Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128 results about "Low insertion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low insertion force (LIF) is a technology used in integrated circuit sockets that are designed so the force required to insert or remove a package is low. Initially, the LIF connectors were designed as a cheaper alternative compared to zero insertion force (ZIF) connectors, to facilitate programming and testing of equipment. Compared with standard IC sockets, they achieve a lower friction force between the contacts of the device and the socket, making insertion and removal of the device easier, while at the same time eliminating the need for the complex mechanism that is used in ZIF sockets.

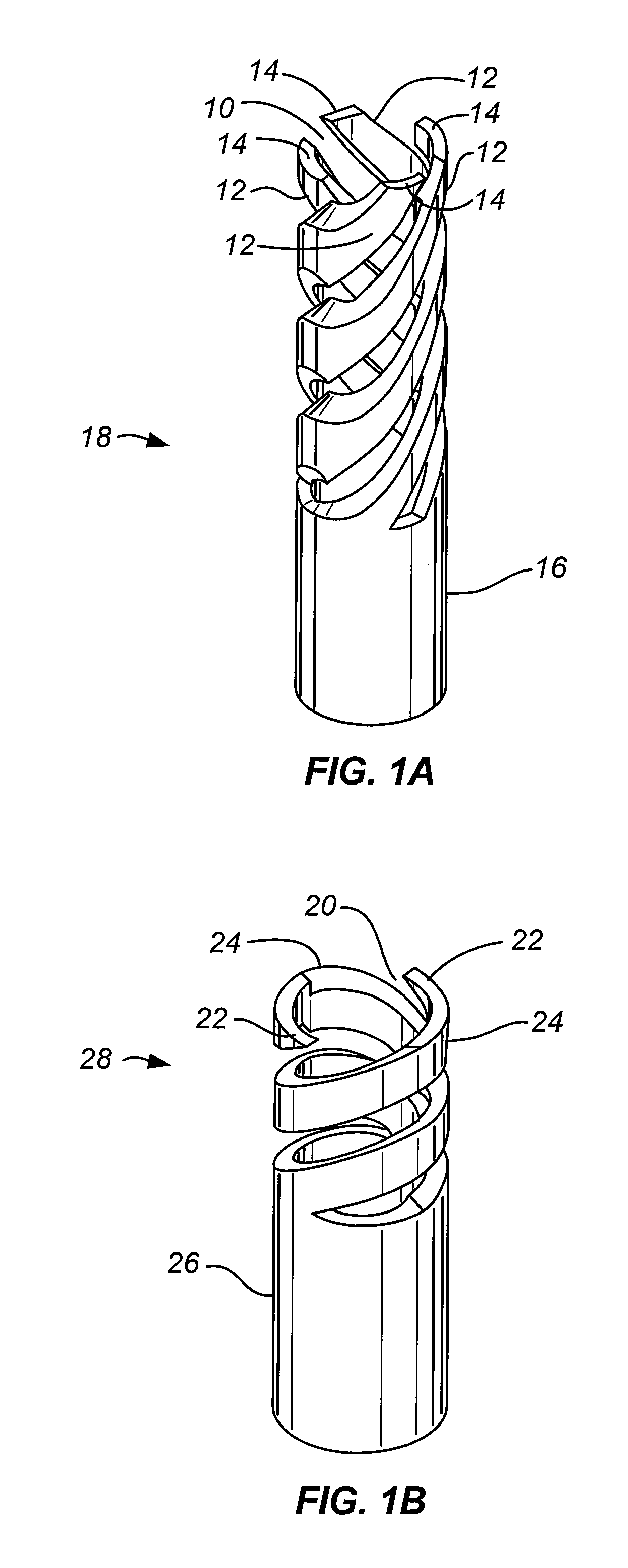

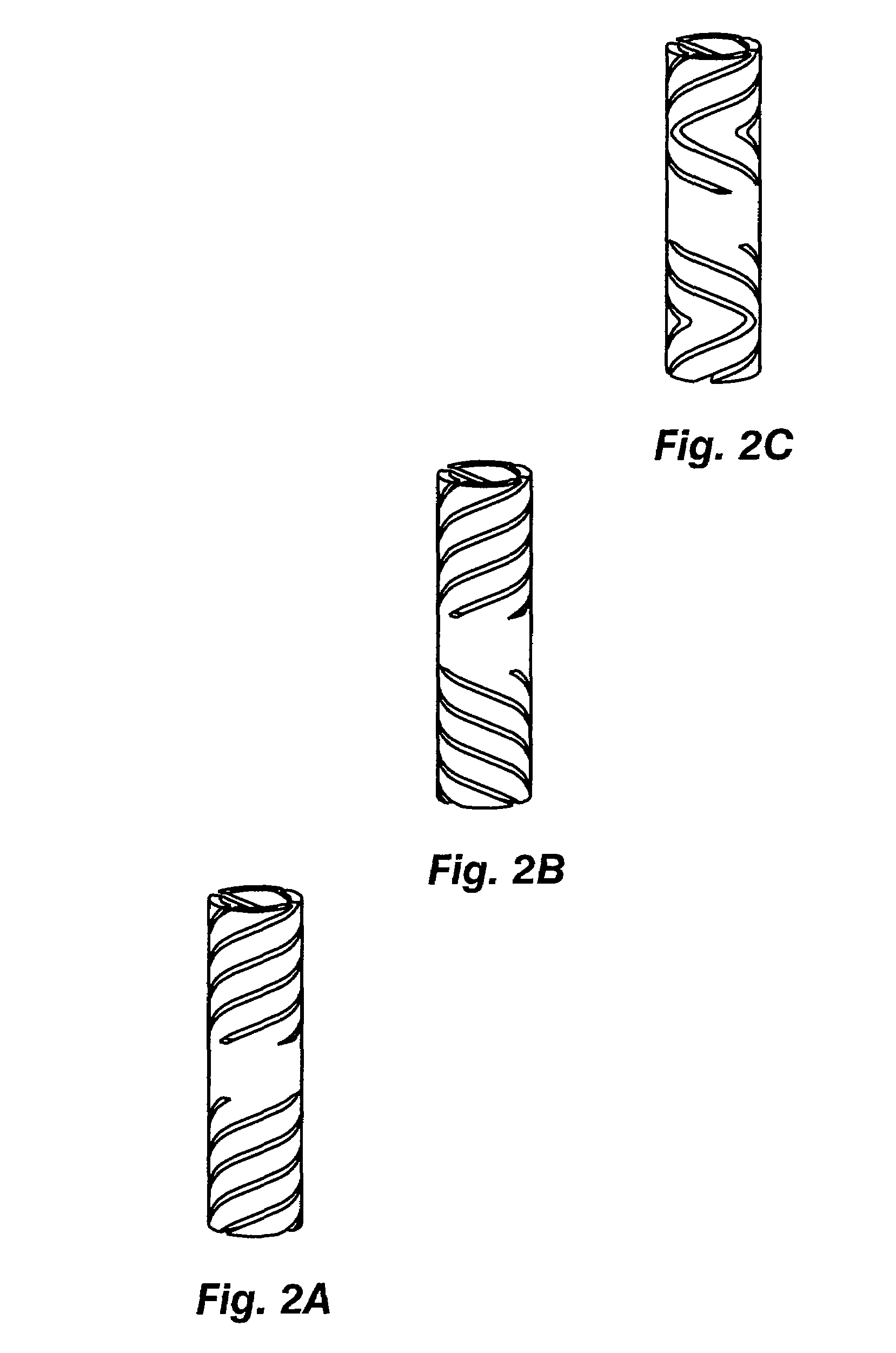

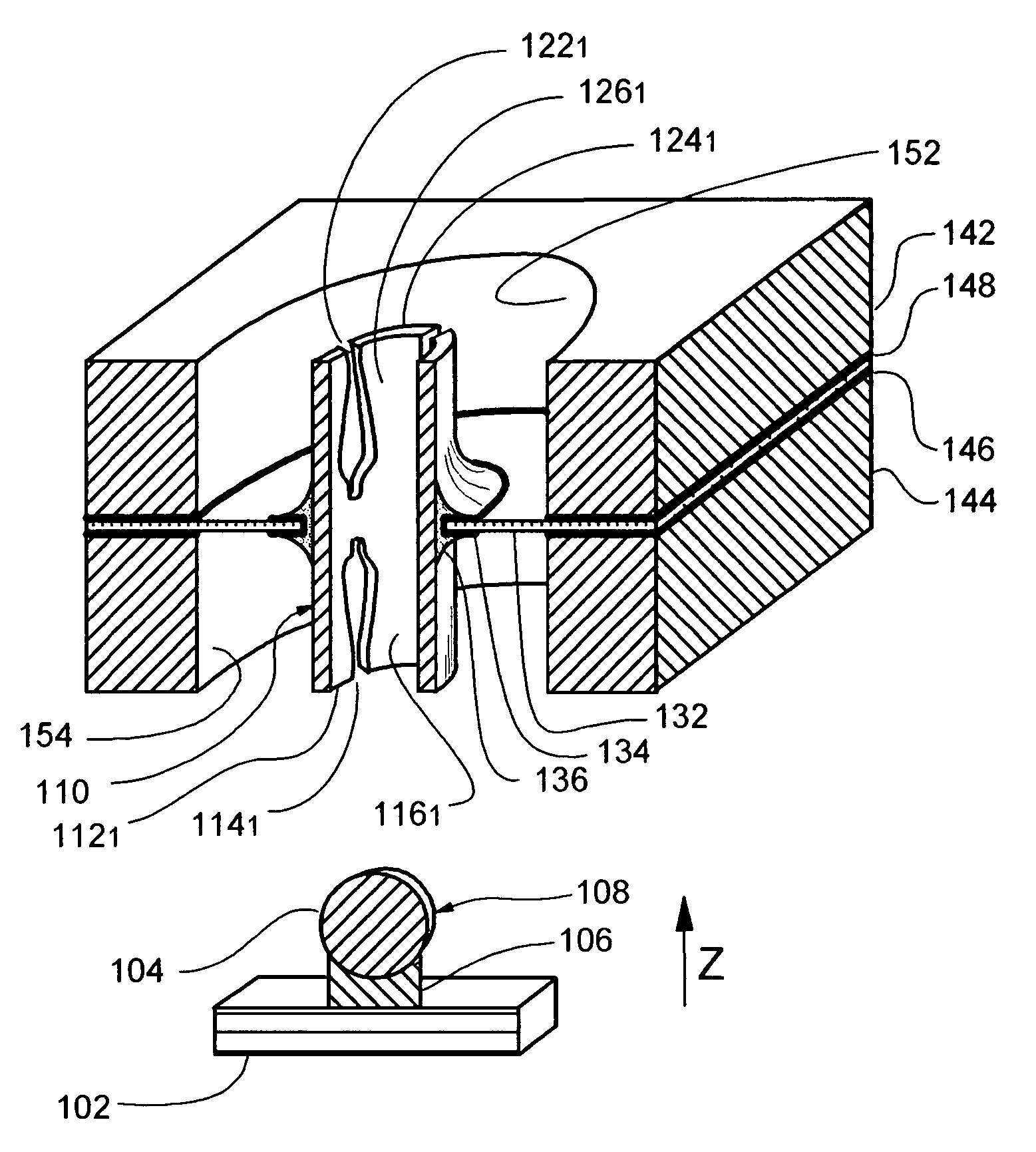

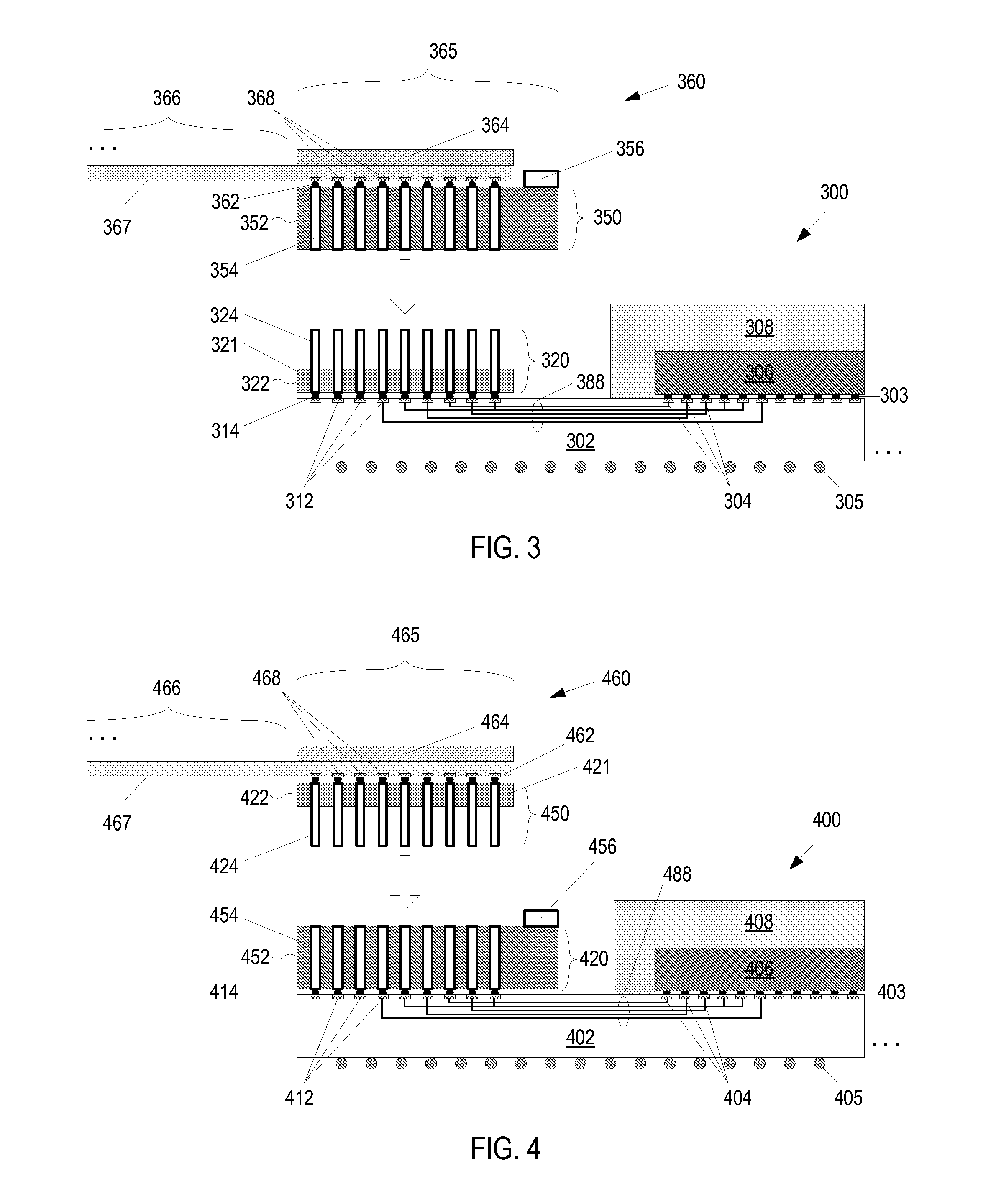

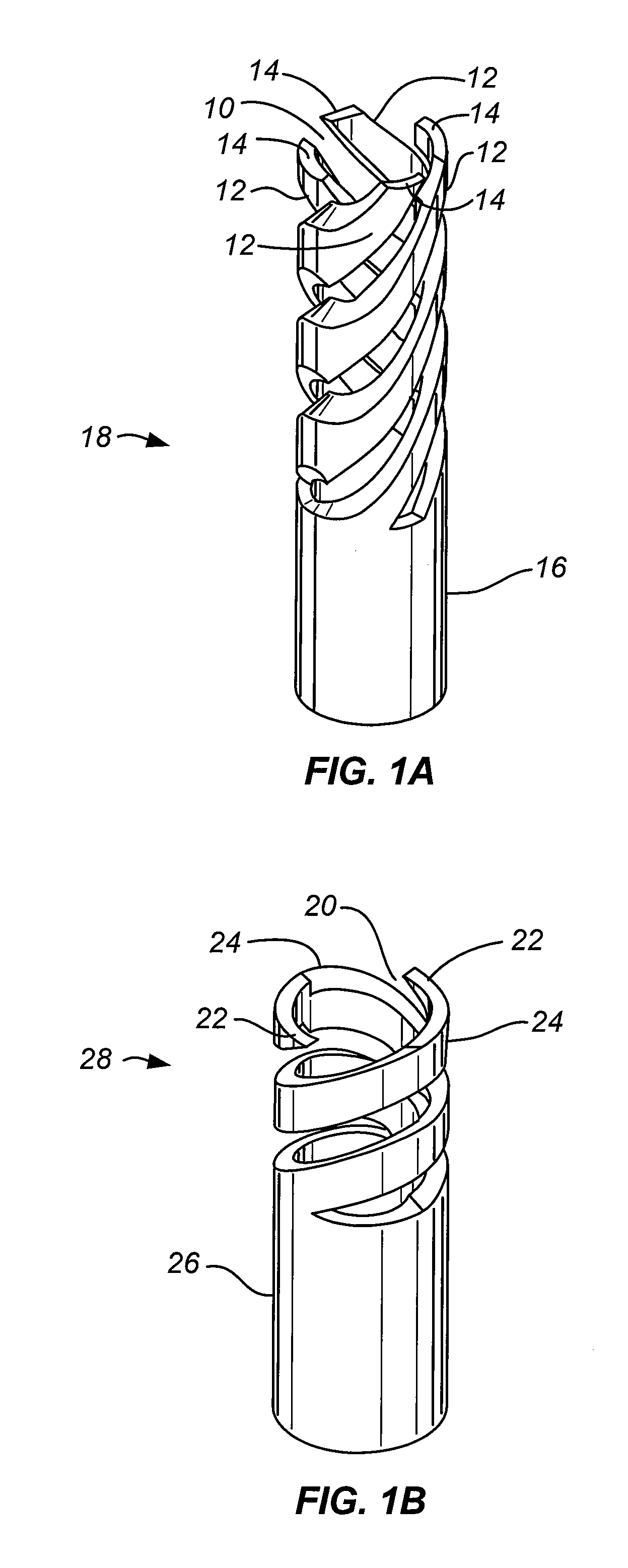

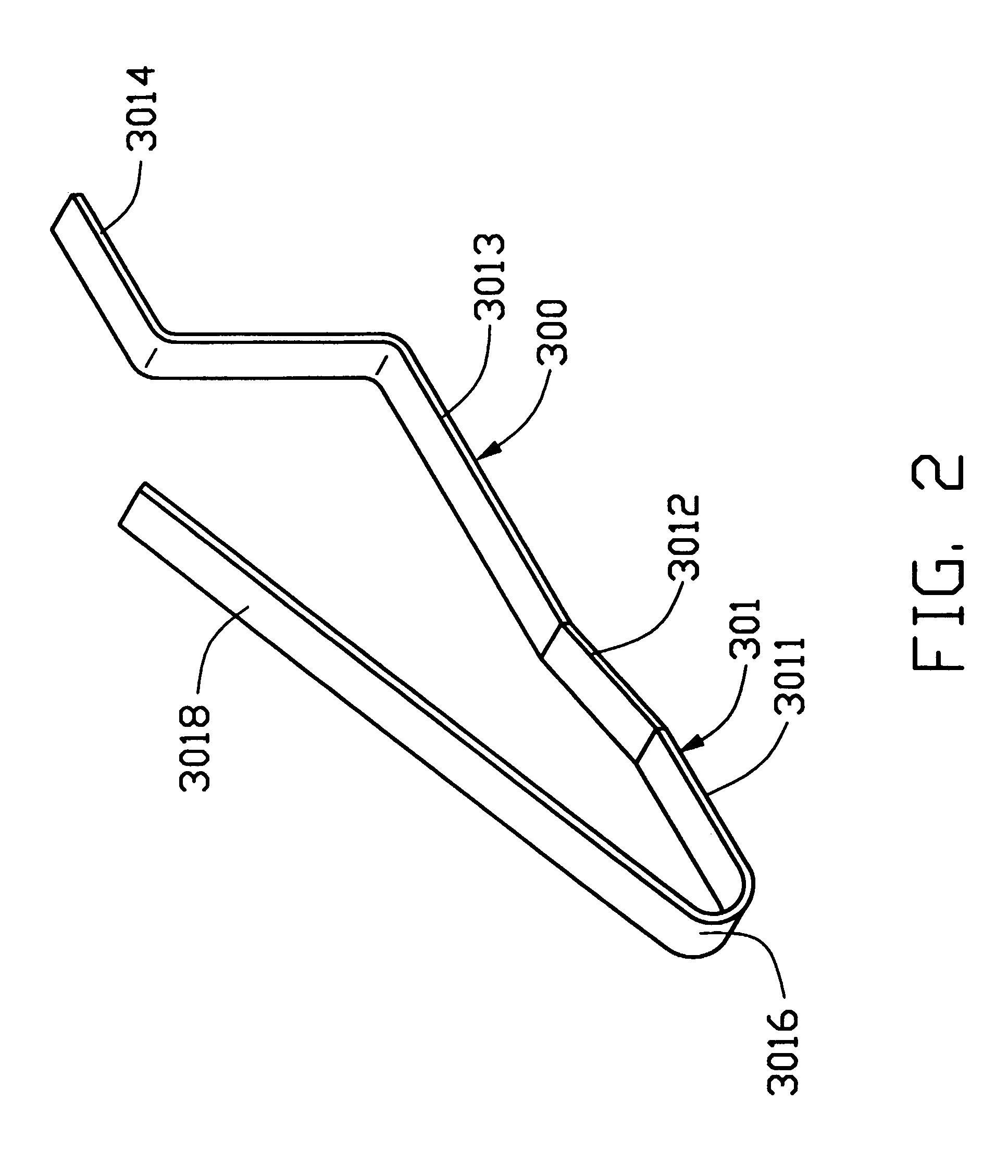

High performance electrical connector

InactiveUS7393214B2Lower self-esteemImprove performanceSolid-state devicesCoupling contact membersLow insertion forceConductive materials

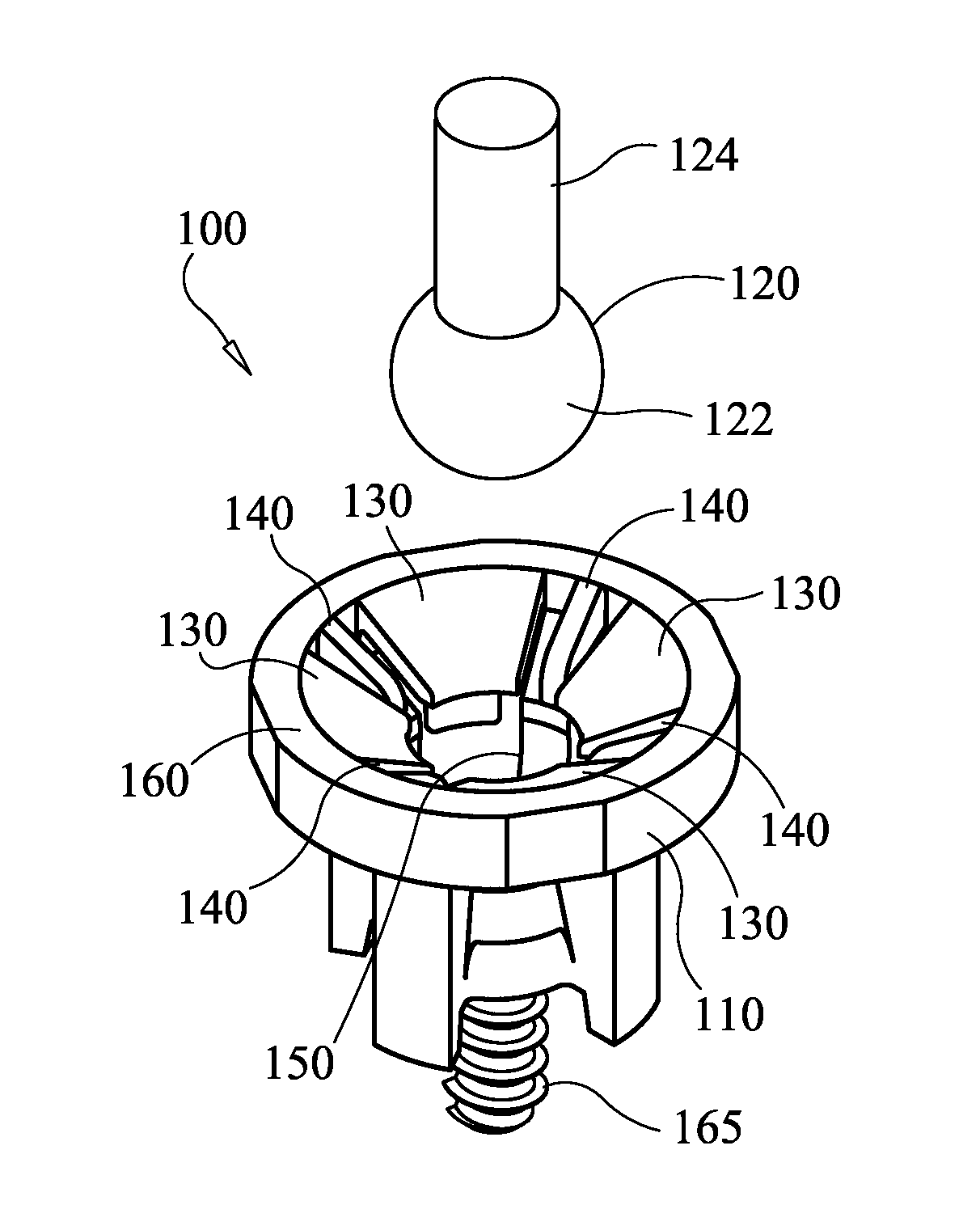

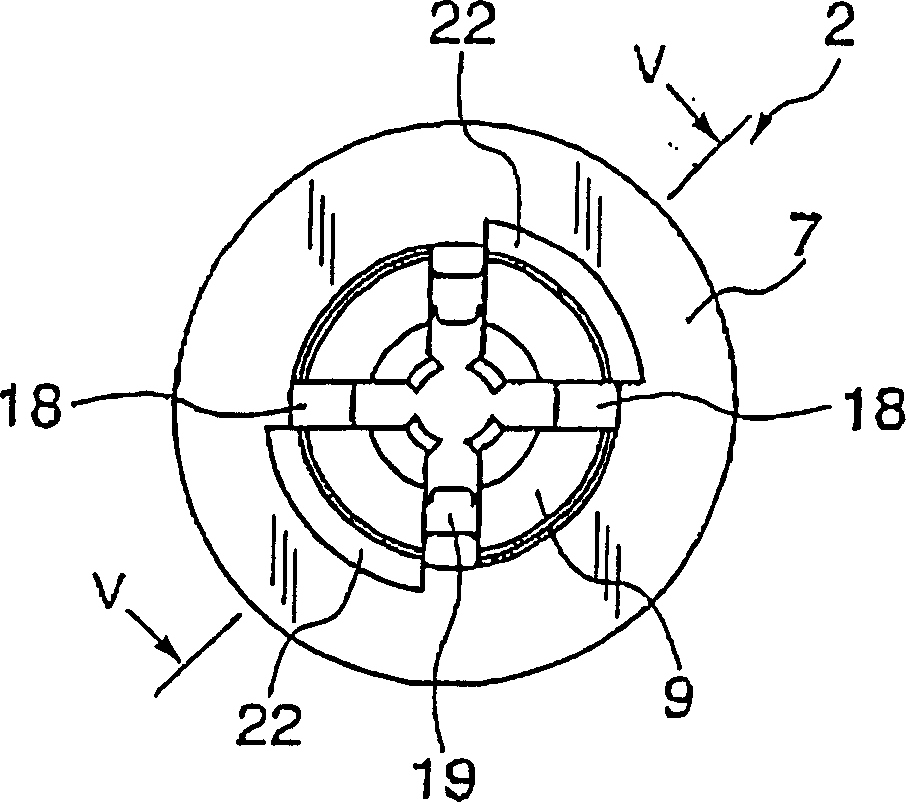

A socket connector for connecting a post or ball wherein the female element grips the post with resilient prongs with end tips at low insertion force but positive contact is maintained and wherein attempted withdrawal is normally inhibited by increasing force applied to the post by the female element in response to the withdrawal force. The female element comprises a tube of resilient conductive material that has been sliced or helically partitioned into opposing helical prongs so as to allow the prongs of the connector to spirally open around the post or ball-like bump and mechanically grip the post or bump as the post or bump is inserted along the longitudinal axis of the tube. The tubular element may be made by forming helical prongs in the end of a tube in helical cuts from about a mid section to one end of the tube.

Owner:CENTIPEDE SYST

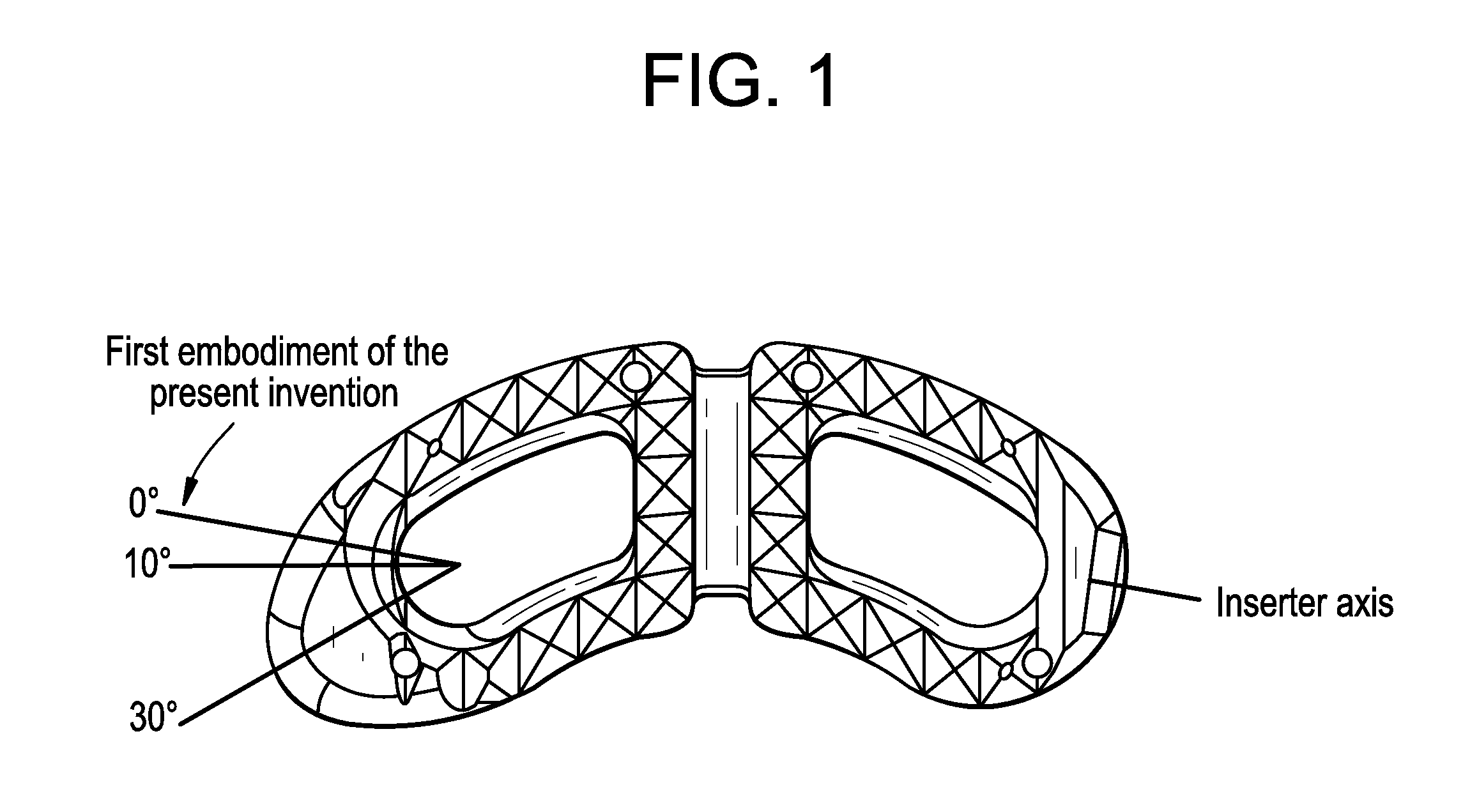

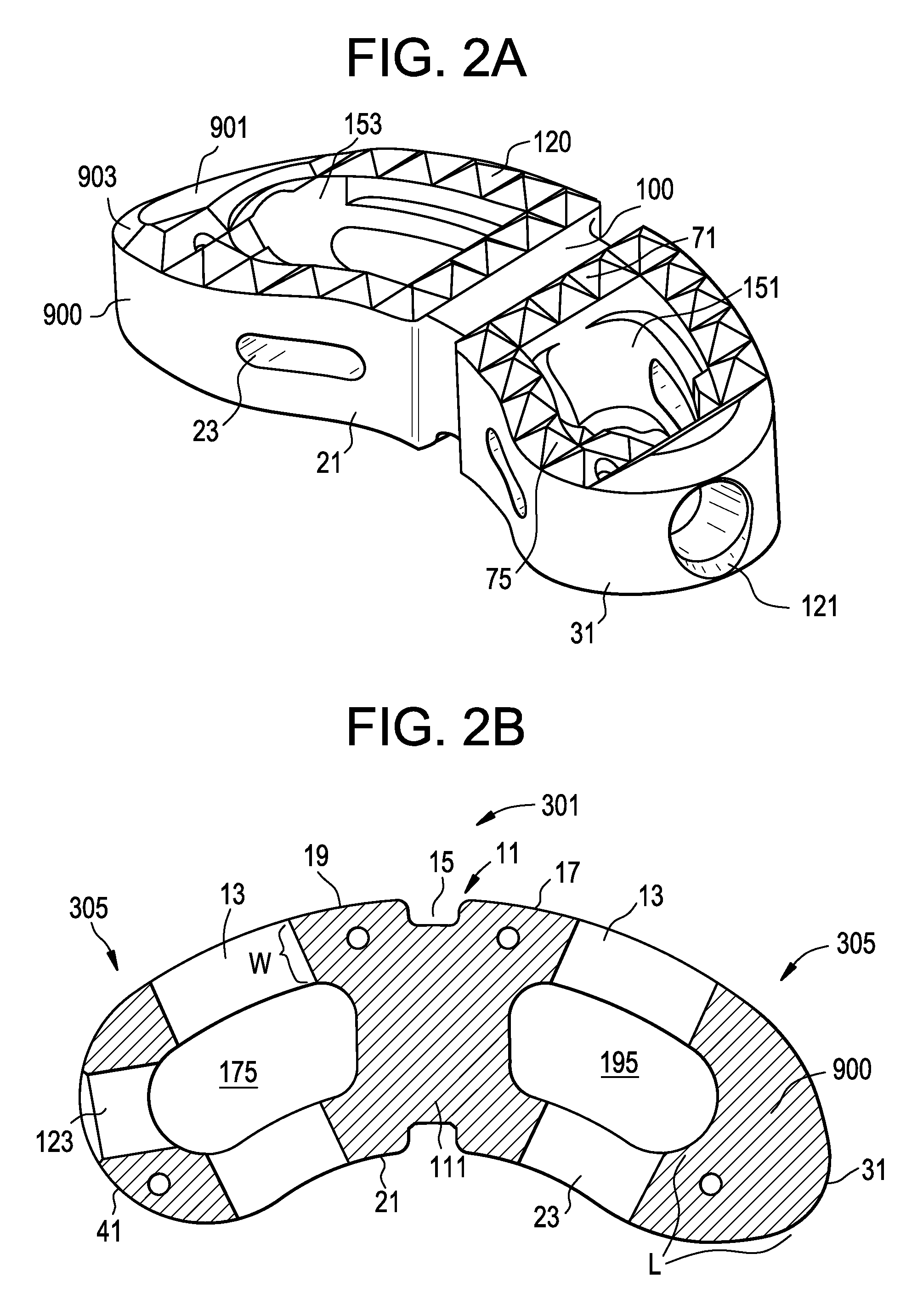

Angled Bullet-Nose Banana Cage

A banana-shaped cage adapted for use as an intervertebral fusion cage, wherein the leading direction of the nose of the banana cage is substantially in-line with the angle of the inserter shaft that inserts the cage into the disc space. It has been found that insertion of this cage requires lower insertion forces than the conventional cage whose leading direction substantially follows the arc of the banana curve.

Owner:DEPUY SYNTHES PROD INC

High temperature connector

ActiveUS7563118B1Easy to assembleEasy to installEngagement/disengagement of coupling partsContact member manufacturingLow insertion forceEngineering

A high temperature electrical connector suitable for use in a high temperature gas sensor. The electrical connector incorporates a ceramic connector body having a pair of opposing ceramic body portions which each house a plurality of conductive terminals. The body portions are in pivoting engagement and fixed in a connector body retainer which also enables their pivoting, hinged movement. The pivoting engagement permits the ceramic body portions and terminals to hinge open to receive a gas sensor with a low insertion force and a hinge closed to provide the desired contact force. The ceramic body portions may also include a taper section in a pivot portion with a taper angle that may be varied to control the pivoting, hinged movement of the electrical connector.

