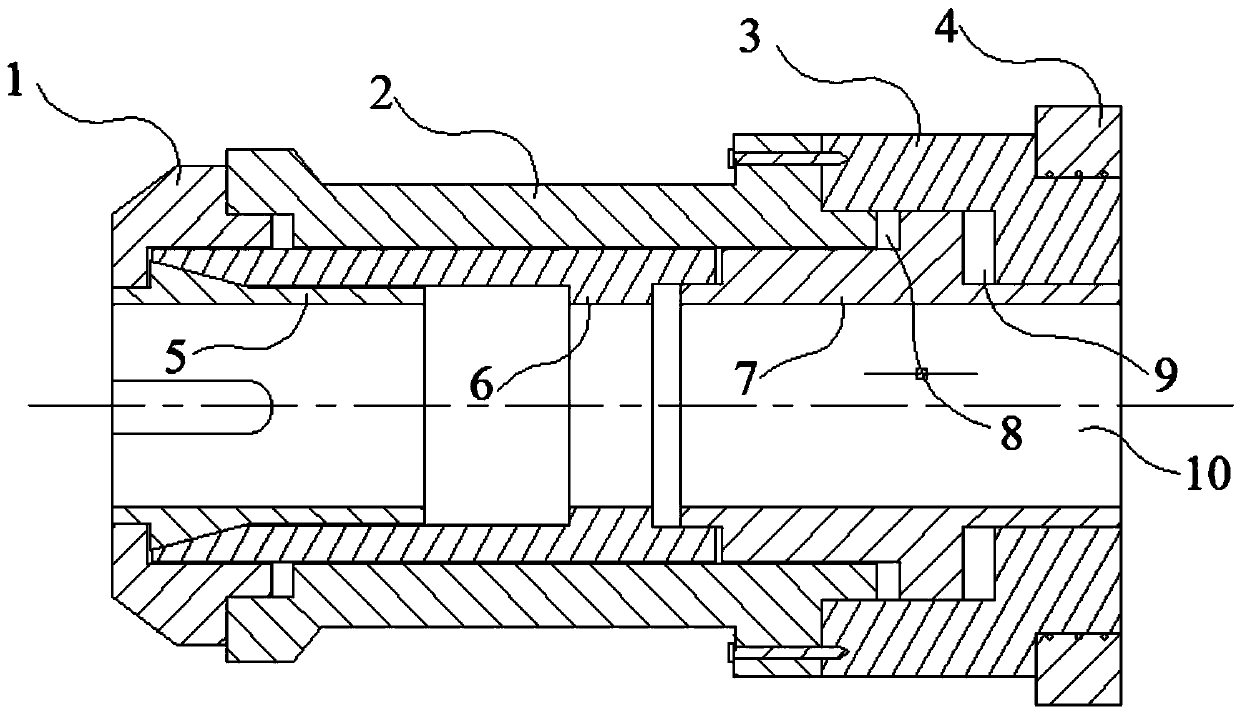

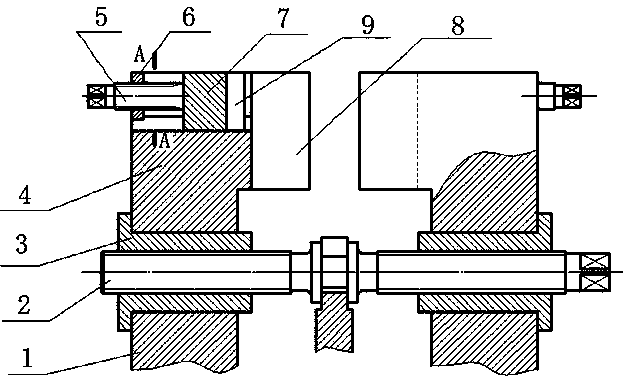

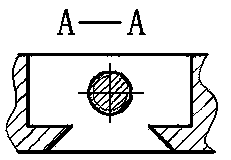

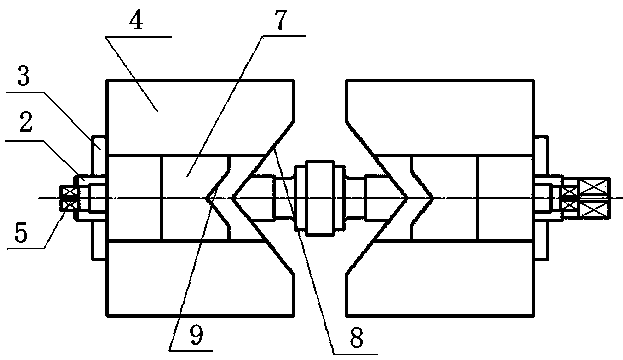

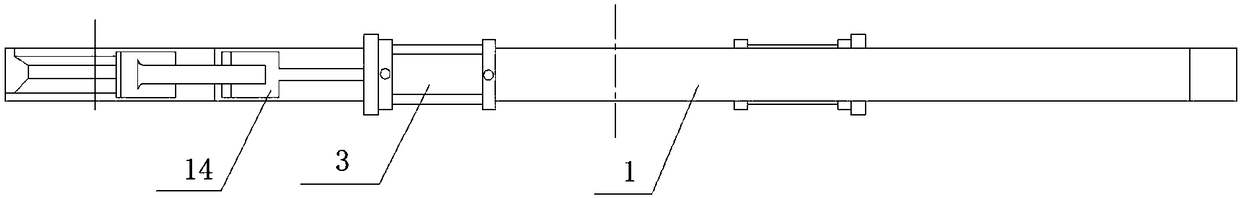

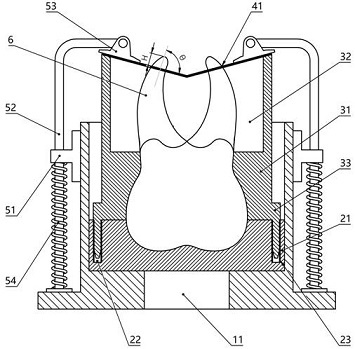

The invention discloses an inward-pushing-type clamping device of a three-dimensional corner clamping tube in a numerically-controlled tube bending machine, and belongs to the field of numerically-controlled tube bending machines. The inward-pushing-type clamping device comprises a flexible chuck, and further comprises a top end fixing sleeve, an outer fixing sleeve, a hydraulic outer cylinder, a bearing, an inward-pushing sleeve, a hydraulic inner cylinder, a first hydraulic cavity and a second hydraulic cavity. The top end fixing sleeve, the outer fixing sleeve, the hydraulic outer cylinder, the bearing, the flexible chuck, the inward-pushing sleeve, the hydraulic inner cylinder, the first hydraulic cavity and the second hydraulic cavity are respectively of a rotationally-symmetric structure, share the same central axis and internally forms a clamping inner cavity jointly. Due to the arrangement and assembling relationship of the components, when the inward-pushing-type clamping device clamps tubes, clamping force is easily controlled, tubes are not damaged, it is ensured that the inward pushing sleeve is steadily pushed to move and the flexible chuck is steadily pushed to contract in the clamping process, and the damage and skid, caused by uneven moving, of a workpiece are avoided.

Owner:ANHUI DEXI DHI TECH

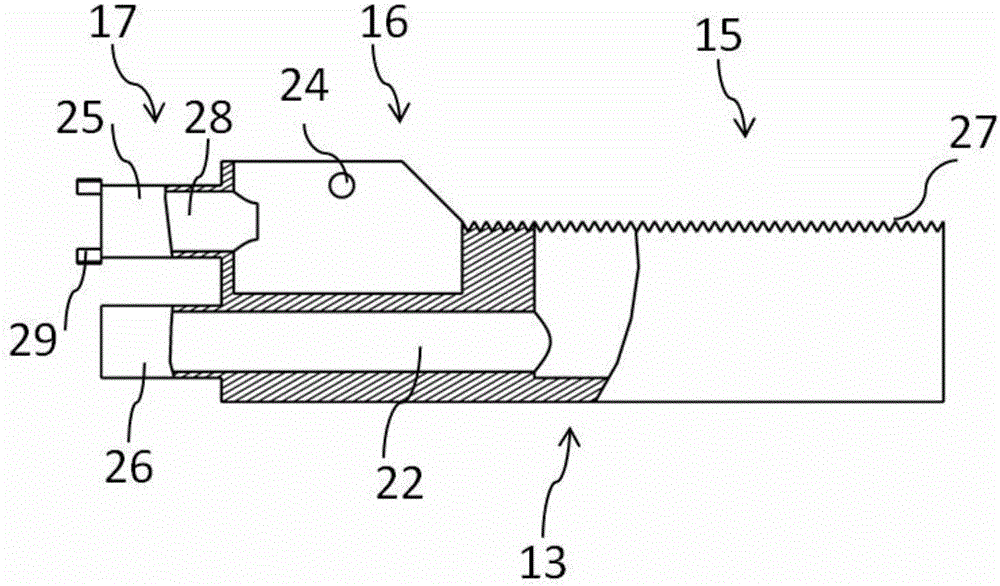

Operating forceps with negative pressure suction function

ActiveCN105078542AIncrease the bearing areaNot easy to slip offCannulasEnemata/irrigatorsPressure systemForceps

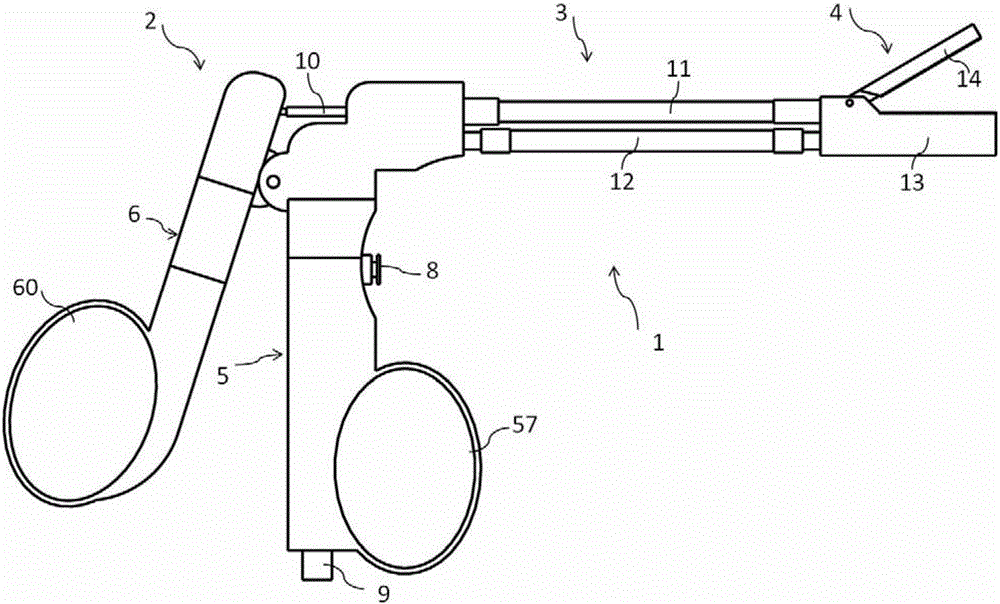

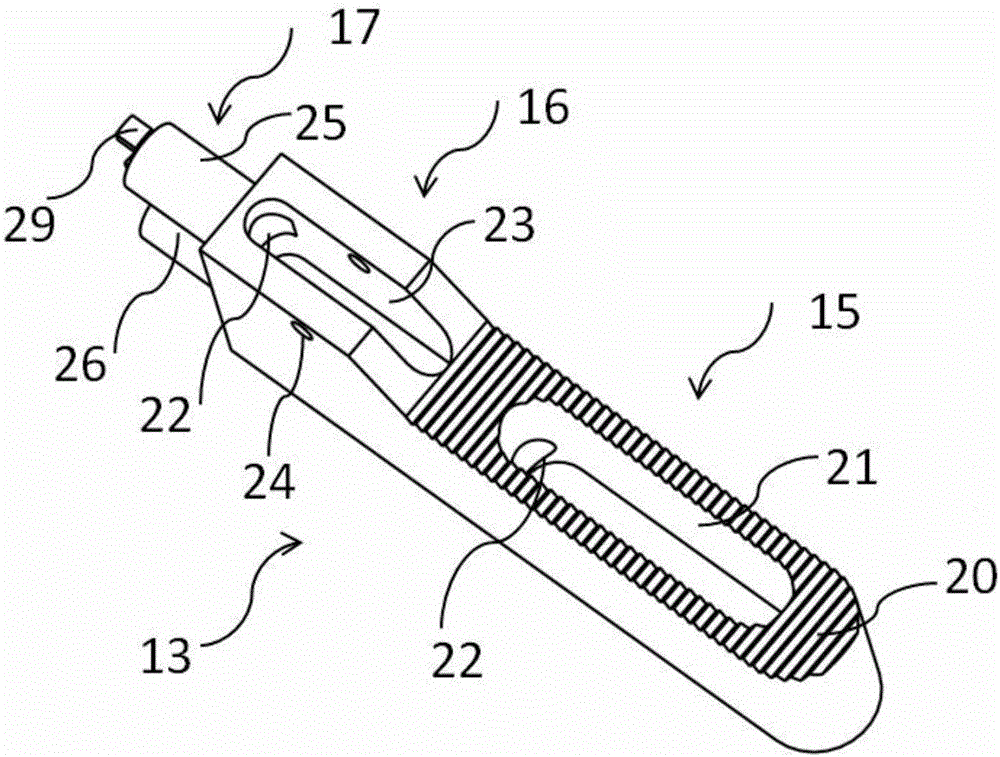

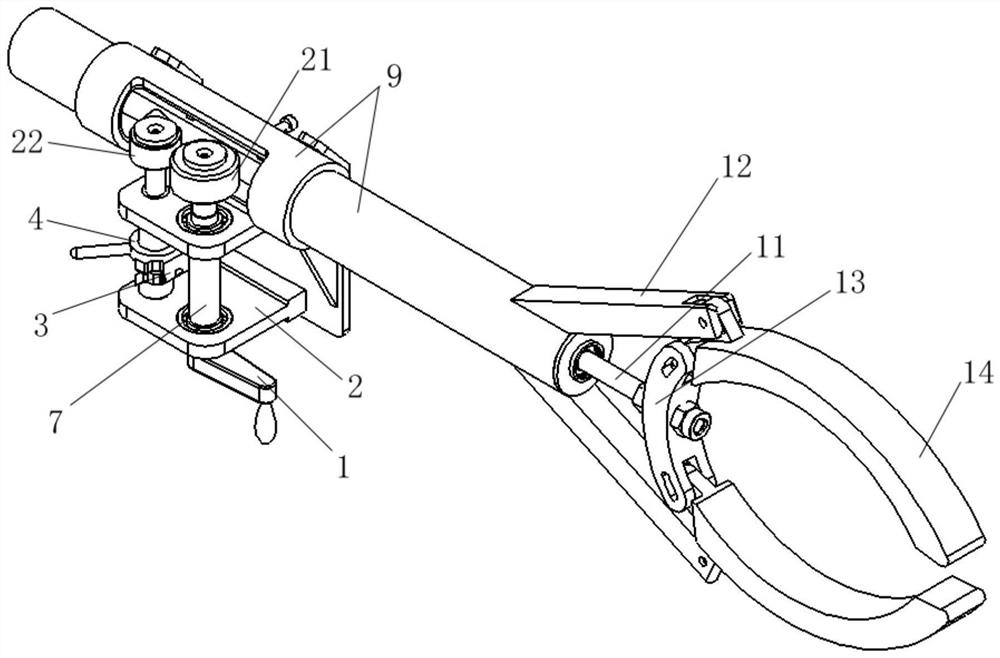

The invention discloses a pair of operating forceps with a negative pressure suction function. The pair of operating forceps comprises forcep handles, forcep levers and a forcep head, wherein the forcep handles are connected with the forcep head through the forcep levers; the forcep head comprises a main claw and an auxiliary claw hinged to the main claw; the forcep handles comprise a fixed handle and a movable handle hinged to the fixed handle; a connector connected with a negative pressure system is arranged on the fixed handle, a handle negative pressure channel communicated with the connector is arranged in the fixed handle in a hidden manner, a lever negative pressure channel communicated with the handle negative pressure channel is arranged in one forcep lever, and a head negative pressure channel communicated with the lever negative pressure channel is arranged in the main claw in a hidden manner; a negative pressure hole communicated with the head negative pressure channel is further formed in the main claw; the fixed handle, the corresponding forcep lever and the main claw are sequentially fixedly connected; the movable handle is connected with the auxiliary claw through a pull rod penetrating through an inner cavity of one forcep lever, and the movable handle pulls the pull rod to control the auxiliary claw and the main claw to be closed and opened. According to the technical scheme, tissue can be clamped under the joint action of mechanical clamping and negative pressure clamping, and the pair of operating forceps has the advantages of controllability of clamping force, little damage to tissue, adaptability to various soft tissue organs, safe and precise operation and the like.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

