Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve connection workability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

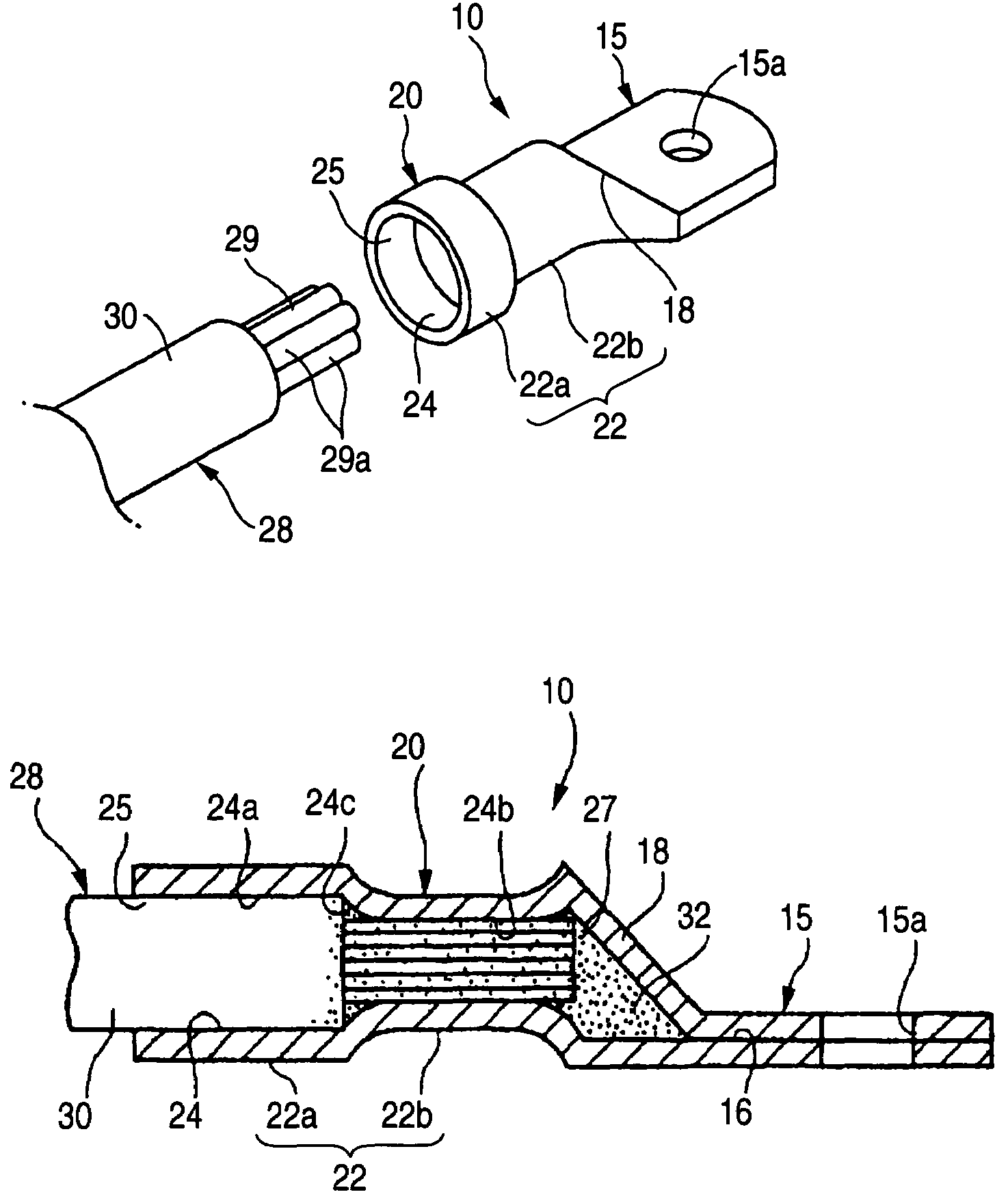

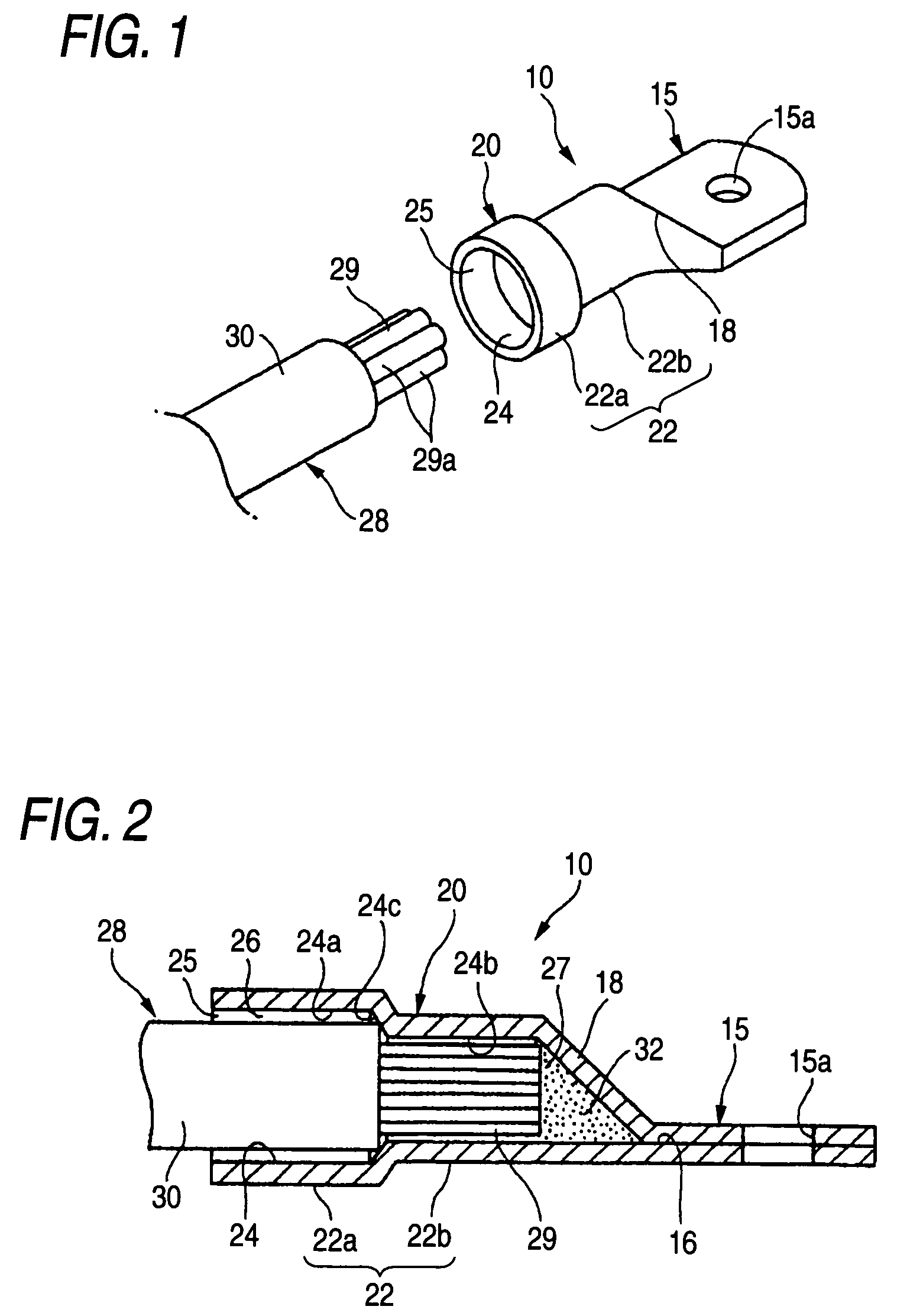

Method of connecting terminal and electric wire

ActiveUS7174633B2Few partsLow costPrinted circuit assemblingElectrically conductive adhesive connectionsEpoxyElectricity

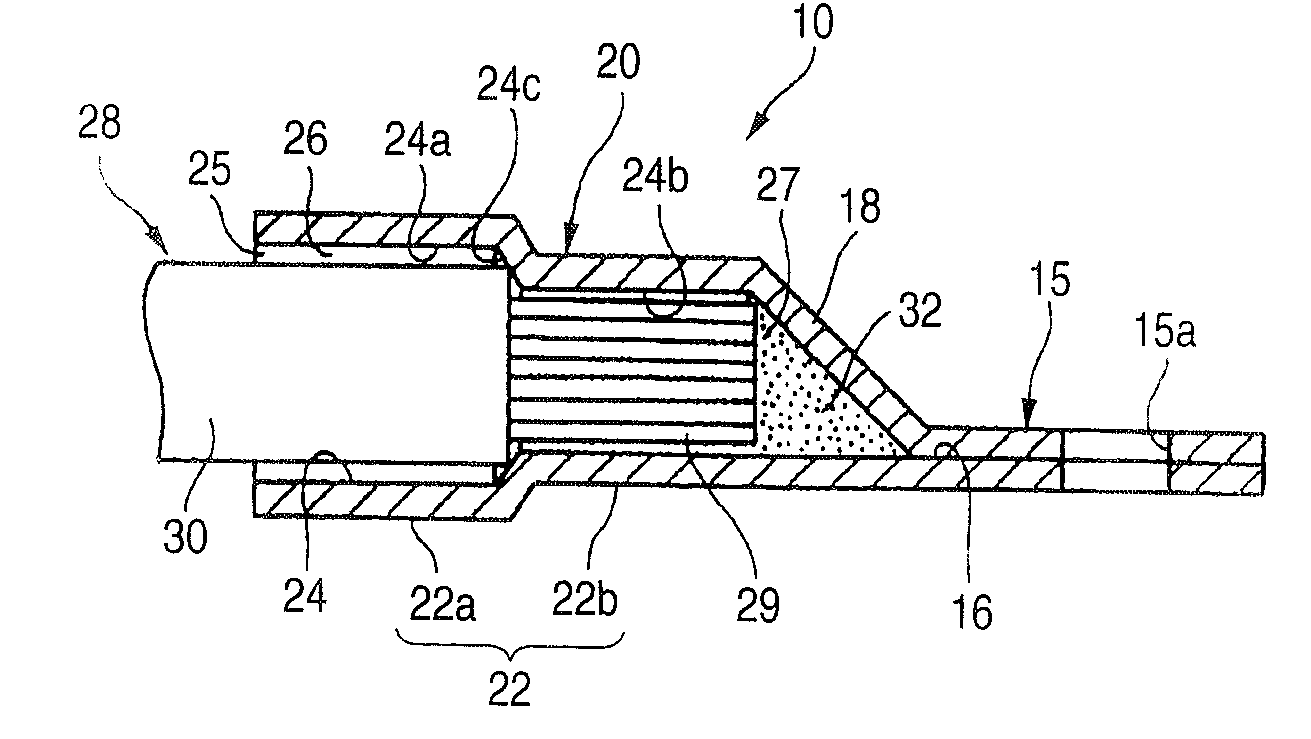

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

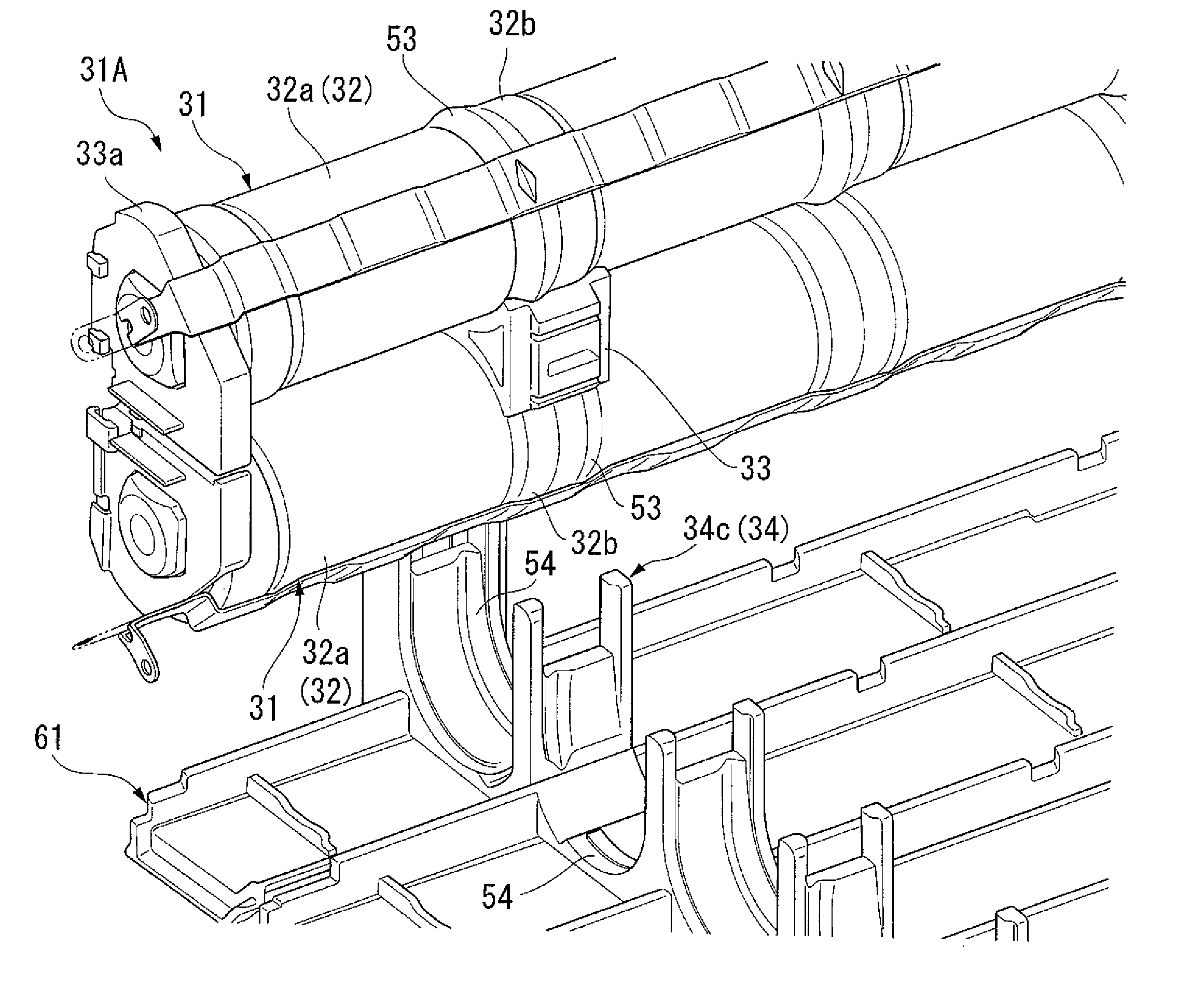

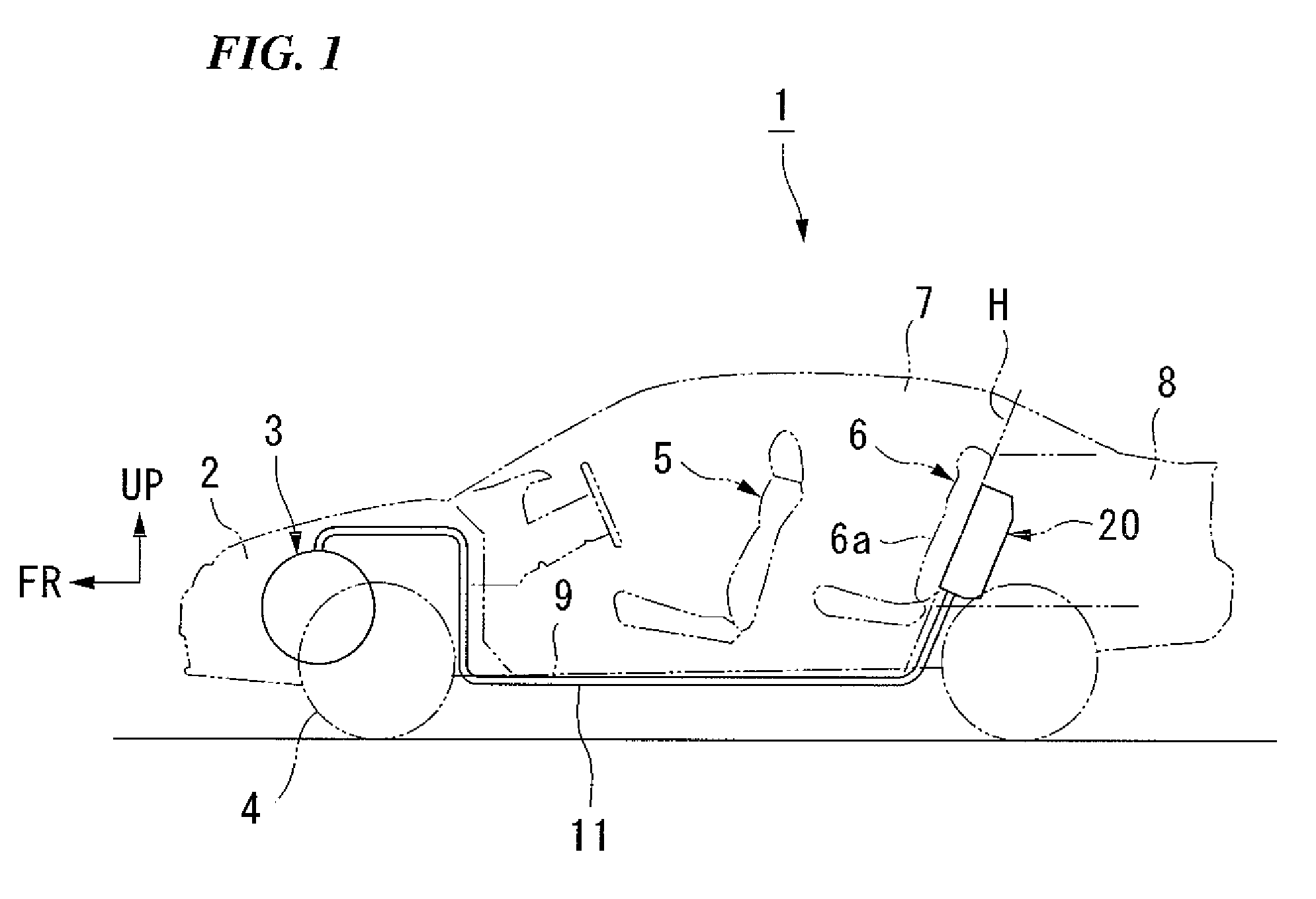

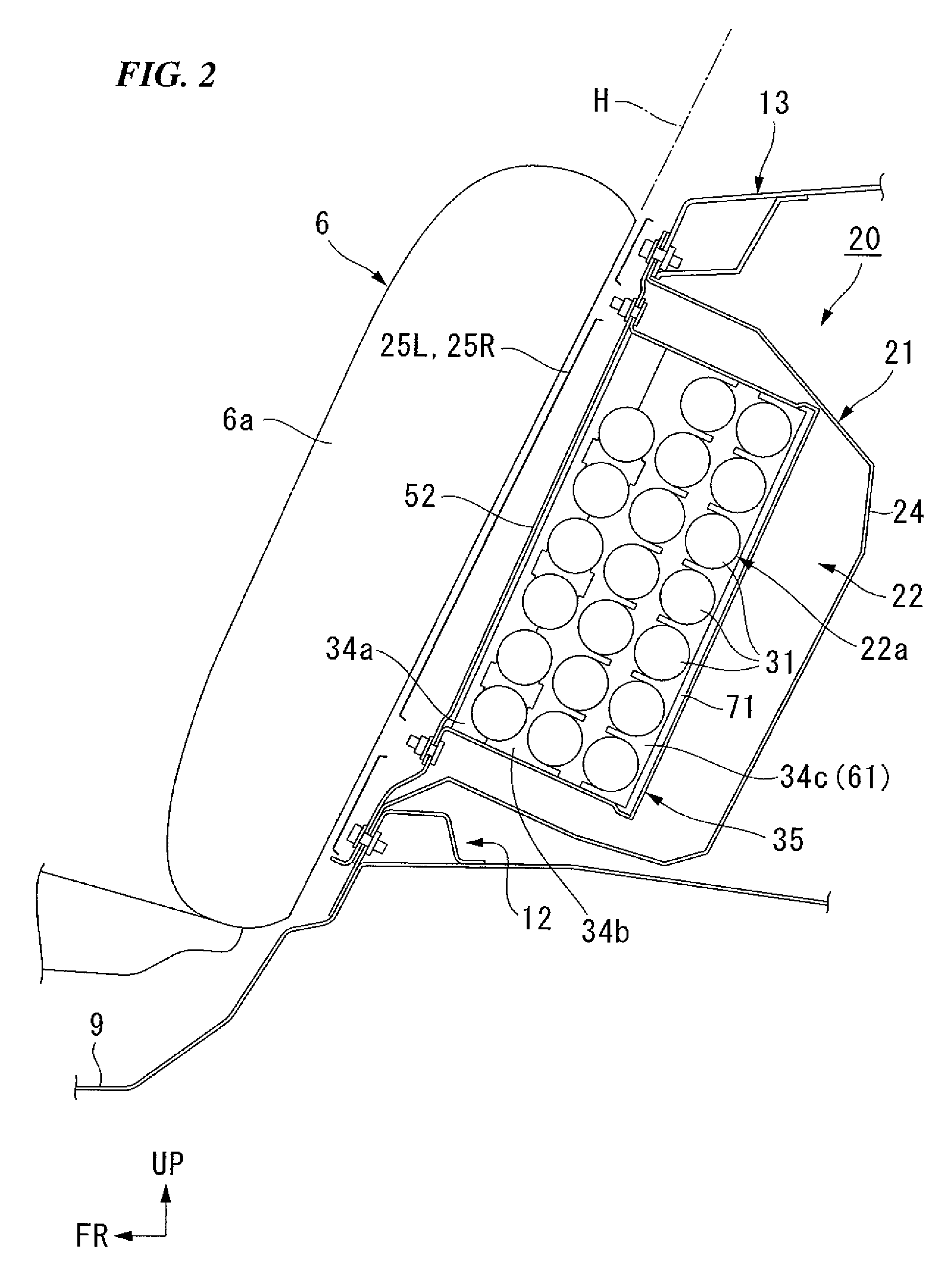

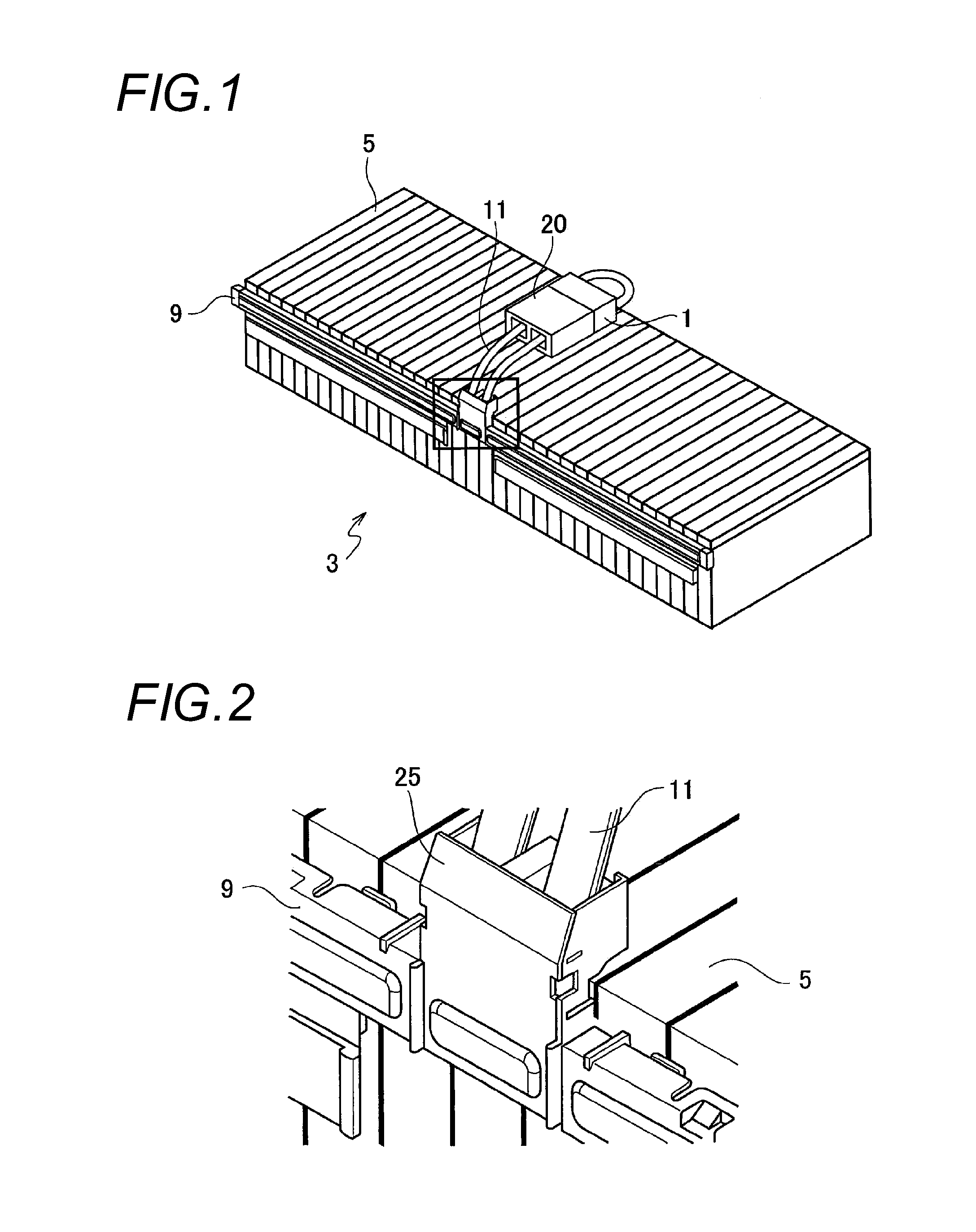

Temperature sensor mounting structure and battery module structure

ActiveUS7766544B2Precise positioningImprove temperature measurement accuracyThermometer detailsBatteries circuit arrangementsMeasurement deviceElectrical battery

A temperature sensor mounting structure for a battery module that is formed by connecting single cells together in series including: a temperature-measuring device that detects the temperature of the battery module; a covering device that covers the temperature-measuring device; and movement-restricting devices that are removably engaged with the battery module and restrict the movement of the covering device.