Owner:DELPHI TECH IP LTD

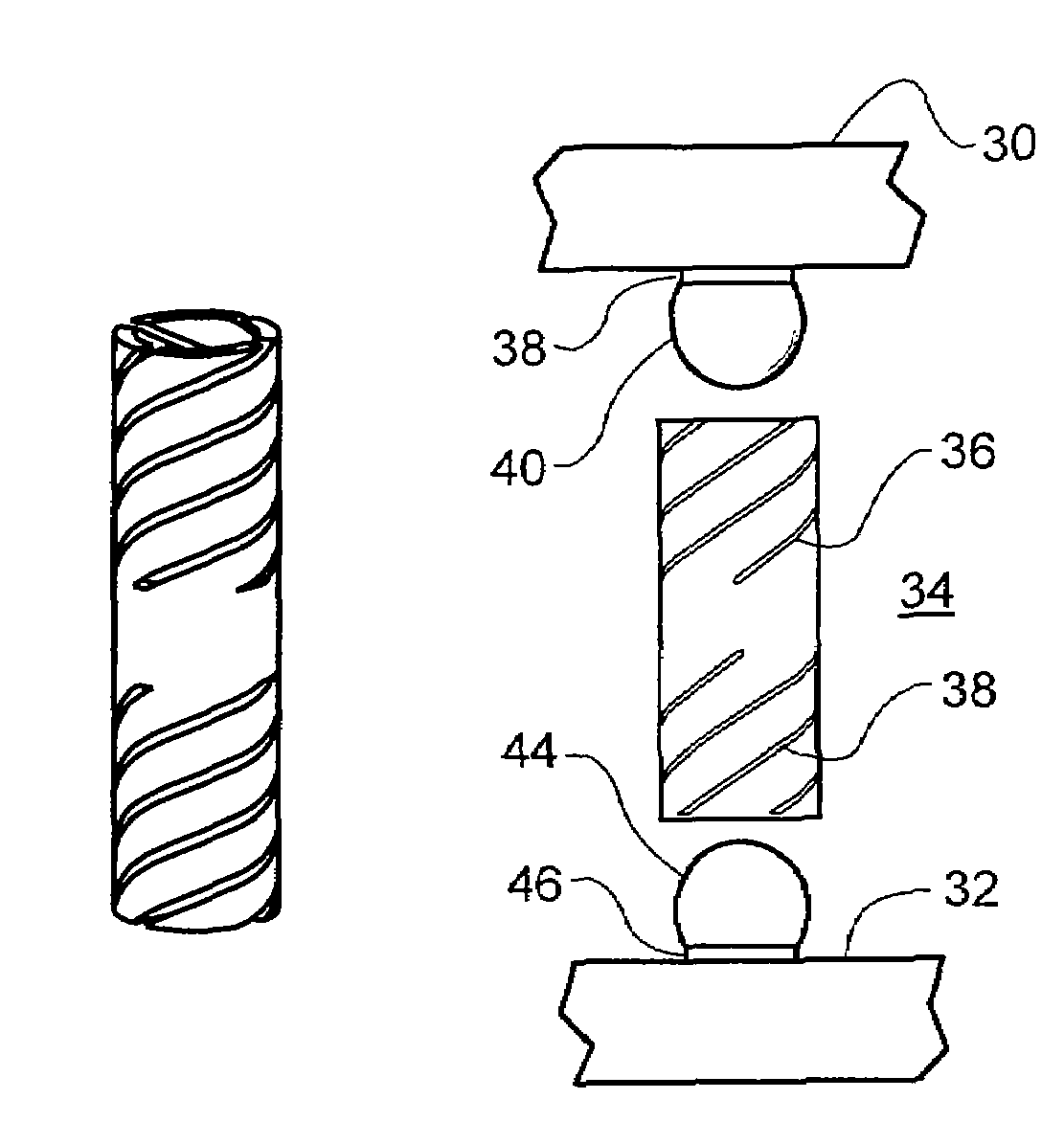

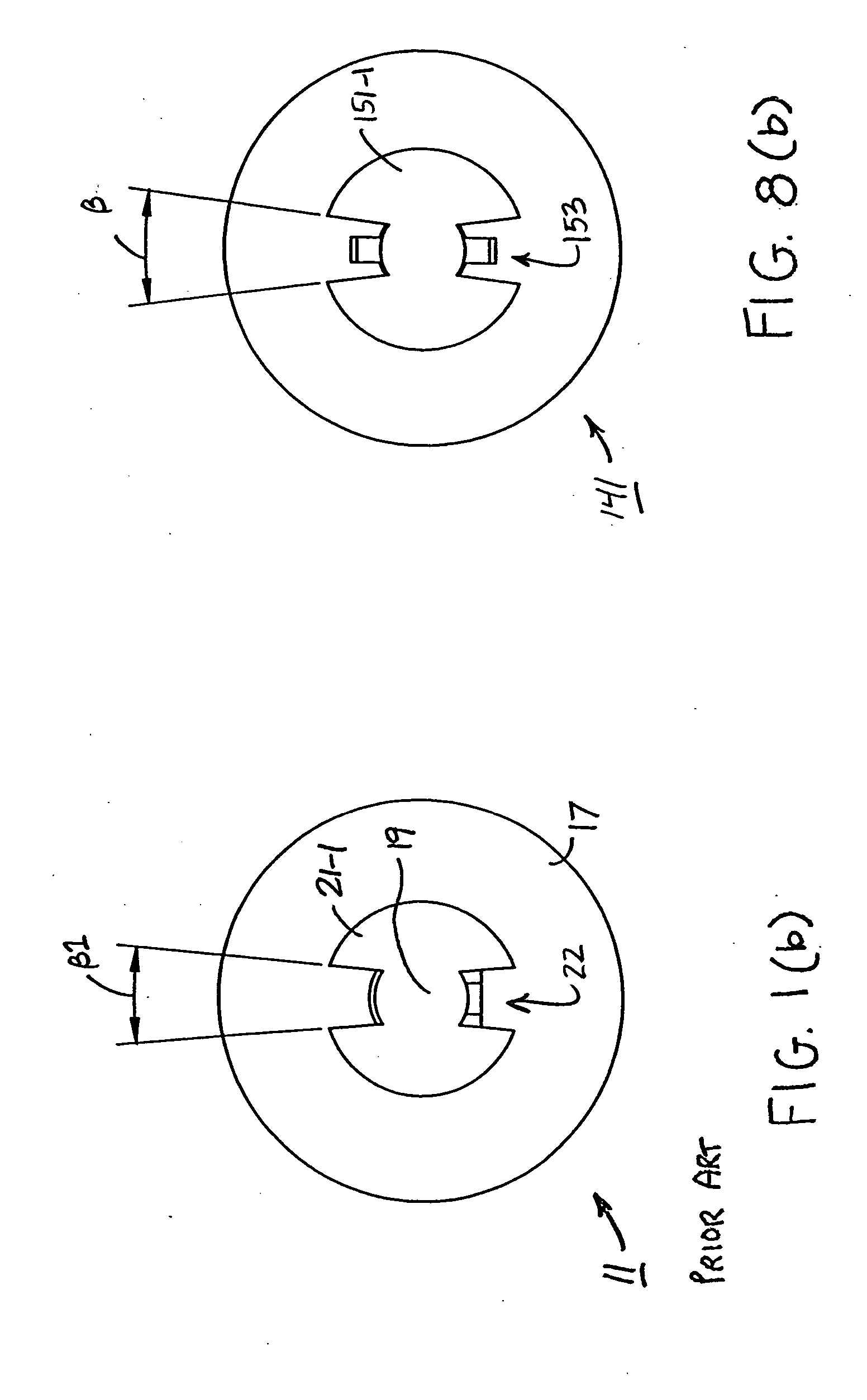

Miniature electrical ball and tube socket with self-capturing multiple-contact-point coupling

InactiveUS7442045B1Reduce mechanical stressLower self-esteemFinal product manufacturePrinted circuit aspectsLow insertion forceCoupling

A socket connector for connecting a bulbous terminal or ball wherein the female element grips the terminal with resilient prongs with end tips at low insertion force but positive contact is maintained and wherein attempted withdrawal is normally inhibited by increasing force applied to the post by the female element in response to the withdrawal force. The female element comprises a tube of resilient conductive material that has been sliced or helically partitioned into opposing prongs of a width that decreases with axial distance from the end of the connector so as to allow the prongs of the connector to grip around the ball-like bulbous terminal and mechanically retain the terminal within the connector. The tubular element of the connector may be made by forming prongs in one or both ends of a tube by cuts of a width that increases with distance from the end of the tube.

Owner:CENTIPEDE SYST

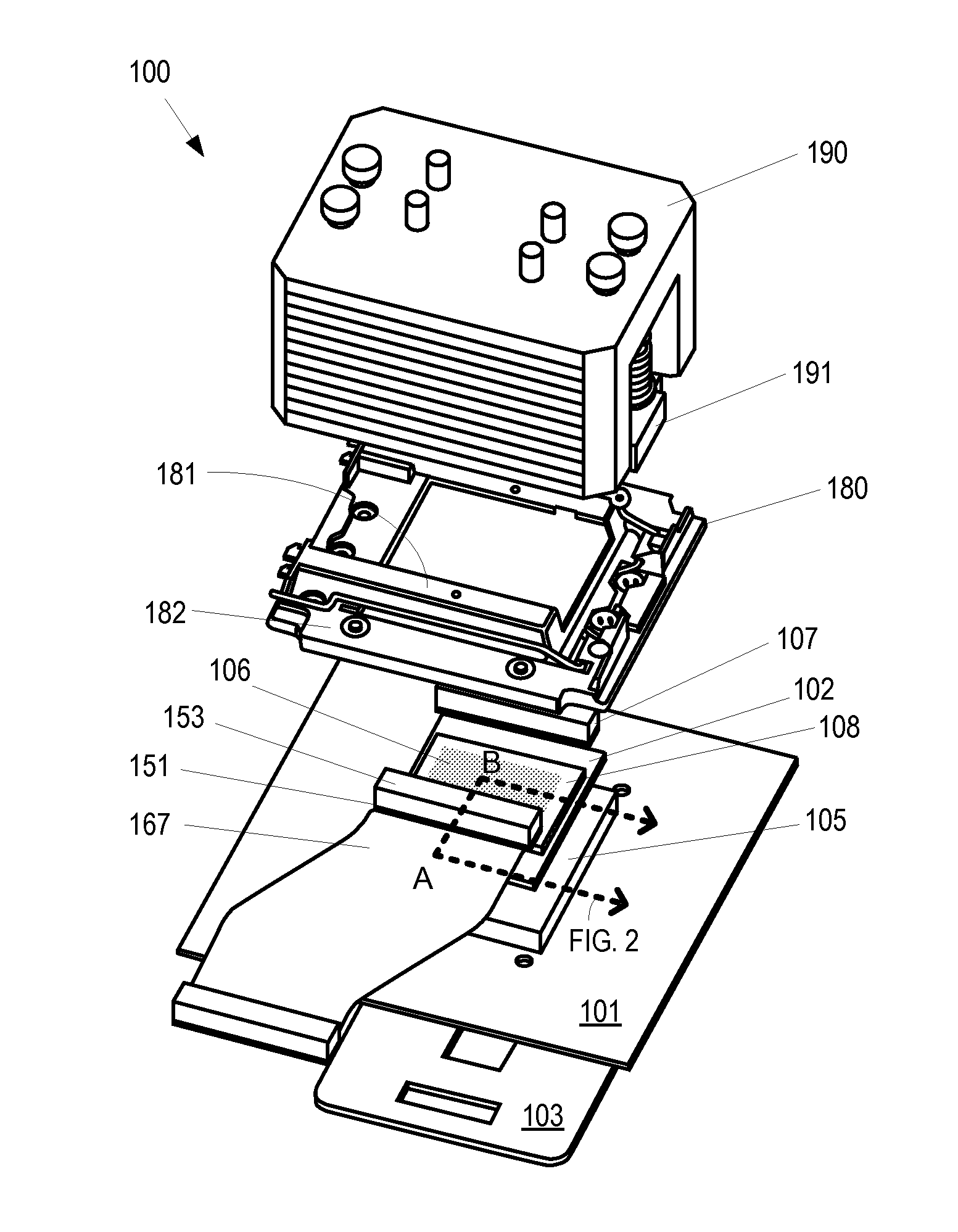

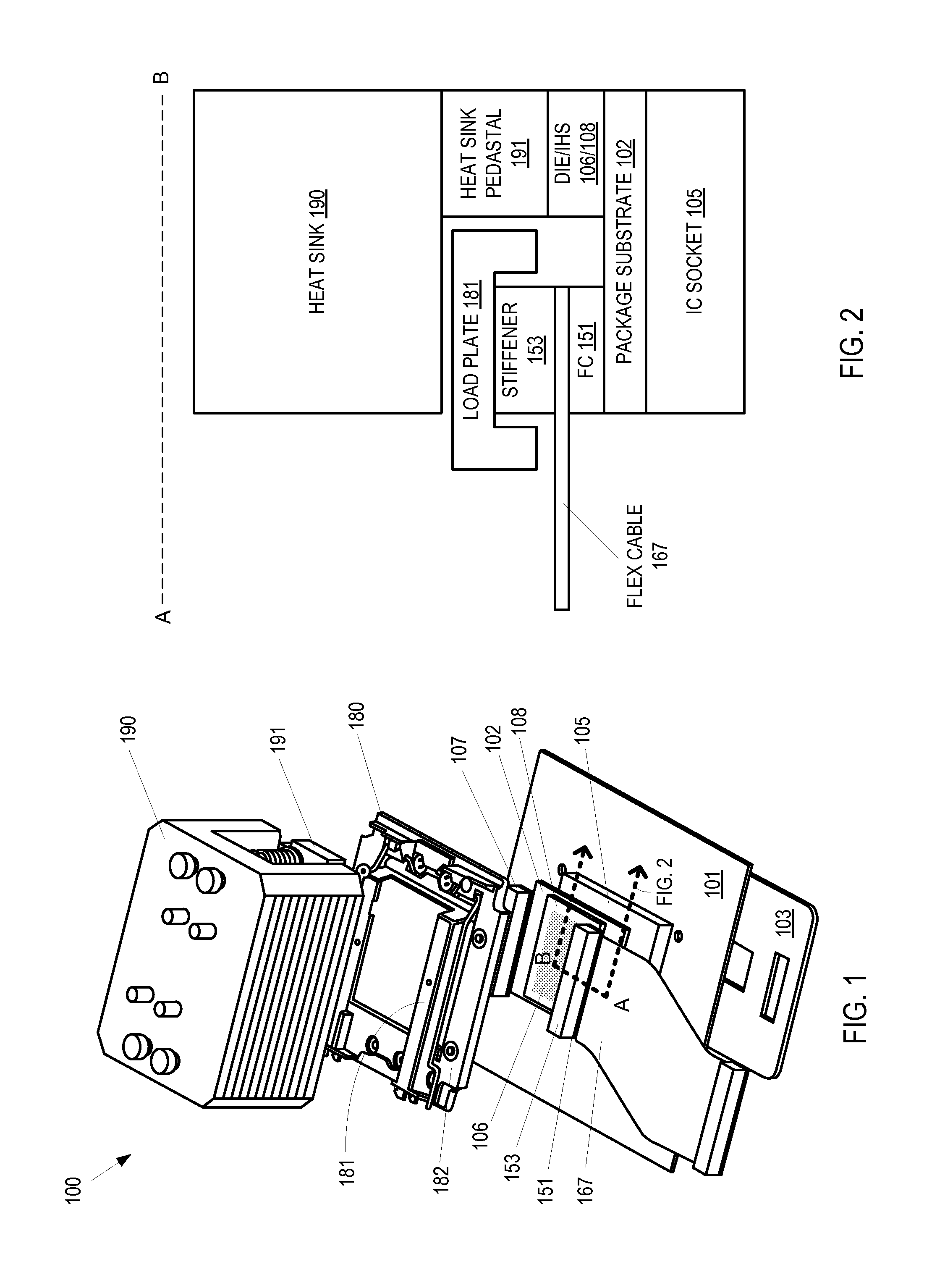

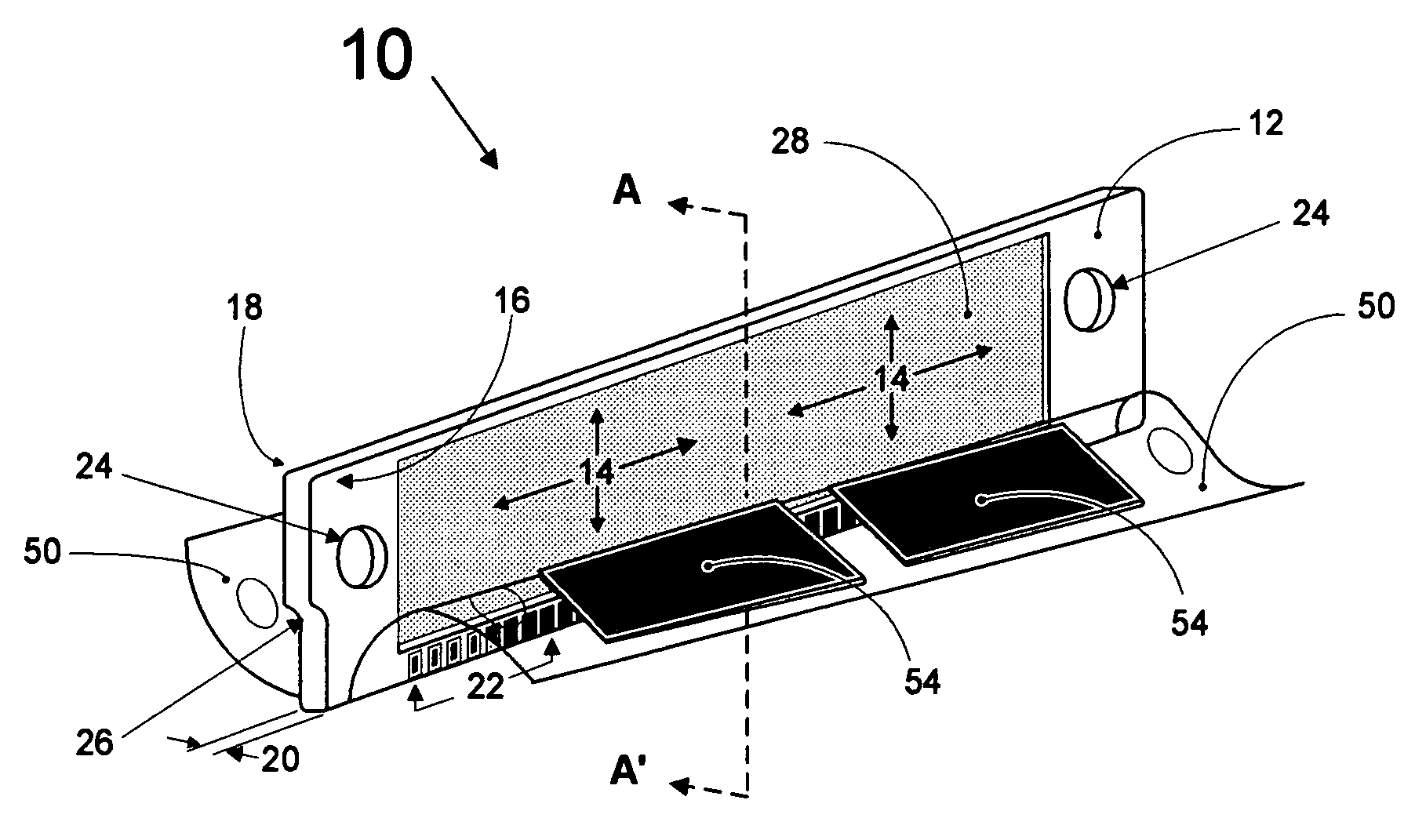

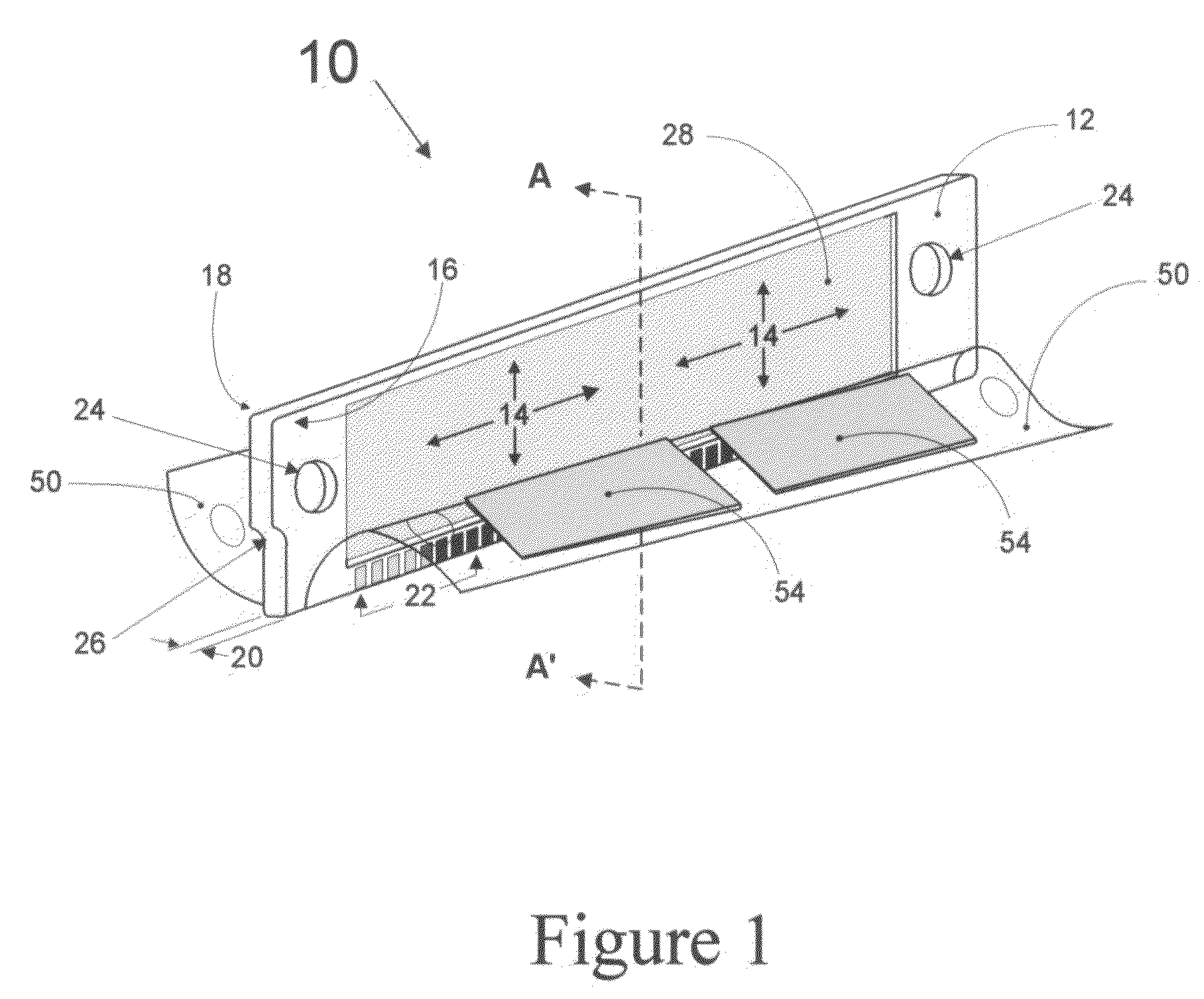

Low profile zero/low insertion force package top side flex cable connector architecture

ActiveUS20140217571A1Coupling device connectionsElectrically conductive connectionsLow insertion forceContact pad

An integrated circuit package is presented. In an embodiment, the integrated circuit package has contact pads formed on the top side of a package substrate, a die electrically attached to the contact pads, and input / output (I / O) pads formed on the top side of the package substrate. The I / O pads are electrically connected to the contact pads. The integrated circuit package also includes a flex cable receptacle electrically connected to the I / O pads on the top side of the package substrate. The flex cable receptacle is non-compressively attachable to a flex cable connector and includes receptacle connection pins electrically connected to the I / O pads.

Owner:INTEL CORP

High Performance Electrical Connector

InactiveUS20070197099A1Lower self-esteemLess magnetic flux penetrationSolid-state devicesCoupling contact membersLow insertion forceConductive materials

A socket connector for connecting a post or ball wherein the female element grips the post with resilient prongs with end tips at low insertion force but positive contact is maintained and wherein attempted withdrawal is normally inhibited by increasing force applied to the post by the female element in response to the withdrawal force. The female element comprises a tube of resilient conductive material that has been sliced or helically partitioned into opposing helical prongs so as to allow the prongs of the connector to spirally open around the post or ball-like bump and mechanically grip the post or bump as the post or bump is inserted along the longitudinal axis of the tube. The tubular element may be made by forming helical prongs in the end of a tube in helical cuts from about a mid section to one end of the tube.

Owner:CENTIPEDE SYST

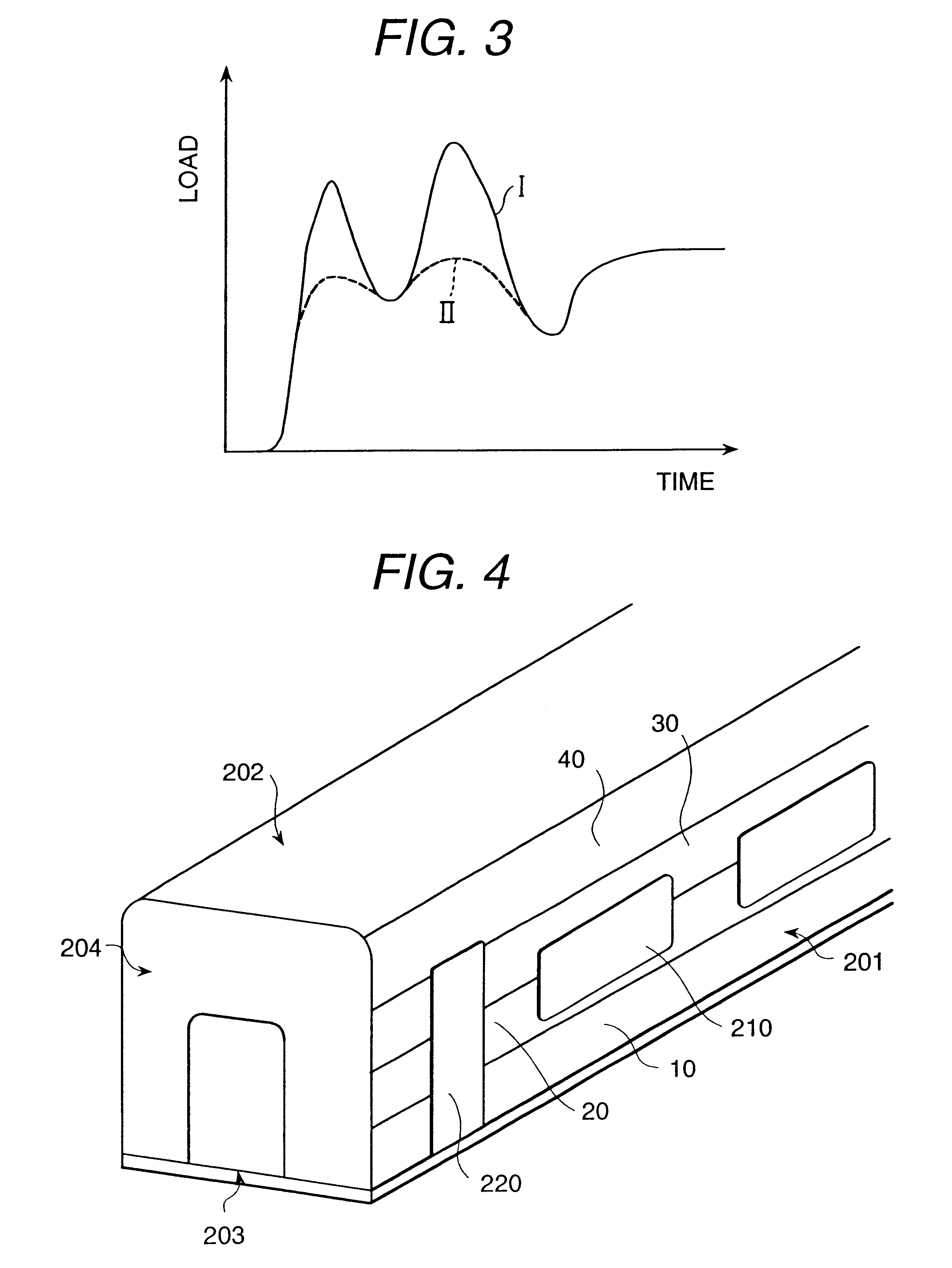

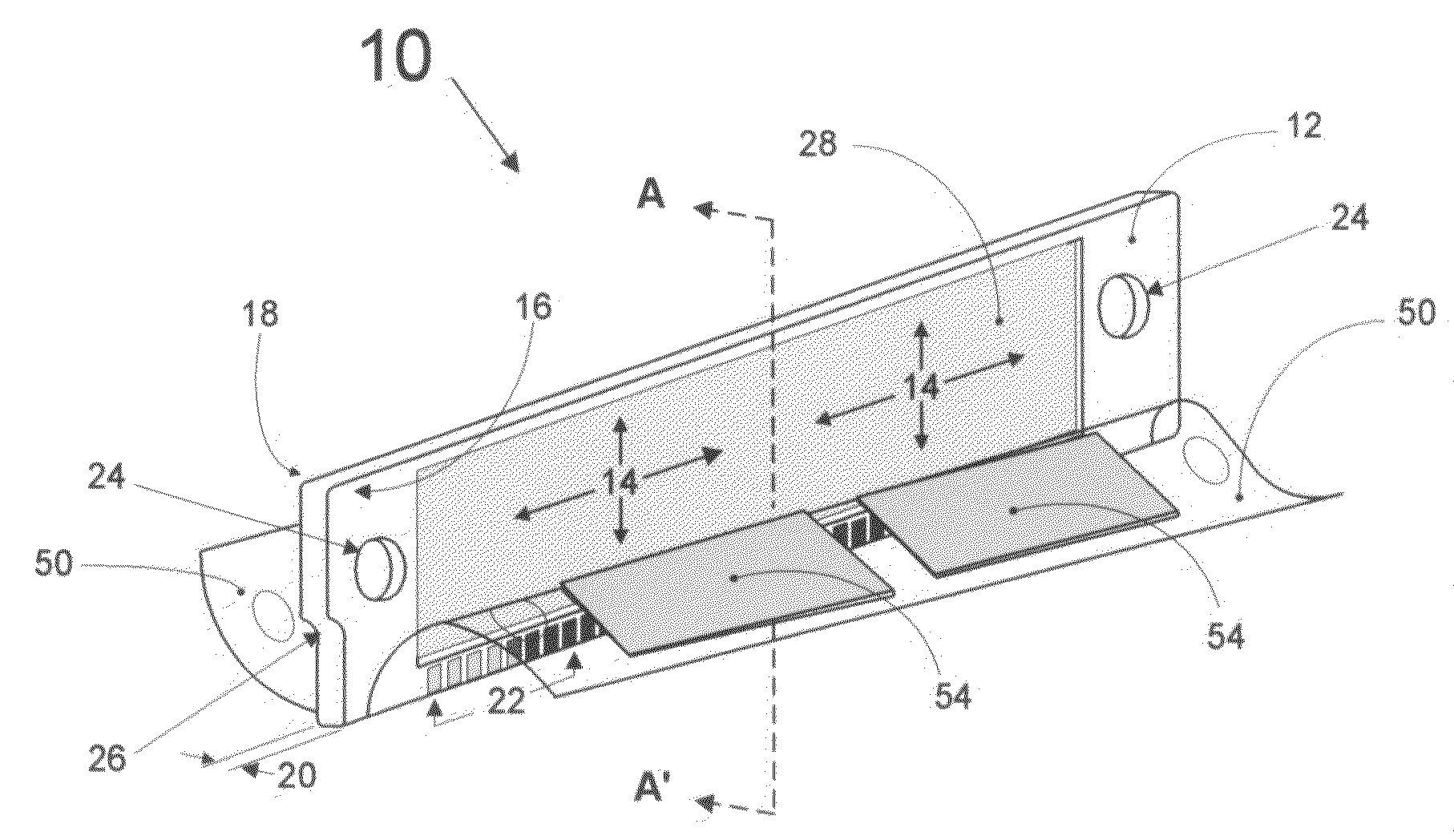

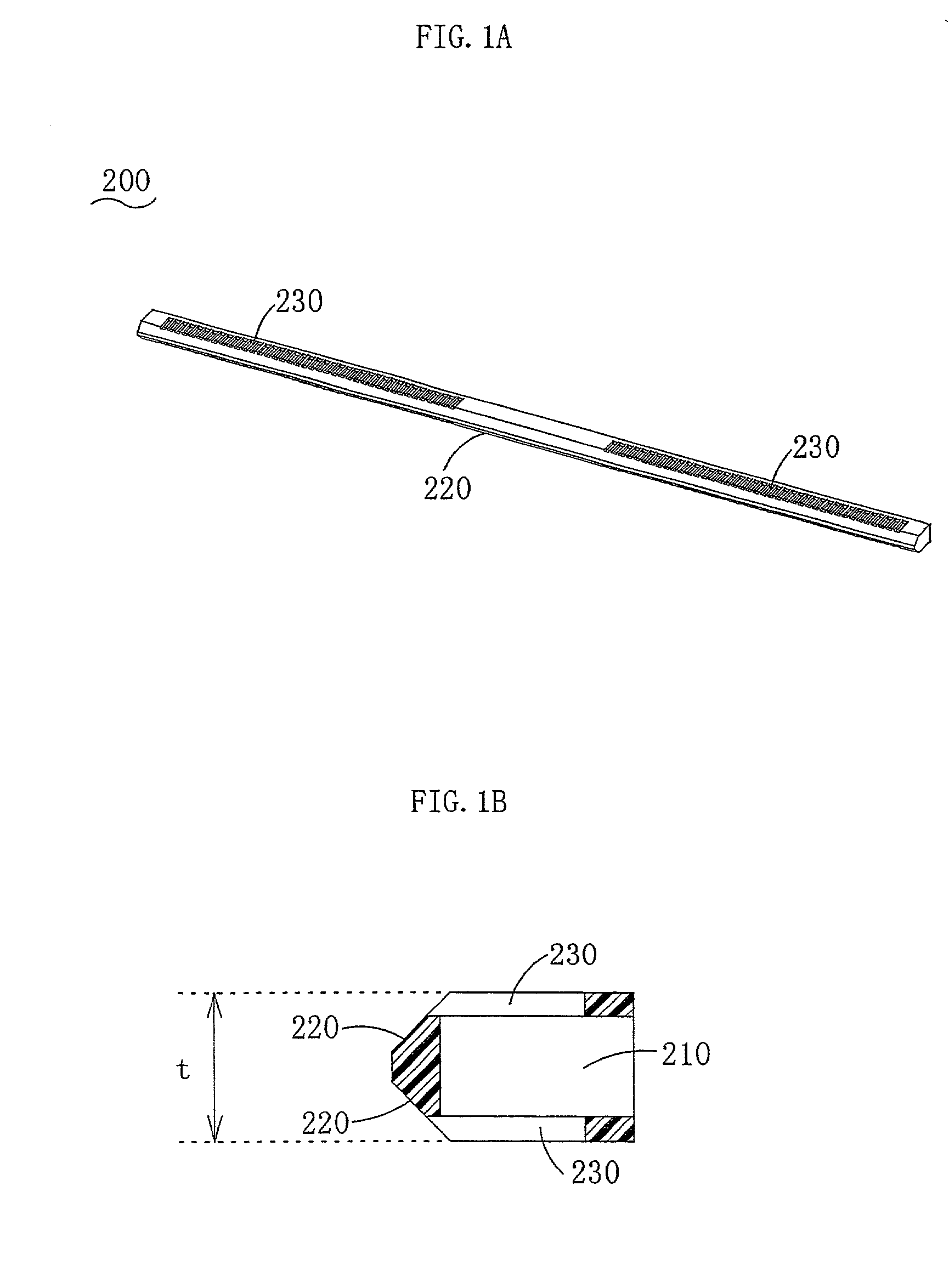

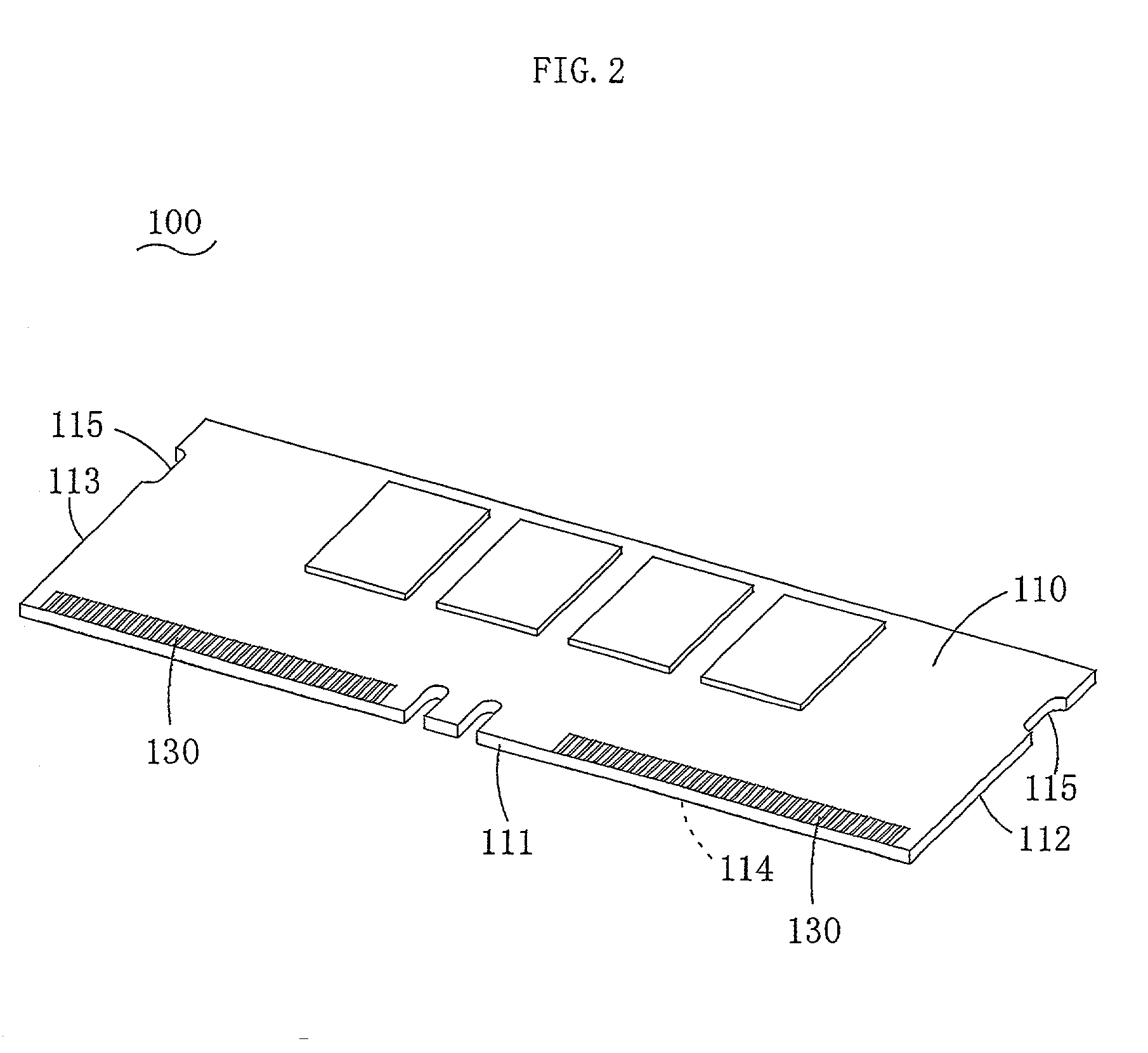

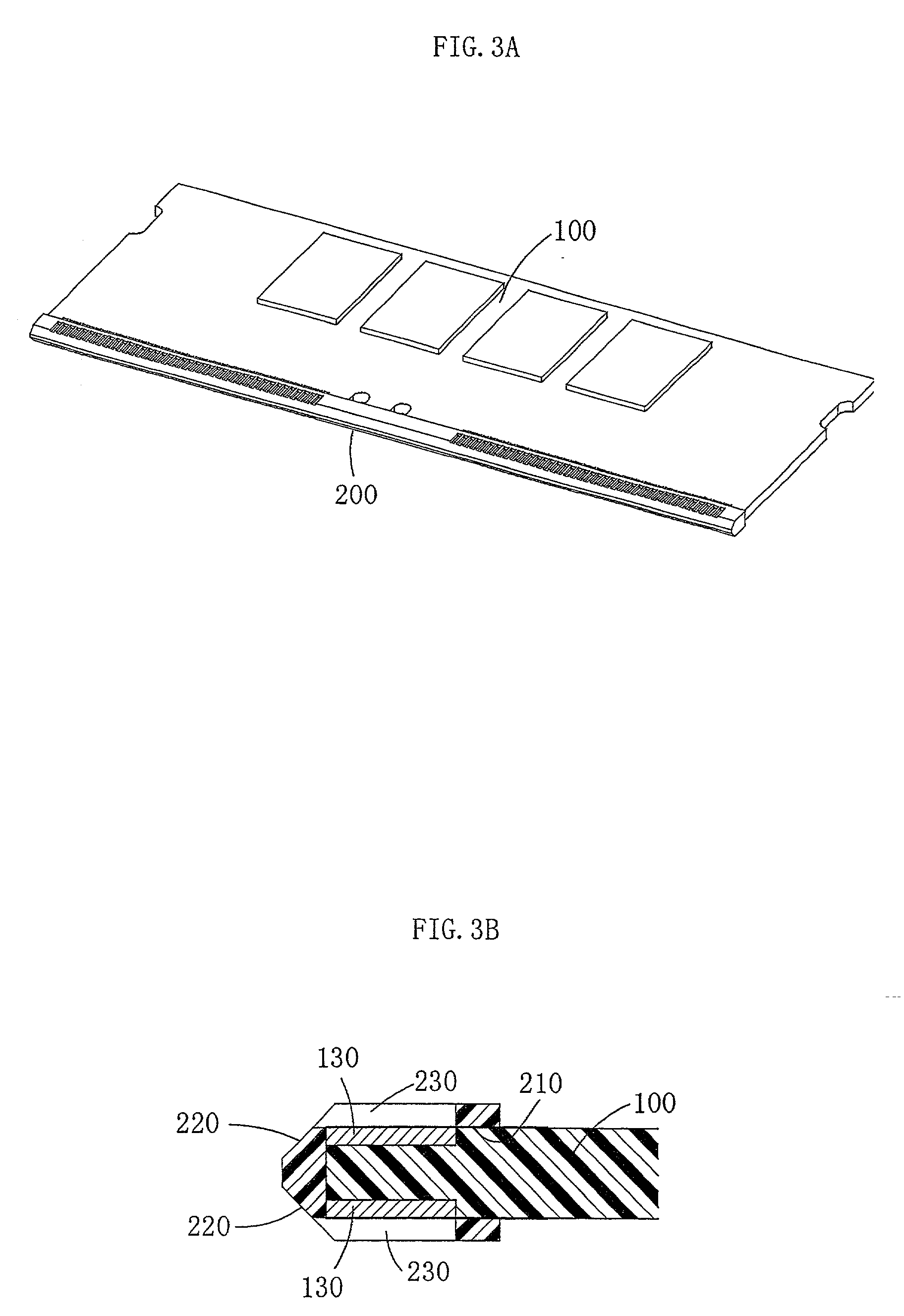

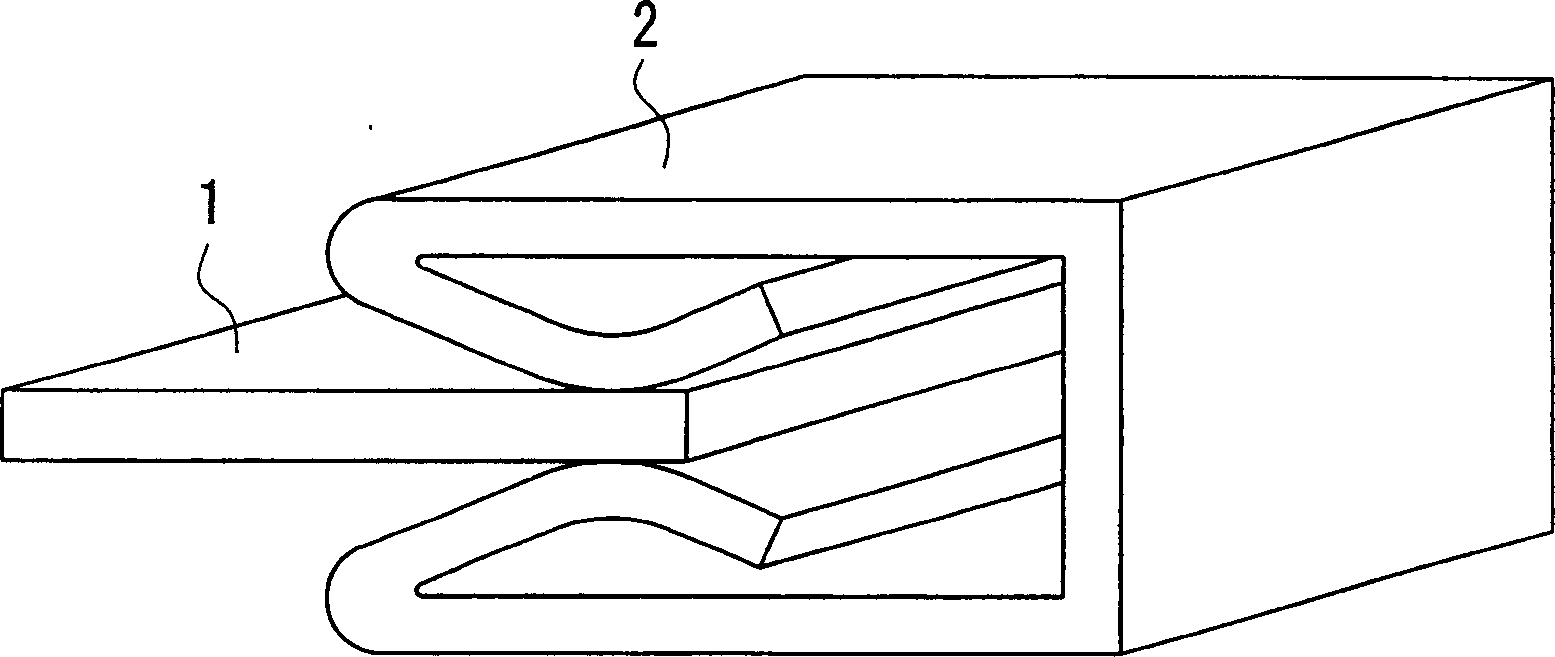

Thin multichip flex-module

ActiveUS20070212902A1Reduce manufacturing costIncrease component densityDigital data processing detailsSemiconductor/solid-state device detailsLow insertion forceEngineering

A low insertion force multichip in-line module comprises: a substantially rigid frame; a flex circuit having a plurality of integrated circuit chips disposed thereon, the flex circuit having contacts at least partially exposed along one edge of the frame; and, a compliant layer disposed between the exposed flex circuit and the rigid frame, whereby controlled deformation of the compliant layer enhances electrical continuity between the contacts and corresponding external electrical pins. Alternatively, a low insertion force multichip in-line module comprises: a substantially rigid frame; a flex circuit having a plurality of integrated circuit chips disposed thereon, the flex circuit having contacts at least partially exposed along one edge of the frame; a socket configured to matably engage the module; and, a compliant layer disposed between the exposed flex circuit and the rigid frame, whereby controlled deformation of the compliant layer enhances electrical continuity between the contacts and corresponding external electrical pins.