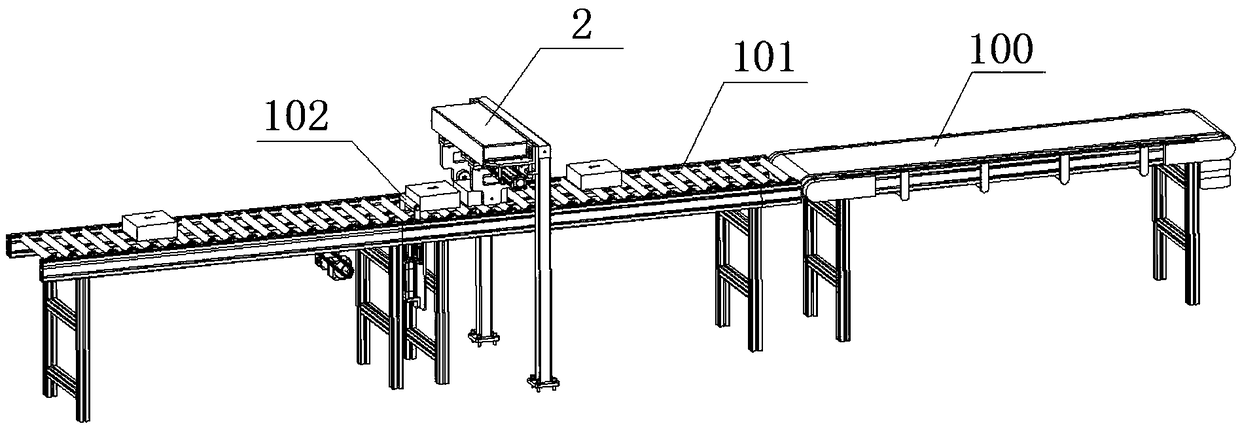

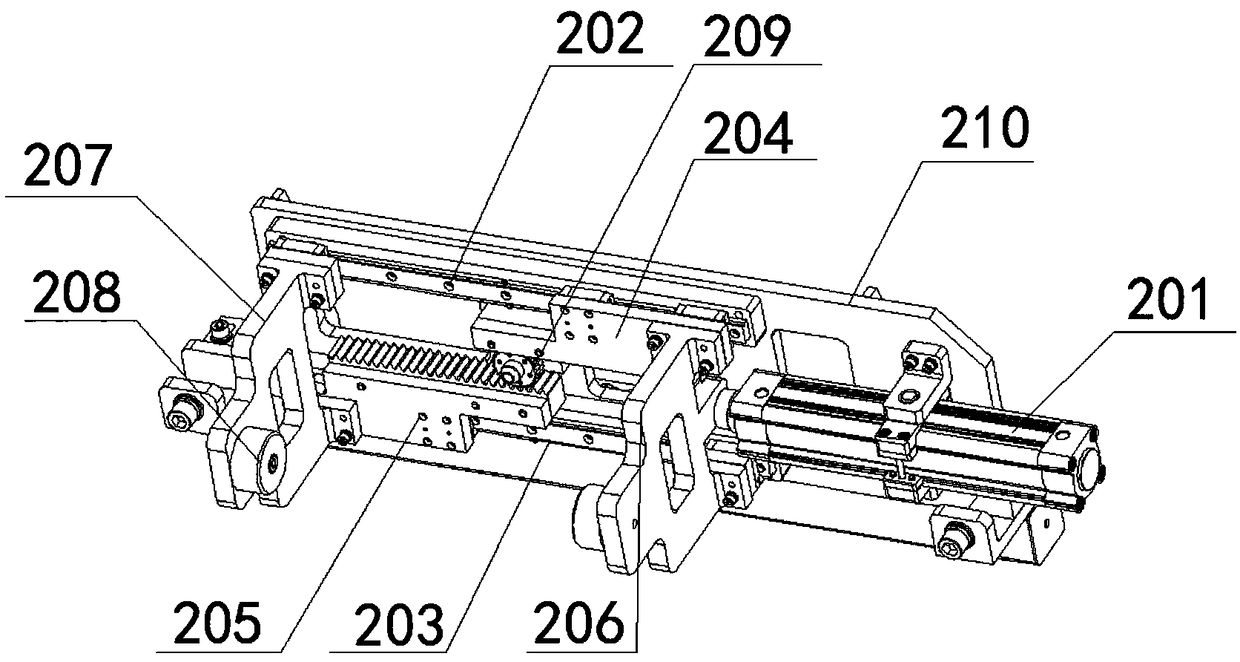

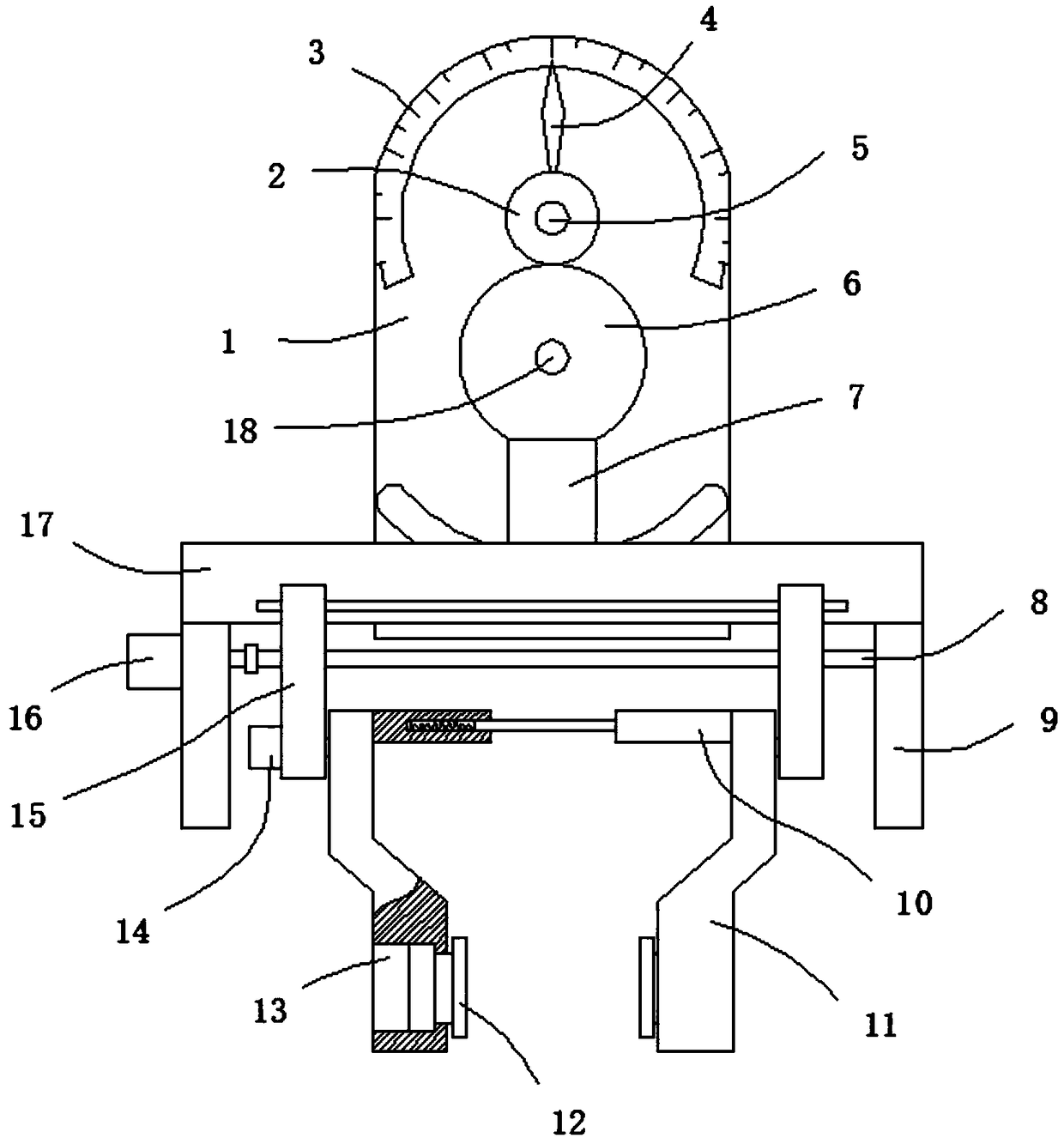

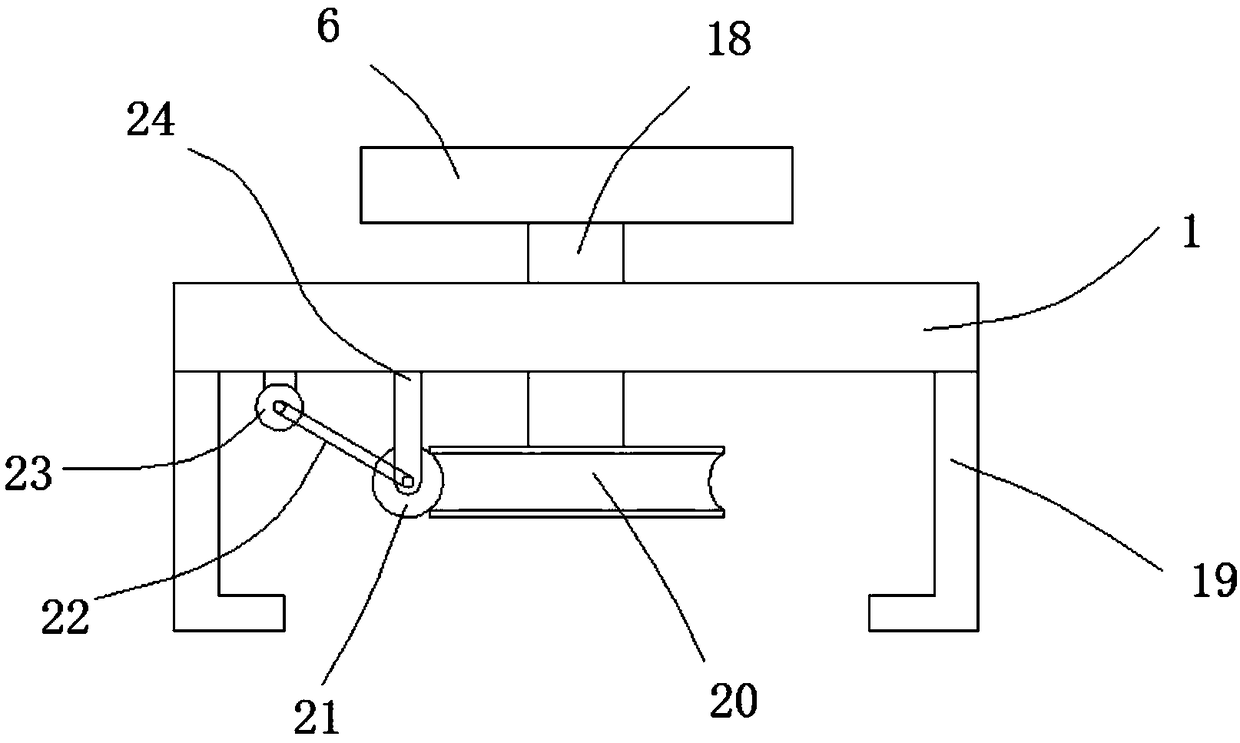

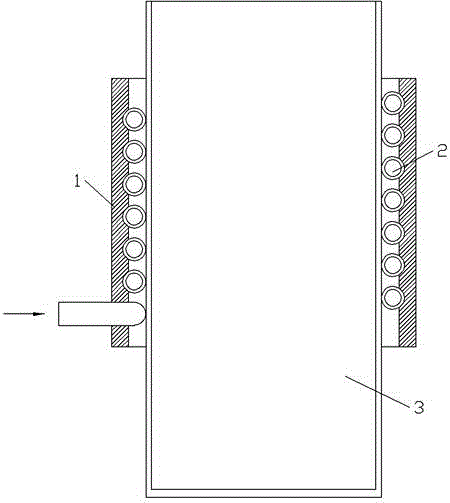

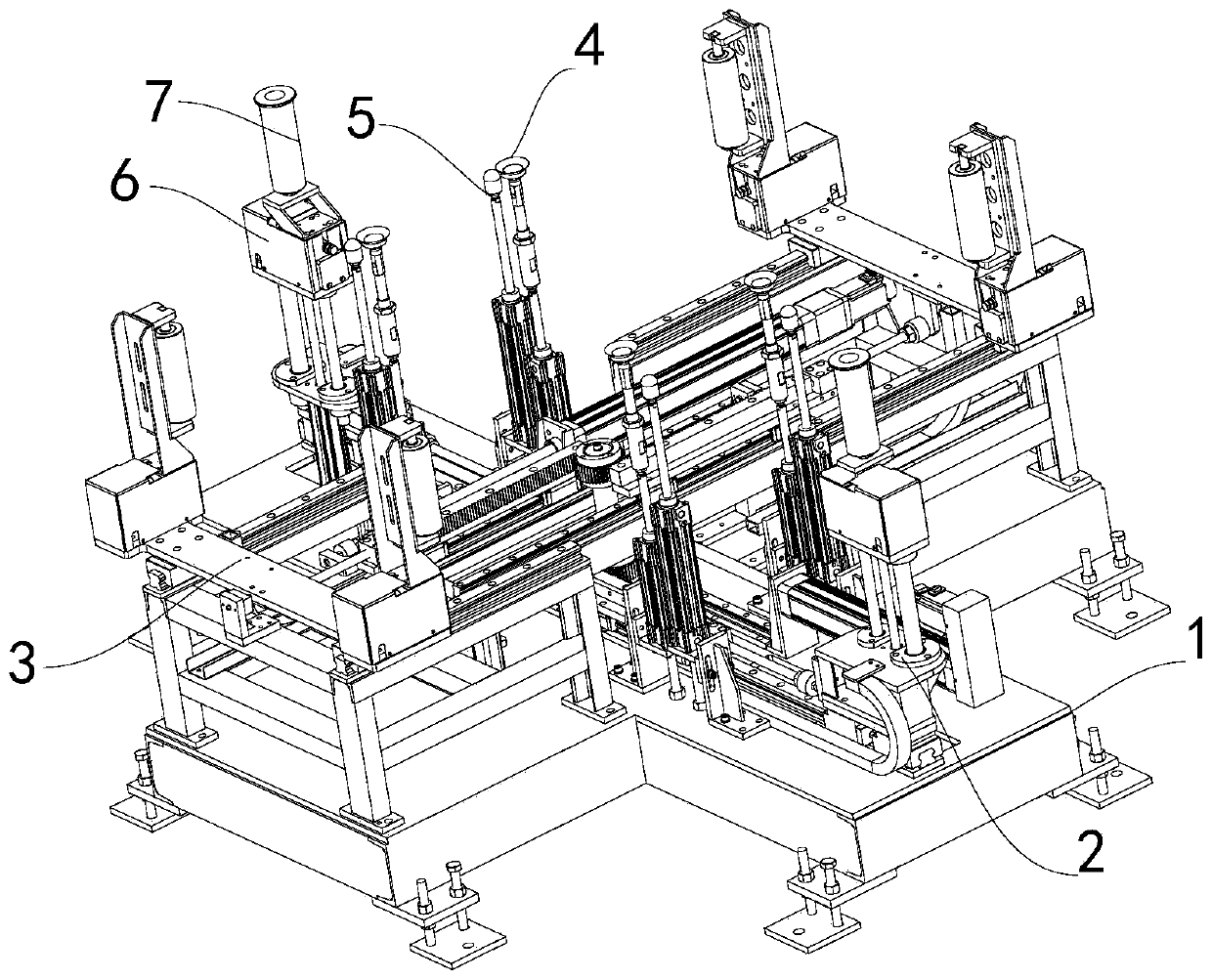

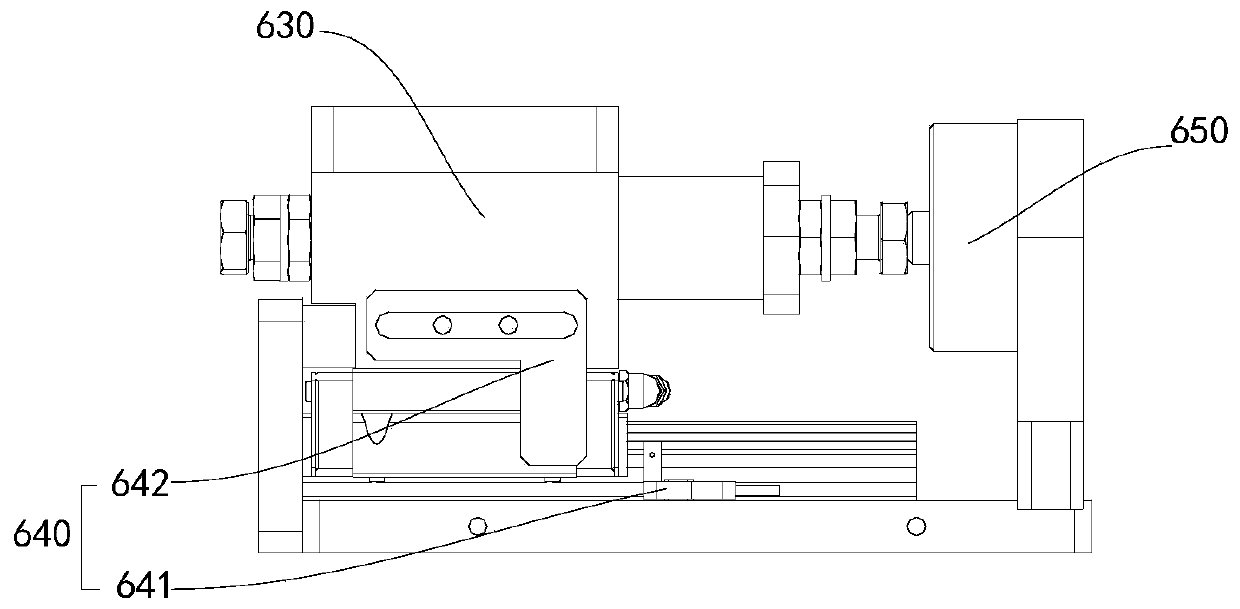

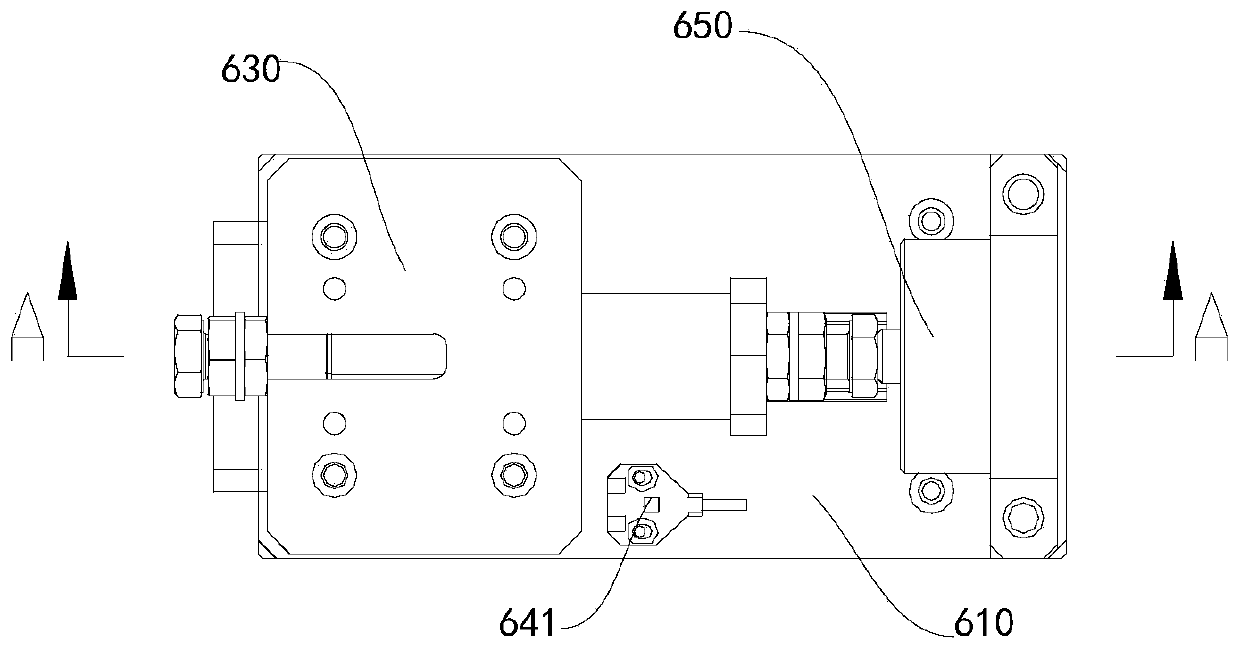

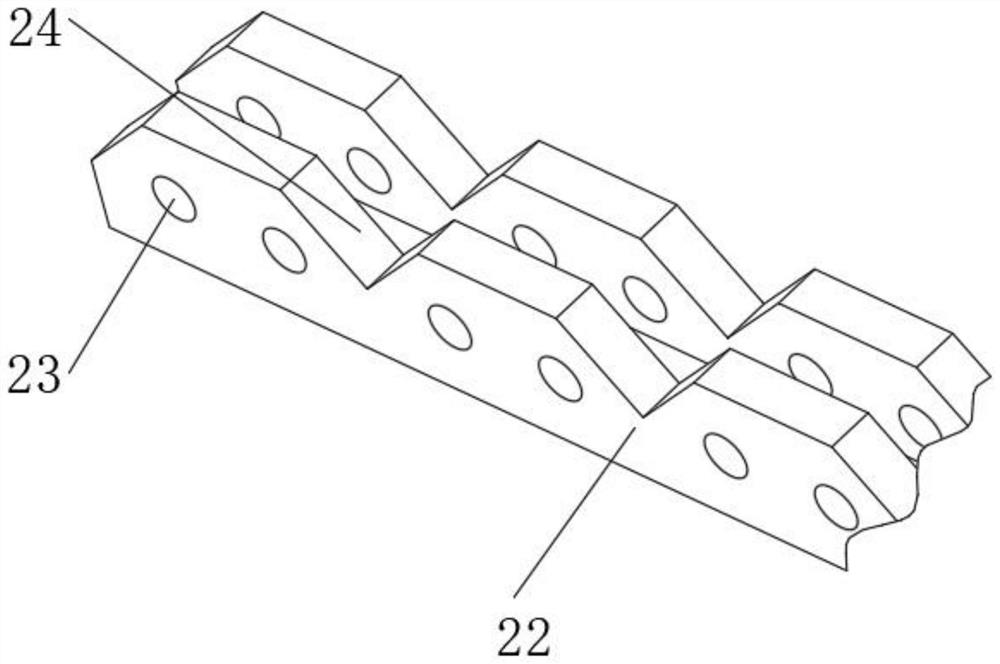

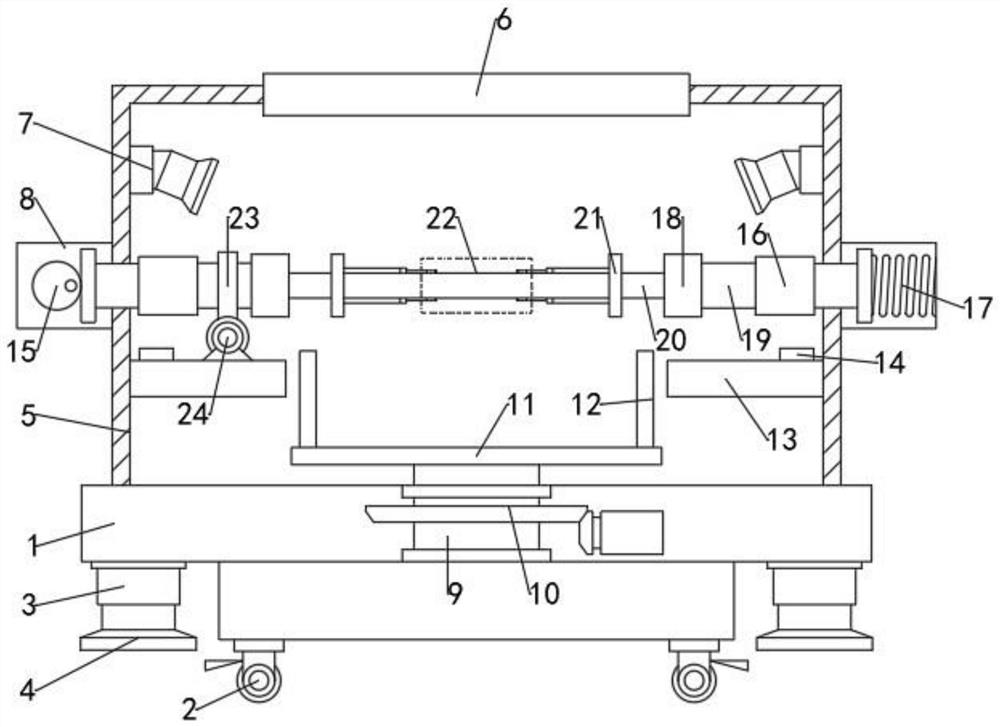

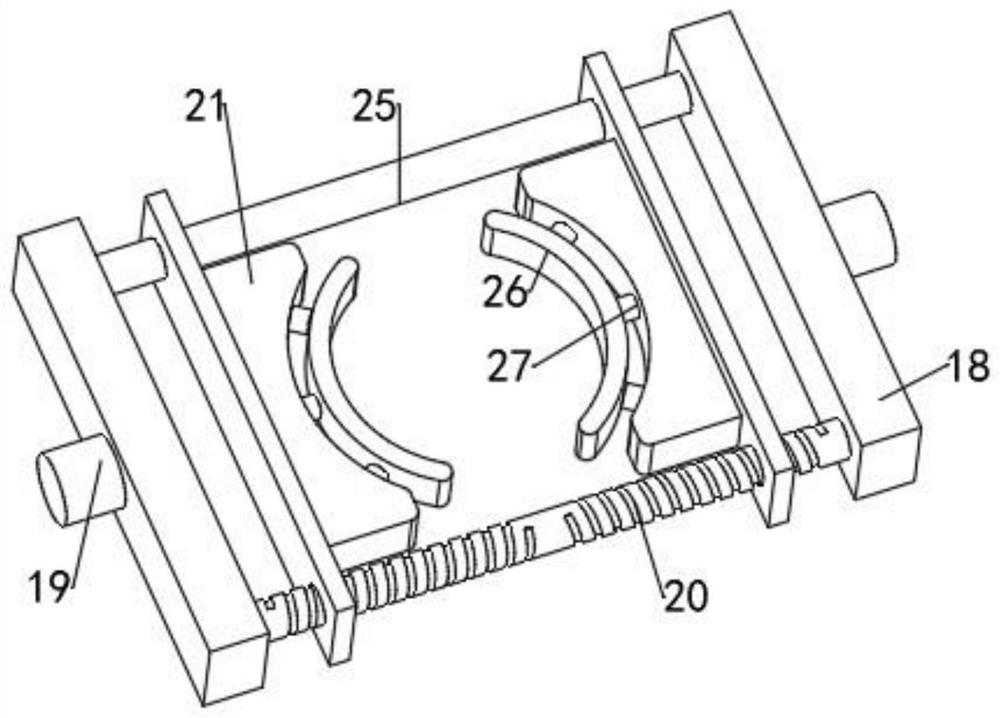

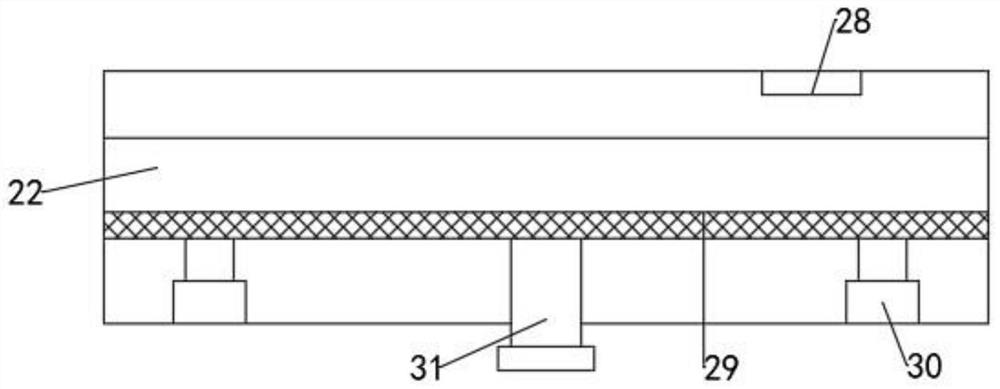

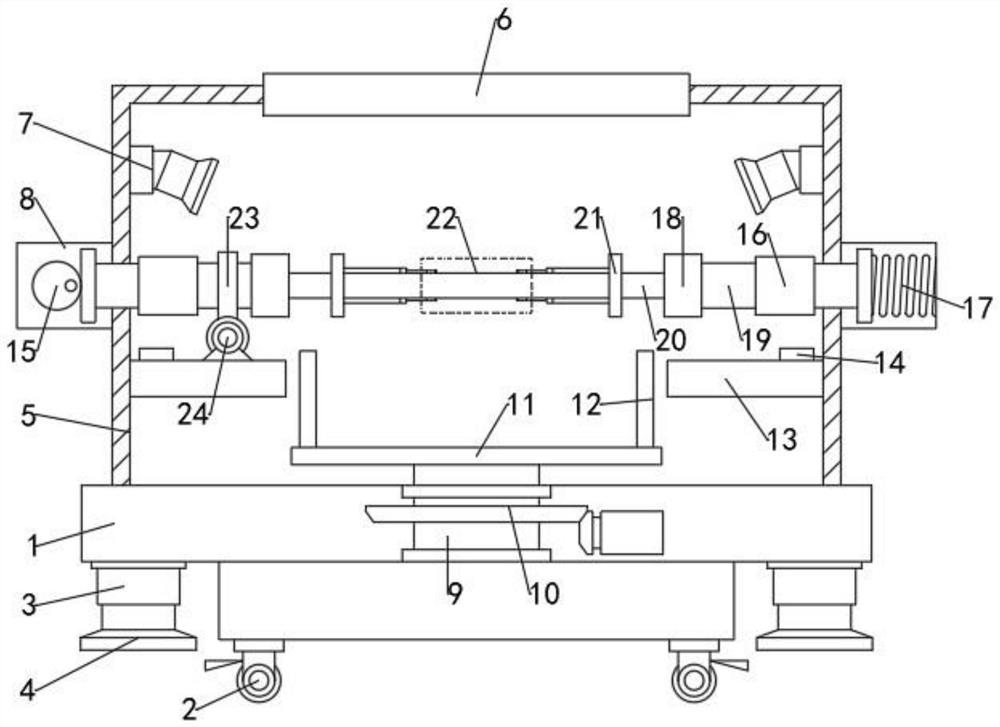

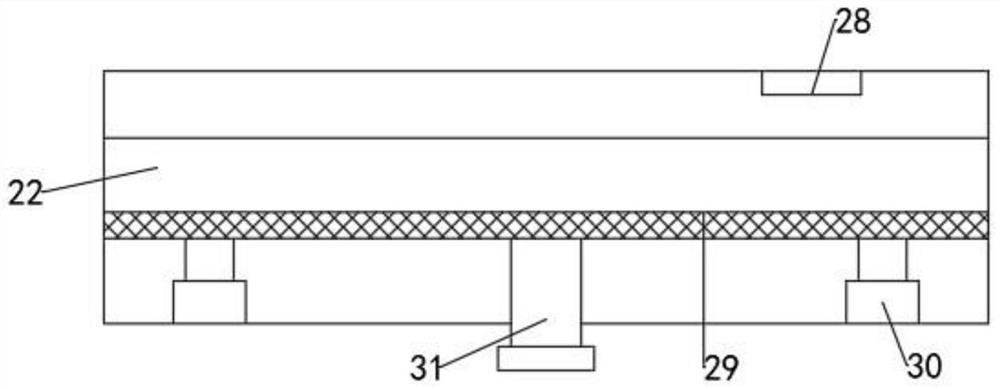

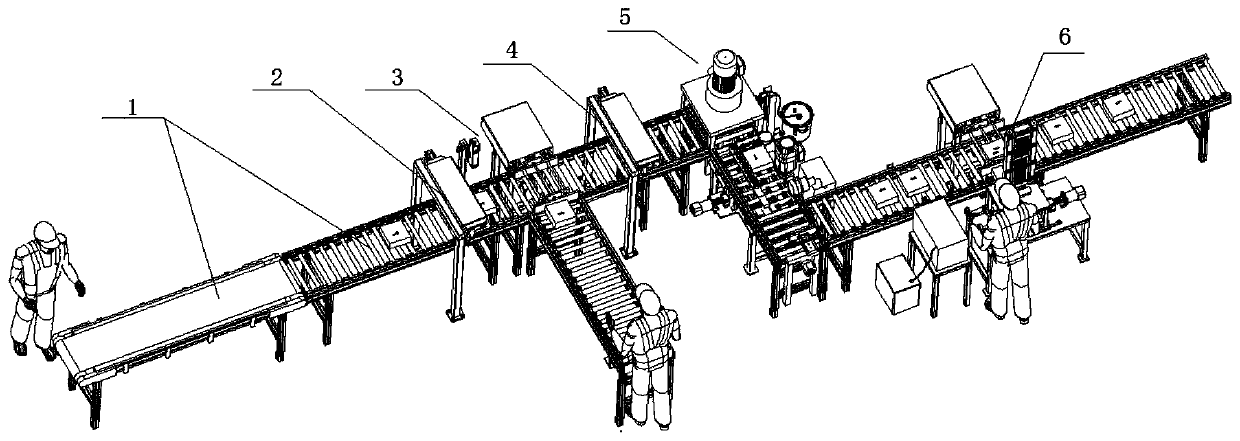

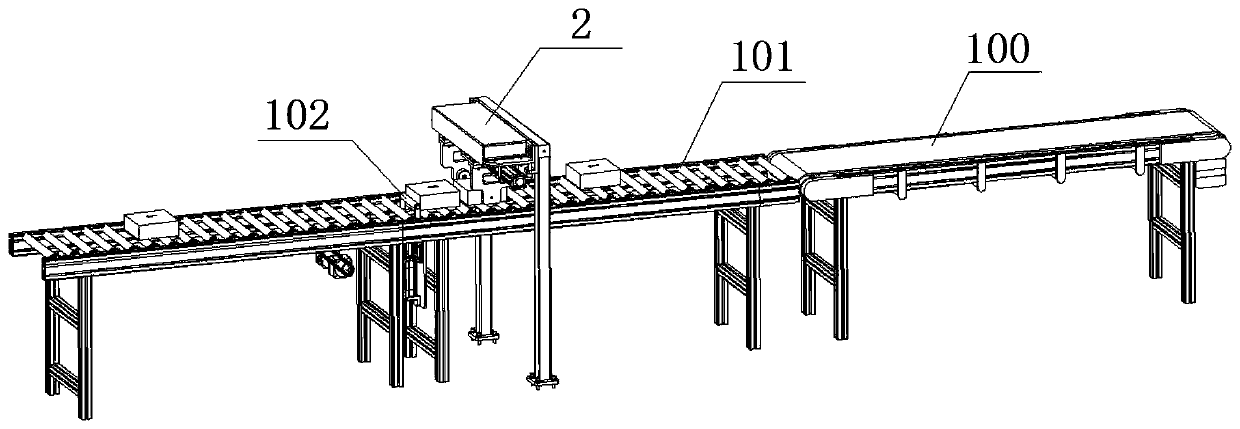

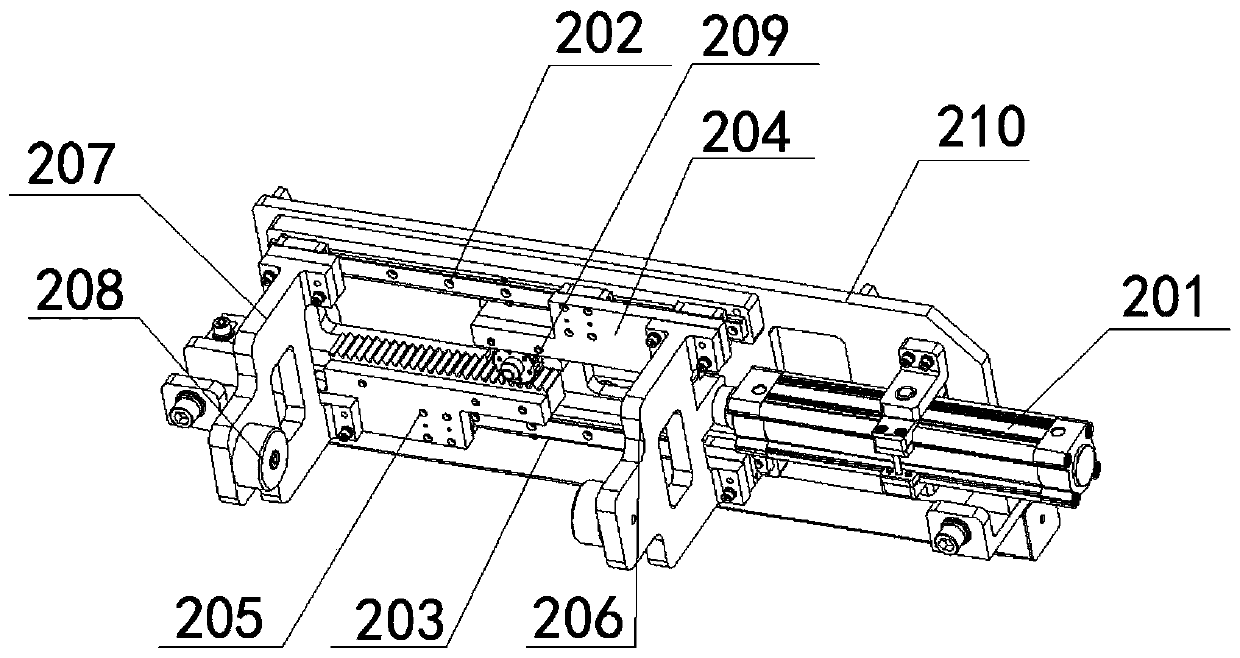

Automatic identifying and detecting operation line for refractory bricks

The invention discloses an automatic identifying and detecting operation line for refractory bricks. The automatic identifying and detecting operation line for the refractory bricks comprises a conveying unit, and the conveying unit is used for conveying the refractory bricks among a primary centering unit, a laser detection unit, a secondary centering unit, a marking and ink jetting unit and an automatic pasting unit in sequence. By means of the automatic identifying and detecting operation line for the refractory bricks, the detection and automatic identification work of the finished refractory bricks in different shapes and even having gradient is achieved, automation is achieved on the whole, and the problems about low operation efficiency, non-uniform identification, large detection errors and the like caused by manual completion of the subsequent operation of the finished refractory bricks in the prior art are solved.

