Special clamp for clamping collar

A special fixture and collar technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of unreliable clamping and difficult control of clamping force, and achieve reliable positioning, easy control of clamping force, and clamping effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

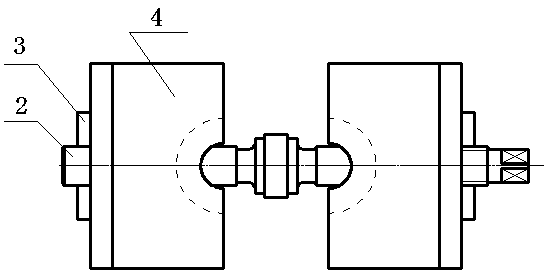

[0020] like figure 1 , figure 2 As shown, the special fixture used for clamping the collar includes a fixture seat, slide rail 1, adjusting screw 2, moving block 3, and clamping block 4. The lower end of slide rail 1 is installed on the fixture seat, and the upper end of slide rail 1 is clamped On the concave edge of the lower end of the moving block 3 , the lower end of the clamping block 4 presses on the concave edge of the upper end of the moving block 3 , and the adjusting screw 2 is engaged with the moving block 3 .

[0021] The clamping surface of the clamping block 4 is composed of three semi-cylindrical surfaces with different diameters, the diameters of the three semi-cylindrical surfaces are 80mm, 90mm, and 80mm respectively, and the clamping block 4 is on the clamping surface Inlaid tungsten carbide-based cemented carbide.

Embodiment 2

[0023] like figure 1 , figure 2 As shown, the special fixture used for clamping the collar includes a fixture seat, slide rail 1, adjusting screw 2, moving block 3, and clamping block 4. The lower end of slide rail 1 is installed on the fixture seat, and the upper end of slide rail 1 is clamped On the concave edge of the lower end of the moving block 3 , the lower end of the clamping block 4 presses on the concave edge of the upper end of the moving block 3 , and the adjusting screw 2 is engaged with the moving block 3 .

[0024] The clamping surface of the clamping block 4 is composed of three semi-cylindrical surfaces with different diameters, the diameters of the three semi-cylindrical surfaces are 40mm, 50mm, and 35mm respectively, and the clamping block 4 is on the clamping surface. Inlaid titanium carbonitride-based cemented carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com