Owner:MICROELECTRONICS ASSEMBLY TECH

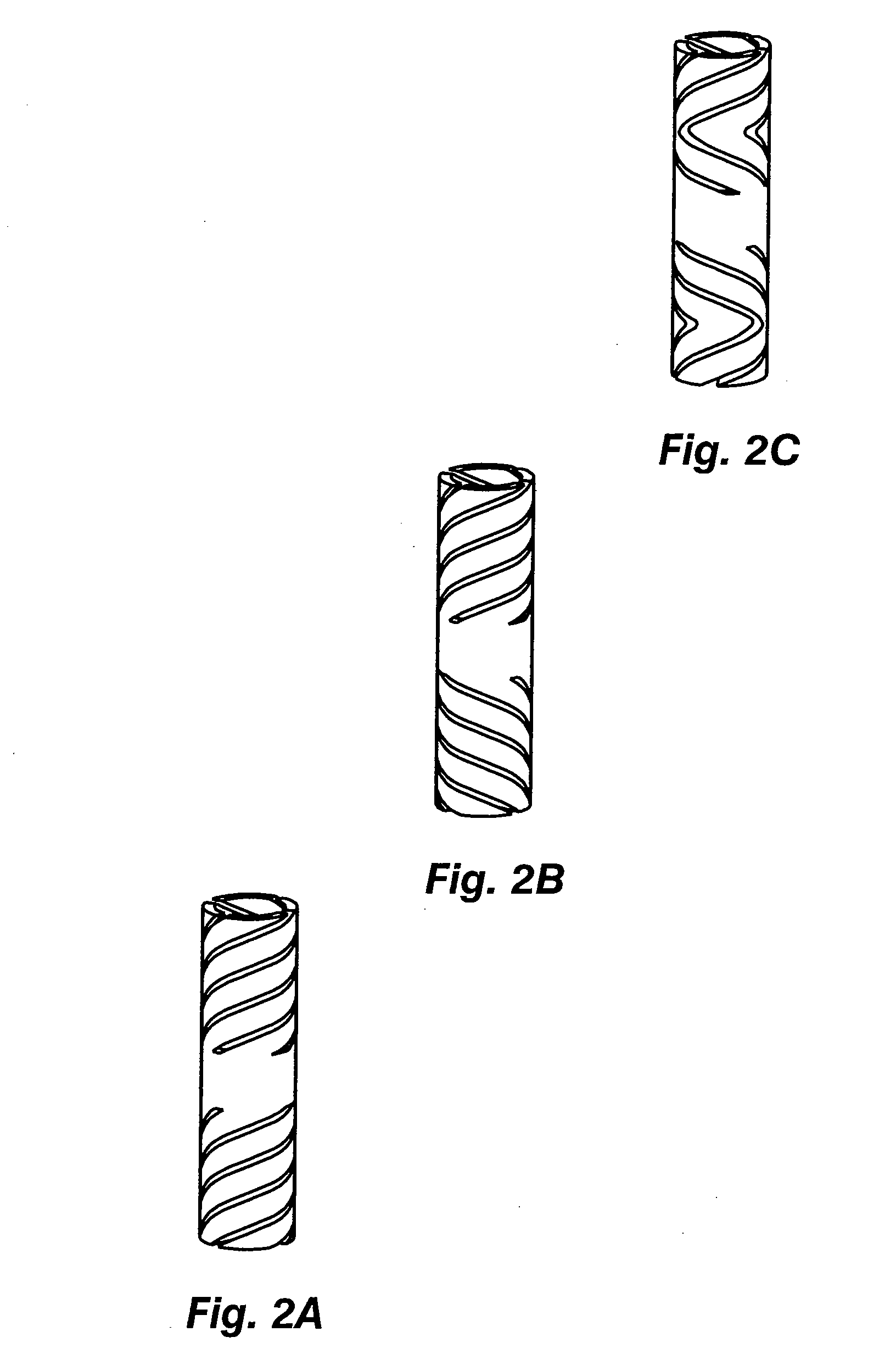

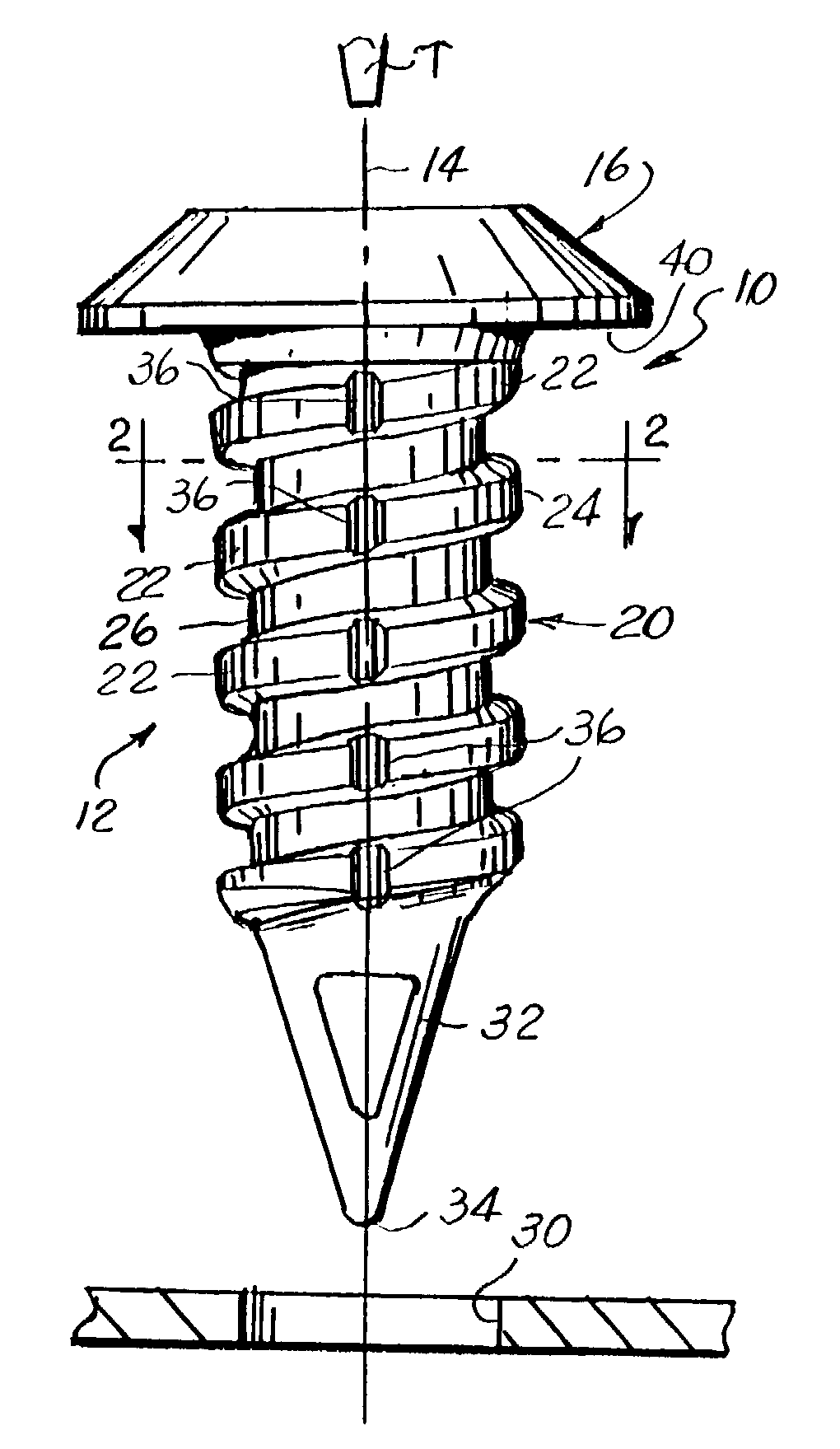

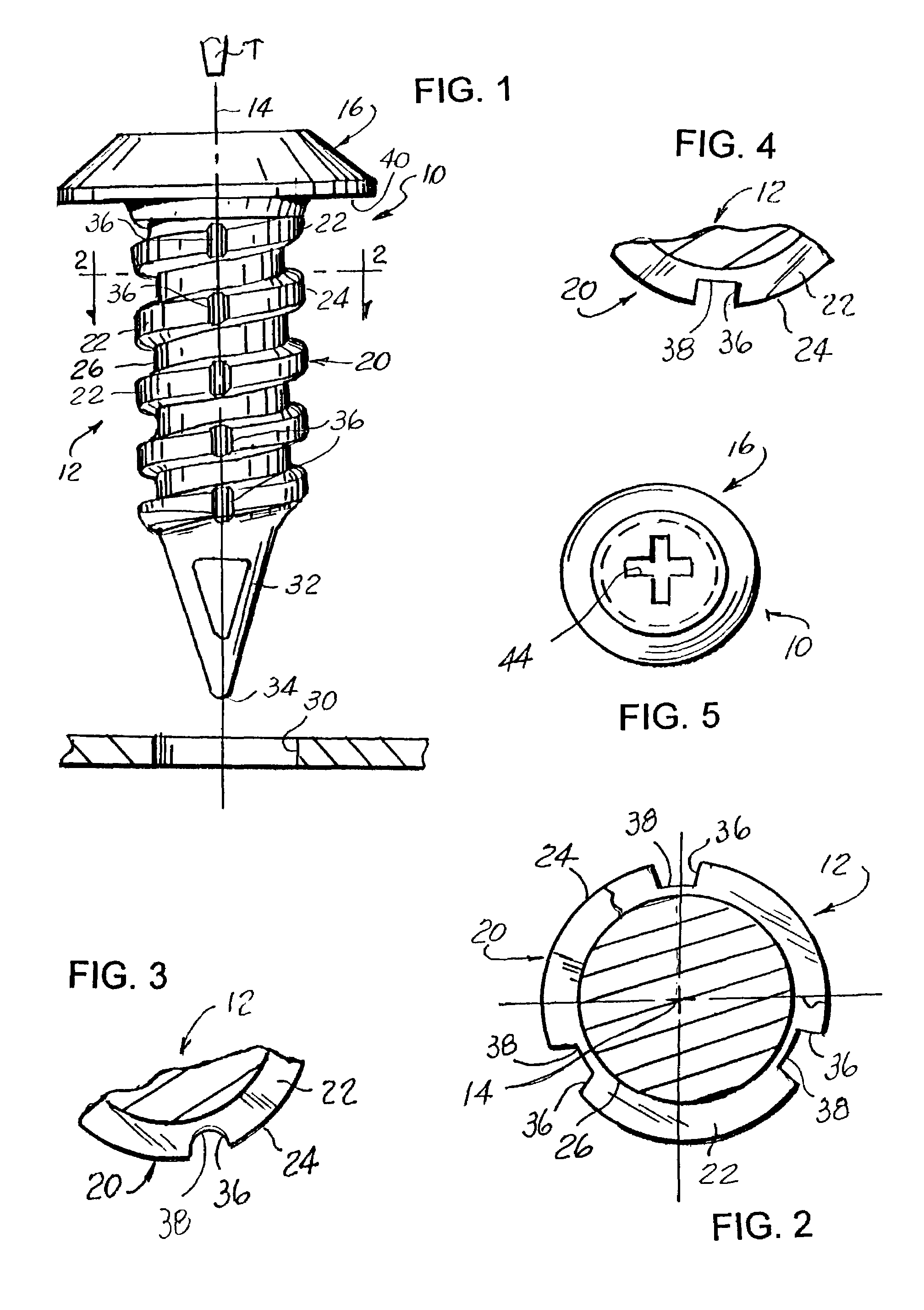

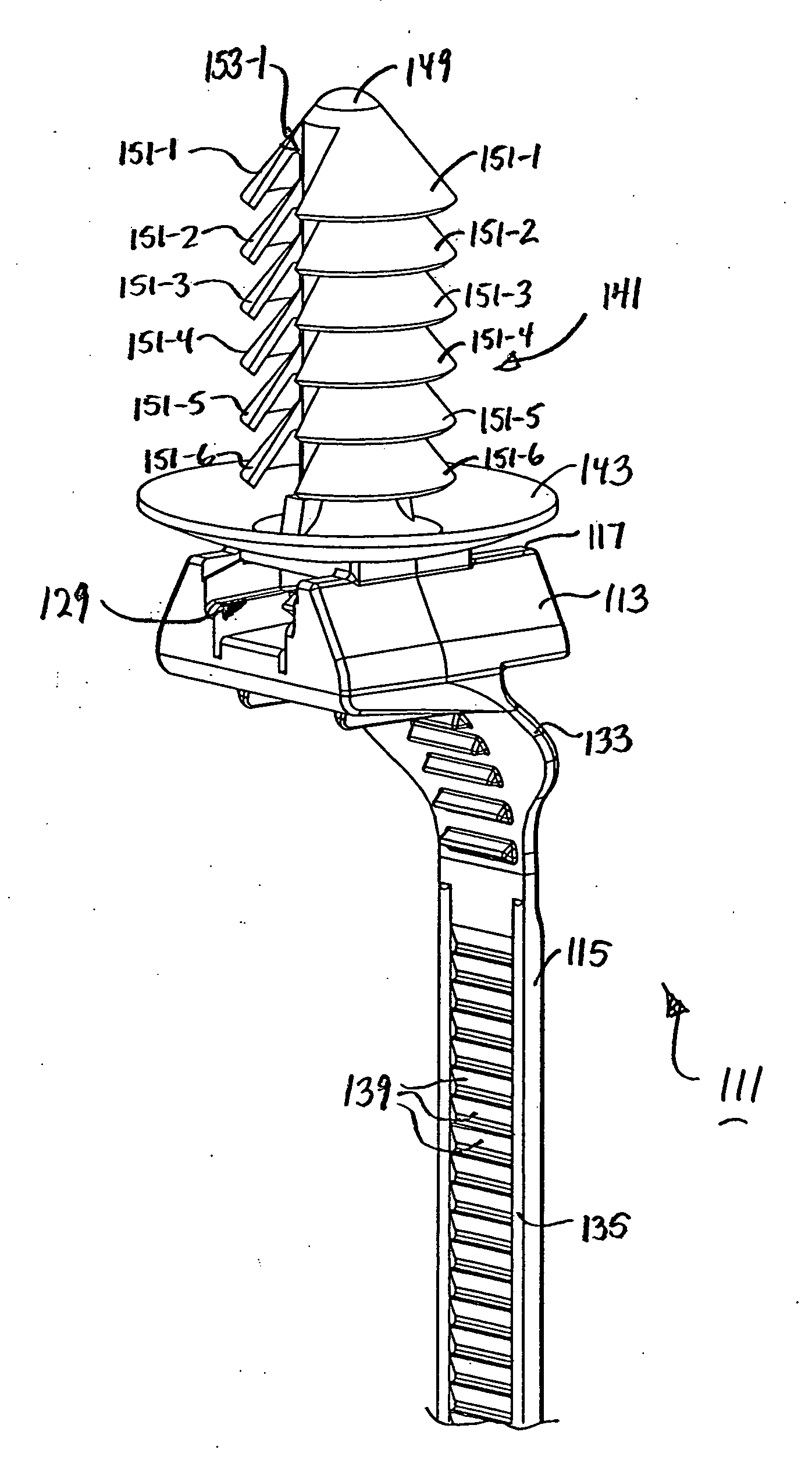

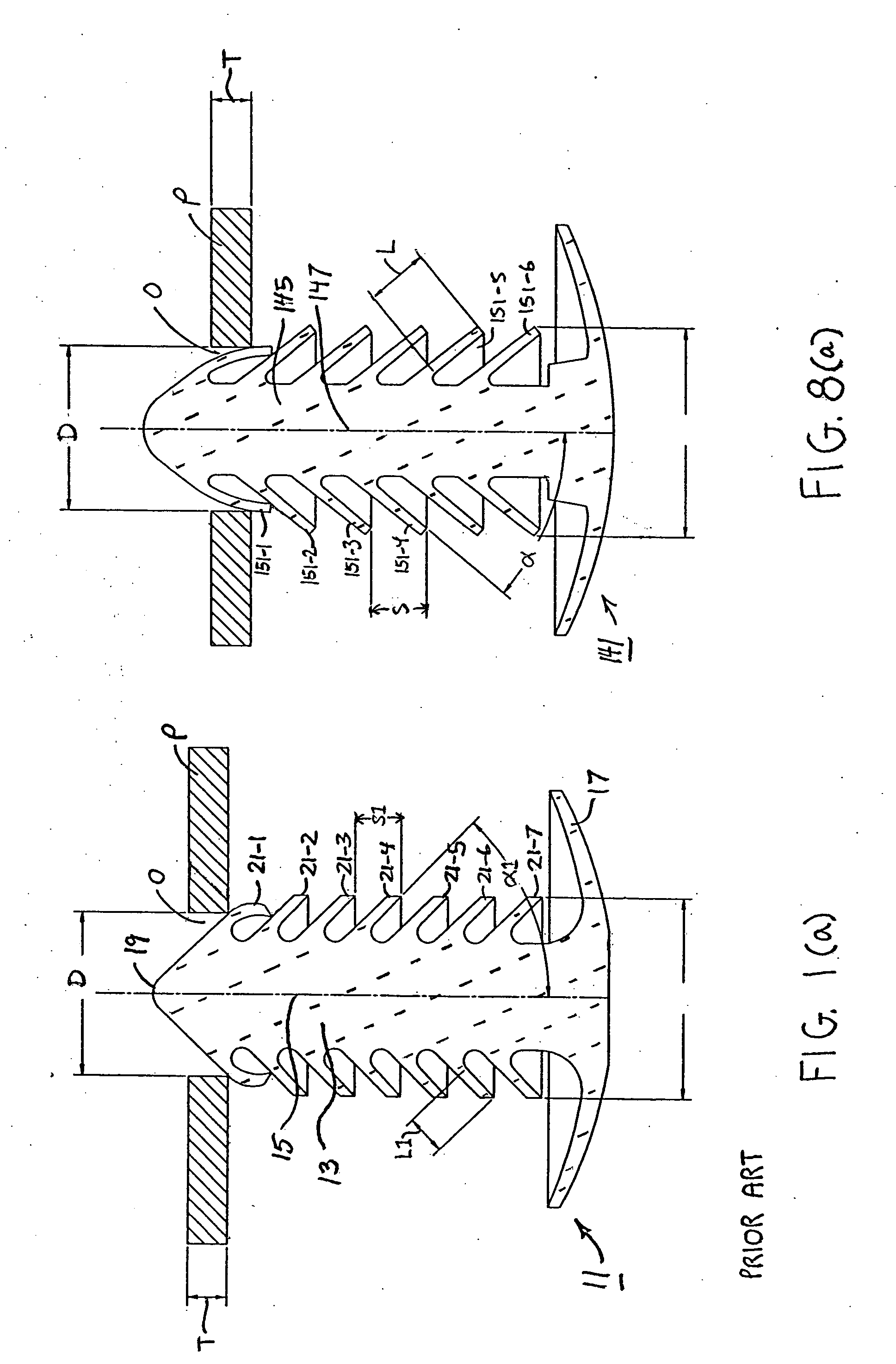

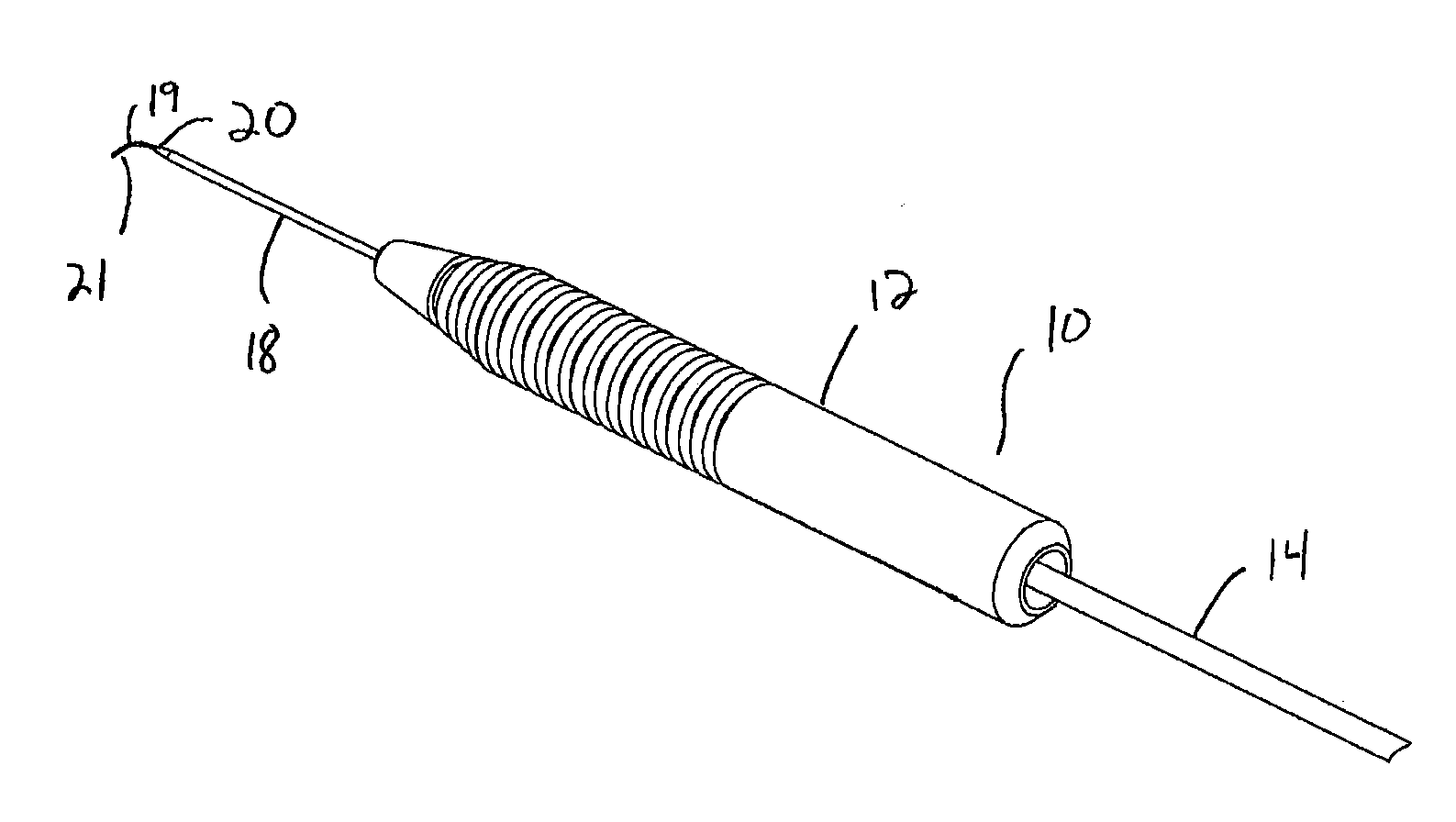

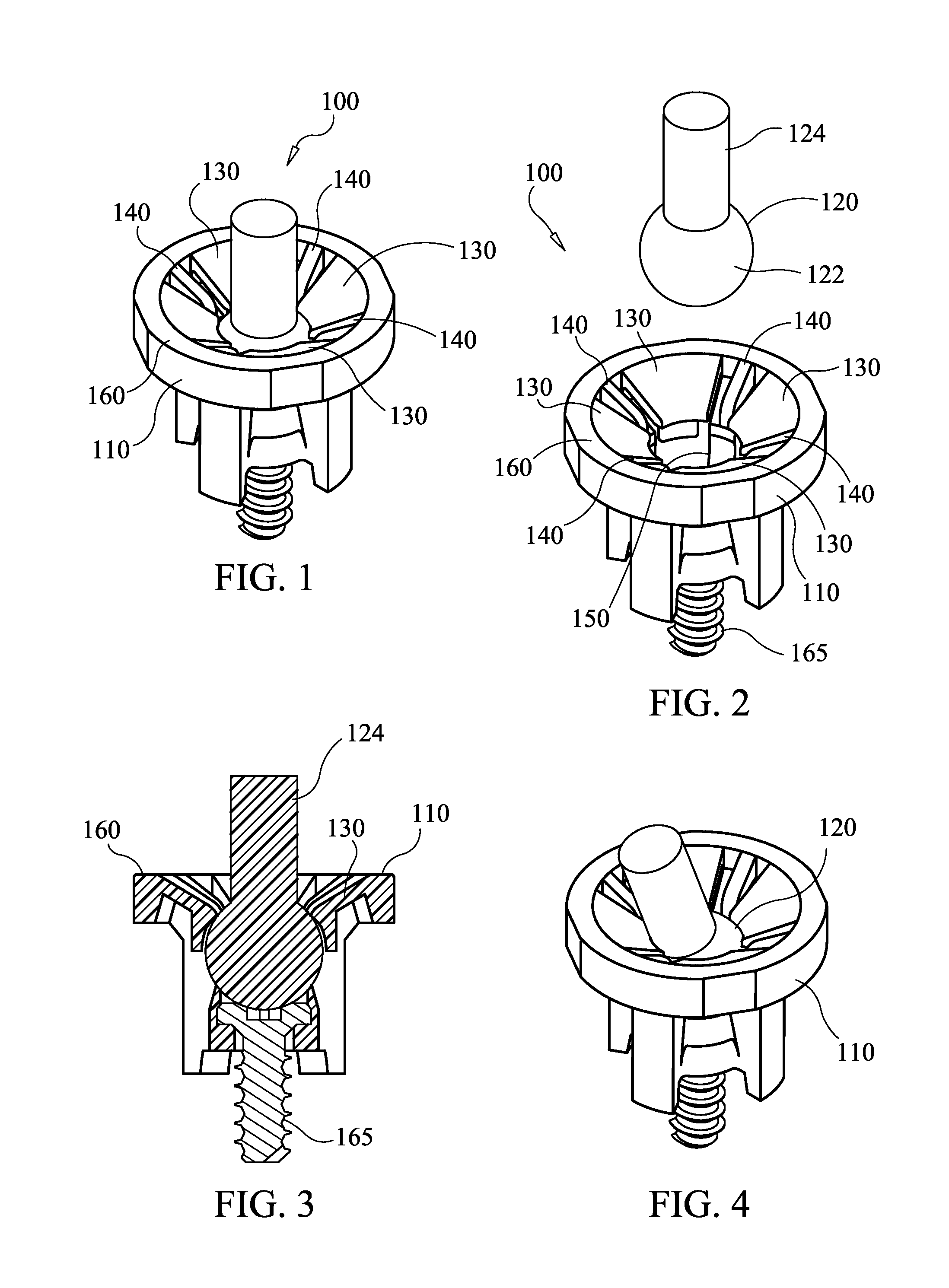

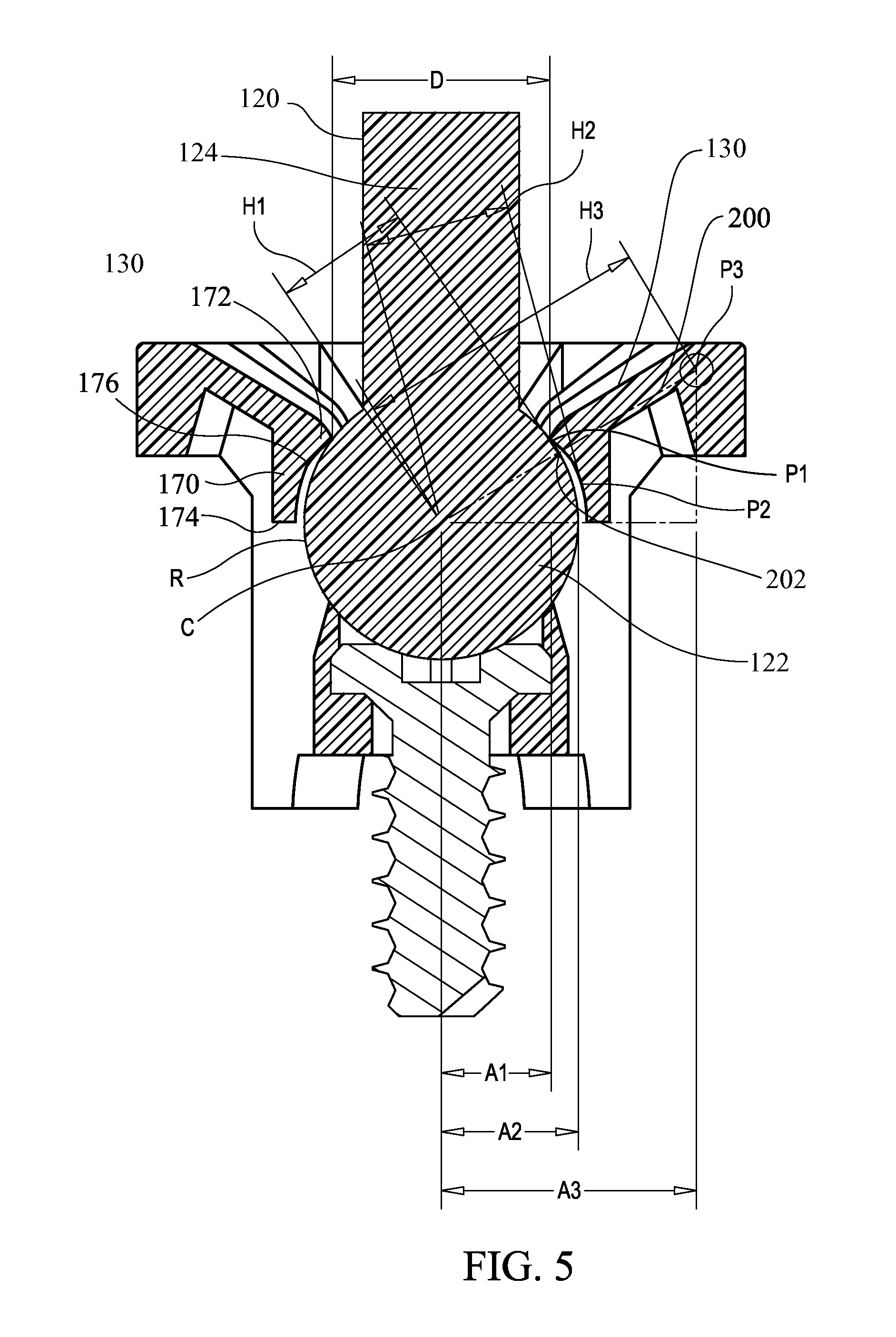

Push-in removable fastener

InactiveUS6979163B2Prevent inadvertent removalAvoid separationSnap-action fastenersNutsLow insertion forceBiomedical engineering

A plastic push-in or drive fastener having a enlarged head and a shank is disclosed. The fastener is configured to allow the shank to be pushed through a complementary shaped aperture or opening in an article using a relatively low insertion force. A helical screw or rib formation on the fastener shank provides a retention force opposing the fastener from being axially withdrawn from the article while readily permitting withdrawal of the fastener from the article in response to rotation of the fastener about its axis. Moreover, the fastener shank is configured to prevent inadvertent separation of the fastener from the article through which it passes.