Owner:BEIHUA UNIV

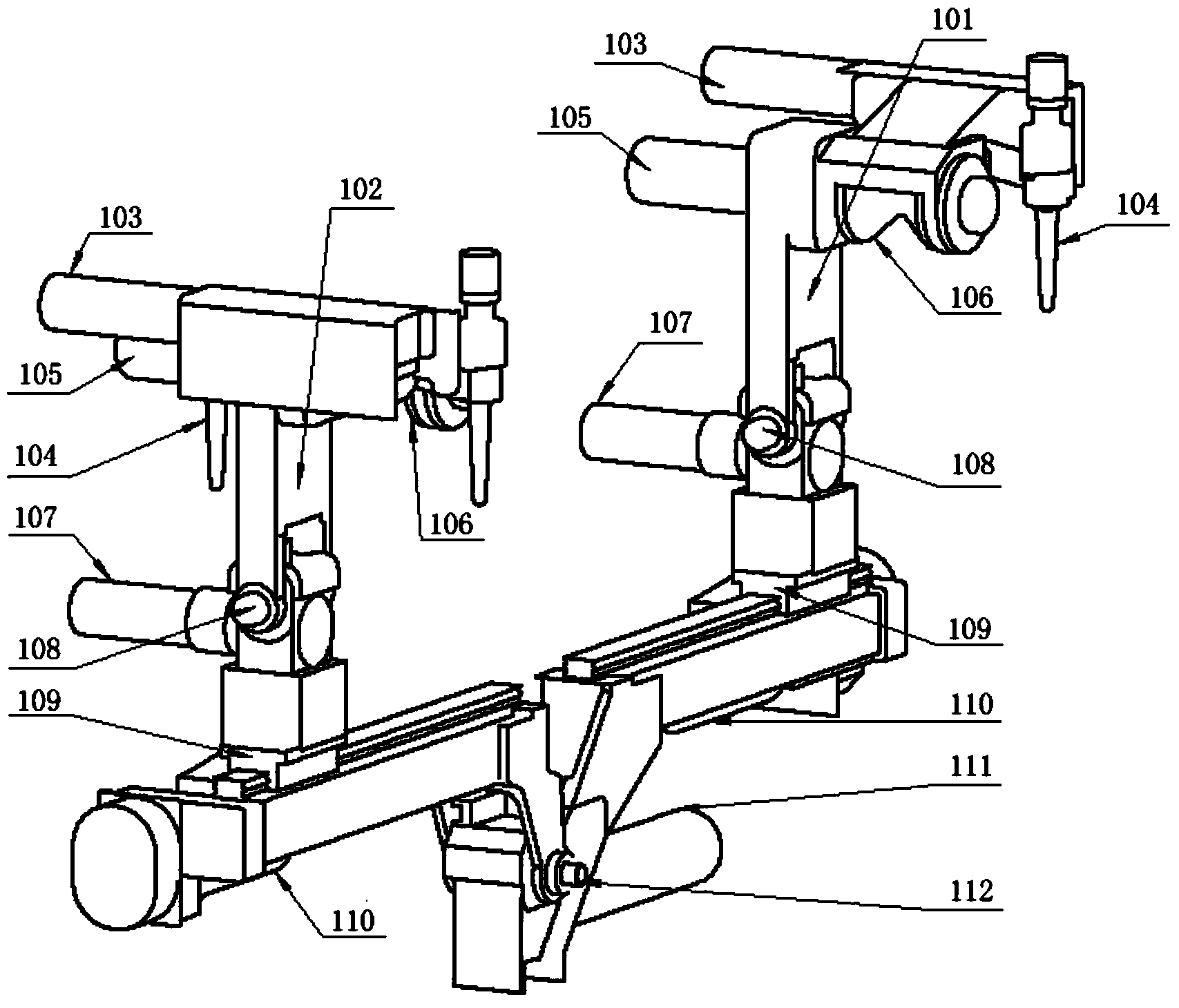

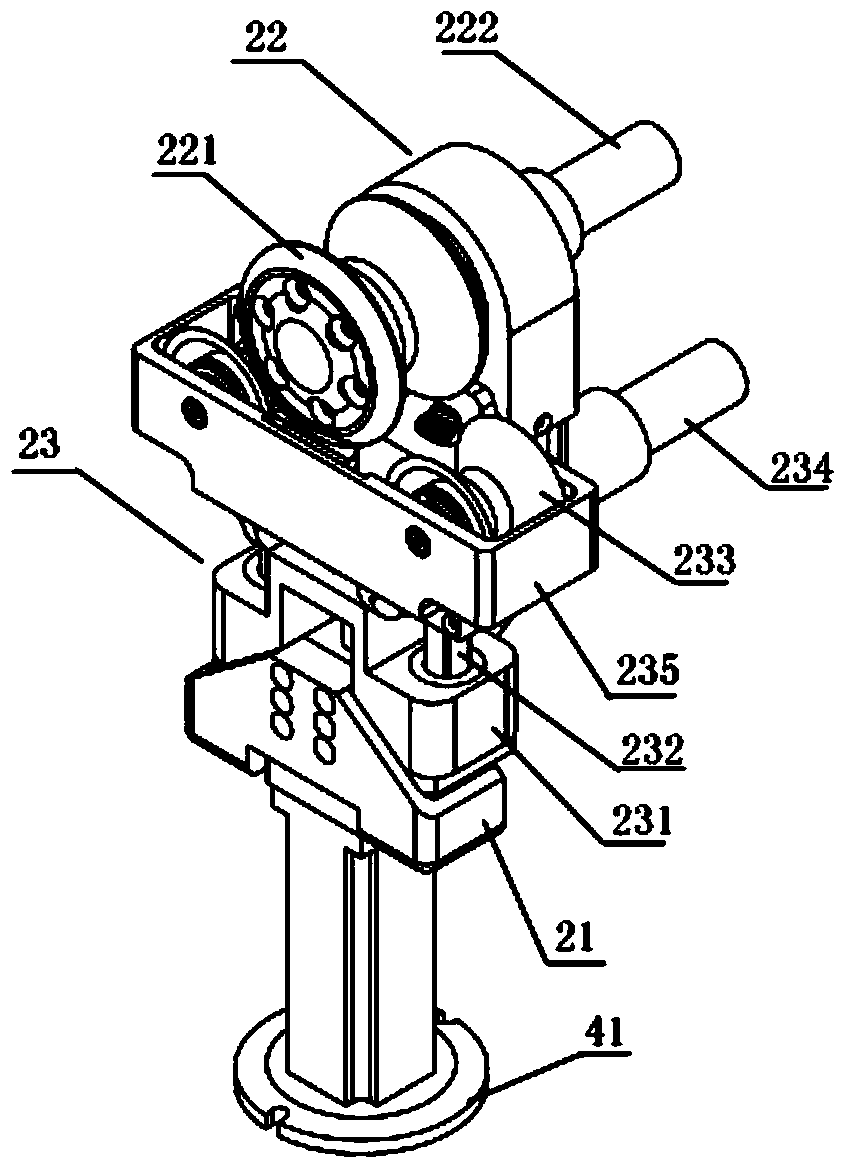

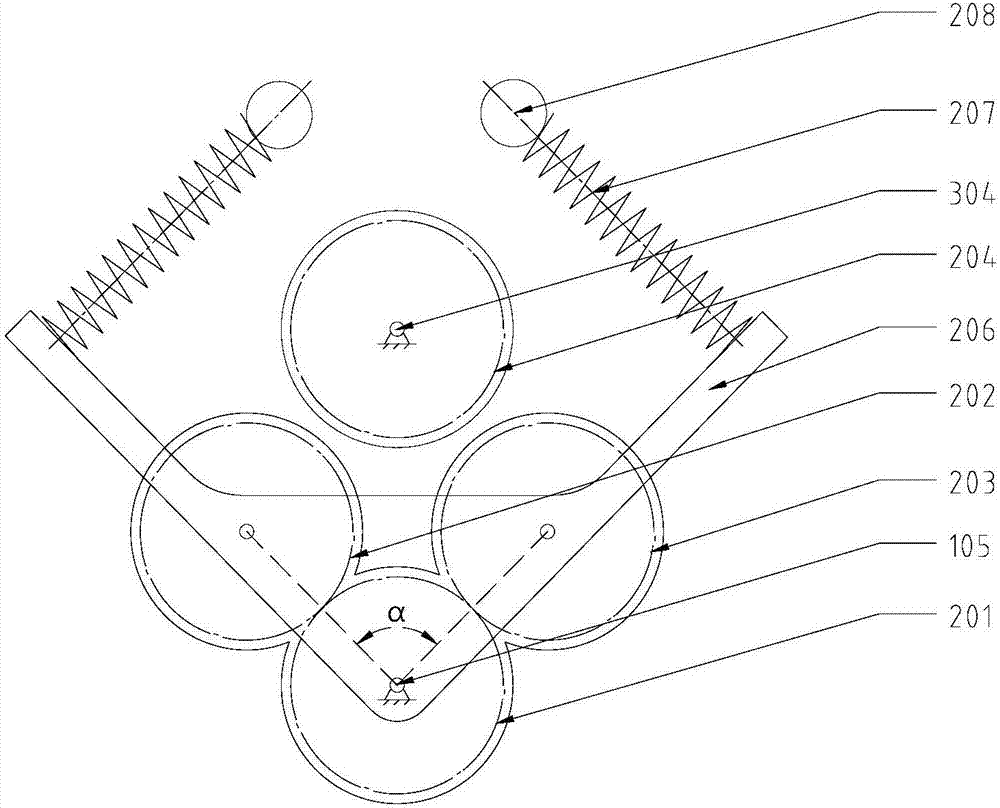

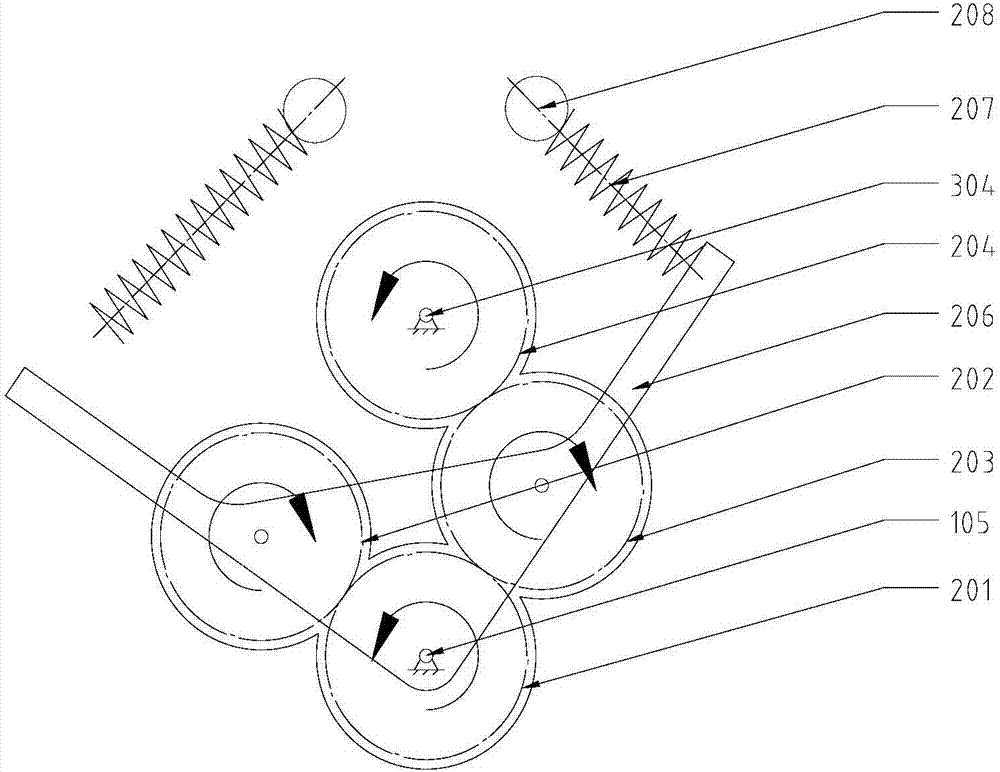

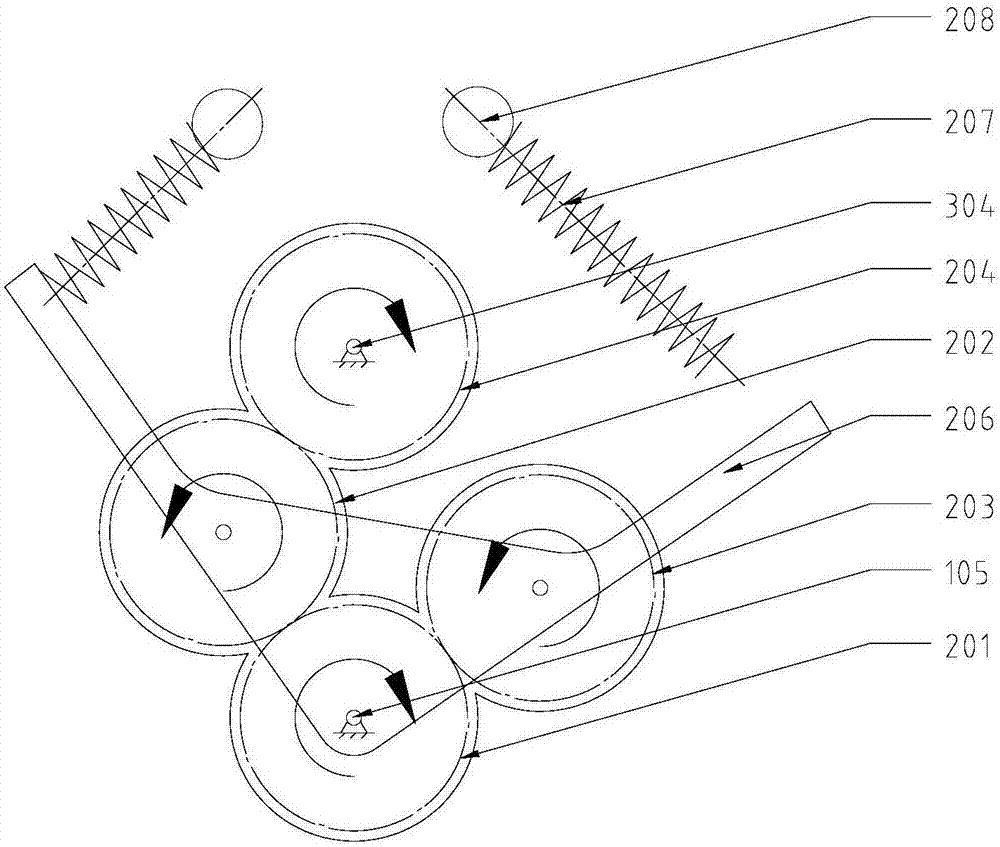

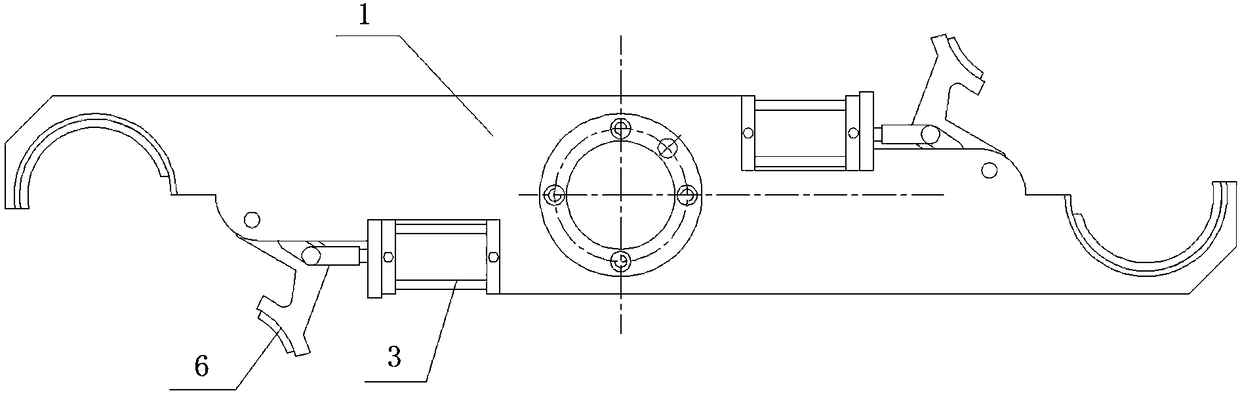

Overturning obstacle crossing type overhead line work robot

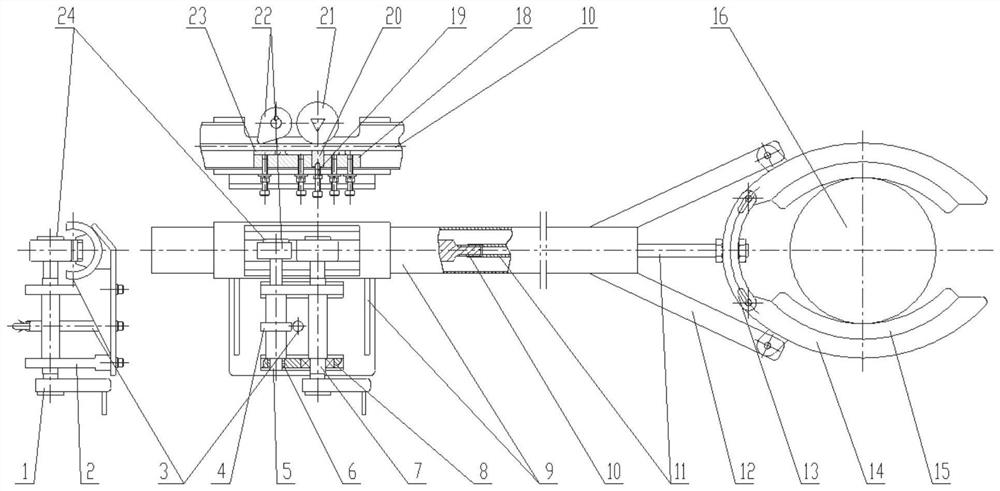

InactiveCN103594967AReduce in quantityImprove climbing abilityApparatus for overhead lines/cablesDrive motorEngineering

The invention provides an overturning obstacle crossing type overhead line work robot which comprises a beam. The two ends of the beam are provided with rotation mechanisms respectively and the rotation mechanisms can rotate around the end portions of the beam in a reciprocating mode. The end portions of the rotation mechanisms are connected with cantilever mechanisms which can slide on an overhead line and can be disengaged from the overhead line. The overturning obstacle crossing type overhead line work robot is large in inspection range, drive motors are few in number, the overall weight is low, the obstacle crossing action is simple, and the obstacle crossing adaptability is high.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV

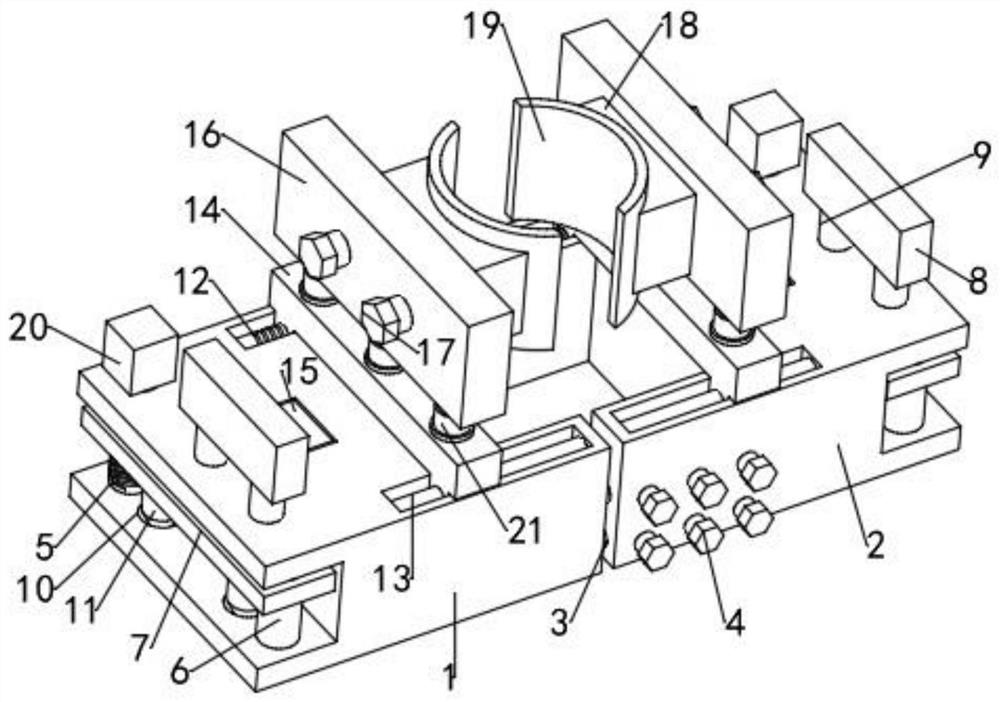

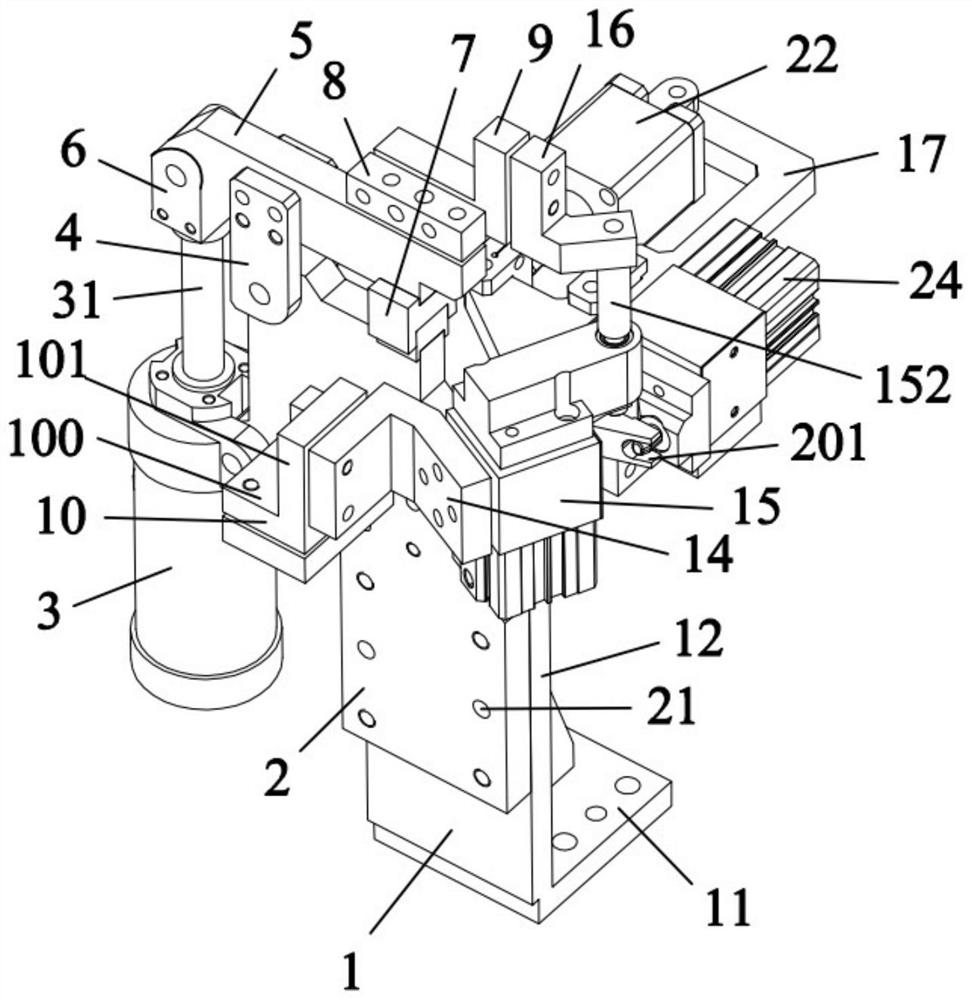

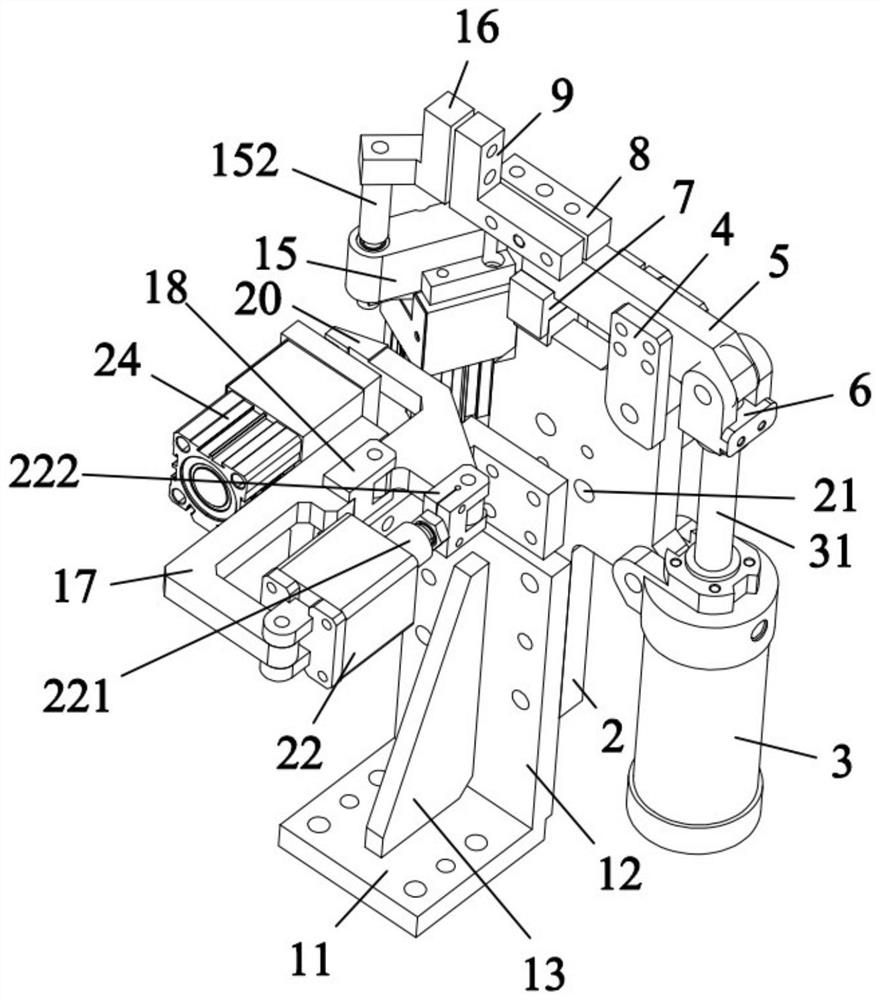

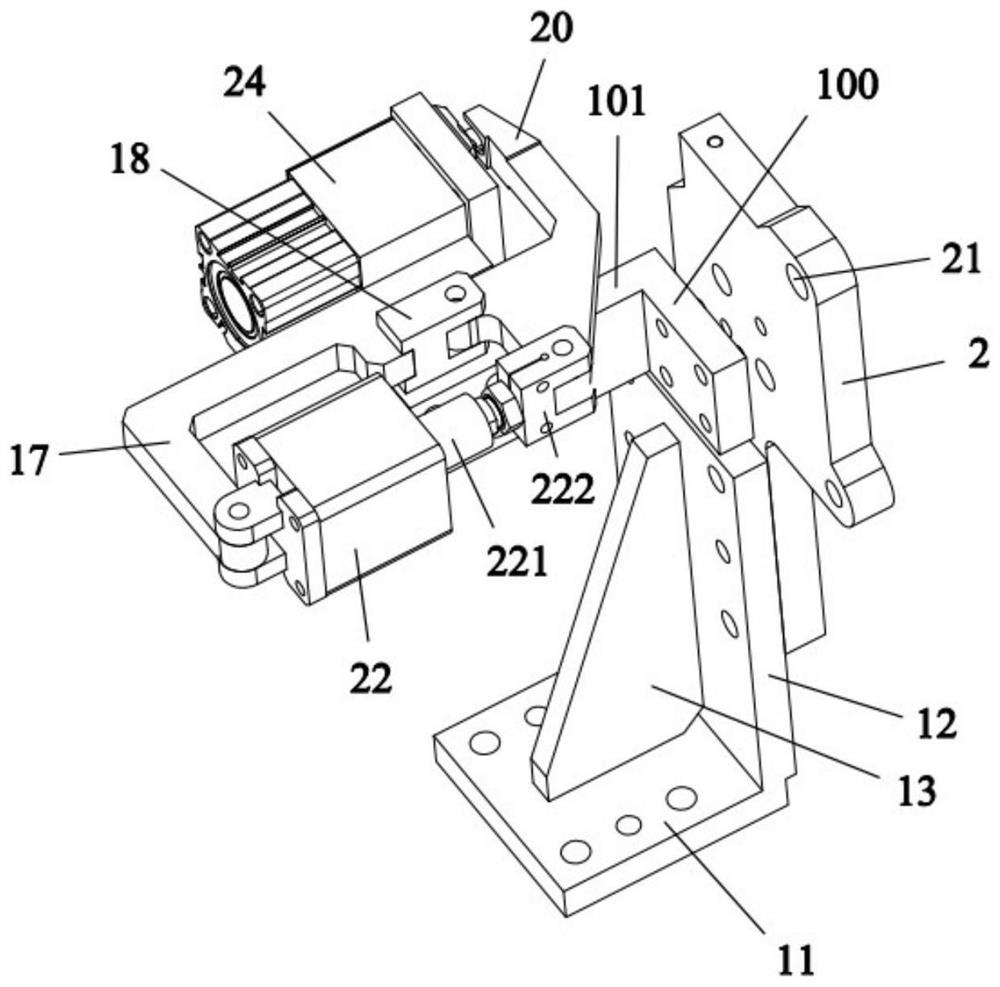

Rotatable multi-angle clamping mechanism for machine tool

InactiveCN108818037ASolve efficiency problemsSolve operational problemsPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention belongs to the field of machine tools, and particularly discloses a rotatable multi-angle clamping mechanism for a machine tool. The problems of low clamping efficiency, troublesome operations and high labor intensity of existing machine tool clamps are solved. The rotatable multi-angle clamping mechanism comprises a base, a first motor and a worm seat are installed at the bottom ofthe base, a worm is rotatably installed on the worm seat, an output shaft of the first motor is connected with the worm through a belt, an angle measuring device is installed at the top of the base, and a rotating shaft is rotatably arranged at the top of the base in a penetrating mode. A worm wheel is fixed to the bottom end of the rotating shaft, a first gear is fixed to the top end of the rotating shaft, a first connecting rod is fixed to the side of the first gear, a rotating seat is fixed to the end, away from the first gear, of the first connecting rod, and first sliding grooves are formed in the upper and lower sides of the rotating seat. The rotatable multi-angle clamping mechanism for the machine tool is simple in structure and flexible in use, and can greatly improve the convenience and efficiency of machine tool clamping.

