Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Tighten evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

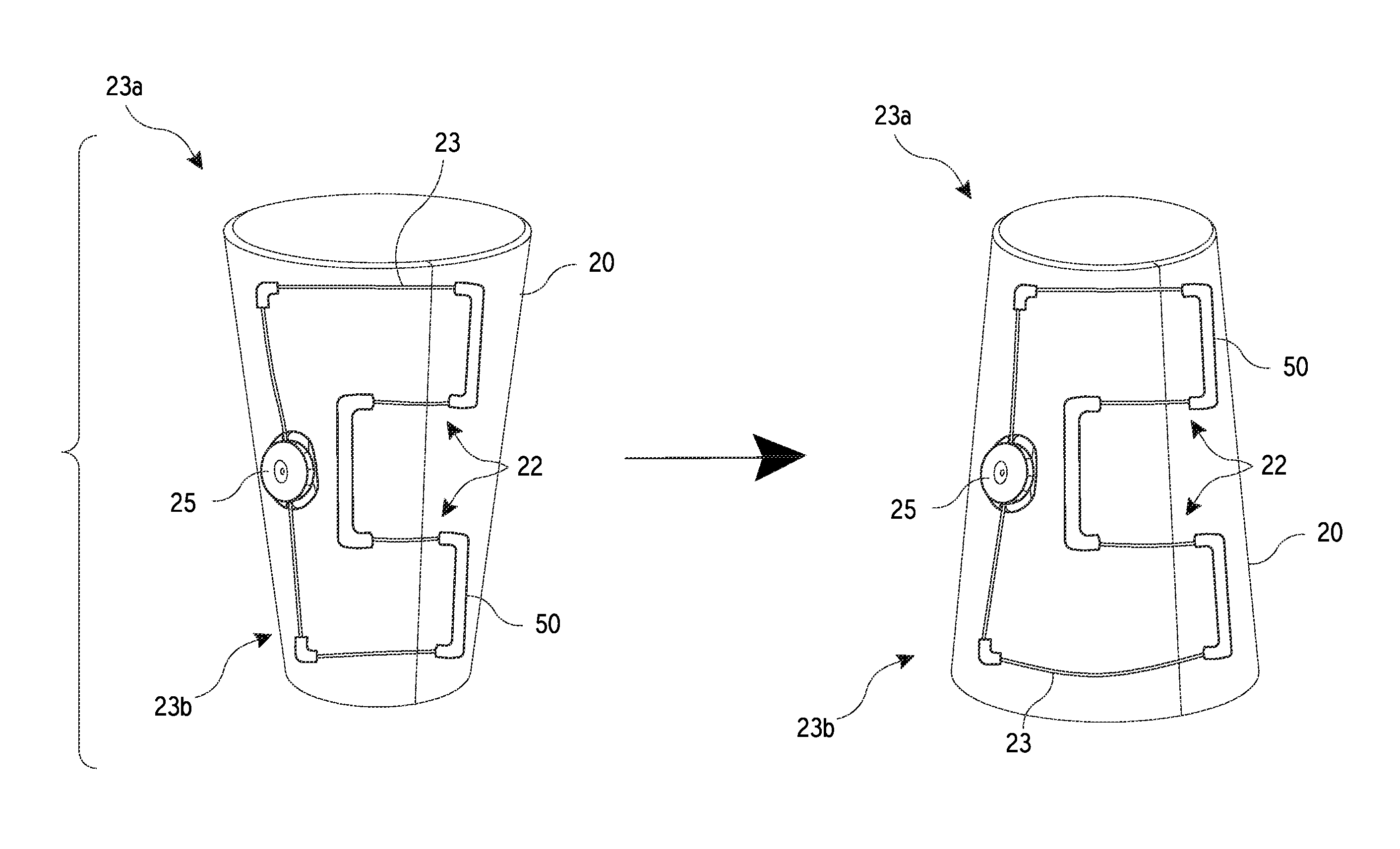

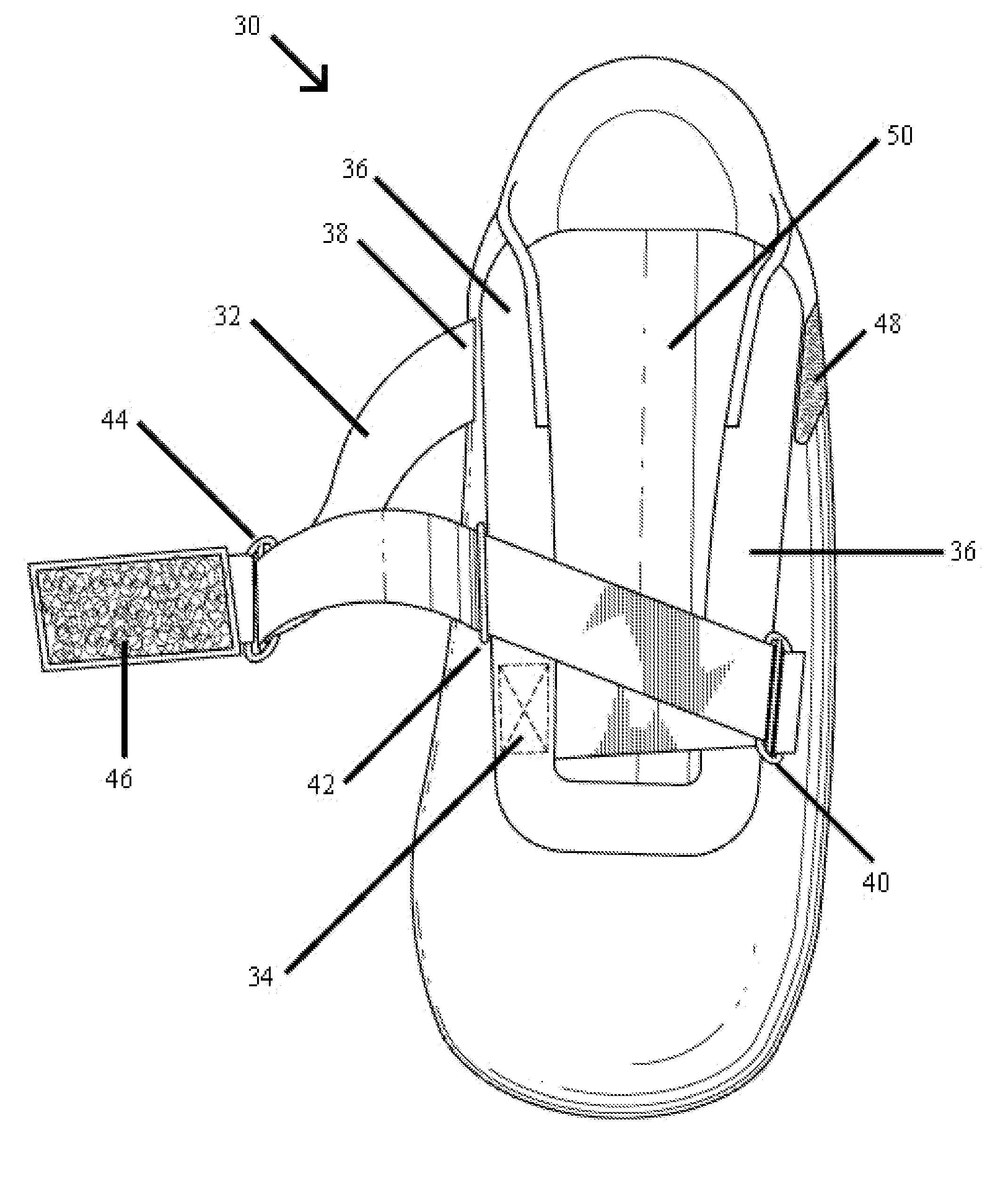

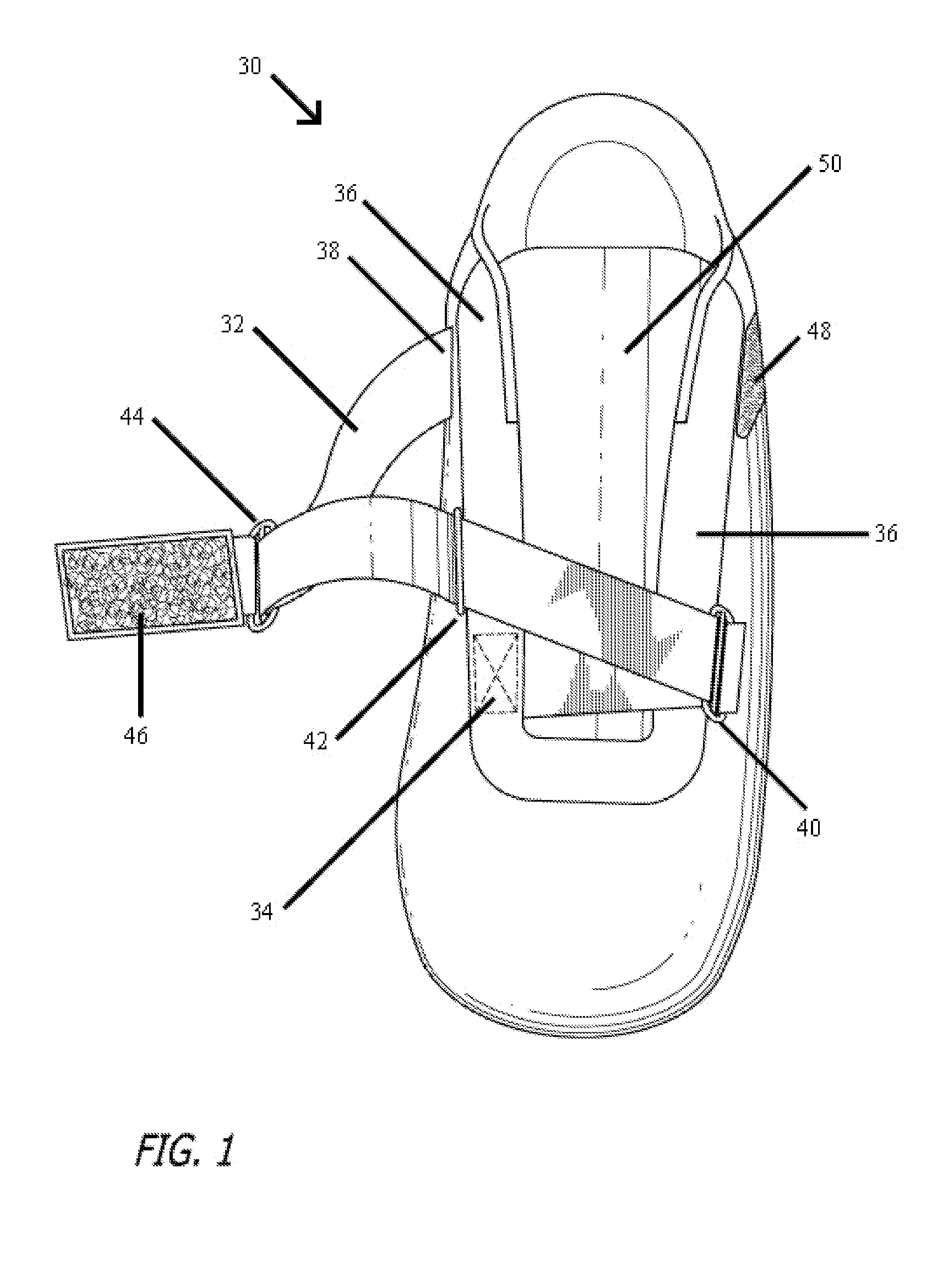

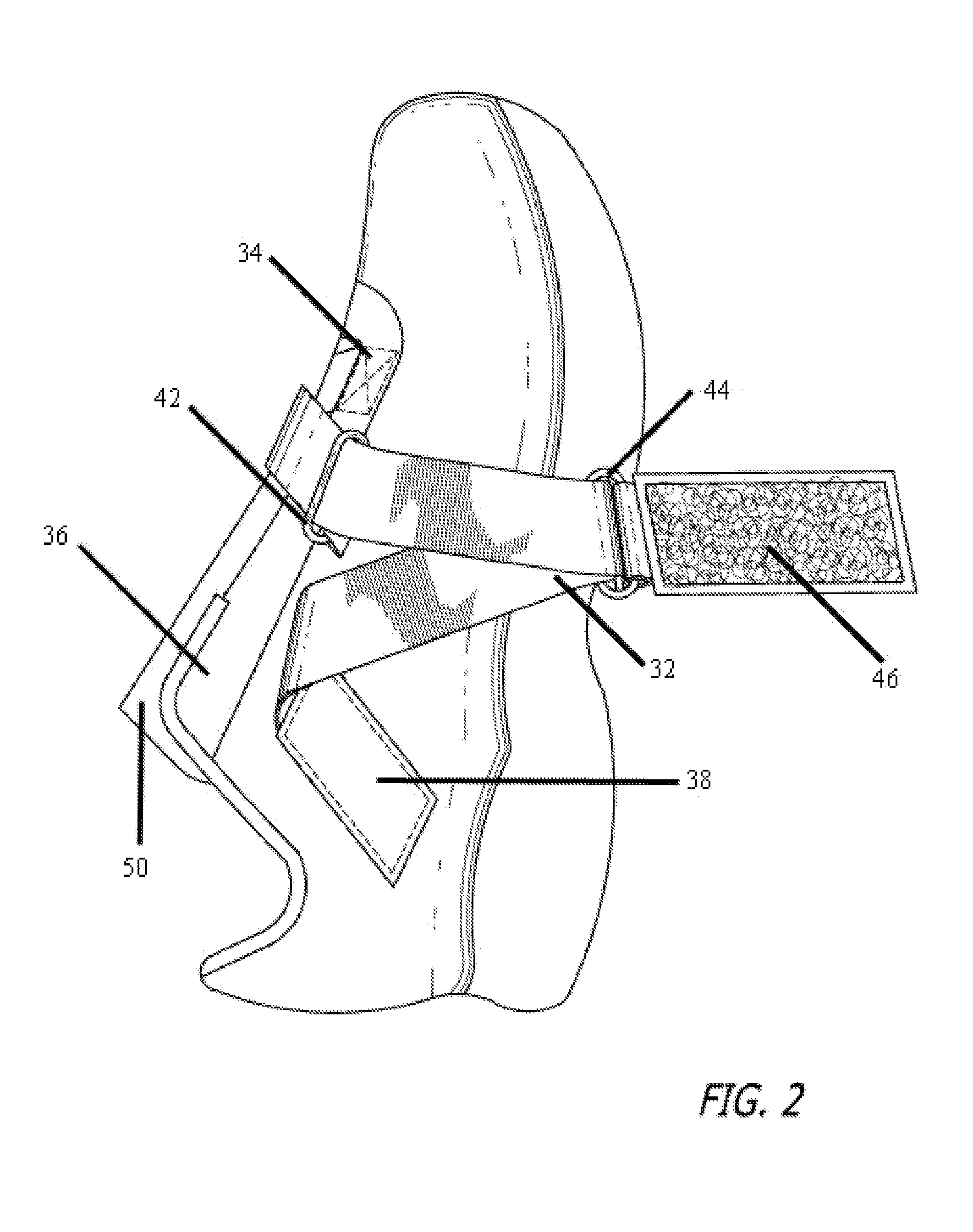

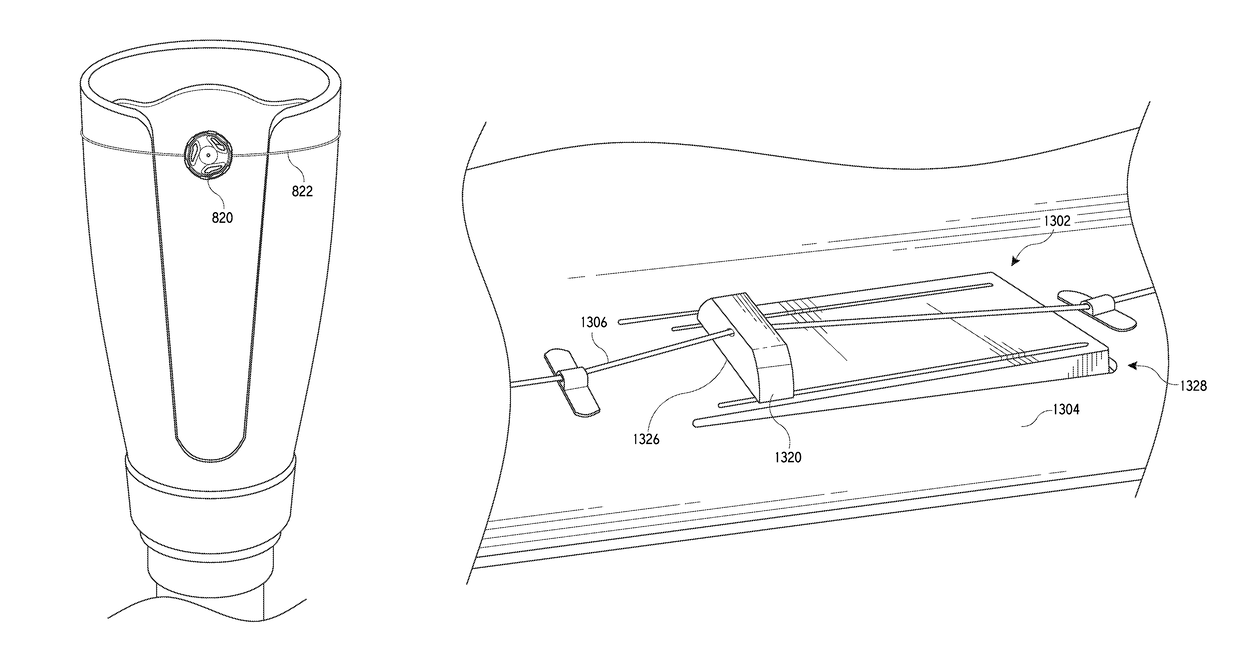

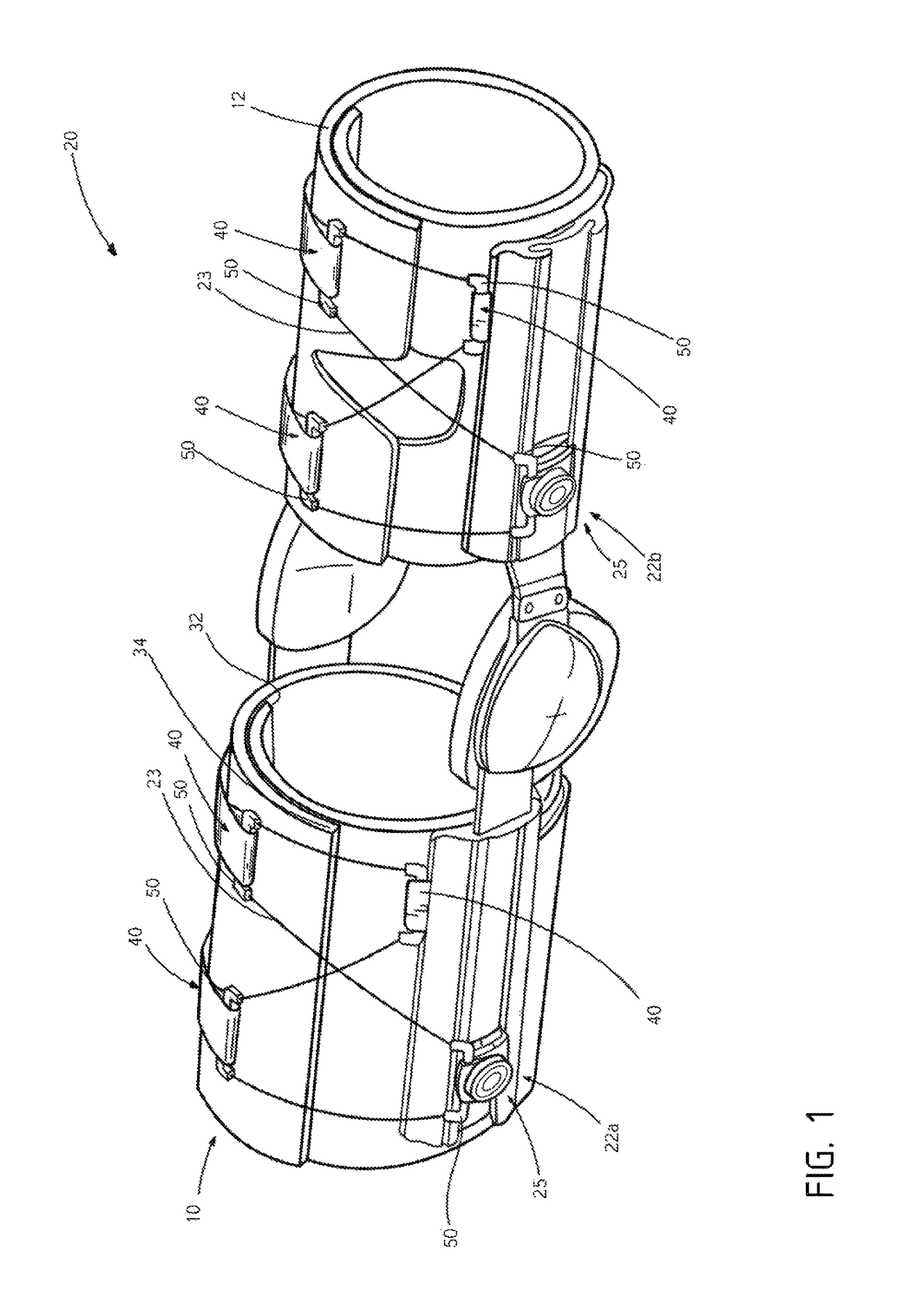

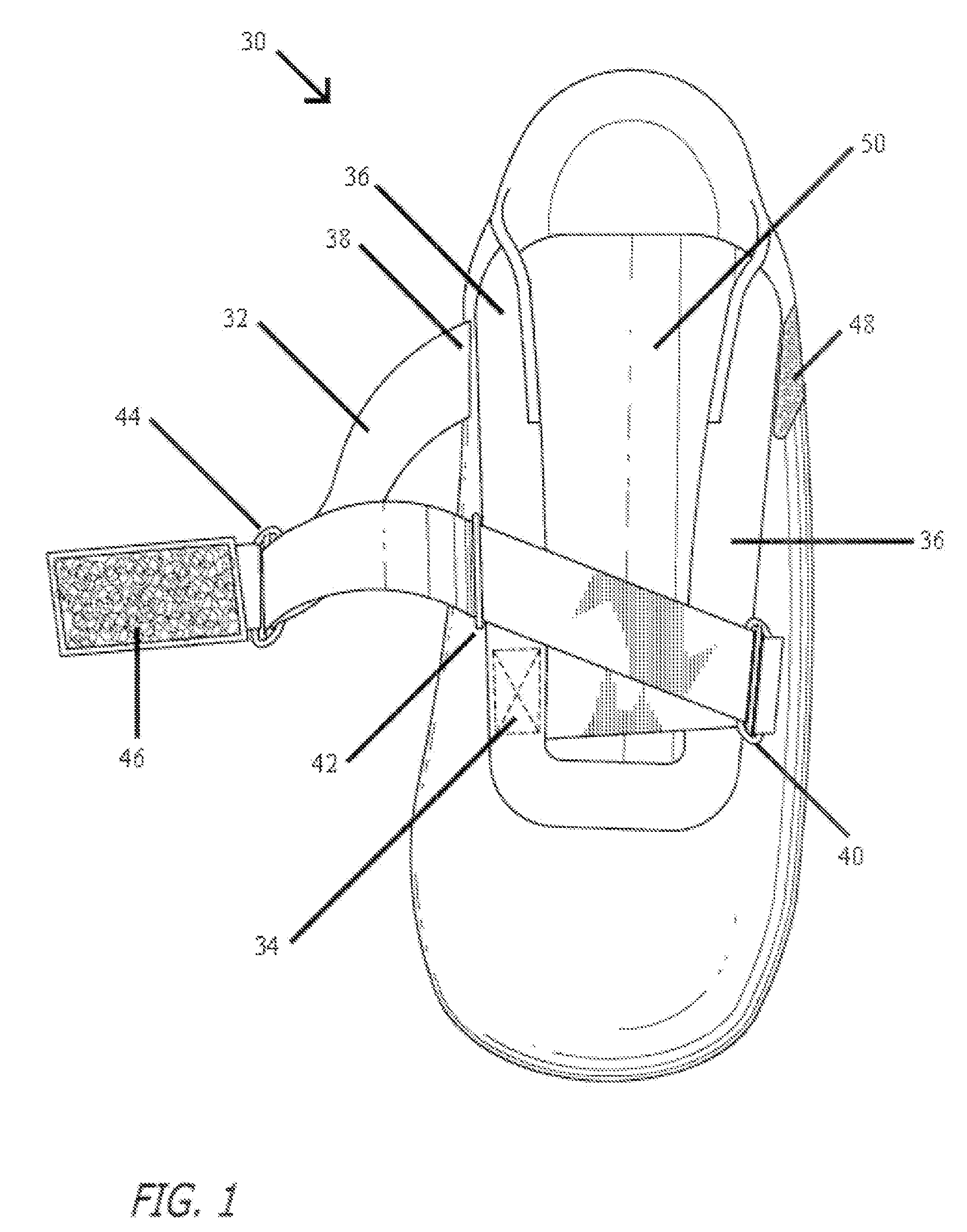

Methods and devices for providing automatic closure of prosthetics and orthotics

ActiveUS20150150705A1Tighten evenlyIncrease displacementNon-surgical orthopedic devicesProsthesisEngineeringTension member

According to an embodiment, a lacing system for opening and closing an article includes a tensioning device having a first mode of operation and a second mode of operation, a first tension member that is coupled with the tensioning device and tensionable thereby, and a second tension member that is coupled with the tensioning device and tensionable thereby. The tensioning device is configured to: effect tensioning of the first tension member to close and tighten the article upon operation of the tensioning device in the first mode of operation and effect tensioning of the second tension member to loosen and open the article upon operation of the tensioning device in the second mode of operation.

