Clamping chuck for correcting and compensating deviation of clamping center of pipe and correction method

A technology for compensating tubes and clamping, which is applied in the field of clamping chucks in three-dimensional tube laser cutting systems, which can solve the problems of poor coaxial accuracy, slow clamping speed, and gaps, and achieve the effect of stable cutting system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings.

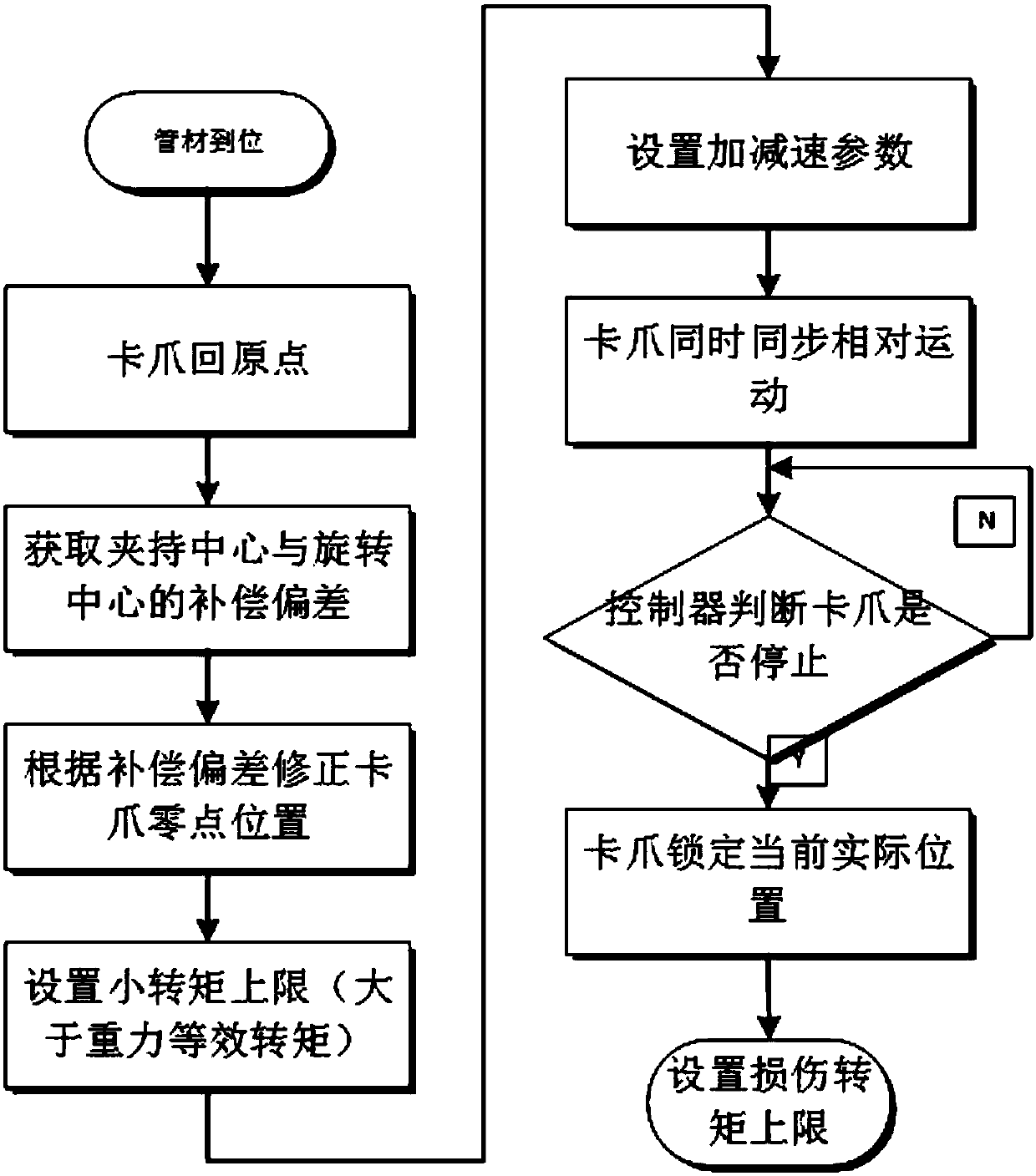

[0031] see figure 1 , the present invention designs a clamping chuck correction method that can correct and compensate for the deviation of the clamping center of the pipe, and the correction is performed according to the following steps:

[0032] Step 1: Put the pipe in place, and the jaws holding the chuck return to the original point;

[0033] Step 2: Measure the deviation Δx and Δz between the pipe clamping center and the rotation center through the numerical control system;

[0034] Step 3: correcting the deviation Δx and Δz measured in step 2;

[0035] Step 4: Set the small torque upper limit;

[0036] Step 5: Set the acceleration and deceleration parameters;

[0037] Step 6: The jaws holding the chuck move synchronously and relative to each other;

[0038] Step 7: The controller continuously reads the claw position, and judges whether the claw position remains un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com