Owner:无锡市海诚机电设备有限公司

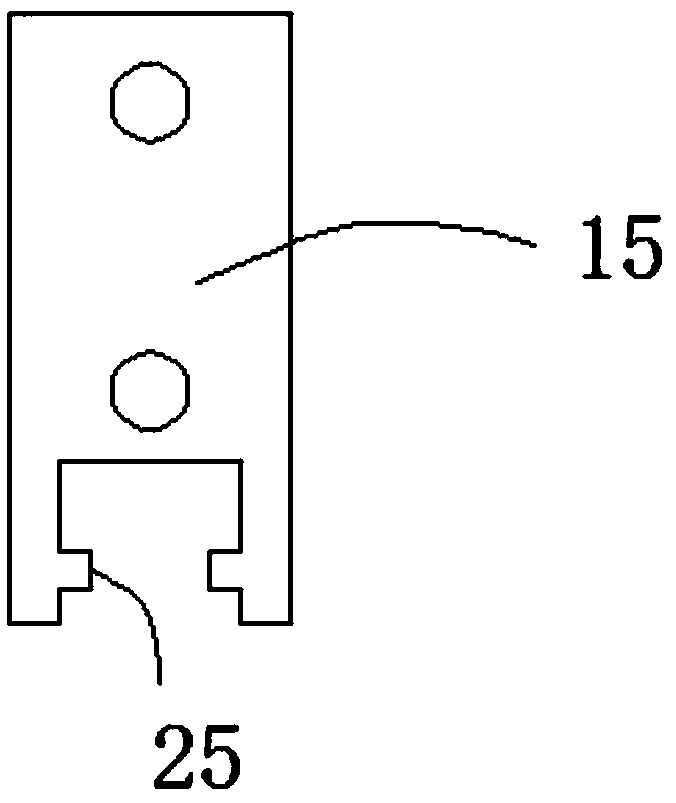

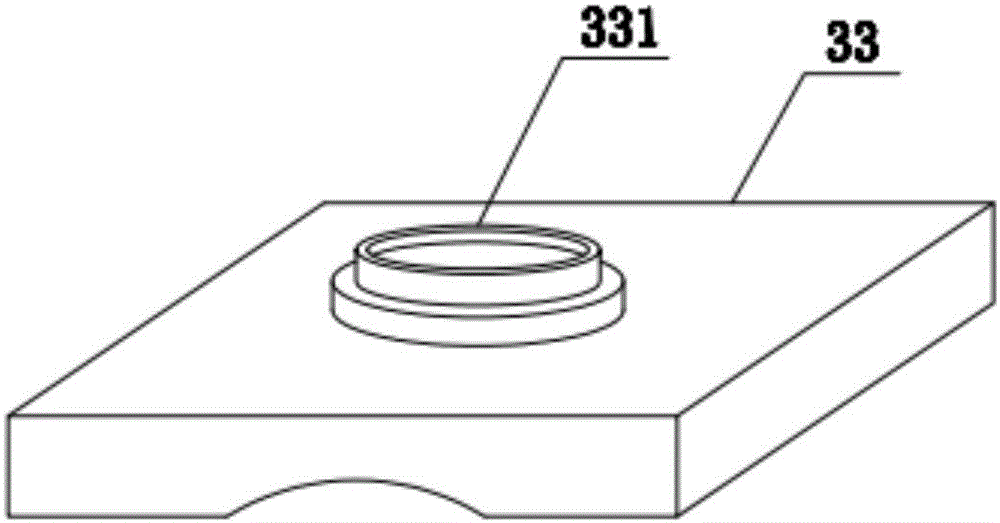

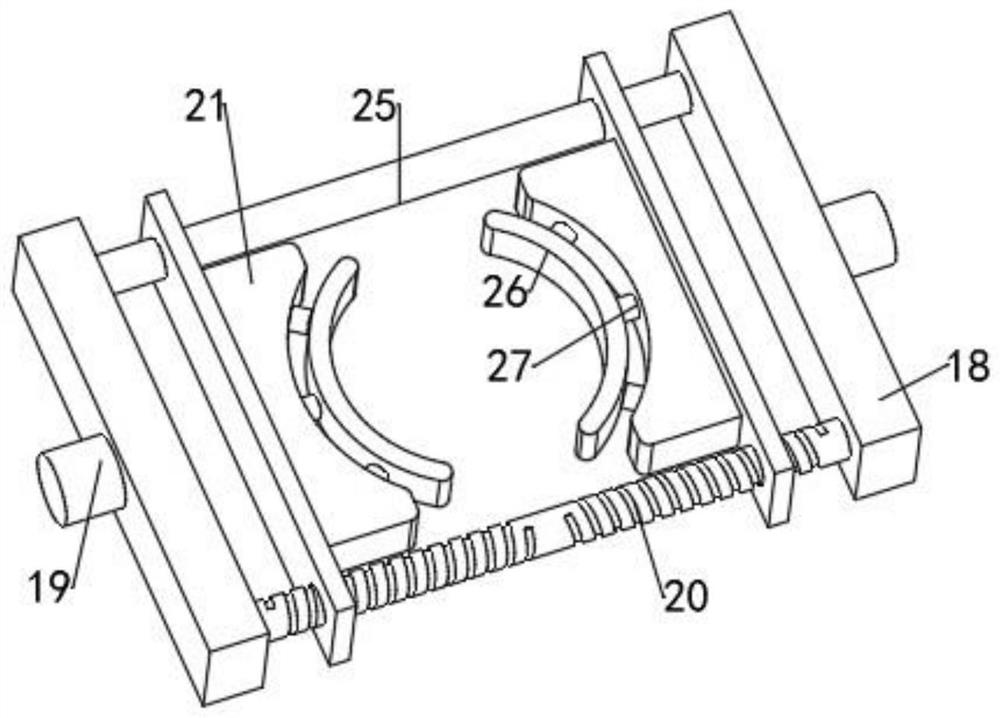

Special composite fixture for clamping shaft collar

InactiveCN103419048AAvoid damageEasy clampingPositioning apparatusMetal-working holdersEngineeringStructural engineering

Owner:WUXI YICHEN MOLD TECH

Special clamp for clamping collar

InactiveCN103433778AAvoid damageEasy clampingPositioning apparatusMetal-working holdersShaft collarMachine tool

The invention discloses a special clamp for clamping a collar and belongs to the field of machine tool clamps. The special clamp for clamping the collar comprises a clamp base, a sliding rail, an adjusting screw, a movable block and a clamping block, wherein the lower end of the sliding rail is arranged on the clamp base, the upper end of the sliding rail is clamped onto the concave edge of the lower end of the movable block, the lower end of the clamping block is pressed onto the concave edge of the upper end of the movable block, the adjusting screw is meshed with the movable block, the clamping face of the clamping block is composed of three semi-cylindrical surfaces with different diameters, and the diameters of the semi-cylindrical surfaces are the same as those of corresponding workpieces respectively. According to the special clamp for clamping the collar, the problems that shaft parts with collars can not be reliably clamped through an existing universal clamp, and the clamping force is not easy to control are solved. The special clamp for clamping the collar has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:WUXI YICHEN MOLD TECH

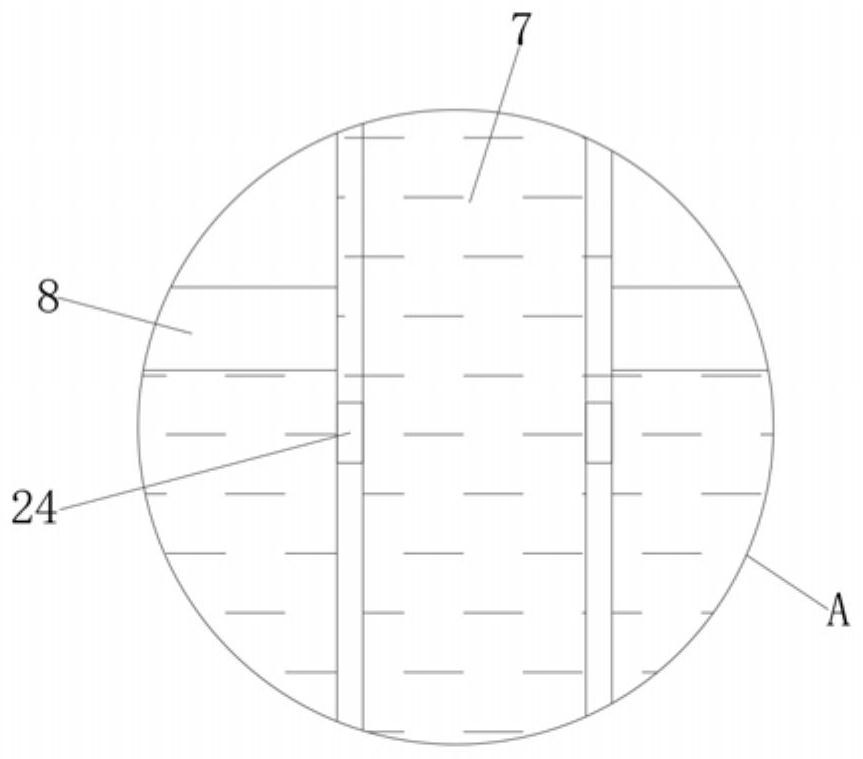

Clamping device for thin-wall cylindrical glass piece

The invention provides a clamping device for a thin-wall cylindrical glass piece. The clamping device comprises a stainless steel sleeve, wherein the inner wall of the sleeve is provided with an inferior-arc-shaped groove extending along a spiral line, a hose with the outer diameter equal to the diameter of the inferior arc is contained in the groove, one end of the hose is blocked, the other end of the hose is connected with an inflating and deflating device which can inflate and deflate the hose, and the thin-wall cylindrical glass piece is placed in the center of the spiral surrounding hose. The thin-wall cylindrical glass piece is placed in the center of the spiral surrounding hose, the inflating and deflating device inflates the hose, and the hose expands with air inflation and makes contact with the outer surface of the thin-wall cylindrical glass piece till the thin-wall cylindrical glass piece is clamped. The hose clamps the thin-wall cylindrical glass piece through inflation and makes elastic contact with the thin-wall cylindrical glass piece, clamping force is convenient to control, and therefore the thin-wall cylindrical glass piece can be firmly clamped and the clamping effect is good.

Owner:高子羊

Square workpiece compound fixture of milling machine

InactiveCN103419045AAvoid damageImprove stabilityPositioning apparatusMetal-working holdersStructural engineeringMachine

The invention discloses a square workpiece compound fixture of a milling machine and belongs to the field of machine tool fixtures. The square workpiece compound fixture comprises a fixture base, a sliding rack, a large regulation screw rod, a movable block, a large clamping block, a small regulation screw rod, a fixed block, a small clamping block, a large clamping surface and a small clamping surface, wherein the lower end of the sliding rack is arranged on the fixture base, the large regulation screw rod is meshed with the movable block; the lower end of the small clamping block is embedded into a dovetail groove at the lower end of the groove of the large clamping block; the small regulation screw rod is meshed with the fixed block; one end of the small regulation screw rod is fixedly connected with the small clamping block; the large clamping block is provided with the large clamping surface; the small clamping block is provided with the small clamping surface. The square workpiece compound fixture disclosed by the invention can be used for solving the problems such as high labor intensity, low workpiece lateral surface processing stability, long part processing auxiliary time and difficulty in clamping force control caused by an existing general fixture as well as low generality and the like caused by a special fixture, and has the advantages of simple structure, reasonable design, and easiness for manufacturing.

Owner:WUXI YICHEN MOLD TECH

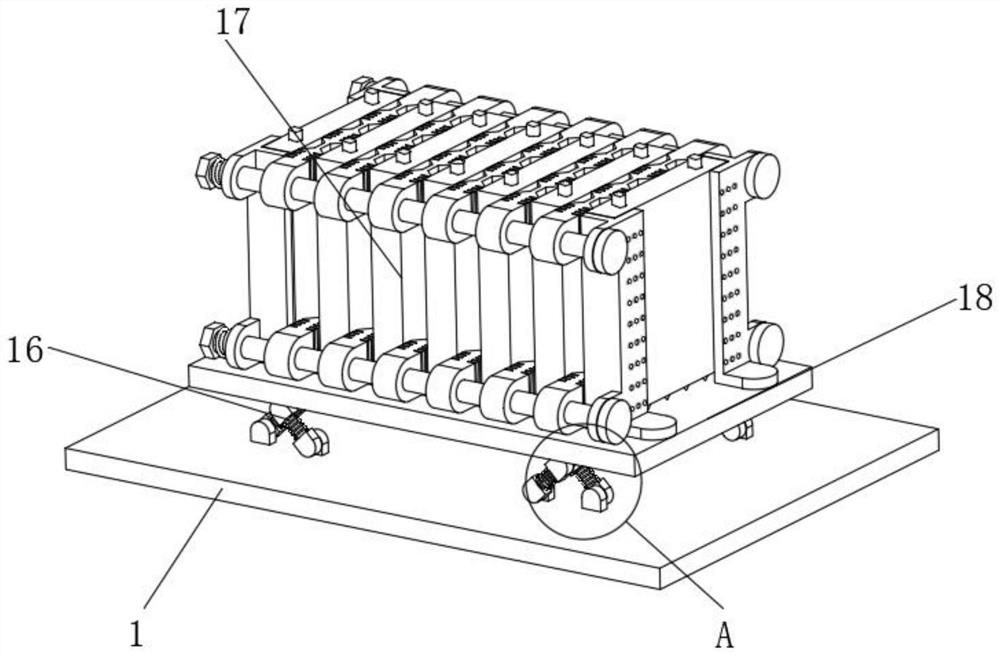

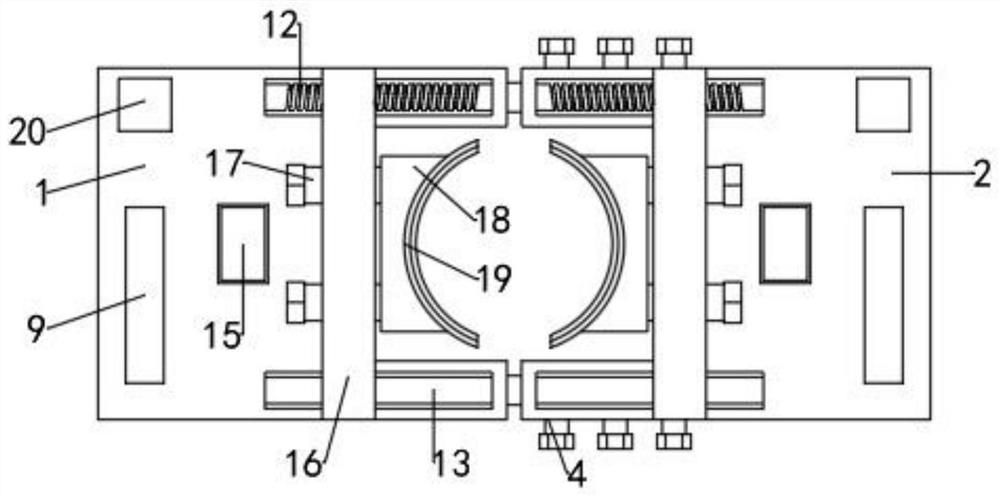

Servo control glass centering intelligent identification and clamping device

ActiveCN110732467ARealize intelligenceRealize real-time monitoringLiquid surface applicatorsWork holdersClassical mechanicsStructural engineering

The invention relates to a servo control glass centering intelligent identification and clamping device. The servo control glass centering intelligent identification and clamping device comprises a base, a longitudinal clamping assembly, a transverse clamping assembly, sucker assemblies, support assemblies, buffering assemblies and blocking columns. The longitudinal clamping assembly and the transverse clamping assembly are arranged on the base in a cross-shaped manner. The support assemblies and the sucker assemblies are correspondingly arranged at the corners where the longitudinal clampingassembly intersects with the transverse clamping assembly on the base. At least one buffering assembly is arranged on each of the two sides, located on the longitudinal clamping assembly, of the transverse clamping assembly. The transverse clamping assembly drives the buffering assemblies located on the two sides of the longitudinal clamping assembly to get close to and away from each other. At least one buffering assembly is arranged on each of the two sides, located on the transverse clamping assembly, of the longitudinal clamping assembly, and the longitudinal clamping assembly drives the buffering assemblies located on the two sides of the transverse clamping assembly to get close to and away from each other. Each blocking column is vertically arranged on the corresponding buffering assembly. The servo control glass centering intelligent identification and clamping device has the beneficial effects that due to the buffering effect of the buffering assemblies, the clamping force isrelatively small in the pushing process.