Owner:BOA TECHNOLOGY

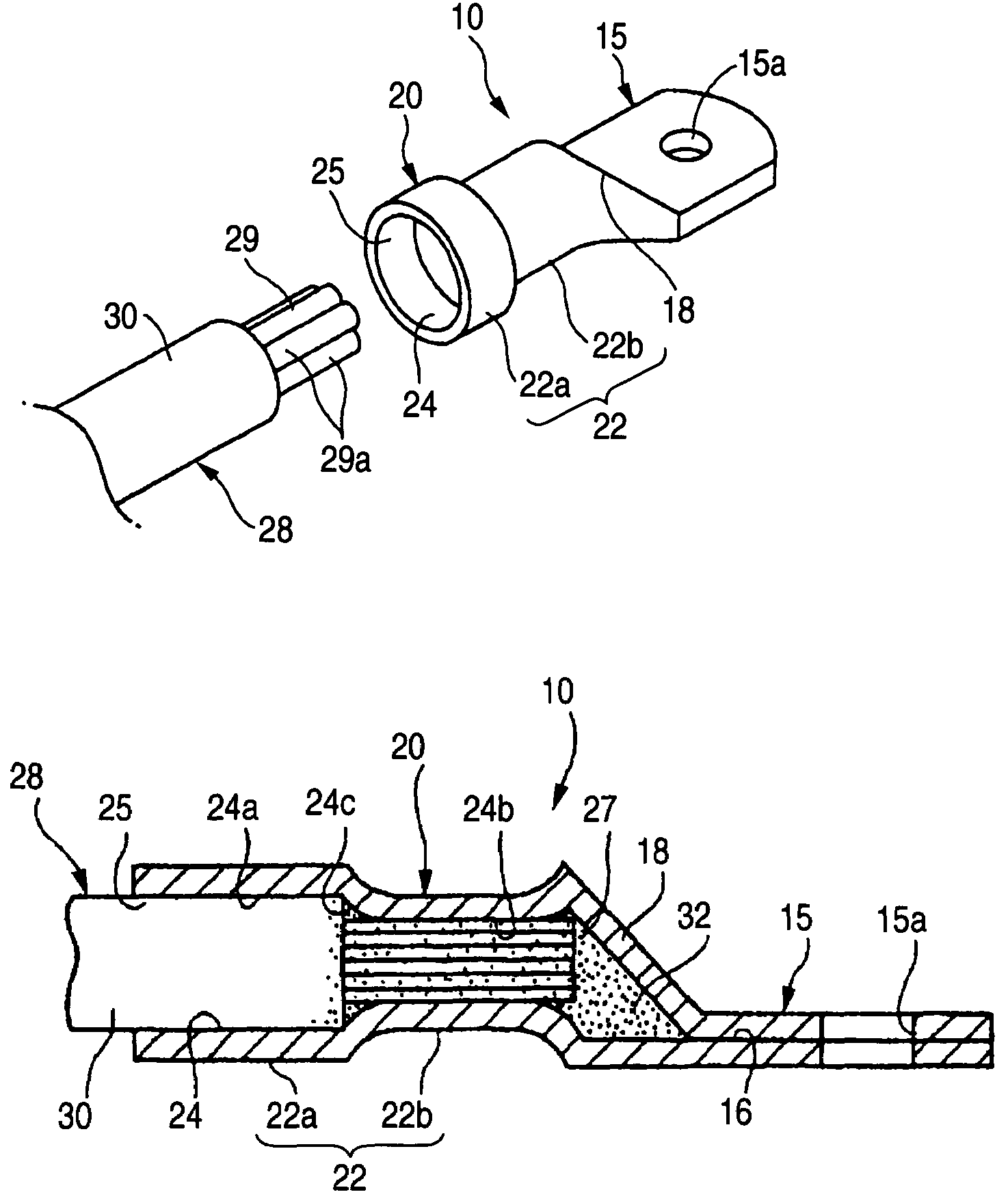

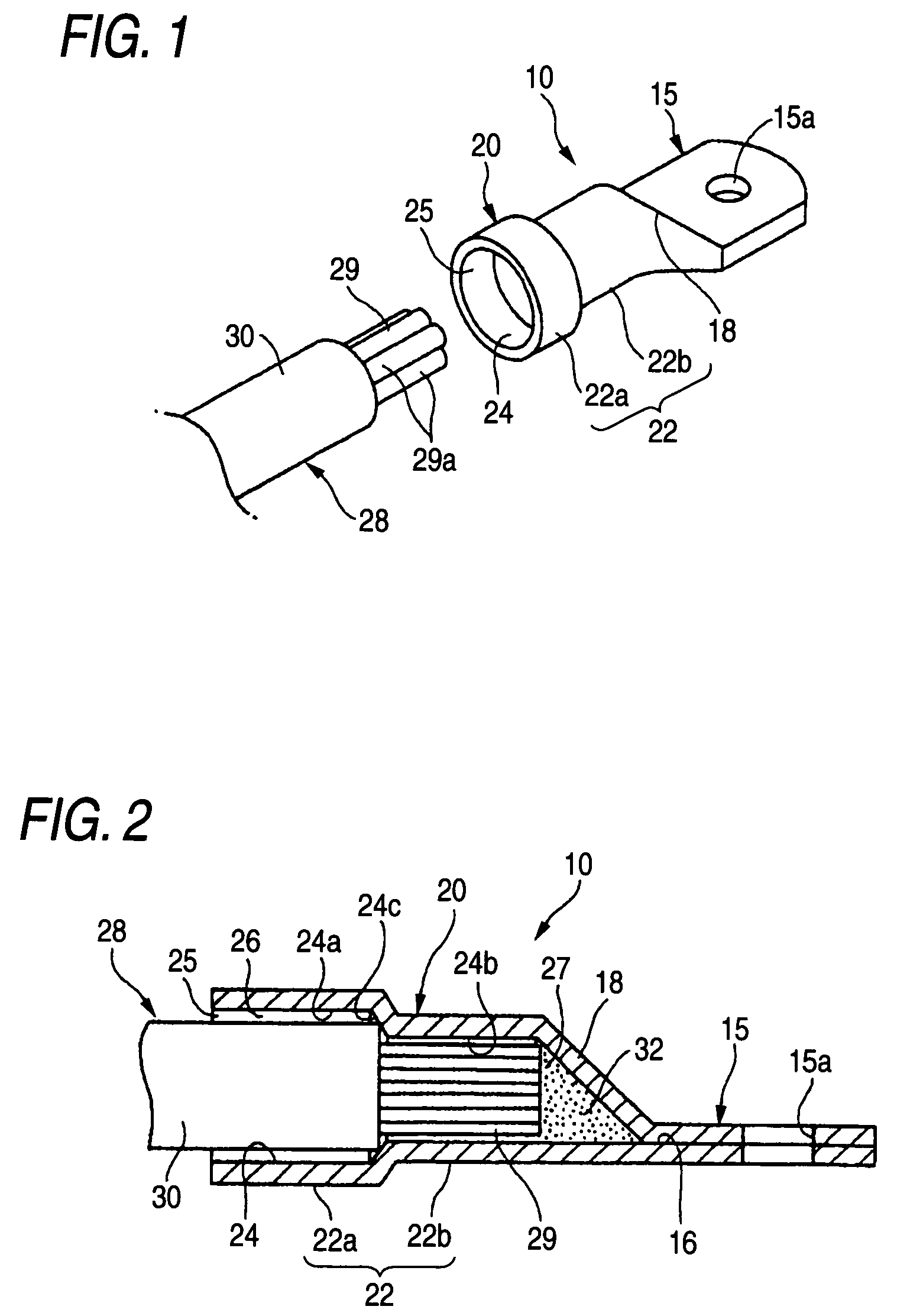

Method of connecting terminal and electric wire

ActiveUS7174633B2Few partsLow costPrinted circuit assemblingElectrically conductive adhesive connectionsEpoxyElectricity