Owner:ILLINOIS TOOL WORKS INC

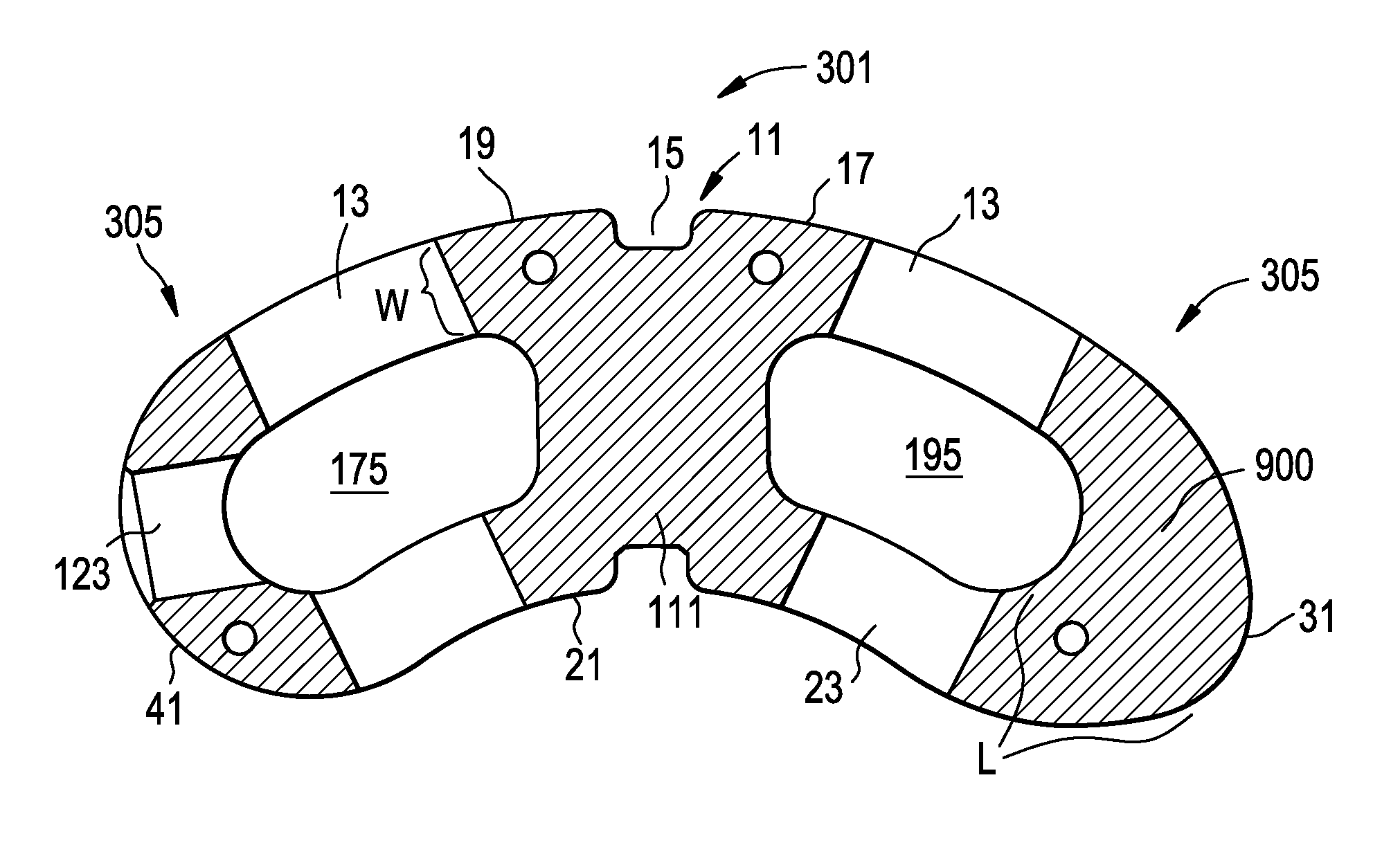

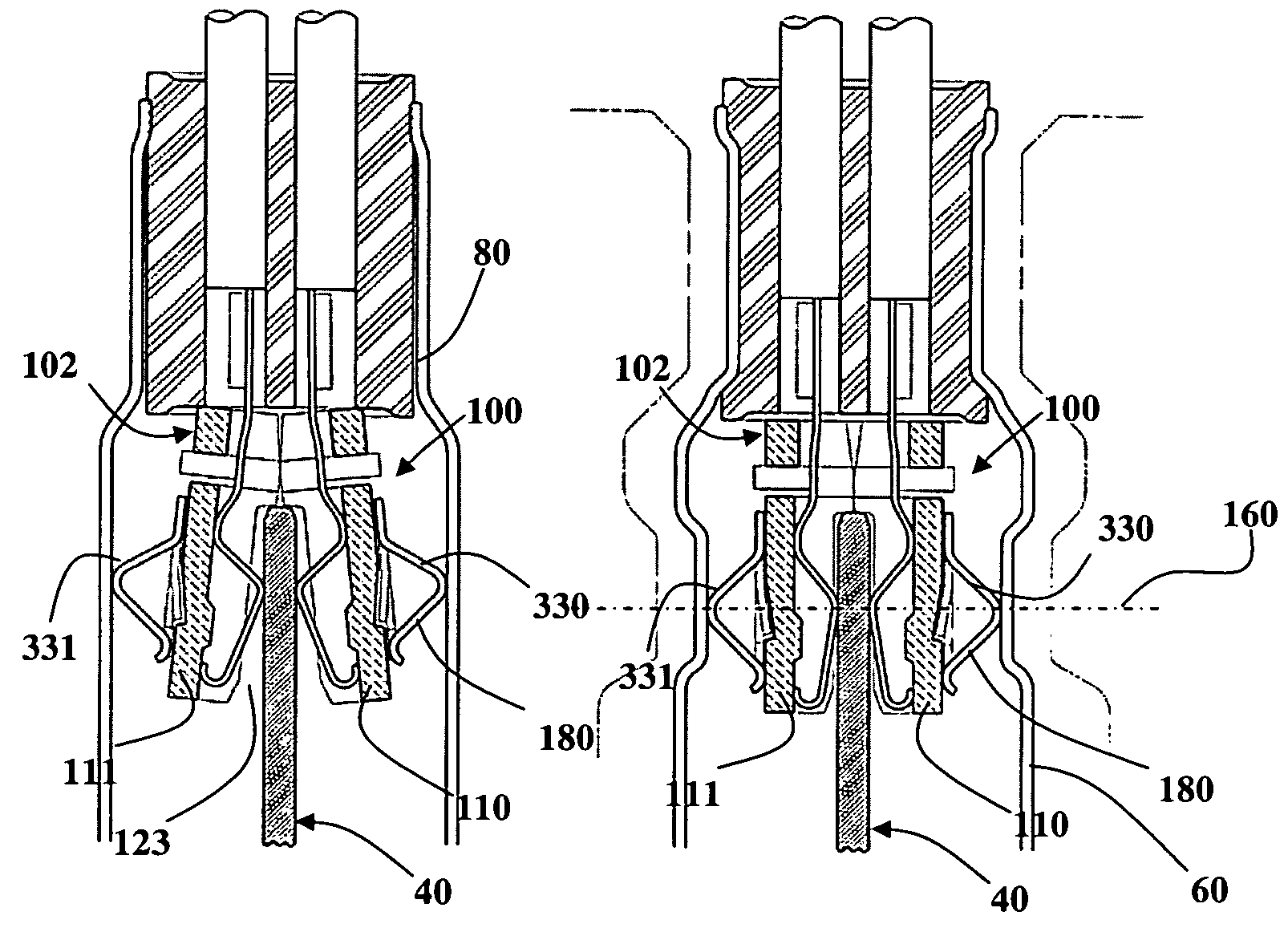

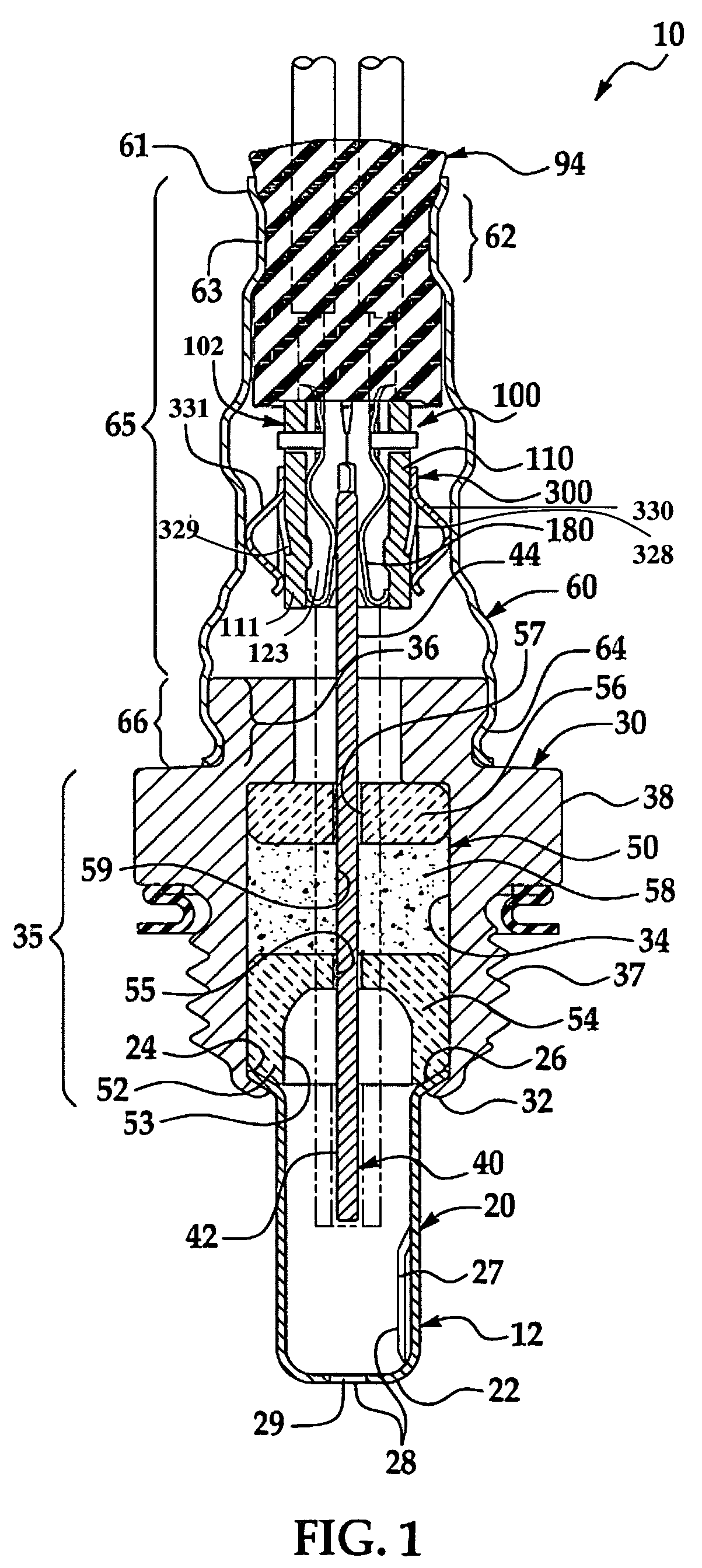

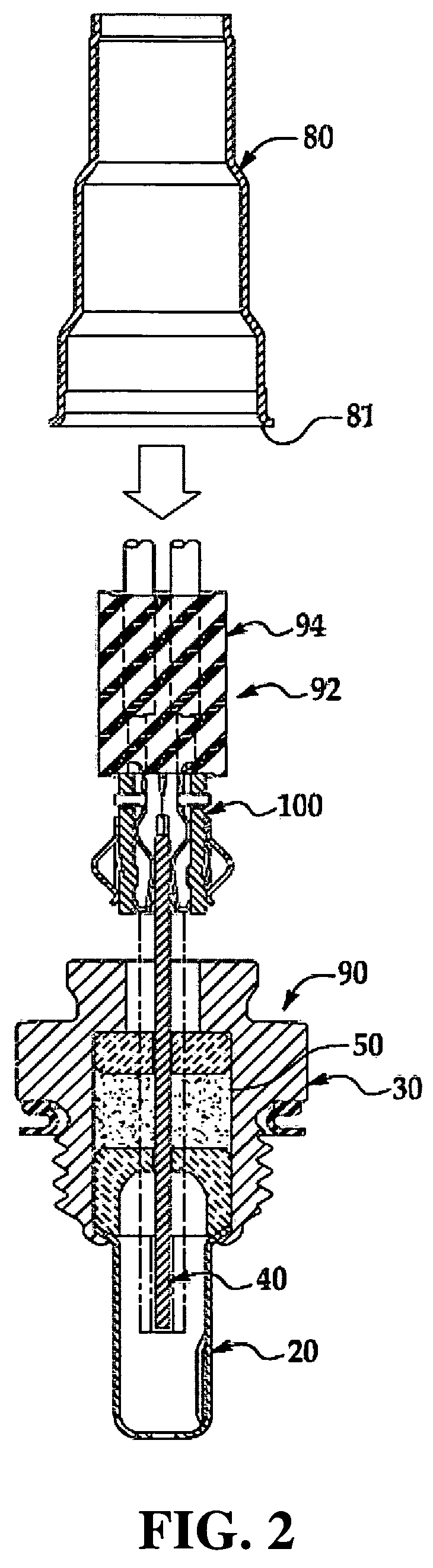

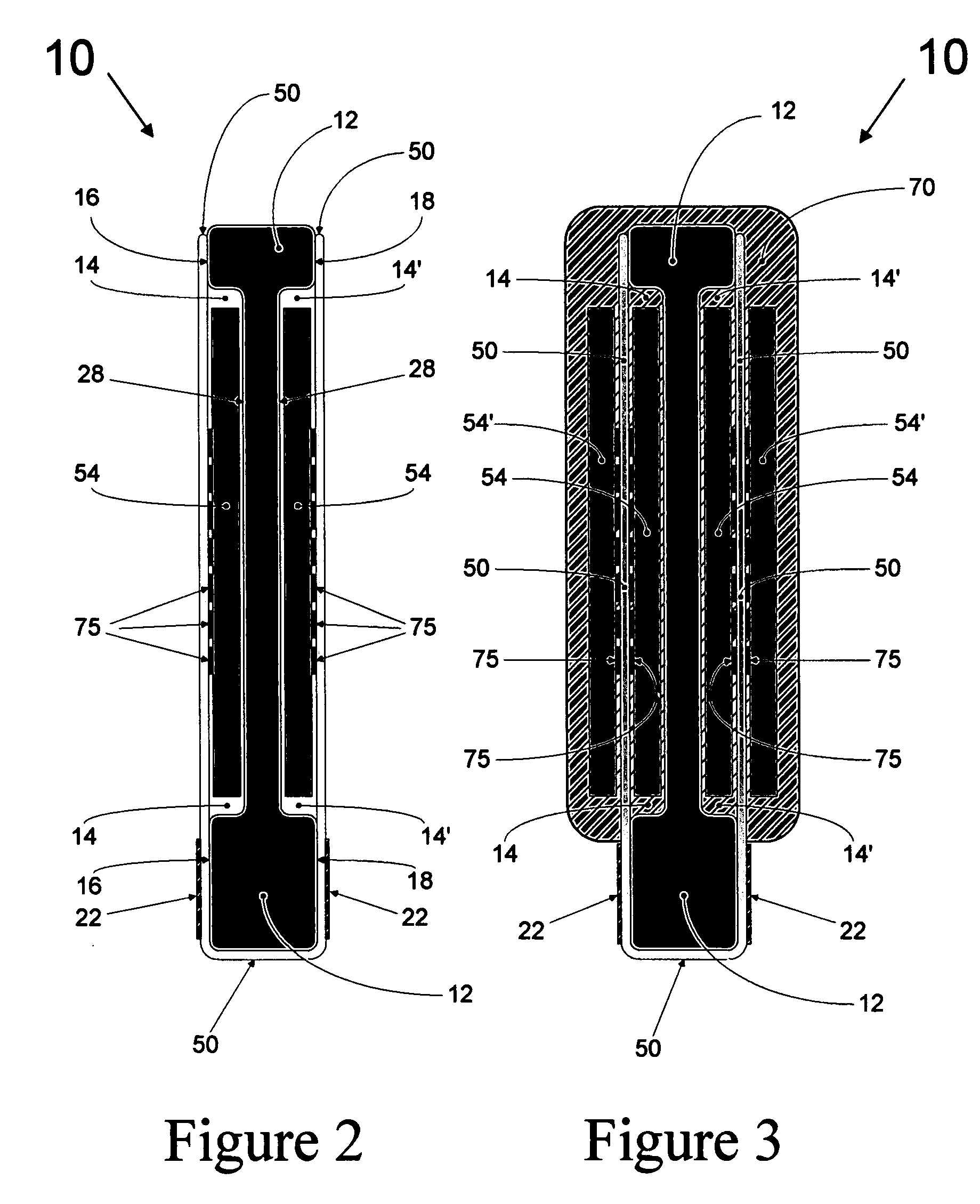

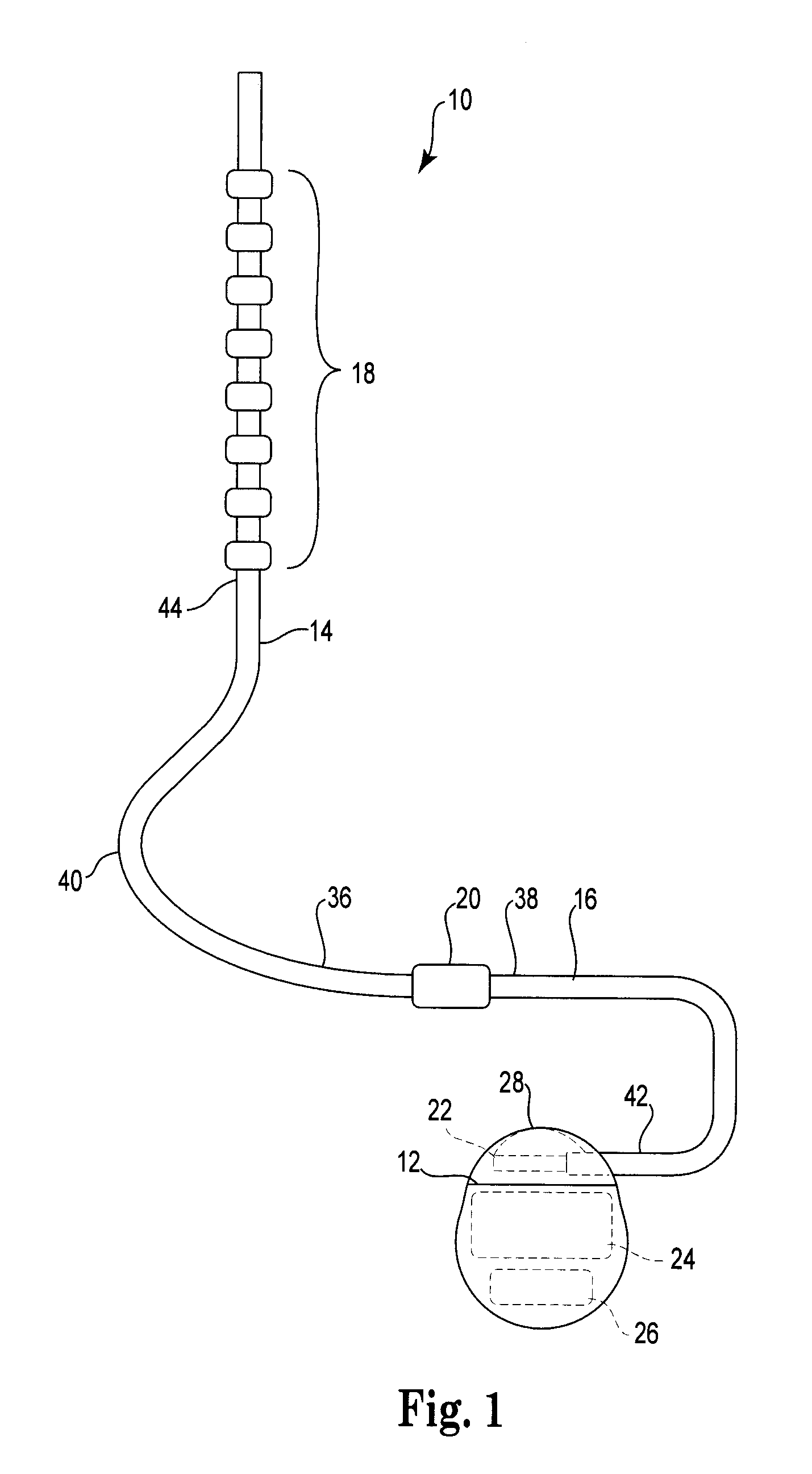

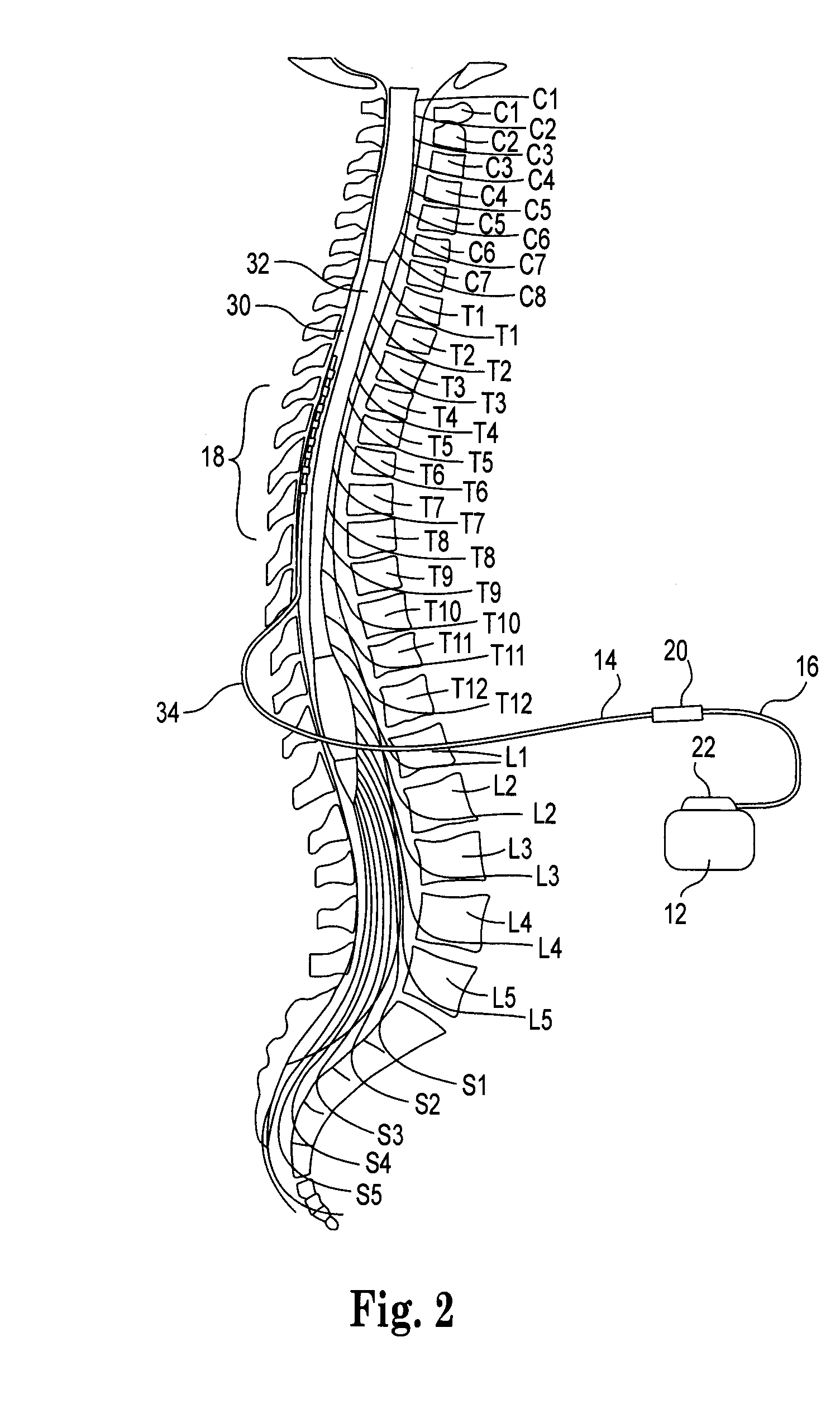

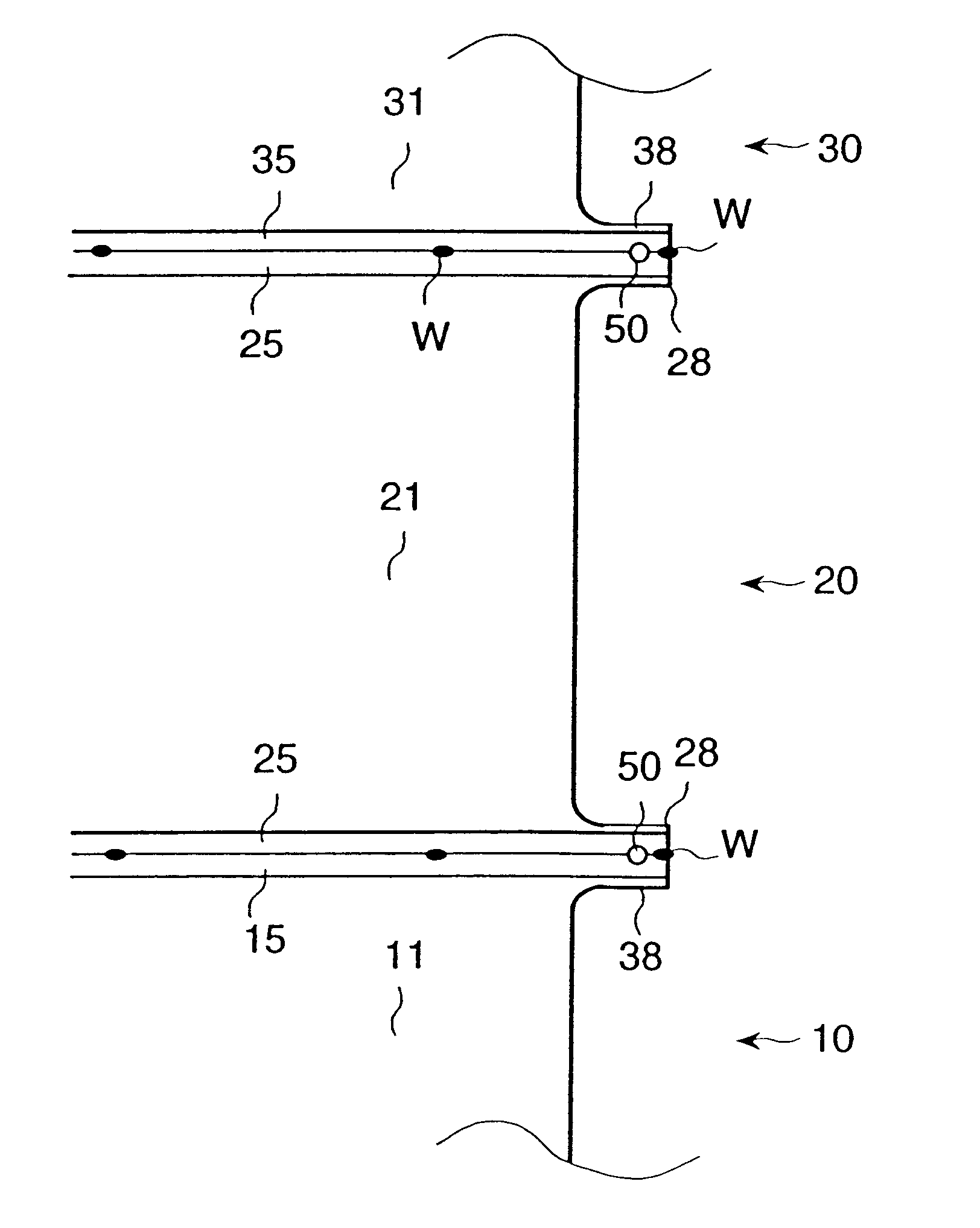

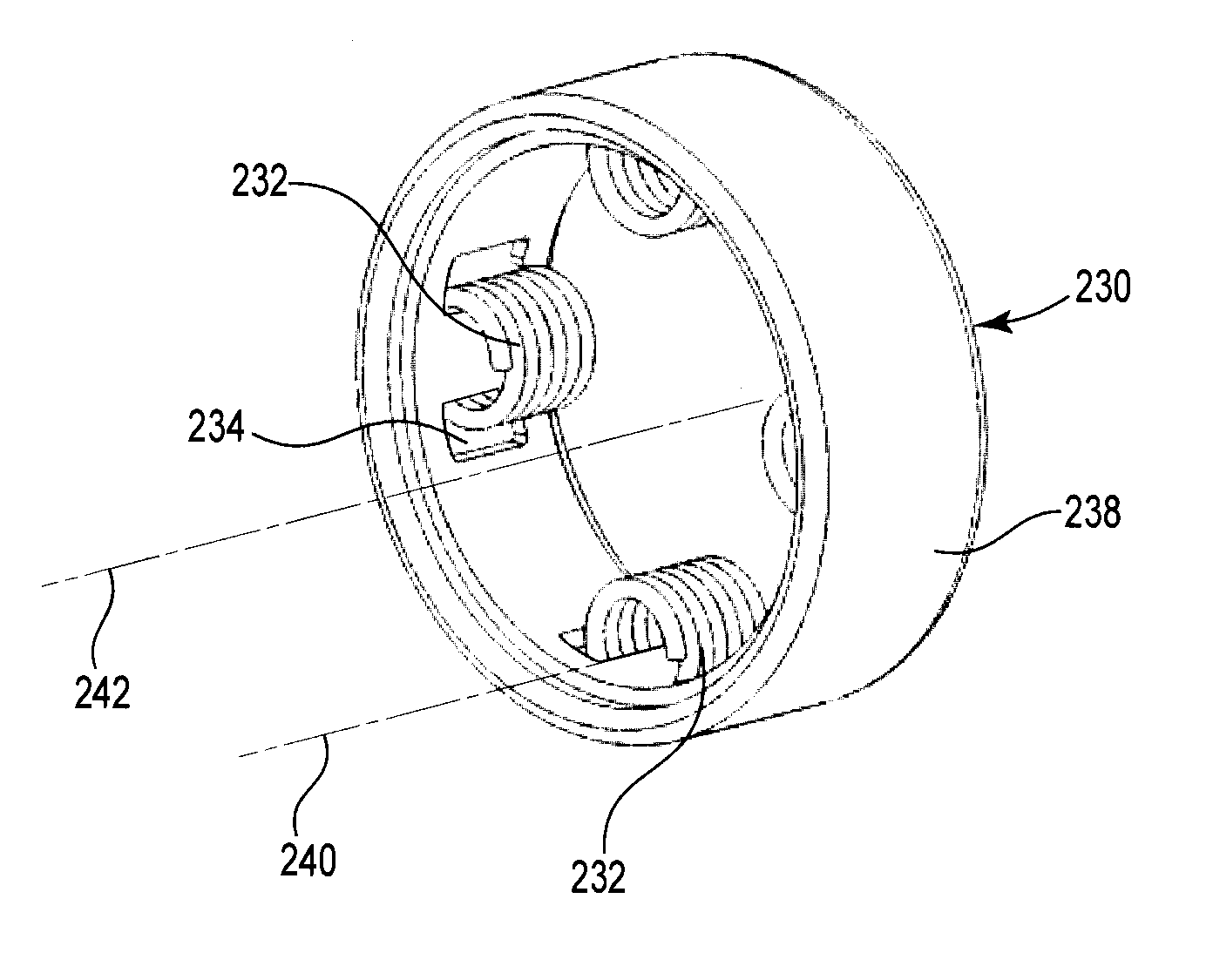

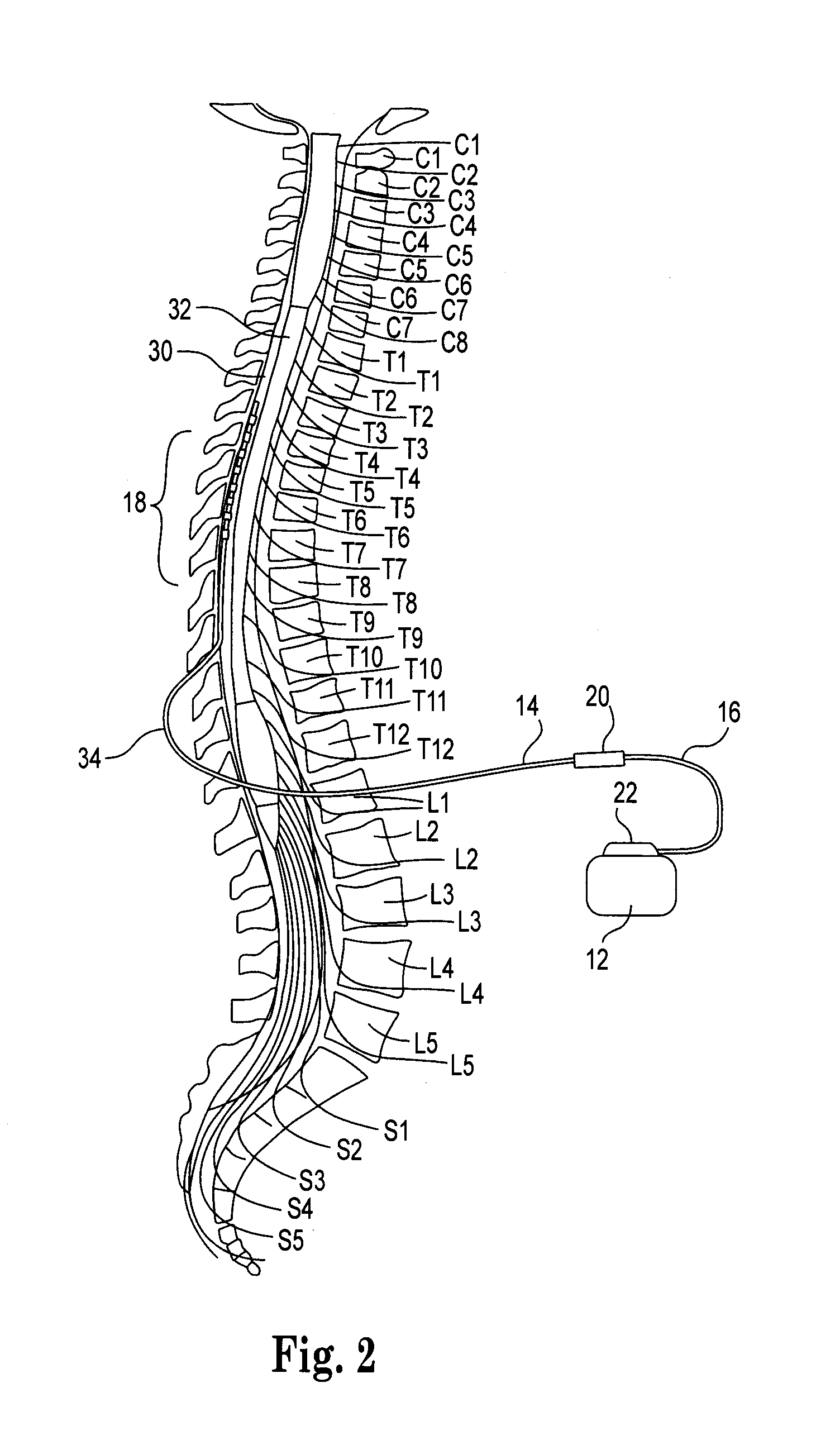

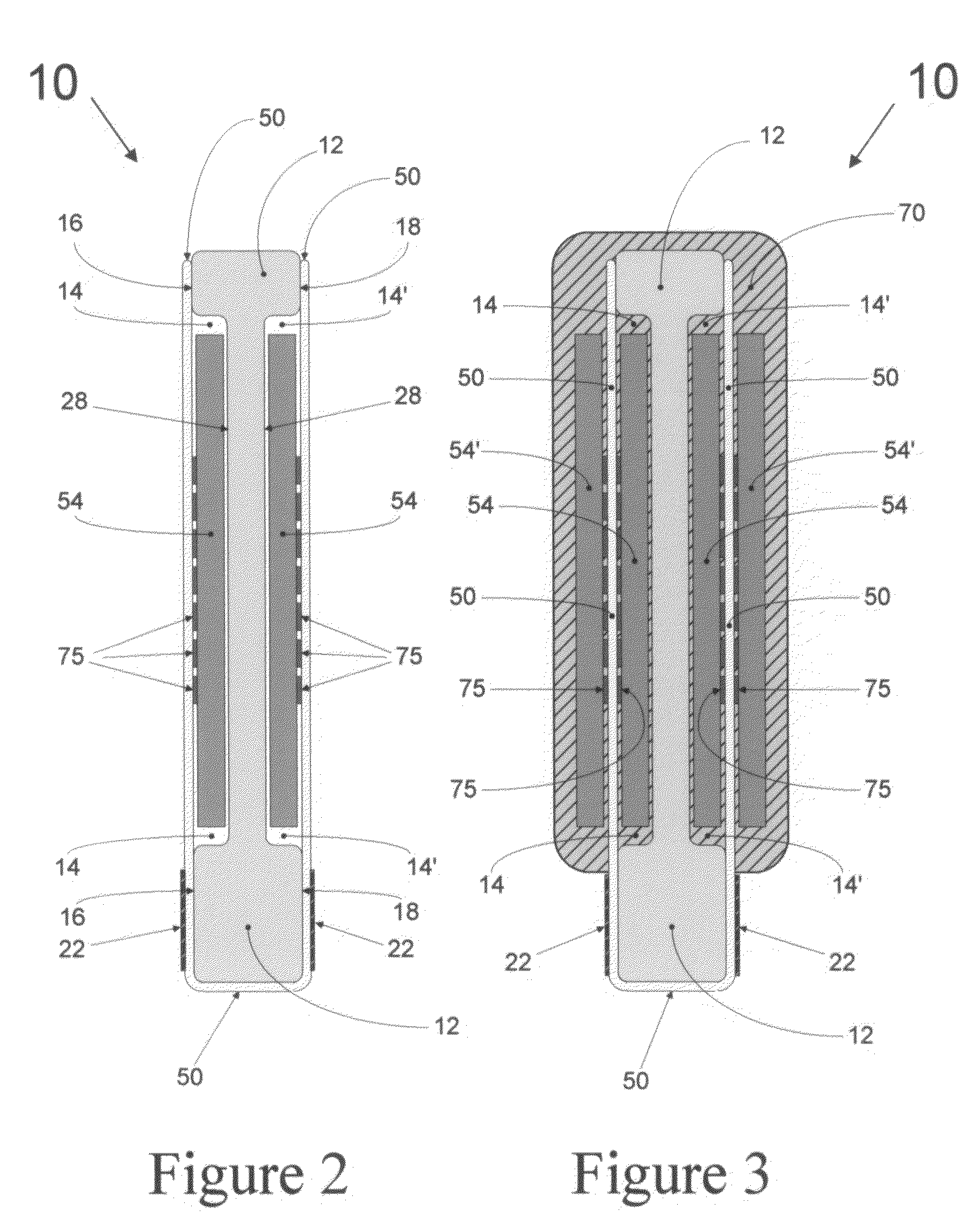

Low insertion force electrical connector for implantable medical devices

ActiveUS8428724B2Wider toleranceSpinal electrodesLine/current collector detailsElectricityLow insertion force

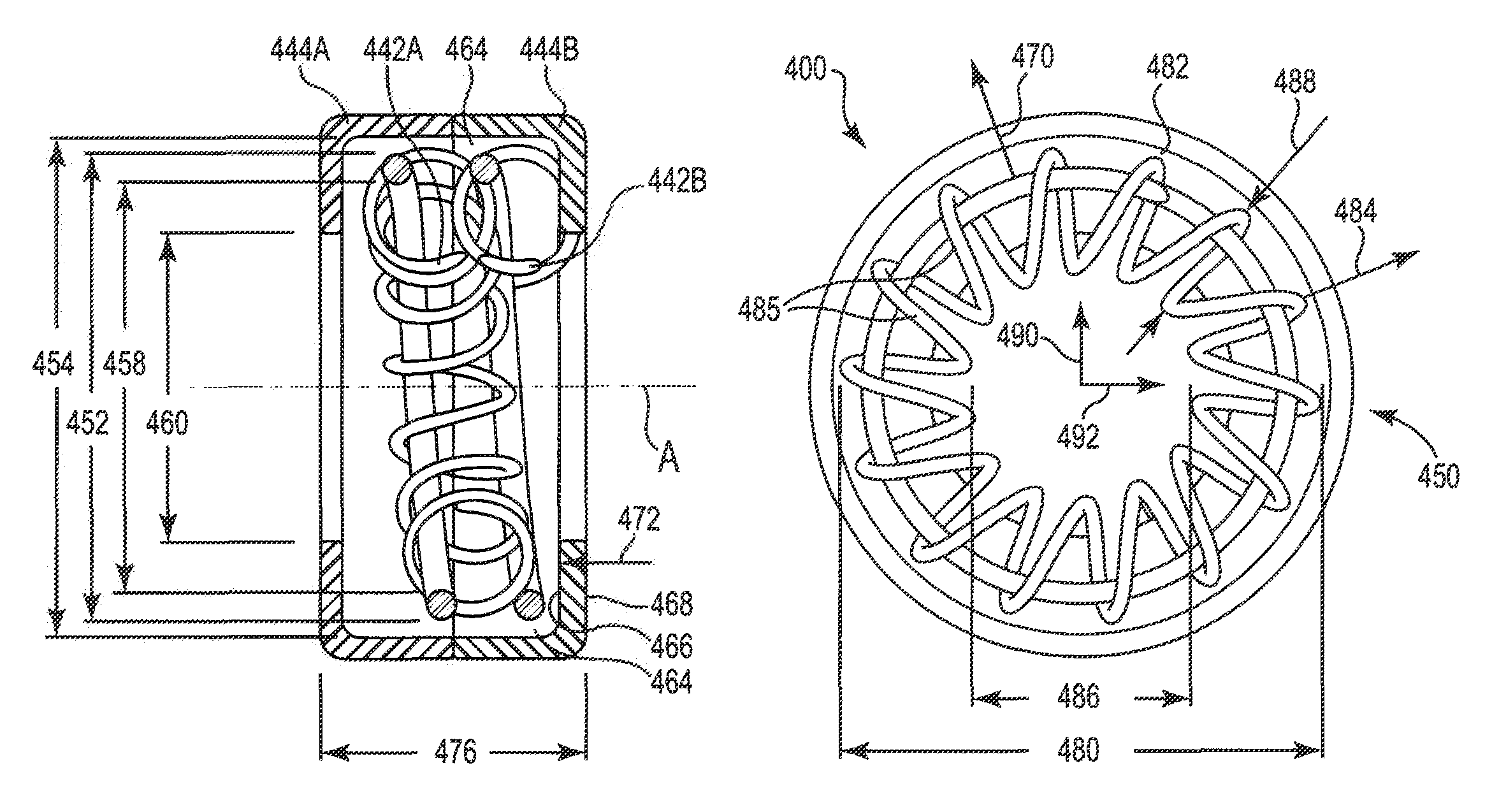

A low-insertion force electrical connector for implantable medical devices. The electrical contact includes a housing with a pair of opposing sidewalls each with center openings oriented generally concentrically around a center axis. The housing also includes a recess with a recess diameter. An inner coil is located in the recess with a coil axis generally co-linear with the center axis of the center openings. The inner coil includes an outer diameter less than the recess diameter, and an inner diameter greater than a center opening diameter. An outer coil is threaded onto the inner coil to form a generally toroidal-shape. The outer coil has an outer diameter less than the recess diameter, and an inner diameter less than the center opening diameter. The outer coil is radially expanded within the recess in response to engagement with contact rings on the implantable medical device, such that the outer diameter of the outer coil is at least equal to the recess diameter.