Owner:WUHAN DEBAO EQUIP CO LTD

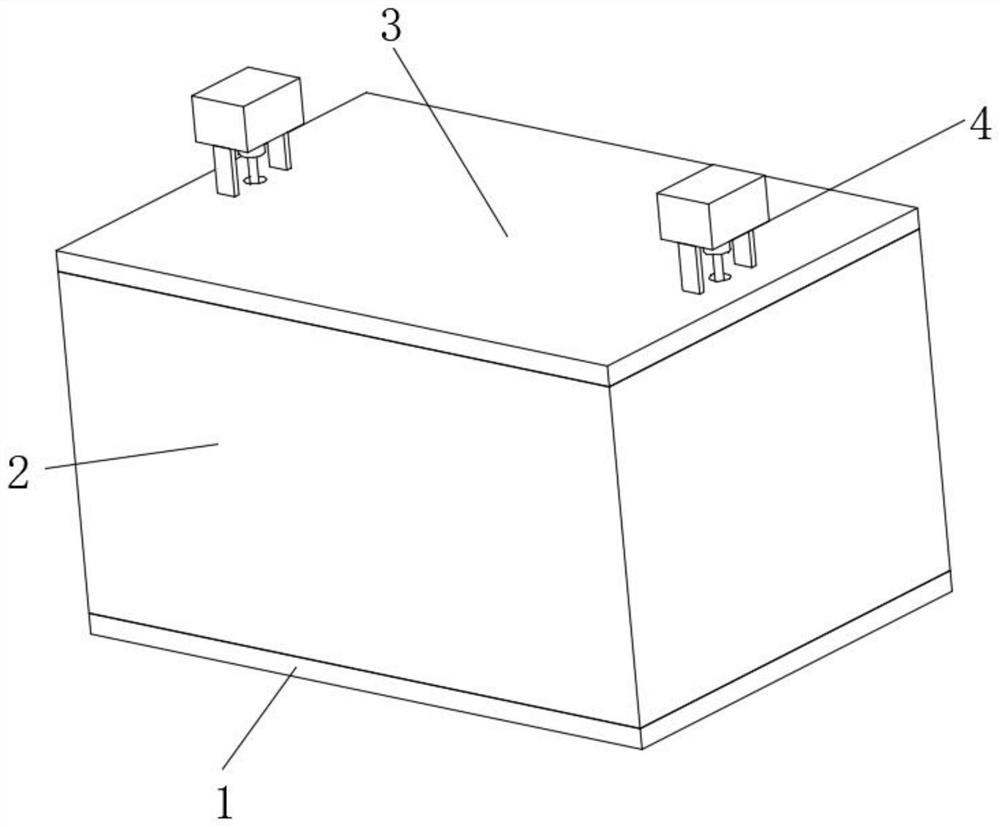

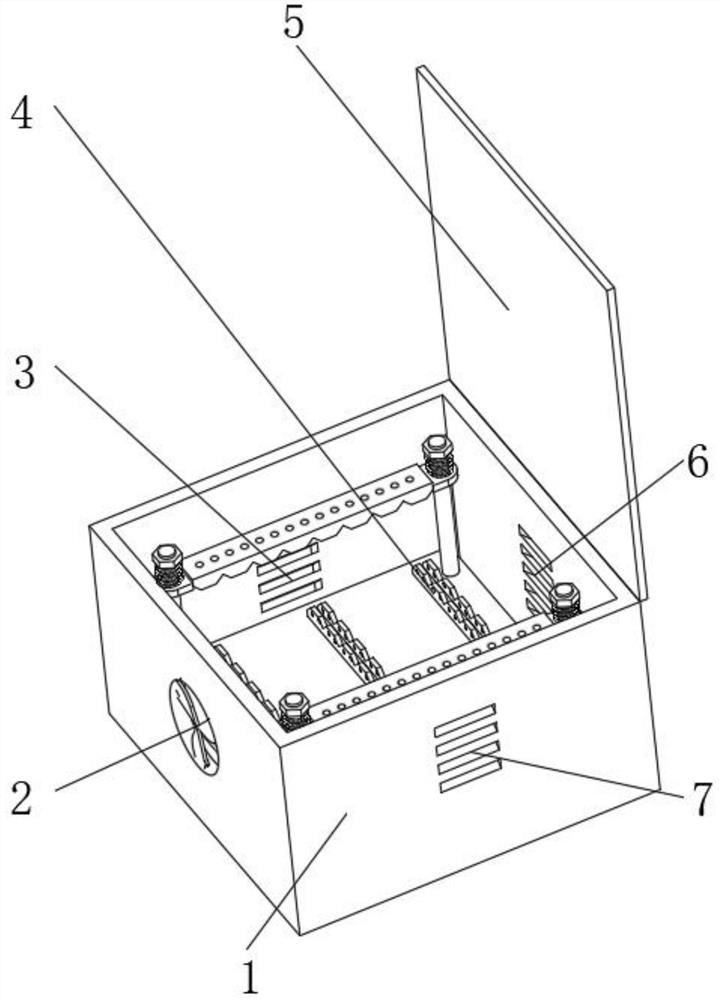

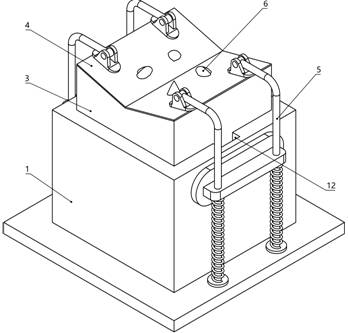

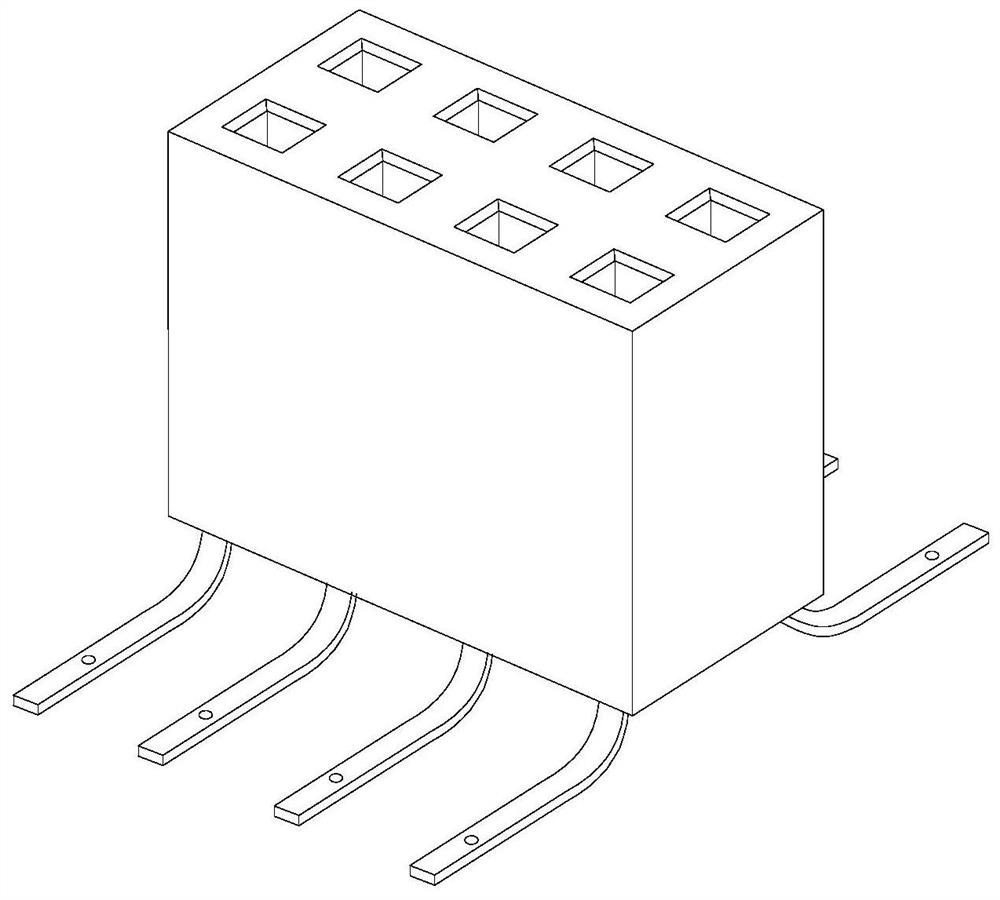

Energy-saving and environment-friendly multifunctional power storage device

InactiveCN111987390AWon't enterReliable coolingSecondary cellsEqualizing valvesEngineeringPower engineering

The invention discloses an energy-saving and environment-friendly multifunctional power storage device, and relates to the technical field of electric power engineering. In order to solve the problemthat heat dissipation can be automatically started and stopped, the energy-saving and environment-friendly multifunctional power storage specifically comprises a base, a shell body is fixed to the outer wall of the top part of the base through bolts; a top cover is fixed to the outer wall of the top part of the shell body through bolts; at least two groups of active valve mechanisms are arranged on the outer wall of the top cover; an electric power storage mechanism is arranged on the outer wall of the top part of the base; each active valve mechanism comprises a first piston, a second pistonand a third piston; a first accommodating cavity is fixed to the outer wall of the top part of the top cover through a first supporting leg and a second supporting leg; each first piston is slidably connected to the inner wall of the first accommodating cavity in a sealed mode; and the outer wall of the bottom part of each first piston is fixedly connected to the corresponding second piston through a first connecting rod. According to the principle that the volume of gas is fixed, the higher the temperature is, the higher the pressure is, the opening and closing state of a sliding groove can be automatically adjusted according to the actual internal and external environment temperature, and reliable operation of equipment is guaranteed.

Owner:陈玲玲

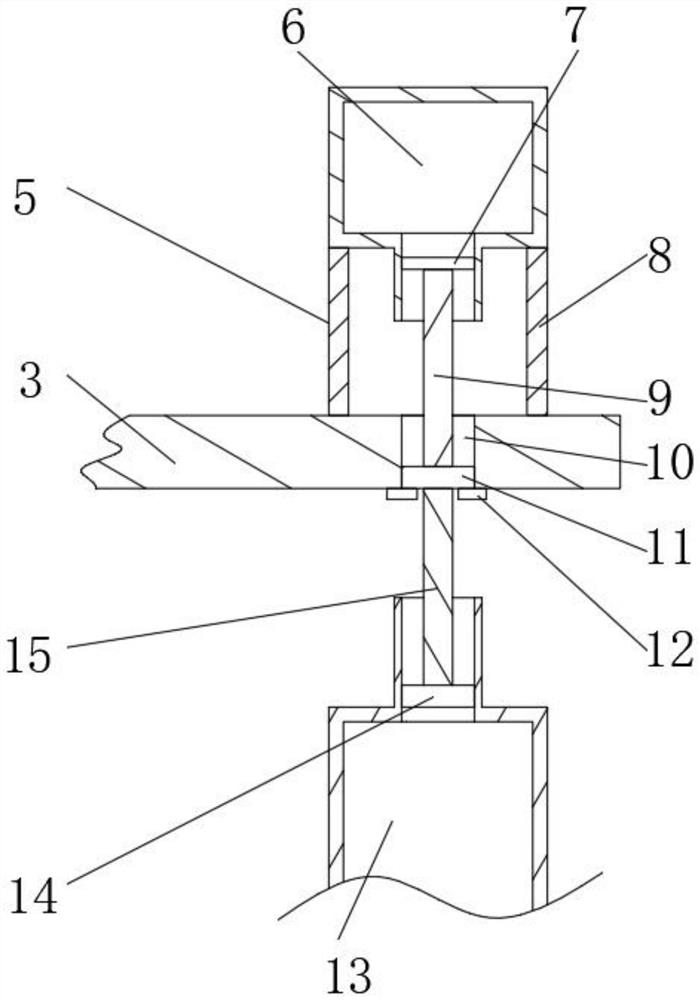

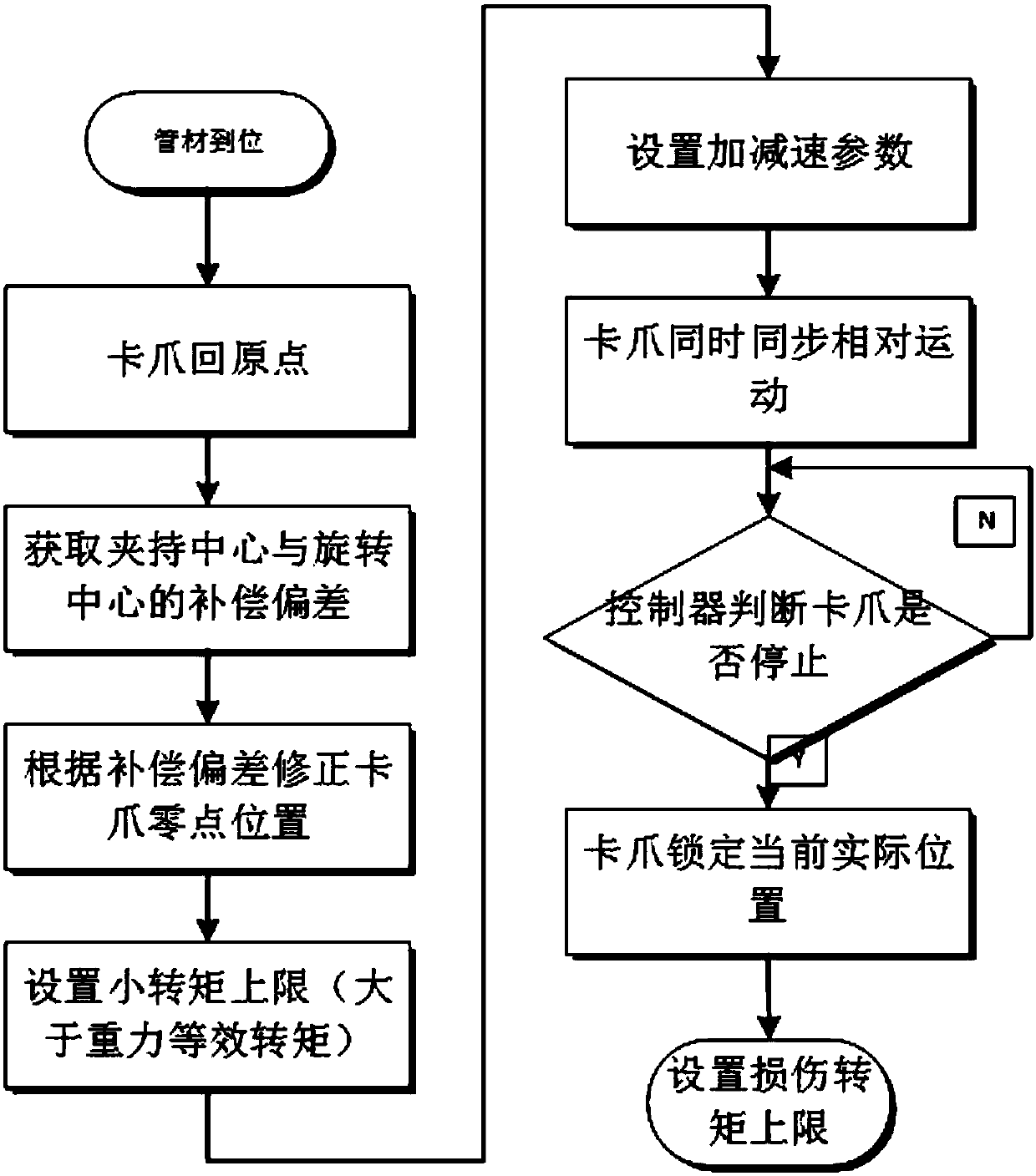

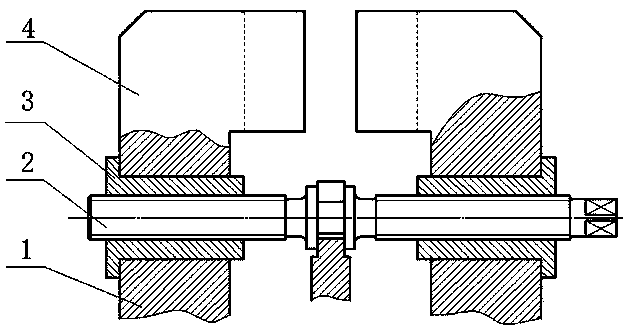

Clamping chuck for correcting and compensating deviation of clamping center of pipe and correction method

ActiveCN108608124ASo as not to damageGuaranteed coincidenceTotal factory controlLaser beam welding apparatusCentre of rotationEngineering

The invention relates to the technical field of a clamping chuck in a three-dimensional pipe laser cutting system, in particular to a clamping chuck capable of correcting and compensating deviation ofthe clamping center of a pipe and a correction method. The clamping chuck and the correction method are characterized in that clamping jaws move to designated positions and then are locked, after themaximum moment is set, in the movement process, the passive force provided by the clamping jaws of the clamping chuck only needs to be large enough to maintain the situation that the pipe does not relatively move and needs to avoid the situation that the pipe is damaged due to overlarge clamping force. Compared with a traditional clamping chuck which only has two states, namely, on and off, and has too large clamping force hard to adjust during clamping, the clamping chuck has the advantages that great improvement is achieved, meanwhile, it is ensured that the mass center of the pipe coincidewith the rotating center of the clamping chuck, so that the whole cutting system is more stable, and the clamping force is controllable.

Owner:上海柏楚电子科技股份有限公司

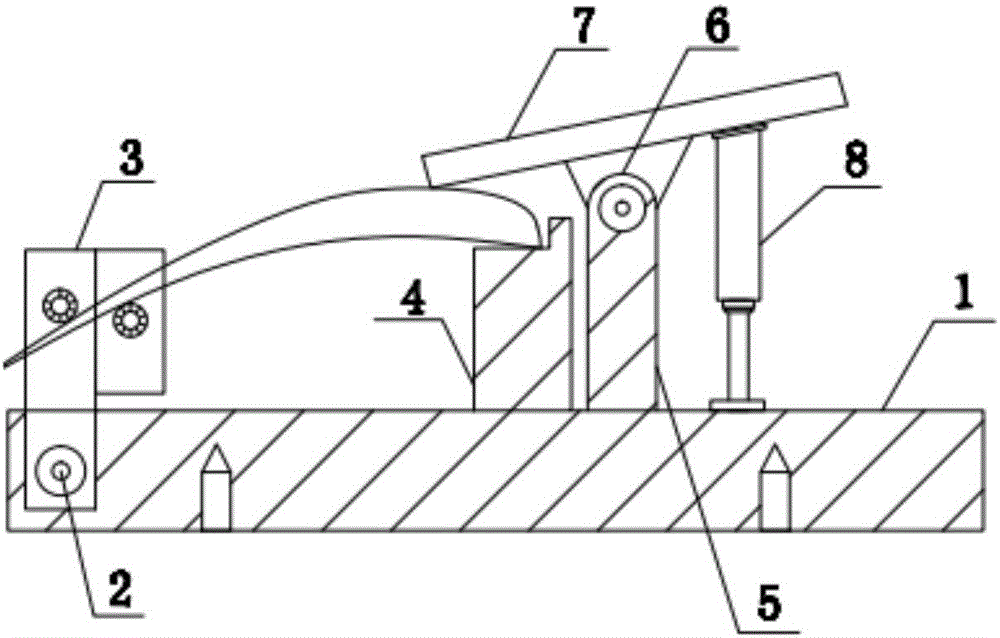

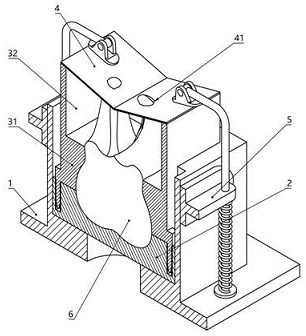

Blade positioning clamping device used for blade type frame measuring tool

InactiveCN106737305AAvoid damageClamping force is easy to controlWork holdersHydraulic cylinderEngineering

The invention discloses a blade positioning clamping device used for a blade type frame measuring tool in the technical field of blade positioning clamping. The blade positioning clamping device comprises a base plate, a locking device is movably connected with the left end of the base plate through a rotary shaft, and a supporting pin is installed at the top of the base plate. A supporting rod is arranged on the right side of the supporting pin, a pressing rod is movably connected with the top of the supporting rod through a pin shaft, and the bottom of the right side of the pressing rod is connected with the output end of a hydraulic cylinder. A movable pressing plate and a fixed pressing plate are transversely arranged on an inner cavity of the locking device, the movable pressing plate is located at the top of the fixed pressing plate, and an adjusting screw is rotatably connected with the top of the movable pressing plate. According to the blade positioning clamping device used for the blade type frame measuring tool, through design of the leverage principle, the root of a blade is pressed through vertically-downward force generated on the rearward face of the root of the blade; and due to the fact that the blade tip of the blade is fine, the blade is clamped through a manually-locking mode, so that clamping force is more easily controlled, and the blade is prevented from being damaged in the clamping process.

Owner:FALCON AEROTECH LTD

Square workpiece fixture of milling machine

InactiveCN103419044AAvoid damageImprove stabilityPositioning apparatusMetal-working holdersStructural engineeringMachine

The invention discloses a square workpiece fixture of a milling machine and belongs to the field of machine tool fixtures. The square workpiece fixture comprises a fixture base, a sliding rack, a regulation screw rod, a movable block and a clamping block, wherein the lower end of the sliding rack is arranged on the fixture base; the upper end of the sliding rail is clamped on the concave edge of the lower end of the movable block; the lower end of the clamping block is pressed on the concave edge of the upper end of the movable block; the regulation screw rod is meshed with the movable block; the clamping surface of the clamping block consists of four planes; the included angle of every two adjacent planes is identical with the angle of the corresponding outside corner of a square workpiece. The square workpiece fixture can be used for solving the problems such as high labor intensity, low workpiece lateral surface processing stability, long part processing auxiliary time, difficulty in clamping force control and the like caused by an existing general fixture, and has the advantages of simple structure, reasonable design, and easiness for manufacturing.

Owner:WUXI YICHEN MOLD TECH

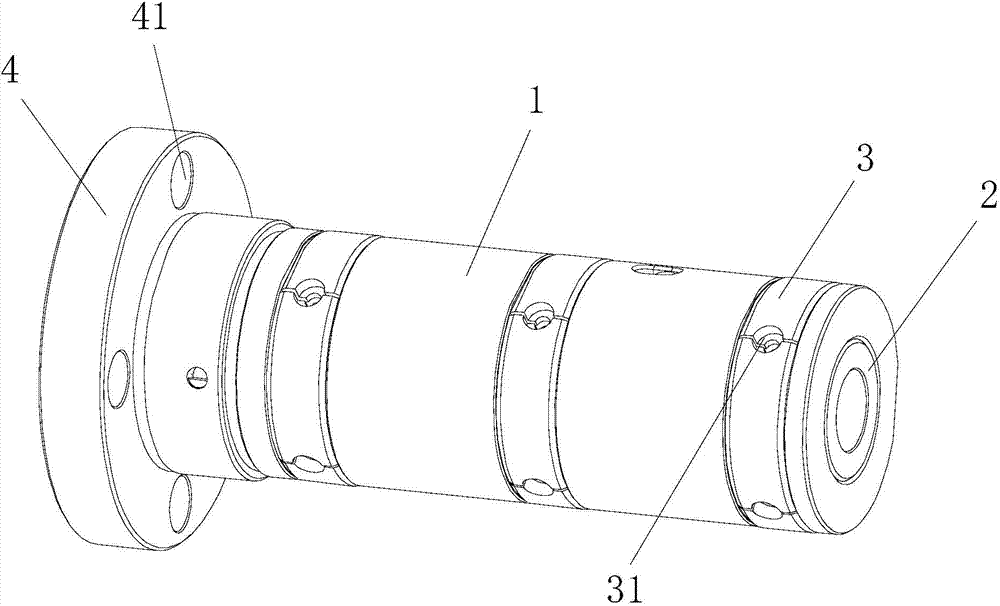

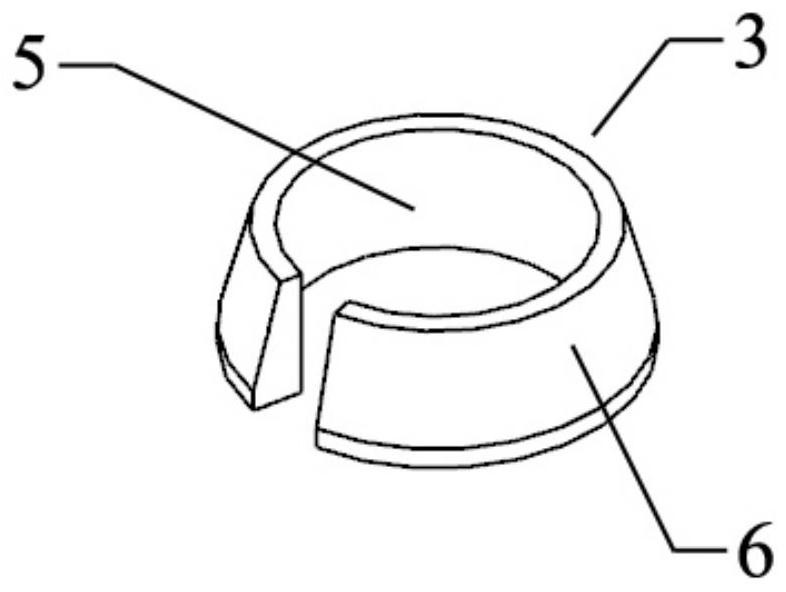

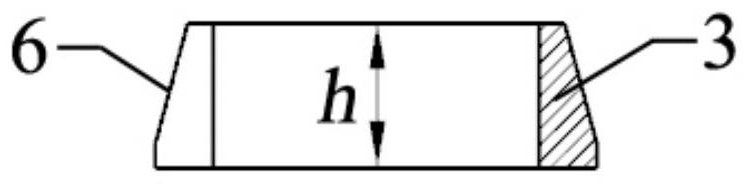

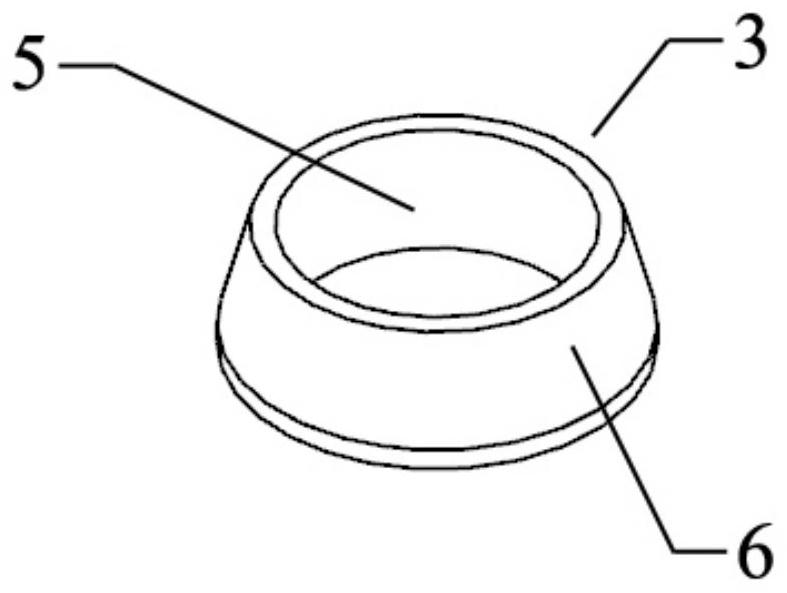

Elastic chuck

ActiveCN104772494ASimple structureClamping force is easy to controlTransportation and packagingChucksEngineeringFrustum

Owner:东莞市才立金属科技有限公司

Electric safety clamp technology capable of rapidly conducting releasing and clamping

InactiveCN106863181AClamping force is easy to controlFlexible operationWork holdersPositioning apparatusContact forceElectric control

The invention relates to an electric safety clamp technology capable of rapidly conducting releasing and clamping, and belongs to an electronic control clamp technology. By controlling a motor to rotate forwards and backwards through switches, different engagement manners of varying contact gear sets are controlled, a threaded rod is then driven, jaws are rapidly driven to be opened and closed, and manual clamping is conducted in an auxiliary manner; by means of an arranged safety circuit, it is ensured that only contact force is exerted on workpieces and no large clamping force is exerted on the workpieces, and the practical valid clamping force is manually exerted; and the circuit cannot be closed until a movable caliper body is separated from all the switches through manual disassembling so that the motor can be driven and safety of the subsequent machining can be ensured. Under the condition that safety clamping is achieved, rapid workpiece clamping / disassembling is achieved, it is effectively avoided that the clamping quality is influenced by too much mechanical intervention, and the electric safety clamp technology is suitable for places where the workpieces are machined and clamped in a semiautomatic or manual manner and is particularly suitable for rapidly clamping thin-walled pieces or pressure-sensitive pieces.