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

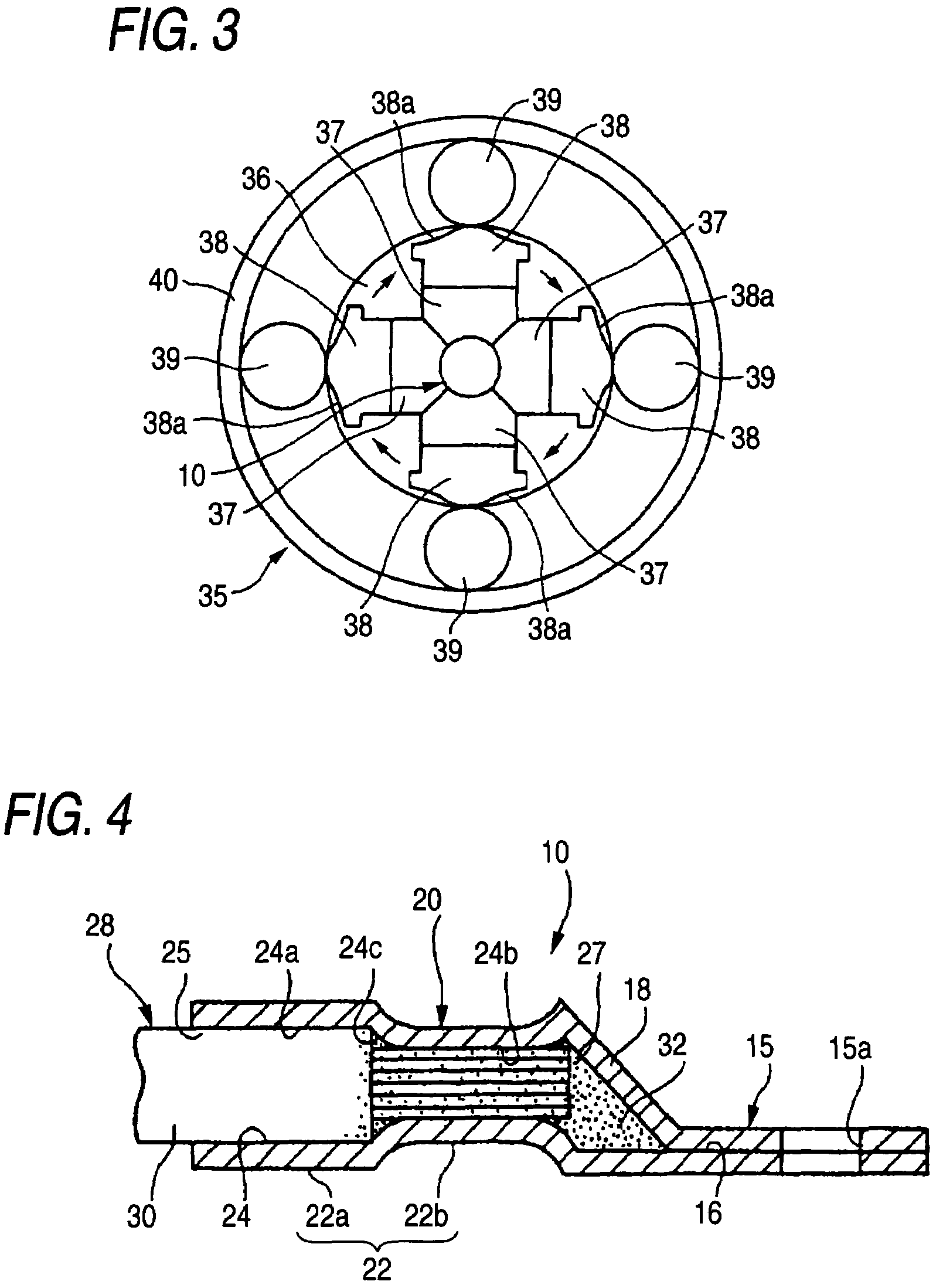

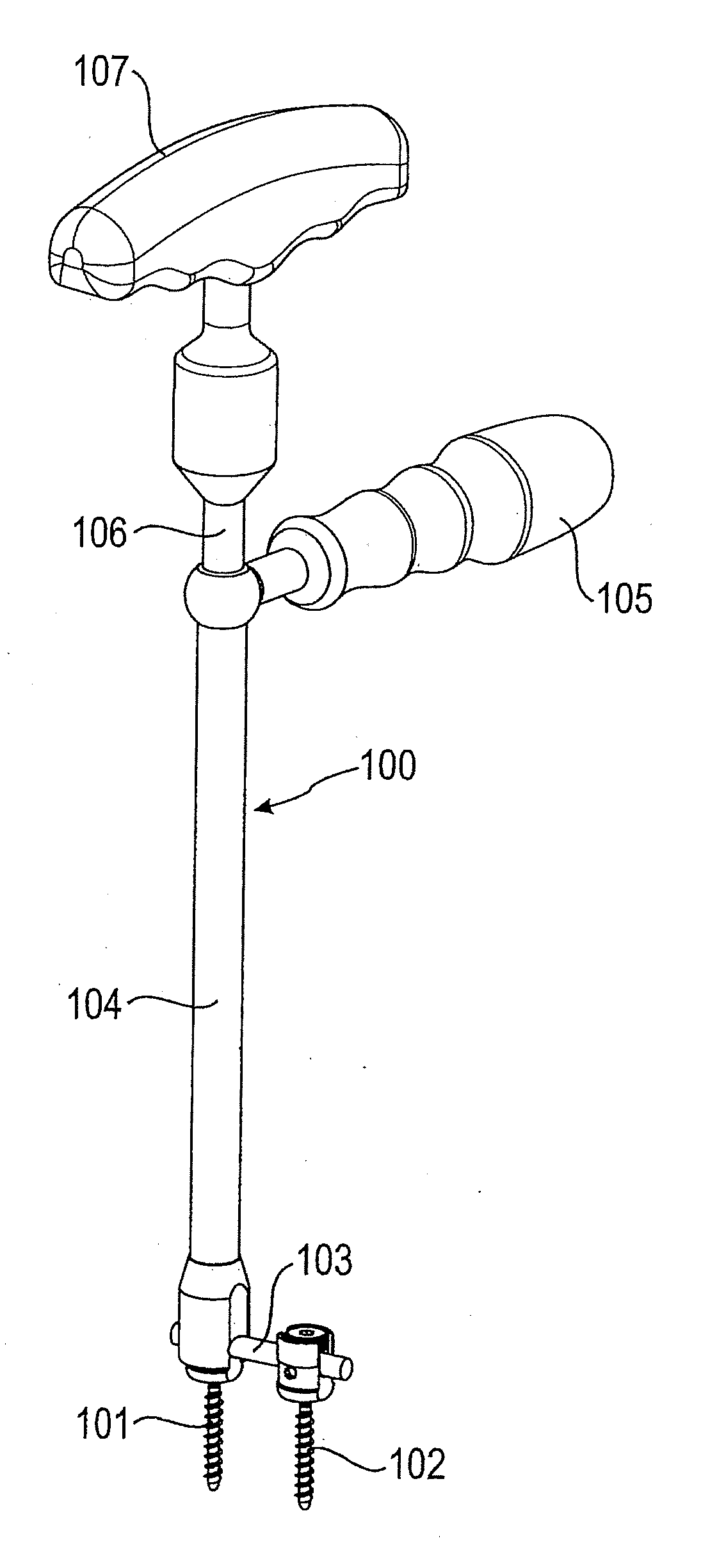

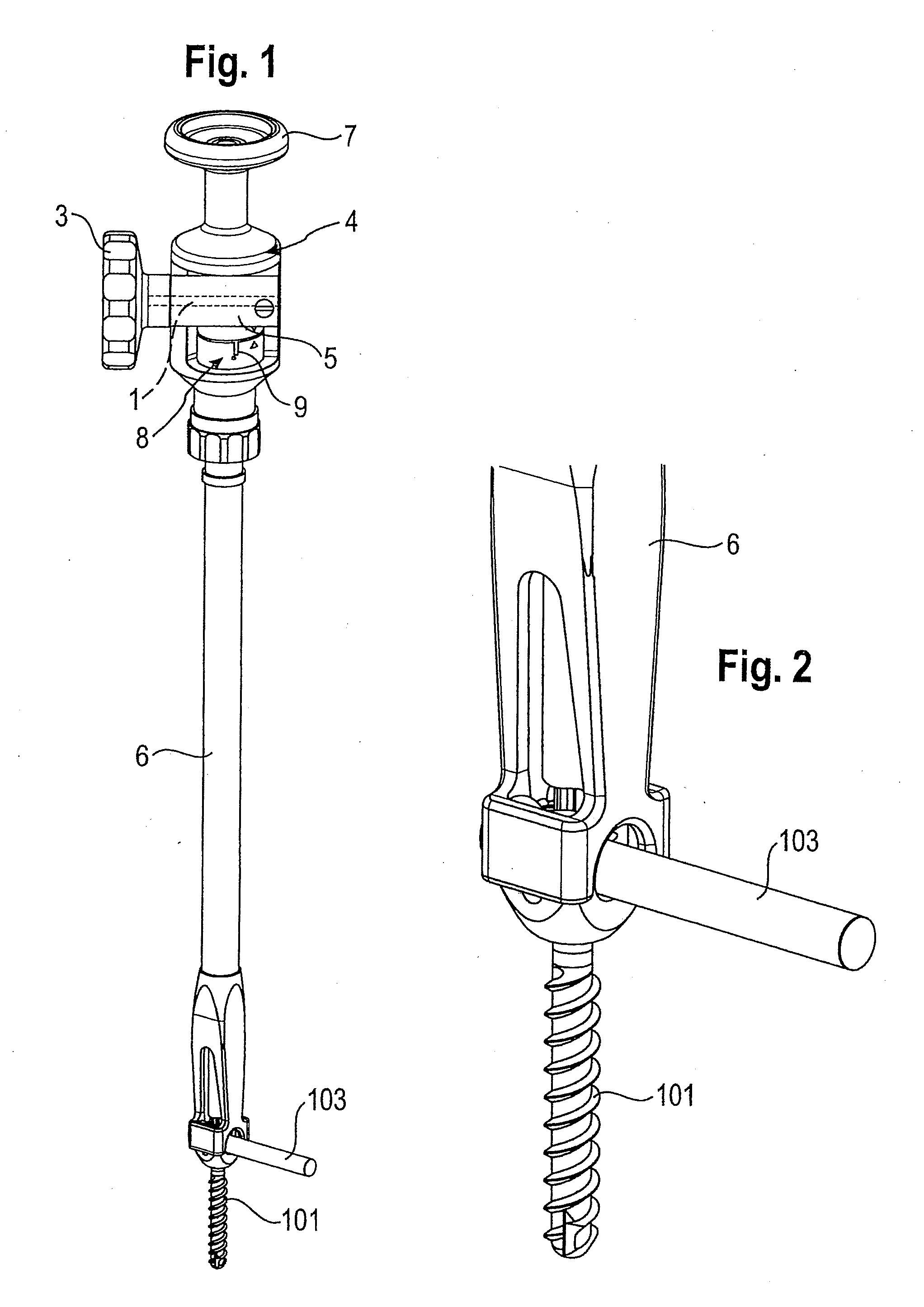

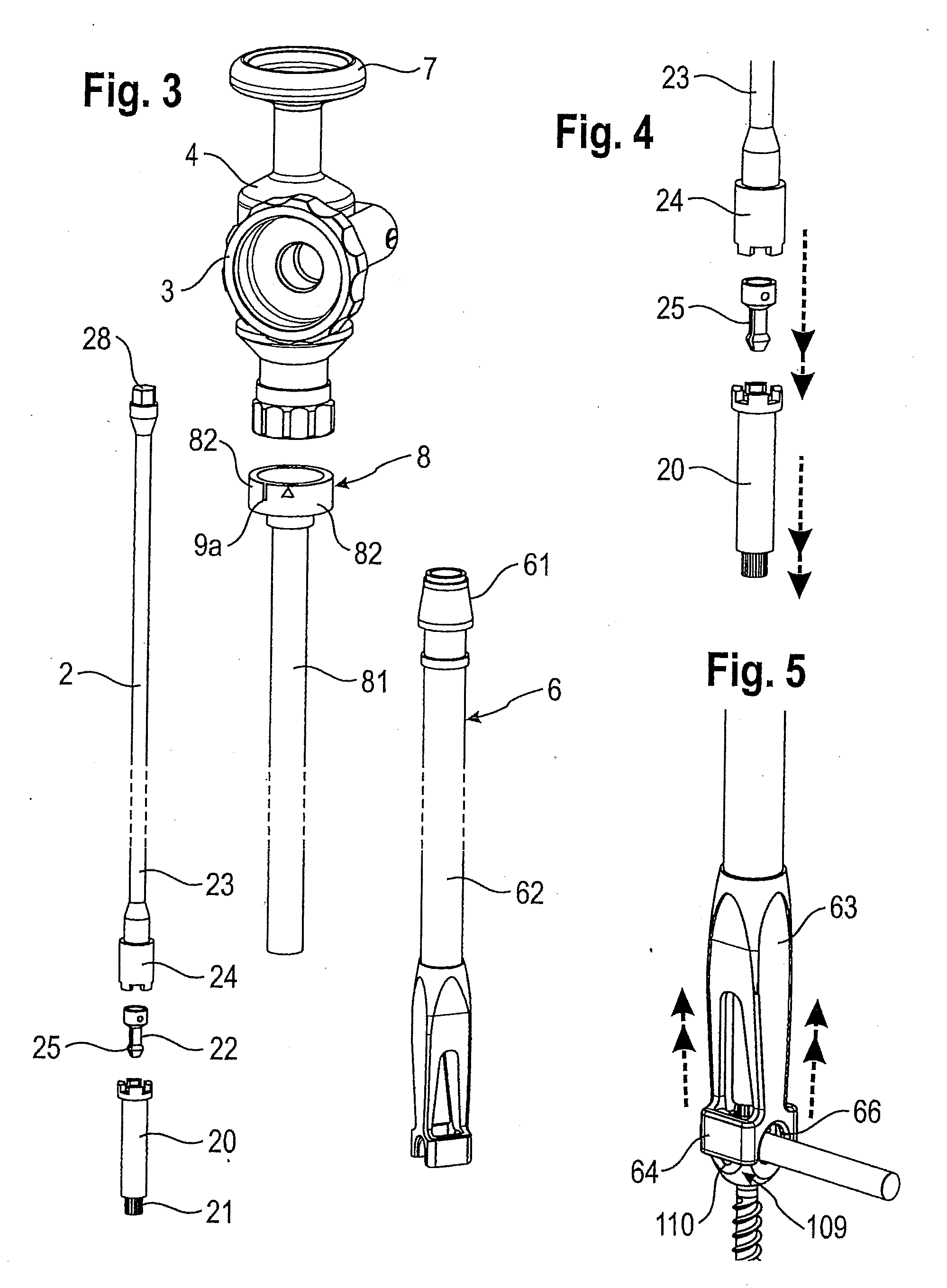

Tool for Use with a Bone Anchor, in Particular for Spinal Surgery

ActiveUS20110004222A1Easy to carryReduce loadInternal osteosythesisDiagnosticsSpinal columnDrive shaft

A tool is provided for use with a bone anchor, wherein the bone anchor has an anchoring section and a receiving portion for receiving a rod to be connected to the anchoring section and a locking element, the tool comprising a tip portion for engaging the locking element; a mechanism to apply torque to the tip portion comprising a drive shaft and a driven shaft coupled by a gear unit, where the drive shaft has a different axis than the driven shaft, and where the driven shaft comprises an engagement portion configured to connect the driven shaft to the gear unit; and a counter-holding portion for engaging the receiving part, wherein the counter-holding portion is rotatable with respect to the tip portion.