Owner:HONDA MOTOR CO LTD

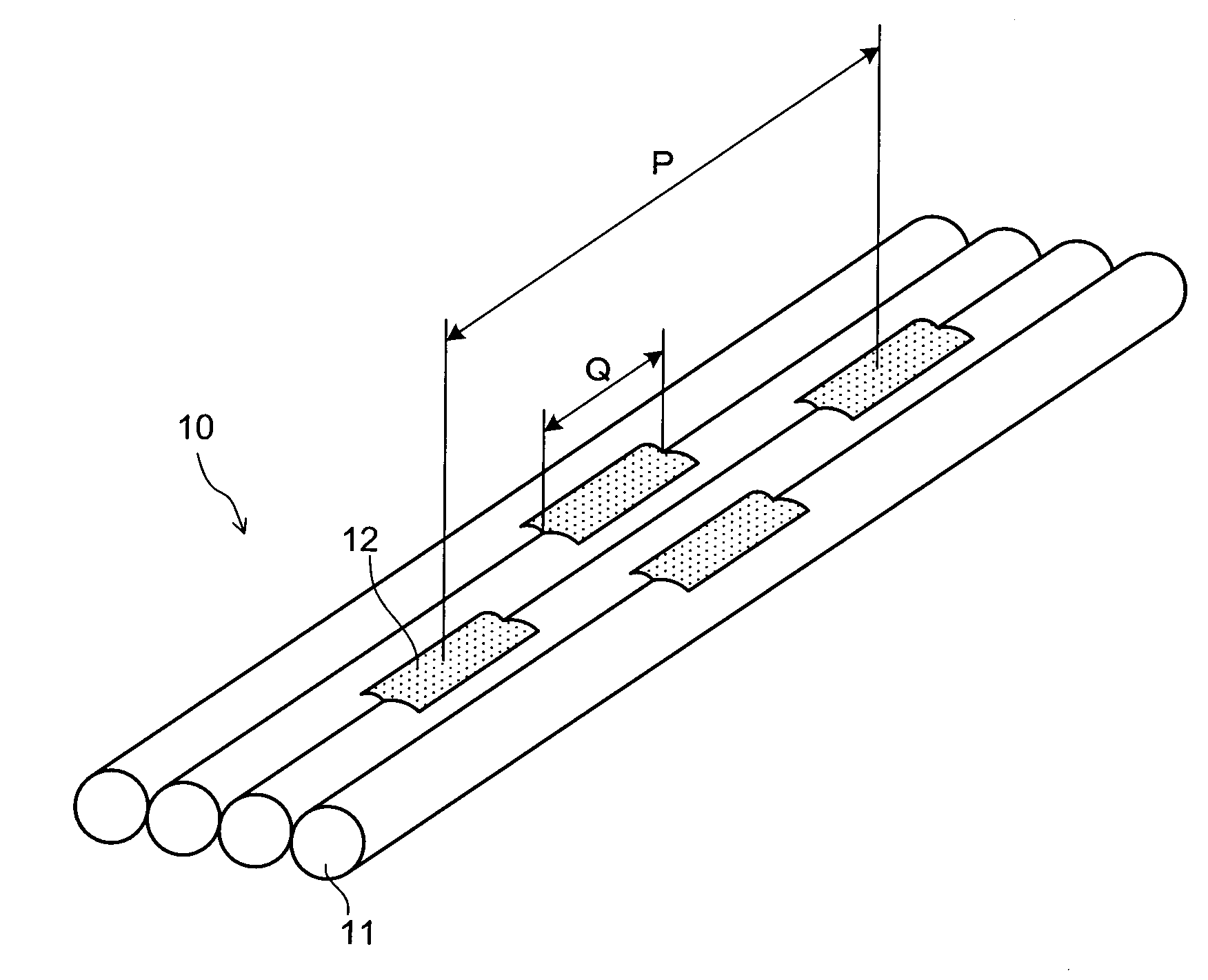

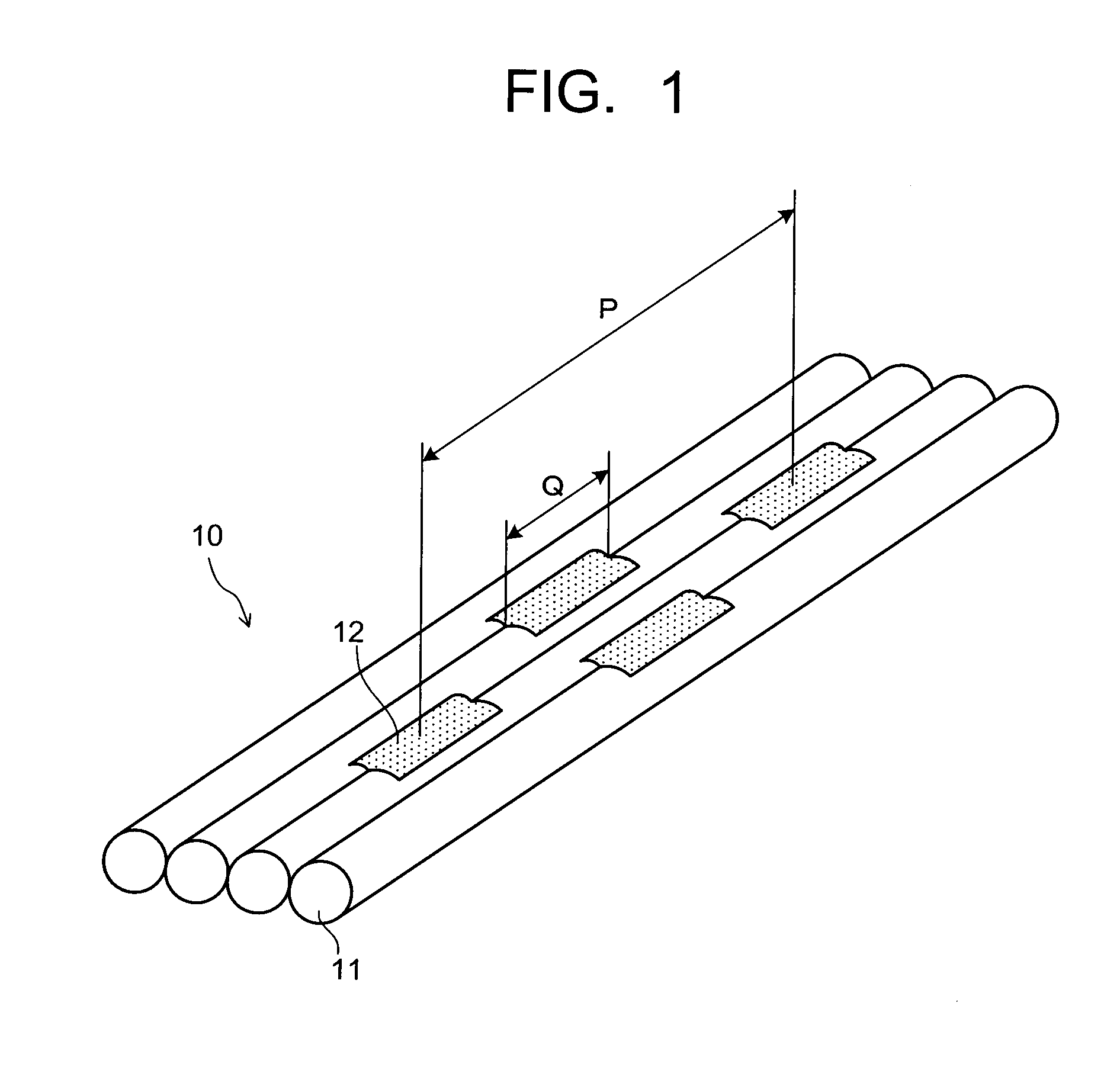

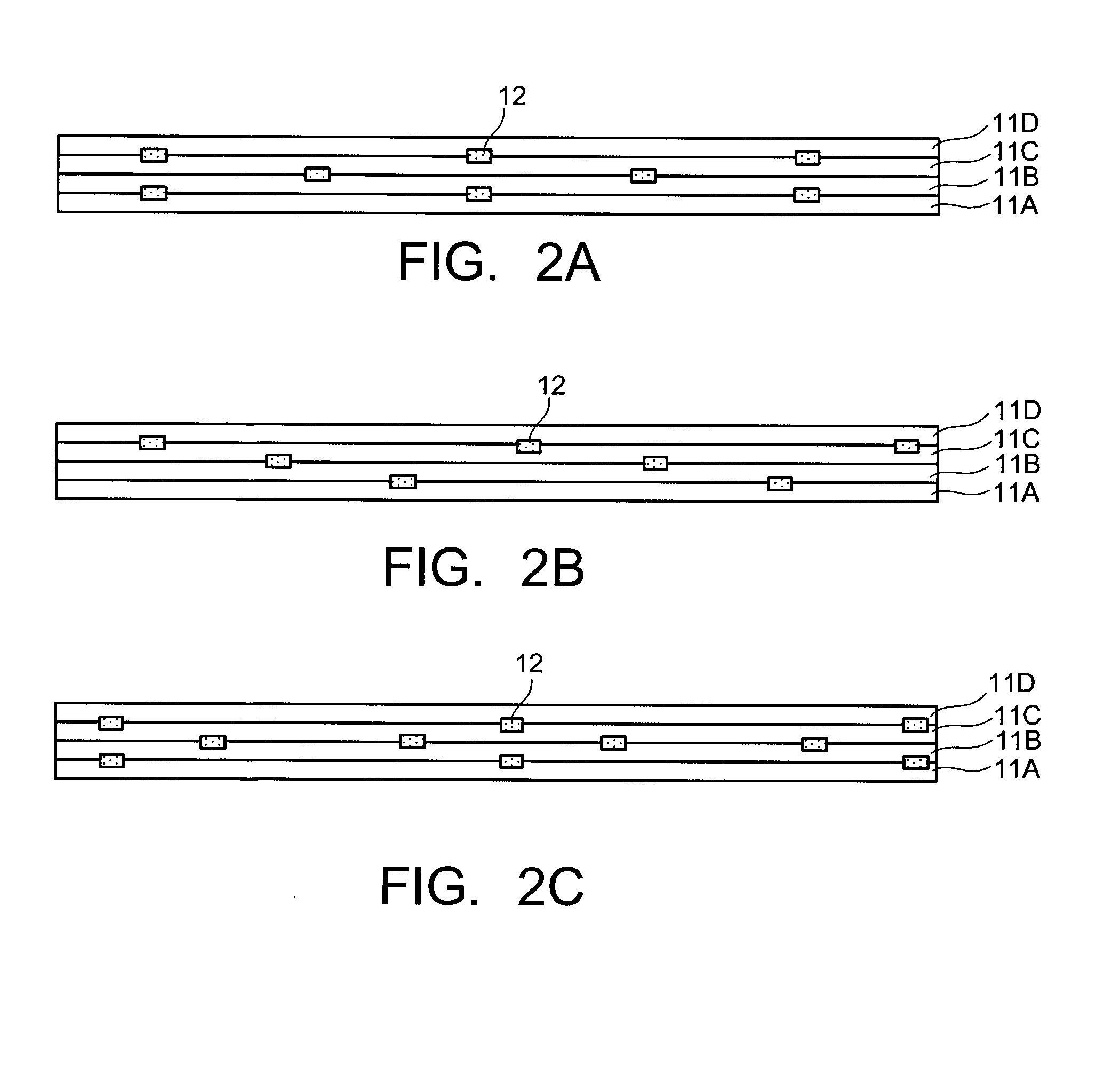

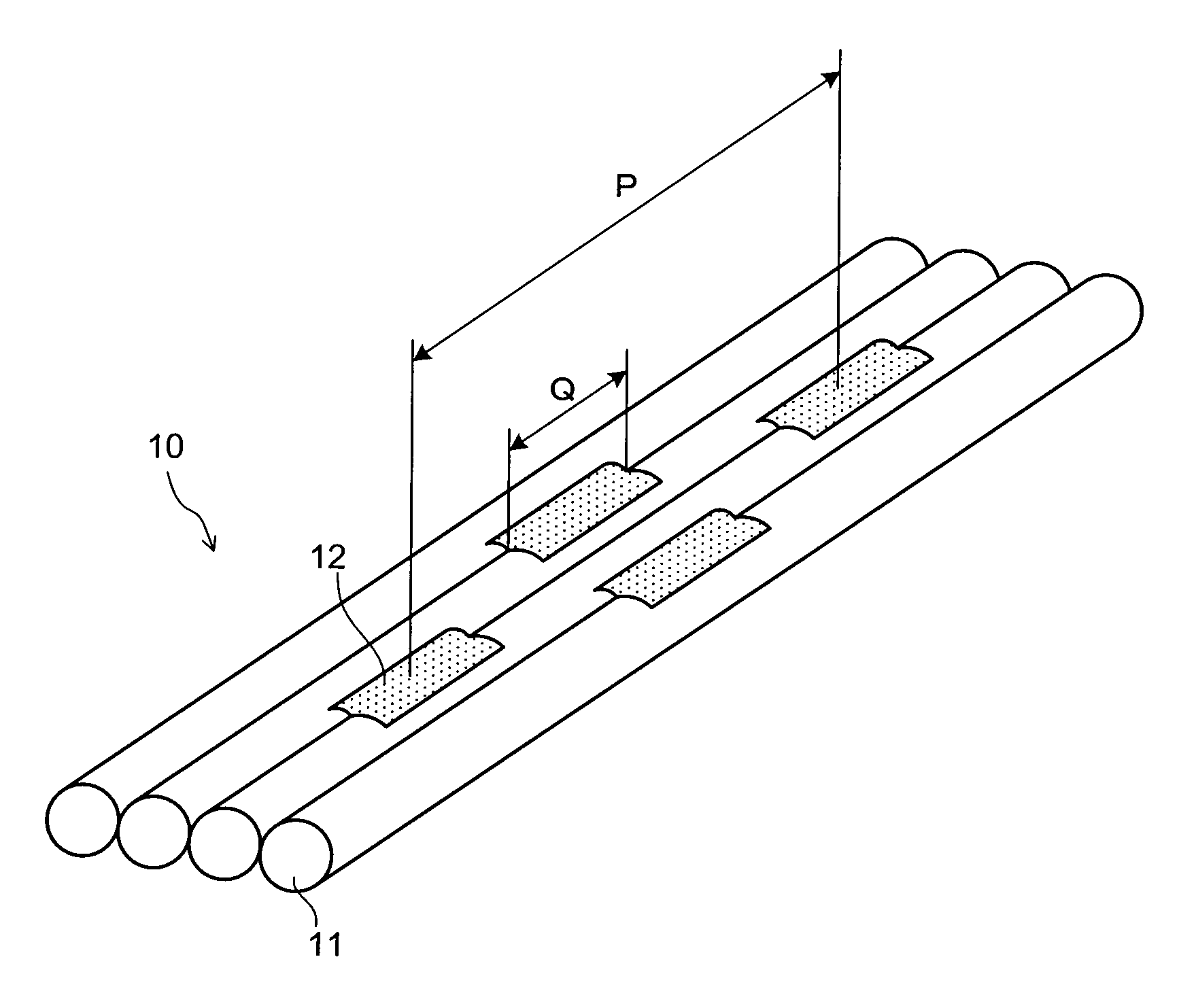

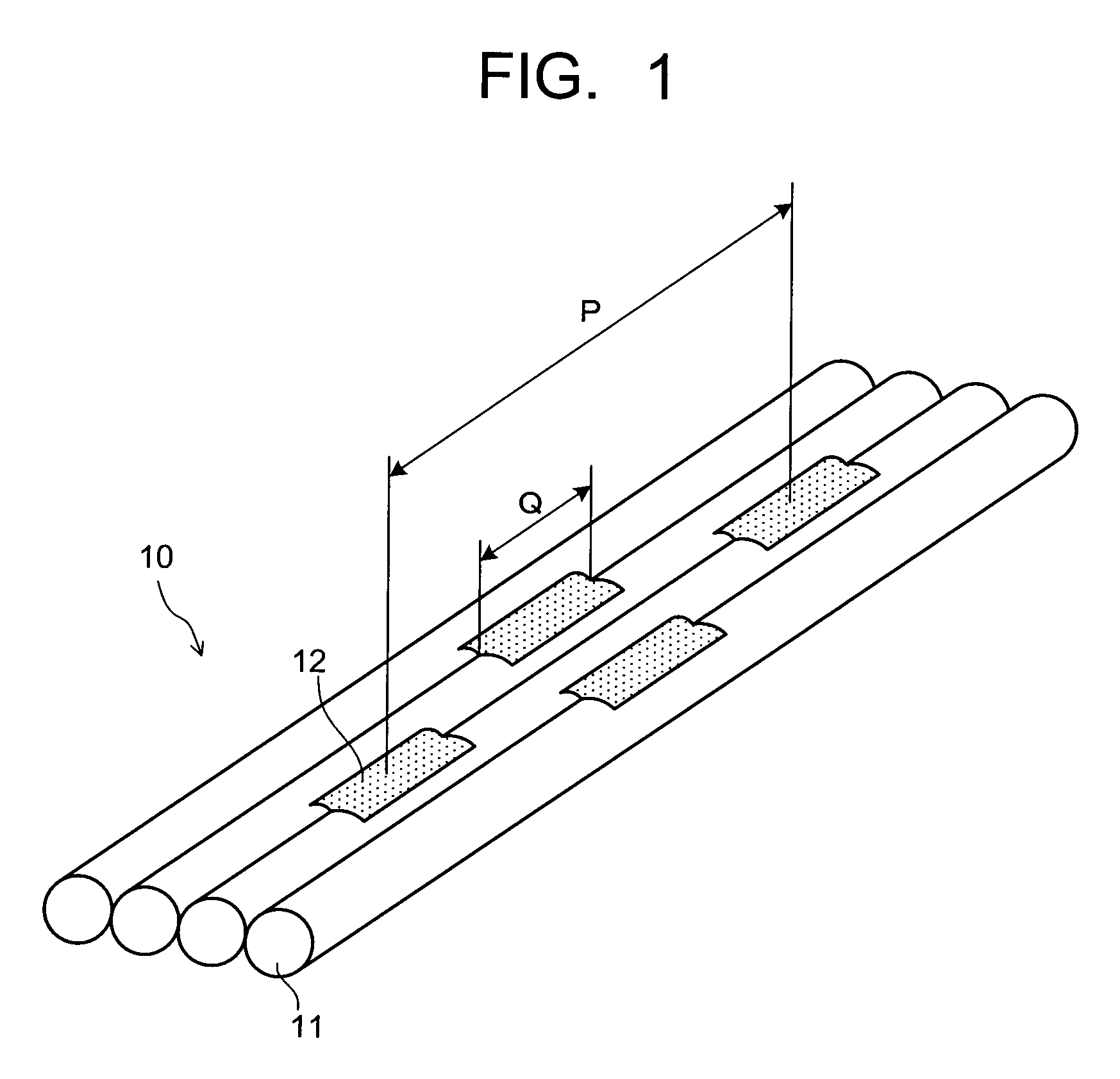

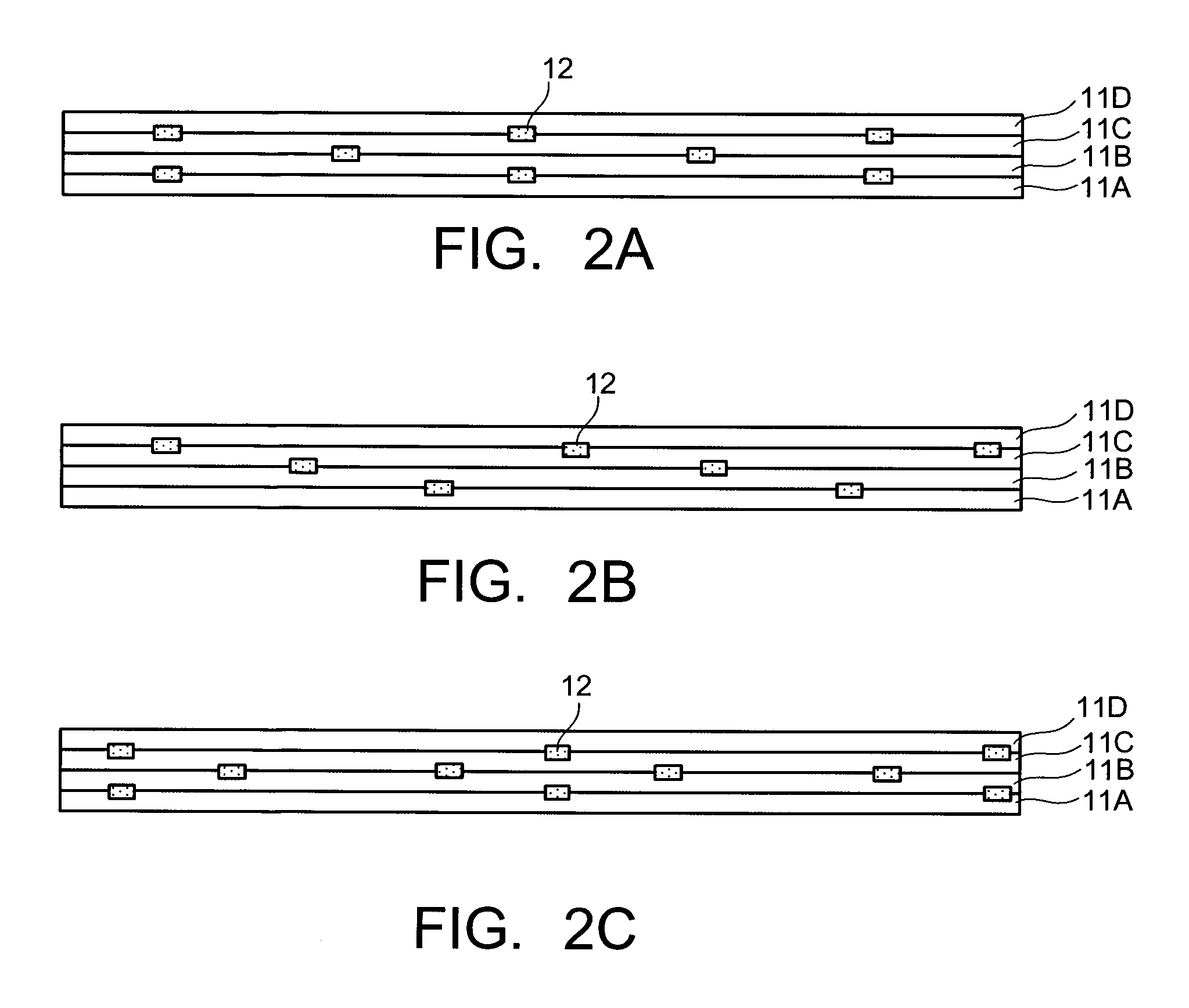

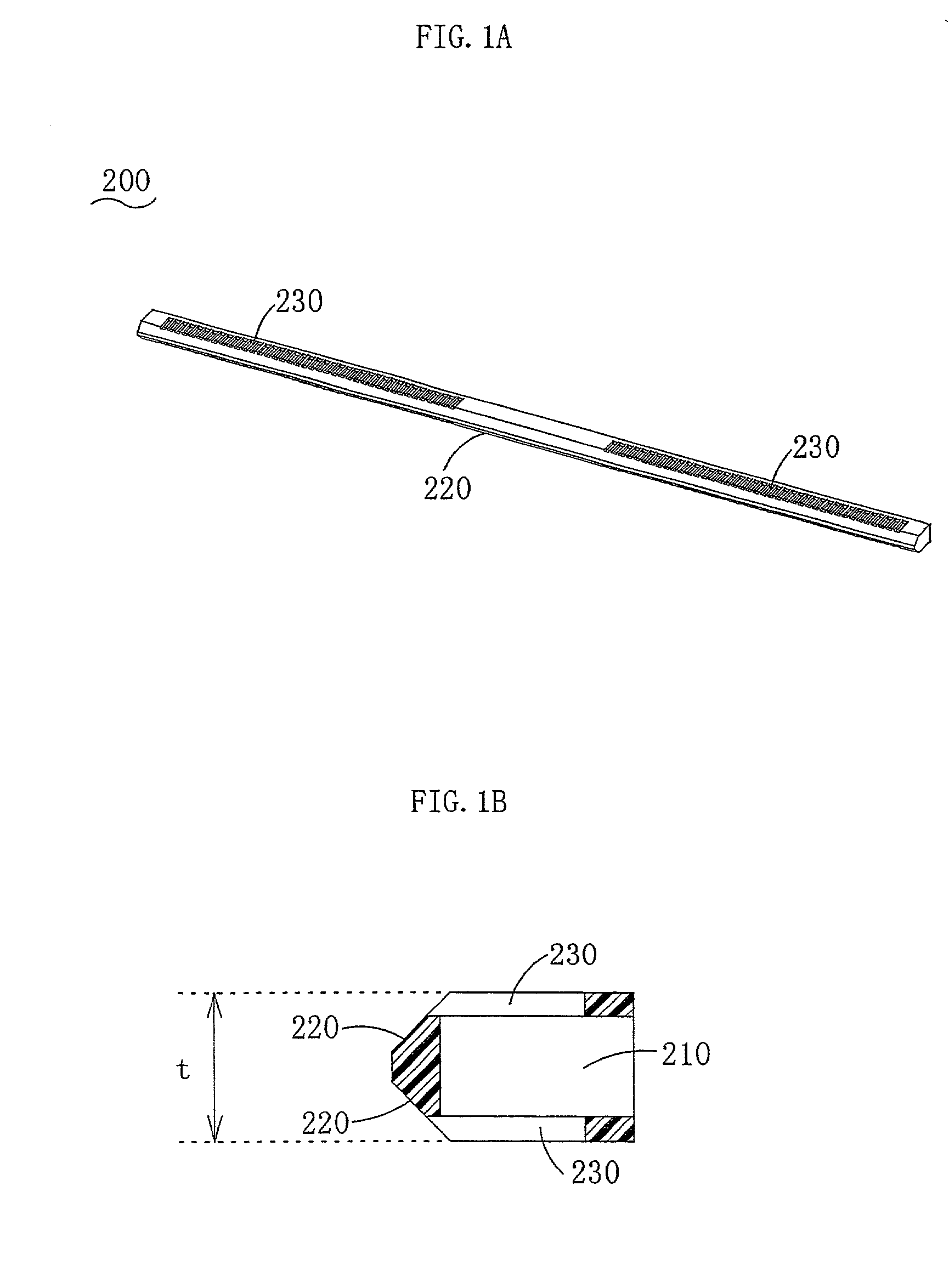

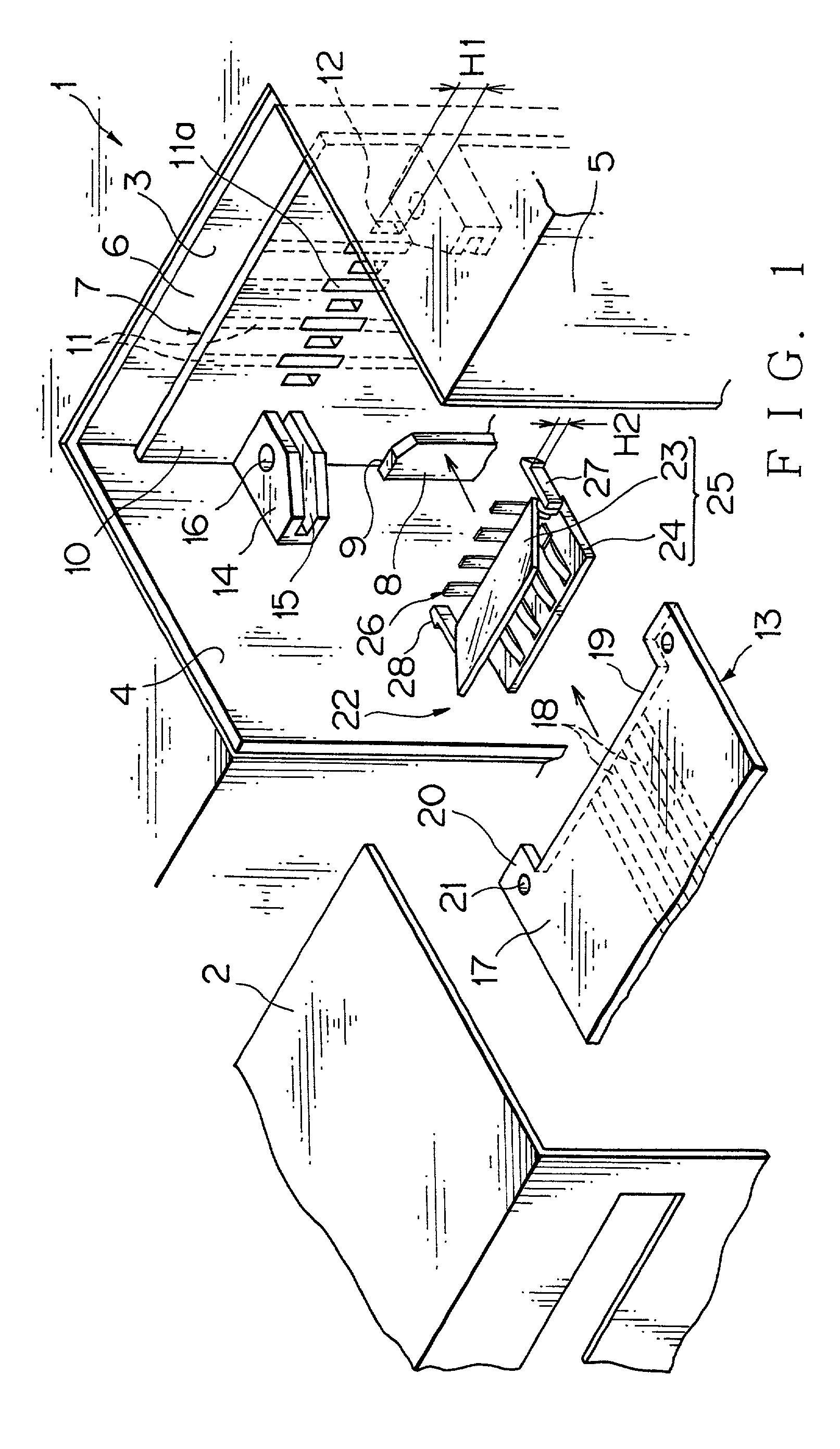

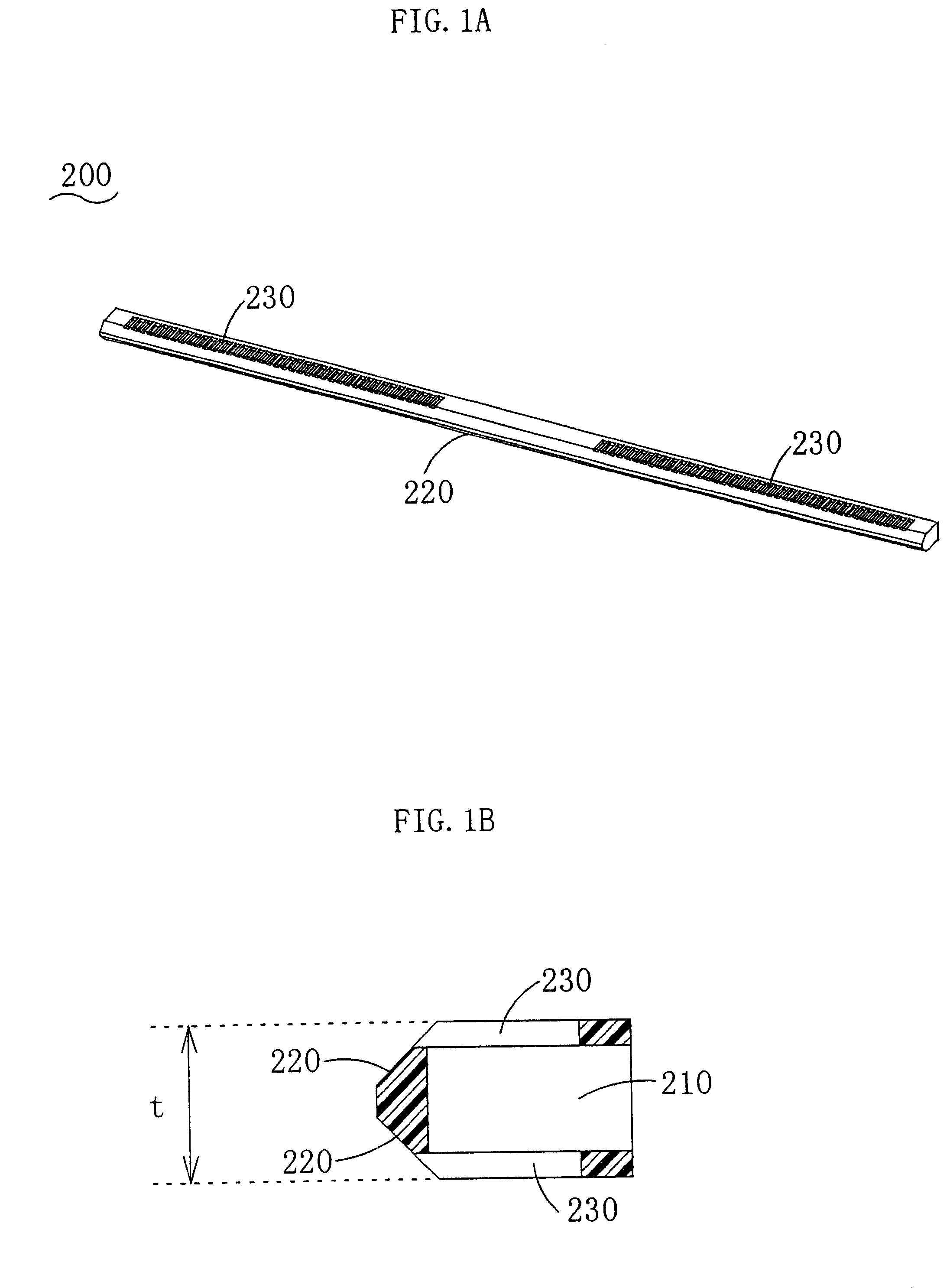

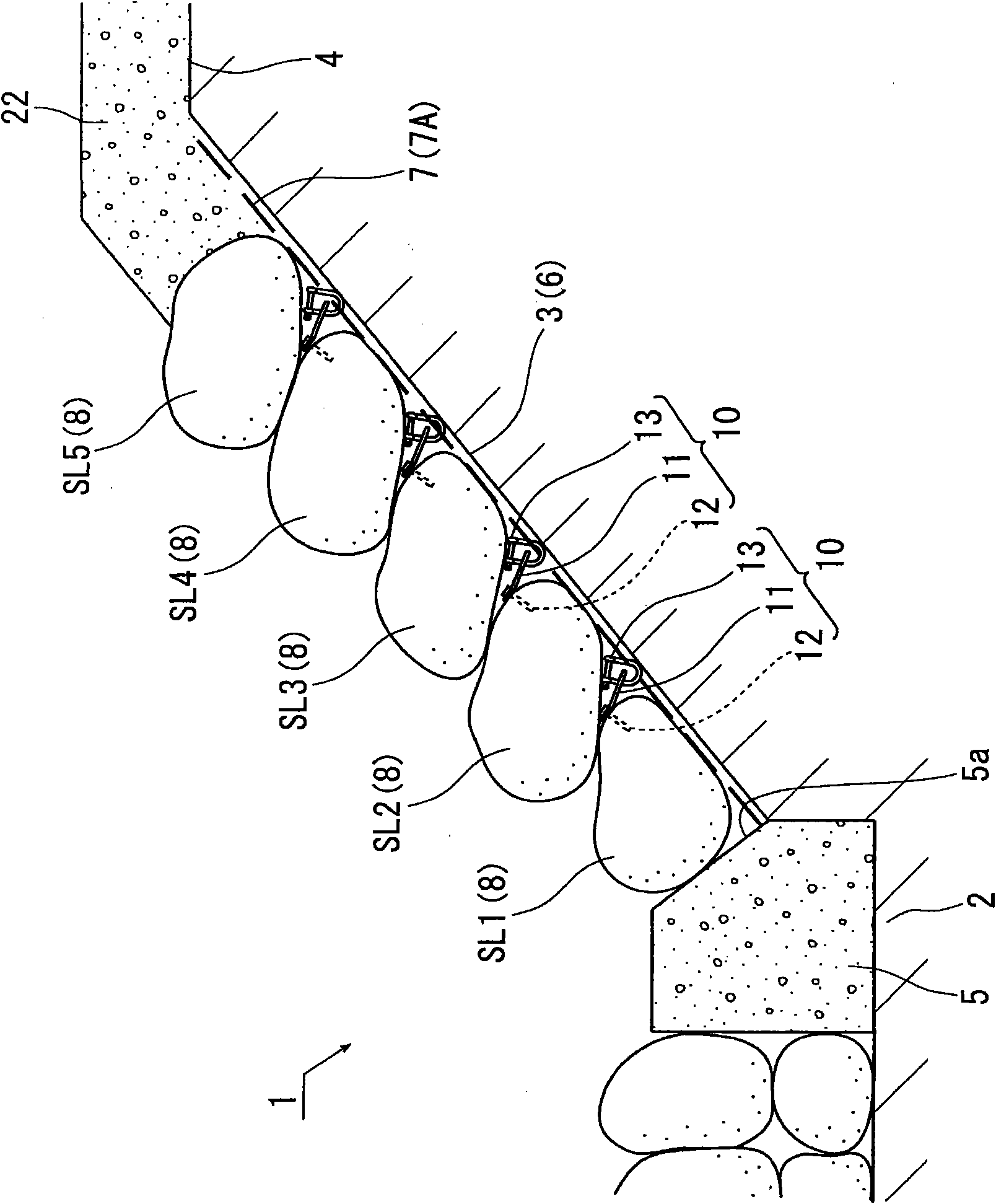

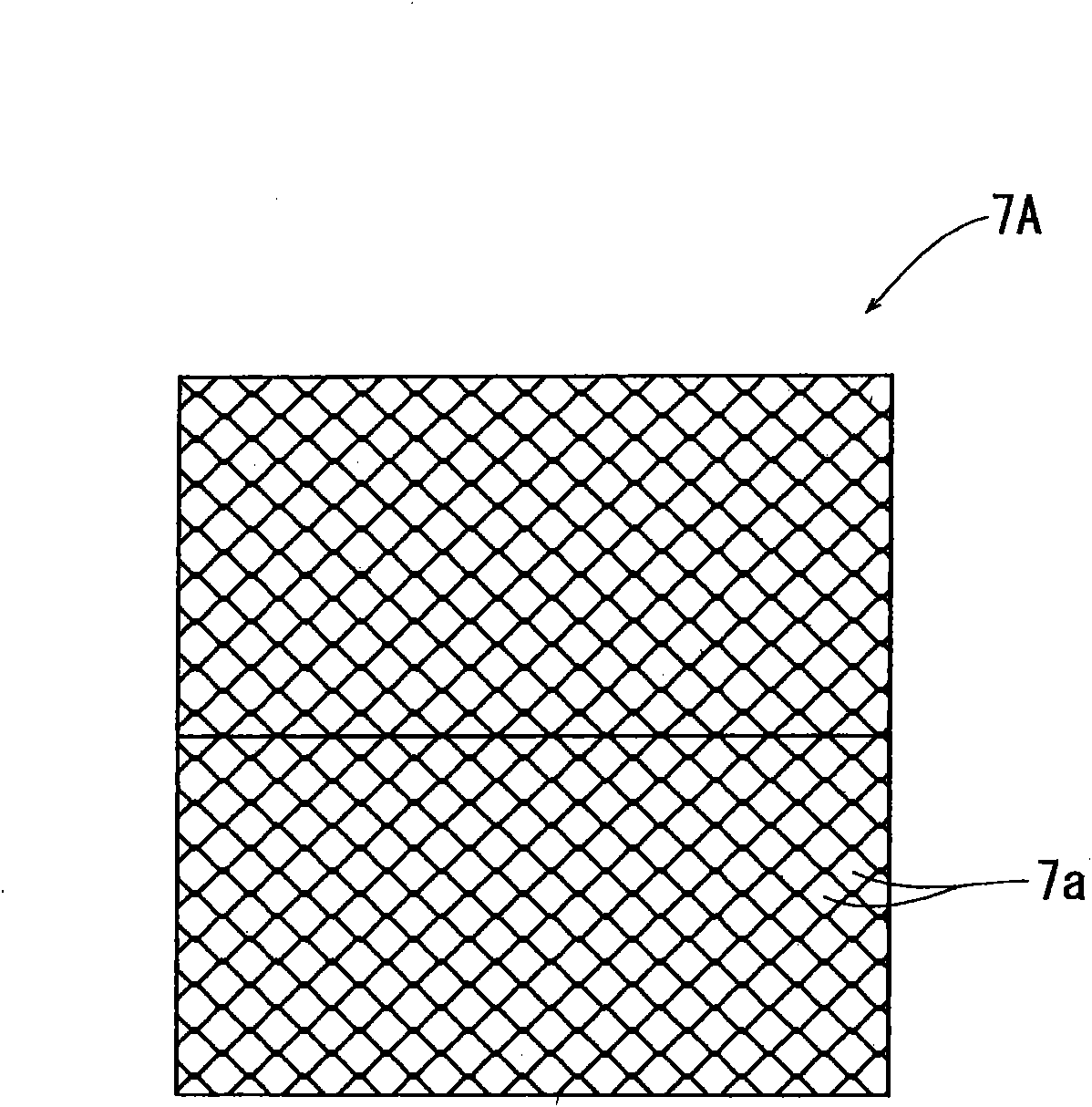

Optical fiber ribbon, method of manufacturing optical fiber ribbon, and optical cable

ActiveUS20140016905A1Reduce strainImprove connection workabilityFibre mechanical structuresBundled fibre light guideEngineeringOptical fiber cable

There is provided an optical fiber ribbon capable of realizing, in an optical cable, sure reliability, a reduction in size and weight, higher density, and a further improvement in workability, a method of manufacturing the same, and an optical cable using such an optical fiber ribbon. An optical fiber ribbon 10 includes four single-core coated optical fibers 11 arranged in parallel on a same plane; and coupling parts 12 arranged at intervals in a length direction and a width direction, each coupling only adjacent two of the single-core coated optical fibers 11, wherein an interval P of the coupling parts 12 coupling the same two single-core coated optical fibers is not less than 20 mm nor more than 90 mm and a length Q of each of the coupling parts 12 is not less than 1 mm nor more than 10 mm.

Owner:FUTONG GRP CO LTD 50 +1

Optical fiber ribbon, method of manufacturing optical fiber ribbon, and optical cable

ActiveUS8787718B2Solve the lack of reliabilityImprove connection workabilityFibre mechanical structuresBundled fibre light guideHigh densityVolumetric Mass Density

There is provided an optical fiber ribbon capable of realizing, in an optical cable, sure reliability, a reduction in size and weight, higher density, and a further improvement in workability, a method of manufacturing the same, and an optical cable using such an optical fiber ribbon. An optical fiber ribbon 10 includes four single-core coated optical fibers 11 arranged in parallel on a same plane; and coupling parts 12 arranged at intervals in a length direction and a width direction, each coupling only adjacent two of the single-core coated optical fibers 11, wherein an interval P of the coupling parts 12 coupling the same two single-core coated optical fibers is not less than 20 mm nor more than 90 mm and a length Q of each of the coupling parts 12 is not less than 1 mm nor more than 10 mm.

Owner:FUTONG GRP CO LTD 50 +1

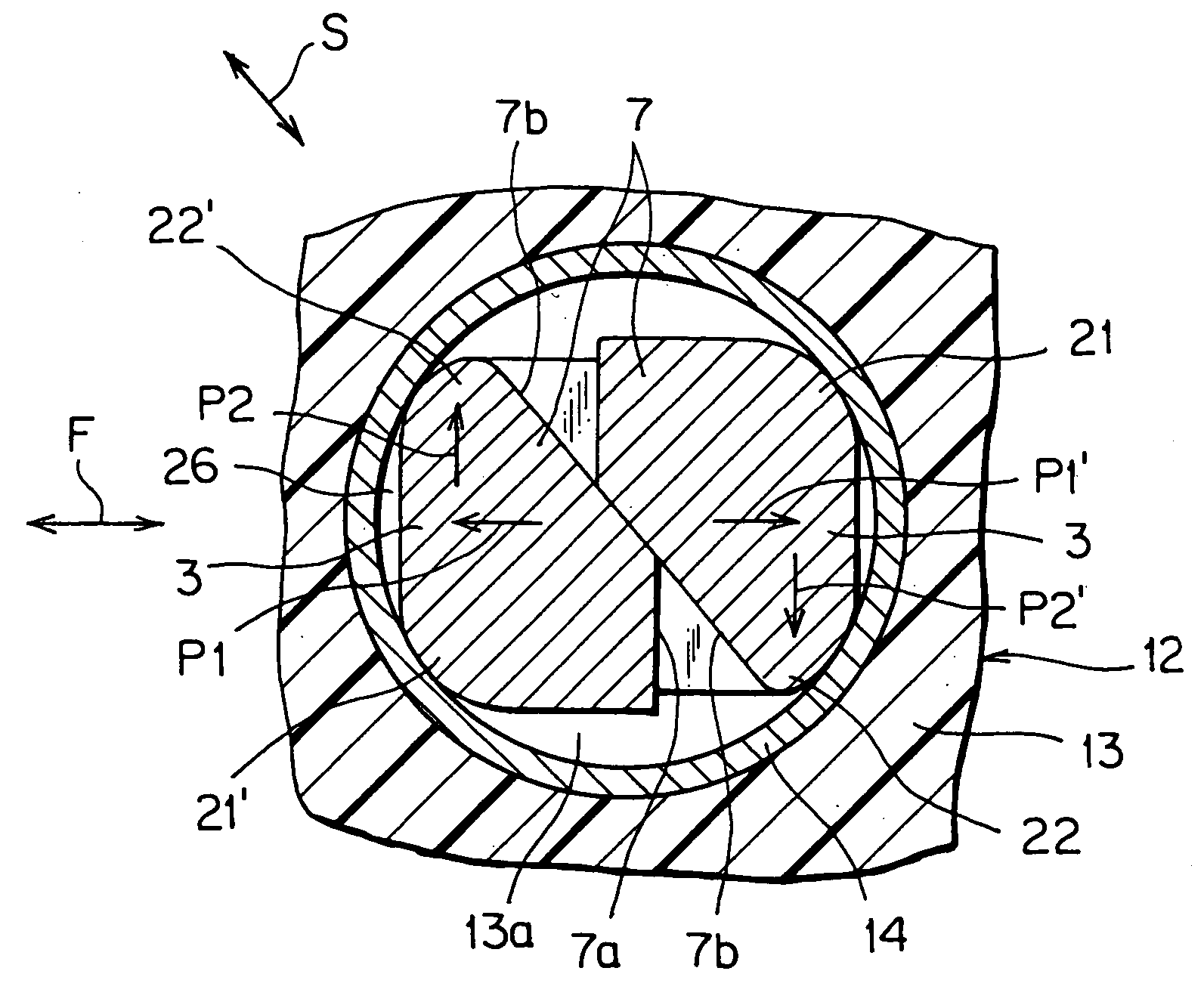

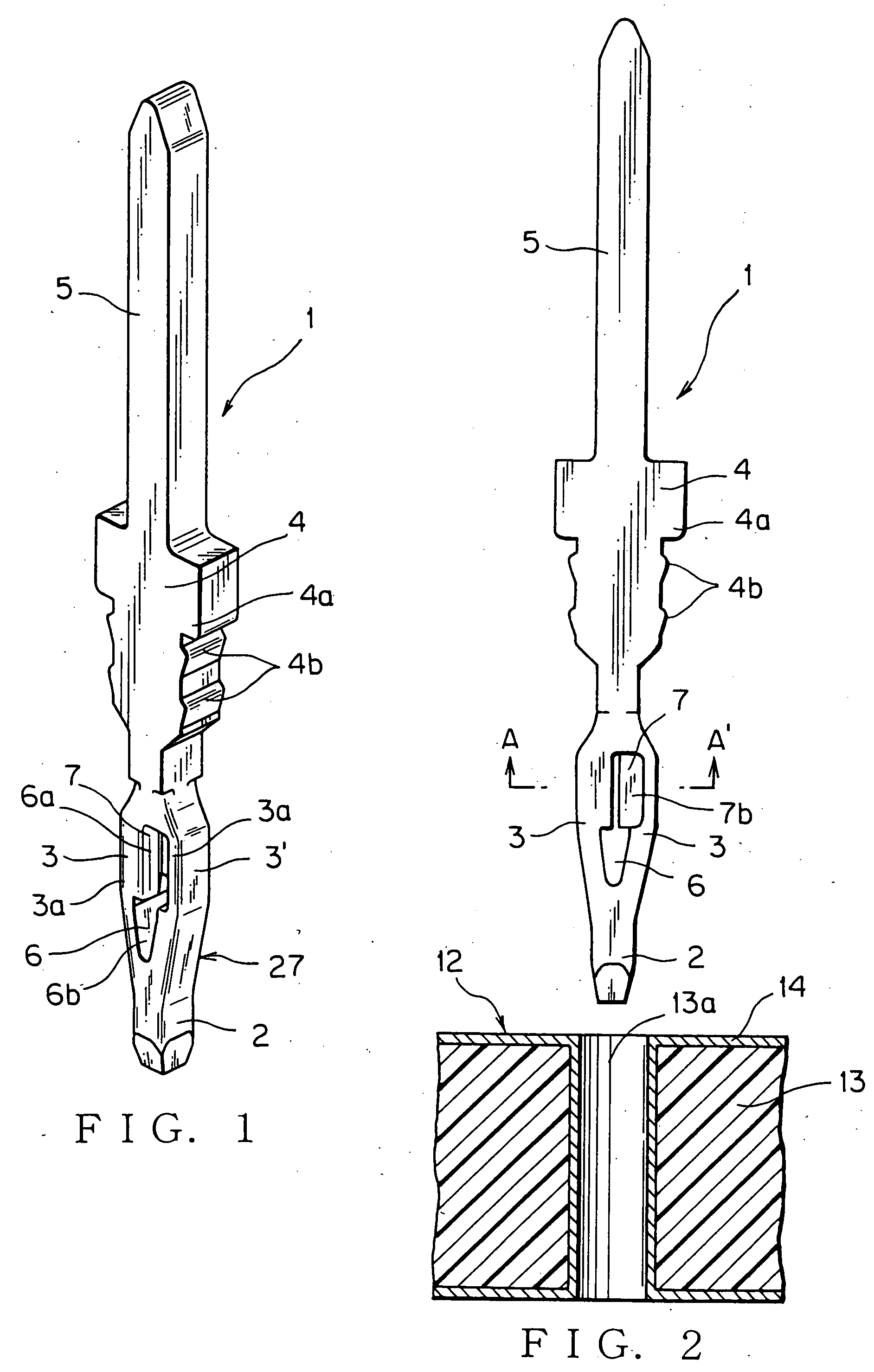

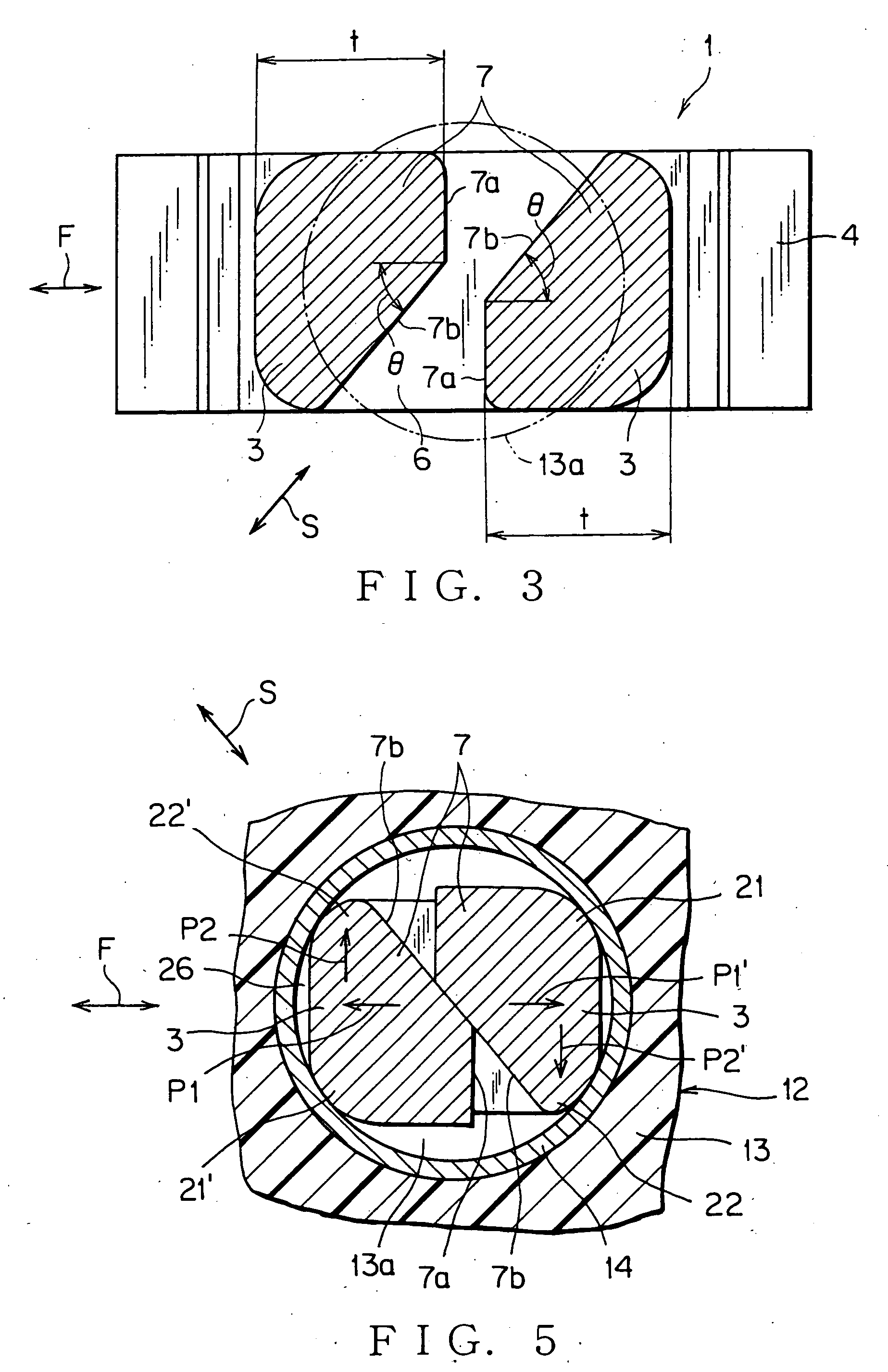

Press-fit terminal and circuit board module using the same

InactiveUS20050250356A1Improve connection workabilityIncrease forceElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Wiring harness and a method of providing wiring structure of the same

ActiveUS20110133548A1Save distanceShorten the line lengthLine/current collector detailsElectric devicesCable harnessElectrical and Electronics engineering

Owner:YAZAKI CORP

Method of connecting terminal and electric wire

InactiveUS20070184715A1Low costImprove conductivitySecuring/insulating coupling contact membersElectrically conductive adhesive connectionsAdhesiveSwaging