Owner:姜序敏

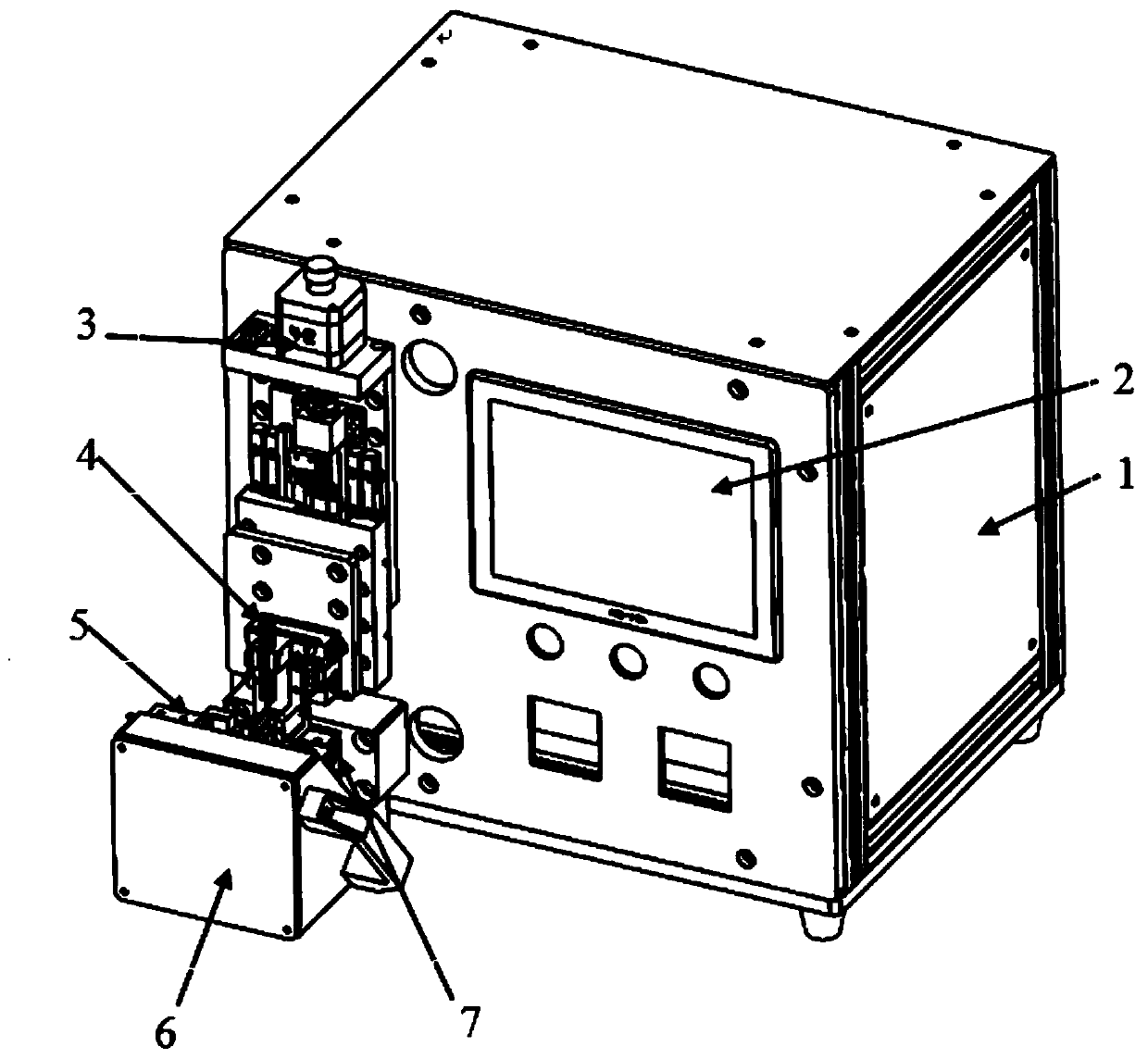

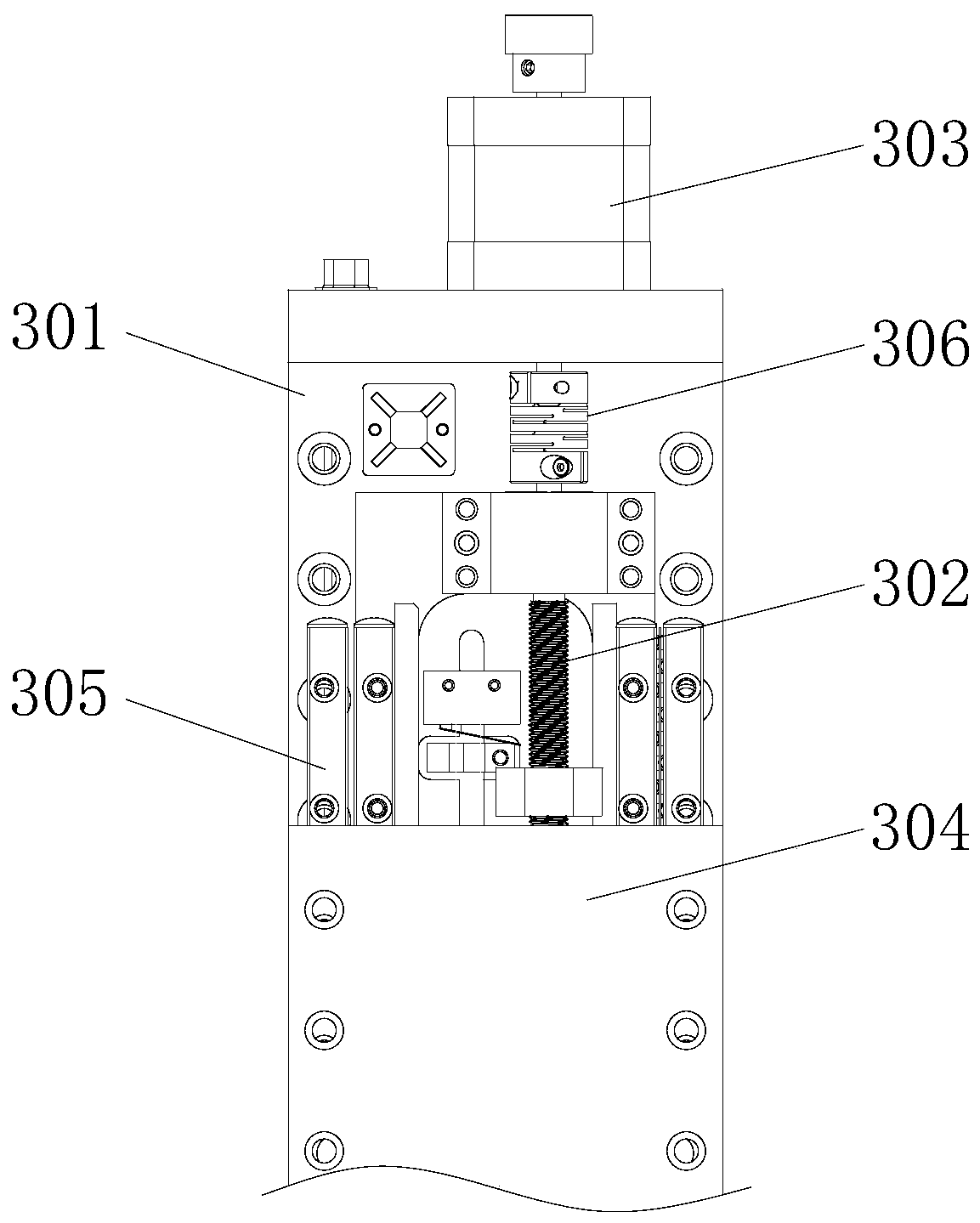

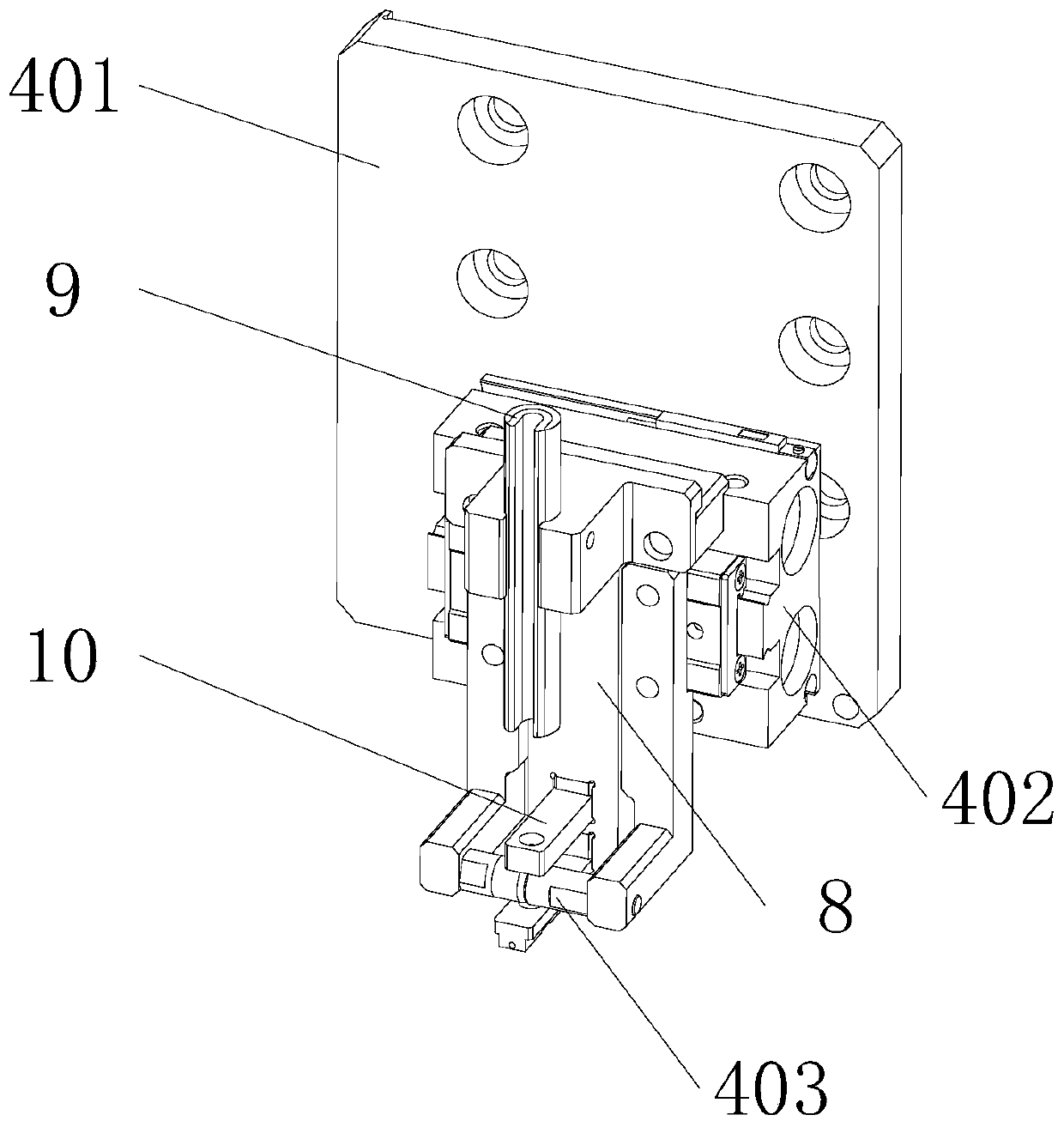

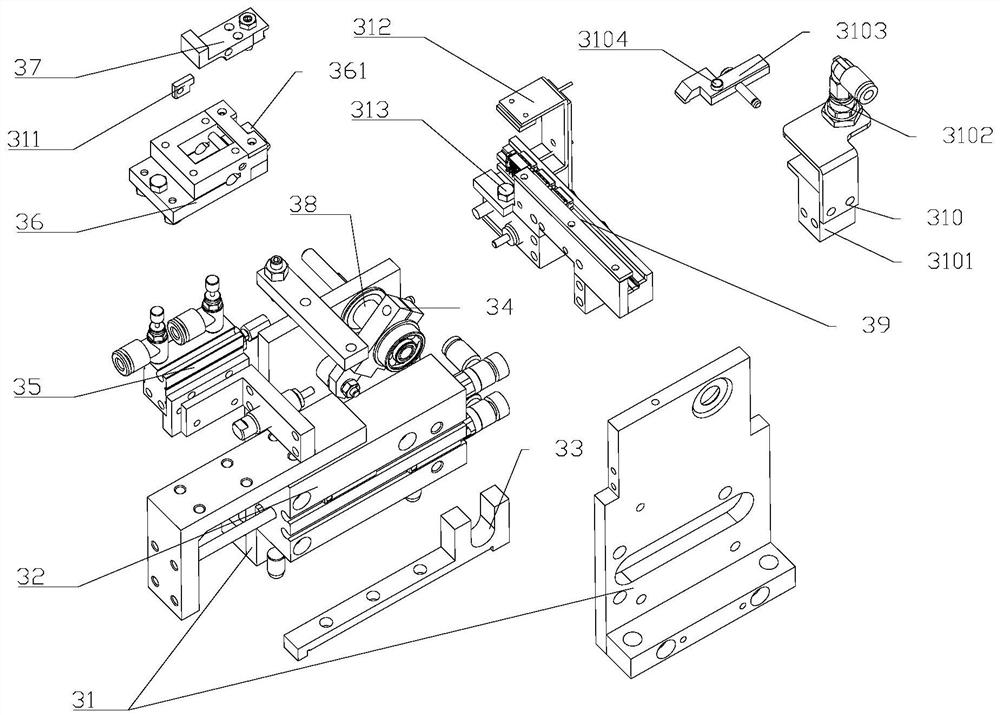

Automatic optical fiber stripping machine

PendingCN110764189AControllable clamping forceHigh degree of automationFibre mechanical structuresPhysicsHuman–machine interface

The invention relates to an automatic optical fiber stripping machine. The automatic optical fiber stripping machine comprises a rack, wherein the rack is provided with a man-machine interface and a stripping mechanism, the stripping mechanism comprises a servo straight line module, a clamping component and a cutting component, the servo straight line module is vertically installed on the rack, the clamping component is arranged on the servo straight line module, the cutting component is arranged below the clamping component, the clamping component comprises a connection plate, a first double-end cylinder and two cylindrical clamp heads, and the cutting component comprises a second double-end cylinder and two cutting units. In the automatic optical fiber stripping machine, the air cylindercontrols to clamp the optical fiber, so that the clamping force is controllable, and the product is not damaged; stripping length of the optical fiber can be controlled accurately by using the servostraight line module and setting parameters of the man-machine interface; the optical fiber is stripped at high automation degree, so that the production efficiency is improved greatly; and the product with optical fiber stripped has small difference, can be produced in large scale, and lowers labor cost.

Owner:SUZHOU TFC OPTICAL COMM CO LTD

New energy automobile battery protection device

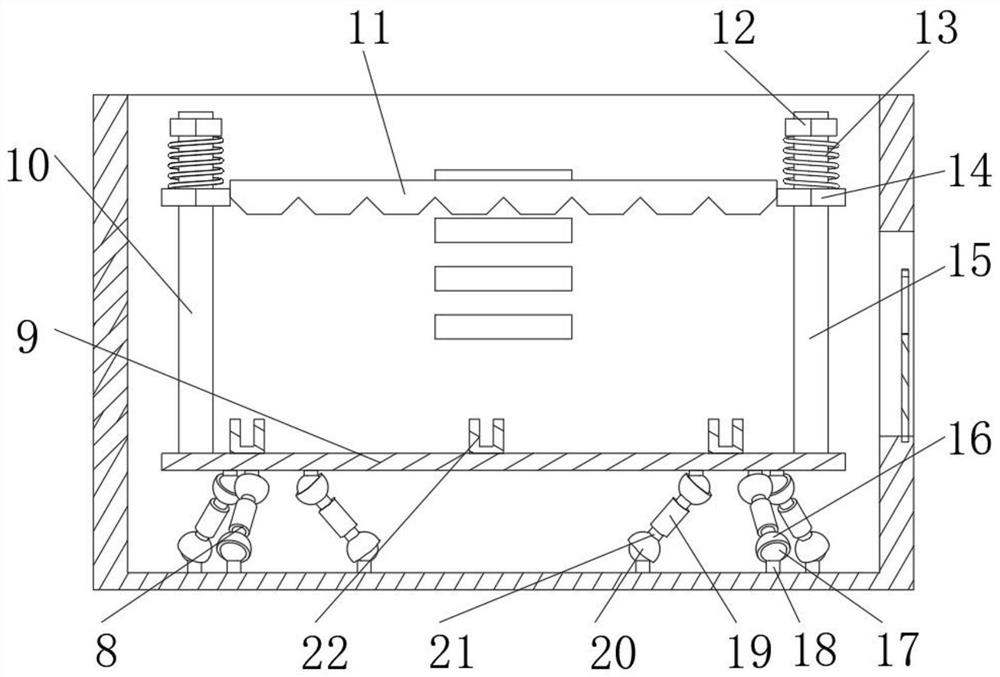

PendingCN112563644AImprove protectionRestraint torsionCell component detailsAxial displacementAutomotive battery

The invention discloses a new energy automobile battery protection device, and relates to the technical field of new energy batteries. the invention aims to solve the life problem; the device specifically comprises a shell, a battery placement mechanism is arranged in the shell, the battery placement mechanism comprises four sets of damping assemblies, a placement base and a clamping assembly, thefour sets of damping assemblies are arranged at the four corners of the bottom of the placement base correspondingly, and each set of damping assembly comprises three sets of damping rods and six sets of universal ball structures; the top and the bottom of each set of damping rods are movably connected to the inner wall of the bottom of the shell and the outer wall of the bottom of the placementbase through universal ball structures respectively, the three sets of damping rods form a triangular pyramid structure, each damping rod comprises a first sleeve and a second sleeve, and the inner wall of the first sleeve and the inner wall of the second sleeve are movably connected with the same piston rod. According to the device, a spring II can be effectively prevented from being subjected tonon-axial displacement and spiral torque, the spring II can be well protected, and the service life thereof is prolonged.

Owner:李拙

Fruit tree supporting device for fruit tree cultivation

InactiveCN112772267AStable supportEnsure orderly growthLiquid fertiliser distributionCultivating equipmentsFruit treeAgricultural engineering

The invention discloses a fruit tree supporting device for fruit tree cultivation. The device comprises a first mounting seat and a second mounting seat which are matched with each other, a horizontal clamping screw rod and a second transmission rod are assembled on the first mounting seat in a spaced mode, a sliding seat is assembled between the clamping screw rod and the second transmission rod, and a base is connected to the upper end of the sliding seat. A connecting base is assembled on one side of the base through a plurality of evenly-distributed assembling bolts, and circular-arc-shaped limiting plates are installed on the connecting base. According to the fruit tree supporting device for fruit tree cultivation, the base, the connecting base and the limiting plates are assembled through the assembling bolts, the suitable connecting base and the limiting plates can be selected conveniently for fruit trees of different varieties and different growth periods, and the fruit tree supporting effect is improved. The first mounting base and the second mounting base are easy to disassemble and assemble and can be conveniently placed and spliced around the fruit trees. Through cooperation of a pressure sensor and a limiting spring, the clamping force of the two limiting plates on the fruit tree support is conveniently controlled, and orderly growth of the fruit trees is ensured.