Owner:BIEDERMANN TECH GMBH & CO KG

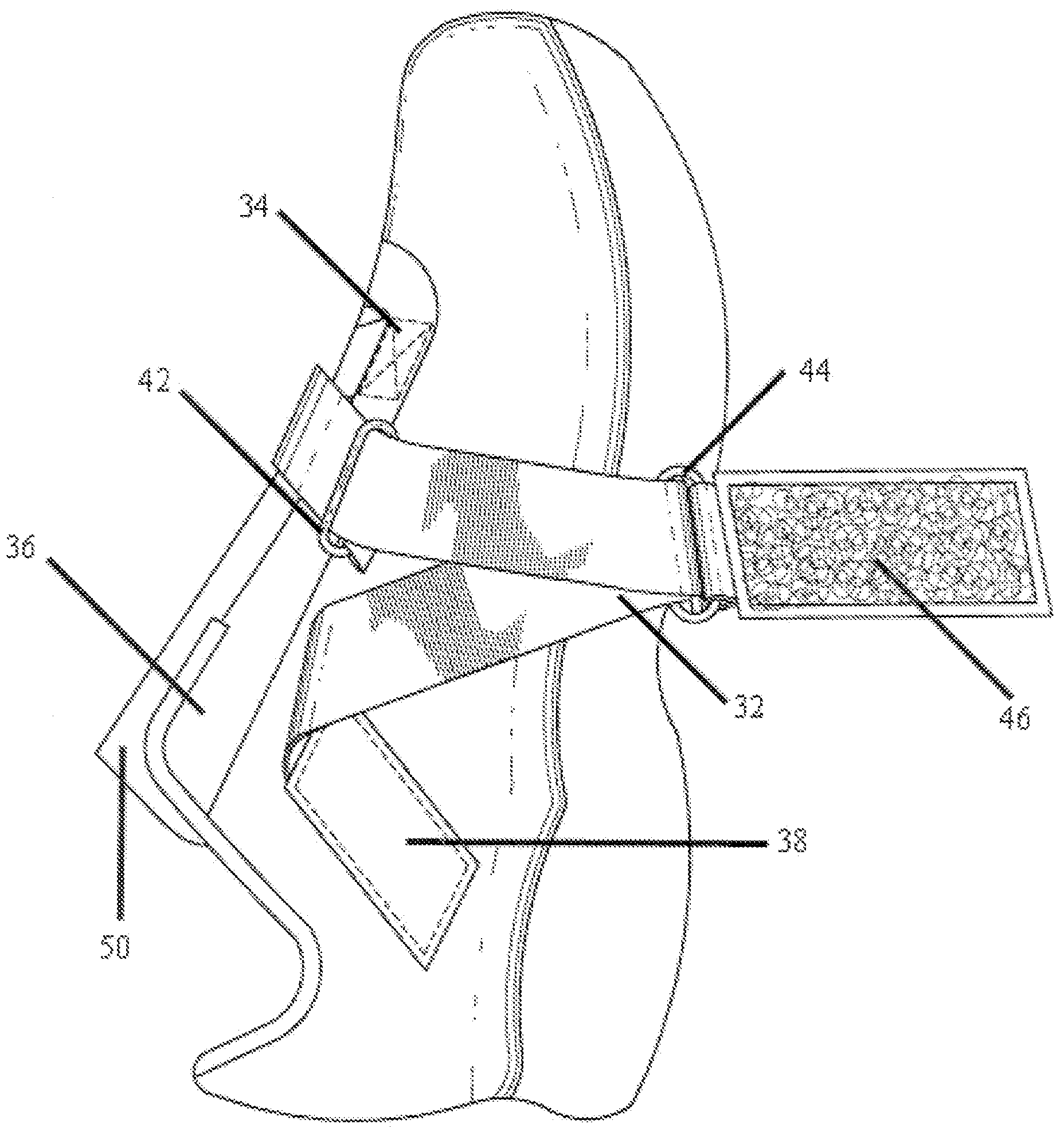

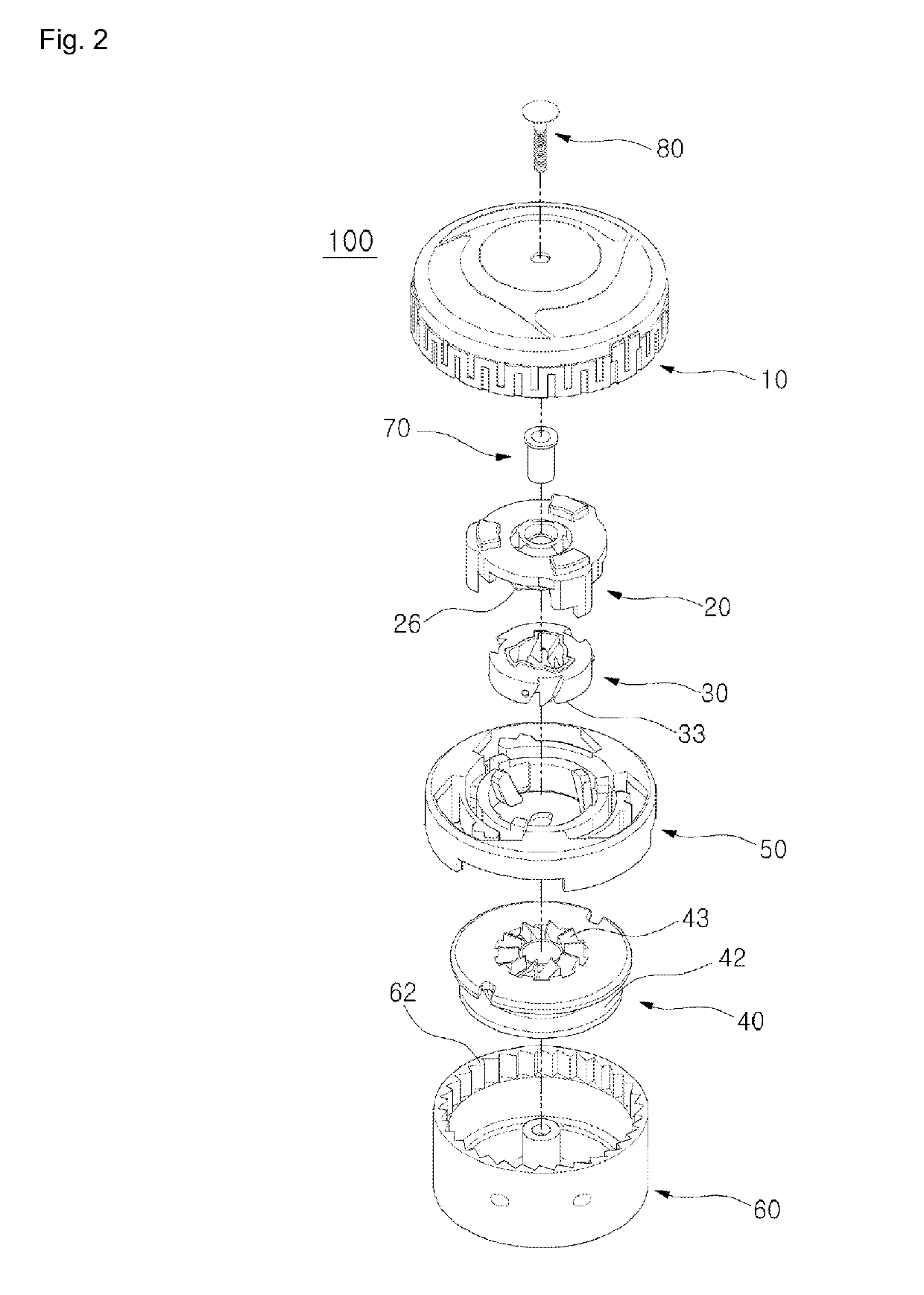

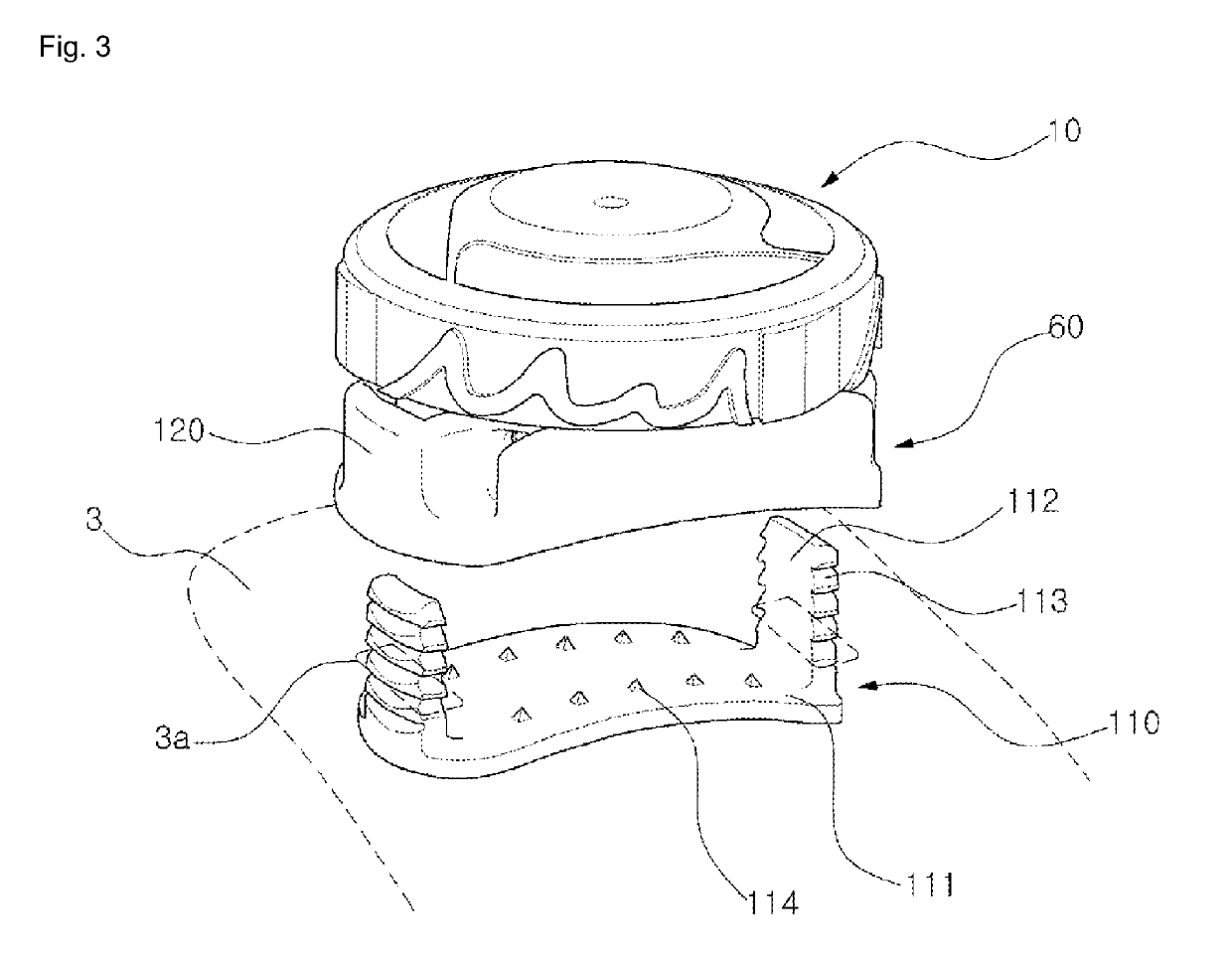

Closure device for shoe

Owner:SKECHERS US II

Method of connecting terminal and electric wire

InactiveUS20070184715A1Low costImprove conductivitySecuring/insulating coupling contact membersElectrically conductive adhesive connectionsAdhesiveSwaging

The invention comprises filling a conductive adhesive on a hole end of a wire connection part in tubular shape of the terminal which has an electric contact part at one side and the wire connection part at the other side, inserting an electric wire from a hole opening of the wire connection part toward the hole end, and reducing evenly a size of a tubular wall of the wire connection part, thereby causing the conductive adhesive to infiltrate into a space of the electric contact part or between wires. The invention also comprises tightening the tubular wall of the wire connection part by a rotary swaging process. Further, the conductive adhesive is a nickel paste which is a mixture of nickel powders in a liquid epoxy resin based binder. In addition, at least one of a core wire portion of the electric wire or the terminal is aluminum or aluminum alloy.