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

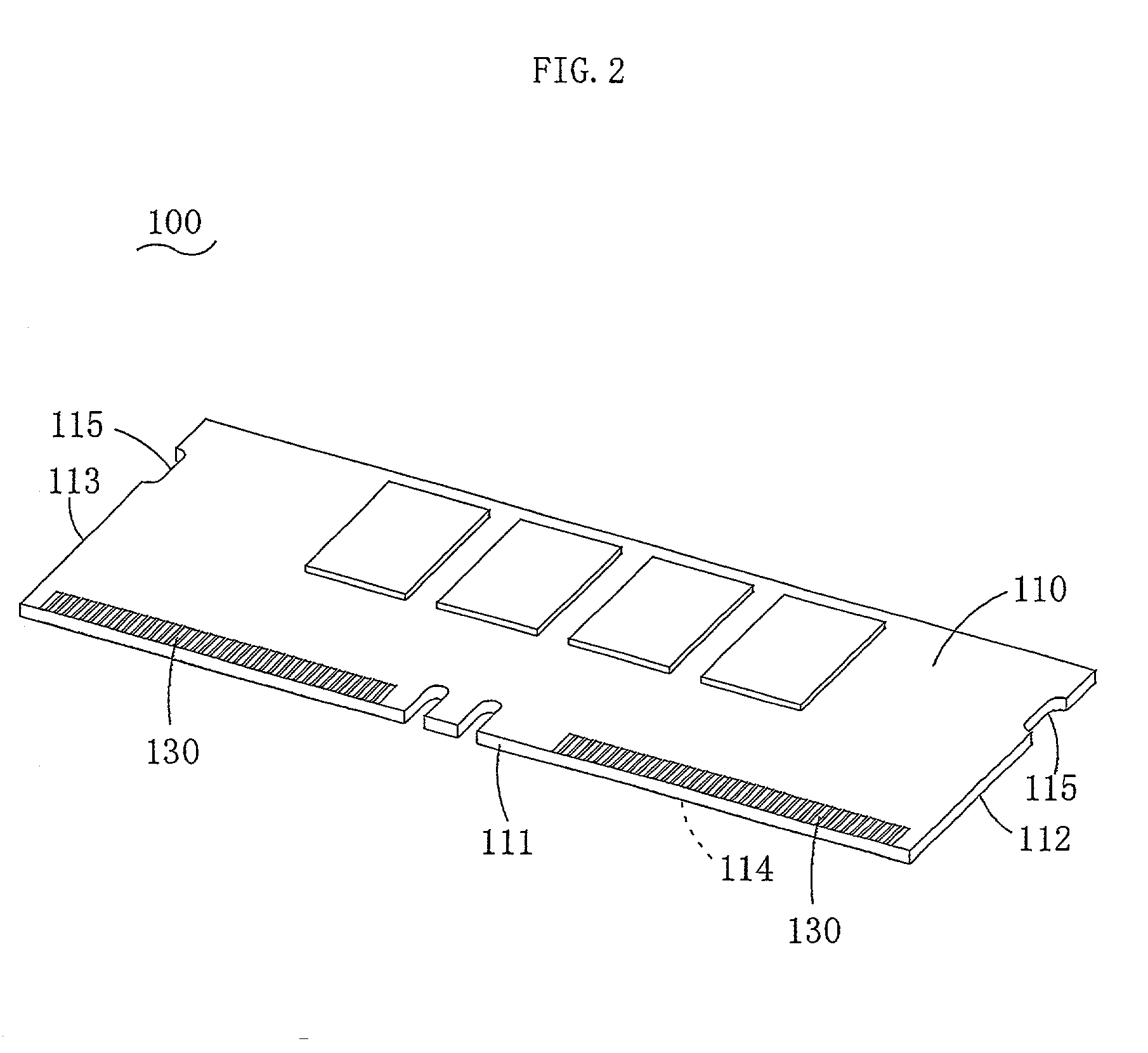

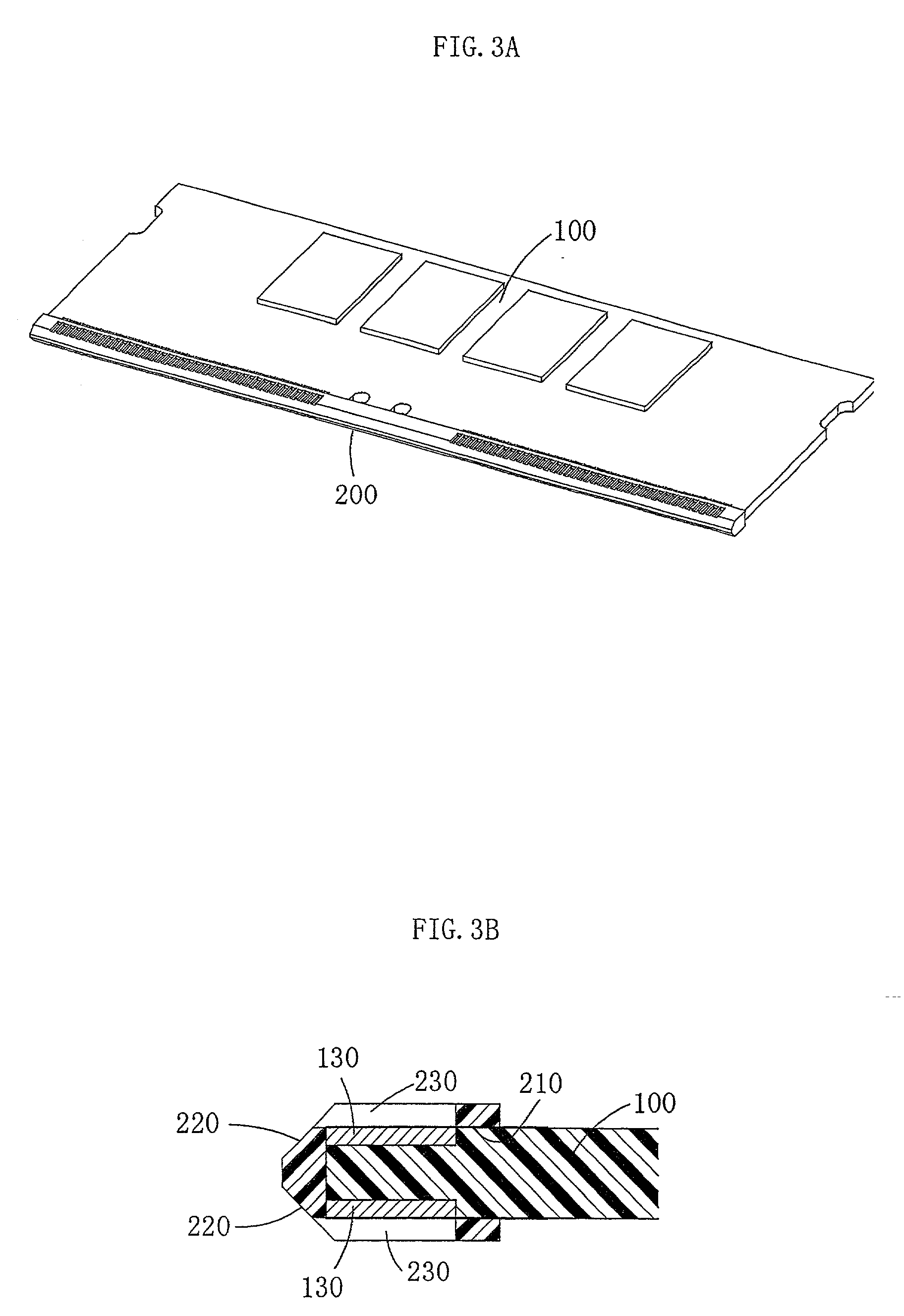

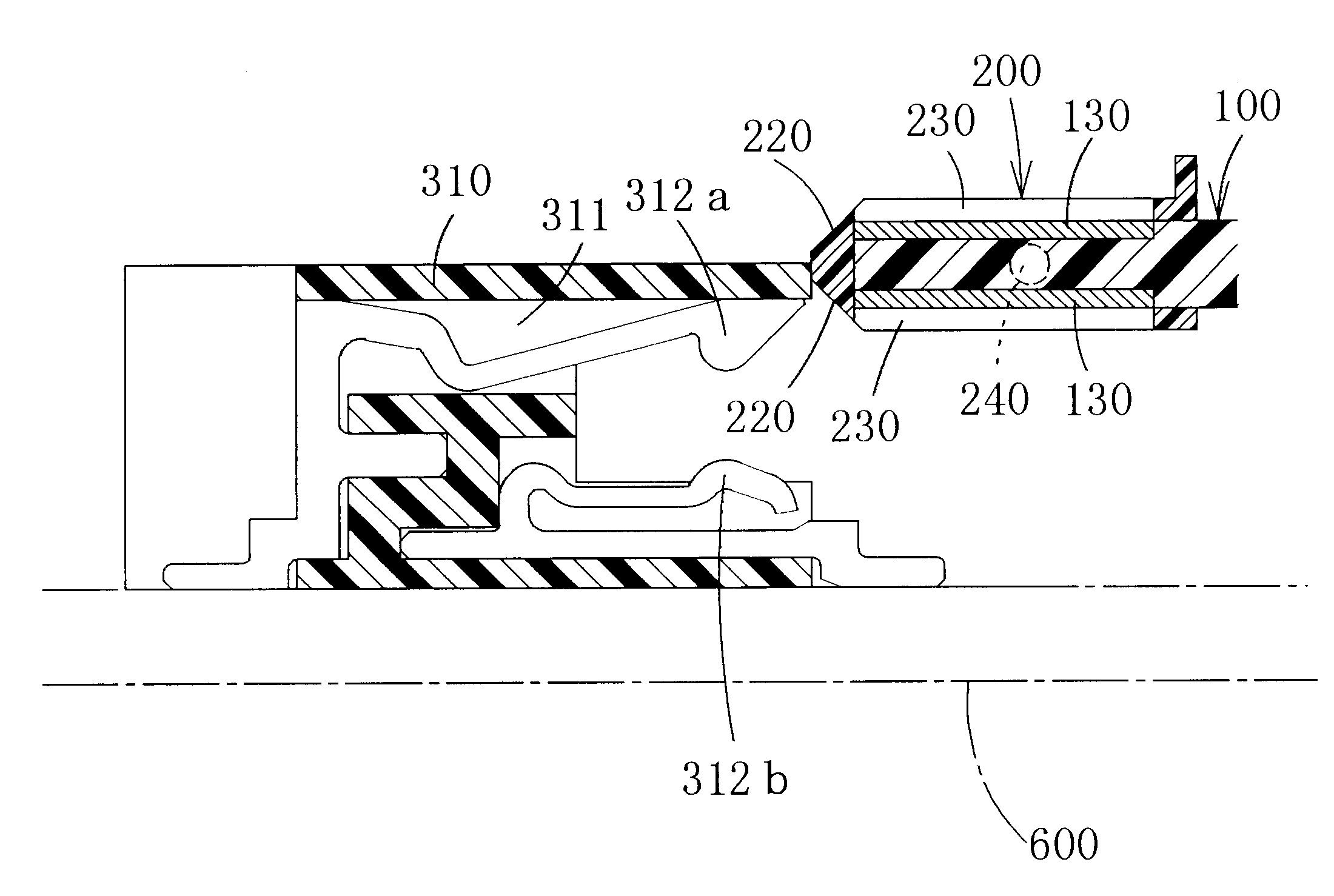

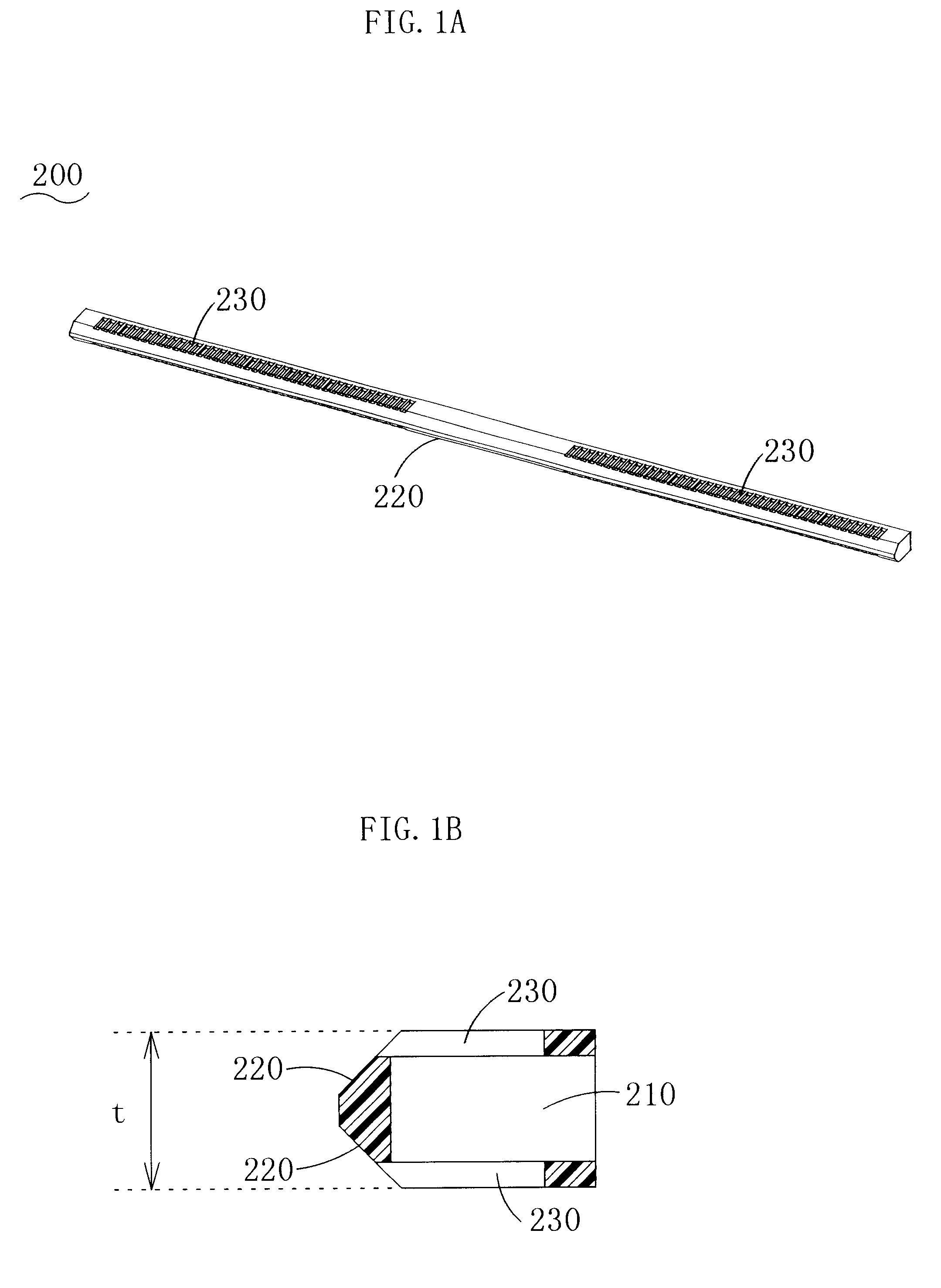

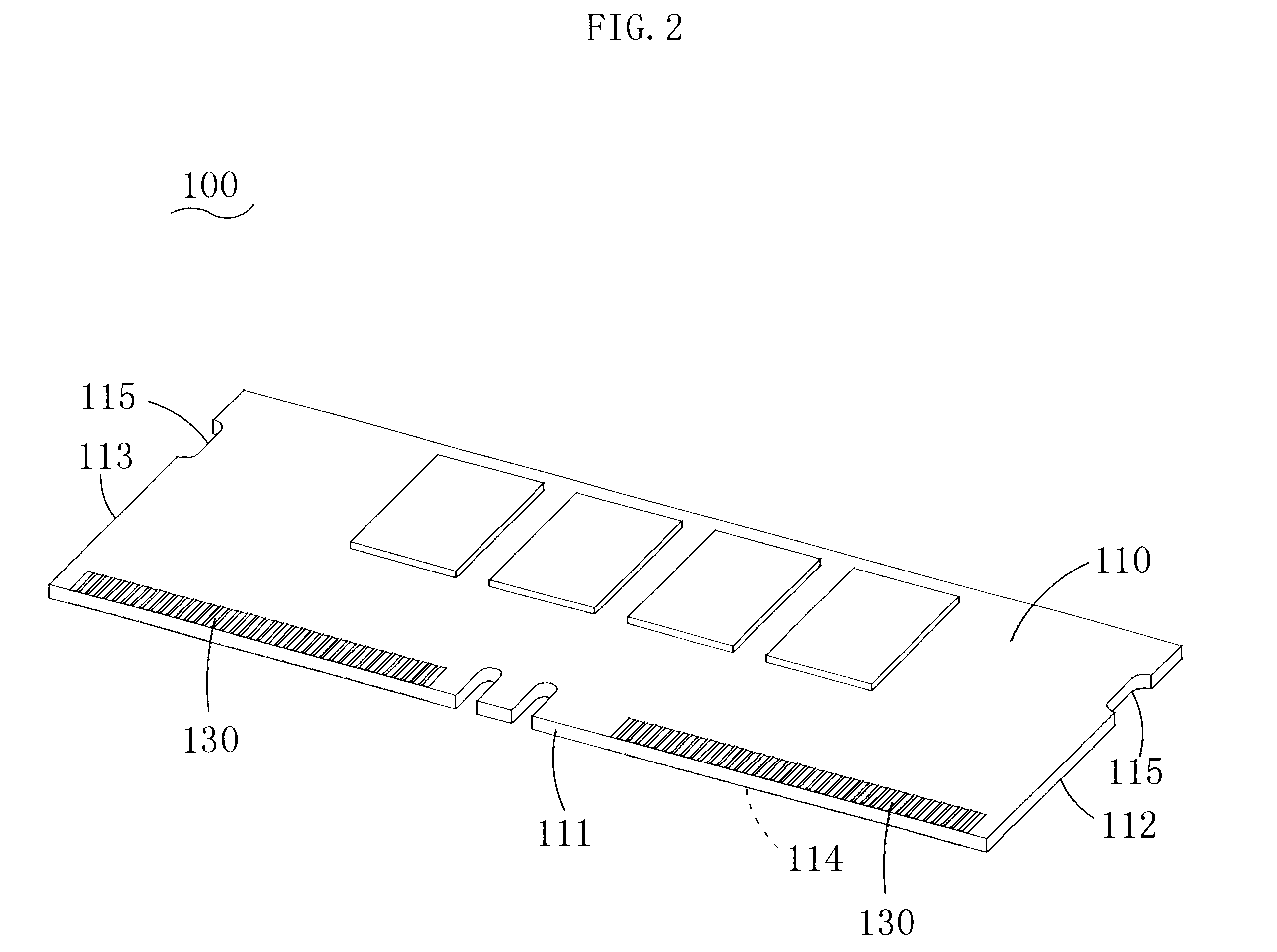

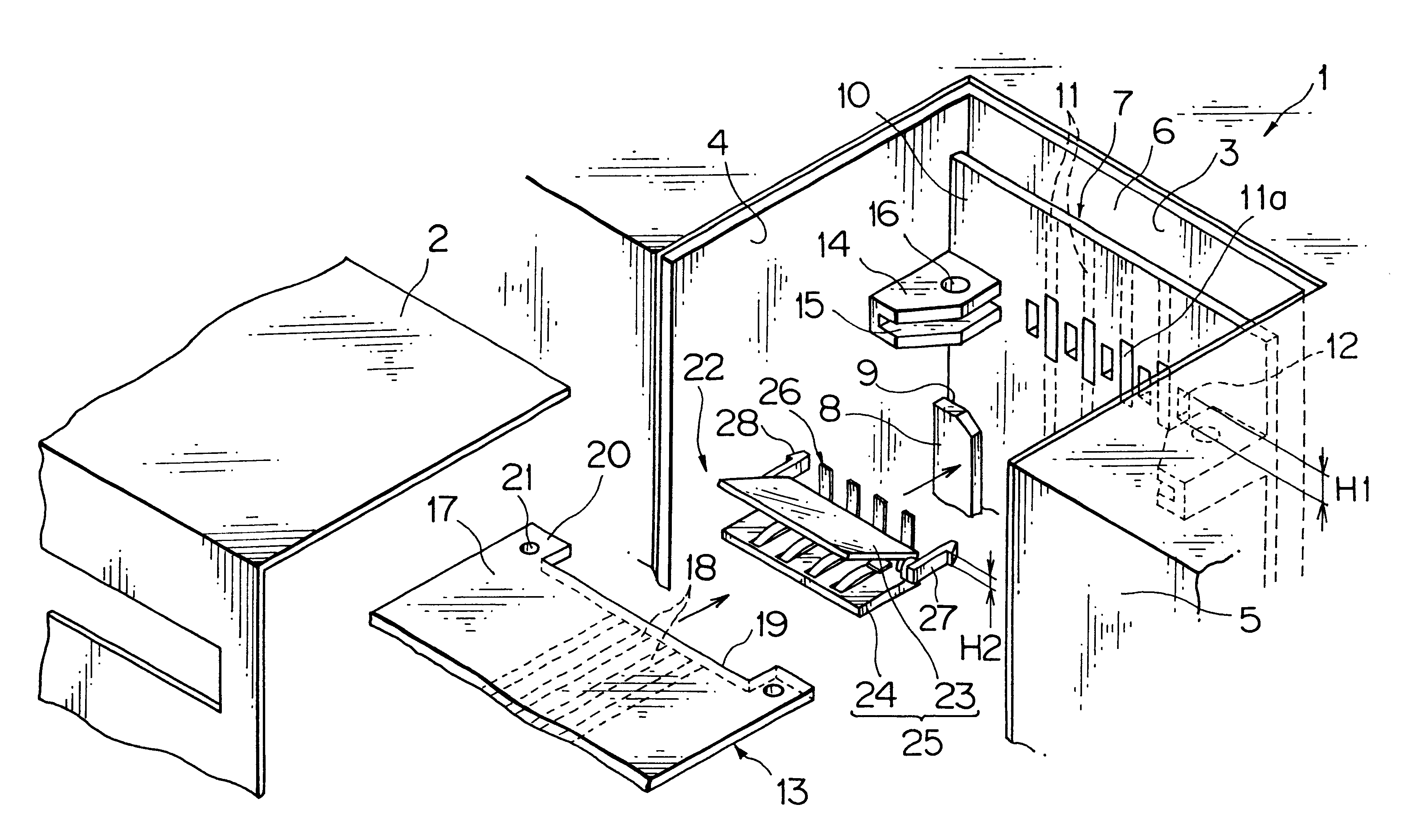

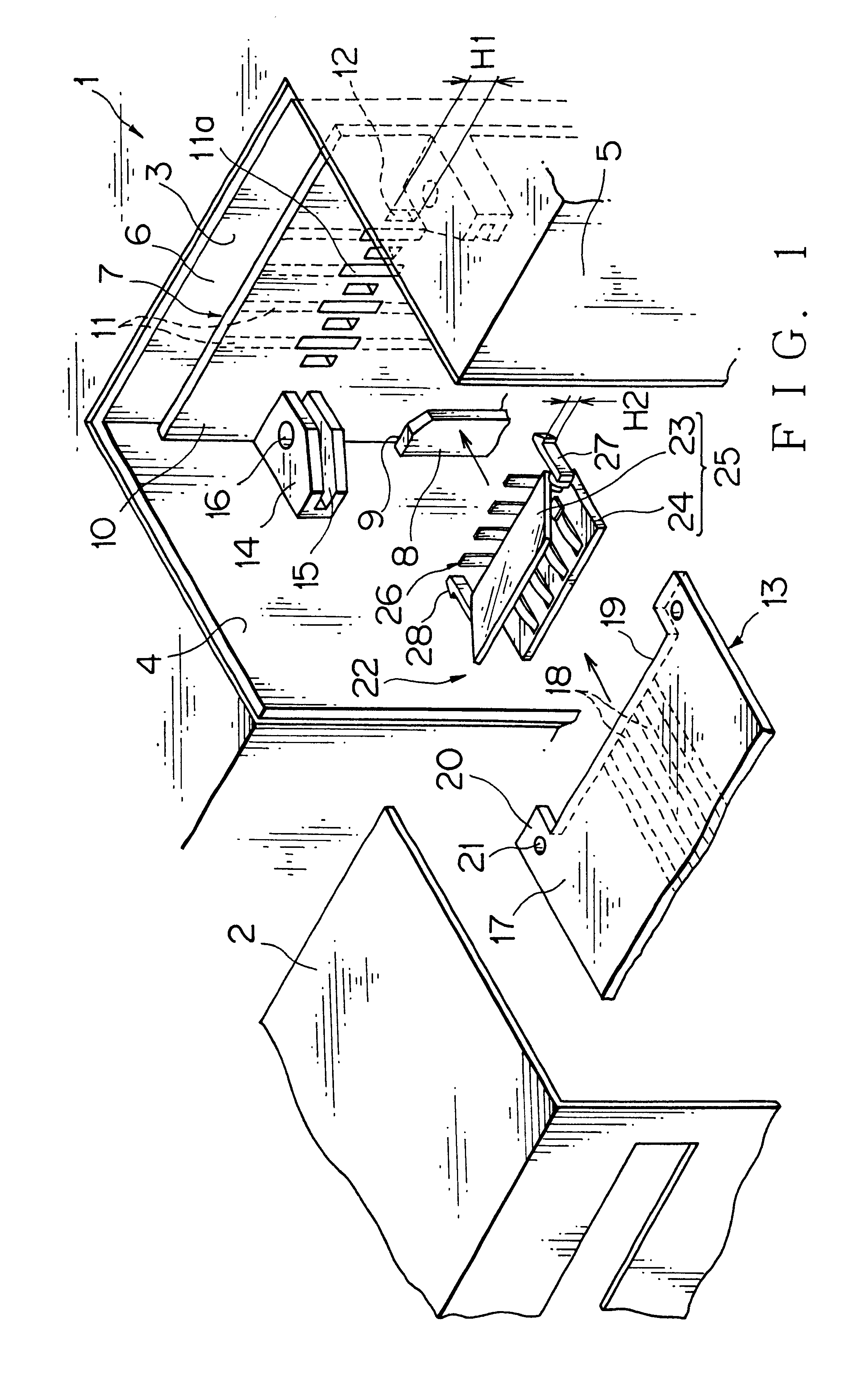

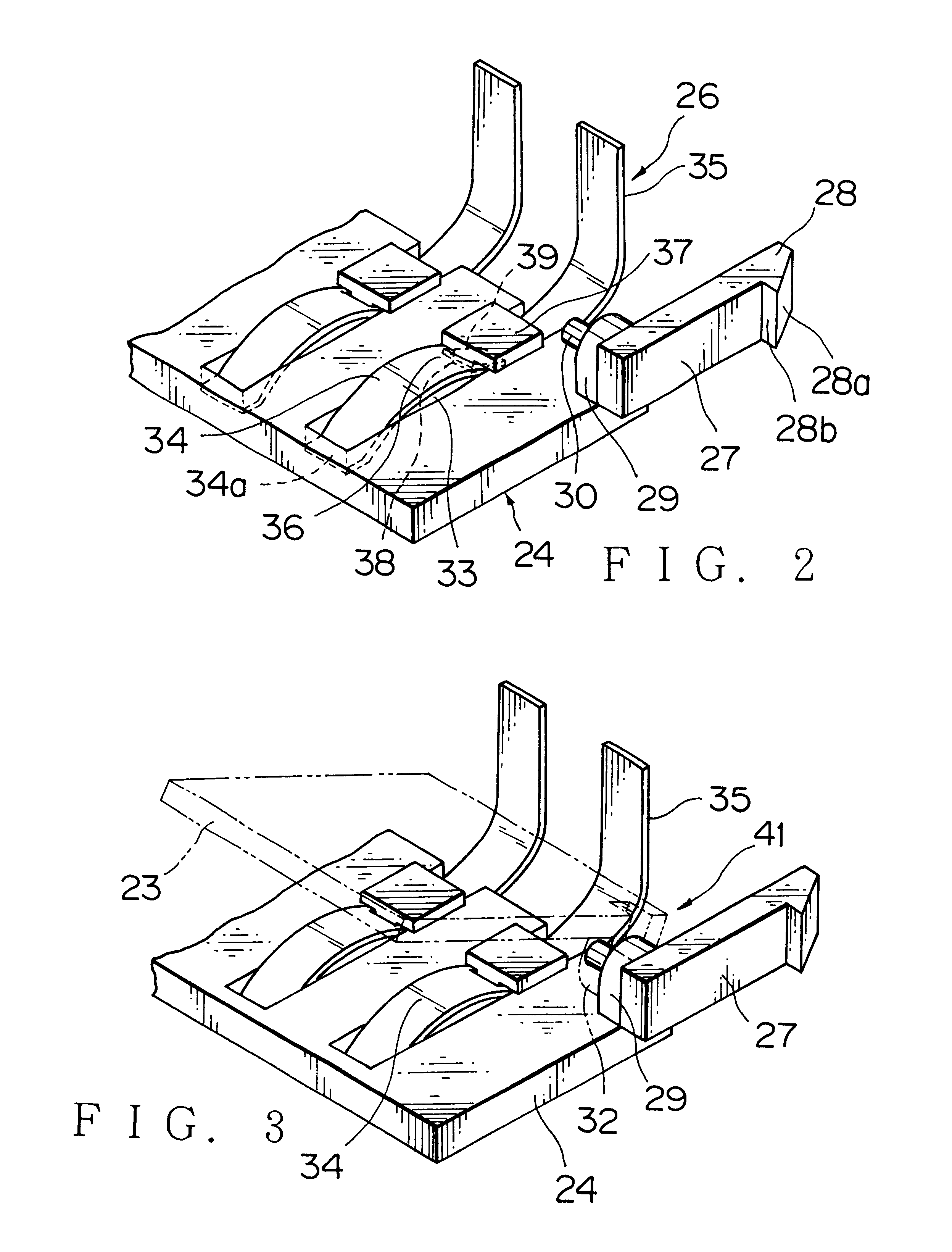

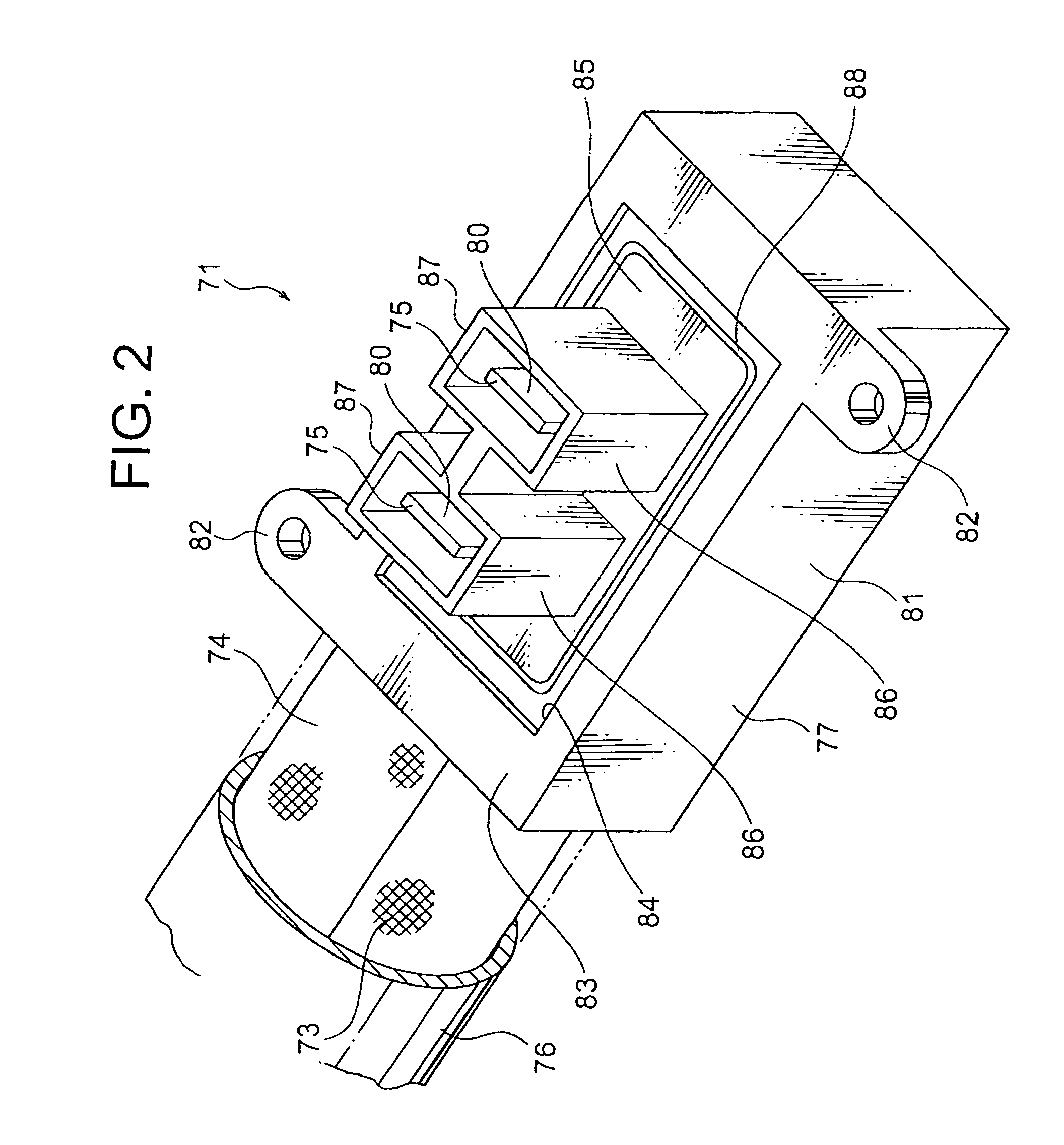

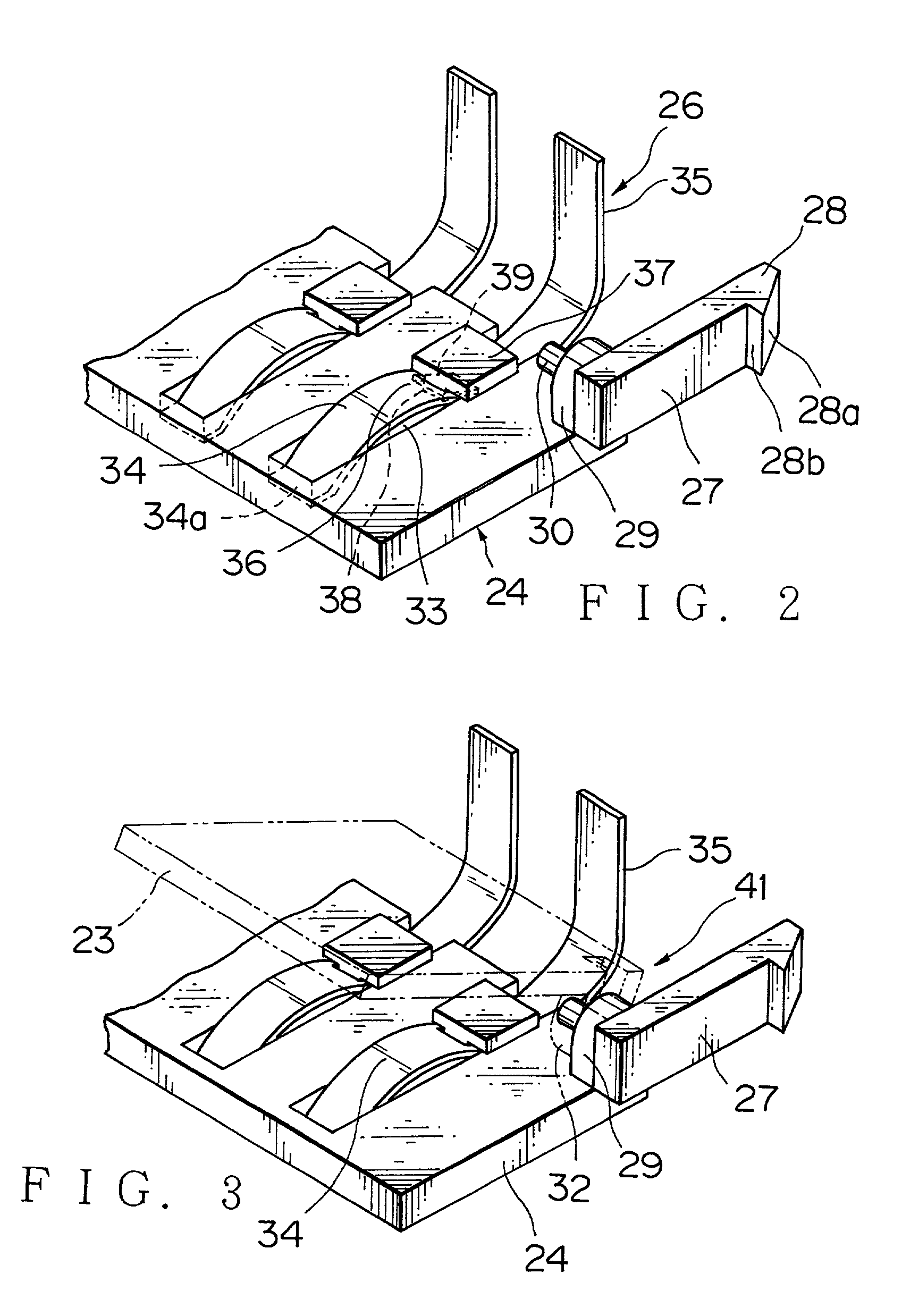

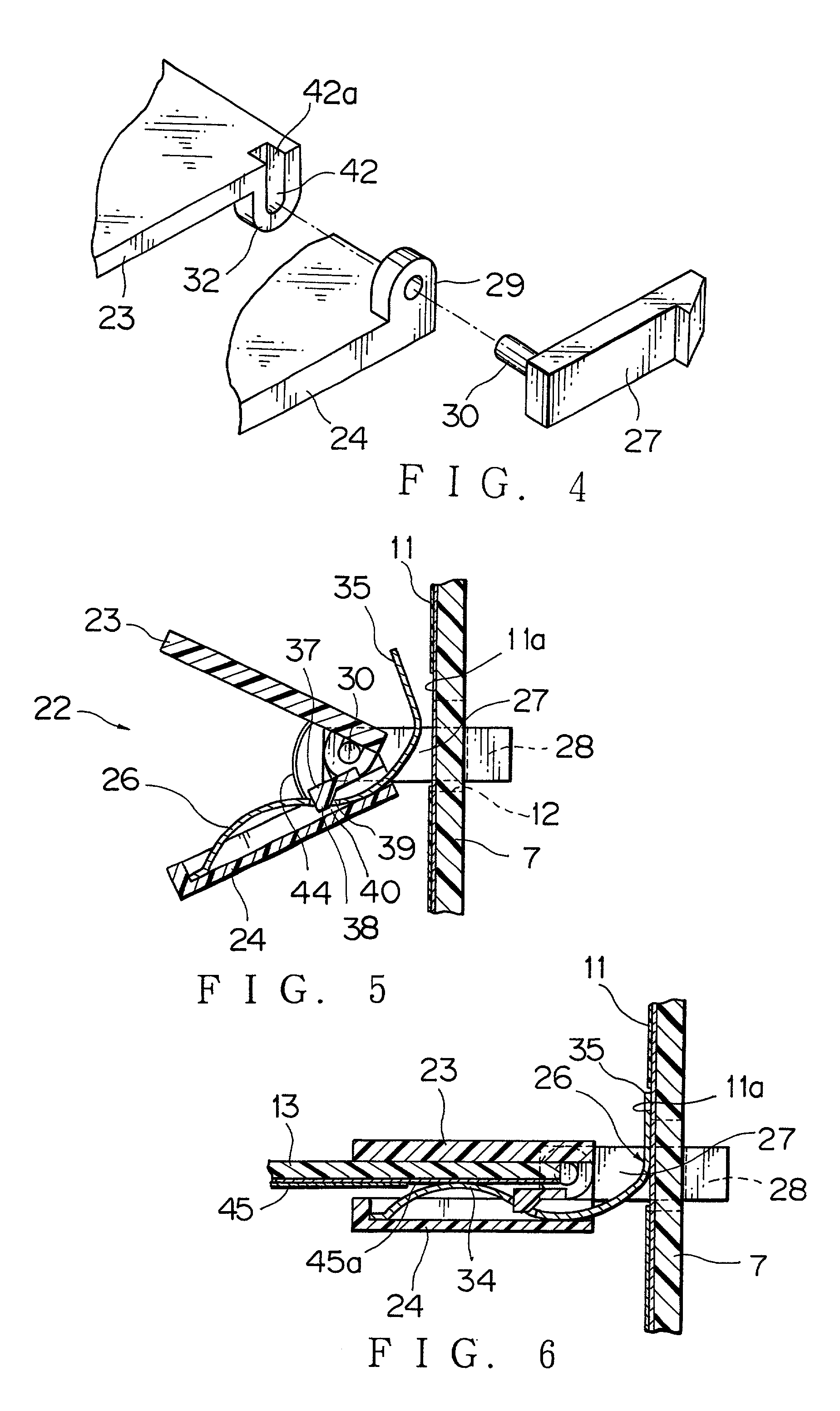

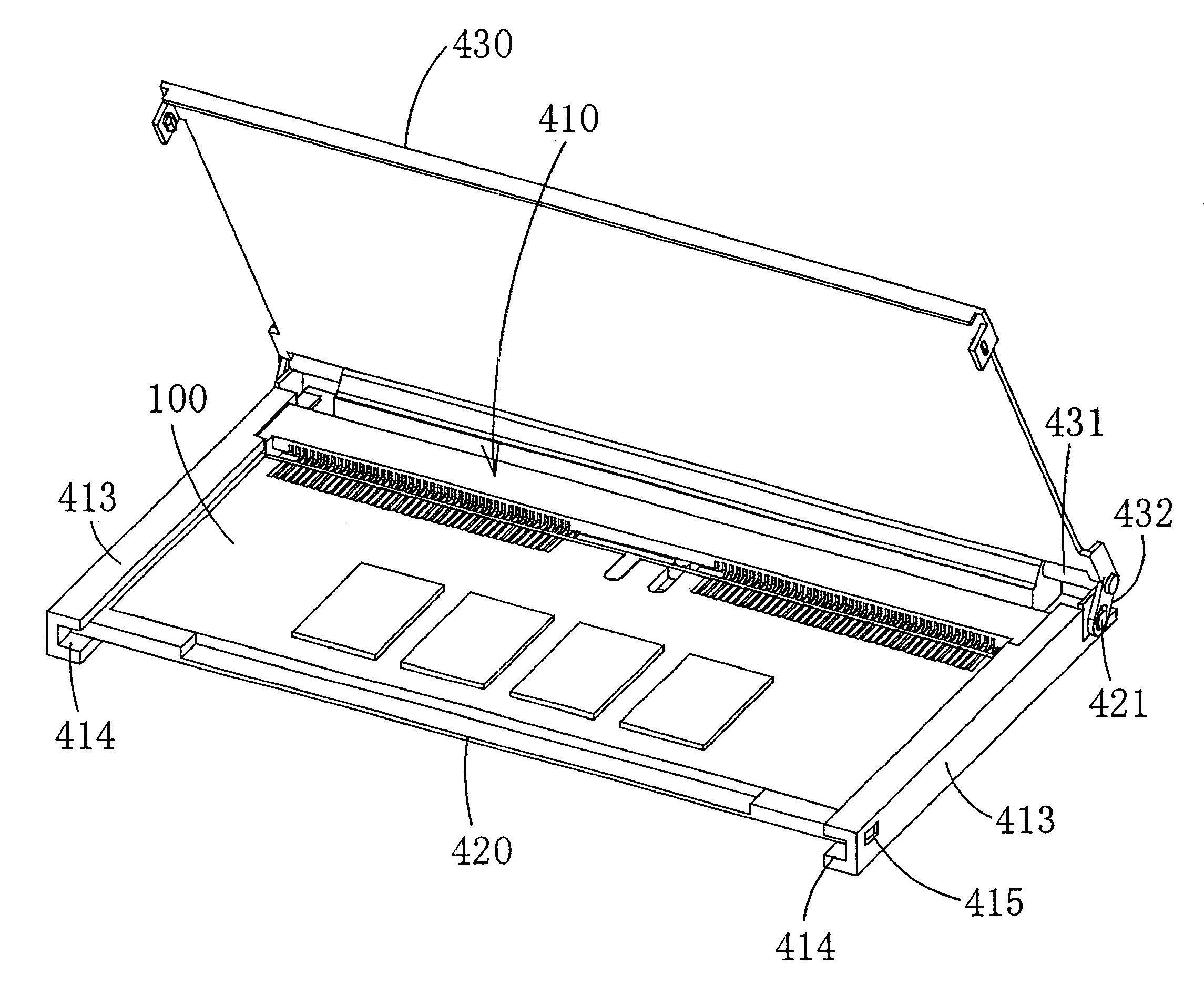

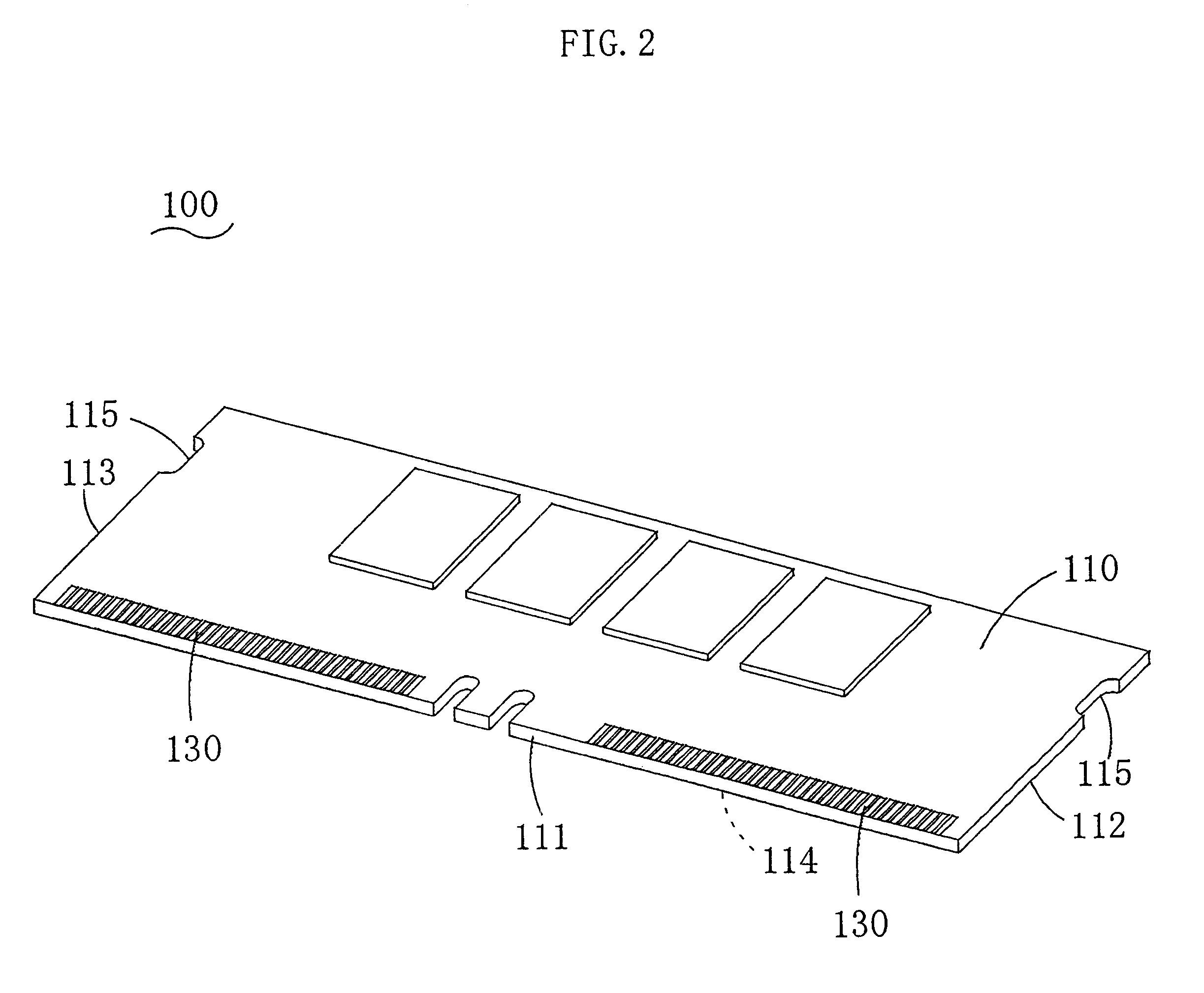

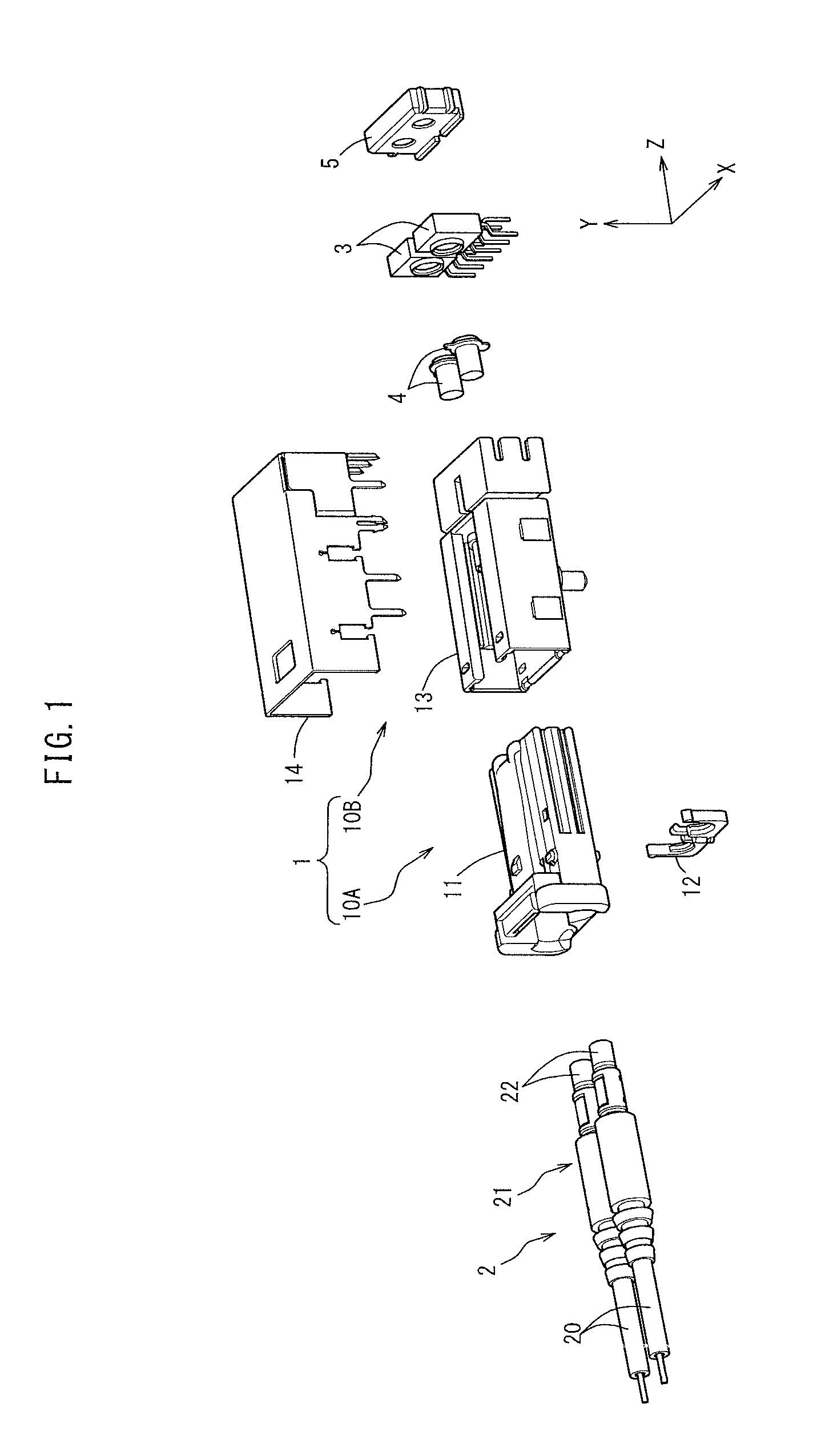

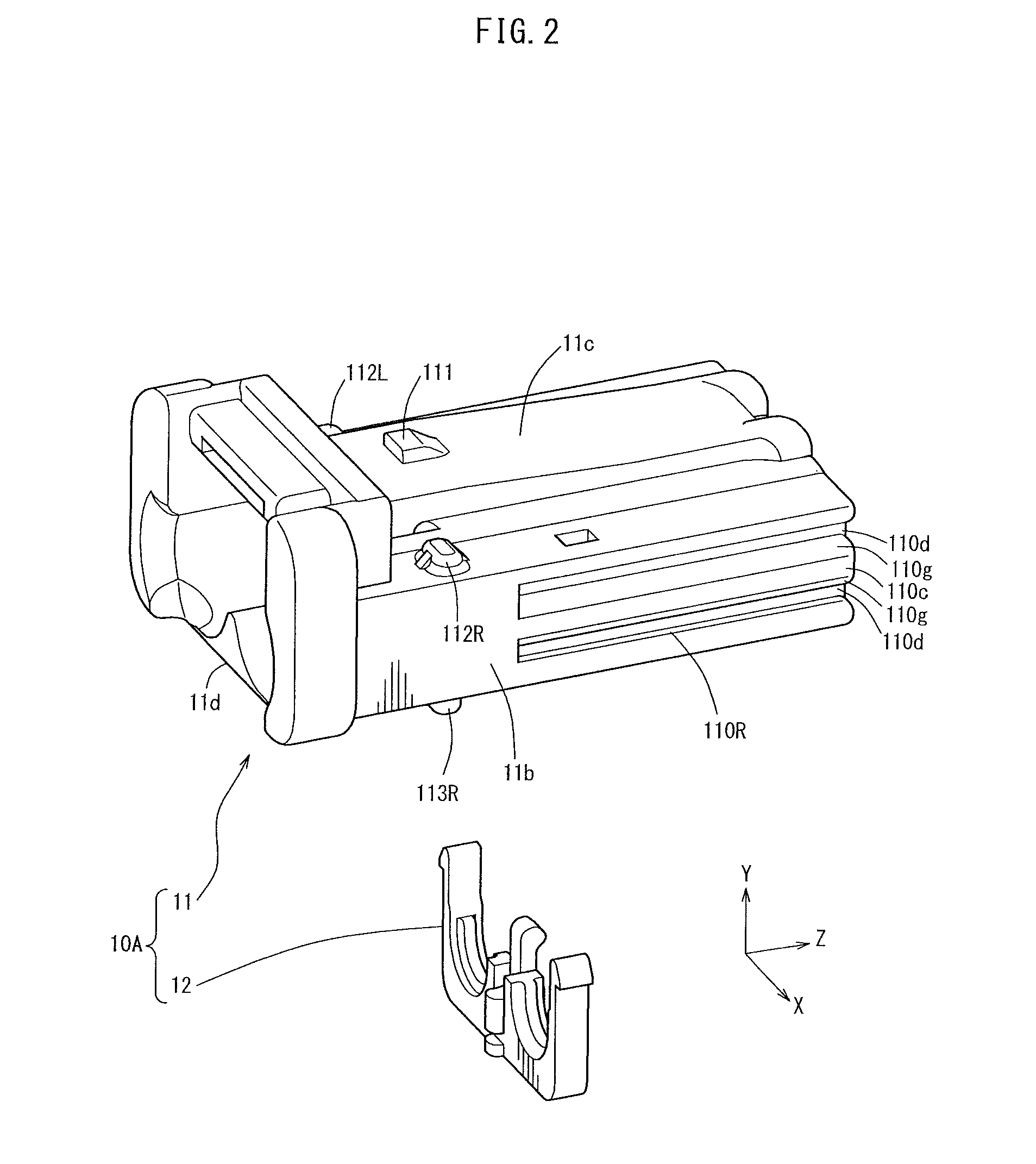

Cap and low insertion force connector for printed circuit board

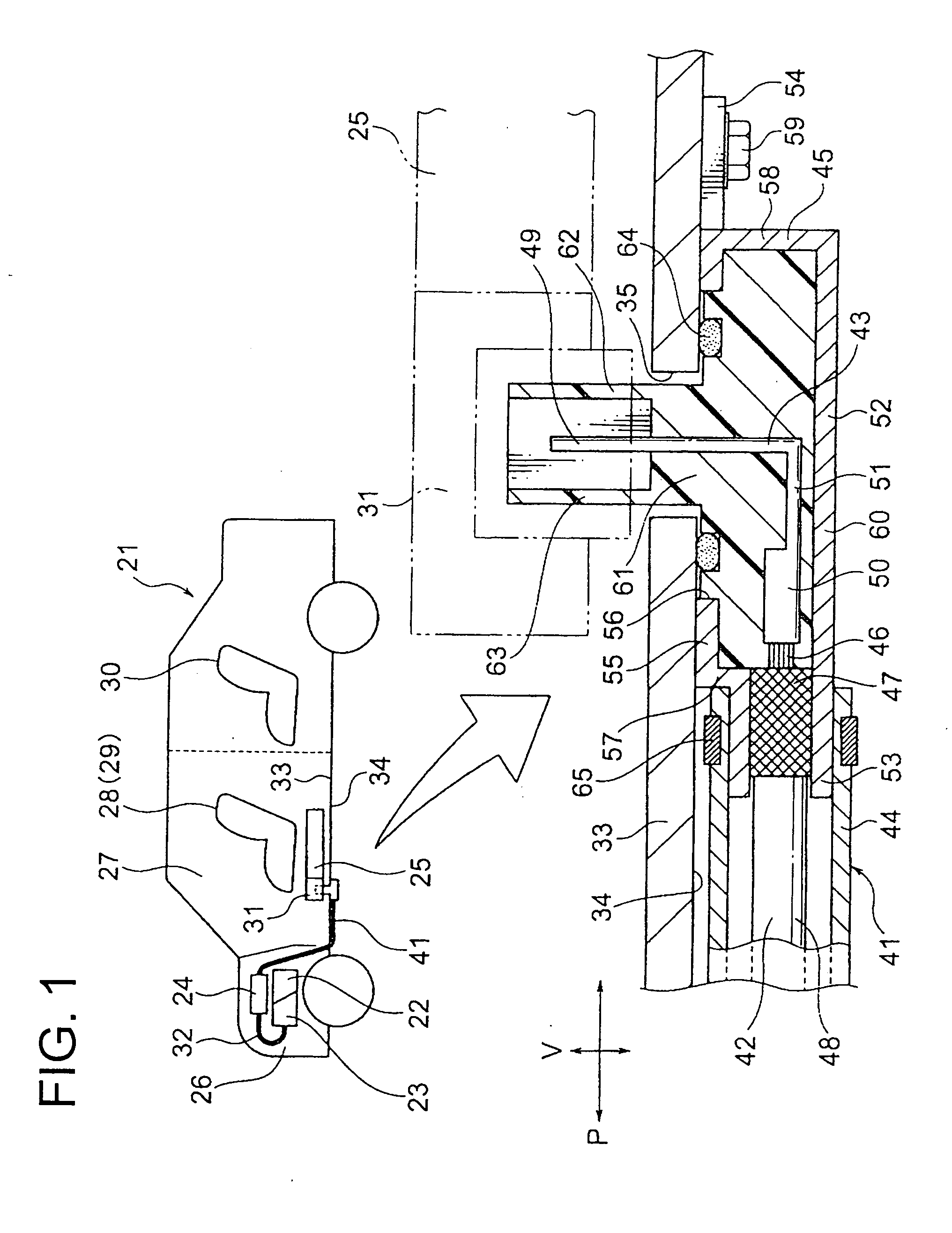

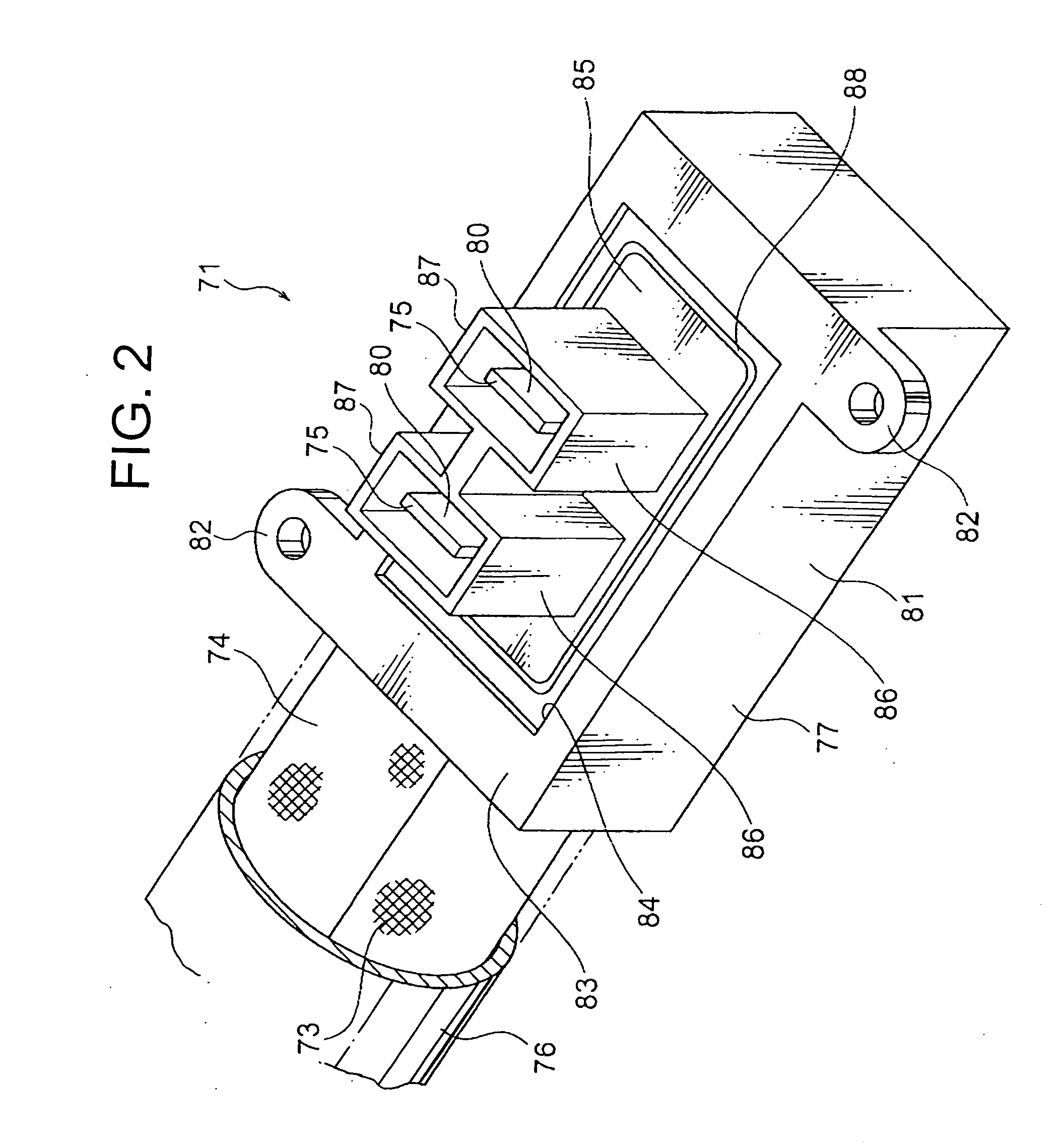

InactiveUS20010014546A1Insertion forceImprove connection workabilityEngagement/disengagement of coupling partsIncorrect coupling preventionLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board. A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front. The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

Cap and low insertion force connector for printed circuit board

InactiveUS6439919B1Insertion forceImprove connection workabilityIncorrect coupling preventionPrinted circuit aspectsLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board.A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front.The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

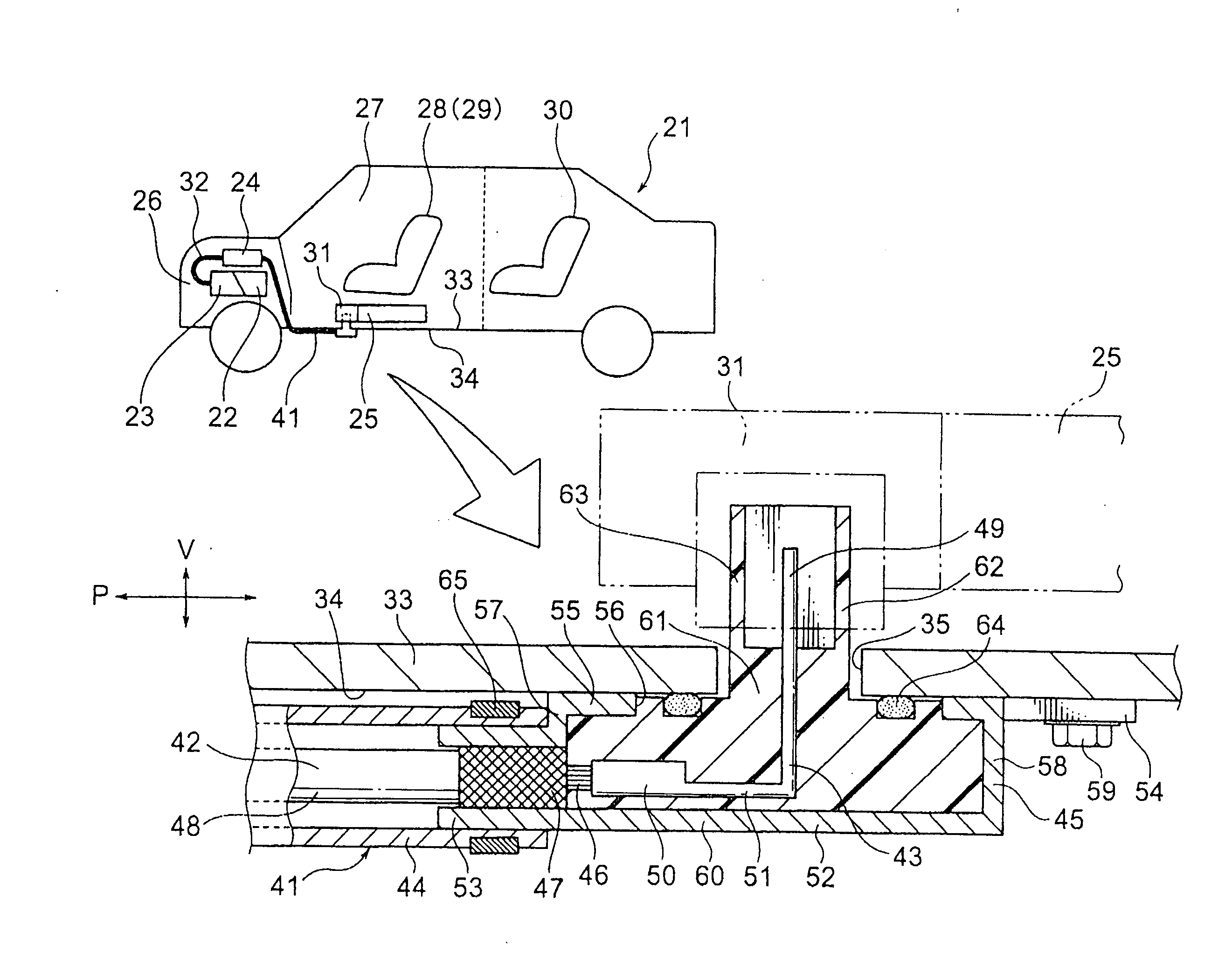

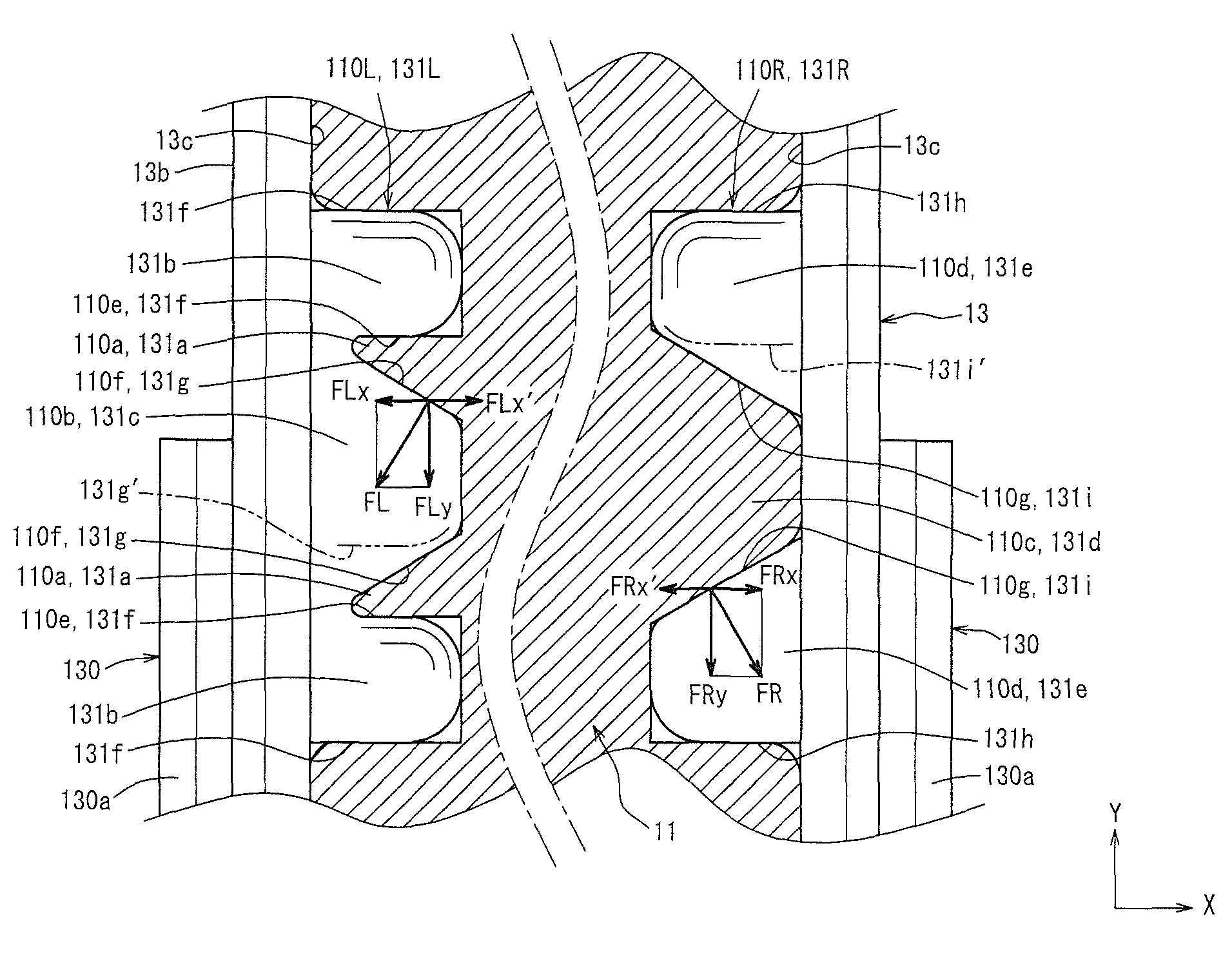

Connector and a connecting structure of circuit boards therewith