Owner:赵劲飞

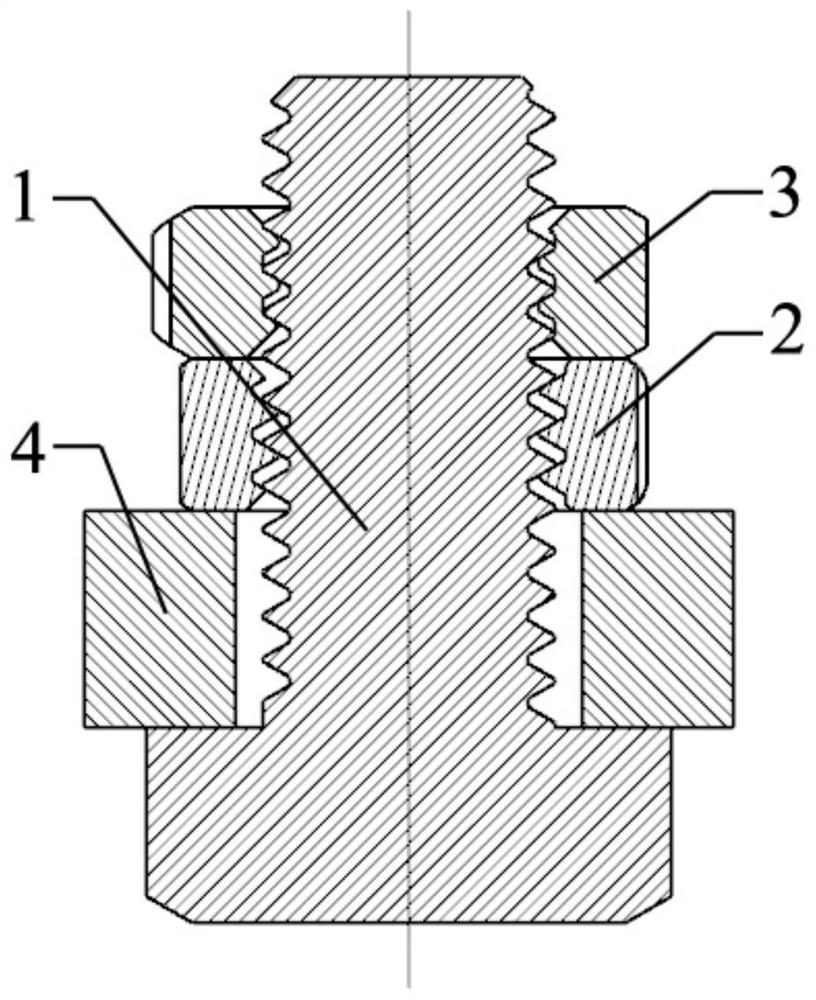

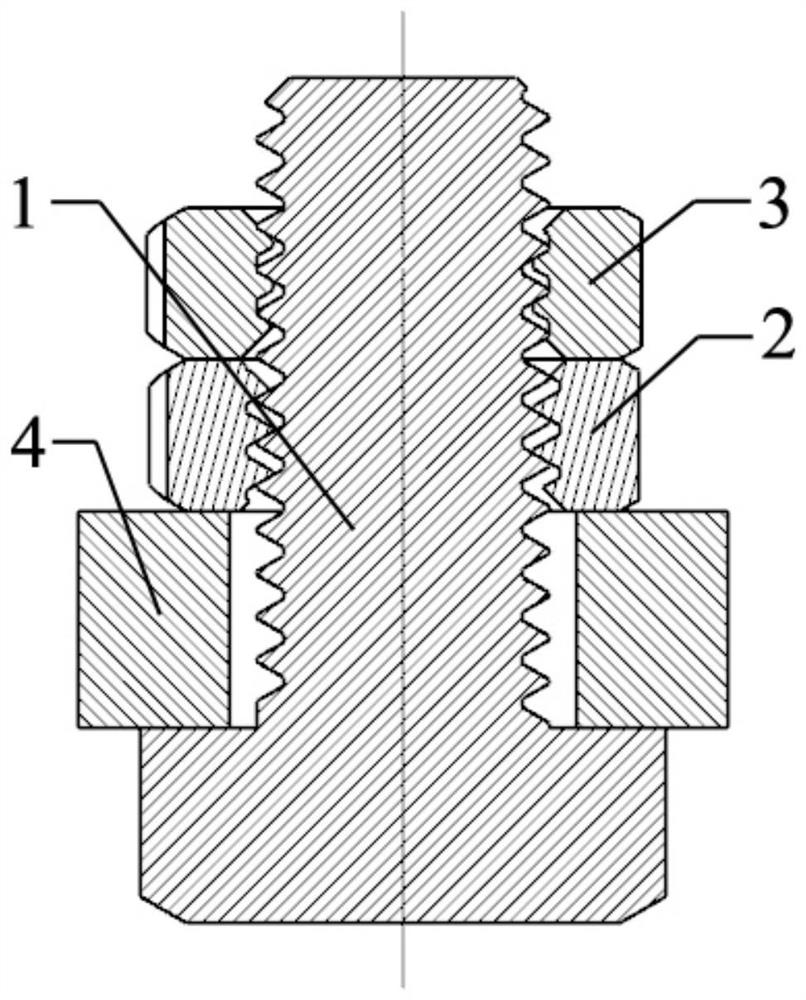

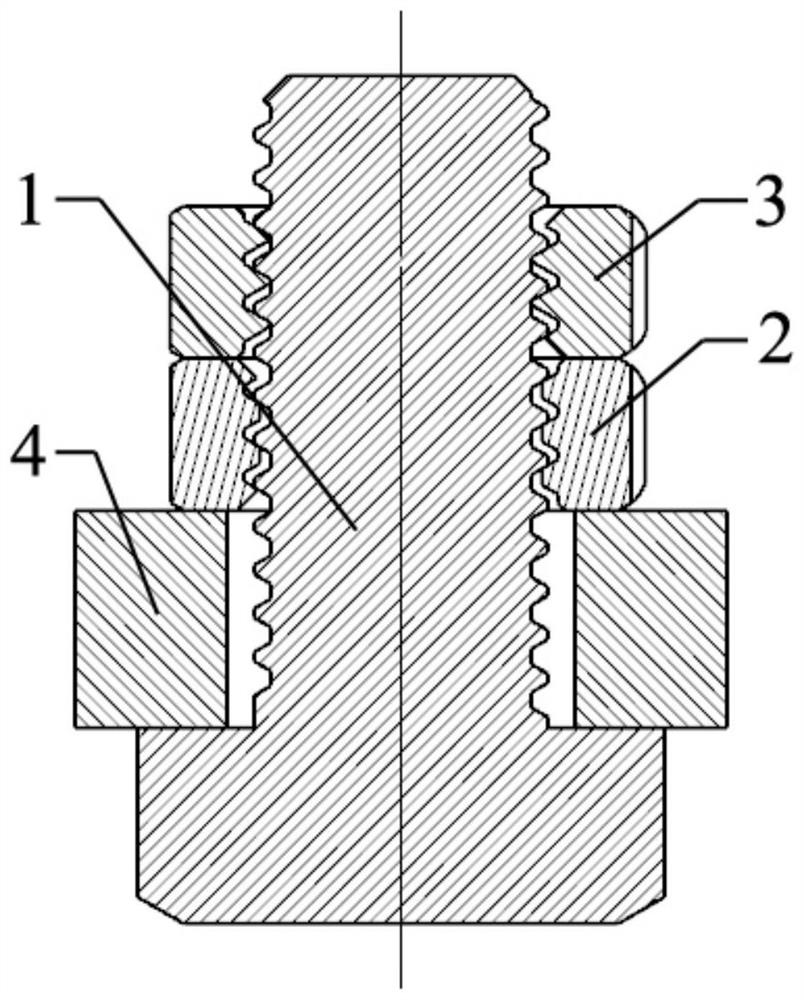

Fastener capable of preventing automatic rolling movement in loosening direction

PendingCN112814986AAutomatic rolling movement against loose directionClamping force is easy to controlNutsBoltsFastenerEngineering

The invention discloses a fastener capable of preventing automatic rolling movement in a loosening direction. The fastener comprises a bolt, a first nut, a gasket and a second nut, the center of the gasket is provided with a through hole for a screw rod of the bolt to pass through, and the top of the gasket is provided with a conical convex surface. A conical concave surface is arranged at one end of the second nut, and after the bolt, the first nut, the gasket and the second nut are mounted and screwed on a workpiece, the bottom of the first nut is in contact with the workpiece. The bottom of the gasket is in contact with the top of the first nut. After the gasket deforms, a contact structure without a transverse gap is formed between the conical convex surface and the conical concave surface, and a contact structure without a transverse gap is formed between a through hole and the external thread of the bolt. Therefore, during transverse vibration or impact, the first nut, the second nut and the bolt can be effectively prevented from continuously rolling in the loosening direction.

Owner:许松林

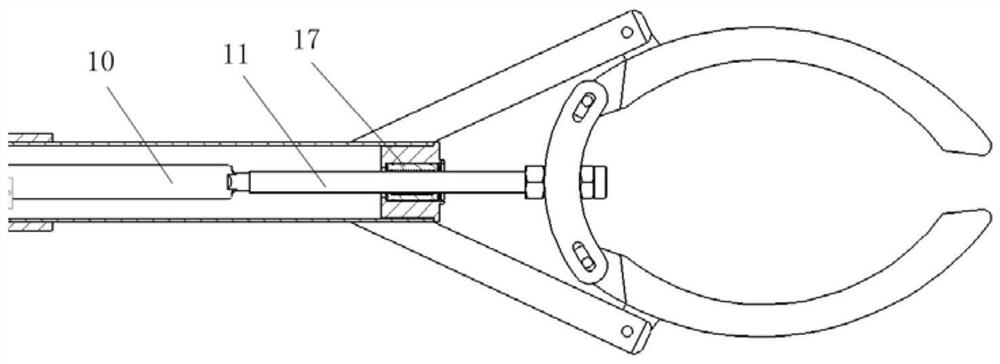

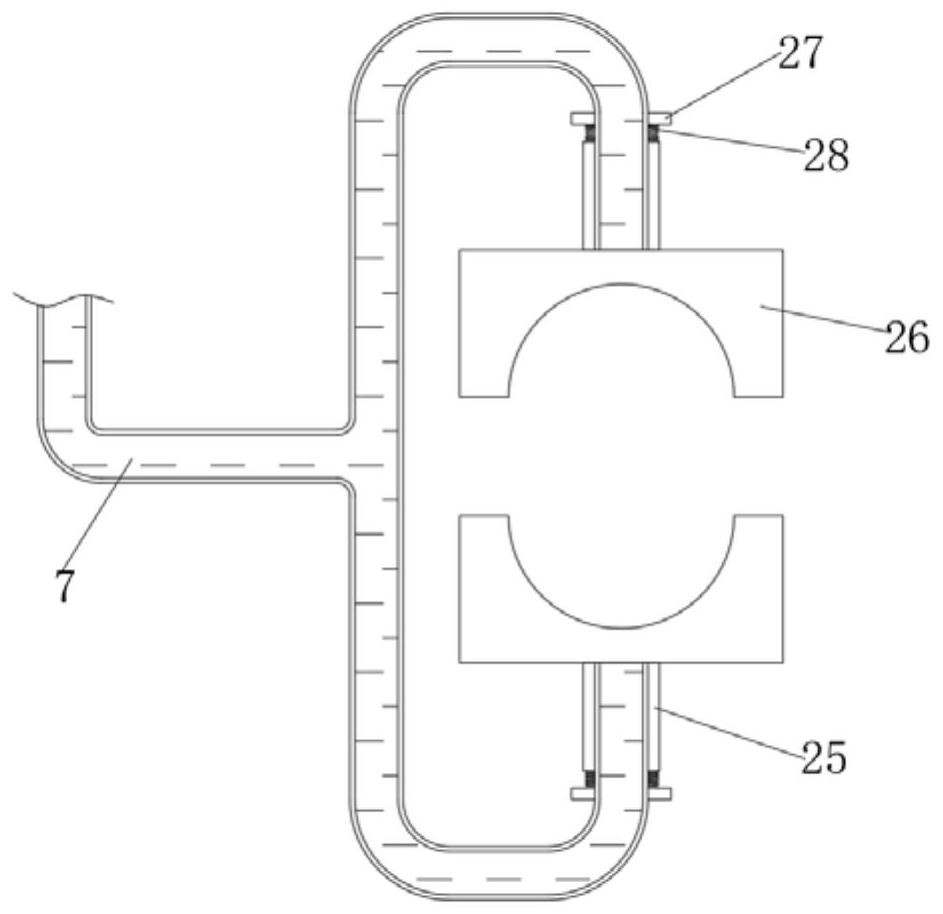

Machining center pneumatic tool changing mechanical hand

PendingCN108188800AReduce accidentsGood economic and social benefitsPositioning apparatusMetal-working holdersManipulatorEngineering

The invention discloses a machining center pneumatic tool changing mechanical hand. The machining center pneumatic tool changing mechanical hand comprises a mechanical arm, a pin shaft, an air cylinder, a U-shaped push rod, a roller and a mechanical claw. The mechanical hand has the beneficial effects that controllable clamping force is provided, tool falling is avoided, unloosening after tool clamping is avoided, when the mechanical arm clamps and loosens the tool, the mechanical hand is simple and rapid, in the tool changing process, the mechanical hand can rapidly clamp or loosen the tool with the precise strength, accidents are reduced, in a machining center automatic tool changing device, the mechanical hand plays a role in grabbing and conveying the tool, the tool is taken down froma tool changer and then is loaded on a spindle, and meanwhile, the tool is taken down from the spindle and is loaded into the tool changer.

Owner:INNER MONGOLIA UNIV OF TECH

Thread pair capable of preventing automatic rolling movement in loosening direction

PendingCN112833081AAutomatic rolling movement against loose directionClamping force is easy to controlNutsBoltsScrew threadContinuous rolling

The invention discloses a thread pair capable of preventing automatic rolling movement in a loosening direction. The thread pair capable of preventing the automatic rolling movement in the loosening direction comprises a bolt, a first nut and a second nut, wherein the major diameter of the internal thread of the second nut is less than the major diameter of the external thread of the bolt, or the minor diameter of the internal thread of the second nut is less than the minor diameter of the external thread of the bolt; after the bolt, the first nut and the second nut are installed and screwed on a workpiece, the bottom of the first nut makes contact with the workpiece, the bottom of the second nut makes contact with the top of the first nut, and the tooth bottom of the internal thread of the second nut and the tooth top of the external thread of the bolt are of contact structures which are transversally locked with each other; or the tooth top of the internal thread of the second nut and the tooth bottom of the external thread of the bolt are of contact structures which are transversally locked with each other, so that the first nut, the second nut and the bolt can be effectively prevented from continuous rolling movement in the loosening direction during transverse vibration or impact.

Owner:许松林

Novel culture and separation device for research and development of coronavirus pneumonia vaccines

ActiveCN112481126AEasy to separateEasy clampingBioreactor/fermenter combinationsBiological substance pretreatmentsPetri dishVaccine research

The invention discloses a novel culture and separation device for coronavirus pneumonia vaccine research and development, and the device comprises a base; a cavity is fixed on the base, the cavity isprovided with a sealing cover, and a culture dish is movably arranged in the cavity; according to the novel culture and separation device for coronavirus pneumonia vaccine research and development, the feeding of the two mounting bases is controlled through the clamping lead screws, a culture dish is convenient to clamp, the sliding rods and the clamping springs are arranged between the limiting plates and the mounting bases, the clamping force of the limiting plates on the culture dish is convenient to control, and the culture dish is prevented from being damaged; moreover, through cooperation of a driving wheel and a reset spring, the culture dish is conveniently driven to shake necessarily, and a scraping plate can be driven to slide along the inner wall of the culture dish through a feeding bolt, so that culture substances are conveniently separated from the culture dish, and discharging is facilitated; and through the cooperation of the fan and the temperature sensor, the temperature in the cavity can be conveniently controlled, so that the culture dish can obtain proper culture conditions.

Owner:AB&B BIO TECH CO LTD JS

A device for cultivating and separating novel coronavirus pneumonia vaccines

ActiveCN112481126BEasy to separateEasy clampingBioreactor/fermenter combinationsBiological substance pretreatmentsPetri dishMedicine

The invention discloses a device for cultivating and separating novel coronavirus pneumonia vaccines, comprising a base, a cavity is fixed on the base, the cavity is equipped with a sealing cover, and a petri dish is movable inside the cavity; The device for cultivating and separating the novel coronavirus pneumonia vaccine is used to control the feeding of the two mounting seats through the clamping screw rod, which is convenient for clamping the culture dish. And the clamping spring, it is convenient to control the clamping force of the limit plate on the culture dish and avoid damage to the culture dish; and, through the cooperation of the driving wheel and the return spring, it is convenient to drive the culture dish to shake necessary, and the scraper can be driven by the feed bolt. The material plate slides along the inner wall of the culture dish, which facilitates the separation of the culture material from the culture dish, and facilitates the discharge; through the cooperation of the fan and the temperature sensor, it is convenient to control the temperature in the cavity, so that the culture dish can obtain suitable culture conditions.

Owner:AB&B BIO TECH CO LTD JS

Auxiliary tool for intentional dental replantation

ActiveCN113749796AAvoid direct contactSimple structureDental implantsNerve needlesEngineeringDentistry

The invention relates to an auxiliary tool for intentional dental replantation. The auxiliary tool comprises a fixing part capable of fixing teeth and a supporting part, wherein the fixing part is arranged in the supporting part in a sliding manner. The auxiliary tool is simple in structure and convenient to use; the teeth are stably fixed by adopting the fixing part, so that the auxiliary tool is prevented from being in direct contact with an area of a root of a bone boundary of enamel teeth; and meanwhile, the stability of cutting off roots of the teeth is ensured.

Owner:SICHUAN UNIV

Fruit picking machine capable of controlling force through manual friction

PendingCN113796206ASimple structureHandheld picking is easy to usePicking devicesEconomic benefitsHand held

The invention discloses a fruit picking machine capable of controlling force through manual friction. The fruit picking machine comprises a rack assembly, a transmission rod, a power transmission system, a force adjusting mechanism and a grasping structure, and further comprises a self-locking mechanism, wherein the rack assembly is formed by fixedly connecting a hollow long pipe and a rigid supporting plate; the power transmission system comprises a hand wheel, a bearing seat, an input shaft, a bearing, a friction wheel and a friction transmission piece; the force adjusting mechanism comprises a fixing base, a supporting screw and a movable supporting rod. During working, the hand wheel is rotated, and the friction transmission piece moves forward under the action of friction force, so that the three clamping jaws are opened to allow fruits to enter; after the fruits are put in, the hand wheel is rotated in the reverse direction, the friction transmission piece retreats under the action of friction force, the three clamping jaws are gradually closed, and the fruits are captured. In addition, when no torque is input to the hand wheel, the self-locking mechanism can prevent the clamping force in the apple picking process from disappearing. The fruit picking machine is relatively simple in structure, adopts handheld picking and is convenient to use, the damage rate of picked fruits is reduced, and economic benefits are improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A horizontal pipe fixing device for mechanical processing

ActiveCN112059671BControl the size of the clamping forceClamping force is easy to controlPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention discloses a horizontal pipe fixing device for mechanical processing, which comprises a base, a stepping motor is fixedly connected to the base, two first mounting seats are symmetrically fixedly connected to the base, and the two first The mounting bases are all fixedly connected to the outer wall of the stepping motor, and a threaded shaft is rotatably connected to the first mounting base. With the help of the forward and reverse rotation of the stepping motor, the invention drives the threaded shaft to rotate through the movable gear, and then drives the water tank to move up and down in the vertical direction, and controls the water pressure in the conduit by controlling the height of the water tank, thereby realizing the clamping of the pipe by the fixed die. The clamping force is controlled, so that the clamping force of the fixed die on the pipe is controllable, and can be adjusted according to the material and load-bearing performance of the pipe to be processed, so it can effectively prevent the pipe from being damaged due to excessive clamping force. It is extruded and deformed, and can effectively avoid the problem of weak clamping caused by too small clamping force.

Owner:山东创伟外墙保温材料集团有限公司

Support for instrument board welding

PendingCN114515933AClamping force is easy to controlPrevent left and right deflectionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

According to the support for instrument board welding, two clamping air cylinders are matched for clamping, and the clamping force is controllable; by arranging the limiting block, the first balance rod can be limited, positioning can be achieved while time limiting is conducted, and left-right deflection is prevented; the fixing blocks with different apertures are arranged on the connecting plate, so that quick dismounting and mounting can be realized, and in addition, different functional components can be mounted as required; the multiple components are fixedly connected through bolts, and modular installation is achieved; and the clamping blocks are fixedly connected through bolts, so that quick assembly and replacement are facilitated.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE +1

A material turning device for female row

Owner:DONGGUAN HAORUN PRECISION ELECTRONICS

Refractory brick automatic identification and detection line

The invention discloses an automatic identifying and detecting operation line for refractory bricks. The automatic identifying and detecting operation line for the refractory bricks comprises a conveying unit, and the conveying unit is used for conveying the refractory bricks among a primary centering unit, a laser detection unit, a secondary centering unit, a marking and ink jetting unit and an automatic pasting unit in sequence. By means of the automatic identifying and detecting operation line for the refractory bricks, the detection and automatic identification work of the finished refractory bricks in different shapes and even having gradient is achieved, automation is achieved on the whole, and the problems about low operation efficiency, non-uniform identification, large detection errors and the like caused by manual completion of the subsequent operation of the finished refractory bricks in the prior art are solved.

Owner:BEIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com