Owner:CIRTEC MEDICAL CORP

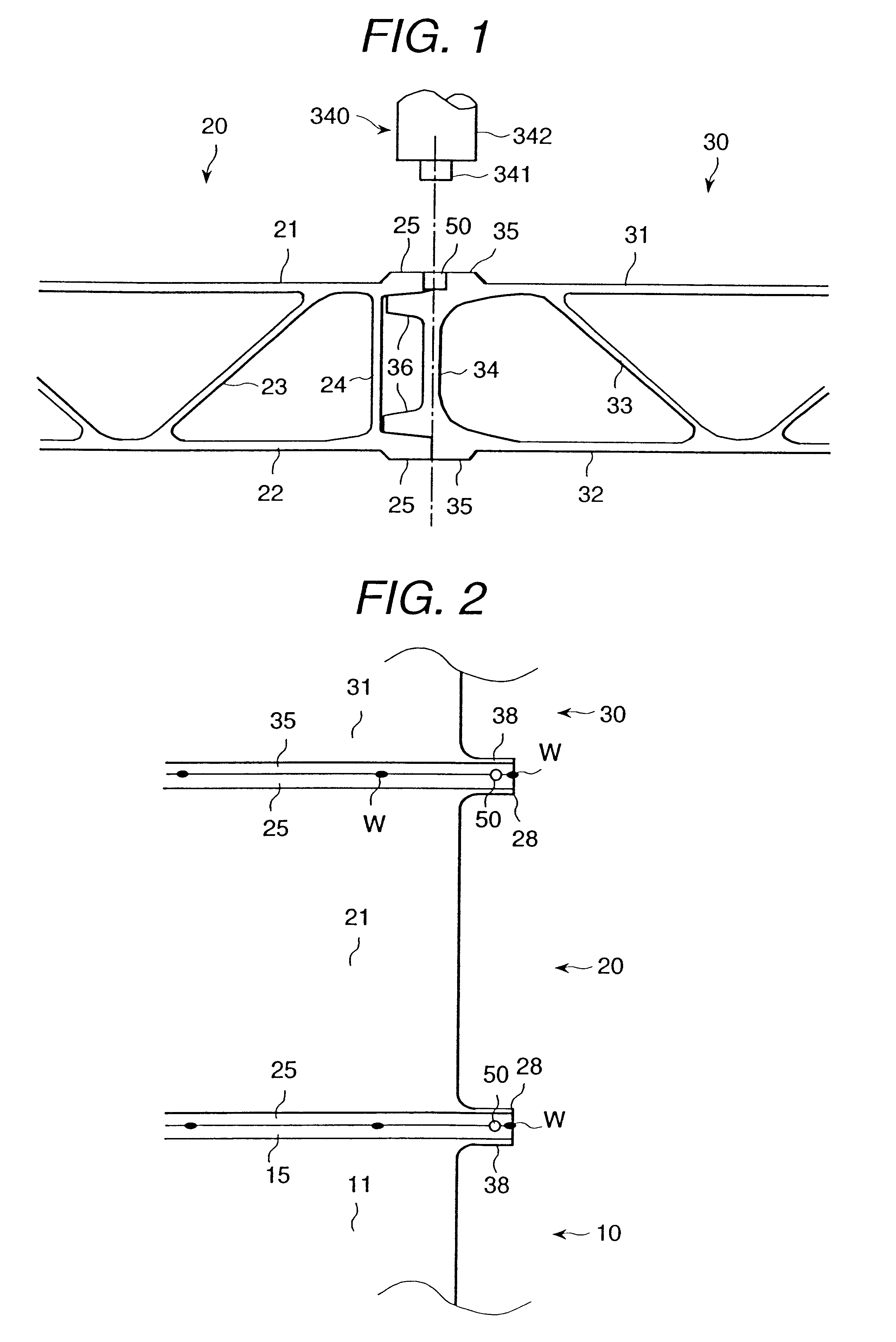

Manufacturing method of a structure body

When an insertion force of a rotary tool 340 has searched, it is made clearly that the force at the insertion initial time is large and when a friction stir joining is an ordinary operation time, the force becomes small. According, it is preferable to make small the insertion force at the insertion initial time. To members 20, 30 to be subjected to a joining at a position where the friction stir joining starts a hole 50 is opened, and this hole 50 after the rotary tool 340 has inserted, since a move of the rotary tool 340 is made to begin, a lowering of the insertion force can be attained.

Owner:HITACHI LTD

Low insertion force electrical connector for implantable medical devices

ActiveUS20120232603A1Wider toleranceSpinal electrodesLine/current collector detailsLow insertion forceEngineering

A low-insertion force electrical connector for implantable medical devices. The electrical contact includes a housing with a pair of opposing sidewalls each with center openings oriented generally concentrically around a center axis. The housing also includes a recess with a recess diameter. An inner coil is located in the recess with a coil axis generally co-linear with the center axis of the center openings. The inner coil includes an outer diameter less than the recess diameter, and an inner diameter greater than a center opening diameter. An outer coil is threaded onto the inner coil to form a generally toroidal-shape. The outer coil has an outer diameter less than the recess diameter, and an inner diameter less than the center opening diameter. The outer coil is radially expanded within the recess in response to engagement with contact rings on the implantable medical device, such that the outer diameter of the outer coil is at least equal to the recess diameter.

Owner:CIRTEC MEDICAL CORP

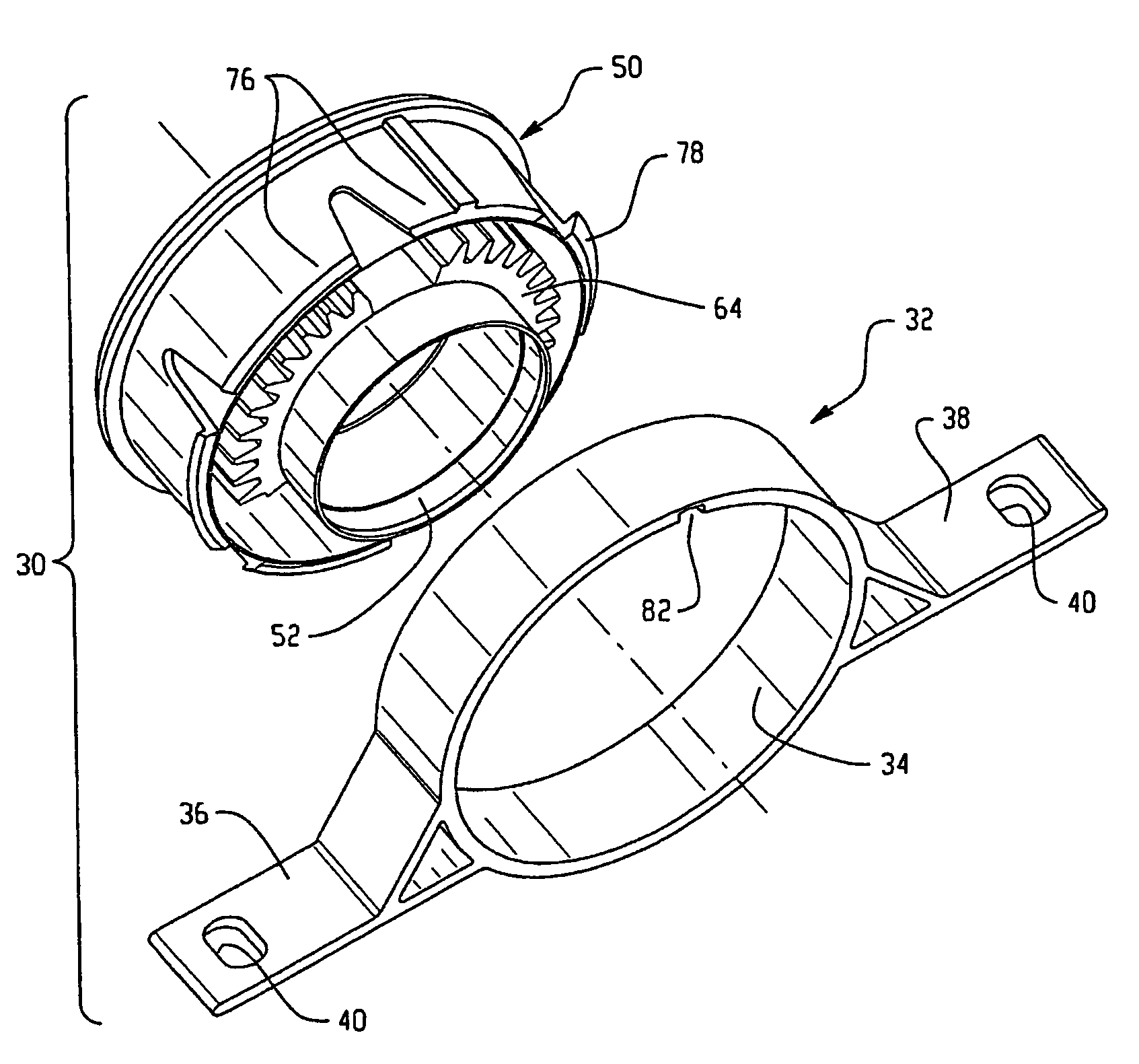

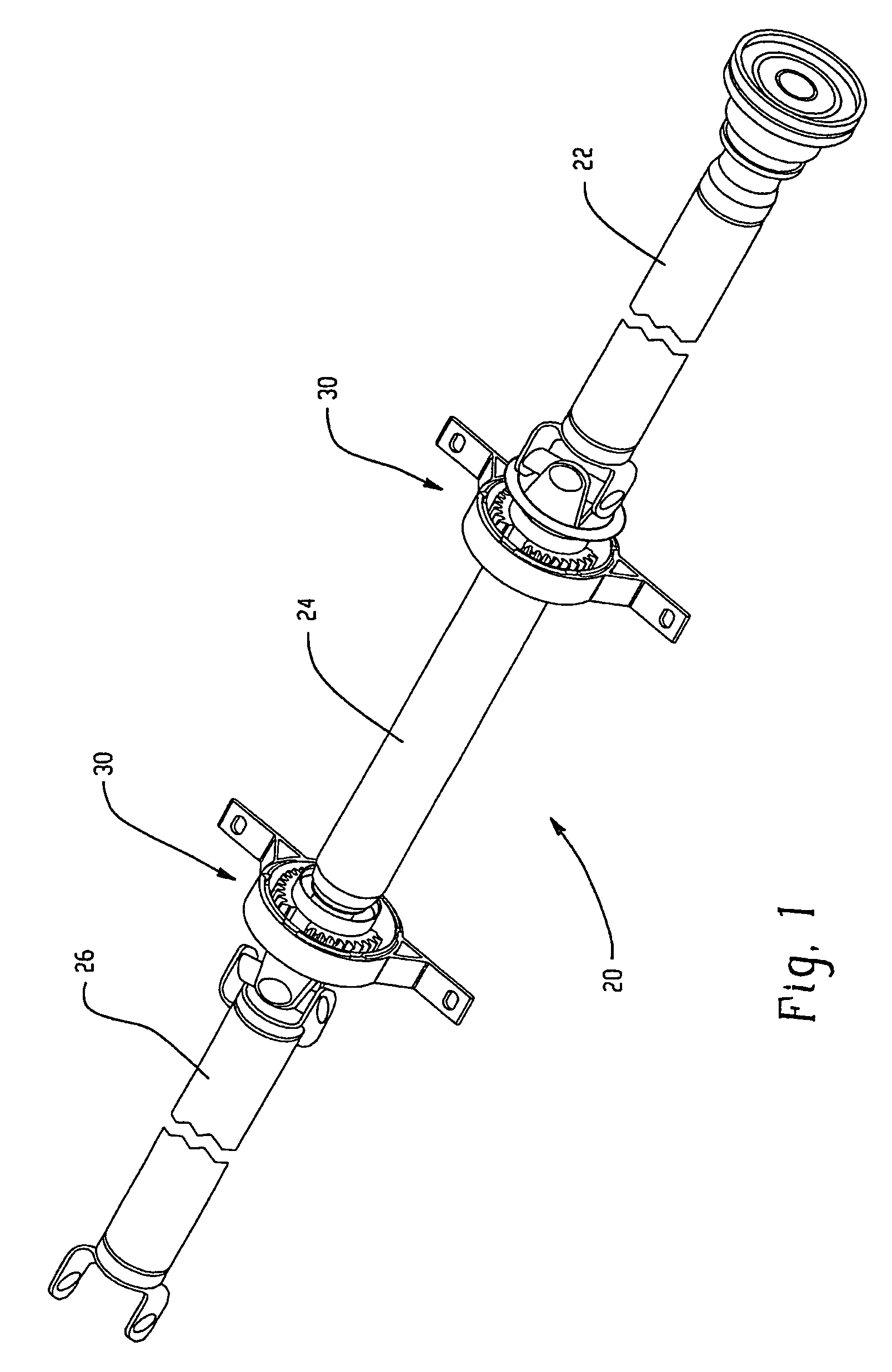

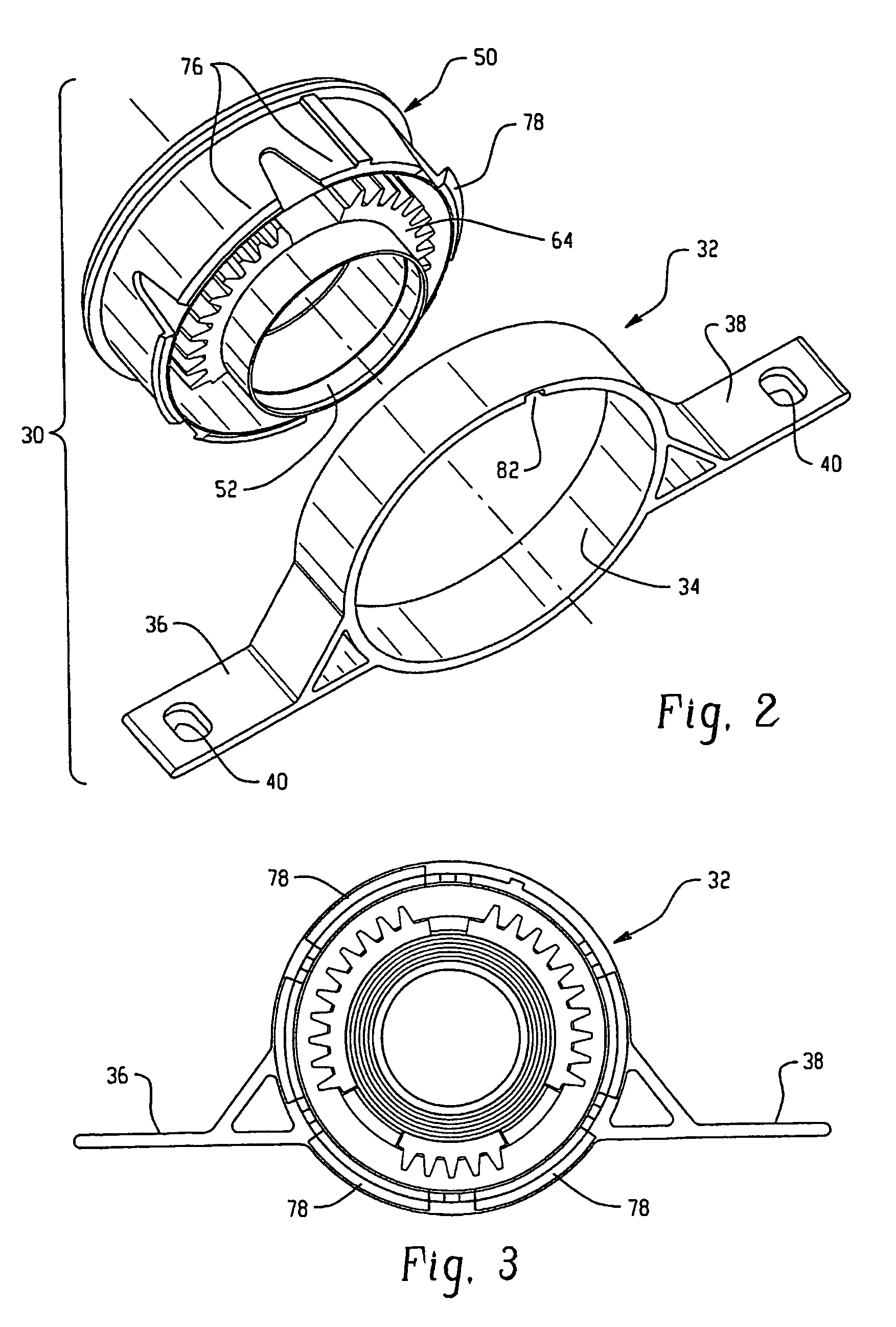

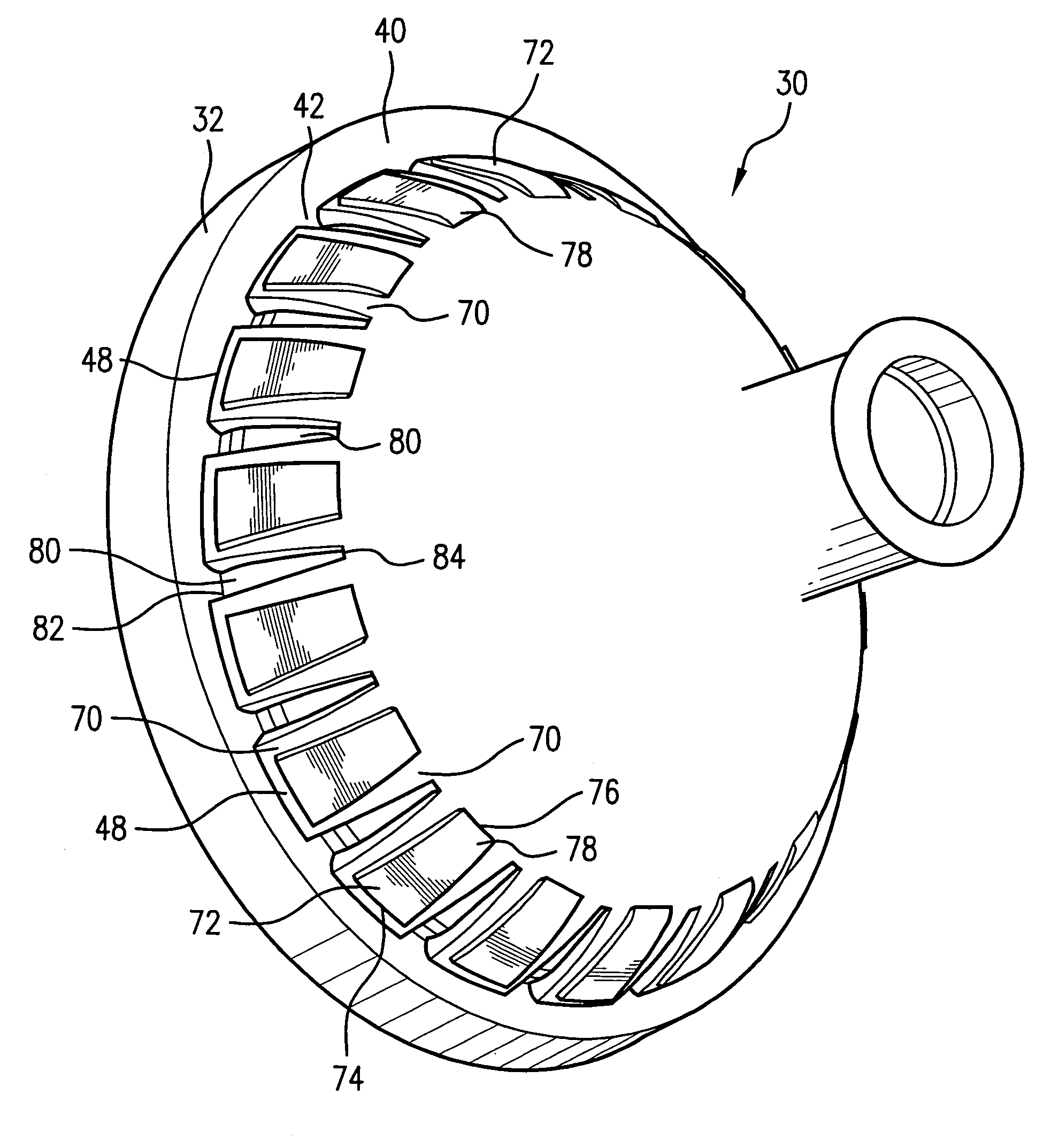

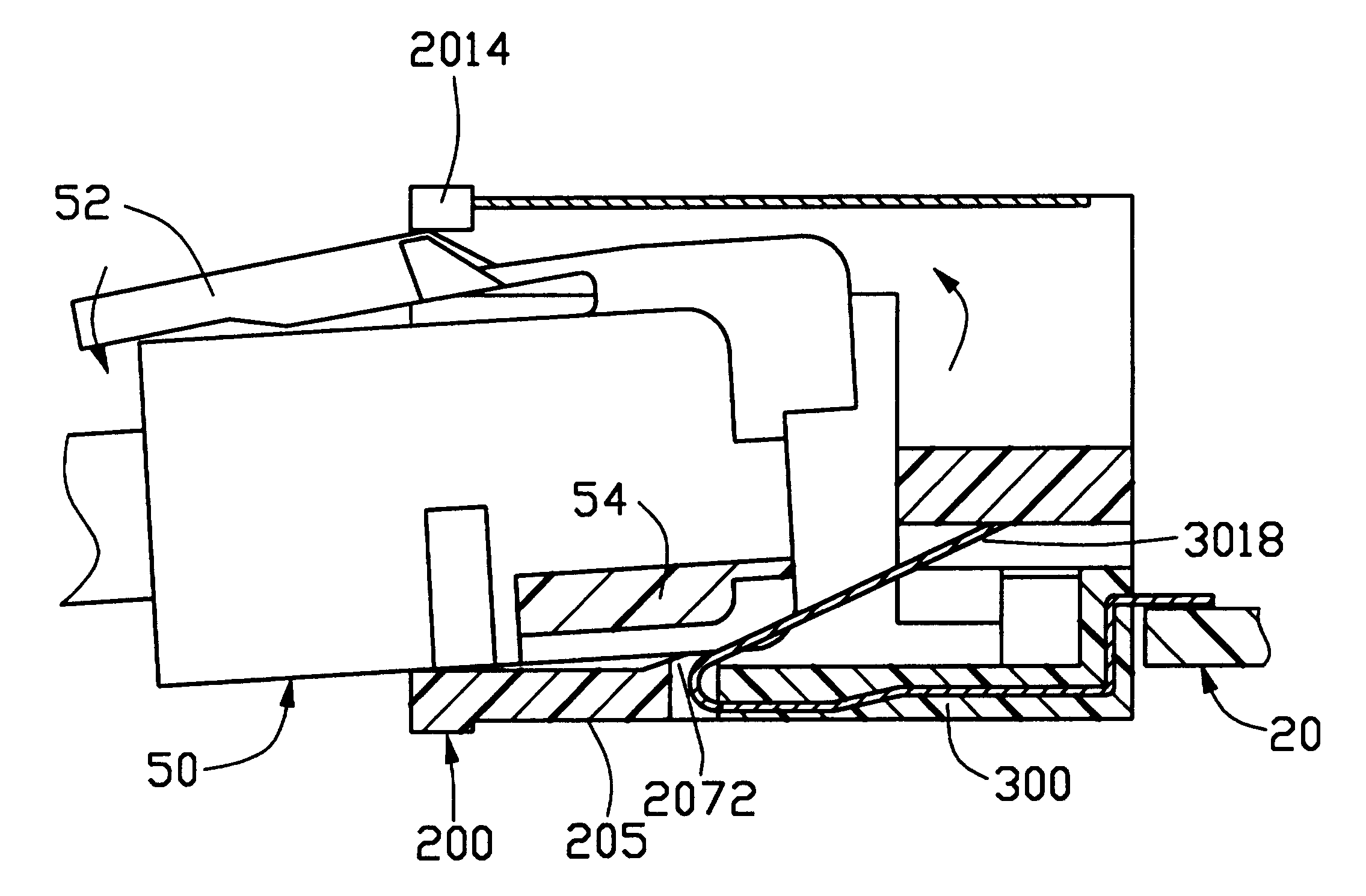

Plastic quick-snap centerbearing isolator mount and method of manufacturing and assembling same

ActiveUS7611288B2Large weightEasy to manufactureMetal-working apparatusEngine componentsElastomerLow insertion force

A resilient mount (30), such as a center bearing isolator mount includes an inner sleeve (52) into which is molded an elastomer / rubber isolator (60), and an insert (70). These components are prepared as a sub-assembly (50) and axially inserted into the opening of an outer bracket (32), whereby fingers (76) deflect radially during insertion and snap-fit radially outward once received through the bracket opening to preclude disassembly. A lower insertion force is required to assemble the components.

Owner:CONTITECH USA INC +1

Low insertion force grommet

InactiveUS7105750B1Easy to compressKeep soft materialElectrical apparatusPipesLow insertion forceContact pad

A grommet mainly made of soft, pliable material has a flange section for sealing against a first side of a vehicle panel around an aperture through the panel. A groove separates the flange section from a conical section that tapers from the groove to a narrower tubular section for tightly fitting around a wire harness passed through the grommet. The conical section has a wider end adjacent the groove that presses against a second, opposite side of the panel when the groove receives an edge of the aperture and the grommet is seated on the panel. The conical section has a region that engages the edge of the aperture as the grommet is pulled to an installed position. A plurality of raised, hard, rigid contact pads are arranged in a circumferential row around the engagement region to provide low friction while sliding past the edge of the aperture when the grommet is pulled through the aperture. The contact pads are spaced apart by recesses that maintain the compressibility of the grommet and keep the soft grommet material between the pads from contacting the edge of the aperture during installation. Angled tabs extend from undersides of the contact pads to help secure the pads on the grommet. The contact pads are connected by a ring structure embedded in the conical section.