InactiveUS6497580B2Firmly connectedImprove connection workabilityRotary current collectorSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Wiring harness and a method of providing wiring structure of the same

ActiveUS9006939B2Save distanceShorten the line lengthInsulated cablesPropulsion by batteries/cellsEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Connector and a connecting structure of circuit boards therewith

InactiveUS20010019904A1Firmly connectedImprove connection workabilityRotary current collectorSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

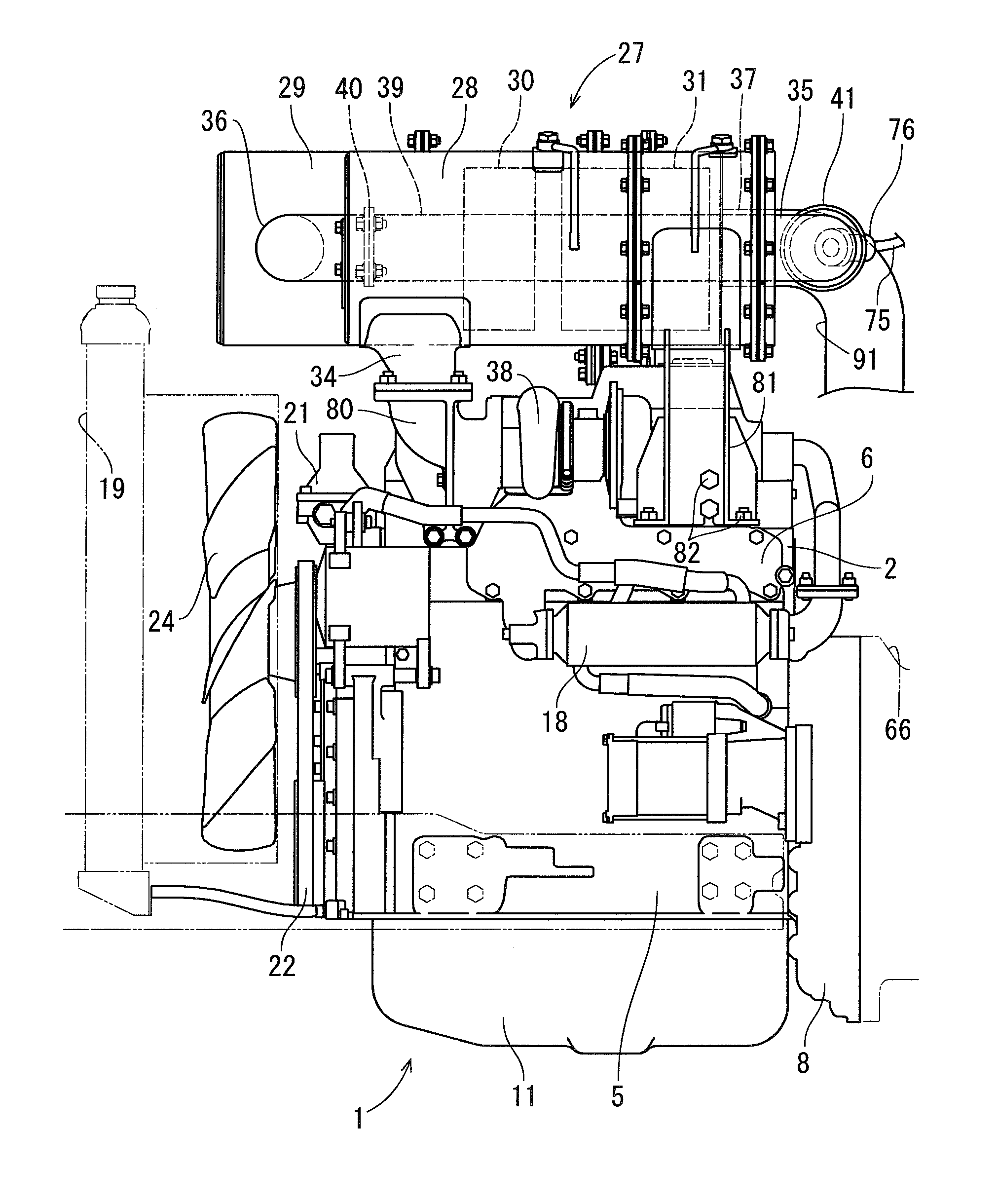

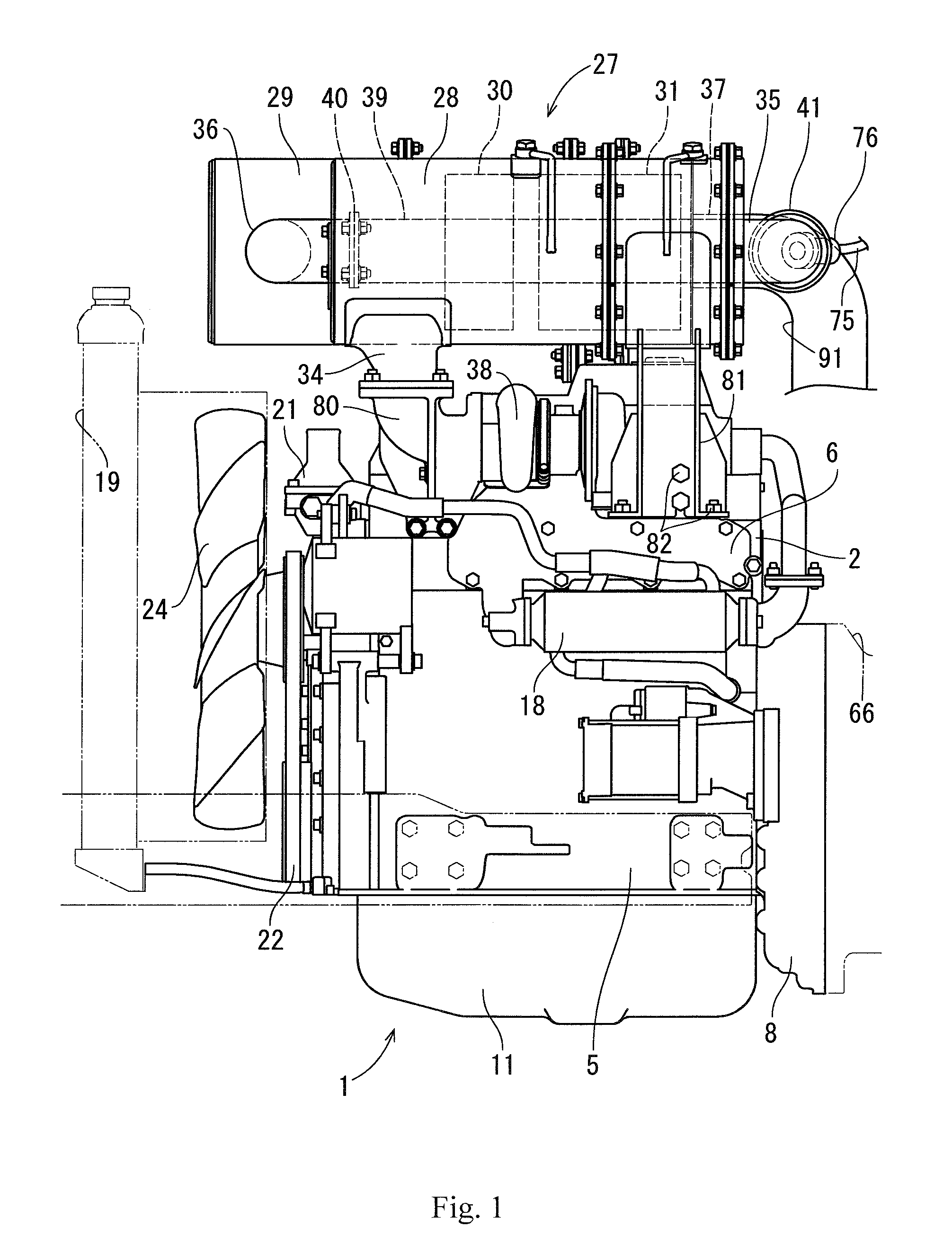

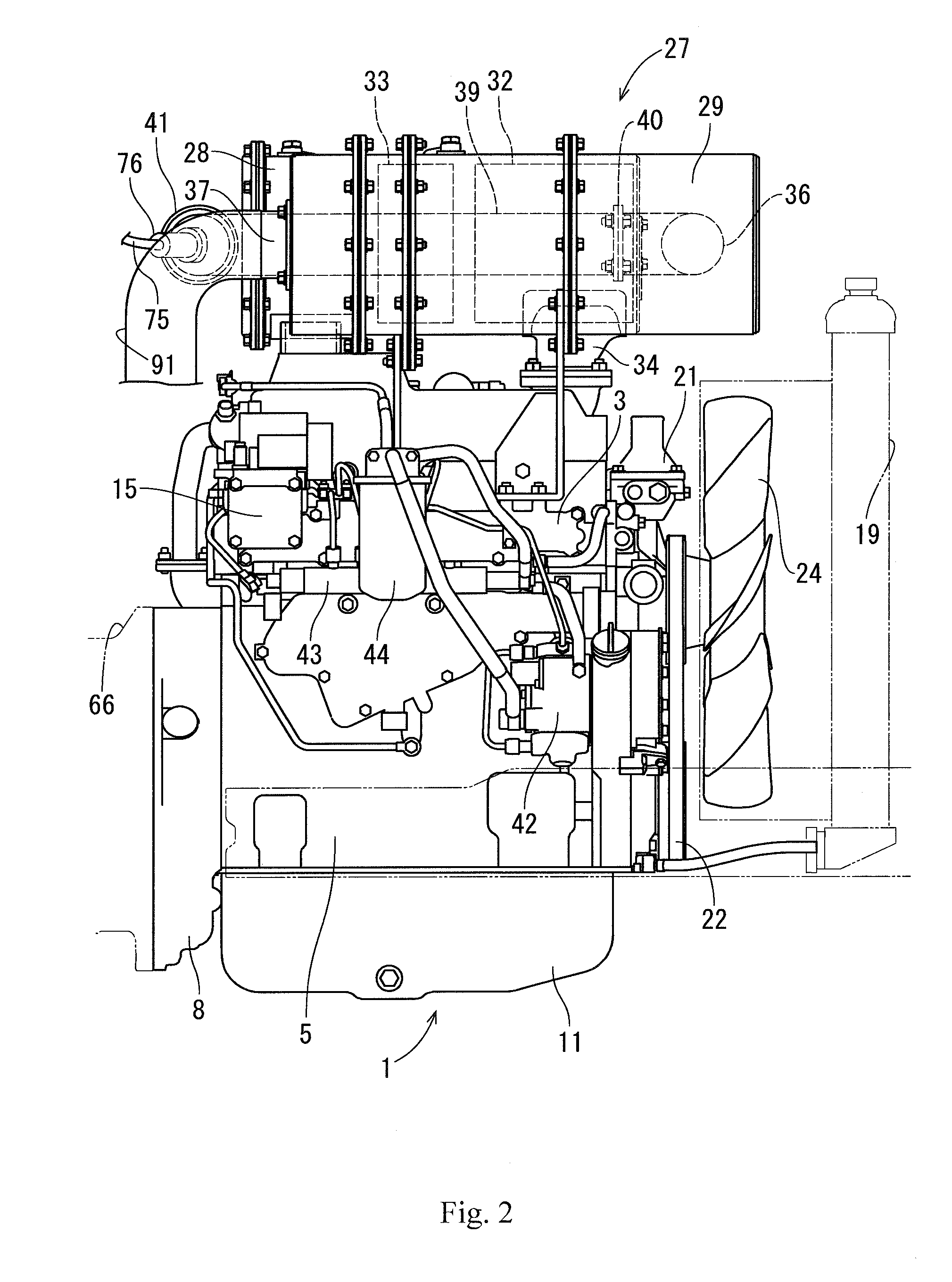

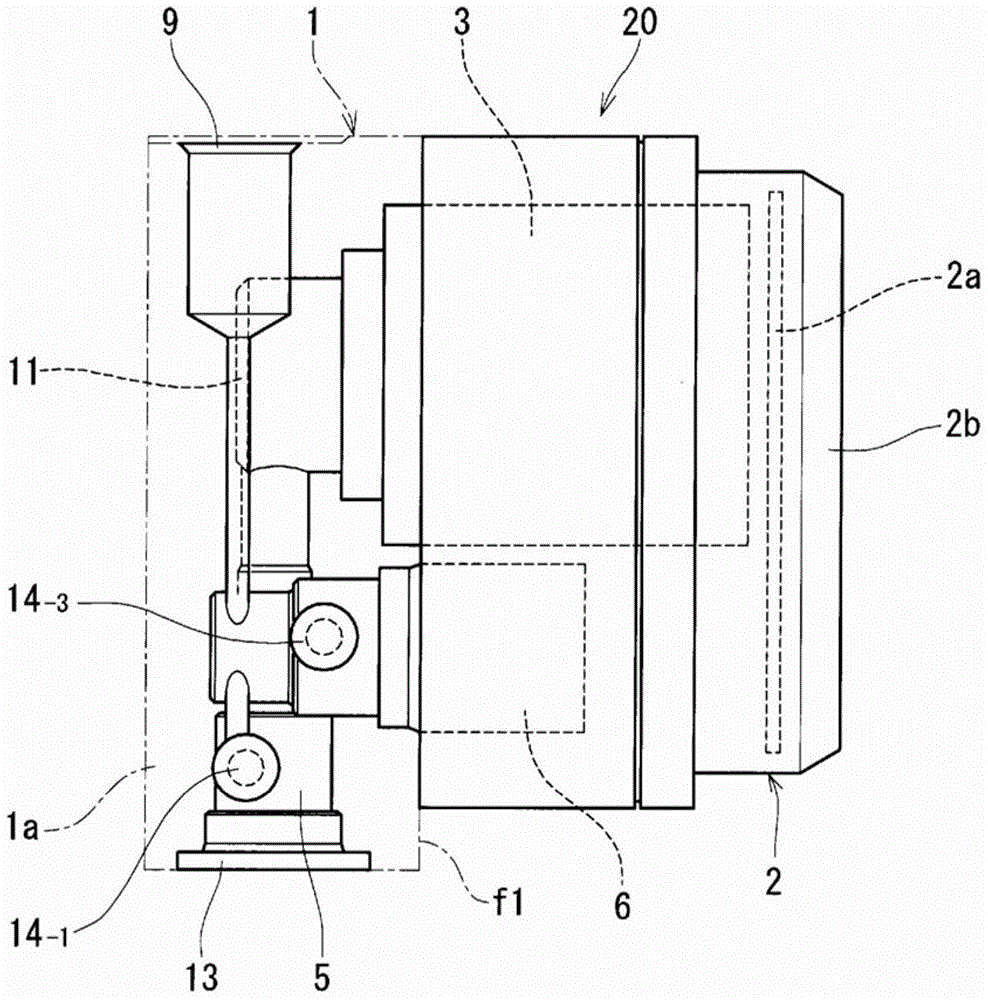

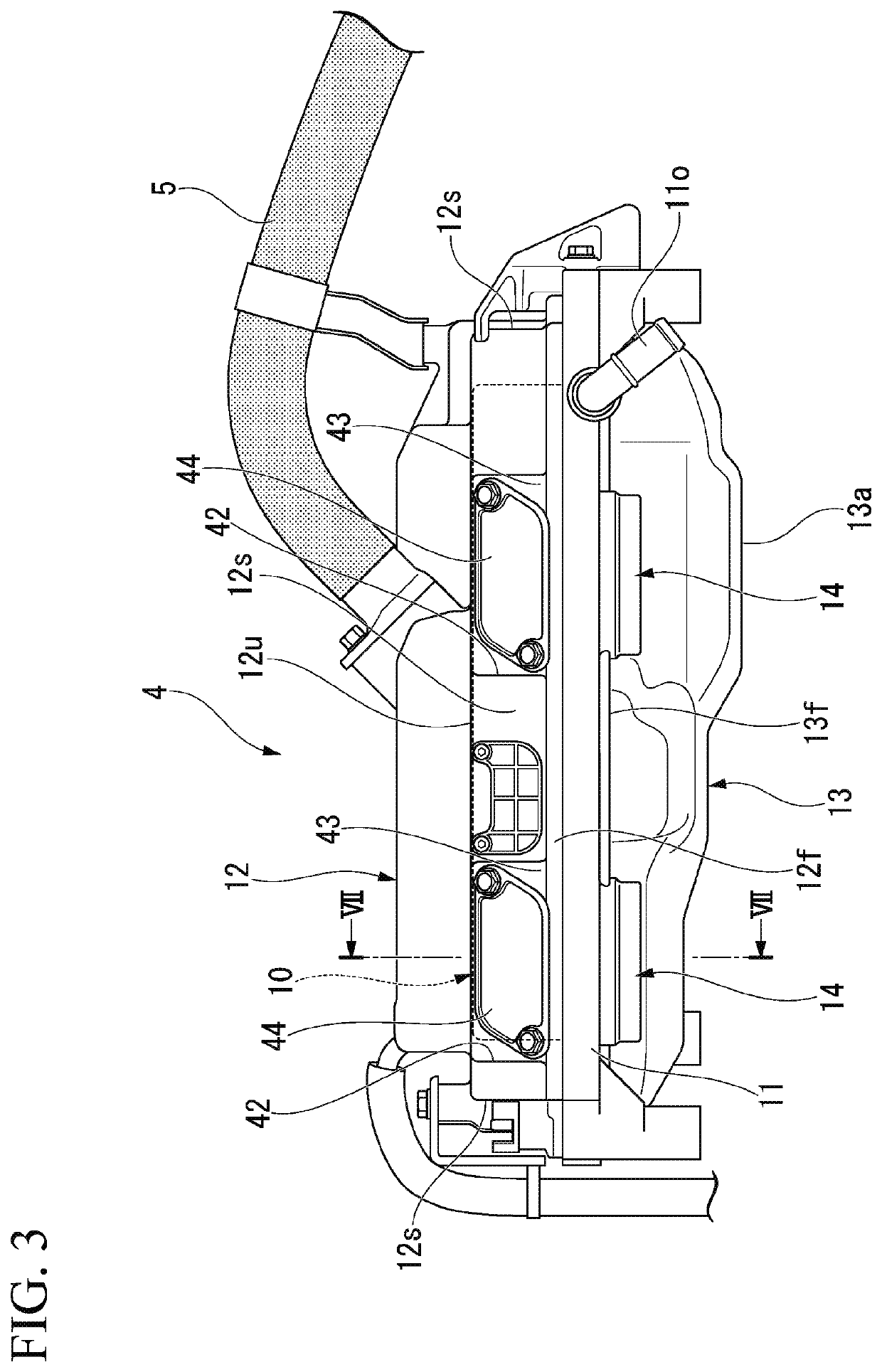

Engine device

ActiveUS9556770B2Smooth movementEasy maintenanceInternal combustion piston enginesExhaust apparatusNitrogen oxidesEngineering

An engine device is provided with an urea mixing pipe which injects urea water into exhaust gas of an engine, and an exhaust gas purification case which removes nitrogen oxide in the exhaust gas of the engine, and is structured such that an exhaust gas inlet pipe of the exhaust gas purification case is connected to an outlet of the urea mixing pipe via a flange body. Exhaust gas outlet side end portions of an outer pipe and an inner pipe of the urea mixing pipe having a double-pipe structure are connected to exhaust gas inlet side end portions of an outer pipe and an inner pipe of the exhaust gas inlet pipe having a double-pipe structure. Fitting small-diameter portions are formed in an end portion of the inner pipe of the urea mixing pipe, and the fitting small-diameter portions are inward insert to an inner portion of the inner pipe of the exhaust gas inlet pipe.

