Servo control glass centering intelligent identification and clamping device

A technology of intelligent identification and servo control, applied in workpiece clamping devices, devices for applying liquid to surfaces, manufacturing tools, etc., can solve problems such as inability to monitor and set up, glass cracking, and high impact force on the centering mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

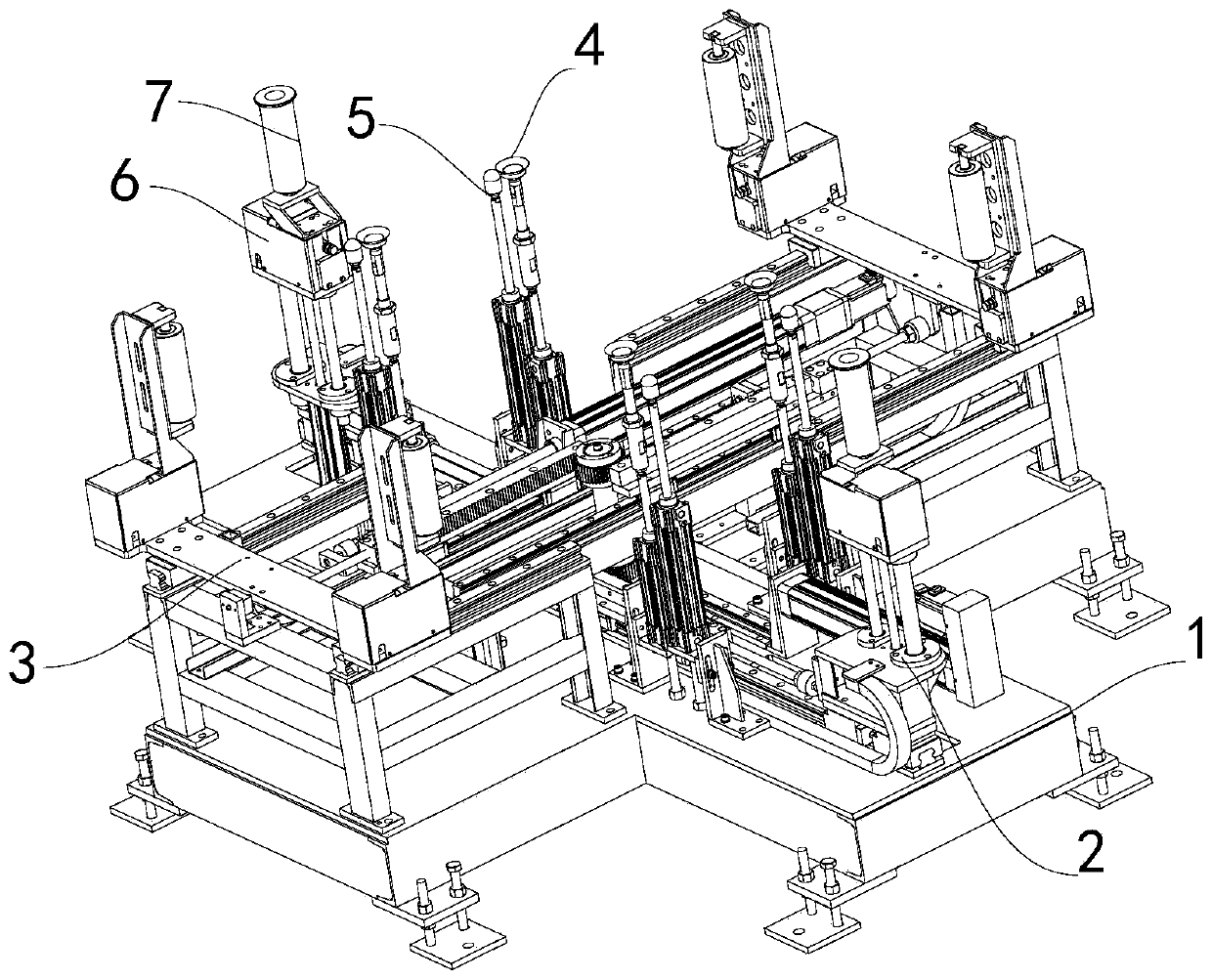

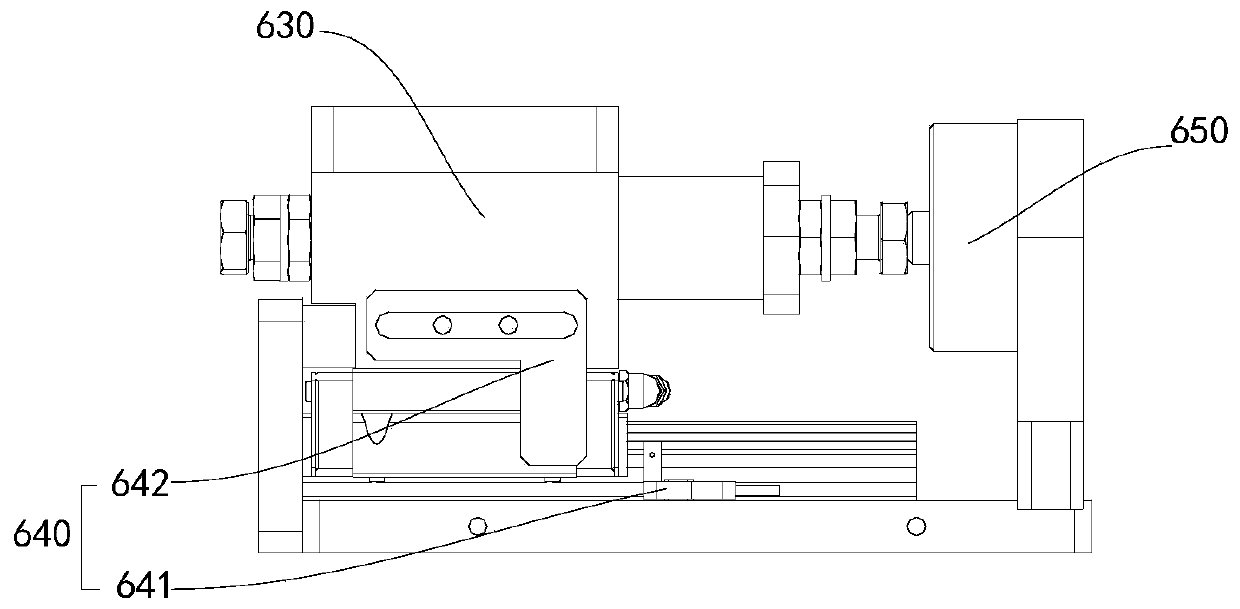

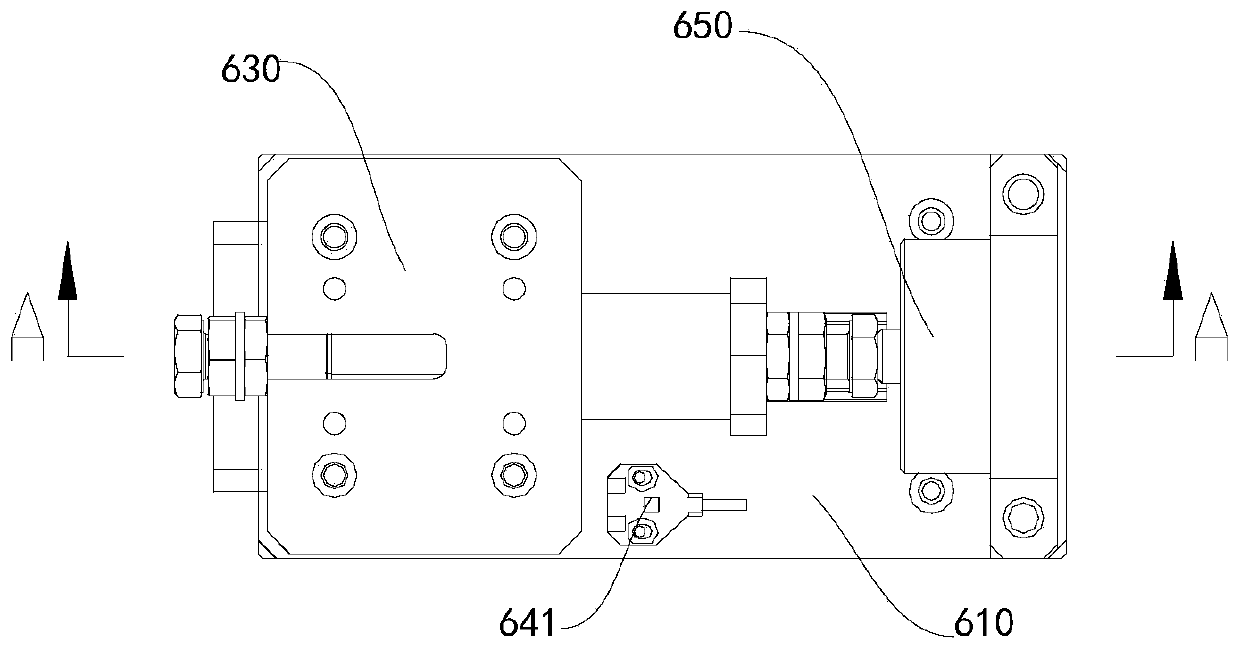

[0034] Example 1, such as figure 1 As shown, a servo-controlled glass centering intelligent identification and clamping device includes a base 1, a longitudinal clamping assembly 2, a transverse clamping assembly 3, a suction cup assembly 4, a support assembly 5, a buffer assembly 6 and a retaining column 7, The longitudinal clamping assembly 2 and the horizontal clamping assembly 3 are arranged on the base 1 in a cross-shaped manner, and the base 1 is provided with a support assembly 5 at each corner where the longitudinal clamping assembly 2 and the horizontal clamping assembly 3 intersect. 1 is provided with a suction cup assembly 4 at each corner where the longitudinal clamping assembly 2 intersects with the horizontal clamping assembly 3; the lateral clamping assembly 3 is provided with at least one buffer assembly 6 on both sides of the longitudinal clamping assembly 2 Each buffer assembly 6 is vertically provided with a stop post 7, and the horizontal servo electric cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com