Owner:YAZAKI NORTH AMERICA

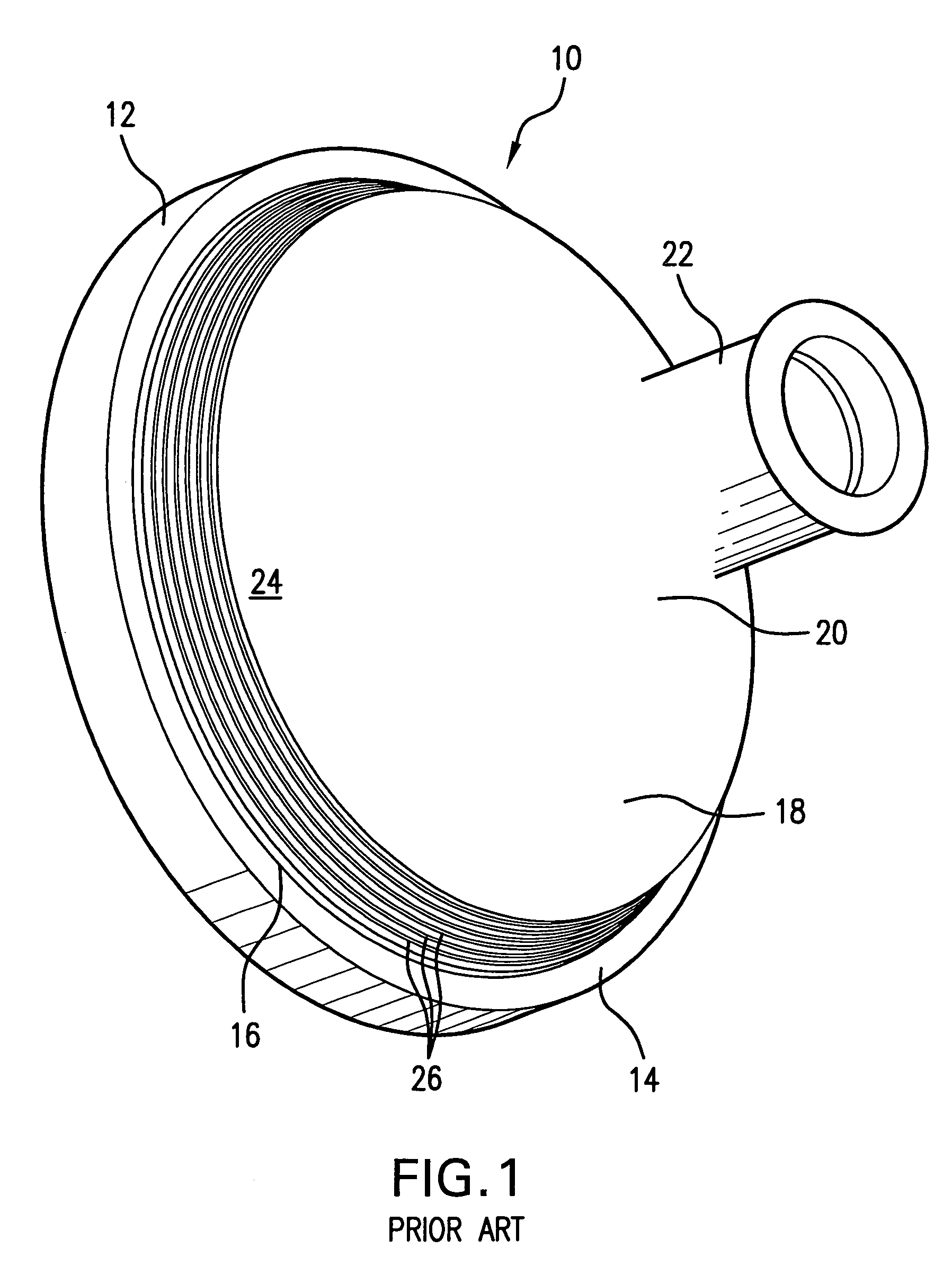

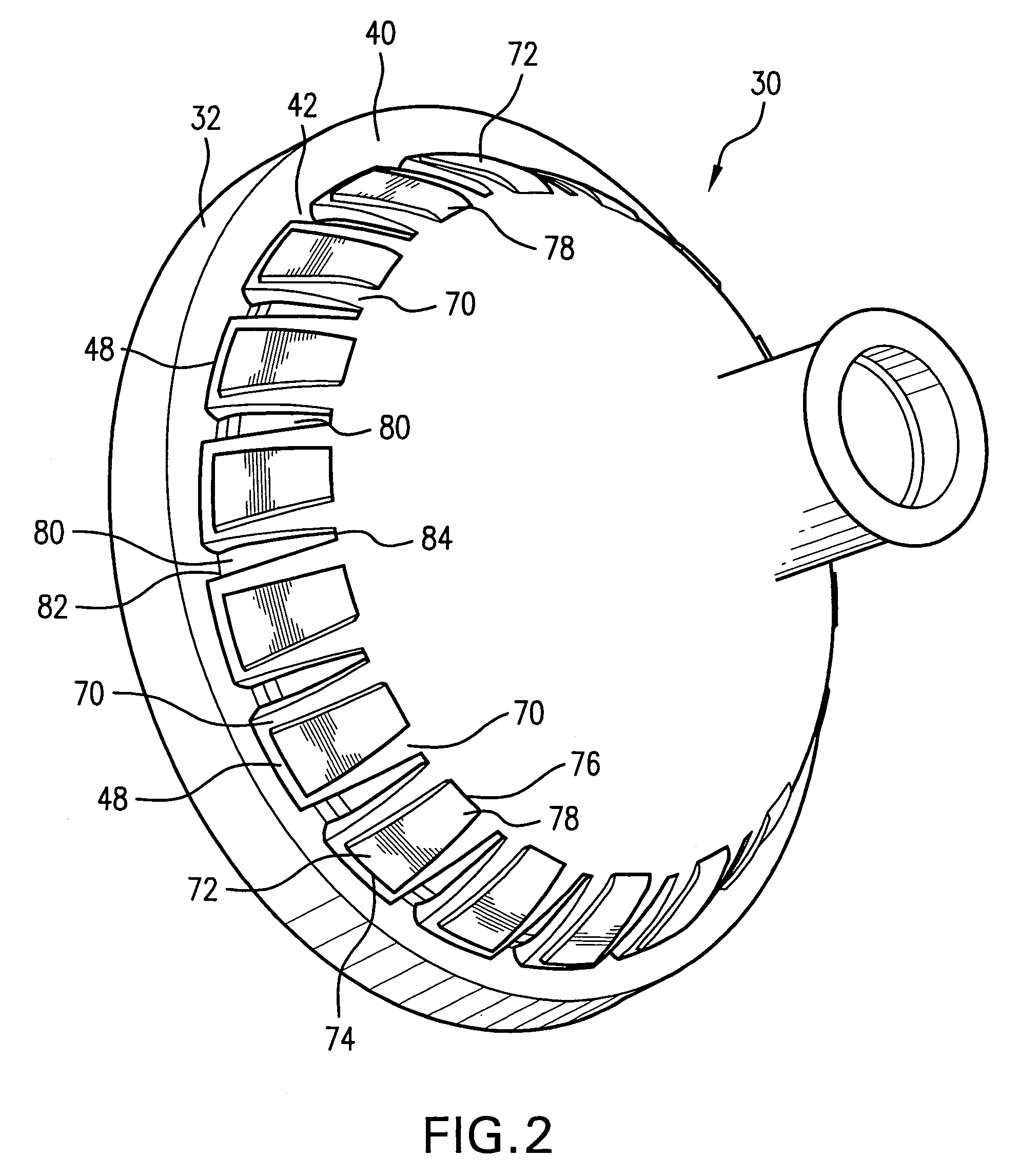

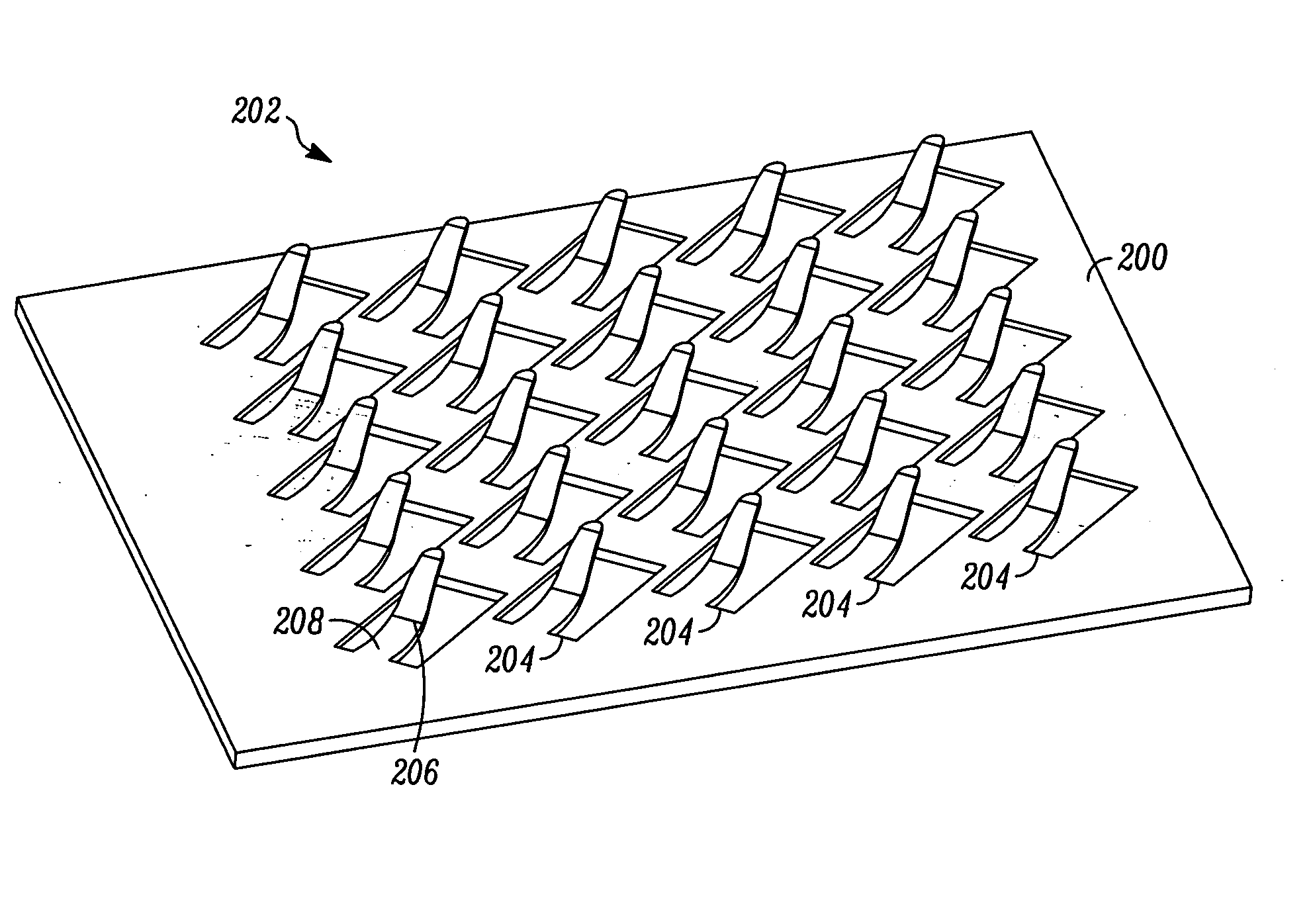

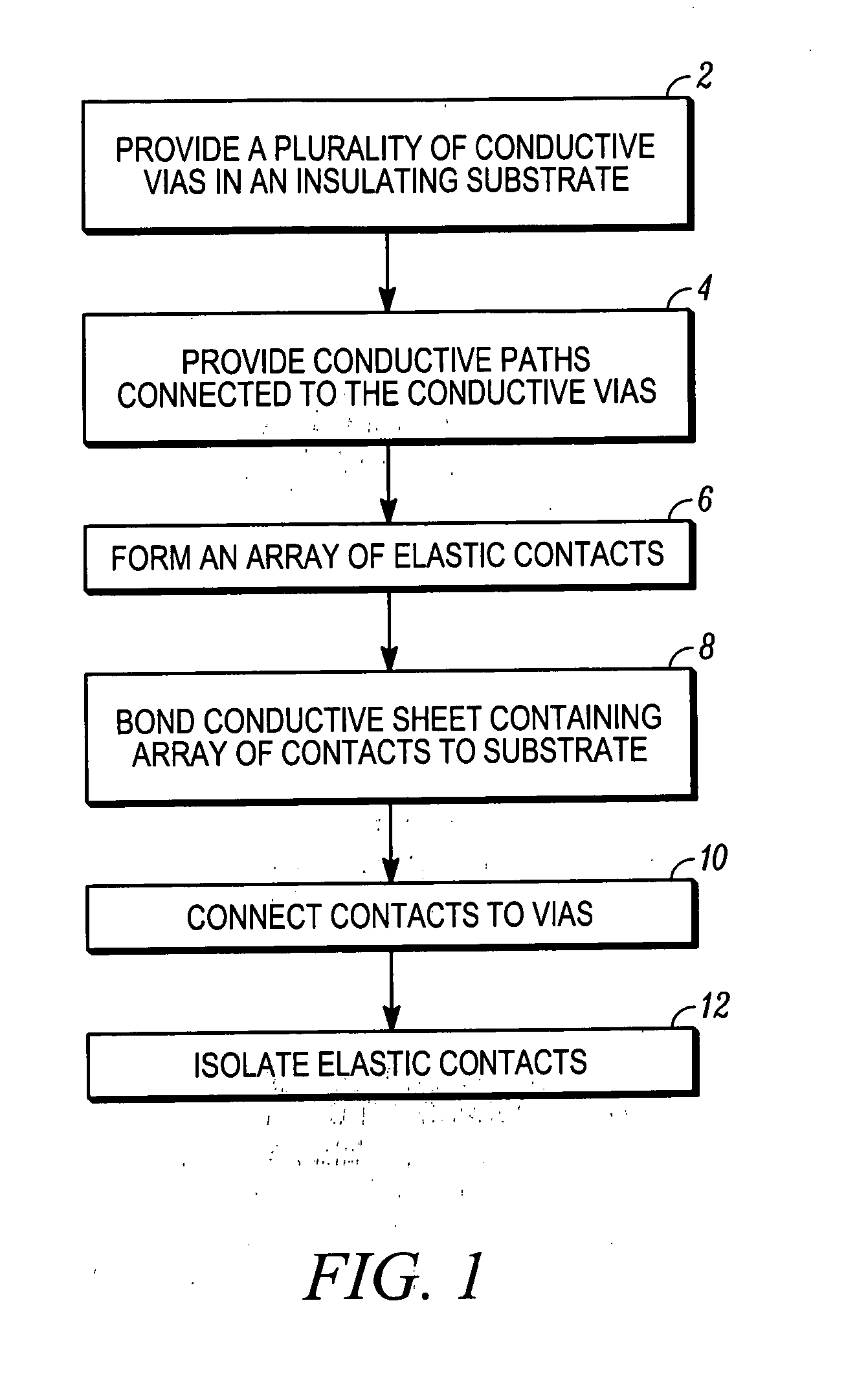

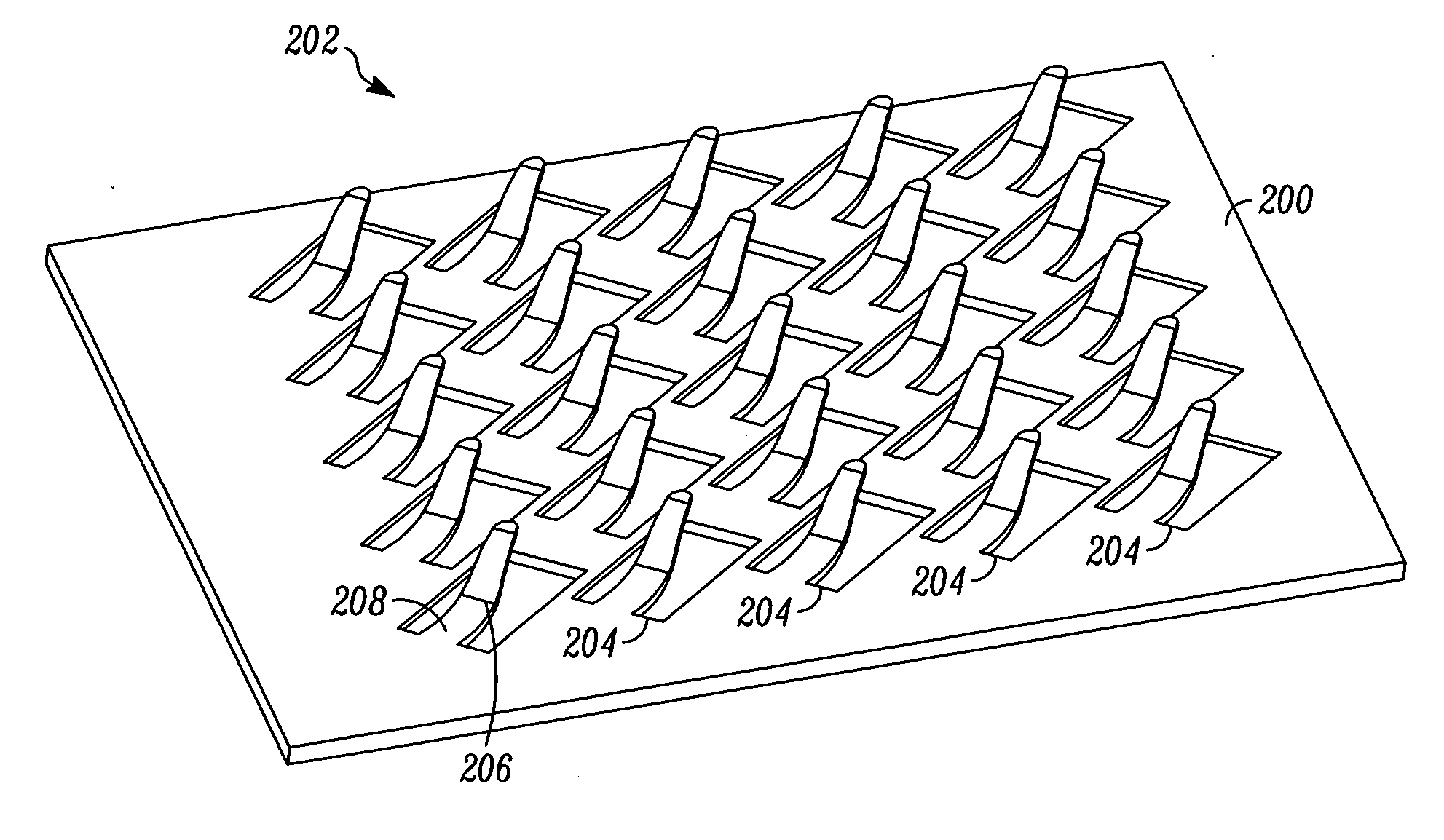

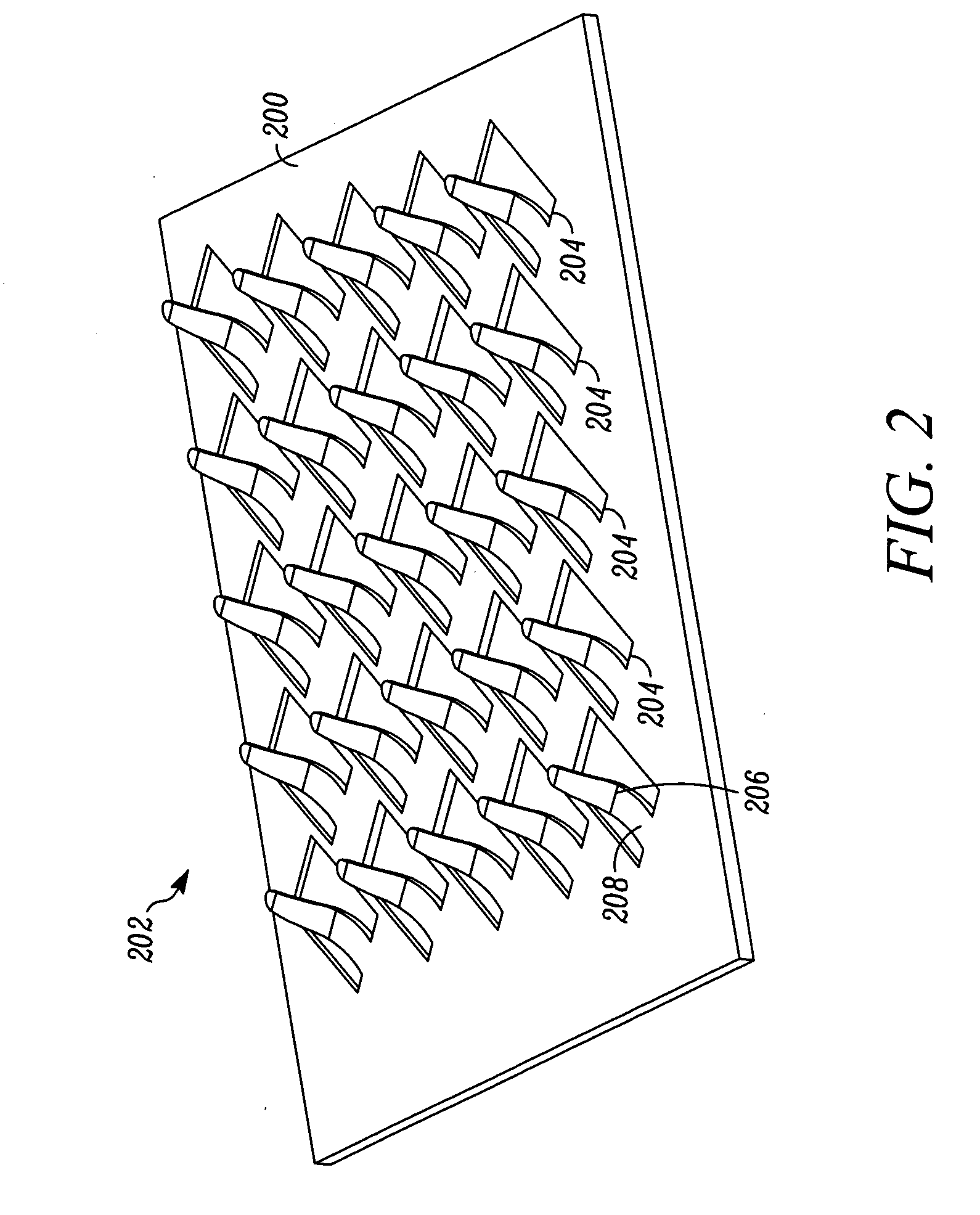

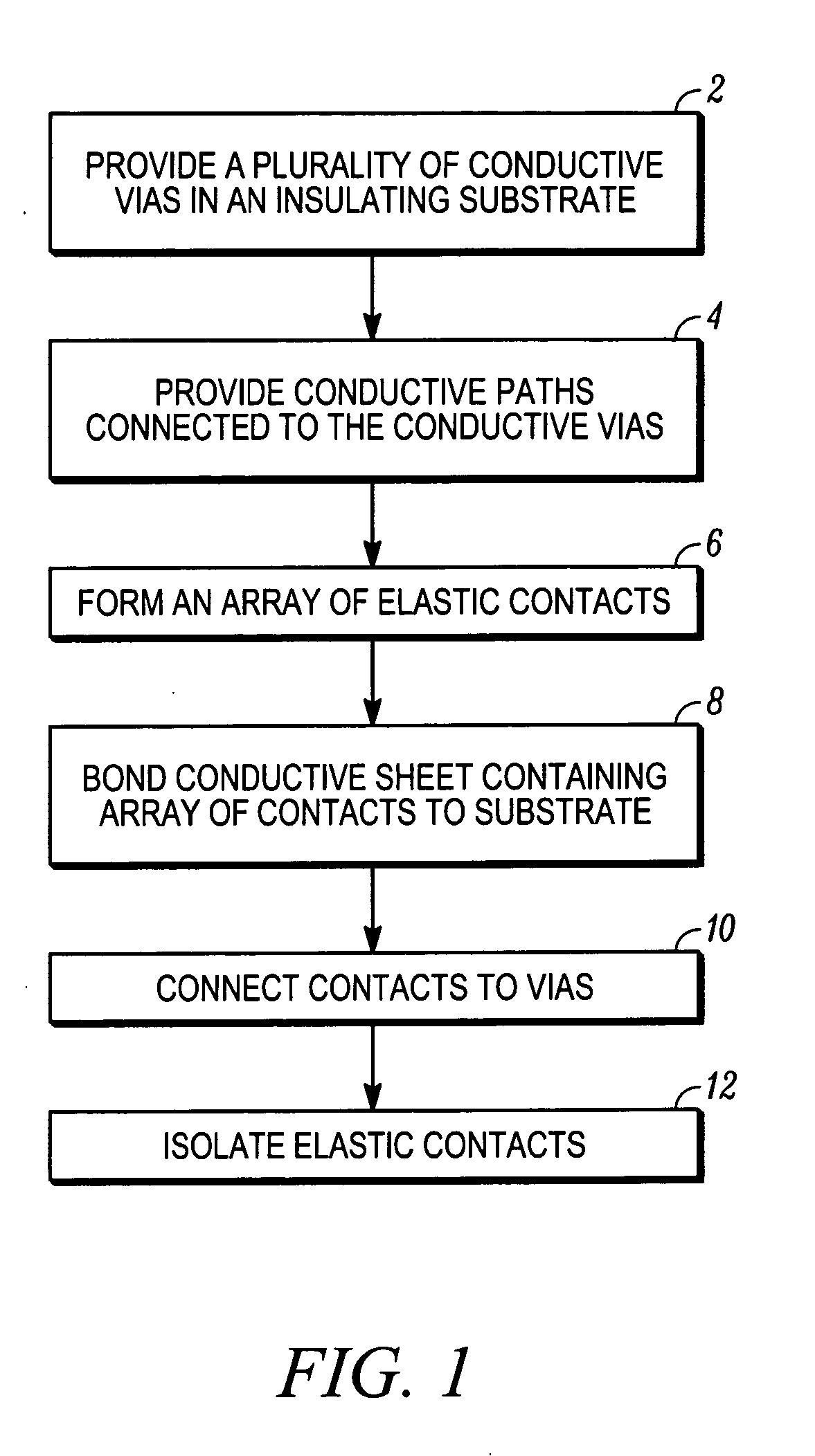

Contact grid array system

InactiveUS20070020960A1Coupling device detailsElectrically conductive adhesive connectionsDevice materialElectrical connection

A scalable, low cost, reliable, compliant, low profile, low insertion force, high-density, separable and reconnectable connector for high speed, high performance electronic circuitry and semiconductors. The electrical connector can be used to make, for example, electrical connections from components such as a Printed Circuit Board (PCB) to another PCB, MPU, NPU, or other semiconductor device. A normalized working range for an array of elastic contacts of the interposer can be about 0.2 to 1.0. A reversible normalized working range is maintained through multiple connections and reconnections using a highly elastic material for the contact arms. In one aspect, a first electrical component having a first array pitch can be connected to a second electrical component having a second array pitch.

Owner:NEOCONIX INC

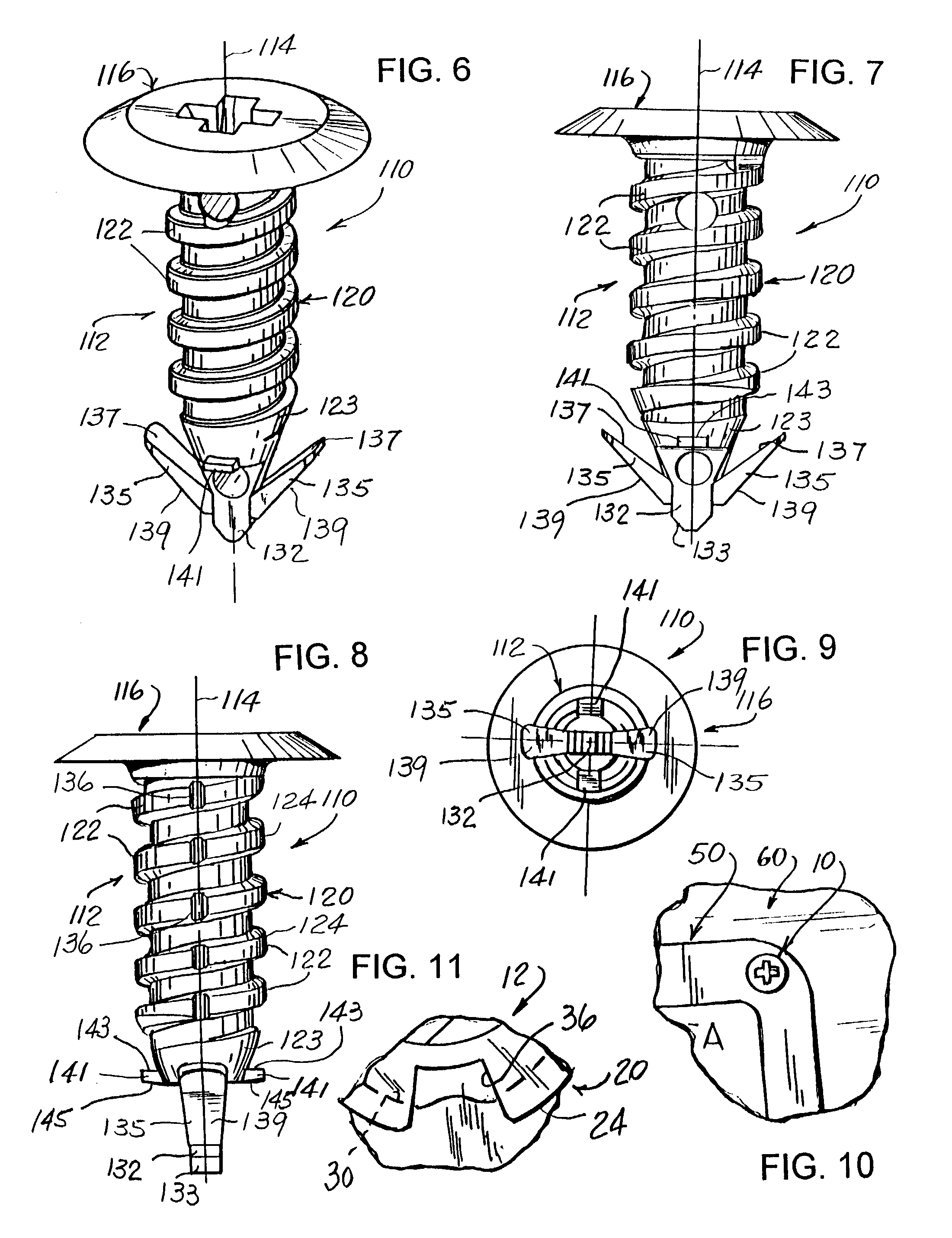

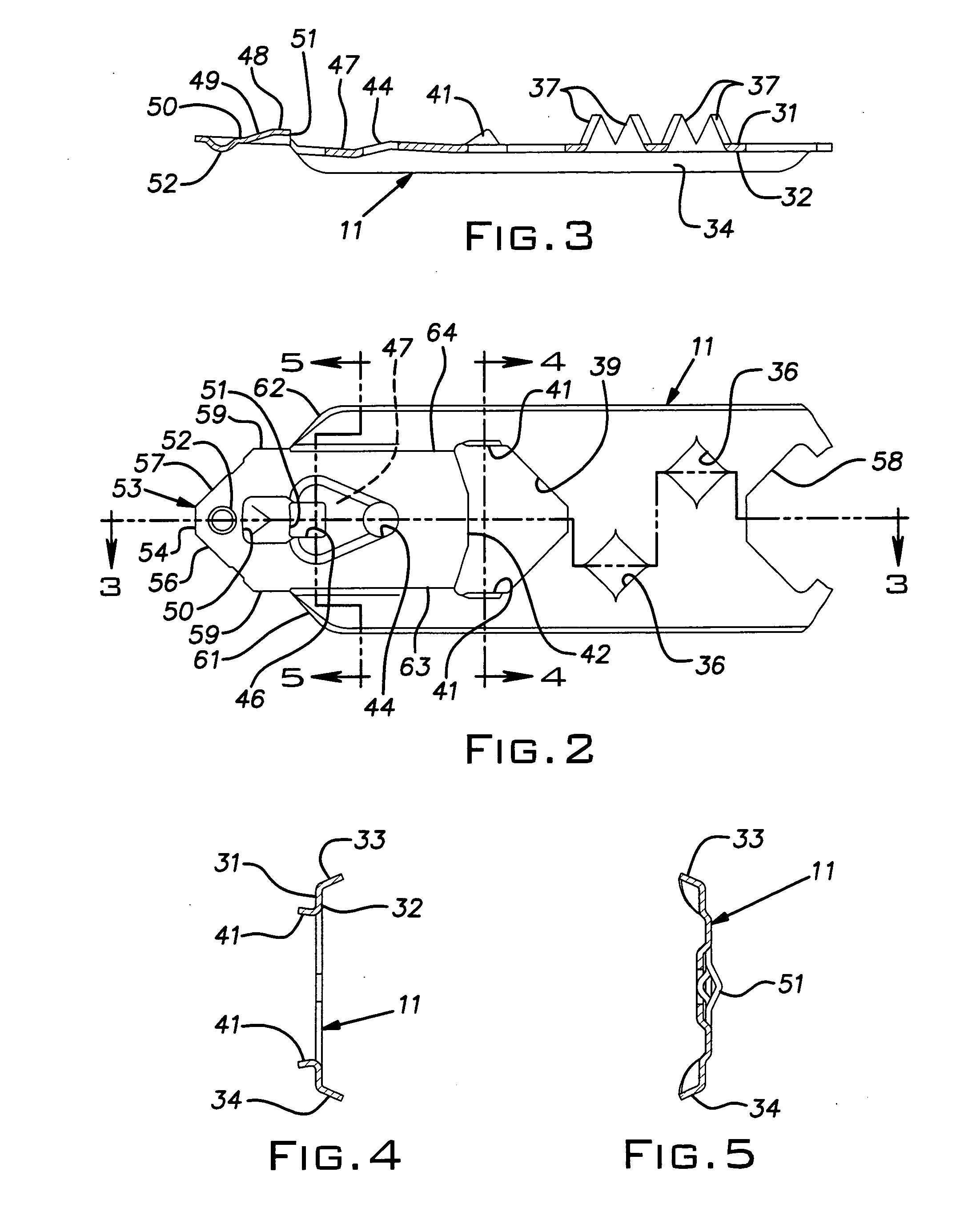

Cable tie with fir-tree type fastener

InactiveUS20060239796A1Easy to useReduce manufacturing costPipe supportsElectrical apparatusFluteLow insertion force

A one-piece cable tie includes a locking head and an attached strap, the locking head being adapted to receive and selectively engage a portion of the strap when the tie is formed into a closed loop. The cable tie additionally includes a fir-tree fastener formed onto the locking head, the fastener being sized and shaped to be fittingly inserted through a quarter-inch circular opening in a panel. The fastener includes a stem and a plurality of flutes formed onto the stem in such a manner so as not to interfere with one another when the fastener is being fittingly inserted through the opening in the panel. Because the fastener does not experience flute interference when inserted through a panel opening, the fastener is characterized as having a relatively low insertion force (i.e., the force required to insert the fastener into the panel opening) while maintaining a relatively high extraction force (i.e., the force required to withdraw the fastener from the panel opening).

Owner:AVERY DENNISON CORP

Thin multichip flex-module

ActiveUS7394149B2Digital data processing detailsSemiconductor/solid-state device detailsLow insertion forceComputer module

A low insertion force multichip in-line module comprises: a substantially rigid frame; a flex circuit having a plurality of integrated circuit chips disposed thereon, the flex circuit having contacts at least partially exposed along one edge of the frame; and, a compliant layer disposed between the exposed flex circuit and the rigid frame, whereby controlled deformation of the compliant layer enhances electrical continuity between the contacts and corresponding external electrical pins. Alternatively, a low insertion force multichip in-line module comprises: a substantially rigid frame; a flex circuit having a plurality of integrated circuit chips disposed thereon, the flex circuit having contacts at least partially exposed along one edge of the frame; a socket configured to matably engage the module; and, a compliant layer disposed between the exposed flex circuit and the rigid frame, whereby controlled deformation of the compliant layer enhances electrical continuity between the contacts and corresponding external electrical pins.

Owner:MICROELECTRONICS ASSEMBLY TECH

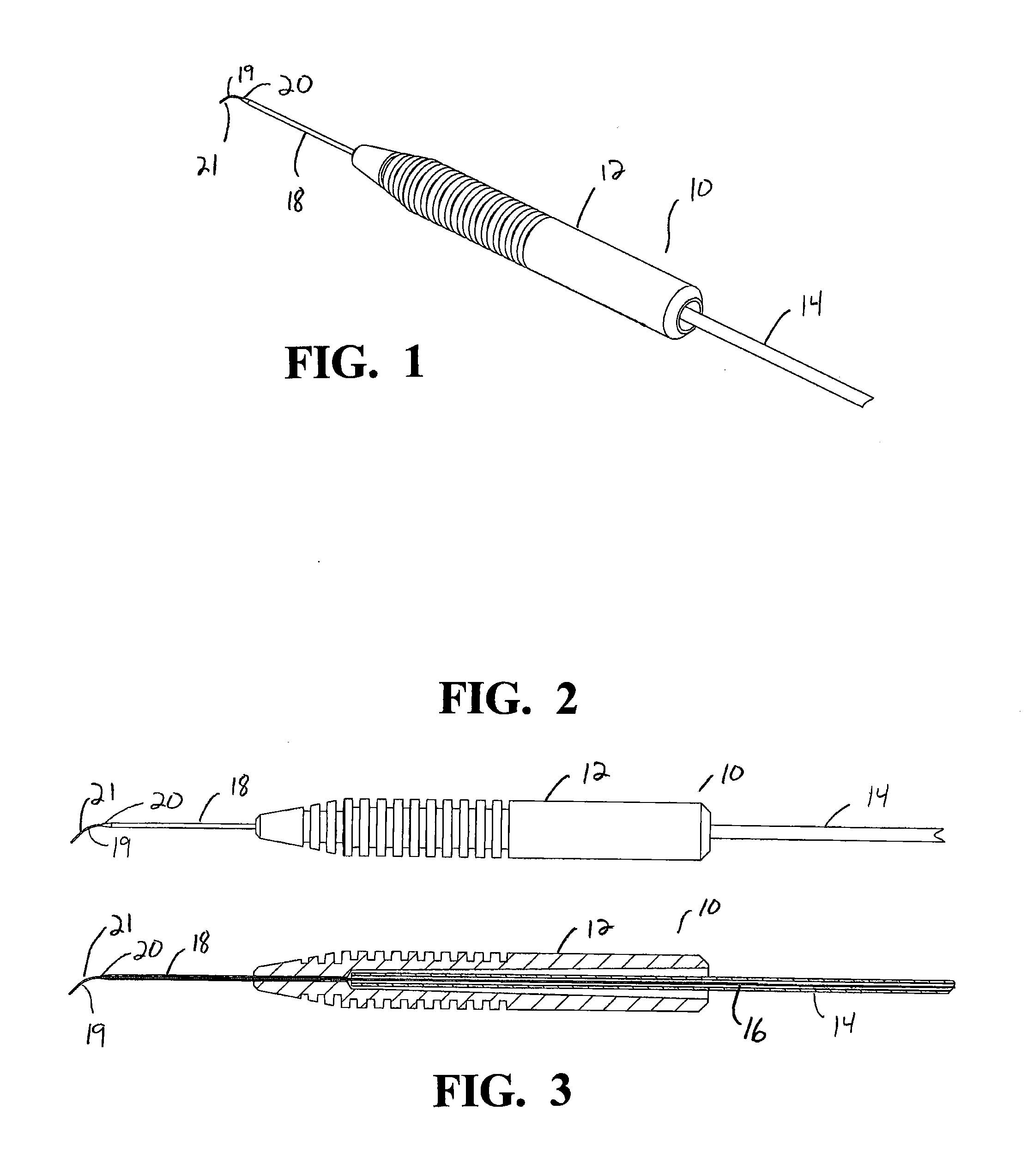

Flexible Surgical Probe

InactiveUS20090093800A1Lower insertion forceLarge treatment areaLaser surgeryDiagnosticsFiberLow insertion force

A probe having a flexible, small diameter fiber sheathed in a small diameter flexible tube comprising the distal tip of the probe. The small diameters of the fiber and tube allow the fiber to be bent in a tighter radius along essentially the entire length of the exposed portion of the fiber, with low tube bending forces during insertion, providing a compact design which eliminates the need for a straight distal portion. The small diameter tube also allows a greater wall thickness outer cannula to be used, thereby increasing instrument rigidity. This compact, rigid design with low insertion forces allows the fiber greater access to the internal posterior structures of the eye, while providing increased instrument rigidity for manipulation of the eye, as well as low insertion forces.

Owner:ALCON INC

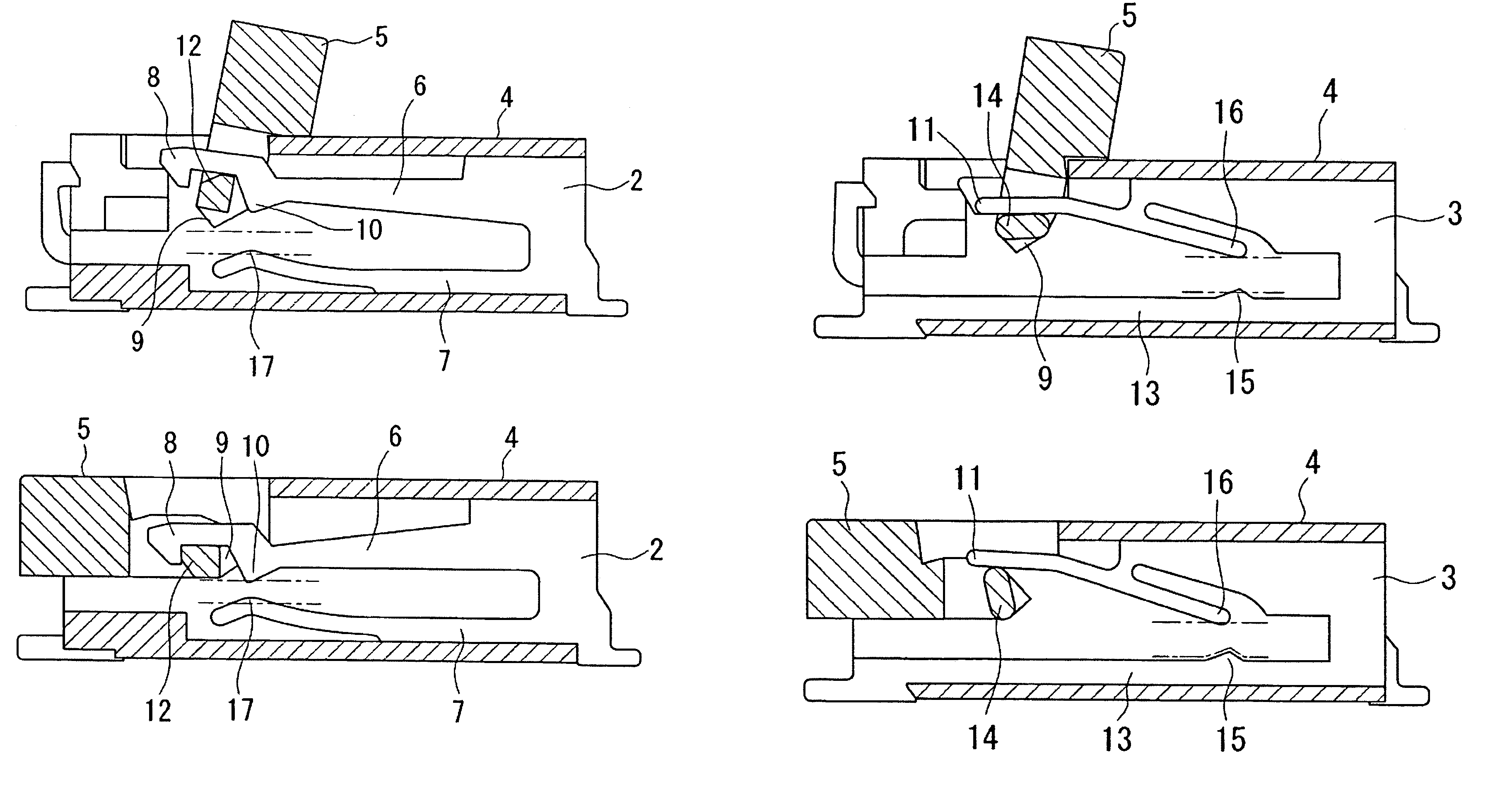

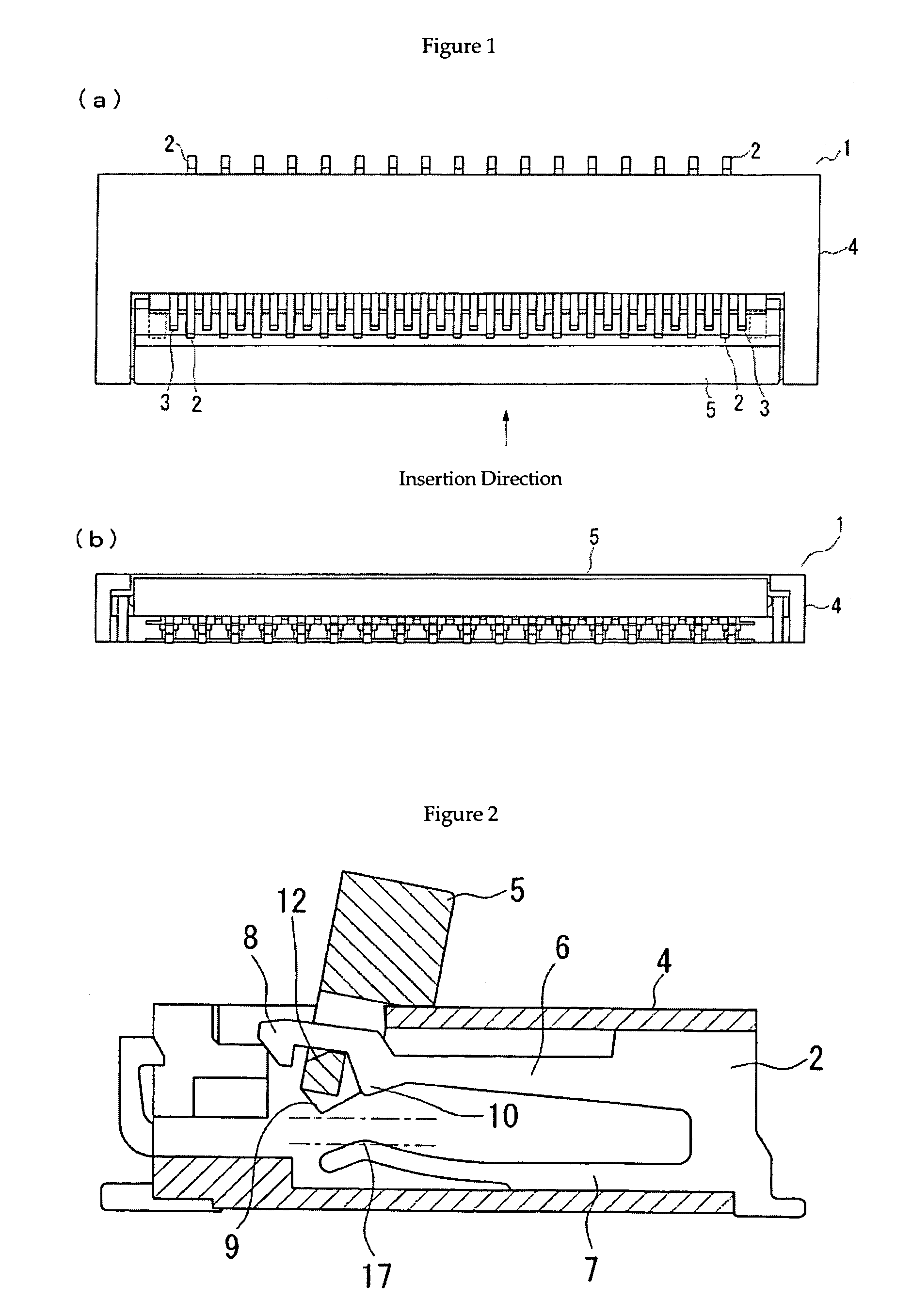

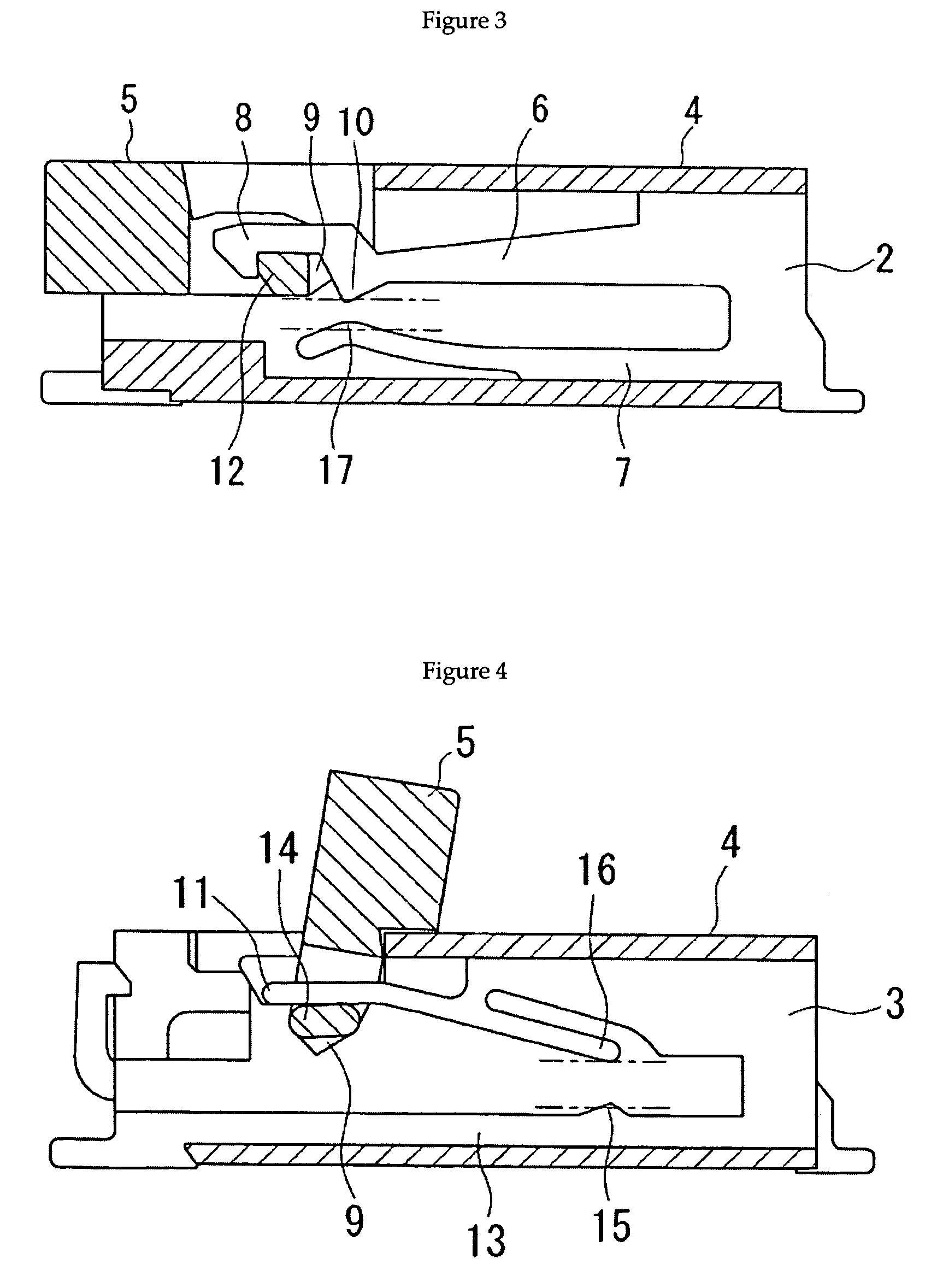

Electrical connector for flexible flat cable

InactiveUS7086884B2Improve rigidityReduce rigidityEngagement/disengagement of coupling partsCoupling contact membersLow insertion forceEngineering