Owner:YANMAR POWER TECHNOLOGY CO LTD

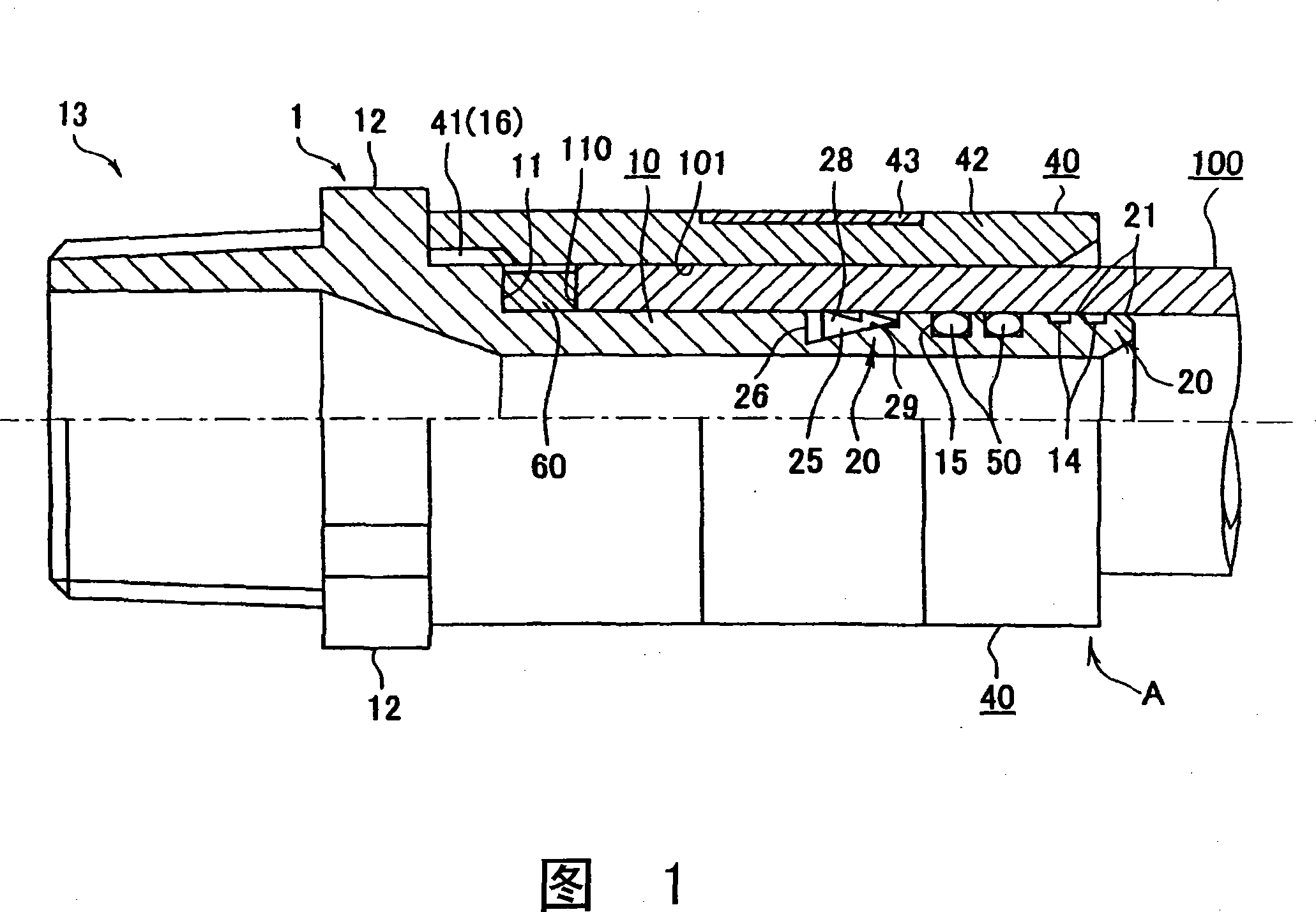

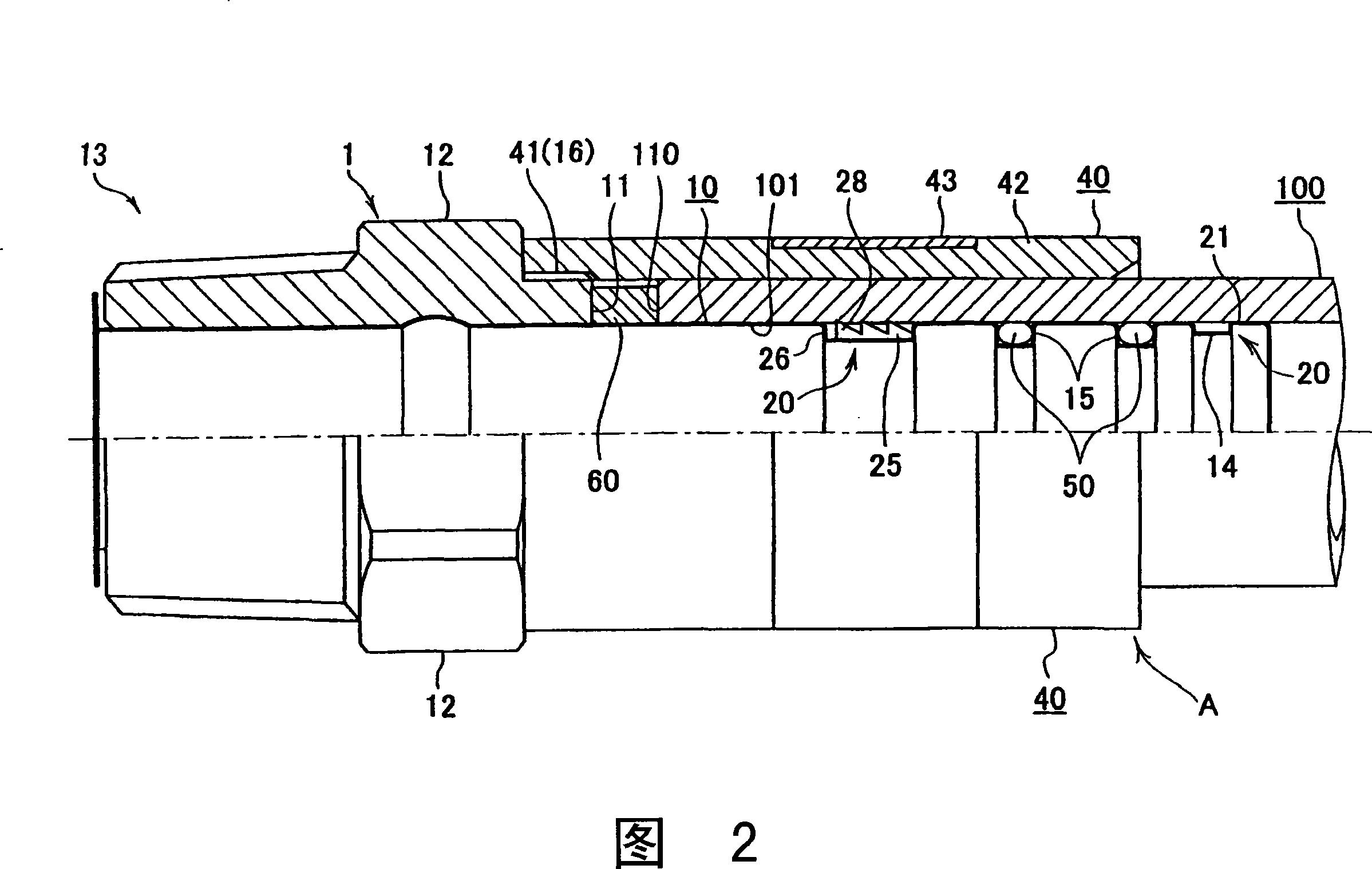

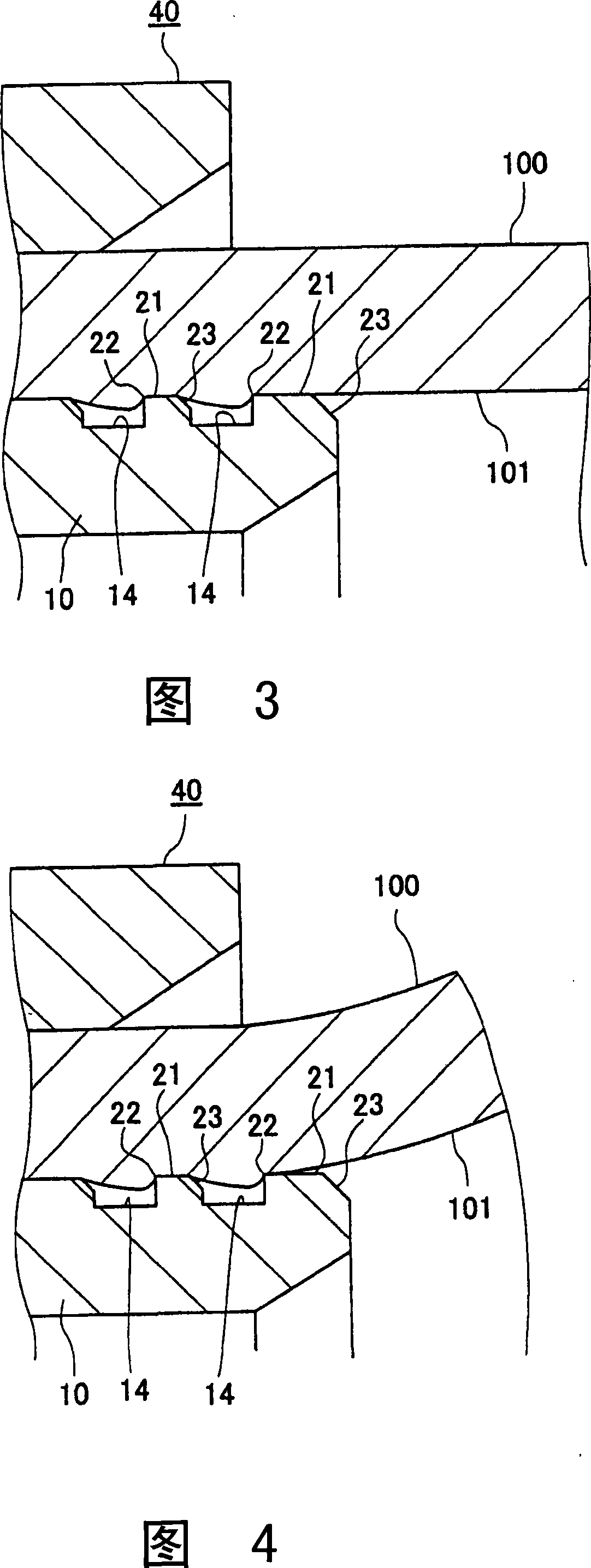

Joint for resin pipe

InactiveCN101210638AReduce inhibitionHigh anti-off performancePipe connection arrangementsEngineeringUltimate tensile strength

A joint for resin pipes, comprising: a joint body (1) having a joint barrel (10); a locking mechanism (20); a sealing body (50); indicator (60); cylindrical cover (40). The locking mechanism (20) includes: a main ring body (25); and an angular tooth portion (22) arranged on the annular convex portion (21) of the connecting cylinder portion 10. The cylindrical cover (40) has a transparent cover body (42) and a band ring (43) preventing the cover (42) from expanding and deforming. The indicator (60) has the insertion length of the resin tube (100) from the initial position fitted on the main ring body (25) to the stepped annular surface (11) at the root of the connecting cylinder (10). Set the effect at the appropriate value. In the present invention, by studying the locking mechanism and the like for preventing the resin tube from slipping, it can exert a high anti-slip performance and obtain a sufficiently large connection strength.