Owner:FRAMATOME CONNECTORS INT SA

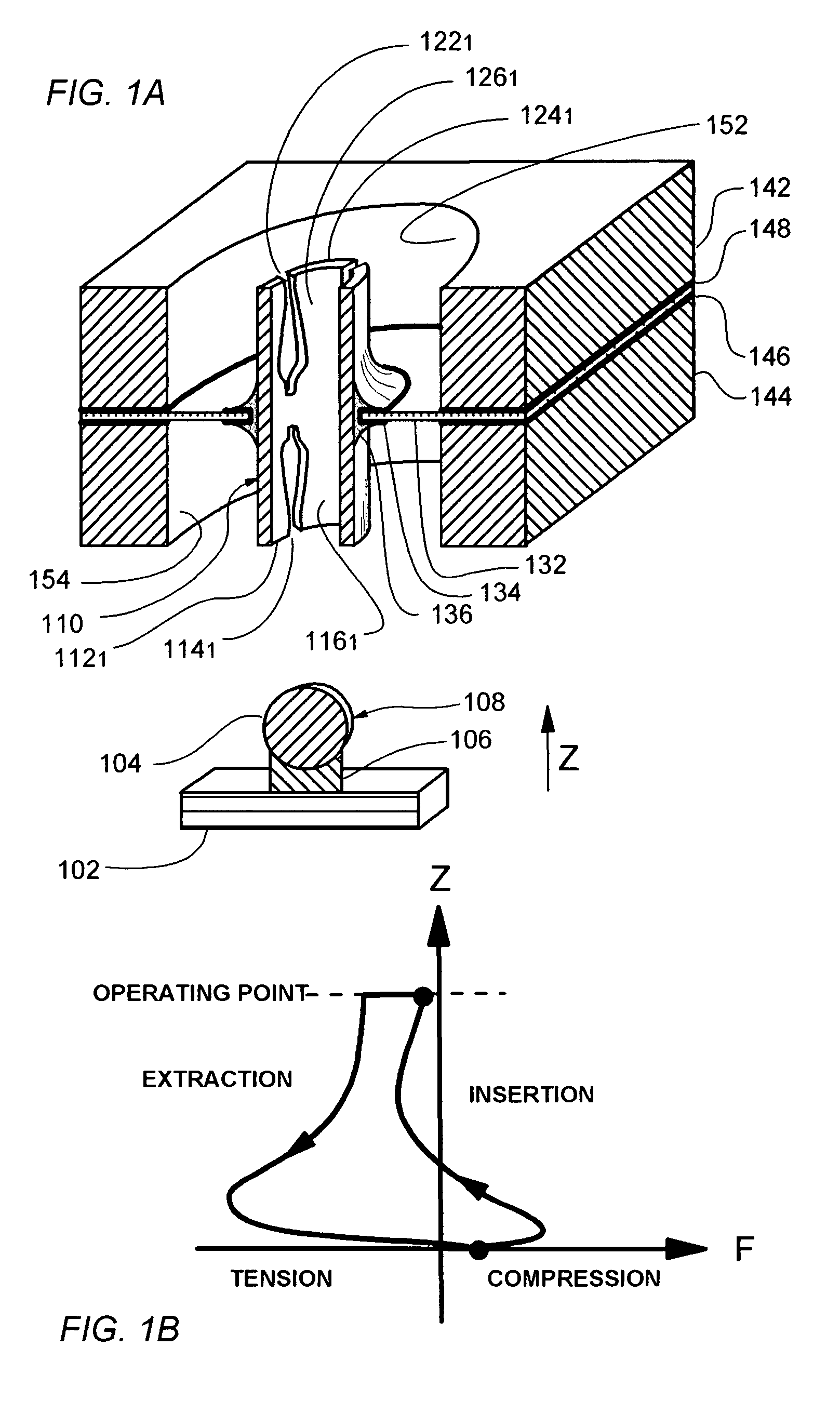

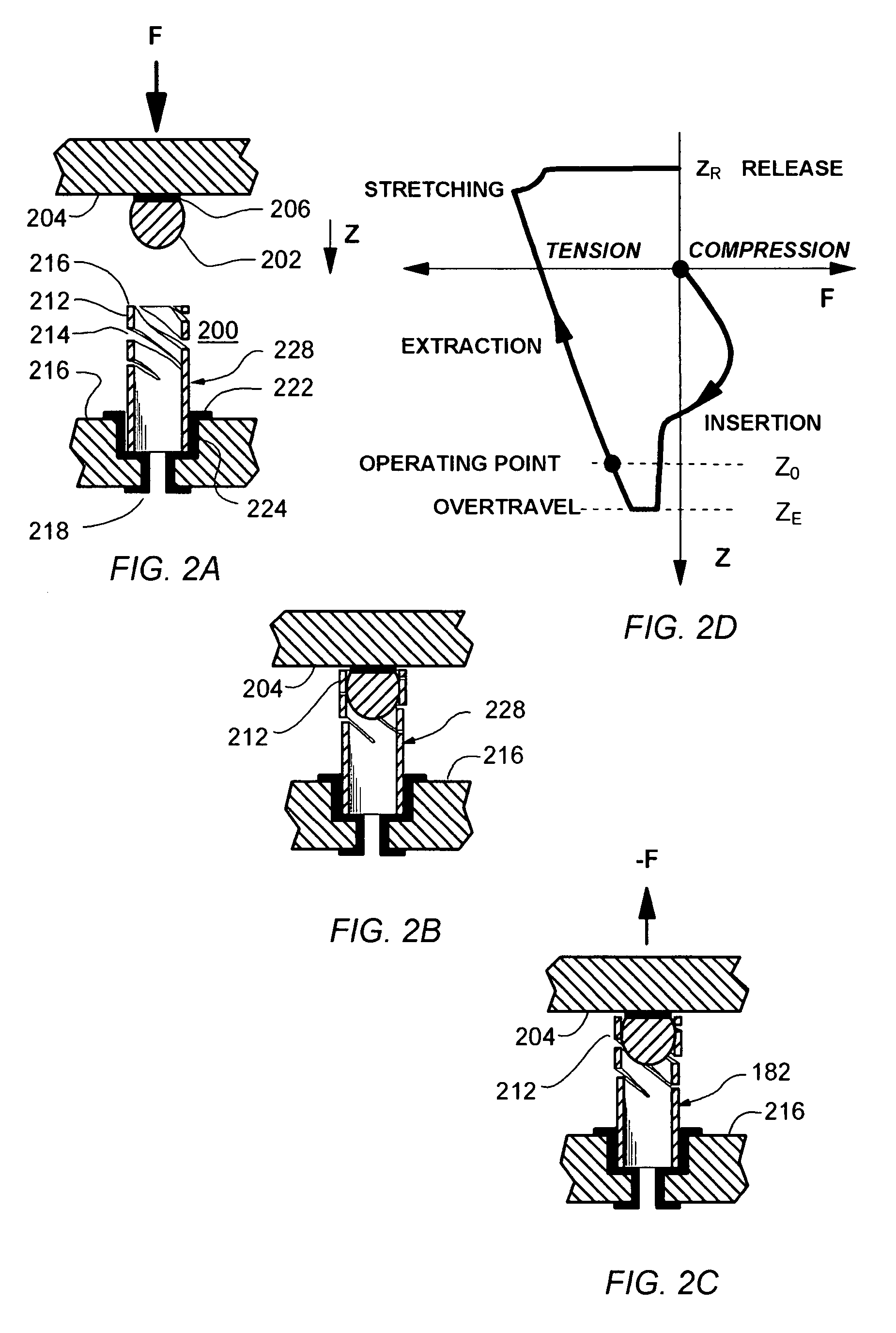

High extraction force ball socket

A ball socket for connection with a ball stud resists accidental pull-out of the ball stud. The ball socket achieves relatively low insertion force but relatively high pull-out force resistance.

Owner:BURTON TECH

Clamp and element connection device

To provide a clip easily and temporarily fixed to a fitting member at a low insertion force, fixed thereto at a high retaining force after the temporary fixing, and comprising a pin and a bush. This clip 1 comprises the bush 2 and the pin 3, a bush shaft part 9 is divided into a plurality of legs by a plurality of slits extending to the tip, and an elastic lock jaw 19 projecting radially inward is formed between the slits and a bush flange 7. The tip of the pin shaft part 9 is formed with a lock groove 31 for being locked to the lock jaw 19 in a temporary fixing state and, when the pin shaft part 30 is completely inserted into the bush shaft part 9, the lock groove 31 receives and locks the pin shaft with the tip of the bush shaft part enlarged. The bush shaft part is provided with two lock parts 22 projecting radially outward in positions separated from the bush flange 7 by a length corresponding to the thickness 21 of the fitting hole part of the fitting member 5. The lock parts 22 are formed in diametrically opposed positions into a staged shape of a prescribed circumferential length.

Owner:EMHART INDUSTRIES INC

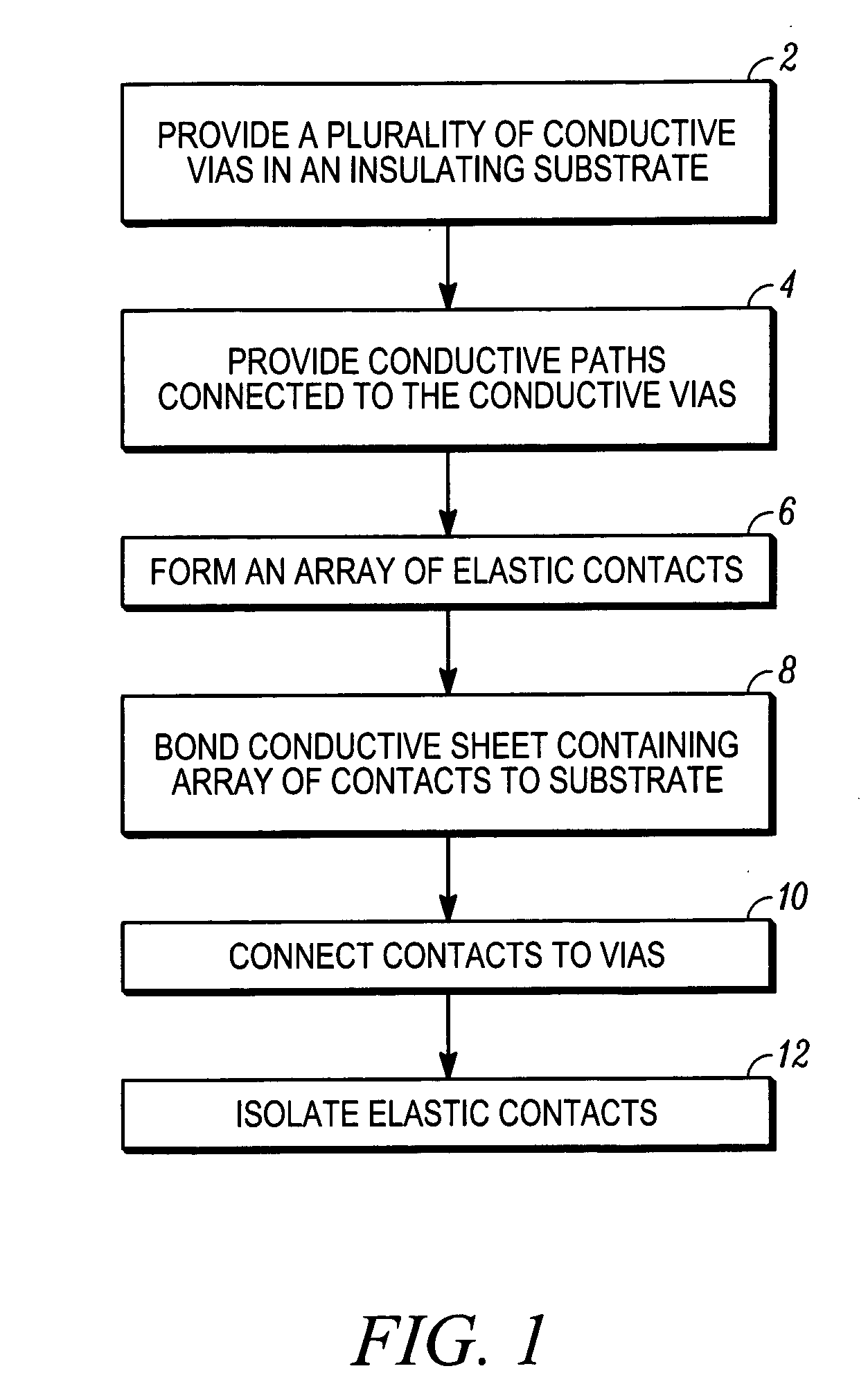

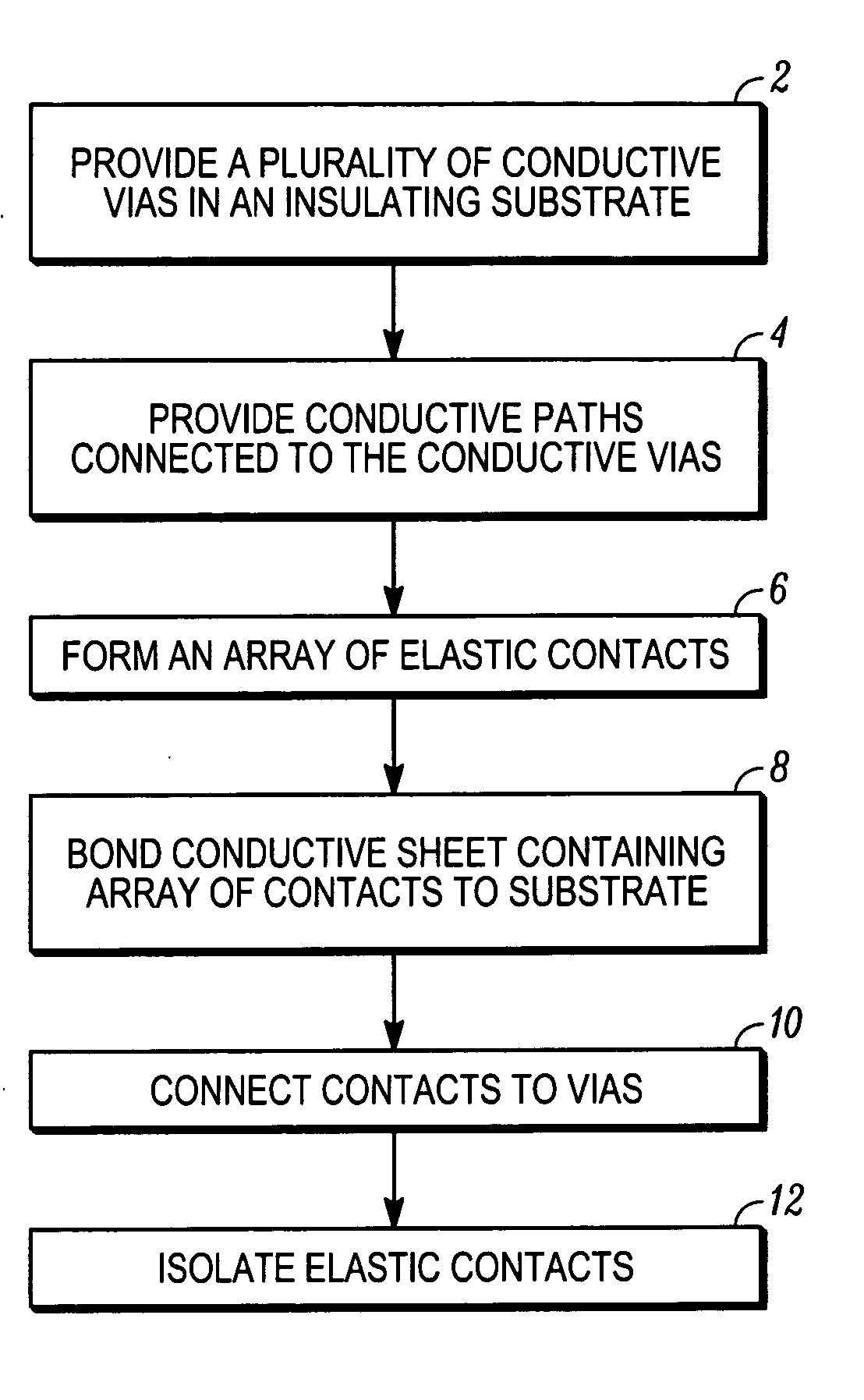

Method for fabricating a contact grid array

ActiveUS20070054515A1Printed circuit assemblingCoupling device detailsHigh densityLow insertion force

A method for producing scalable, low cost, reliable, compliant, low profile, low insertion force, high-density, separable and reconnectable interposer for high speed, high performance electronic circuitry and semiconductors. The method can be used to make, for example, electrical connections from components such as a Printed Circuit Board (PCB) to another PCB, MPU, NPU, or other semiconductor device. A normalized working range for an array of elastic contacts of the interposer can be about 0.2 to 1.0. A reversible normalized working range is maintained through multiple connections and reconnections using a highly elastic material for the contact arms. In one aspect, a first electrical component having a first array pitch can be connected to a second electrical component having a second array pitch.

Owner:NEOCONIX INC

Cap and low insertion force connector for printed circuit board

InactiveUS20010014546A1Insertion forceImprove connection workabilityEngagement/disengagement of coupling partsIncorrect coupling preventionLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board. A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front. The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

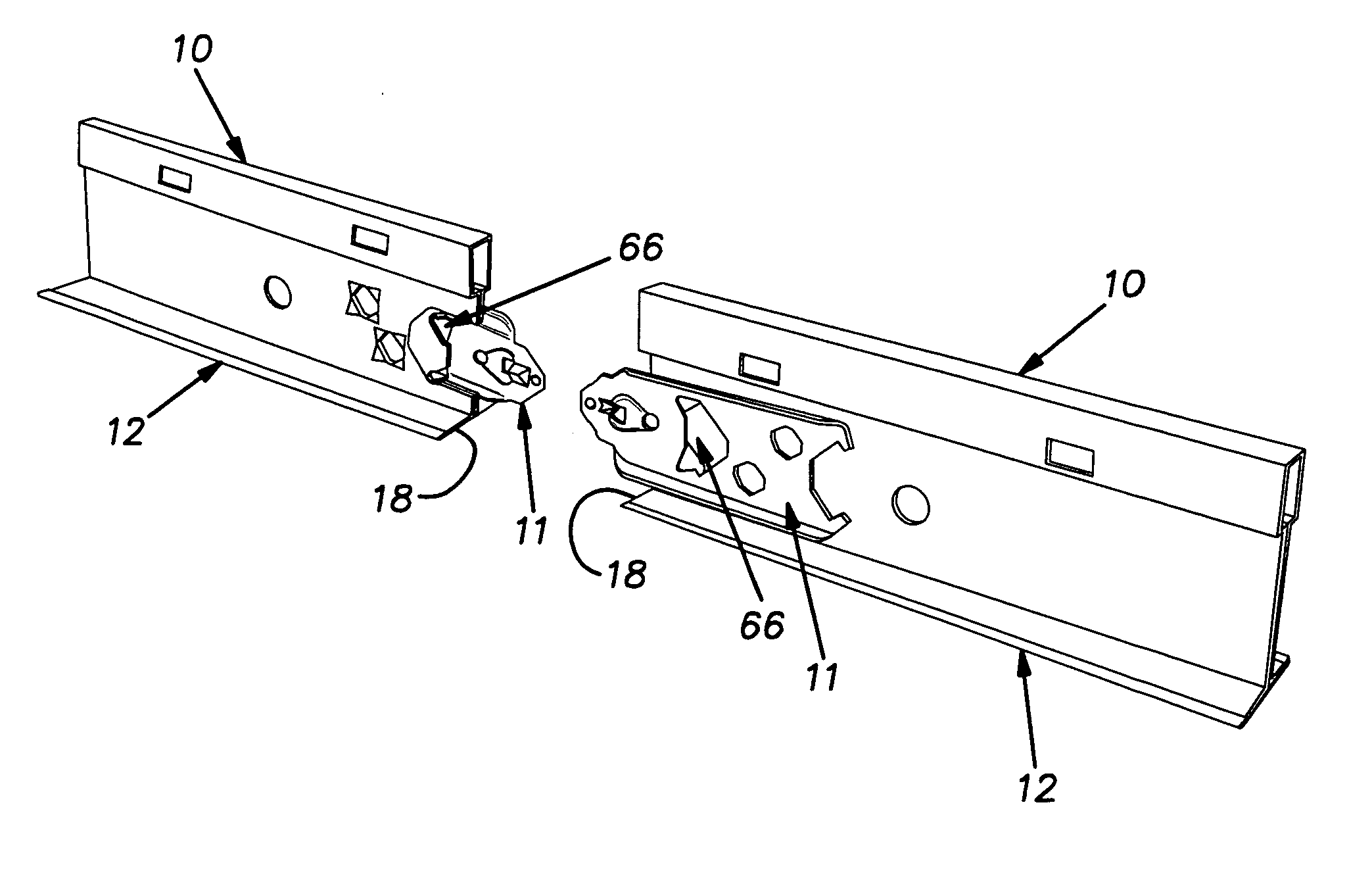

Main tee connection

InactiveUS20060260246A1Reliable high strength jointPrecise positioningCeilingsWallsLow insertion forceButt joint

A main tee with separate clips affixed on its ends for splicing the tee with identical tees in end-to-end butt joints. The tee and clip form a pocket for receiving the projecting end of an opposing clip with a uniform low insertion force. The clip is self-aligning with the pocket and when interconnected the clips precisely align the coupled tees both vertically and horizontally. The clips, formed of relatively strong material, have mutually engageable locking surfaces that ensure a strong joint.

Owner:USG INTERIORS INC

Connector terminal

The connector terminal of the present invention is made of an electroplated Cu alloy plate, and a pair of mutually engaged male terminals 1 and female terminals 2 are provided; wherein in the mutual sliding part of the male terminal 1 and the female terminal 2, the dimension of one of the terminals The Vickers hardness of the other terminal is in the range of 60-700HV, the Vickers hardness of the other terminal is in the range of 20-150HV, and the difference between the Vickers hardness of the two terminals is 15HV or more. The result is low insertion force, removal force and good thermal resistance in addition to stable contact resistance.

Owner:MITSUBISHI SHINDOH CO LTD

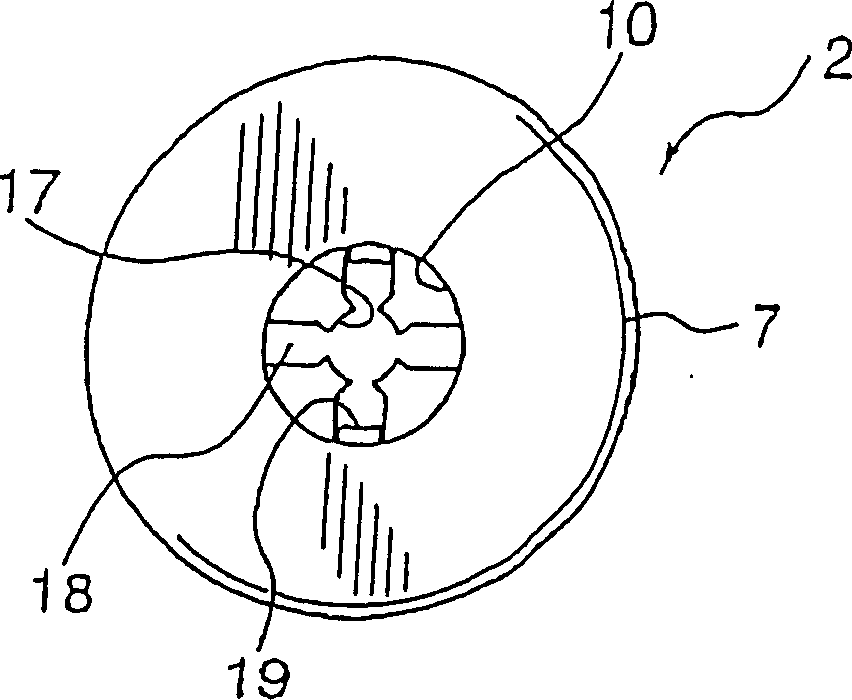

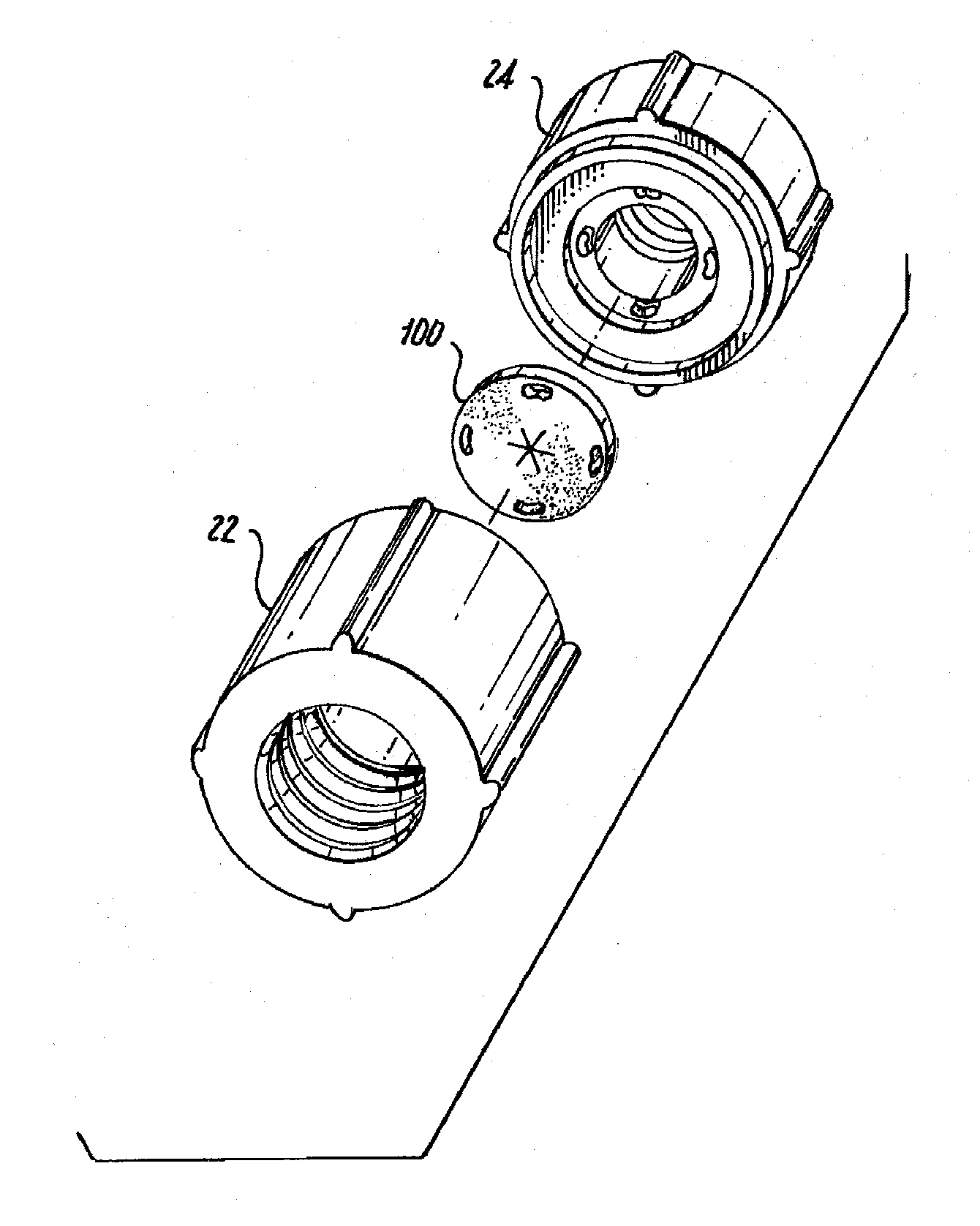

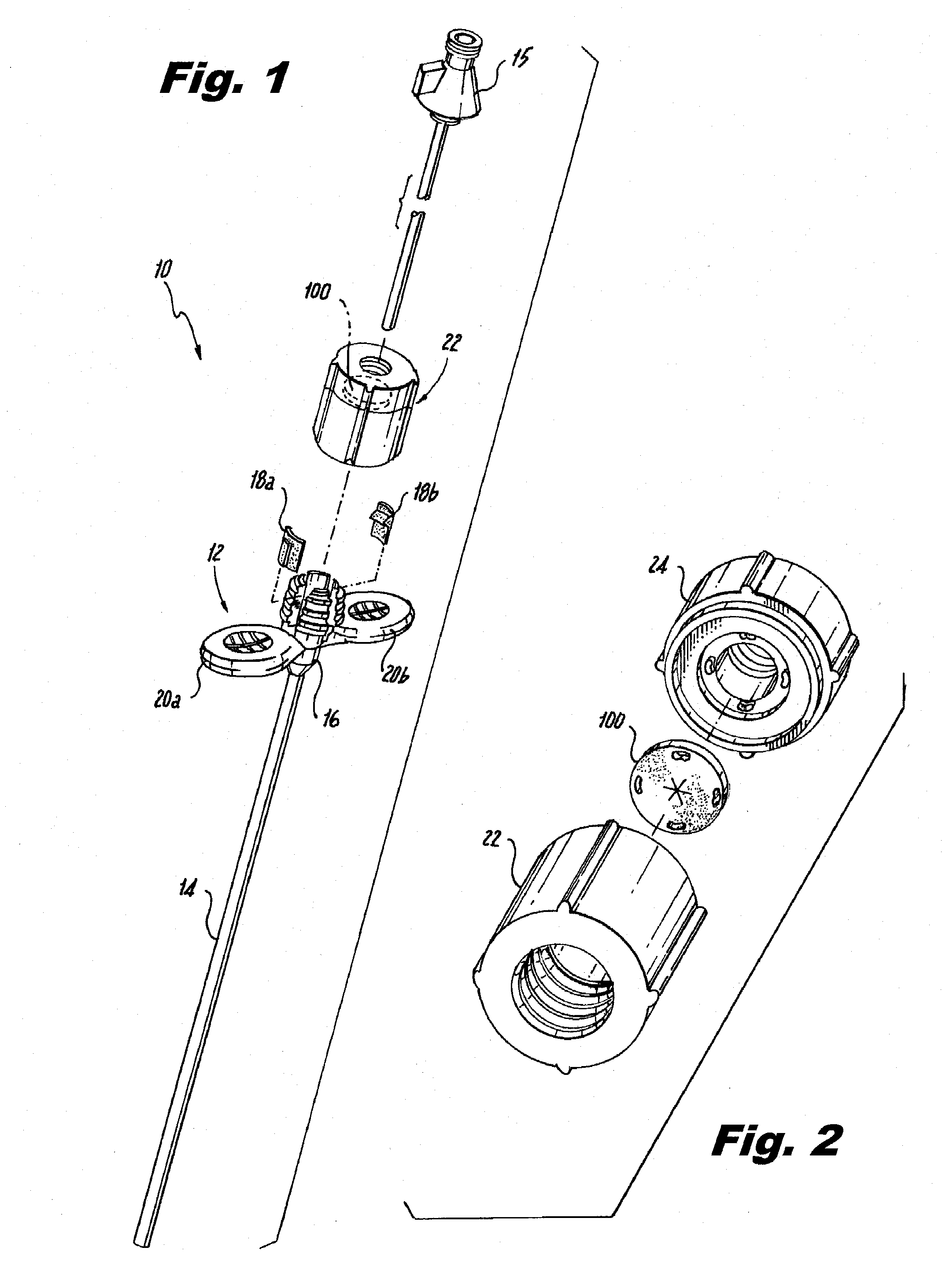

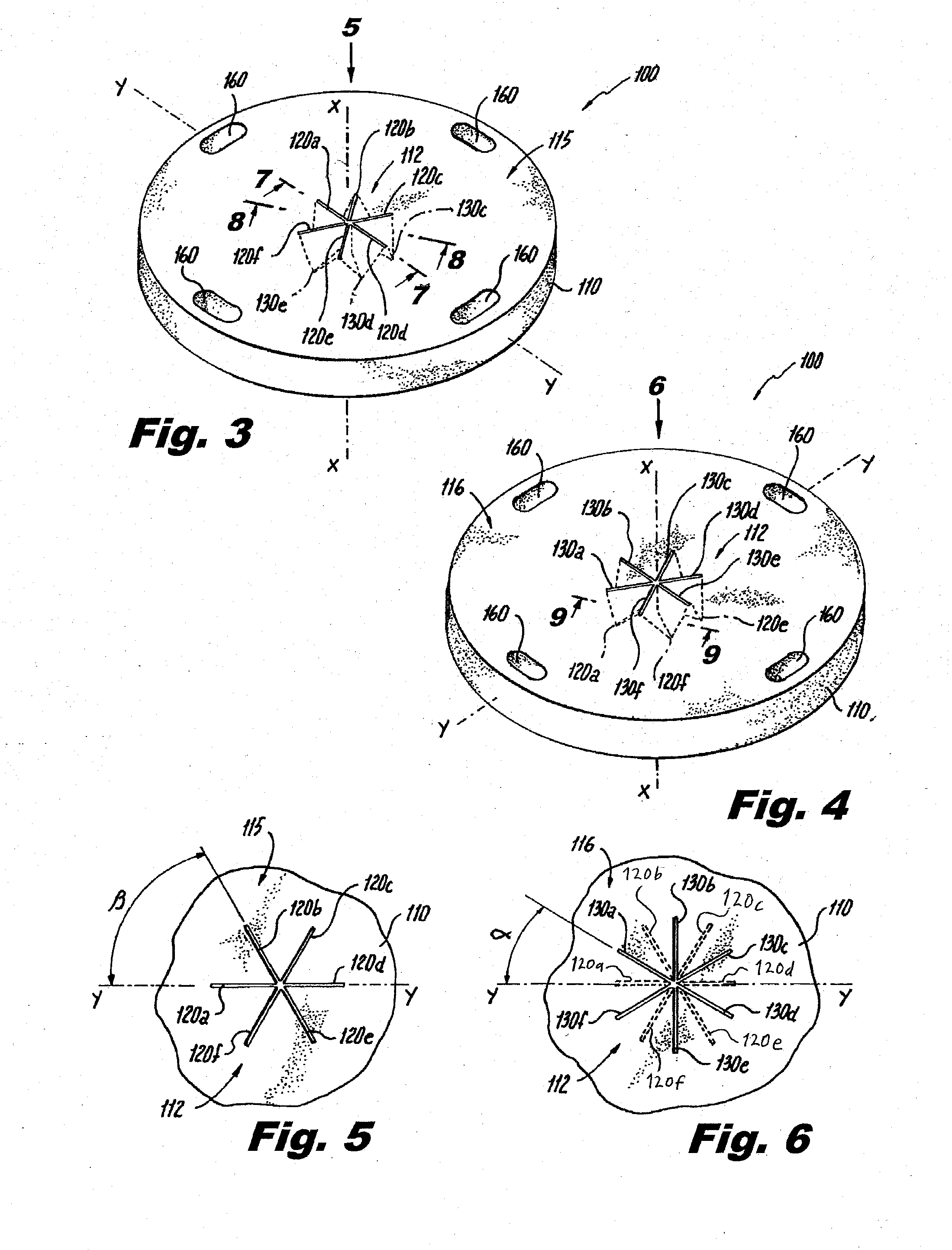

Low insertion force hemostasis valve for vascular introducer

A hemostasis valve for a vascular introducer includes a valve body having a seal region with opposed first and second end surfaces and a central axis extending through the seal region perpendicular to the first and second end surfaces. The first end surface of the seal region has a first grouping of cut lines formed on the first end surface and extending radially outward from the central axis. The second end surface of the seal region has a second grouping of cut lines formed on the second end surface and extending radially outward from the central axis. The first circumferential grouping of intersecting cut lines is axially aligned with and angularly offset from the second circumferential grouping of cut lines. A pair of planar slits extend angularly away from each cut line in the first end surface, through the valve body, to a respective pair of oppositely adjacent cut lines in the second end surface.

Owner:OSCOR

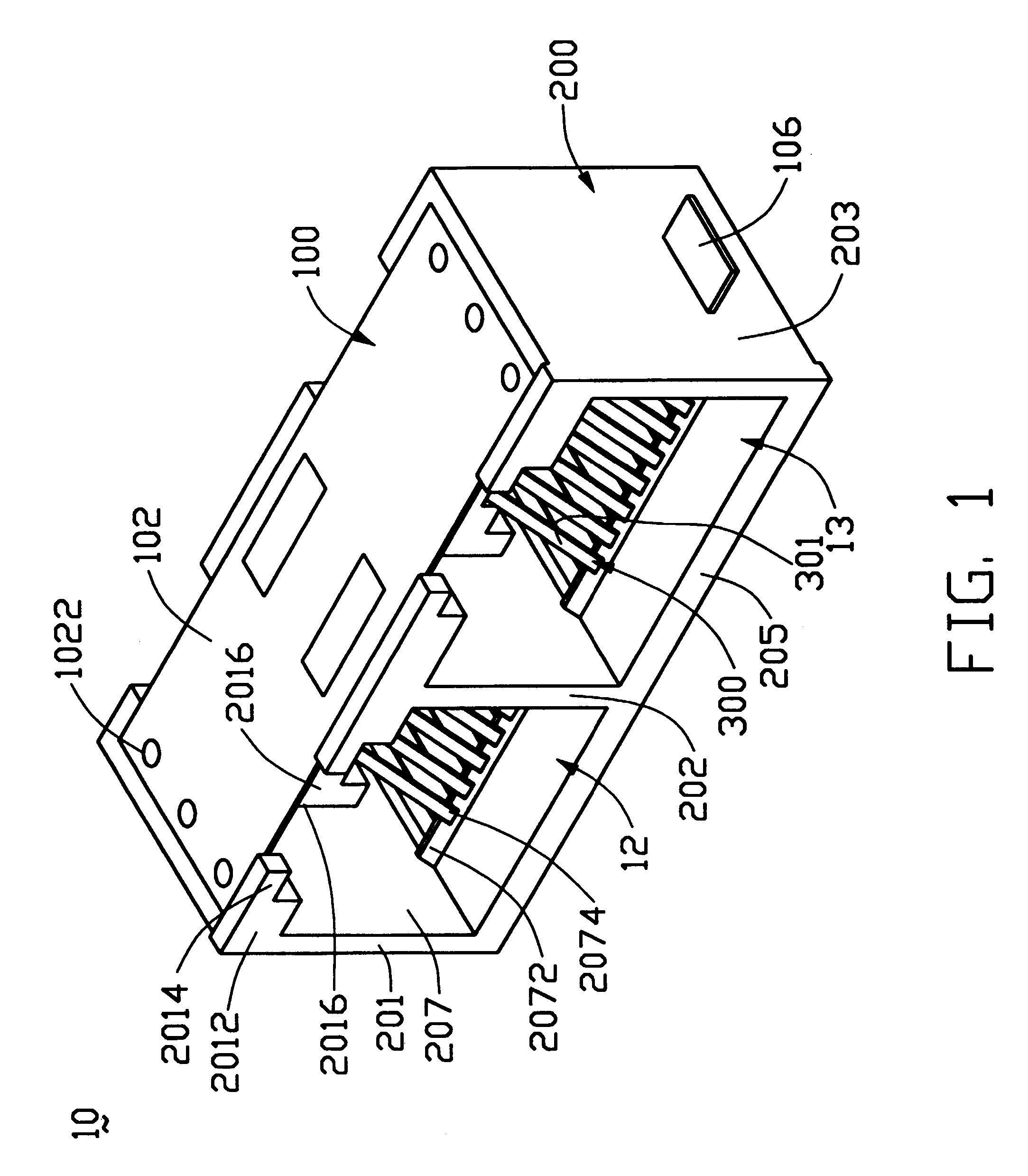

Low profile electrical connector assembly with low insertion force

InactiveUS6220900B1Direct impactLower insertion forceIncorrect coupling preventionTwo-part coupling devicesMating connectionLow insertion force

A lower profile electrical connector assembly for electrical connection with a mating plug connector includes a conductive shell, an insulative housing, and a contact spacer molded with a plurality of contacts. The housing of the electrical connector assembly is equipped with the contact spacer thereby pre-loading the contacts for lowering the insertion force of a mating connector acted on the contacts. Also, a slant formed inside the receiving spacer of the housing is capable to angularly bias the insertion of the mating electrical connector into the housing on stages to avoid the direct impact of the mating connector on the contacts for lowering the insertion force more.

Owner:HON HAI PRECISION IND CO LTD

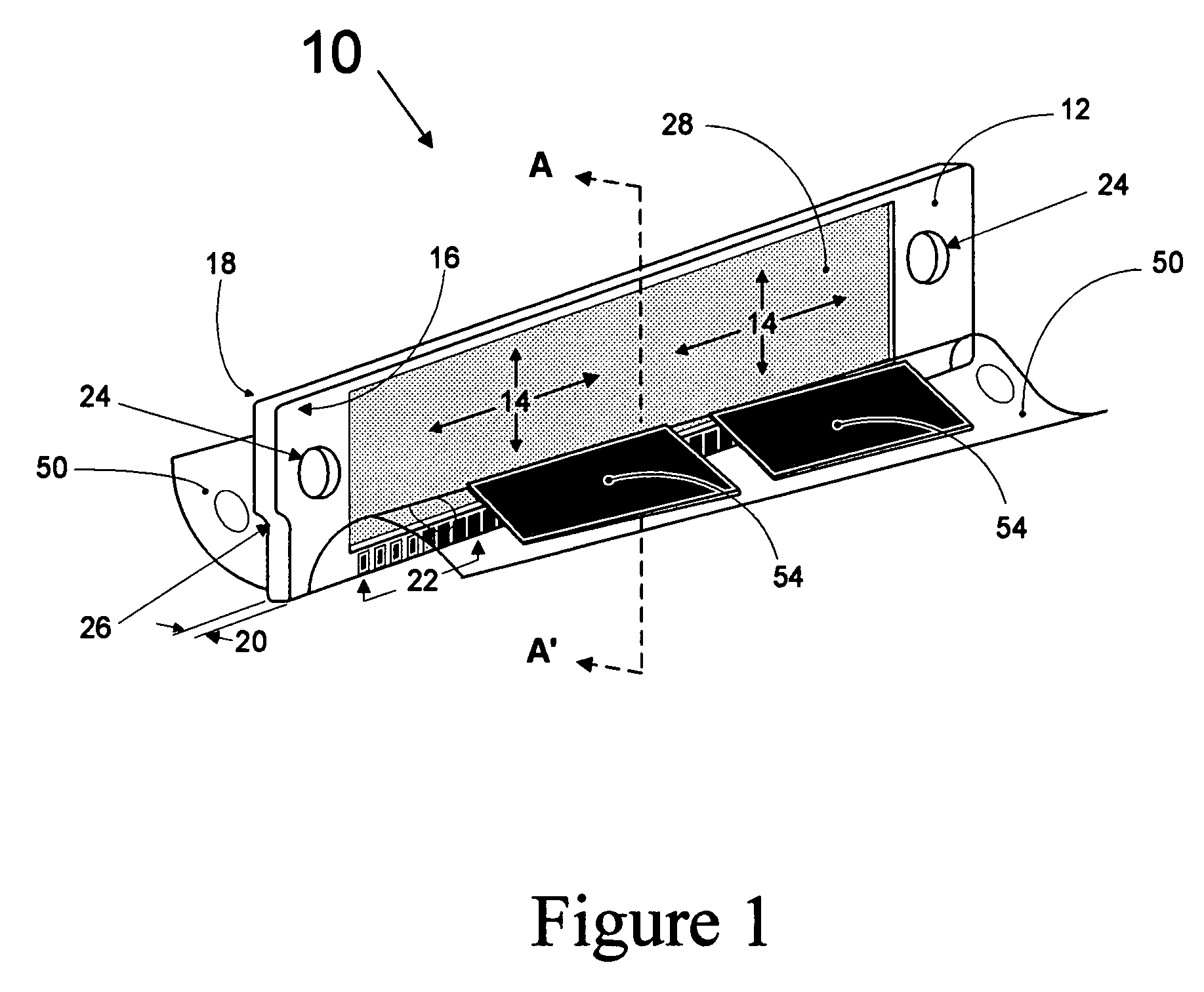

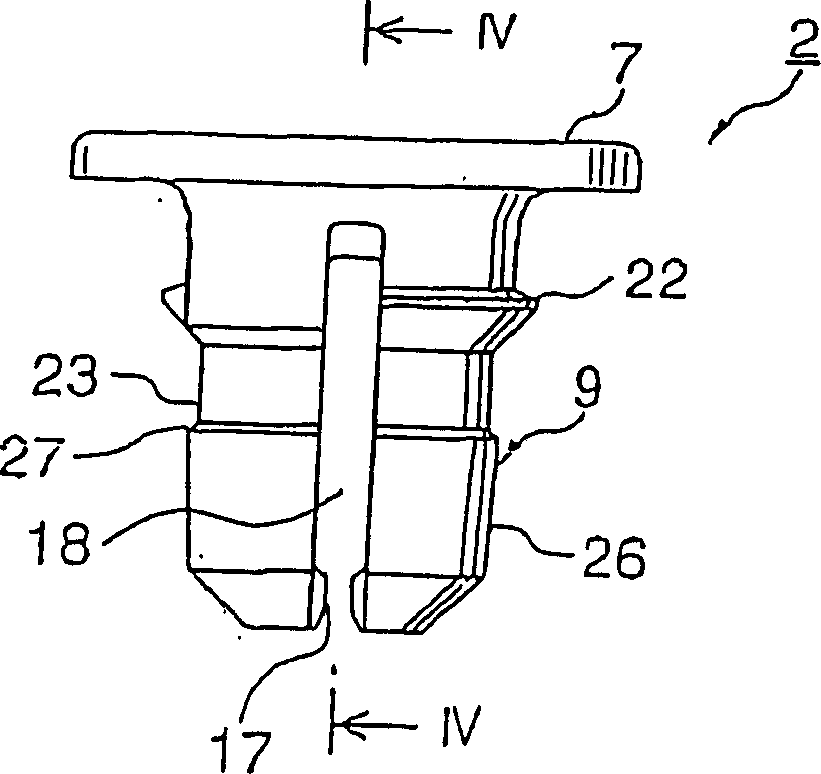

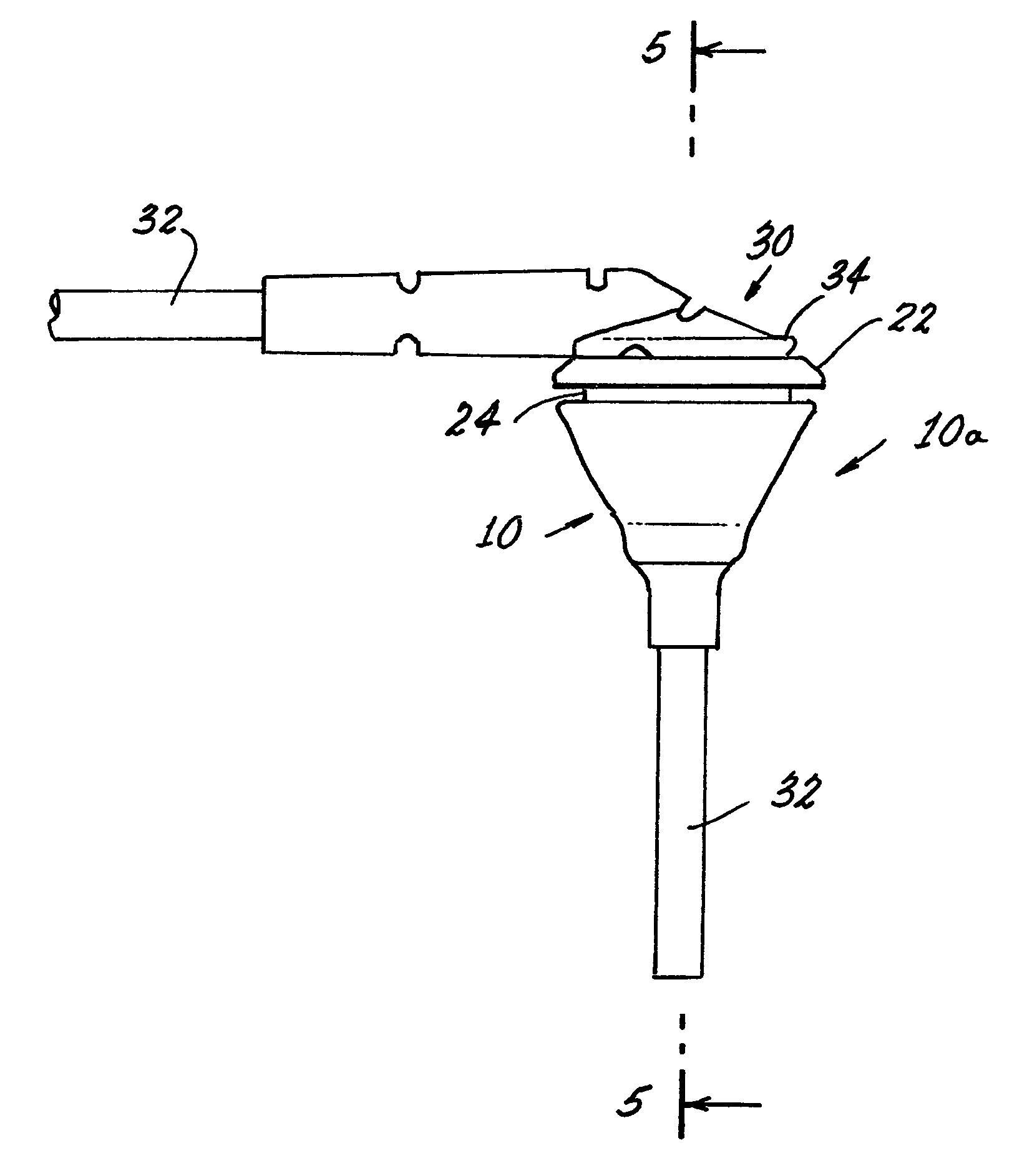

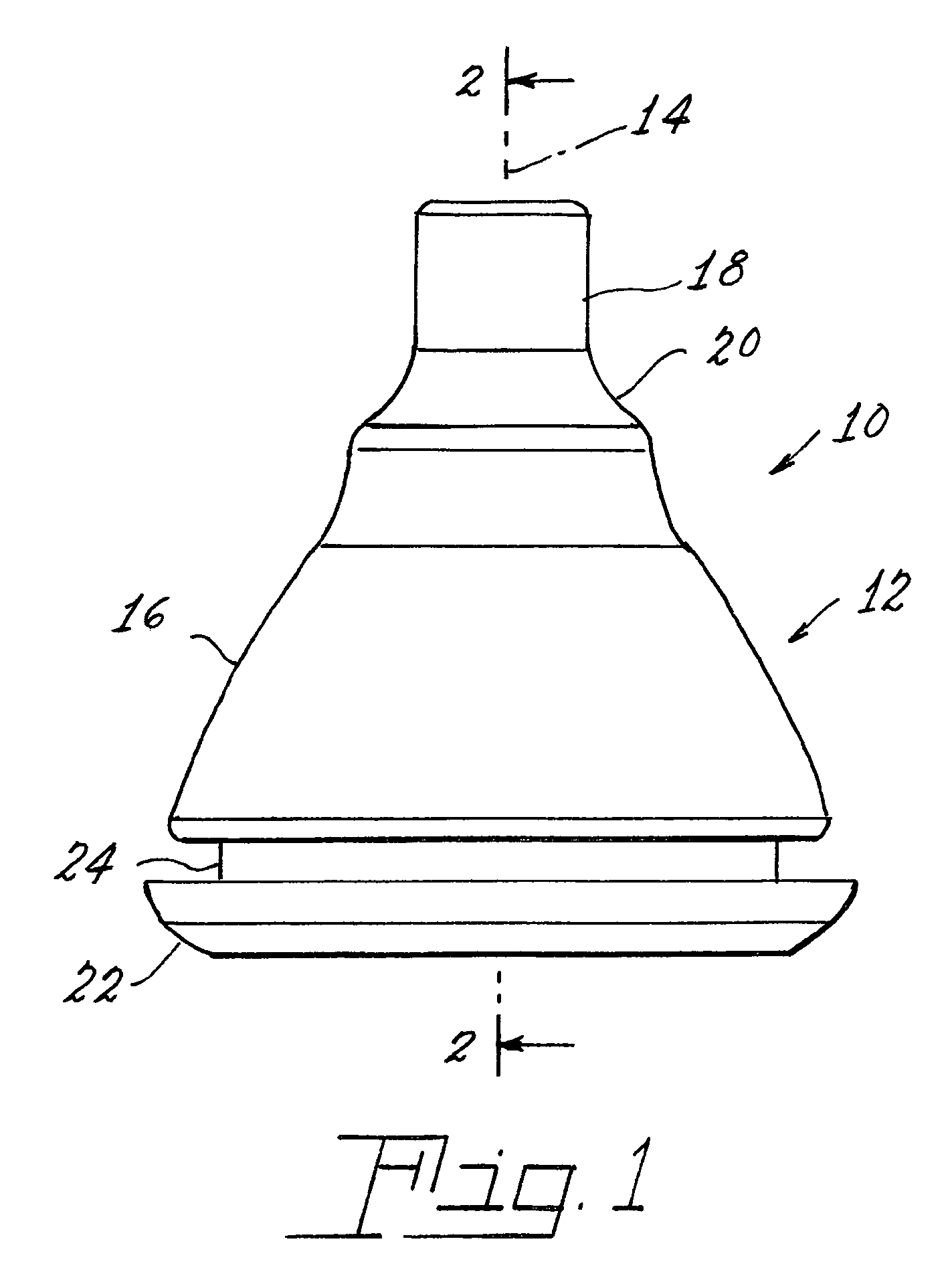

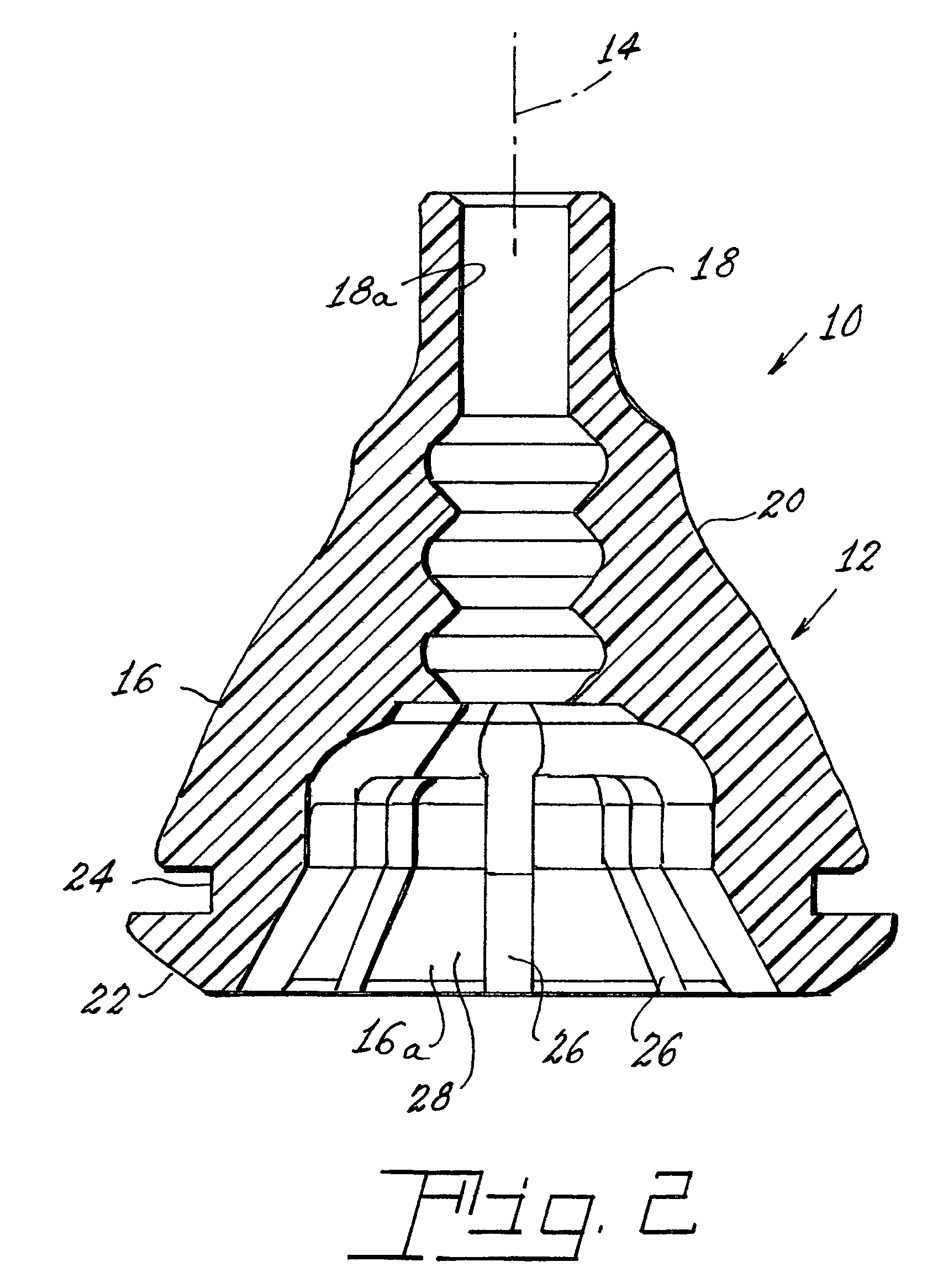

Low insertion force seating grommet assembly

A low insertion force seating grommet assembly (10a) has a hollow body (12) arrayed along a longitudinal axis (14). The body (12) has a wide end (16) and a narrow end (18) connected by an intermediate portion (20). The narrow end (18) has a cylindrical aperture (18a) and the wide end (16) has a cup-shaped aperture (16a). A flange (22) surrounds the wide end (16) and is provided with a wall-opening engaging portion (24). Longitudinally extending relief grooves (26) are formed on the internal surface (28) of the cup-shaped aperture (18a). A cable (32) is frictionally engaged in the cylindrical aperture and penetrates the cup-shaped aperture. A cover (30) closes the cup-shaped aperture. The cable enters the cover along the longitudinal axis and exits the cover at an angle of 90 degrees relative to the longitudinal axis.

Owner:OSRAM SYLVANIA INC

Contact grid array system

InactiveUS20070141863A1Coupling device detailsElectrically conductive adhesive connectionsDevice materialElectrical connection

A scalable, low cost, reliable, compliant, low profile, low insertion force, high-density, separable and reconnectable connector for high speed, high performance electronic circuitry and semiconductors. The electrical connector can be used to make, for example, electrical connections from components such as a Printed Circuit Board (PCB) to another PCB, MPU, NPU, or other semiconductor device. A normalized working range for an array of elastic contacts of the interposer can be about 0.2 to 1.0. A reversible normalized working range is maintained through multiple connections and reconnections using a highly elastic material for the contact arms. In one aspect, a first electrical component having a first array pitch can be connected to a second electrical component having a second array pitch.

Owner:NEOCONIX INC

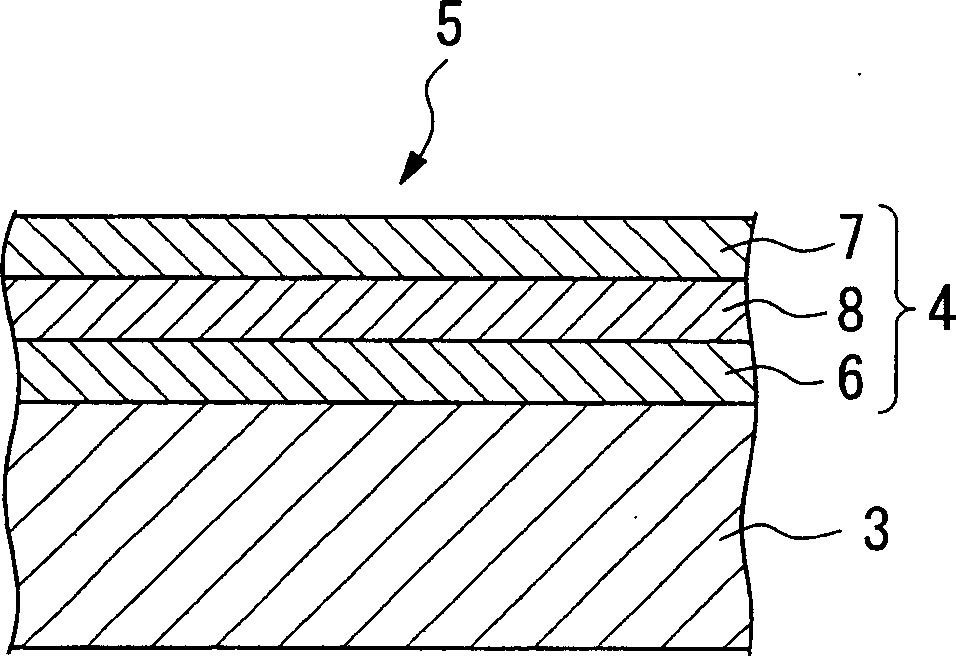

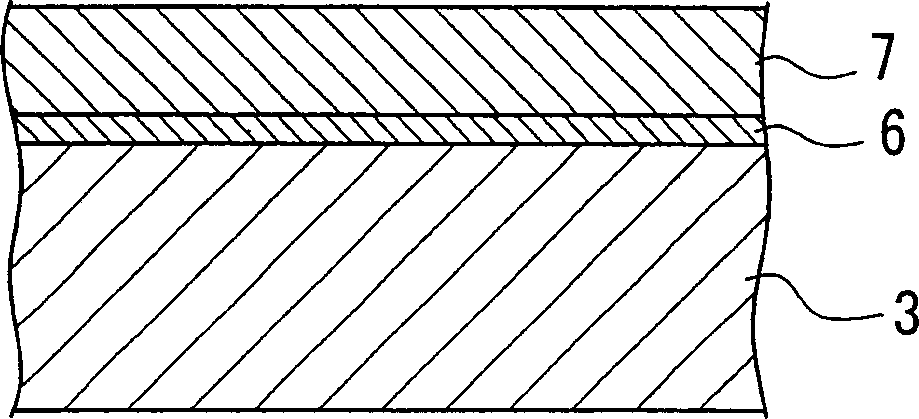

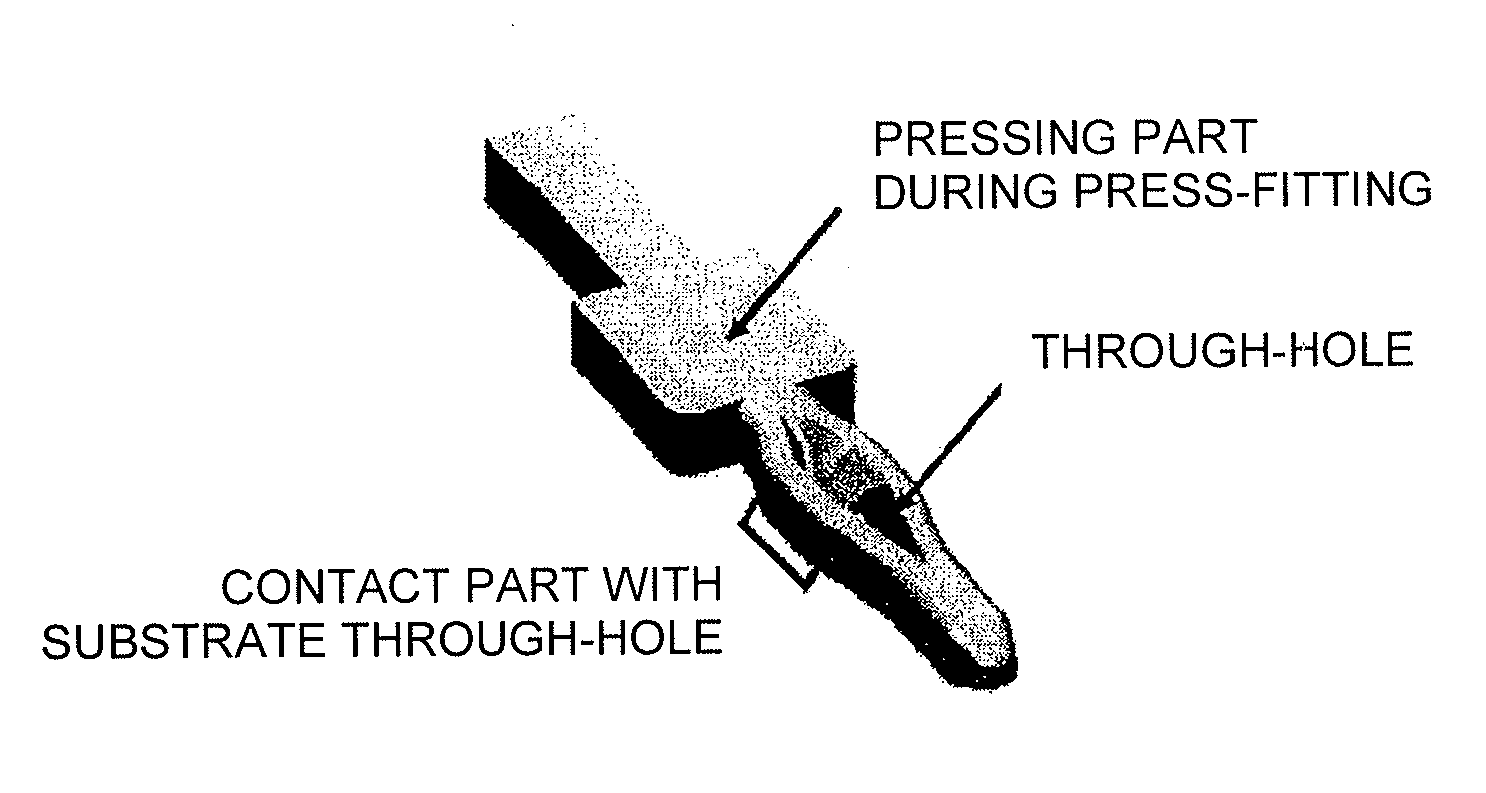

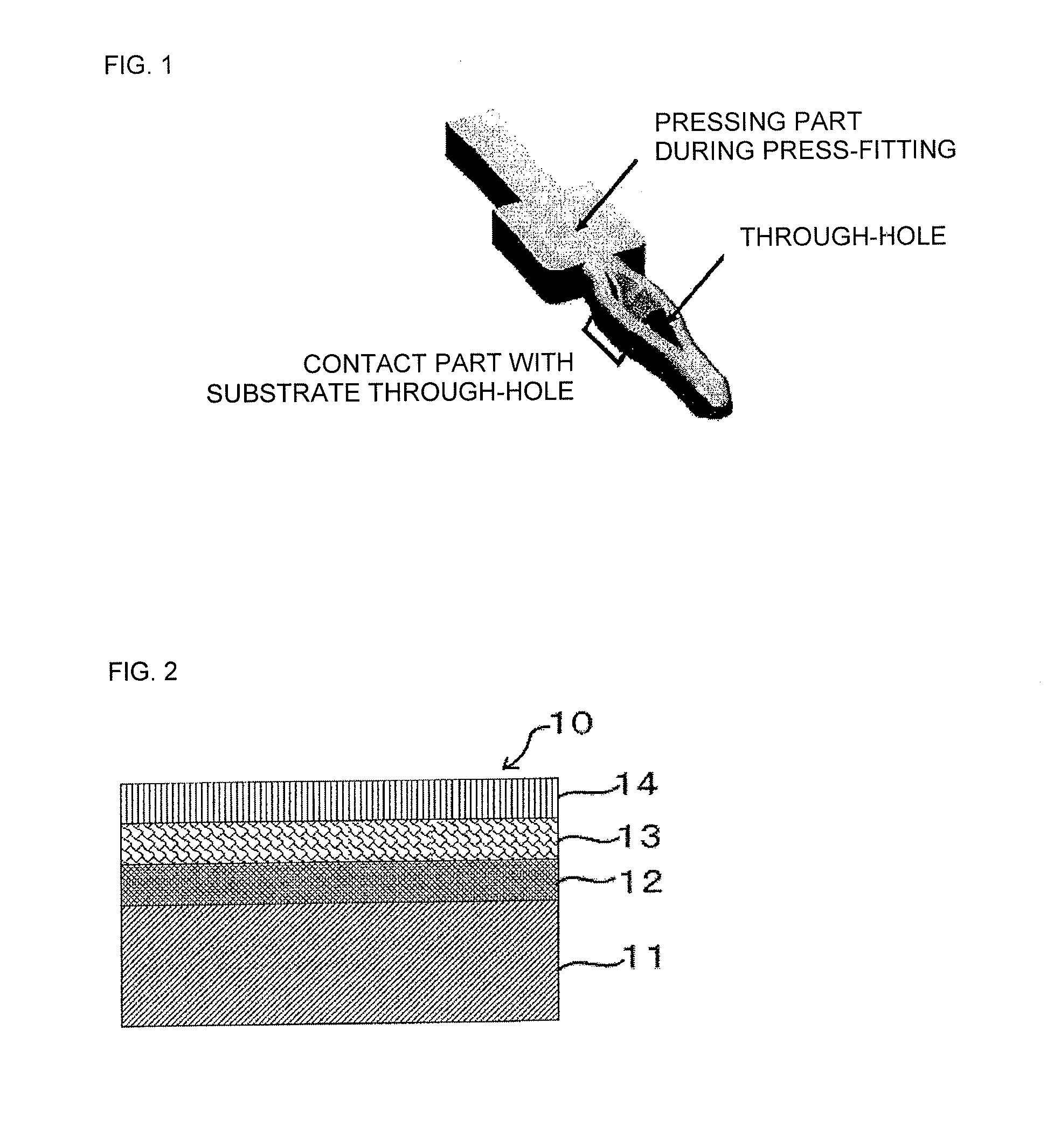

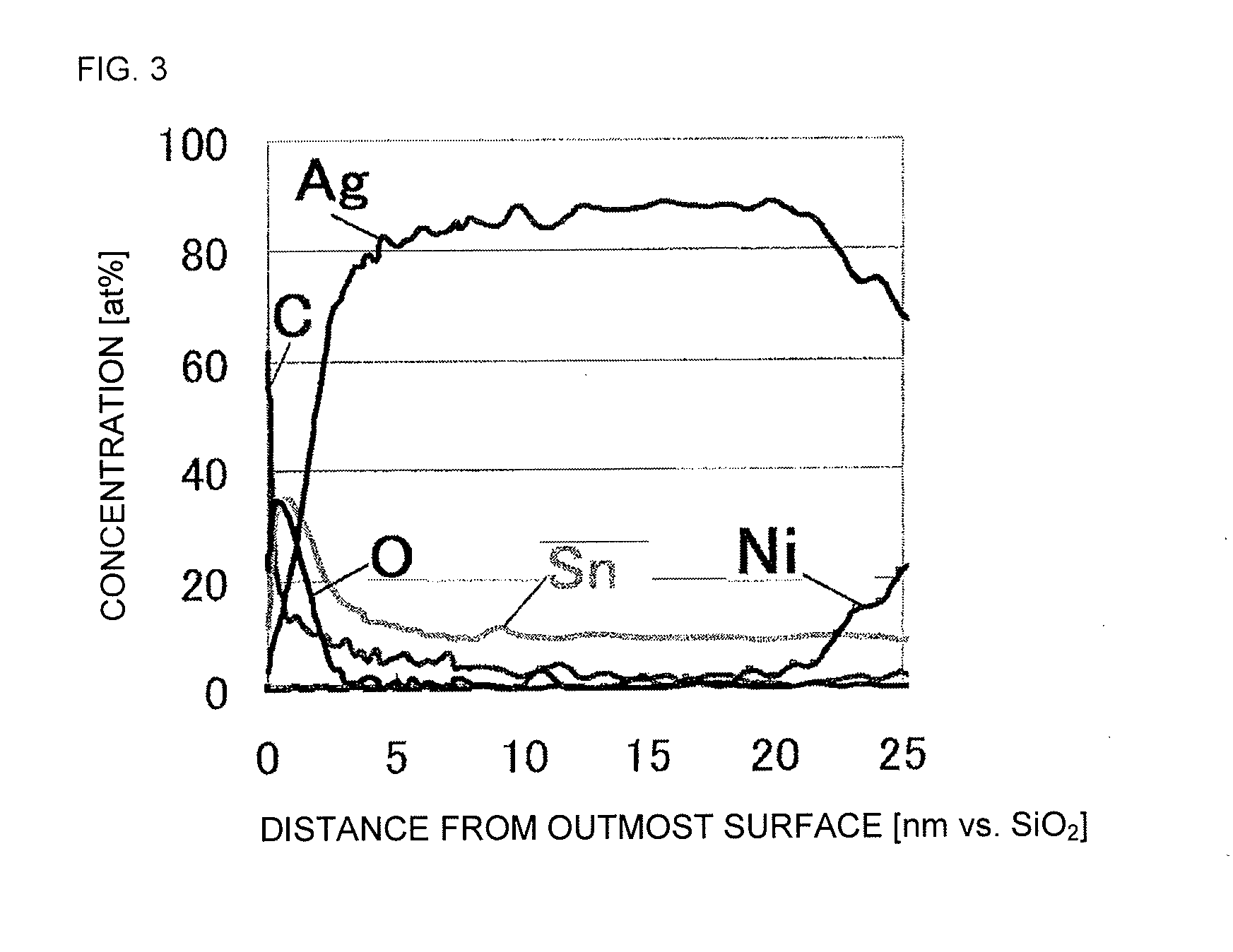

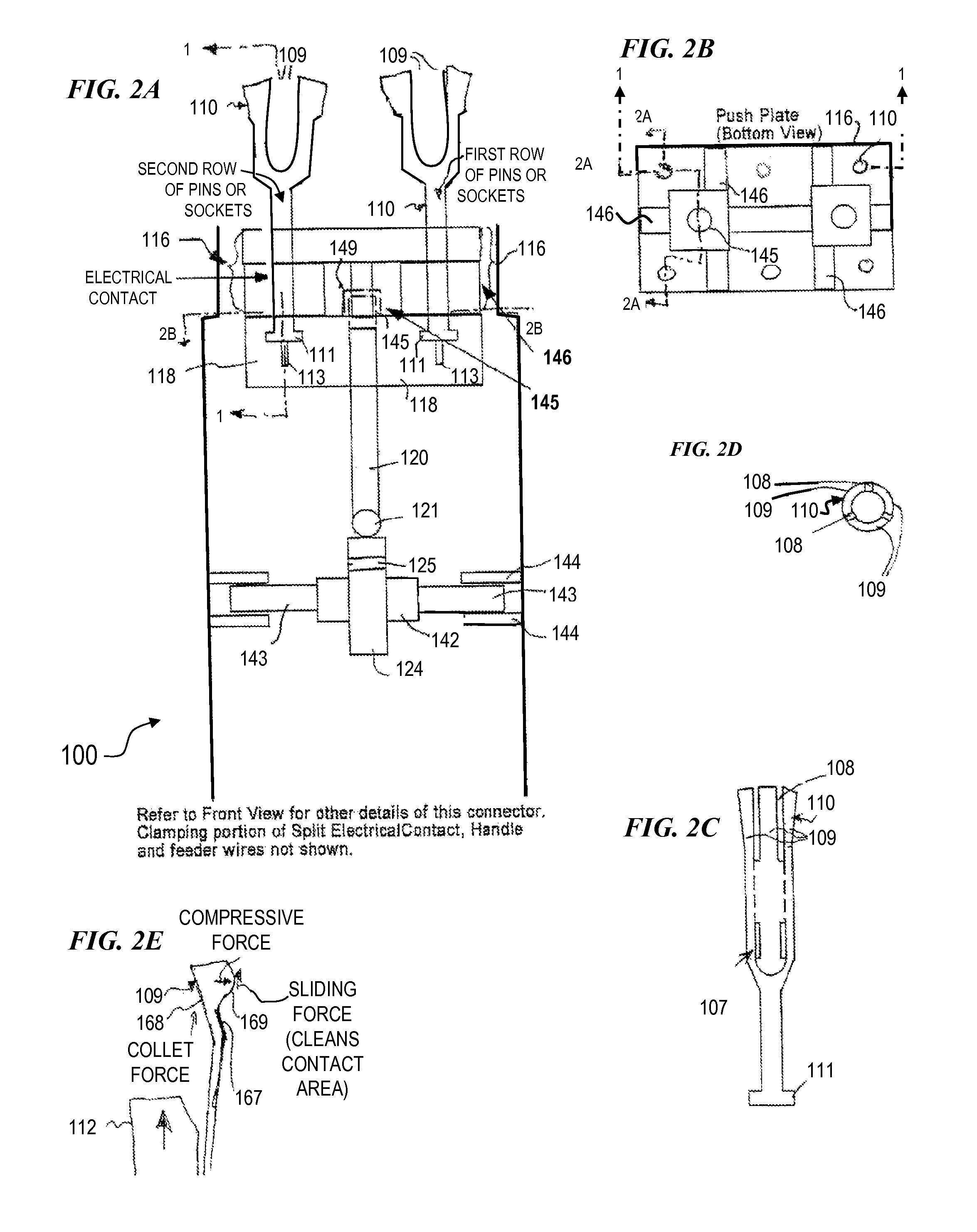

Press-fit terminal and electronic component using the same

ActiveUS20150011132A1Excellent whisker resistanceLower insertion forceElectrically conductive connectionsCoupling contact membersLow insertion forceSurface layer

There are provided a press-fit terminal which has an excellent whisker resistance and a low inserting force, is unlikely to cause shaving of plating when the press-fit terminal is inserted into a substrate, and has a high heat resistance, and an electronic component using the same. A press-fit terminal comprises: a female terminal connection part provided at one side of an attached part to be attached to a housing; and a substrate connection part provided at the other side and attached to a substrate by press-fitting the substrate connection part into a through-hole formed in the substrate. At least the substrate connection part has the surface structure described below, and the press-fit terminal has an excellent whisker resistance. The surface structure comprises: an A layer formed as an outermost surface layer and formed of Sn, In, or an alloy thereof; a B layer formed below the A layer and constituted of one or two or more selected from the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os, and Ir; and a C layer formed below the B layer and constituted of one or two or more selected from the group consisting of Ni, Cr, Mn, Fe, Co, and Cu. The A layer has a thickness of 0.002 to 0.2 μm. The B layer has a thickness of 0.001 to 0.3 μm. The C layer has a thickness of 0.05 μm or larger.

Owner:JX NIPPON MINING& METALS CORP

Method and apparatus for power outlet and plug having low-insertion-force connector

InactiveUS7534124B1High compression forceGood wiping actionEngagement/disengagement of coupling partsVehicle connectorsLow insertion forceContact force

In some embodiments, the present invention provides an independently tightening collet surrounding each socket for each of a plurality of corresponding high-electrical-power prongs, wherein the collet is loosened for normal (low-insertion-force) insertion and withdrawal of the plug from the outlet. Once the plug is inserted, the collet is tightened, providing a high-contact force to lower the contact resistance and to help keep the plug from coming unplugged. In some embodiments, the plug is not “locked”, in that a tension force pulling on the plug will overcome the contact force at a point before the plug or outlet is damaged, and the plug is allowed to come unplugged. In some embodiments, engaging the collet will also provide a wiping or sliding motion between the prong and socket for each connection, thus wiping at least some dirt or corrosion away and providing a lower-resistance better electrical contact.

Owner:MECHANICAL ANSWERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com