Owner:TAIFLEX +2

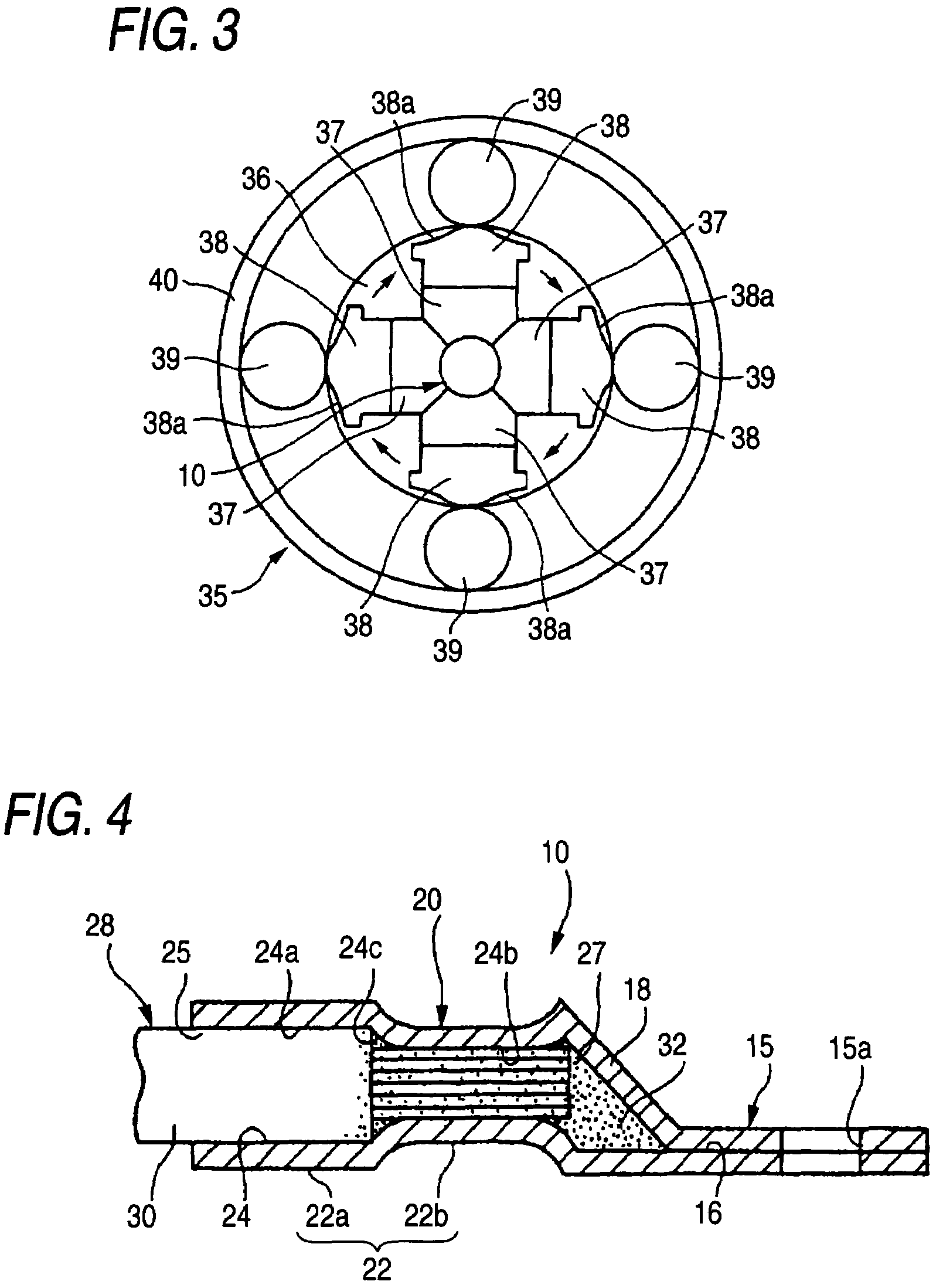

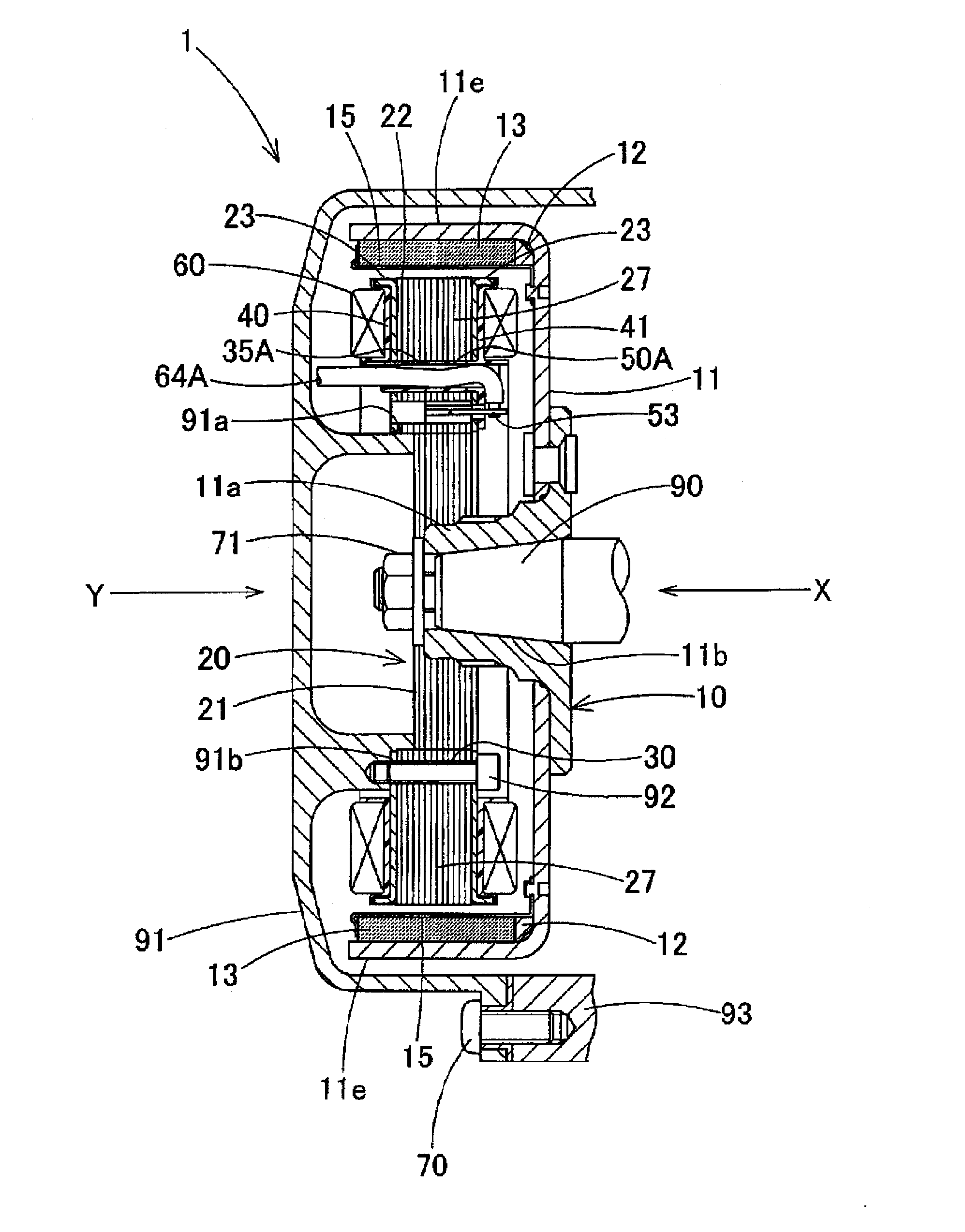

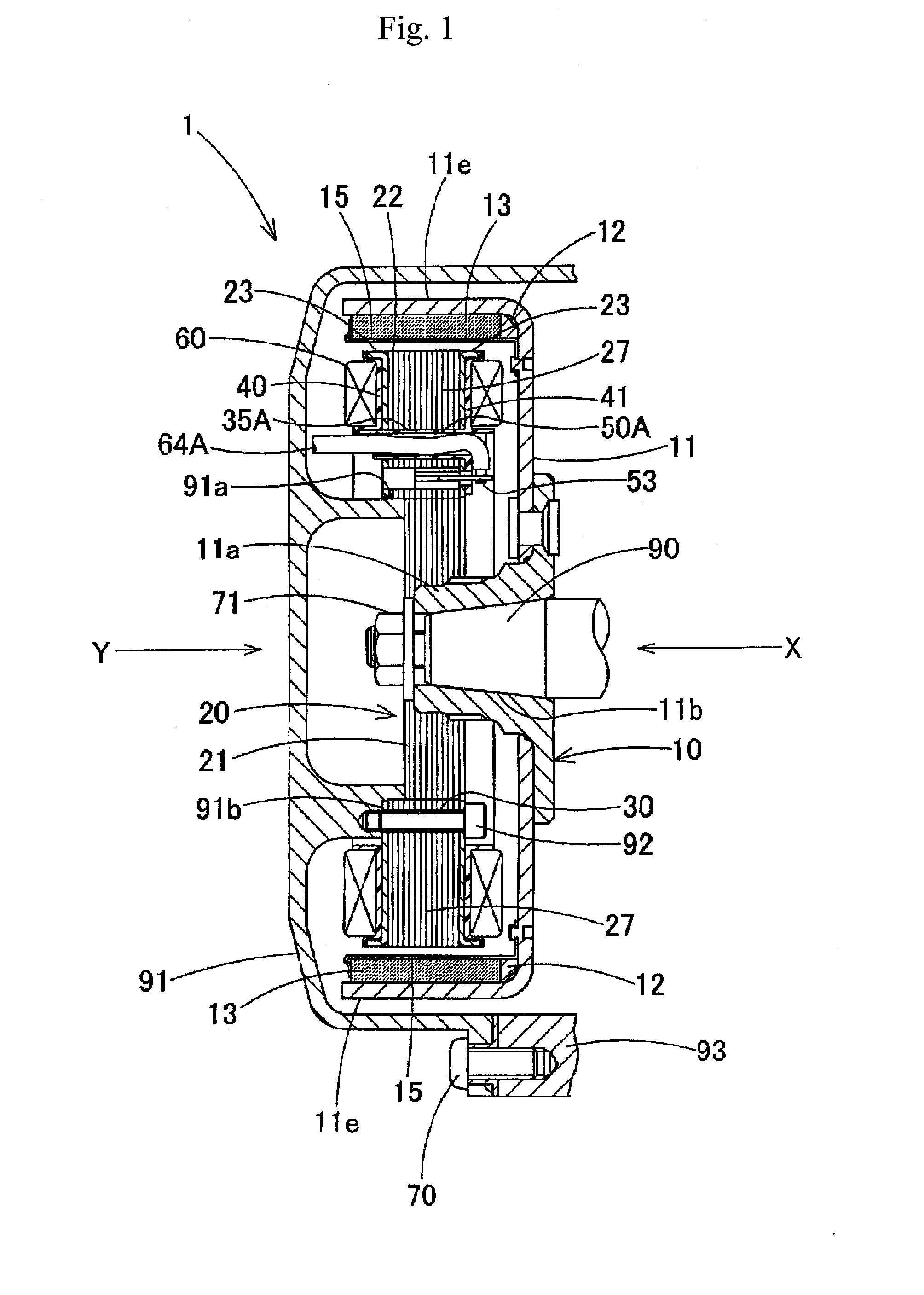

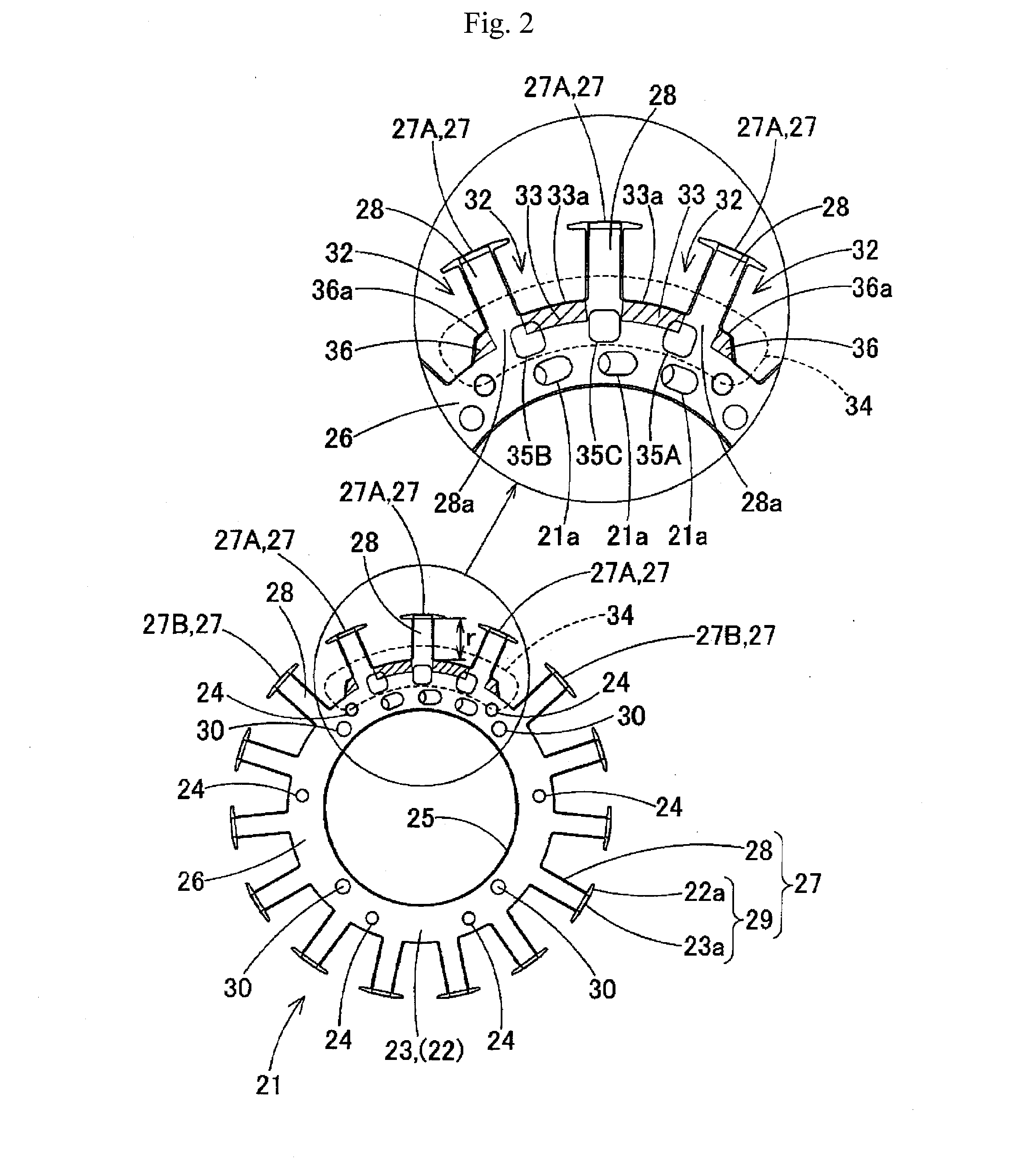

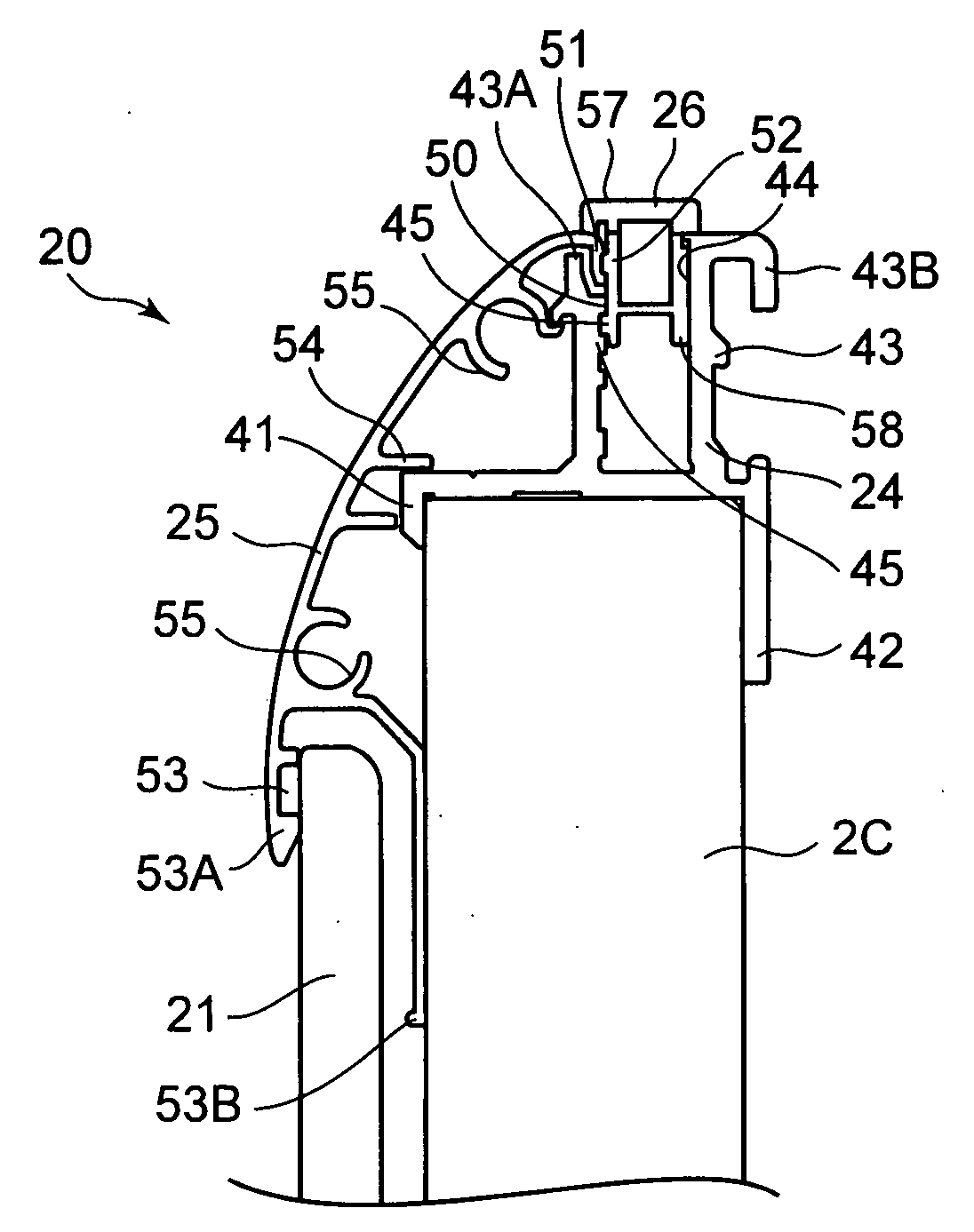

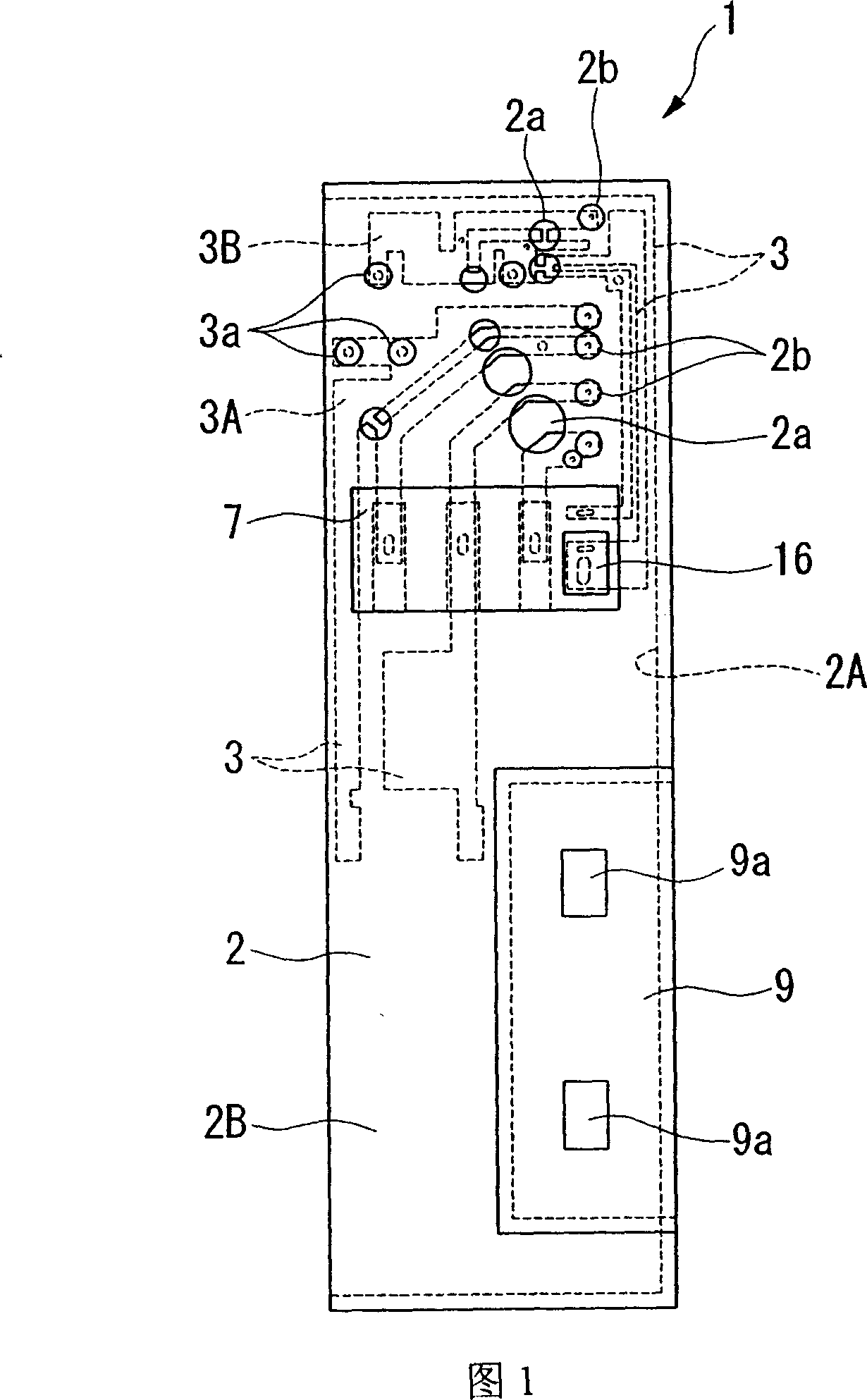

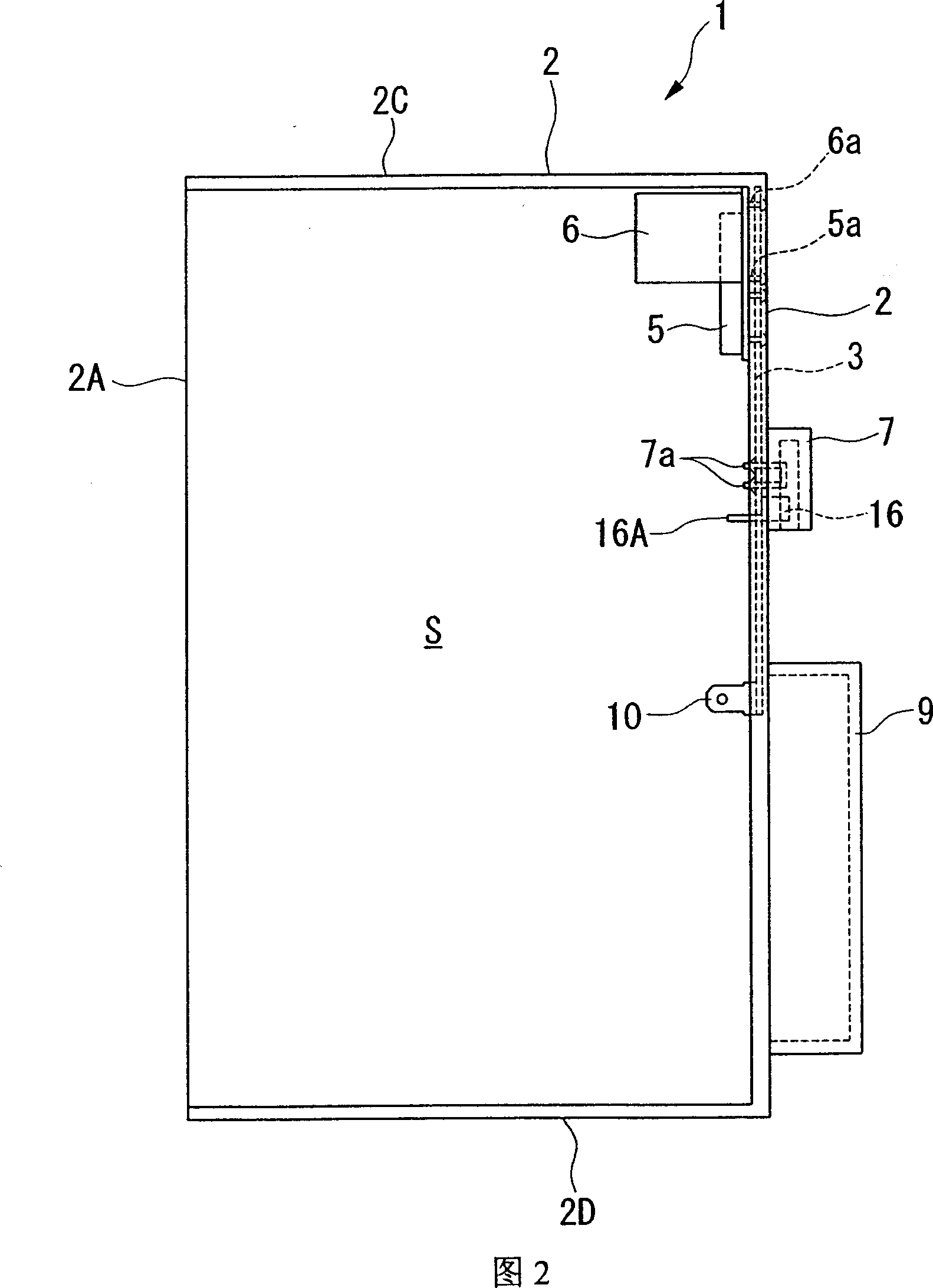

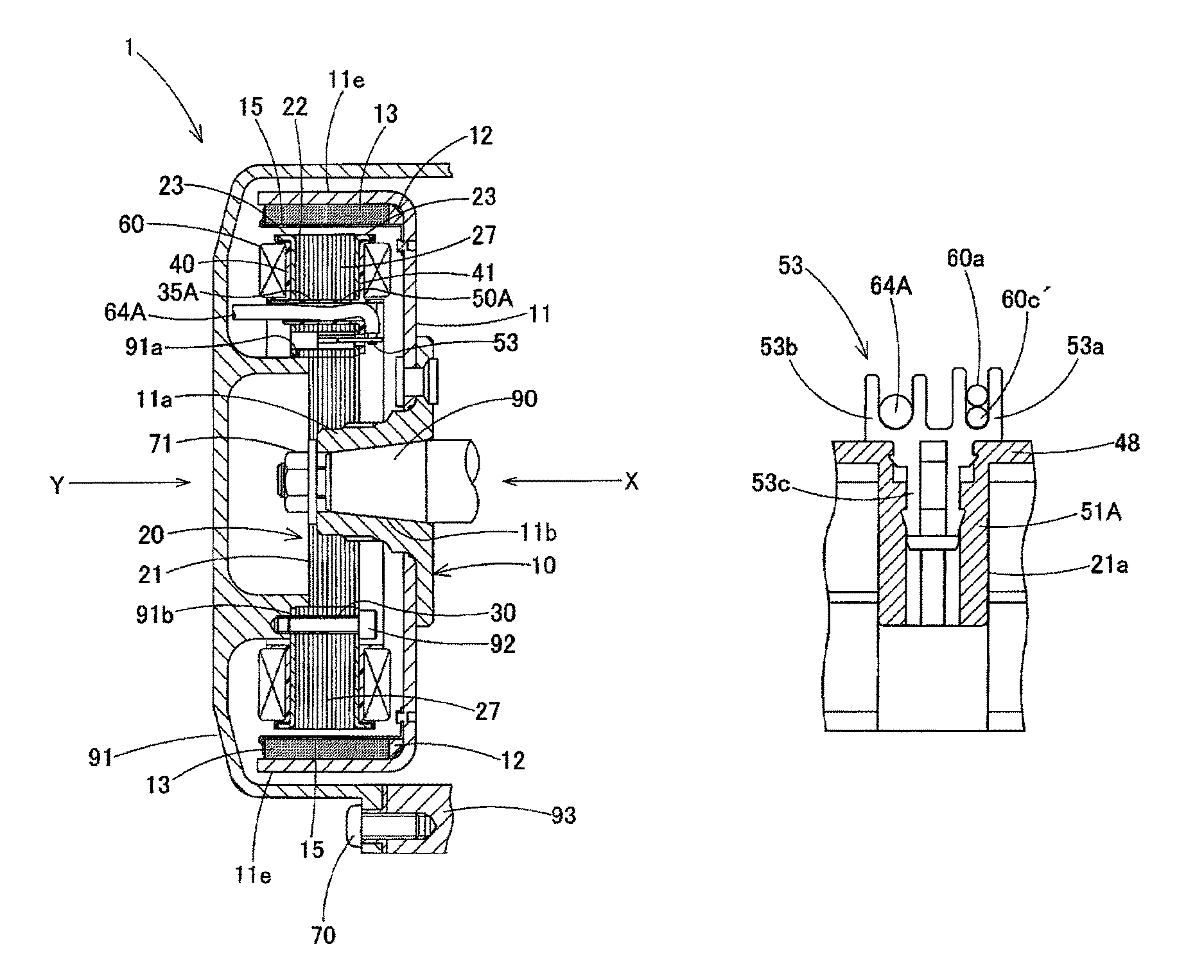

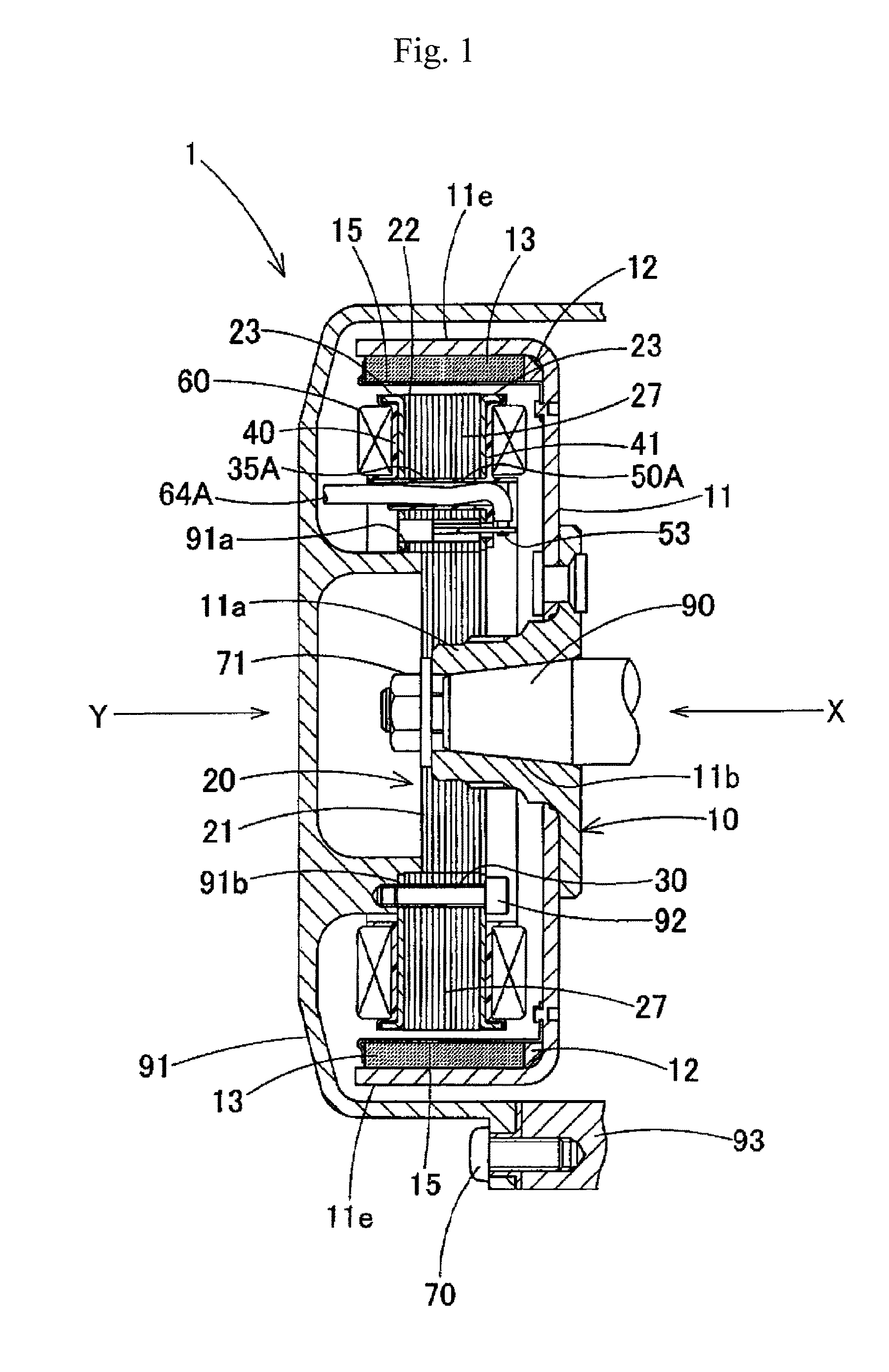

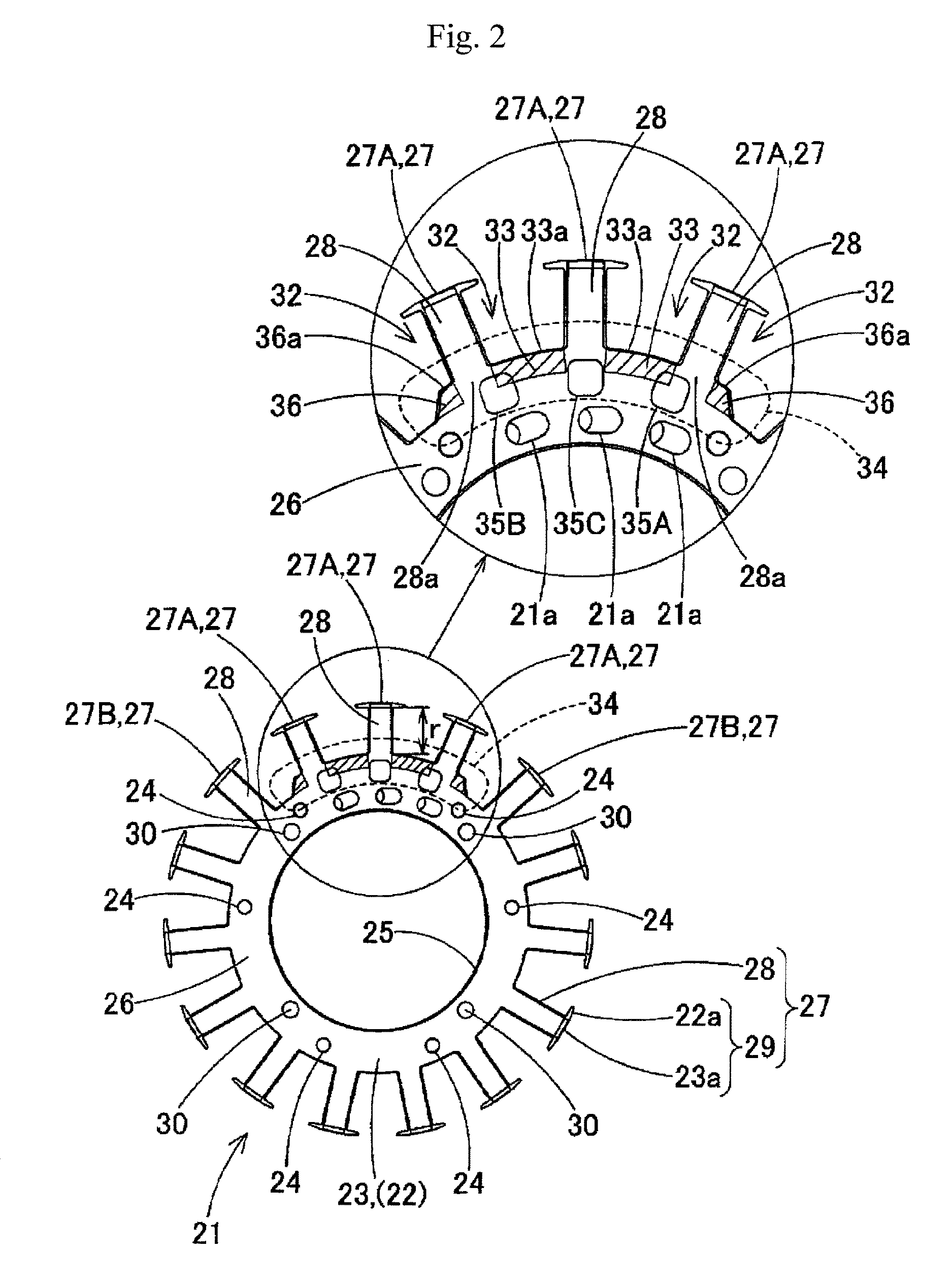

Magnet-type generator

ActiveUS20140333165A1Improve the immunityShort separation distanceWindings insulation shape/form/constructionMagnetic circuit rotating partsRotational axisBobbin

A magnet-type generator 1 has a stator 20 having a stator core 21, bobbins 40, 41 and a coil 60. The stator core has through holes 35A, 35B, 35C passing through the stator core along a rotation axis of the rotor so that lead wires 64A, 64B, 64C for outputting, which are corresponding to respective phases, are inserted into the through holes. The lead wires inserted into the through holes are connected with outgoing wires 60a, 60c′, 60b, 60a′, 60c, 60b′ of the coil at one side (clamping surface side) of the stator core 21 via a terminal (metal connection terminal) 53 fixed to a substrate portion (plate portion) 48 extending from the bobbin. The terminal is arranged near the through holes.

Owner:DENSO TRIM CO LTD

Cap and low insertion force connector for printed circuit board

InactiveUS6464528B2Insertion forceImprove connection workabilityEngagement/disengagement of coupling partsIncorrect coupling preventionLow insertion forceCountermeasure

A cap that is to be fitted to a printed circuit board, which has a conductive pad on the front side of the rectangular board thereof and which is to be connected to the connector. The cap is formed into a bag and is shaped into a wedge that gets thinner towards the front, and the cap has a window for exposing the conductive pad of the printed circuit board.A low insertion force connector that connects a printed circuit board having conductive pads on the front side of the rectangular board thereof. This low insertion force connector comprises a connector body having at least a pair of contacts that contact the conductive pads and clamp the printed circuit board, a slider that carries the printed circuit board and advances to and retreats from the contact, and a guide that is provided at the front end of the slider and is formed into a wedge-shape, which gets thinner towards the front.The present invention reduces the insertion force of the printed circuit board, enhances the connection workability, and eliminates damages or the like to the contacts and the conductive pad to enhance the reliability. The present invention provides a connector that is also effective in countermeasures against heat and electromagnetic waves.

Owner:JST MFG CO LTD

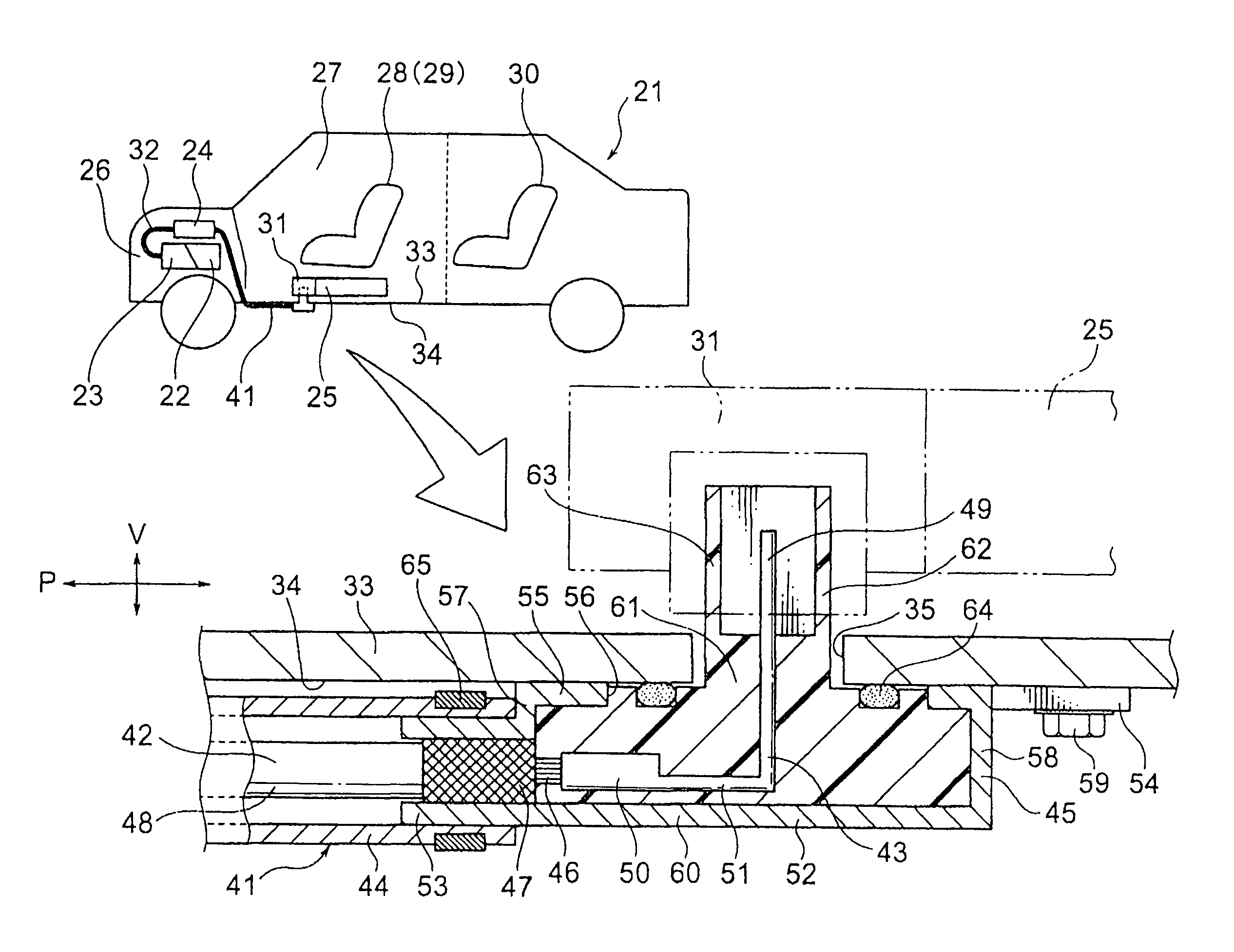

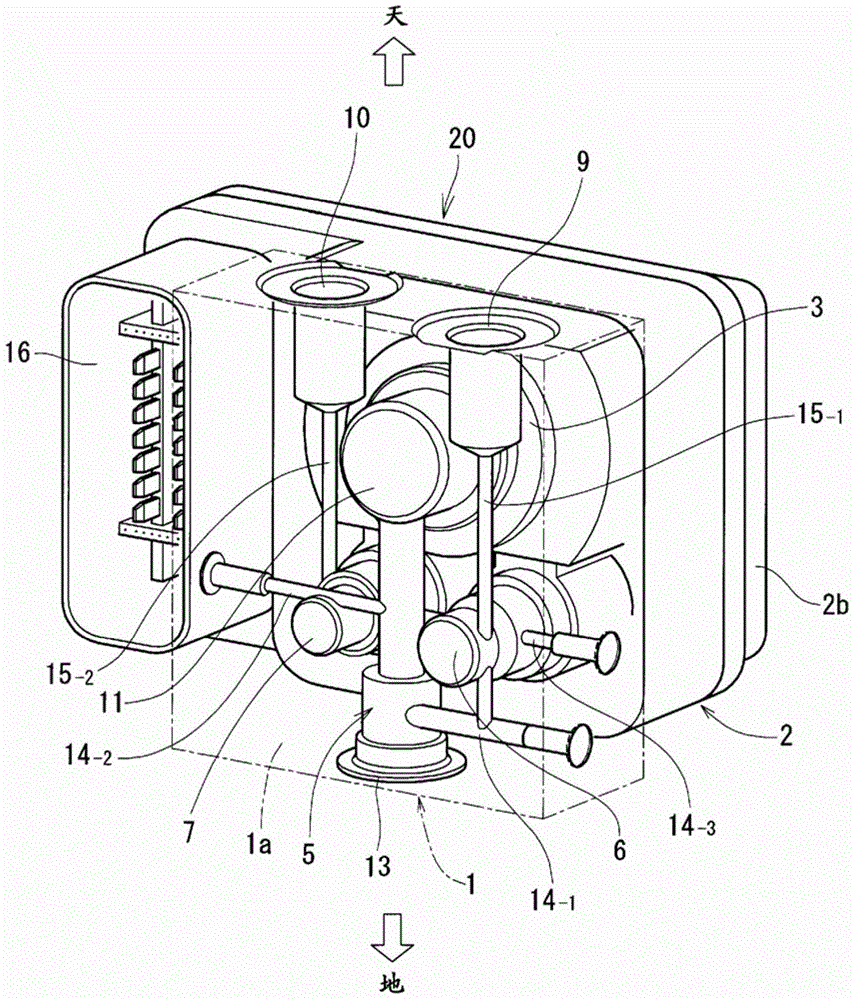

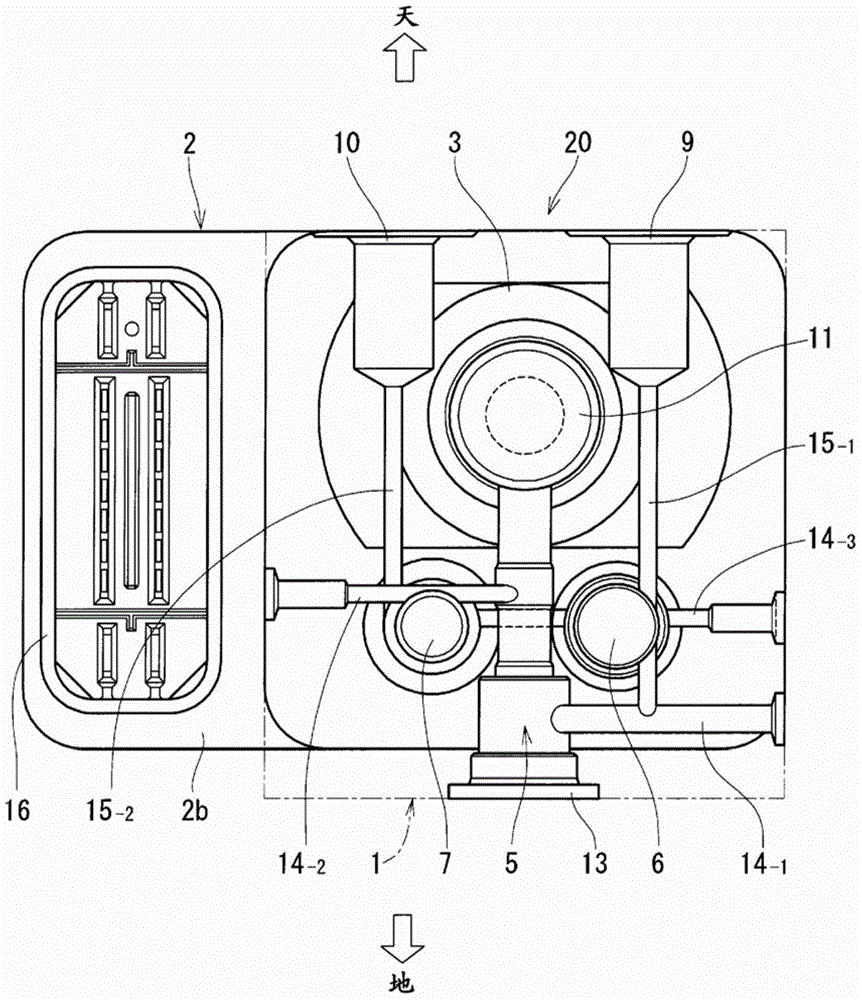

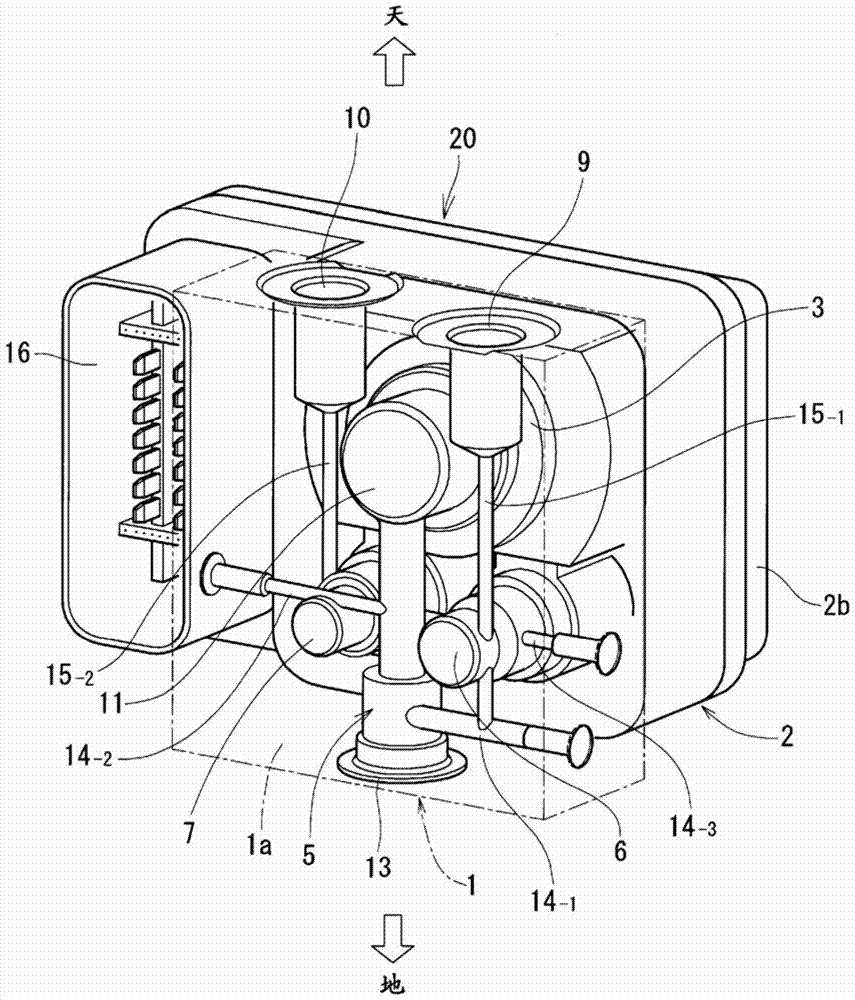

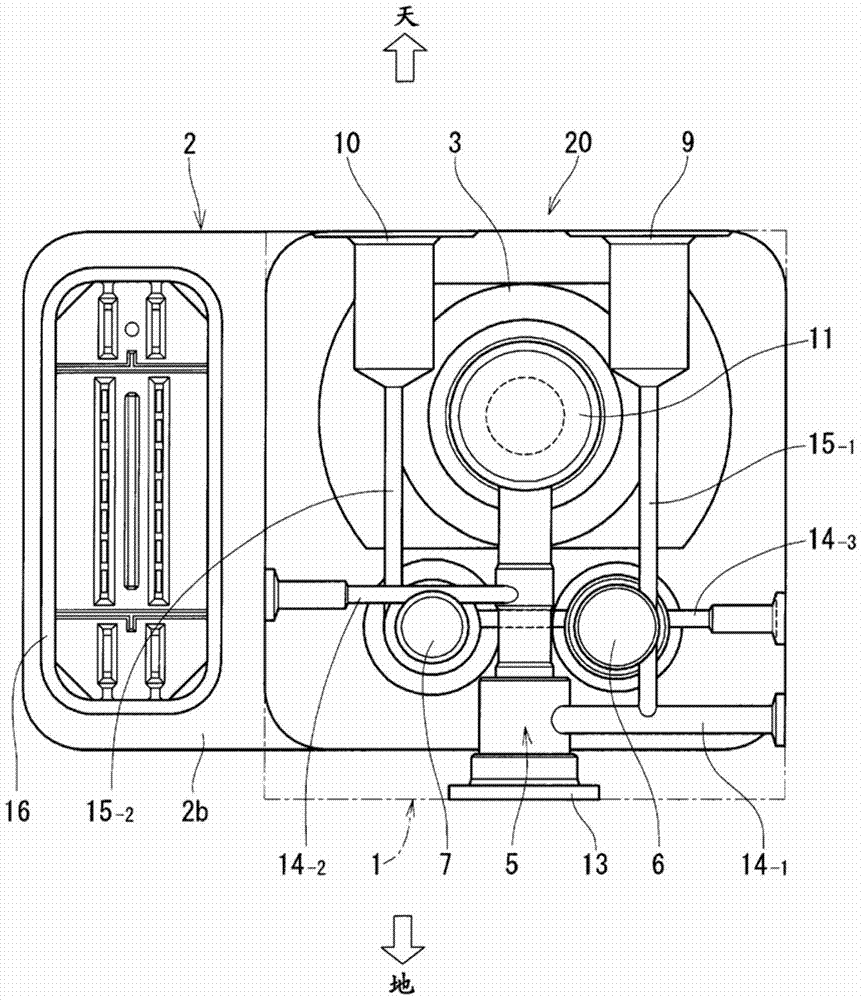

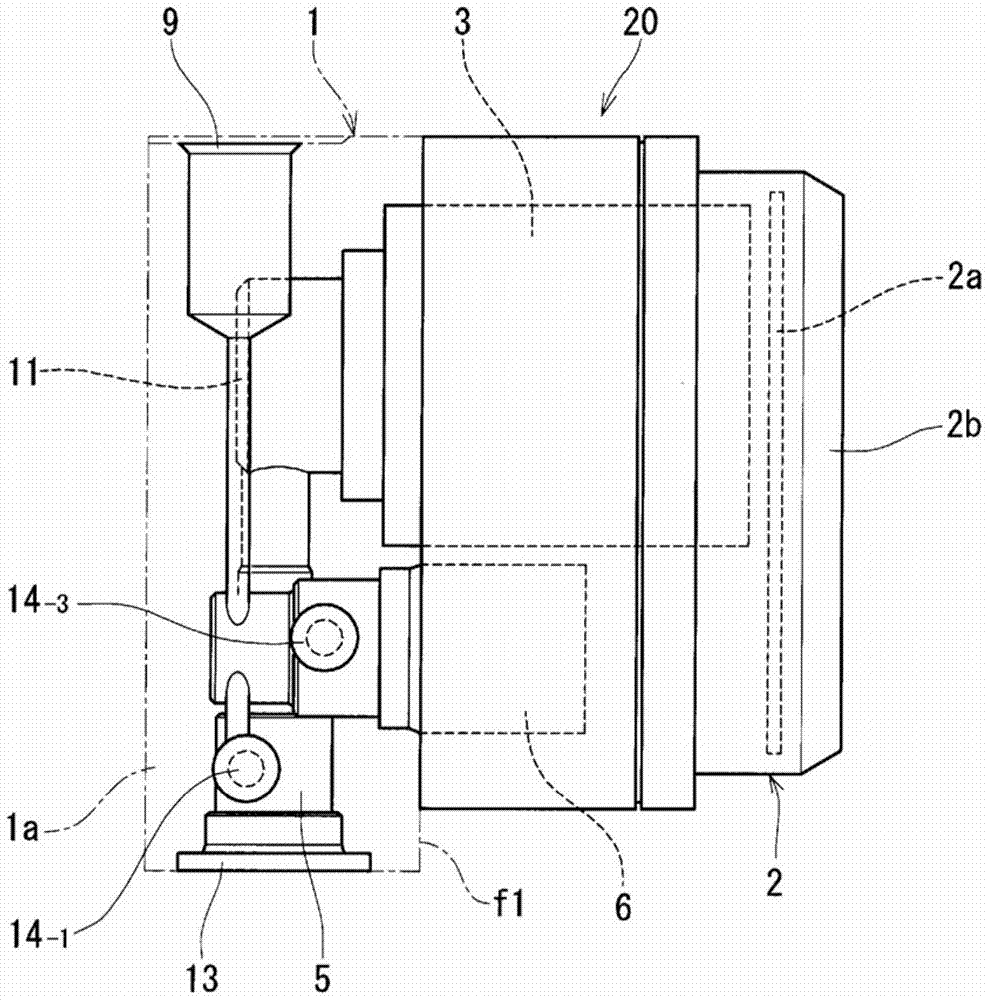

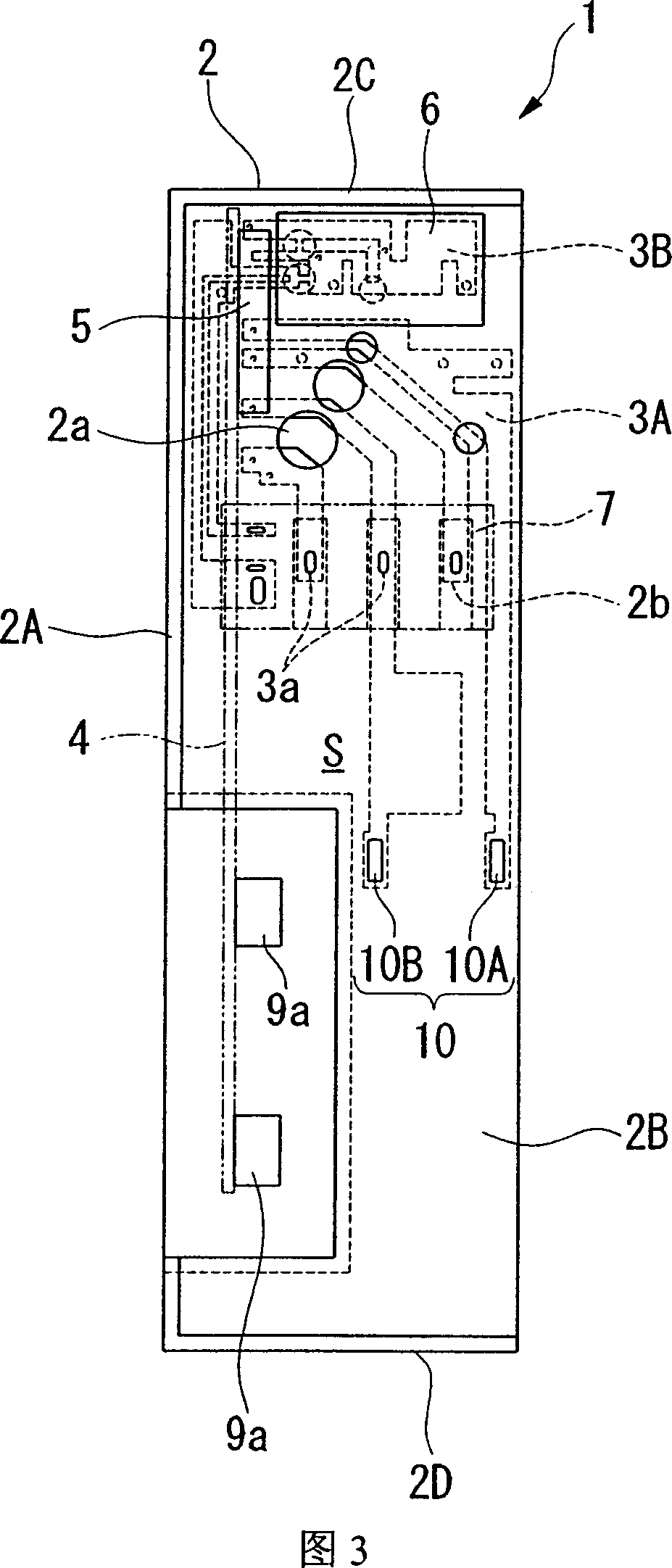

Brake fluid pressure control apparatus

ActiveCN104797471ASave assembly spaceIncrease heightApplication and release valvesEngineeringWheel cylinder

The purpose is to decrease the physical size of a brake fluid pressure control apparatus for implementing pressure increasing / decreasing control for the fluid pressure in a wheel cylinder. A brake fluid pressure control apparatus is provided with: a piston pump (5); a pump drive motor (3); an eccentric cam rotated by the motor to activate the piston pump; a pressure-increasing electromagnetic valve (6); and a pressure-decreasing electromagnetic valve (7), in which the piston pump (5), the eccentric cam, the pressure-increasing electromagnetic valve (6), and the pressure-decreasing electromagnetic valve (7) are assembled in a housing (1a). The single piston pump (5) is installed, with the piston pump (5), when mounted on a vehicle, disposed in an upright posture under or above a cam chamber (11) of the housing in which the eccentric cam is housed.

Owner:ADVICS CO LTD

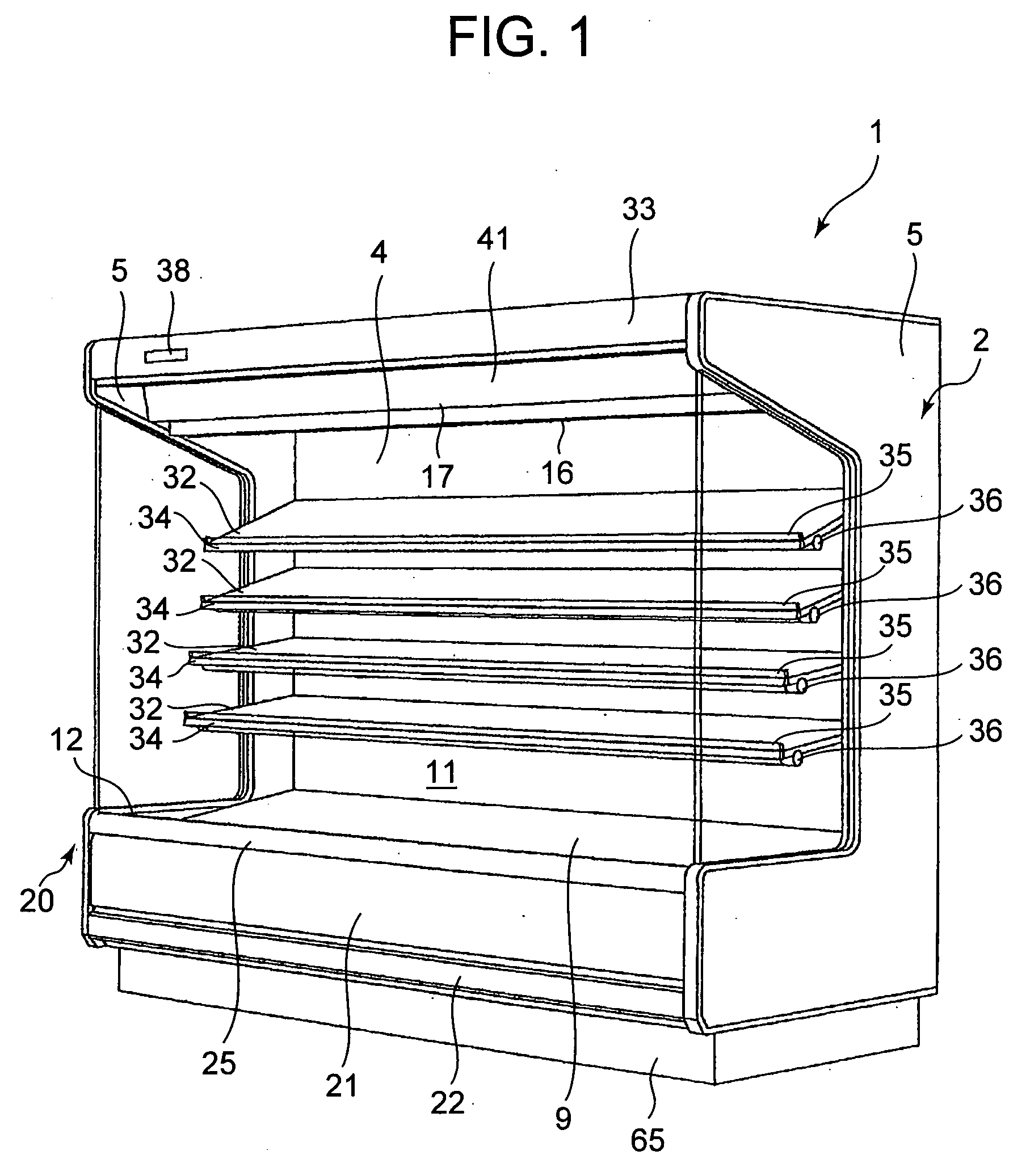

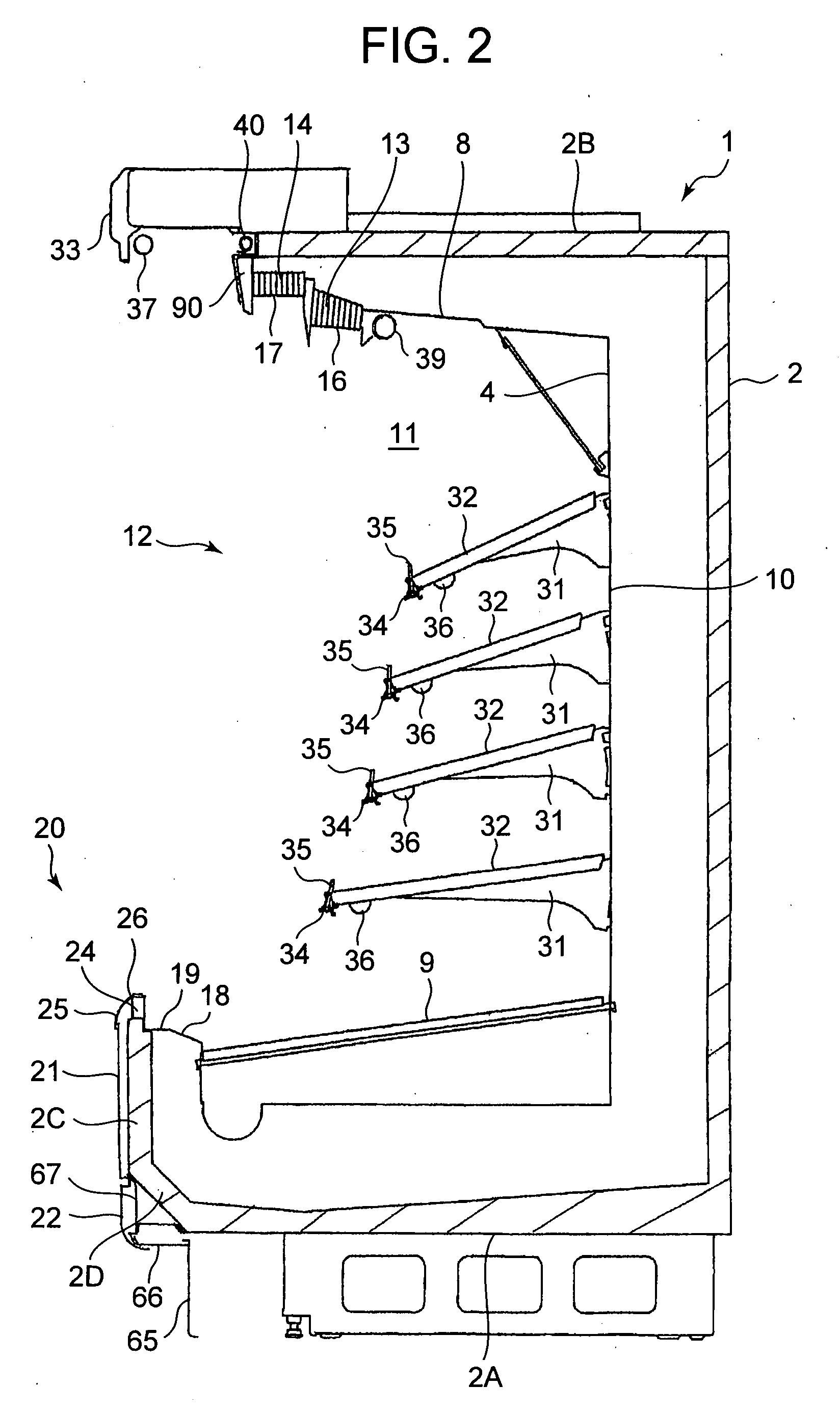

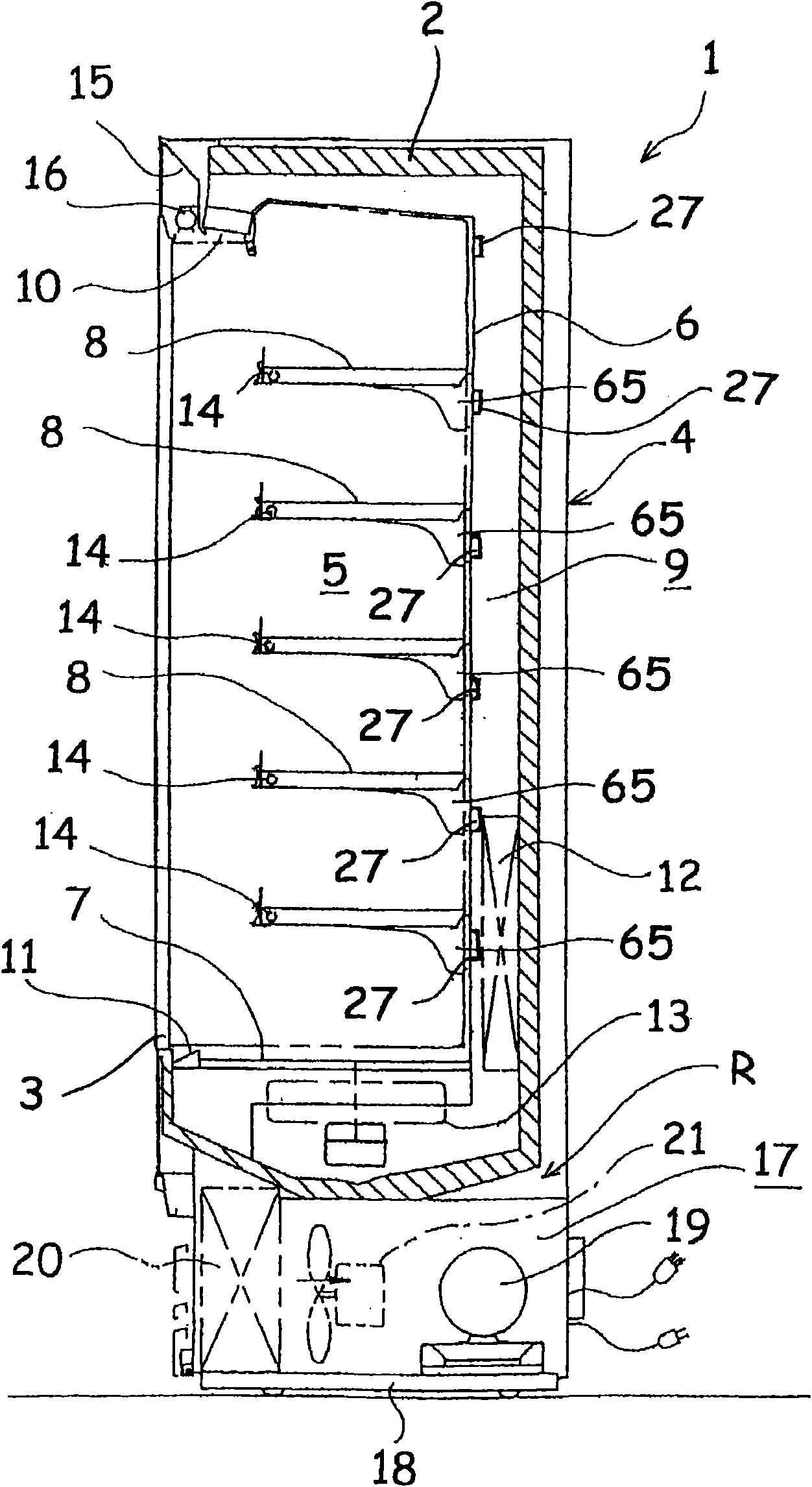

Showcase

InactiveUS20070194670A1Improve workabilityEasy to set upShow cabinetsLighting and heating apparatusEngineeringMechanical engineering

The object is to provide a showcase having a connection device which can improve the workability in connection of adjacent showcases and can improve the appearance. The showcase has a connection device for connection of the show case with another adjacent showcase at one side of the lower retreating section of the front wall of the insulating wall, wherein the features are: the connection device includes a receiving metal fixed to the retreating section and a connecting metal extending over and mounted on the receiving metal and a receiving metal of another adjacent showcase; and the receiving metal has a mounting surface positioned on the front side of the retreating section and directed forward, and the mounting surface has a mounting hole formed for securing the connecting metal thereto.

Owner:SANYO ELECTRIC CO LTD

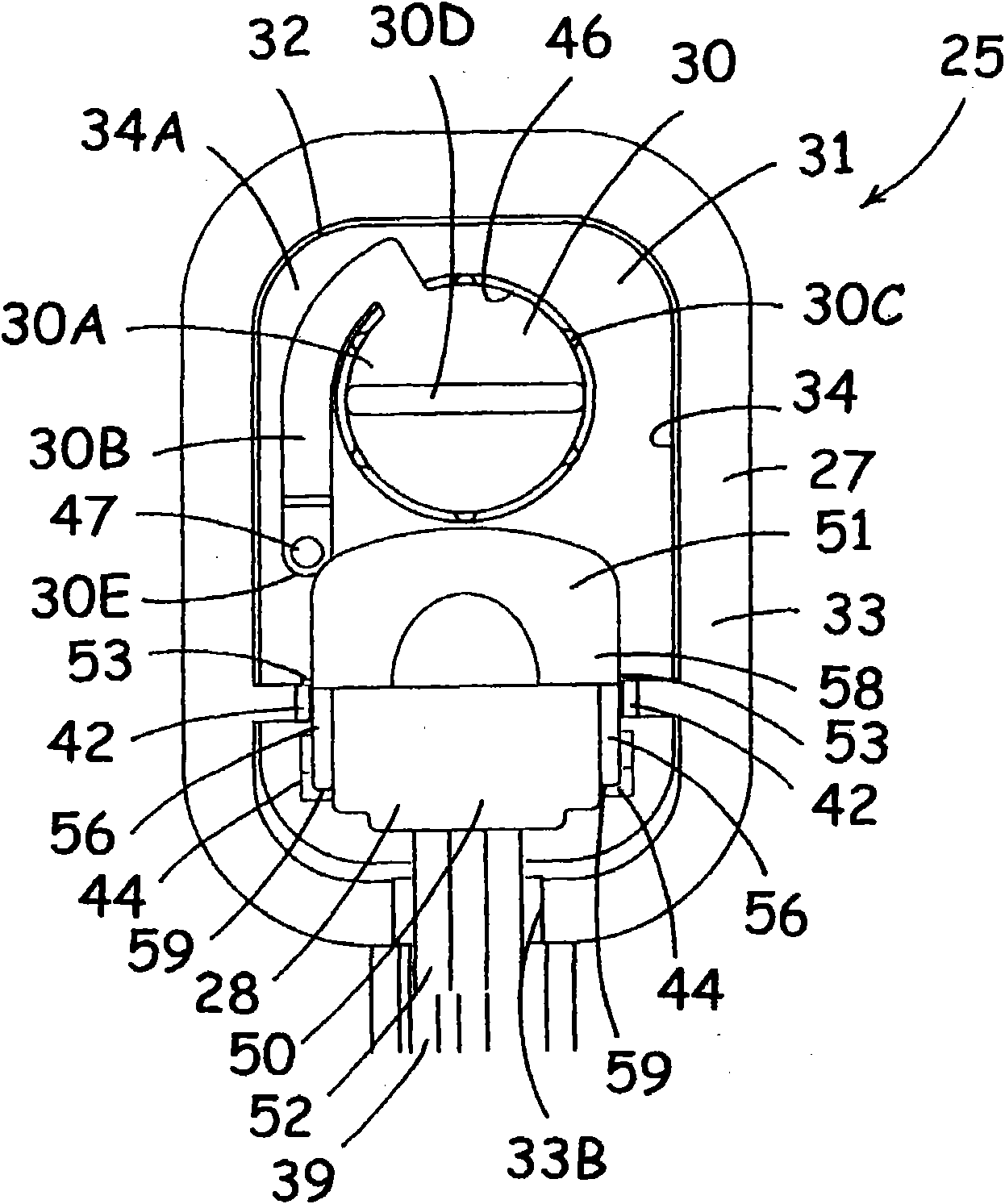

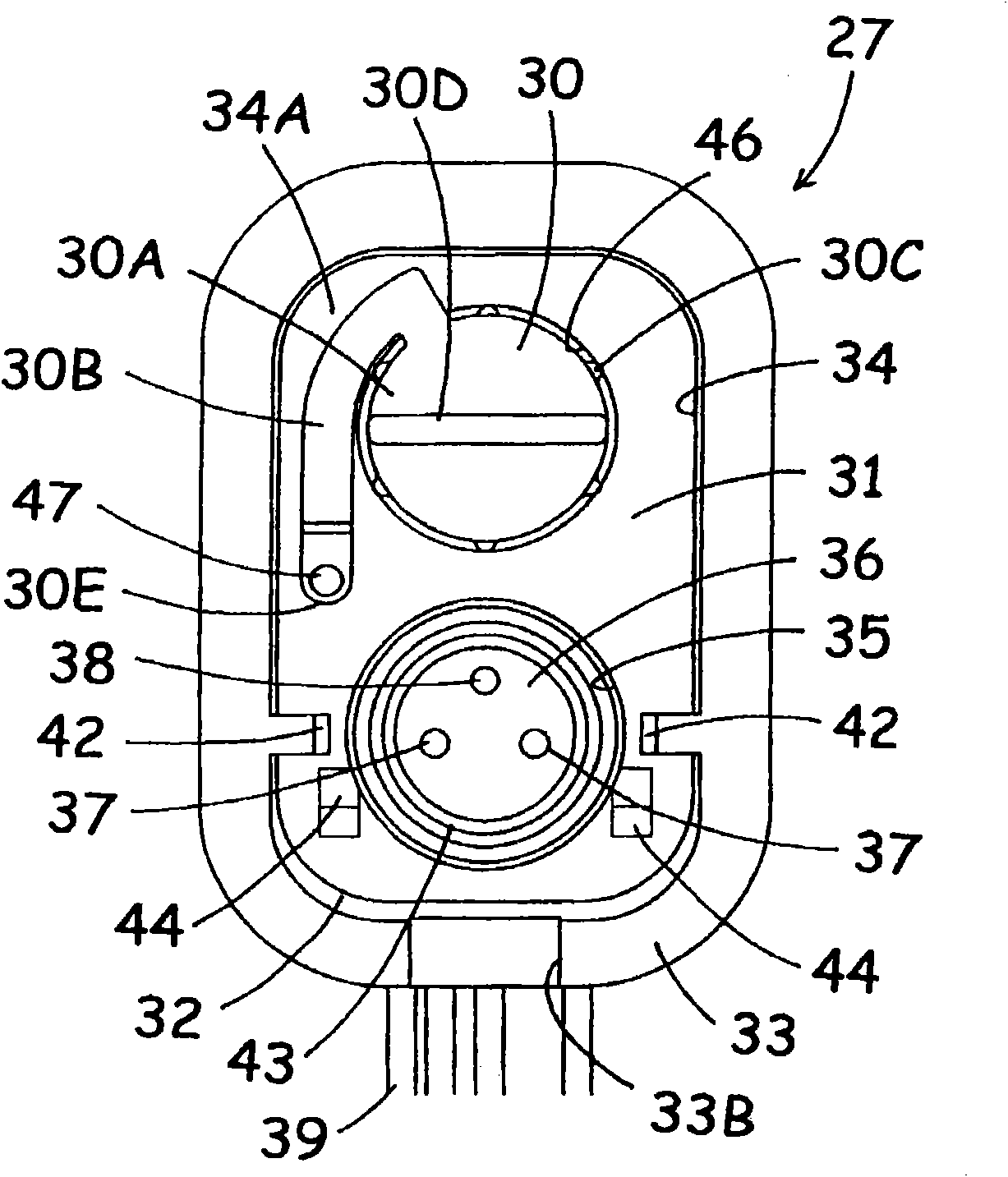

Power connection apparatus

ActiveCN101989711ATurn freelyImprove connection workabilityCoupling device detailsTwo-part coupling devicesElectrical and Electronics engineeringElectrode

There is disclosed a power connection apparatus which can secure connection between a power socket and a power plug and which can simplify the connecting operation properties thereof. A handle rotatably attached to the power plug having terminals includes engaging claw disengageably engaged with engagement portion of the power socket having an electrode portion, an abutment portion which abuts onthe power socket, and a grip portion. The rotation of the grip portion in such a direction as to come away from the power socket is limited by the angle of the rotation of the handle in a direction in which the grip portion comes close to the power socket.

Owner:SANYO ELECTRIC CO LTD

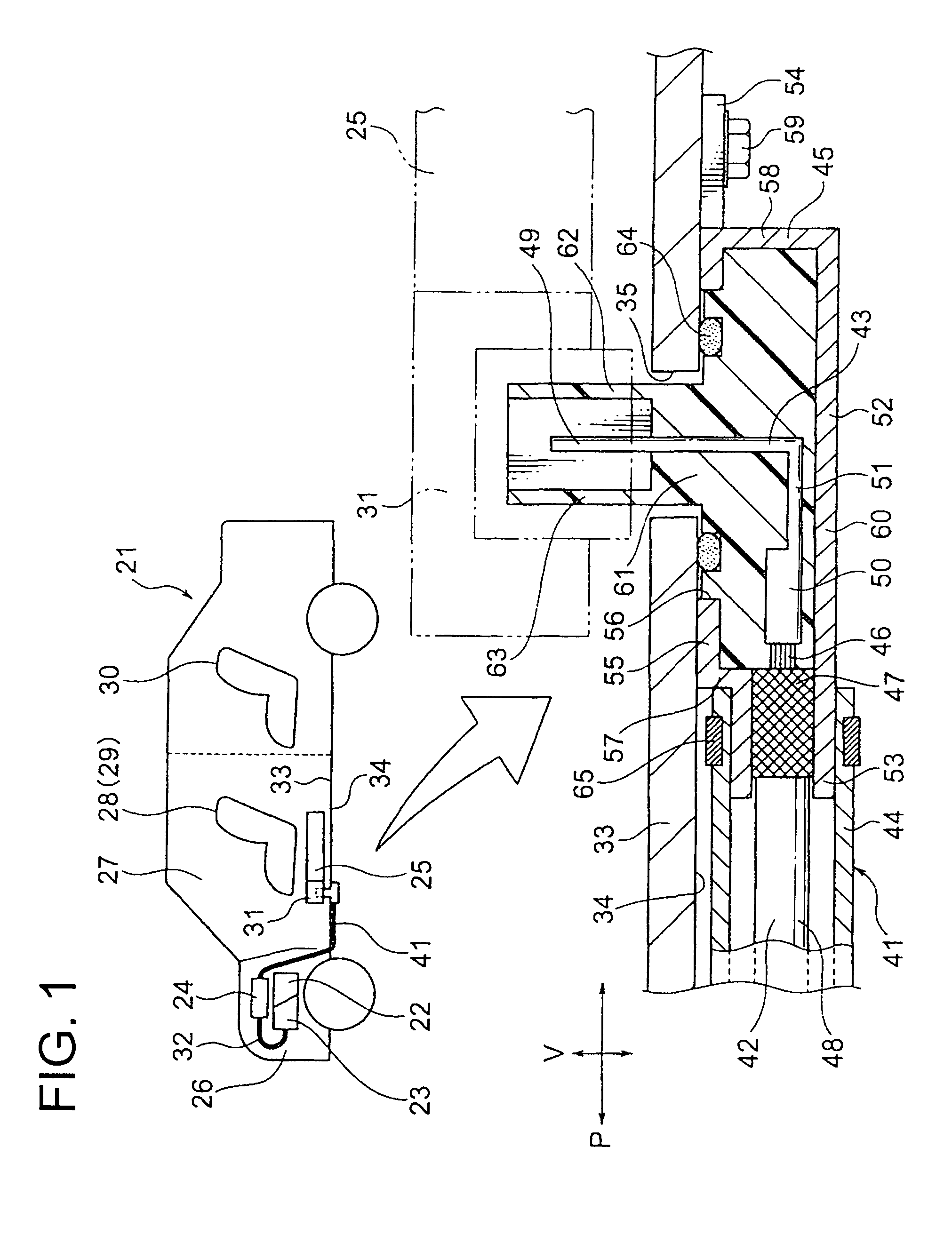

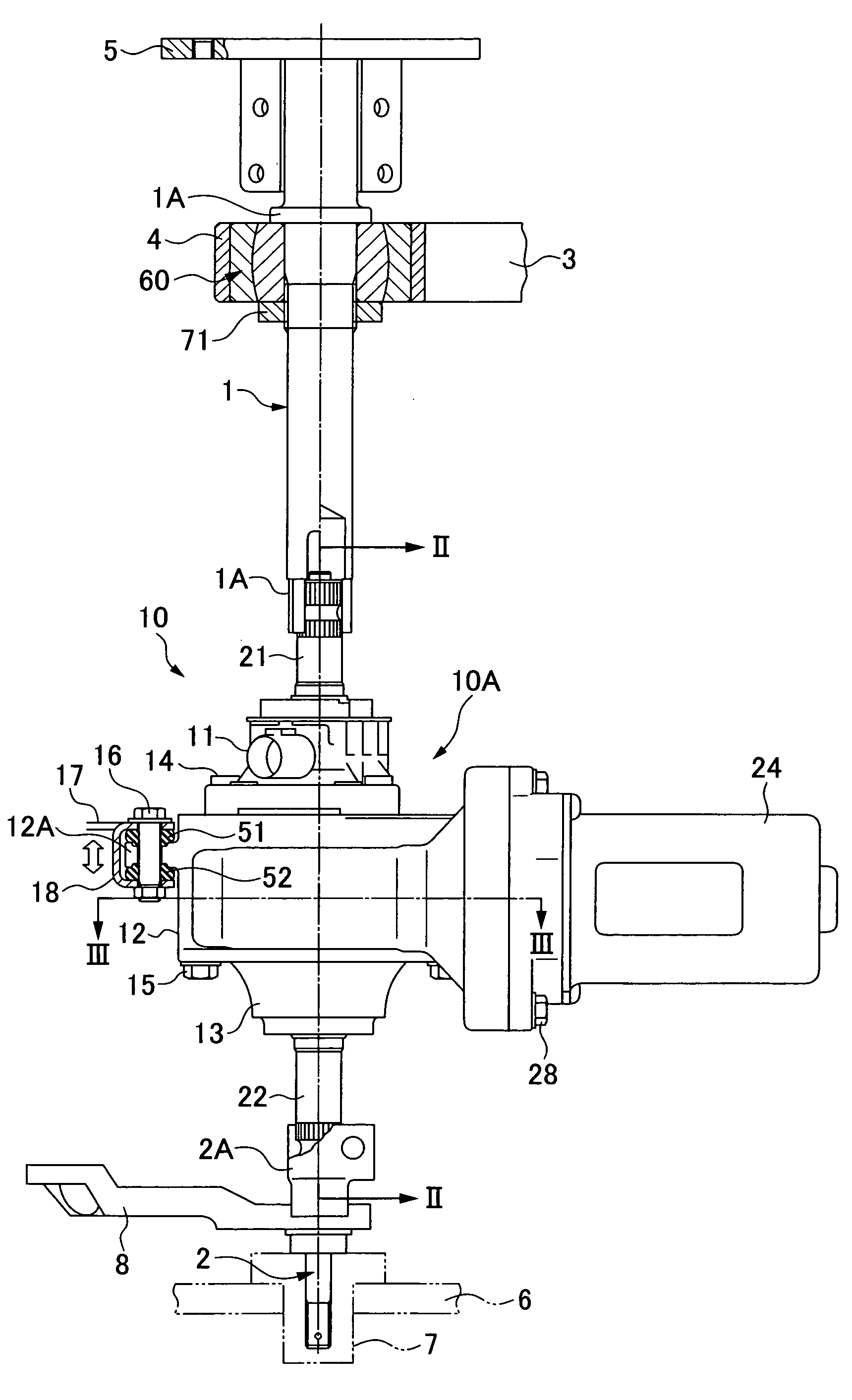

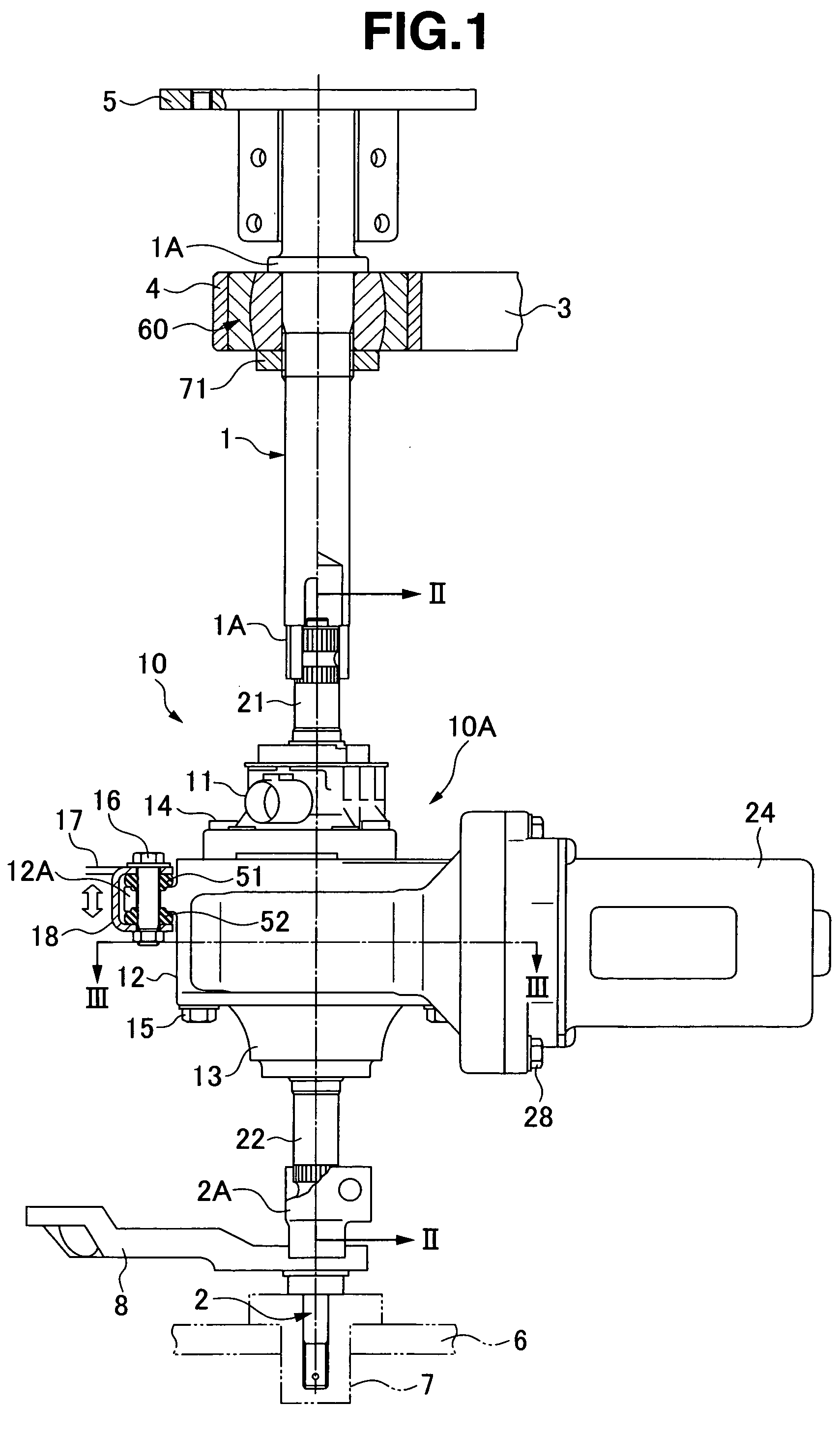

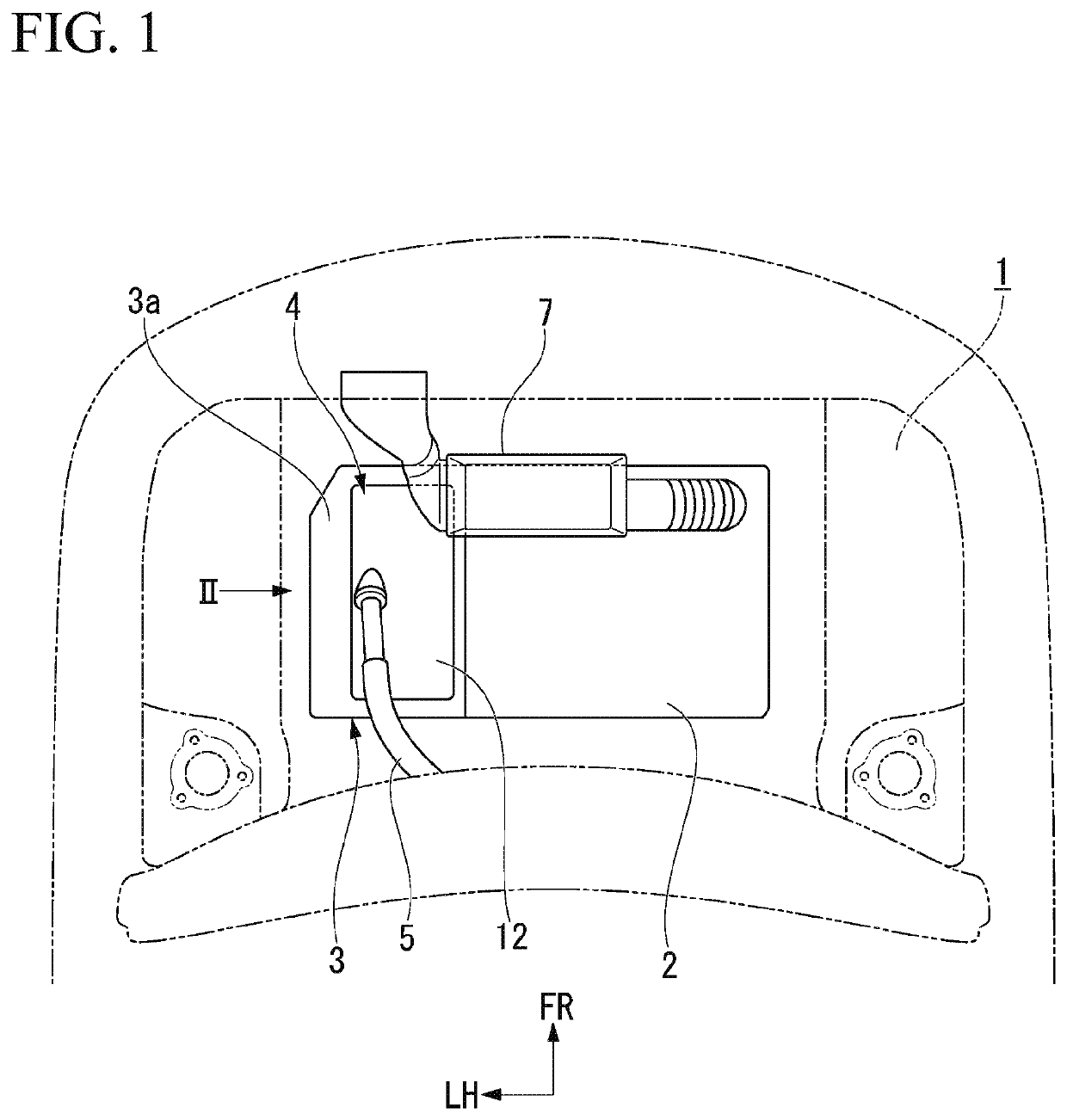

Steering shaft support structure of motor-driven steering assist apparatus

InactiveUS7909129B2Improve connection workabilityStable steering assist performanceSteering linkagesElectrical steeringMotor driveControl theory

Owner:SHOWA CORP

Power control unit

ActiveUS20200274424A1Improve connection workabilityEasy to implementAssociation with control/drive circuitsSupports/enclosures/casingsElectrical conductorControl cell

A power control unit includes a power module, a support block configured to support the power module, an upper case configured to cover the power module from above, and a connection conductor configured to connect an internal power feeding passage on the side of the power module and an external power feeding passage on the side of the motor unit, wherein the connection conductor vertically passes through the support block and includes a connecting fixing section that protrudes upward than the support block and that is connected to the internal power feeding passage by a fastening member, an inclination wall inclined downward toward a side end portion of the upper wall of the upper case is provided on the upper wall of the upper case, and an opening section facing the connecting fixing section of the connection conductor is provided in the inclination wall.

Owner:HONDA MOTOR CO LTD

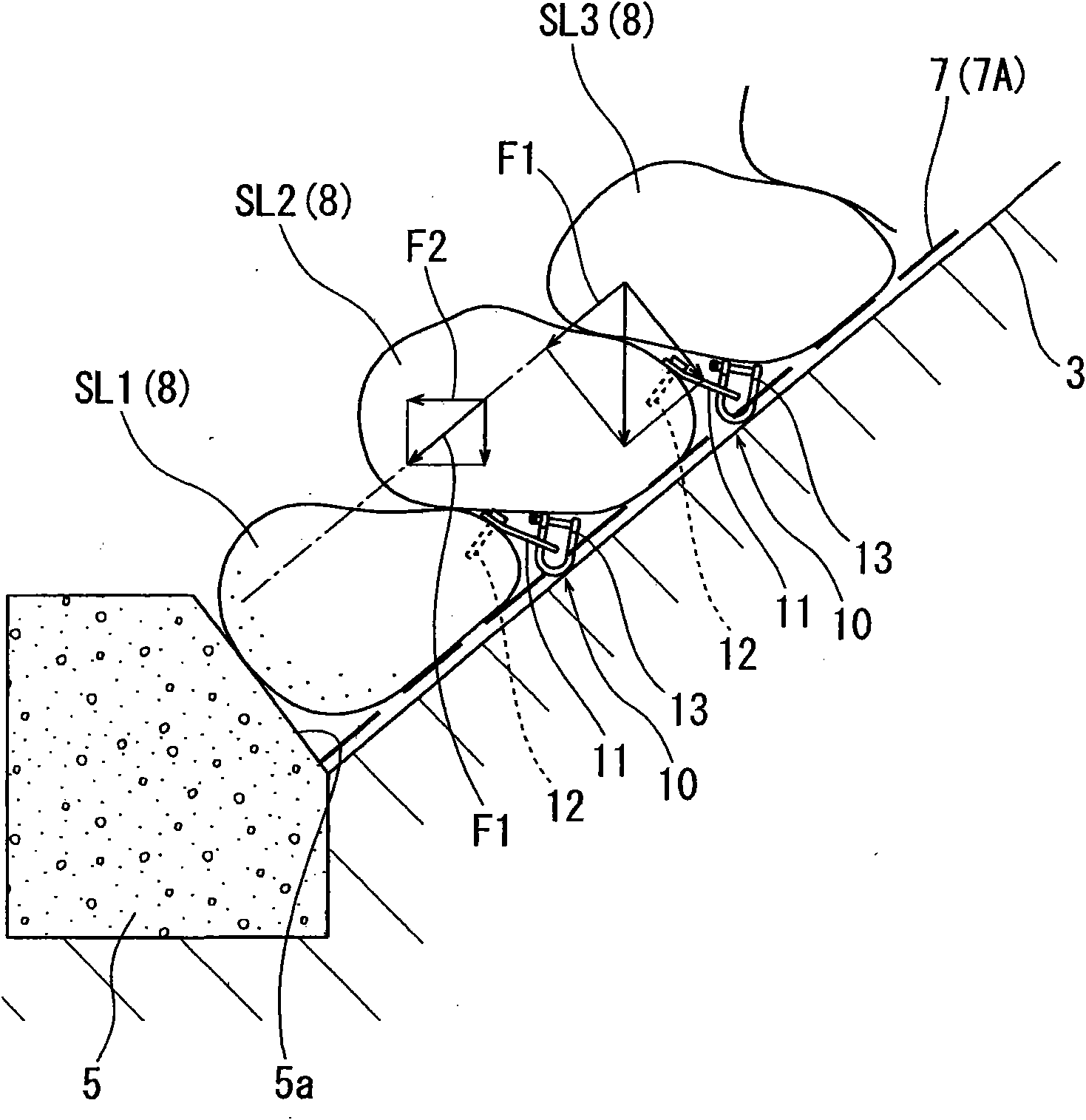

Civil structure and construction method thereof

InactiveCN101660302AContinuous configurationPrevent loss of aestheticsCoastlines protectionExcavationsNatural stoneMetal mesh

The invention provides a civil structure, which can be built in the same way as the construction of the assembly of the civil structure even if no heavy machinery can be used and no civil structure assembly for installing a plurality of block-shaped members at one side of flexible sheet forming a grid-shaped texture is used. a plurality of natural stones (8) are continuously arranged on a metal mesh connecting body (7) in sequence from the lower side to the upper side along a slope (3) by taking the natural stones (8) at the bottom as a support in the way that the natural stones are limited tobe moved to the lower side in the sloping direction of the slope (3), and when each natural stone (8) is arranged on the metal mesh connecting body (7), each natural stone (8) is connected with the metal mesh connecting body (7) by using a connecting member (10). even if no heavy machinery is used, the civil structure (1) can be built manually (by an operator).

Owner:KANKYO KOGAKU KK

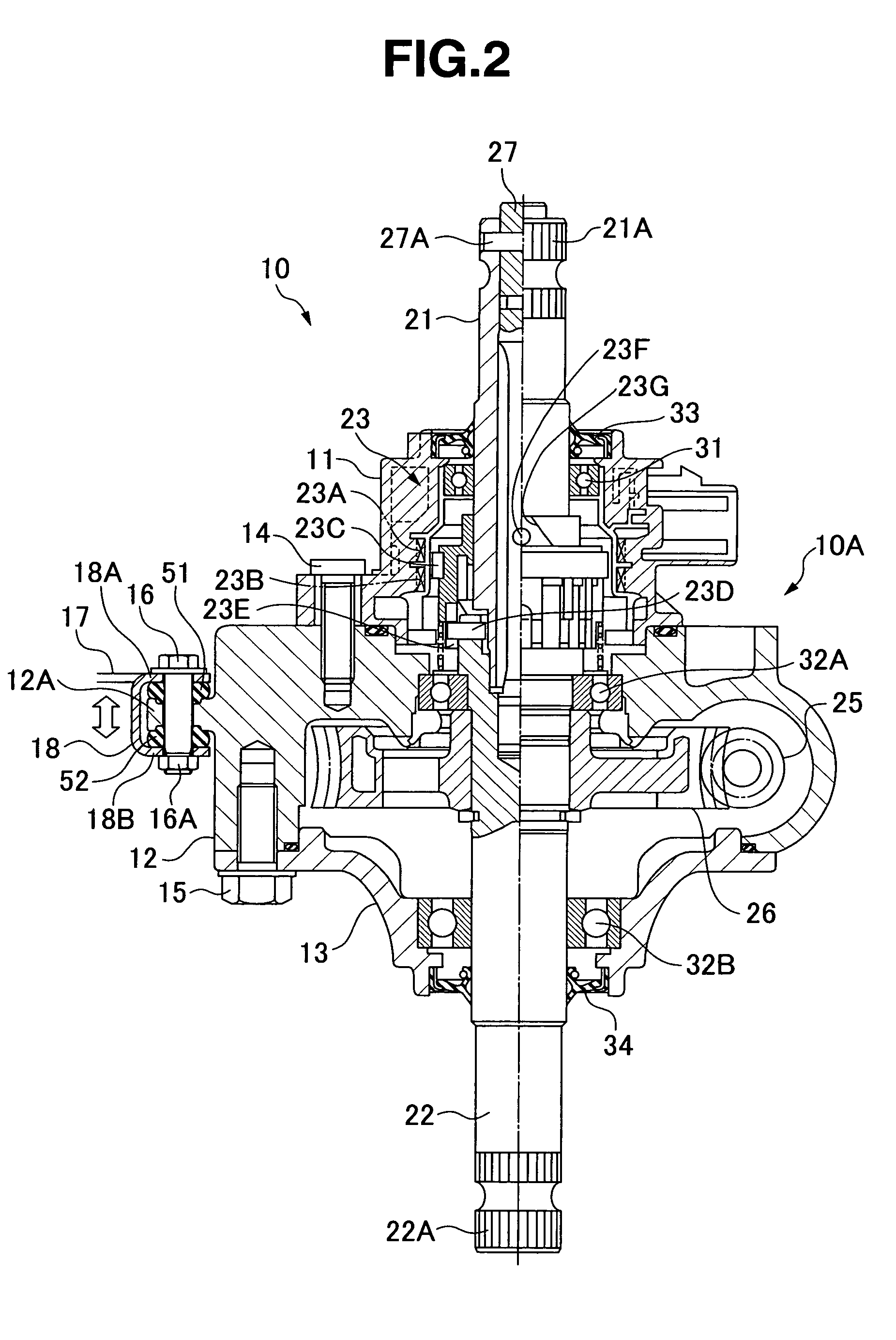

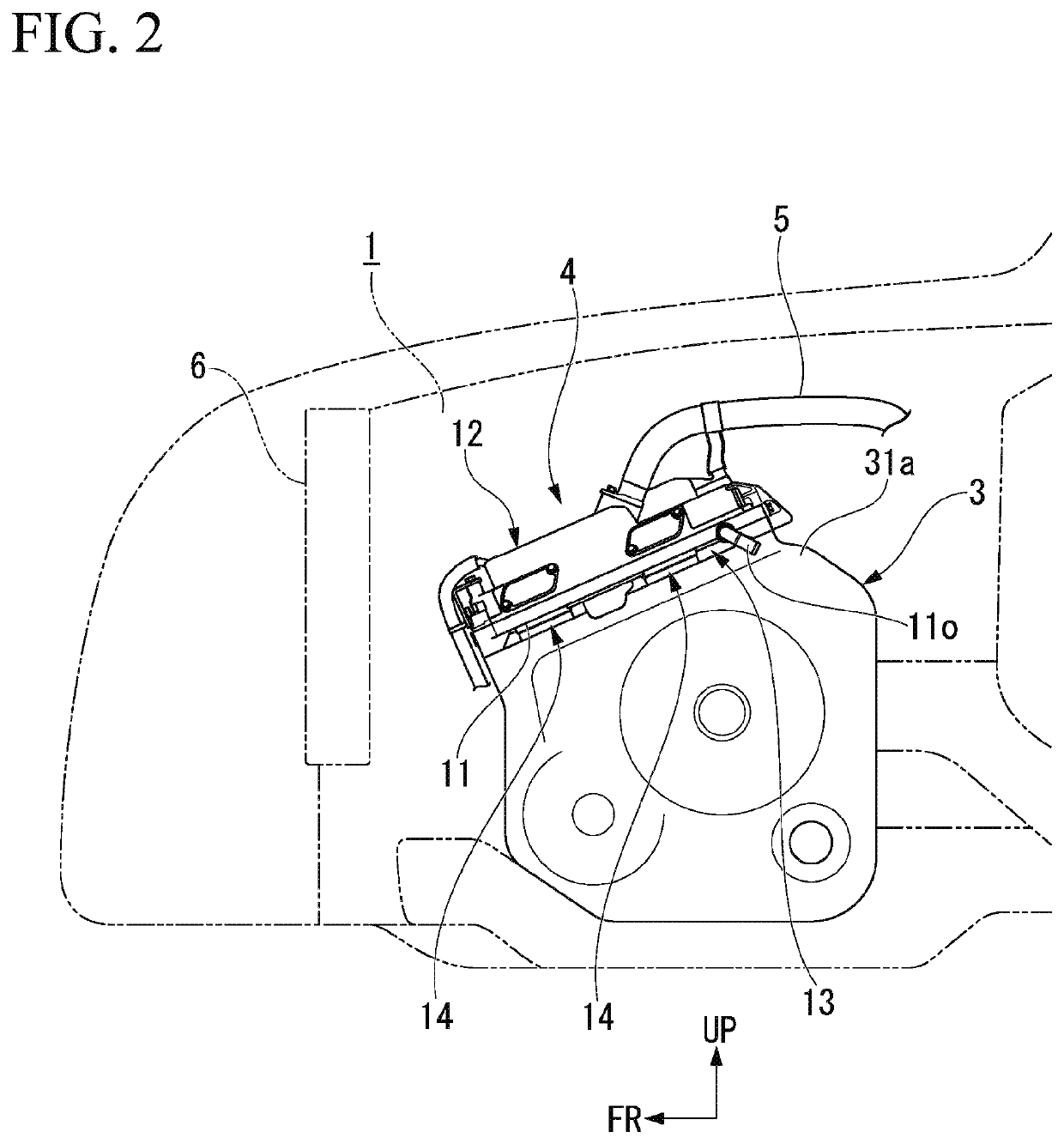

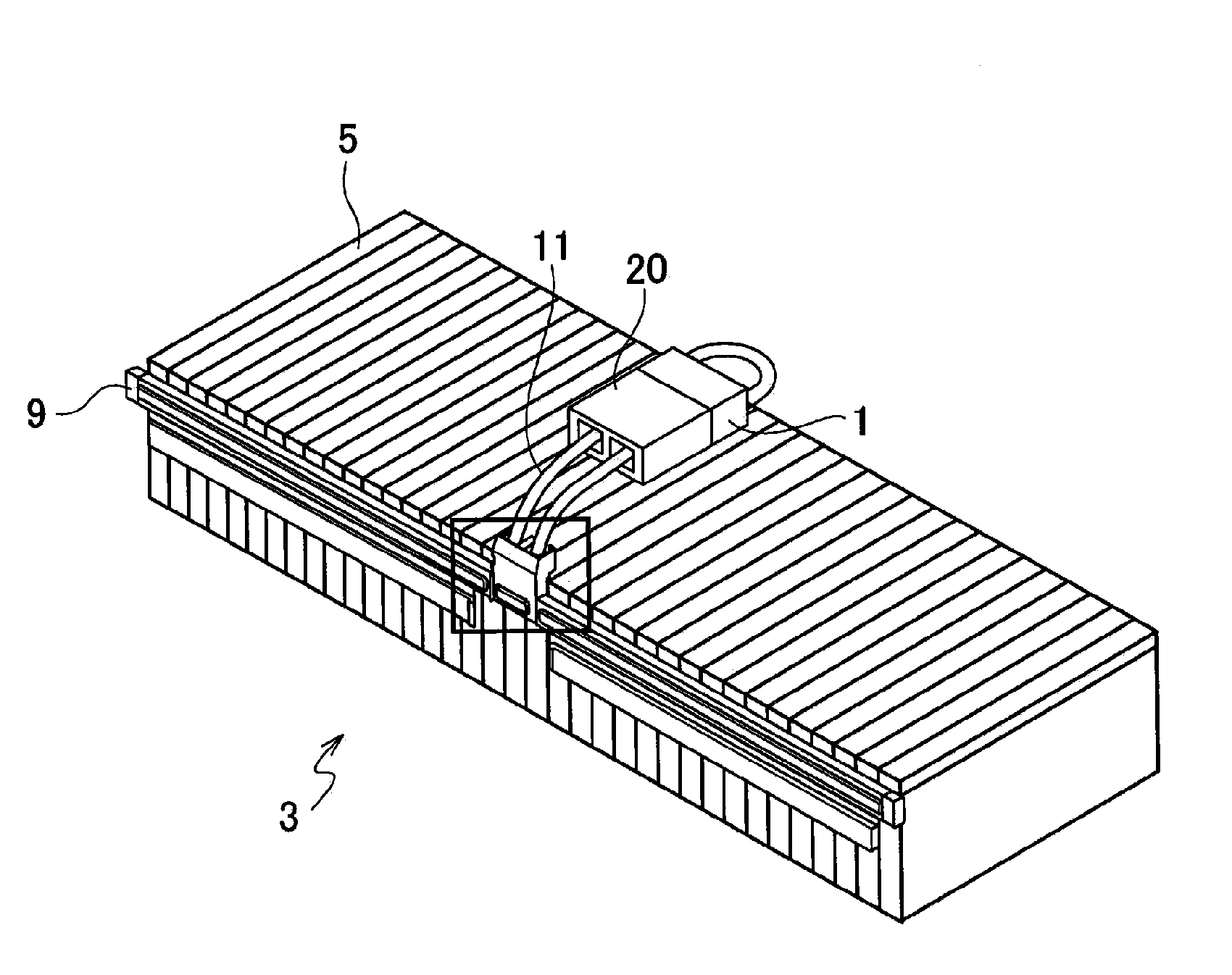

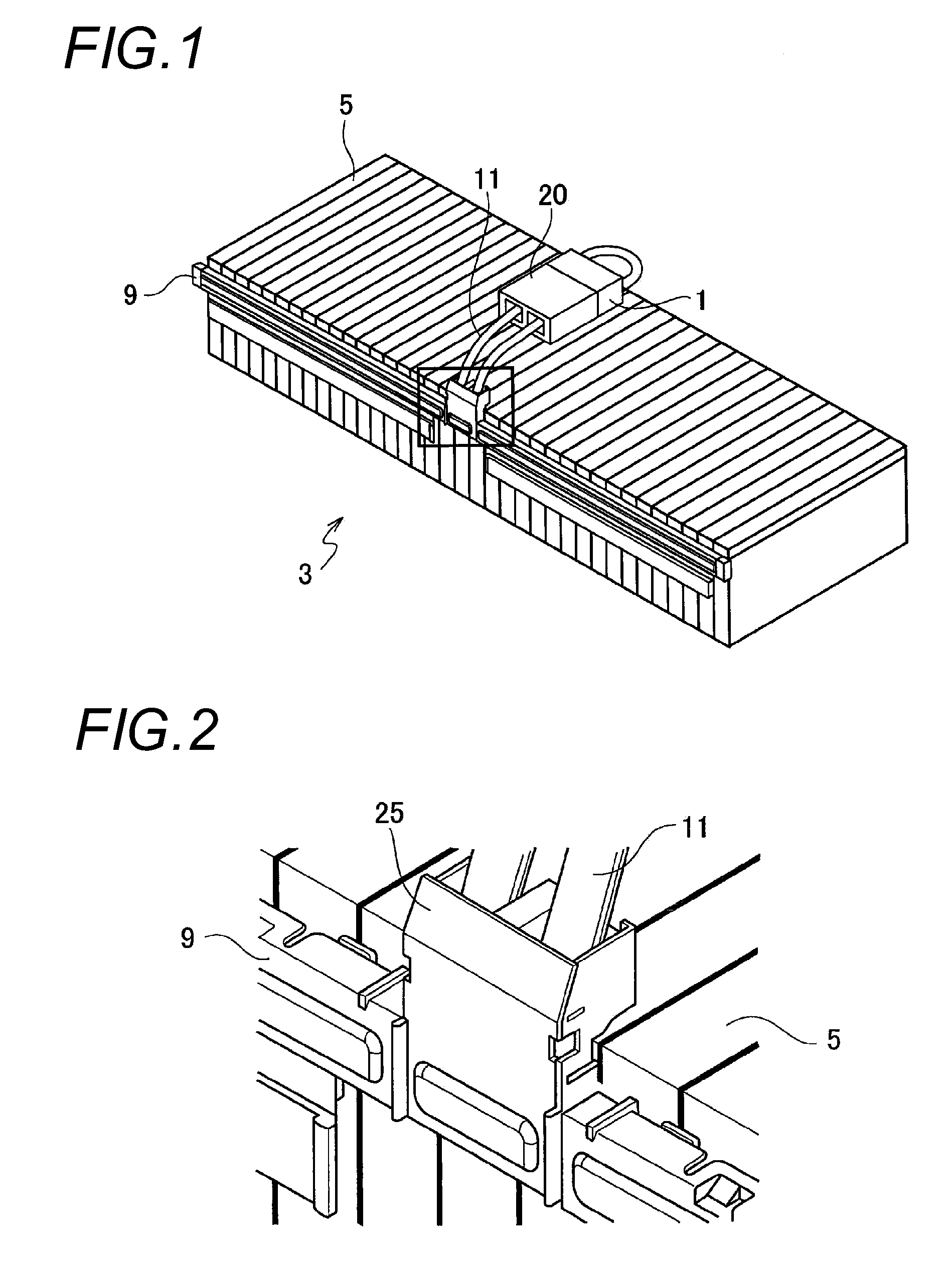

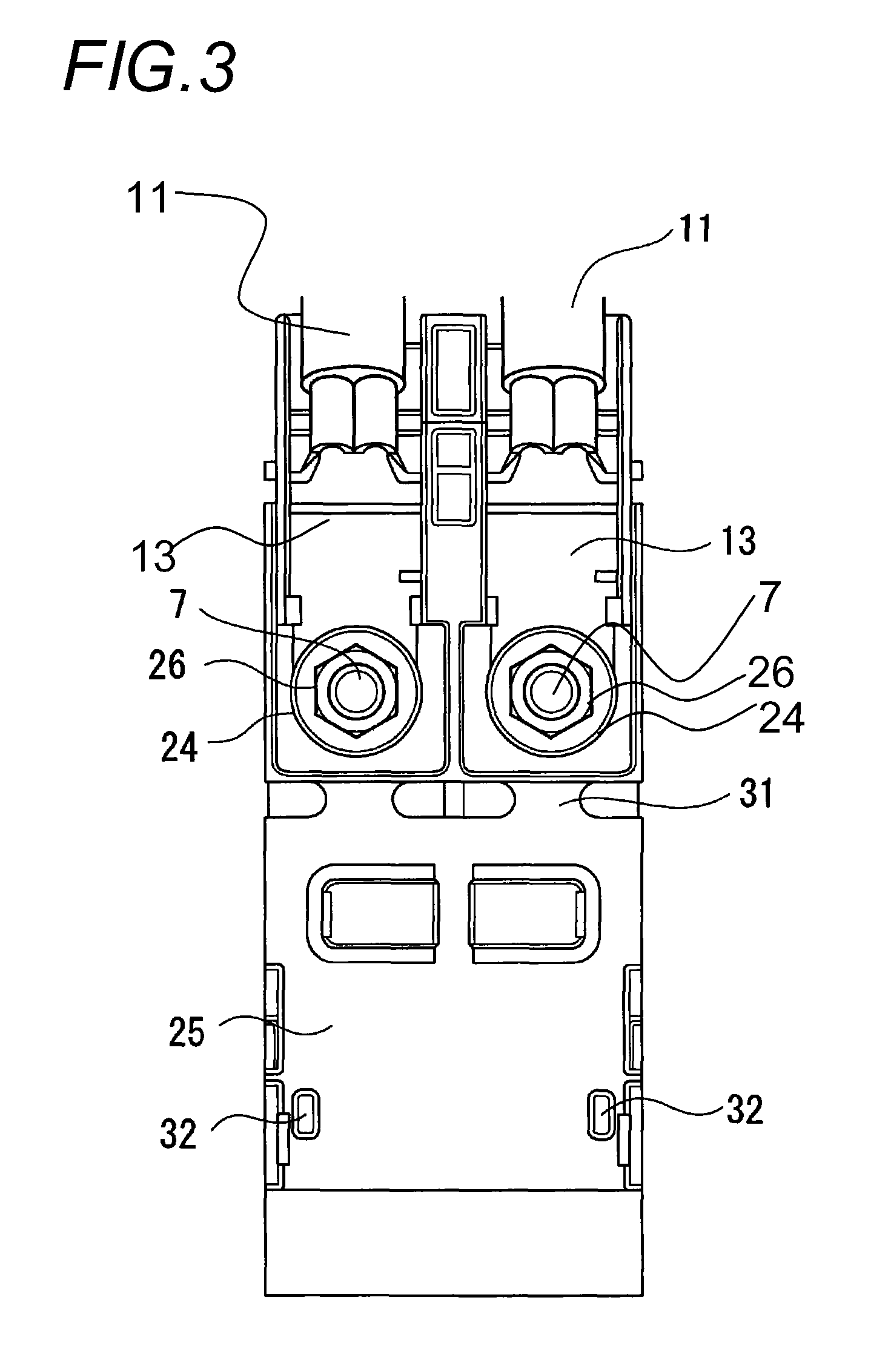

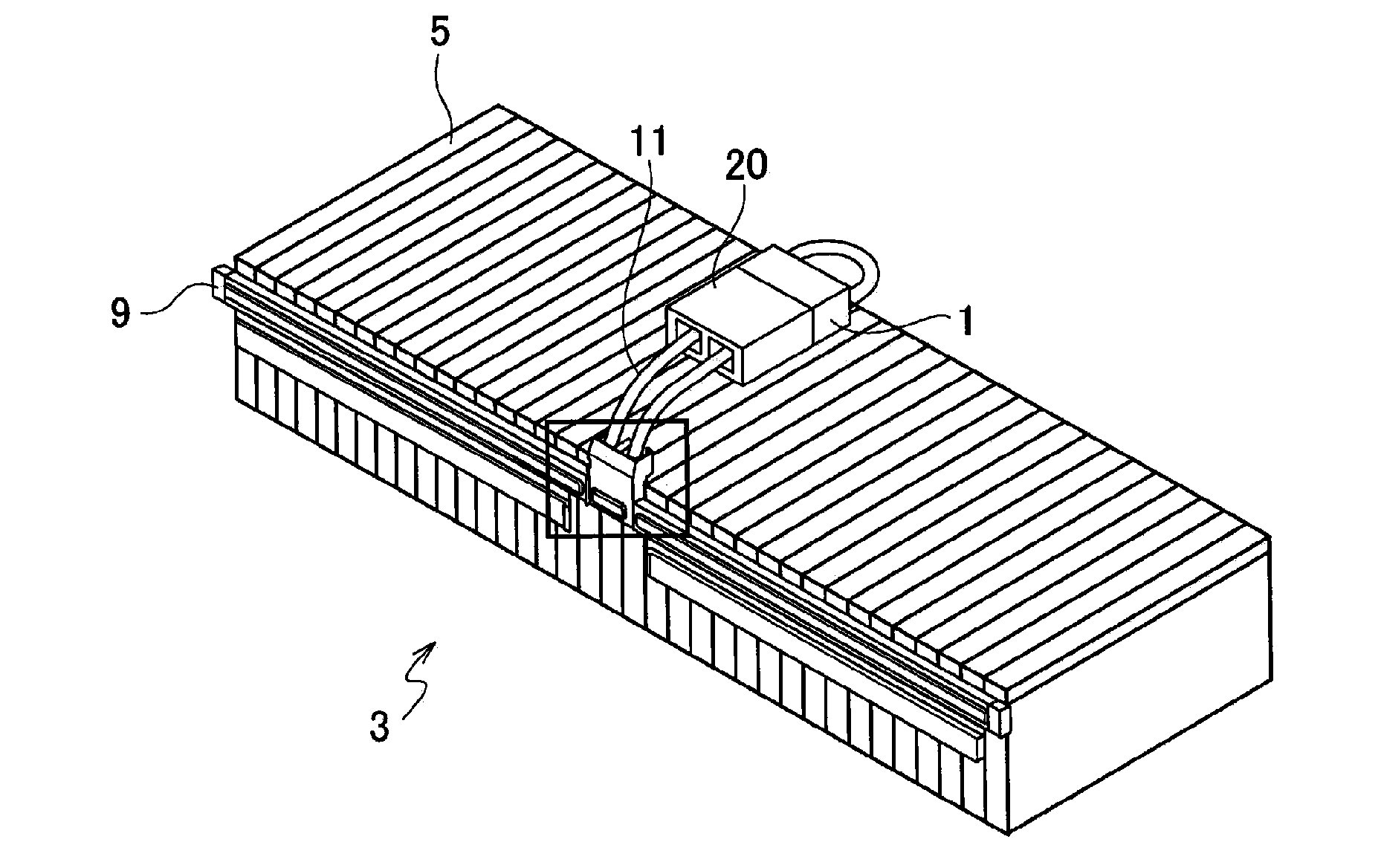

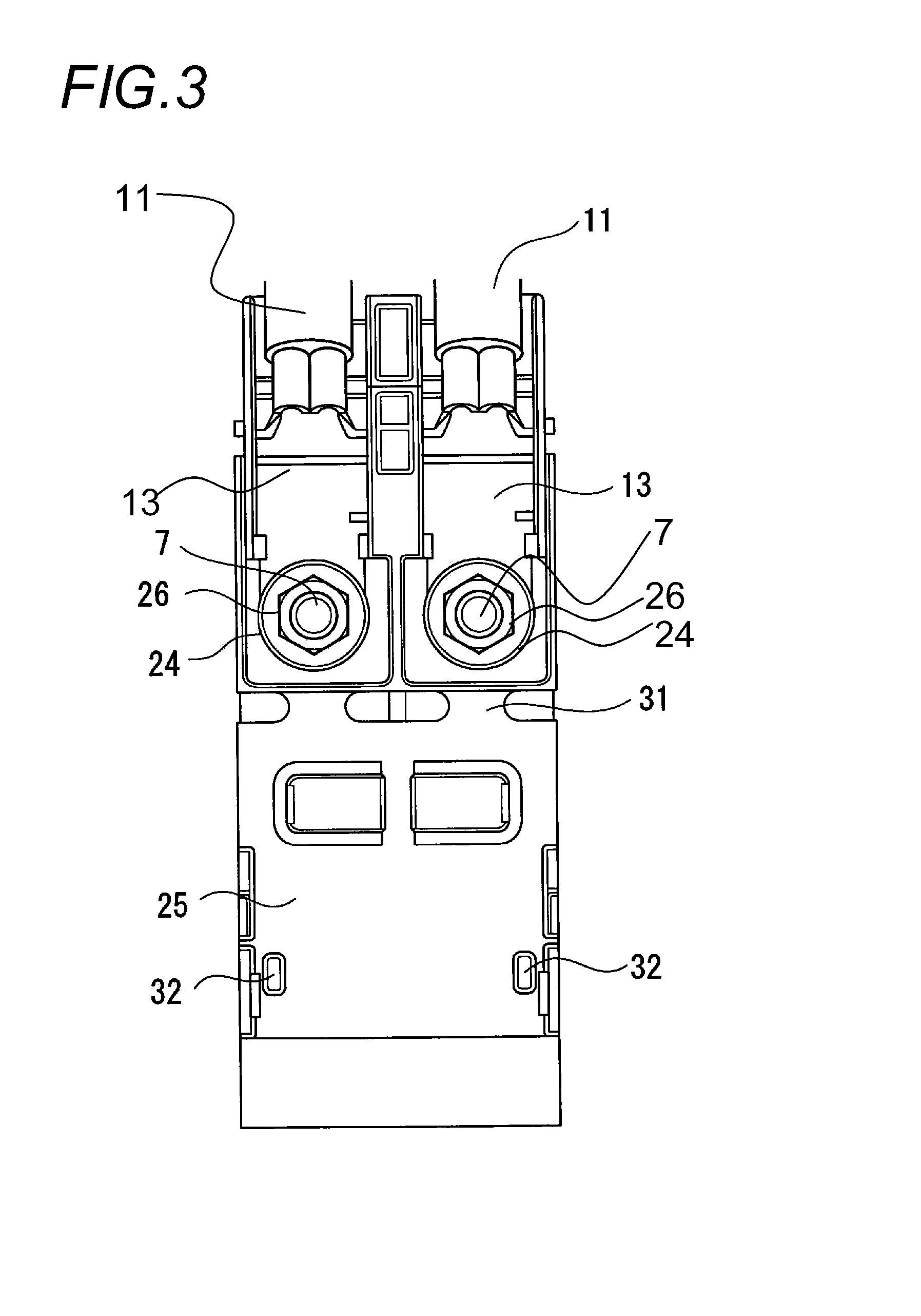

Structure for attaching service plug

ActiveUS9299975B2Improve workabilityImprove connection workabilityCurrent conducting connectionsComputer moduleElectric wire

A structure for attaching a service plug includes an insulating substrate that has openings facing electrodes of a pair of adjacent batteries among a plurality of batteries in a battery module, a pair of connection terminals that are respectively connected to electrodes of the pair of adjacent batteries through the insulating substrate by bolting with nuts, a pair of electric wires whose one ends are connected to the connection terminals respectively, and a connector that is connected to the other ends of the pair of electric wires, and detachably connected with the service plug. The insulating substrate has protrusions which are abutted against the connection terminals respectively, and regulate movement of the connection terminals which simultaneously rotate with rotation of the nuts respectively when being bolted with the nuts.

Owner:YAZAKI CORP

Structure for attaching service plug

ActiveUS20140099524A1Improve connection workabilityImprove workabilityCurrent conducting connectionsEngineeringElectrical wiring

A structure for attaching a service plug includes an insulating substrate that has openings facing electrodes of a pair of adjacent batteries among a plurality of batteries in a battery module, a pair of connection terminals that are respectively connected to electrodes of the pair of adjacent batteries through the insulating substrate by bolting with nuts, a pair of electric wires whose one ends are connected to the connection terminals respectively, and a connector that is connected to the other ends of the pair of electric wires, and detachably connected with the service plug. The insulating substrate has protrusions which are abutted against the connection terminals respectively, and regulate movement of the connection terminals which simultaneously rotate with rotation of the nuts respectively when being bolted with the nuts.

Owner:YAZAKI CORP

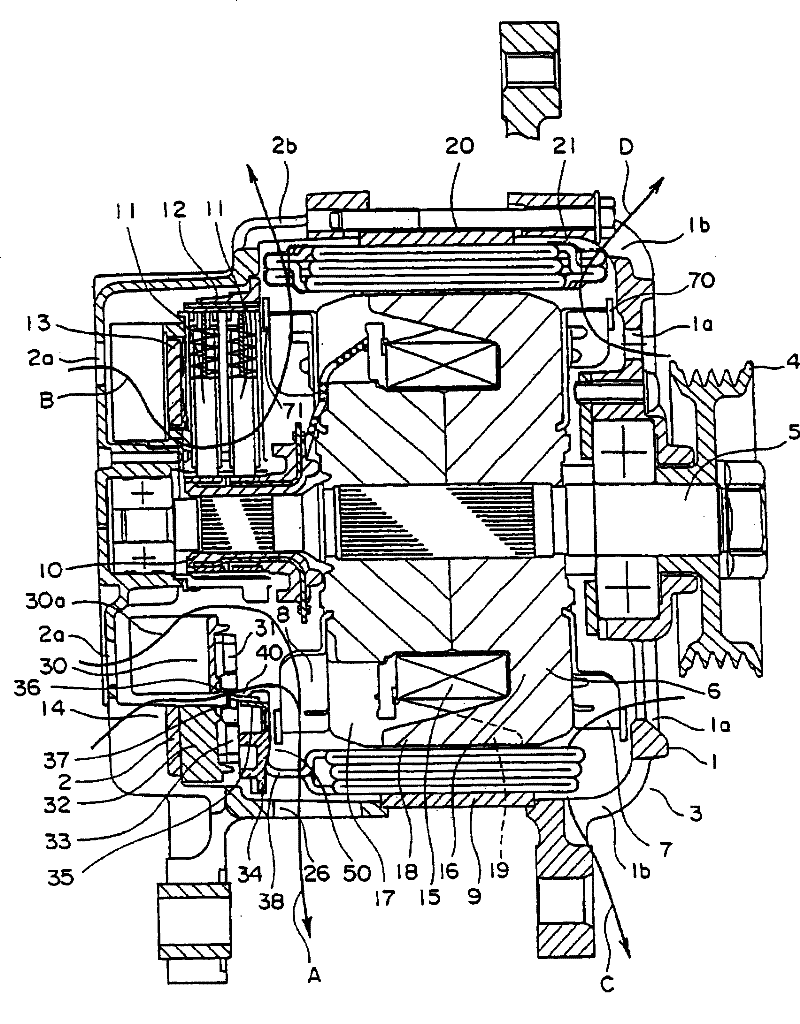

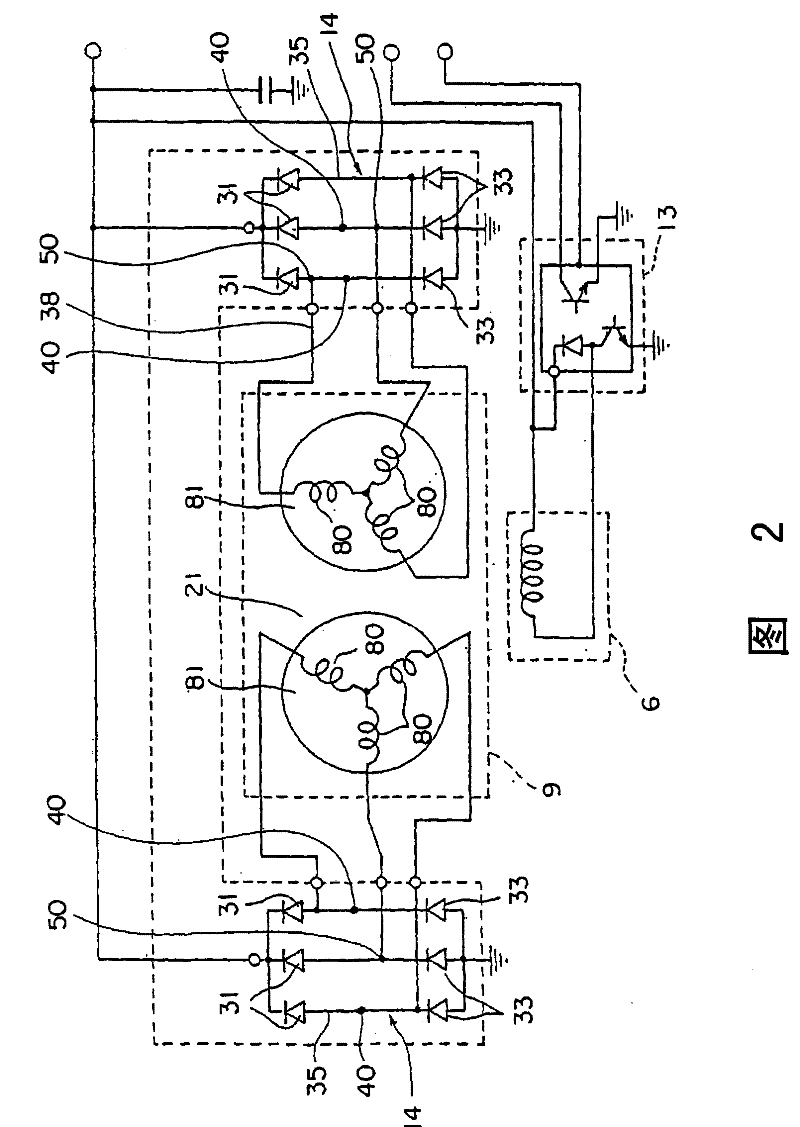

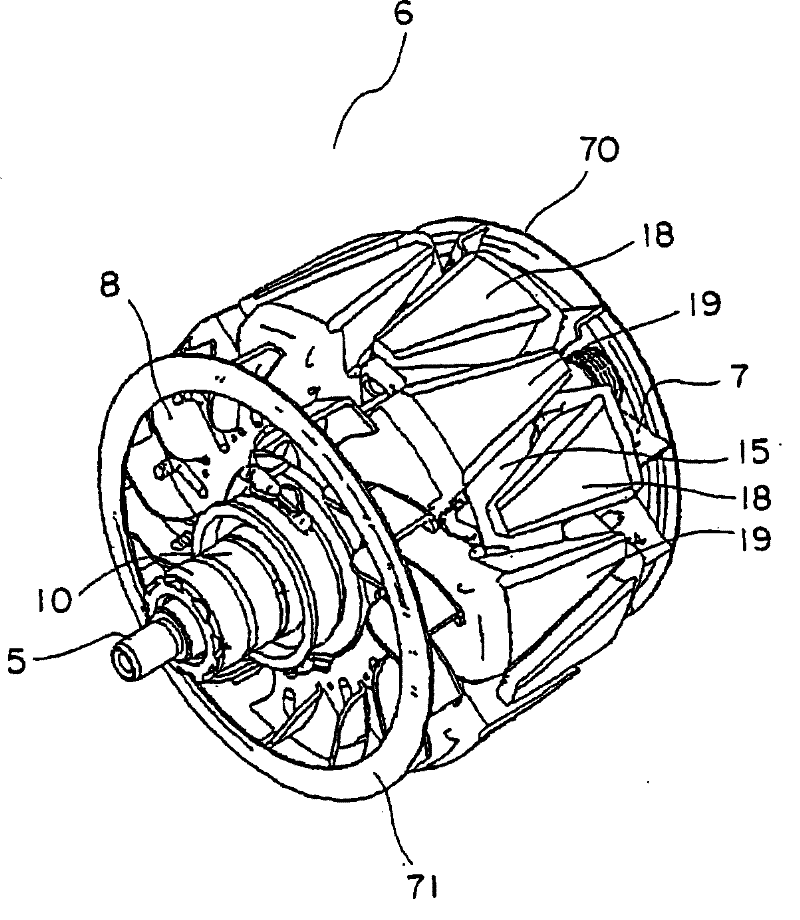

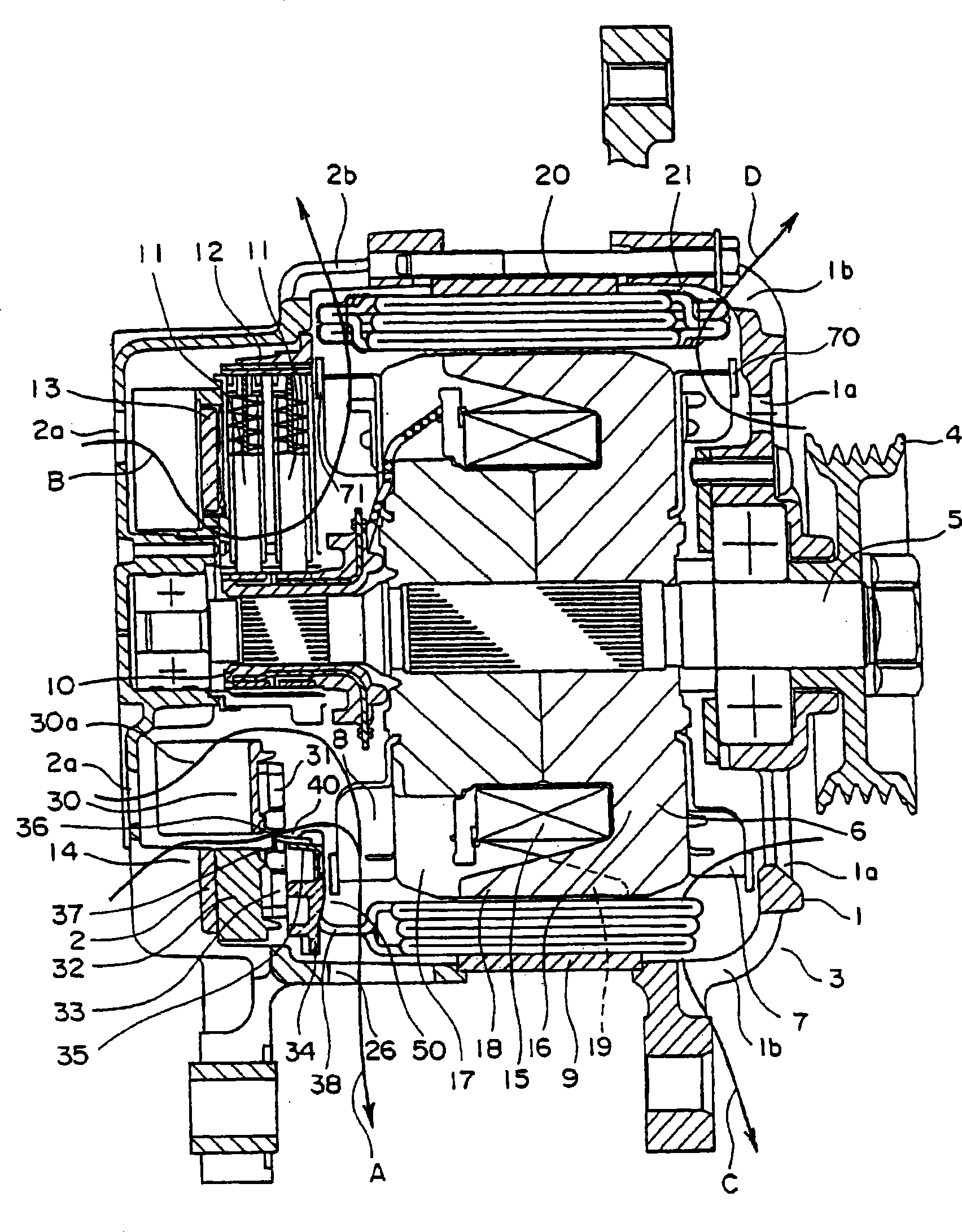

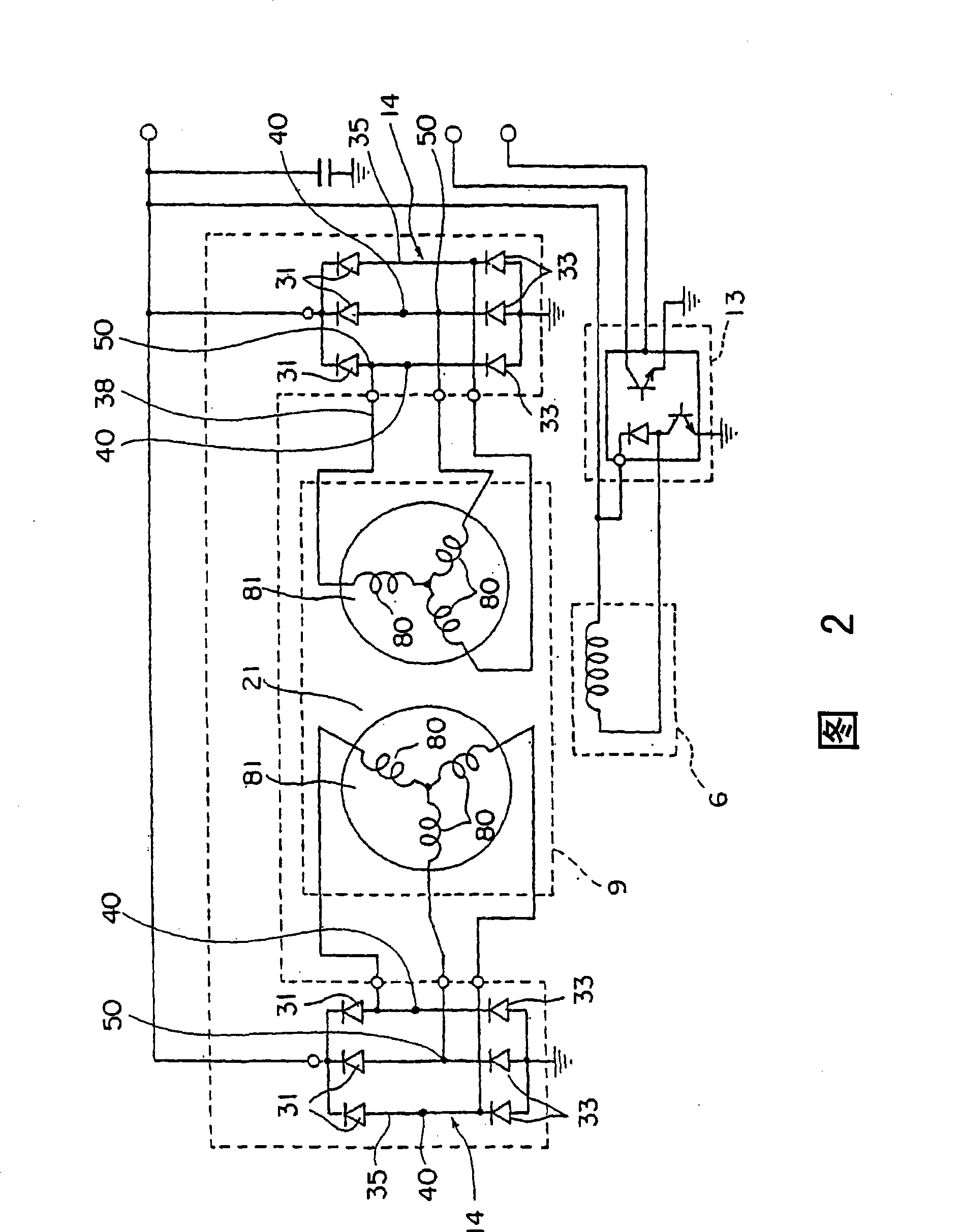

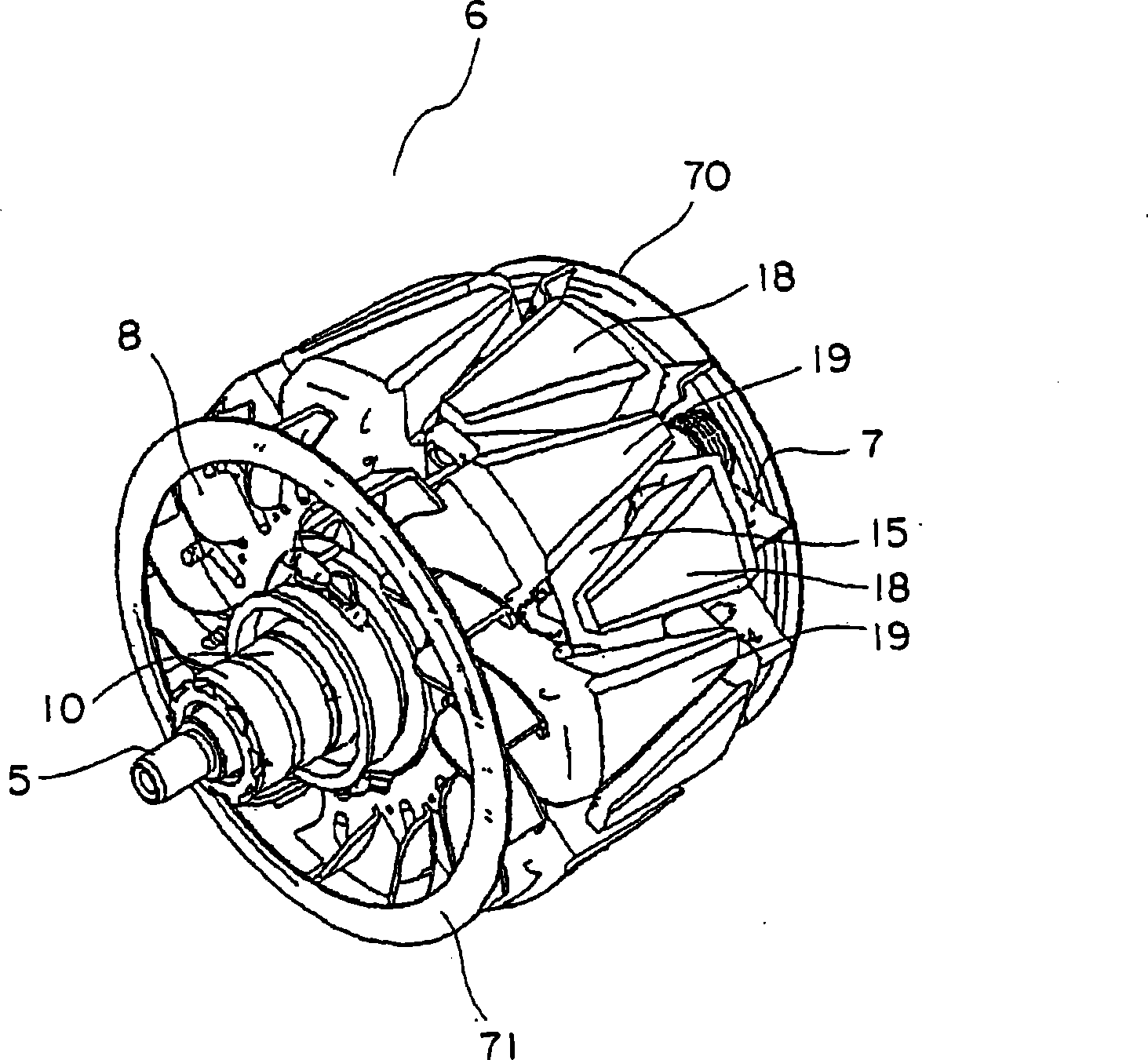

A. C. Power generator

ActiveCN101395787BImprove connection workabilityReduce resistanceSynchronous generatorsCooling/ventillation arrangementEngineeringDynamo

Owner:MITSUBISHI ELECTRIC CORP

A. C. Power generator

ActiveCN101395787AReduced drag and wind noiseImprove connection workabilitySynchronous generatorsCooling/ventillation arrangementElectric generatorBridge circuit

The rectifier of an inventive AC generator comprises a first heat sink; first unidirectional conduction elements arranged at intervals on the surface of the first heat sink; a second heat sink provided spaced apart from the first heat sink, second unidirectional conduction elements arranged at intervals on the surface of the second heat sink; and a circuit board having terminals connected to constitute a bridge circuit with regard to the first unidirectional conduction elements and the second unidirectional conduction elements. The first terminals of the first unidirectional conduction elements and the second terminals of the second unidirectional conduction elements are connected contiguously on the same surface of the terminals, respectively, to constitute terminal side joints. Consequently, connection workability is enhanced between the terminals and the first terminals of the first unidirectional conduction elements and the second terminals of the second unidirectional conduction elements.

Owner:MITSUBISHI ELECTRIC CORP

Optical connector, male connector housing for optical connector, and female connector housing for optical connector

InactiveUS9116316B2Solve the lack of rigidityImprove connection workabilityCoupling light guidesEngineeringMechanical engineering

Owner:FURUKAWA ELECTRIC CO LTD +1

brake hydraulic control unit

ActiveCN104797471BSave assembly spaceIncrease heightApplication and release valvesSolenoid valveWheel cylinder

Owner:ADVICS CO LTD

Electrical protecting cover, electrical device and method for assembling electrical device

ActiveCN1314303CMiniaturizationLow costSupport structure mountingElectrical apparatus casings/cabinets/drawersEngineeringElectrical current

Owner:YONEZAWA DENSEN KK

Magnet-type generator

ActiveUS9537366B2Improve connection workabilityImprove workabilityWindings insulation shape/form/constructionMagnetic circuit rotating partsMagnetStator

A magnet-type generator 1 has a stator 20 having a stator core 21, bobbins 40, 41 and a coil 60. The stator core has through holes 35A, 35B, 35C passing through the stator core parallel to a rotation axis of the rotor so that lead wires 64A, 64B, 64C for outputting current generated at the magnet-type generator 1, which are corresponding to respective phases, are inserted into the through holes. The lead wires inserted into the through holes are connected with outgoing wires 60a, 60c′, 60b, 60a′, 60c, 60b′ of the coil at one side (clamping surface side) of the stator core 21 via a terminal (metal connection terminal) 53 fixed to a substrate portion (plate portion) 48 extending from the bobbin. The terminal is arranged near the through holes.

Owner:DENSO TRIM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com