Owner:YAZAKI CORP

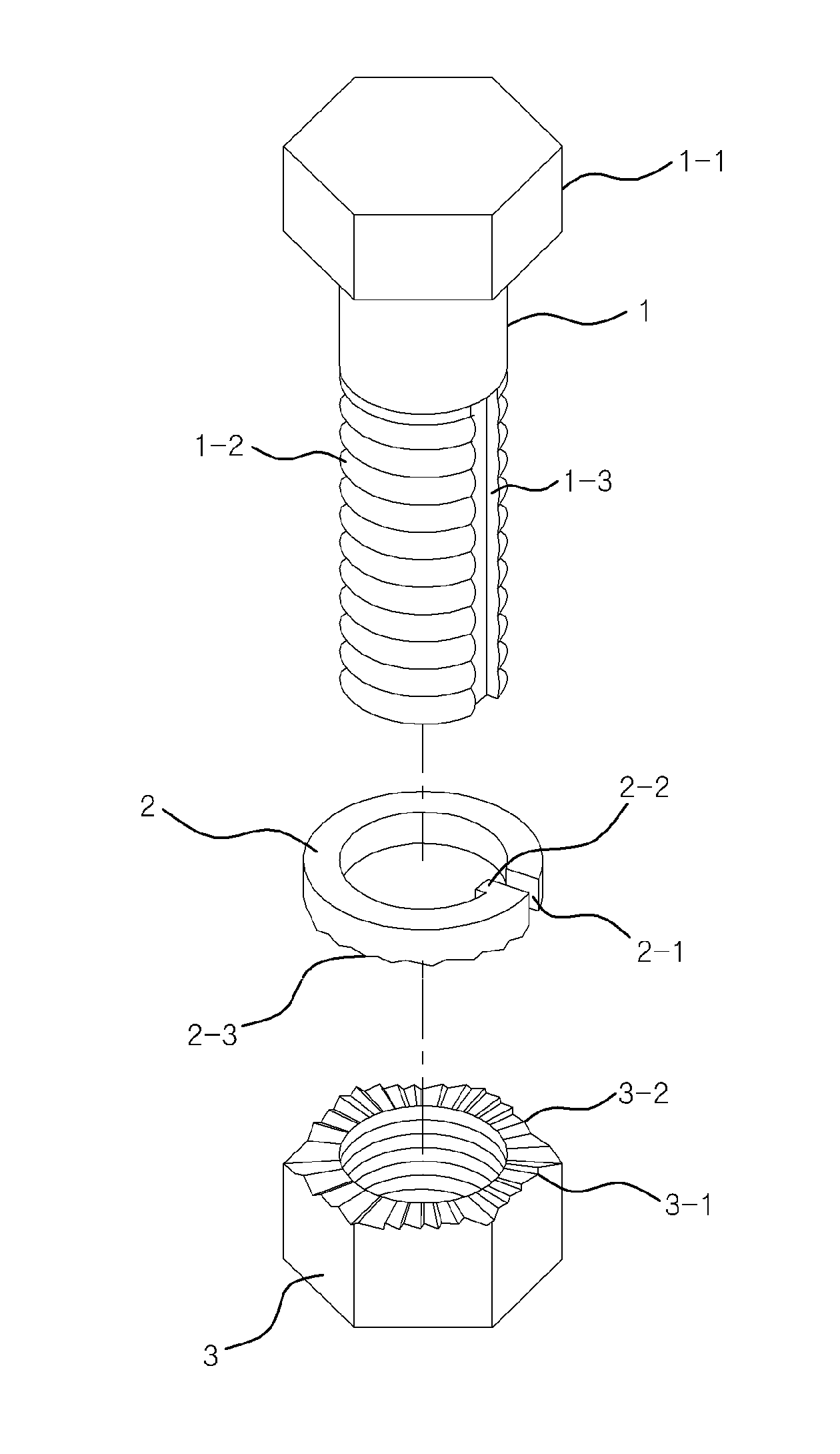

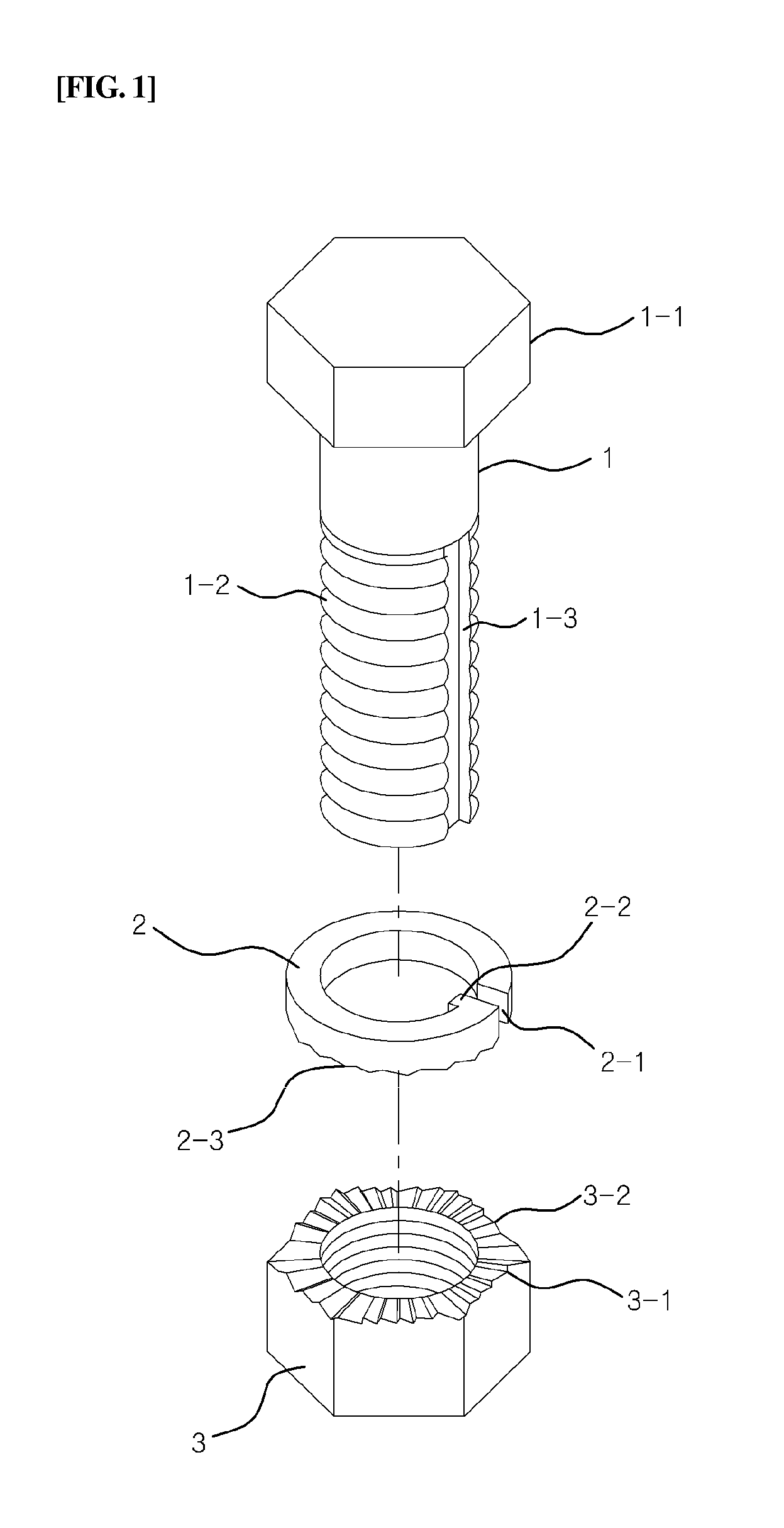

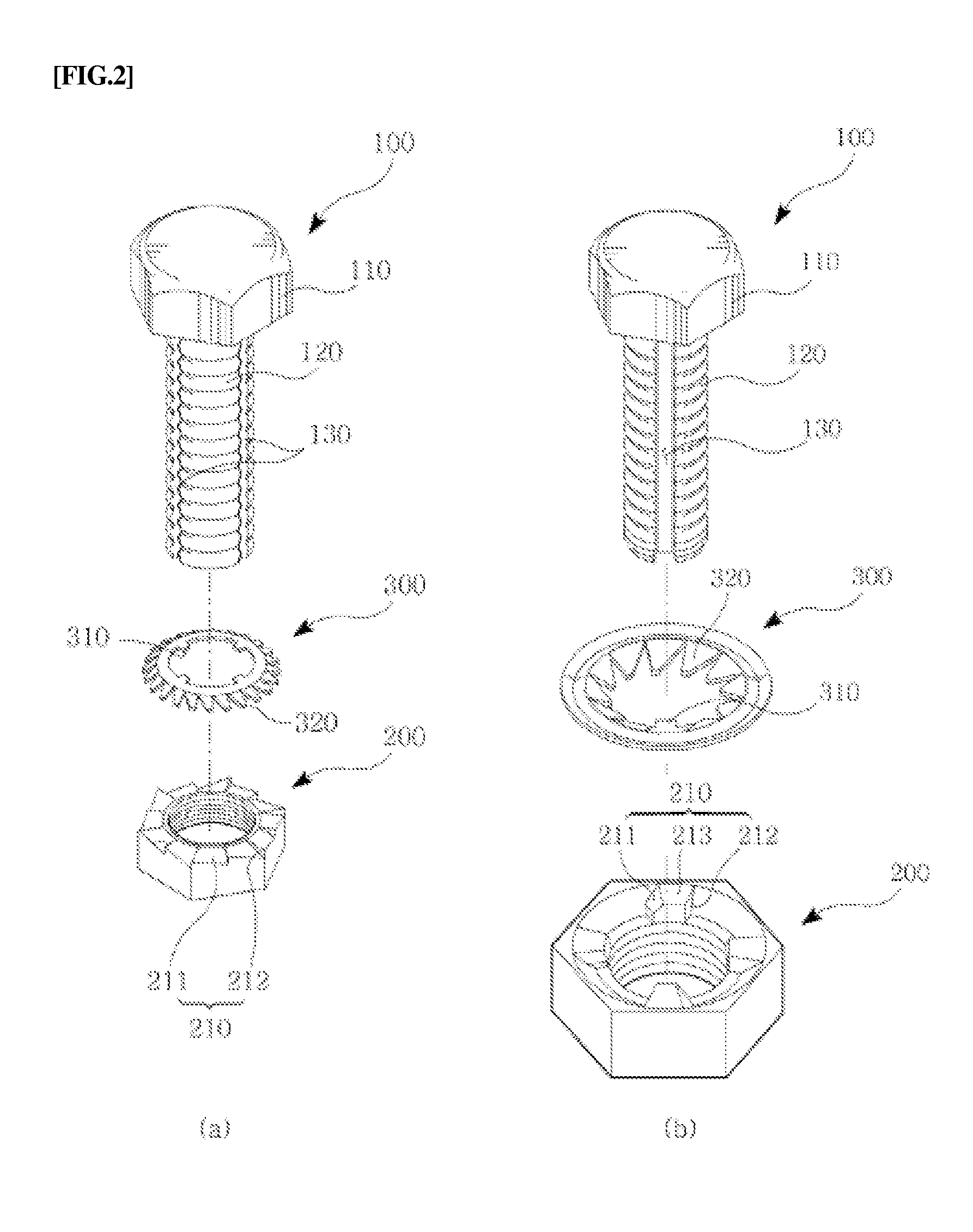

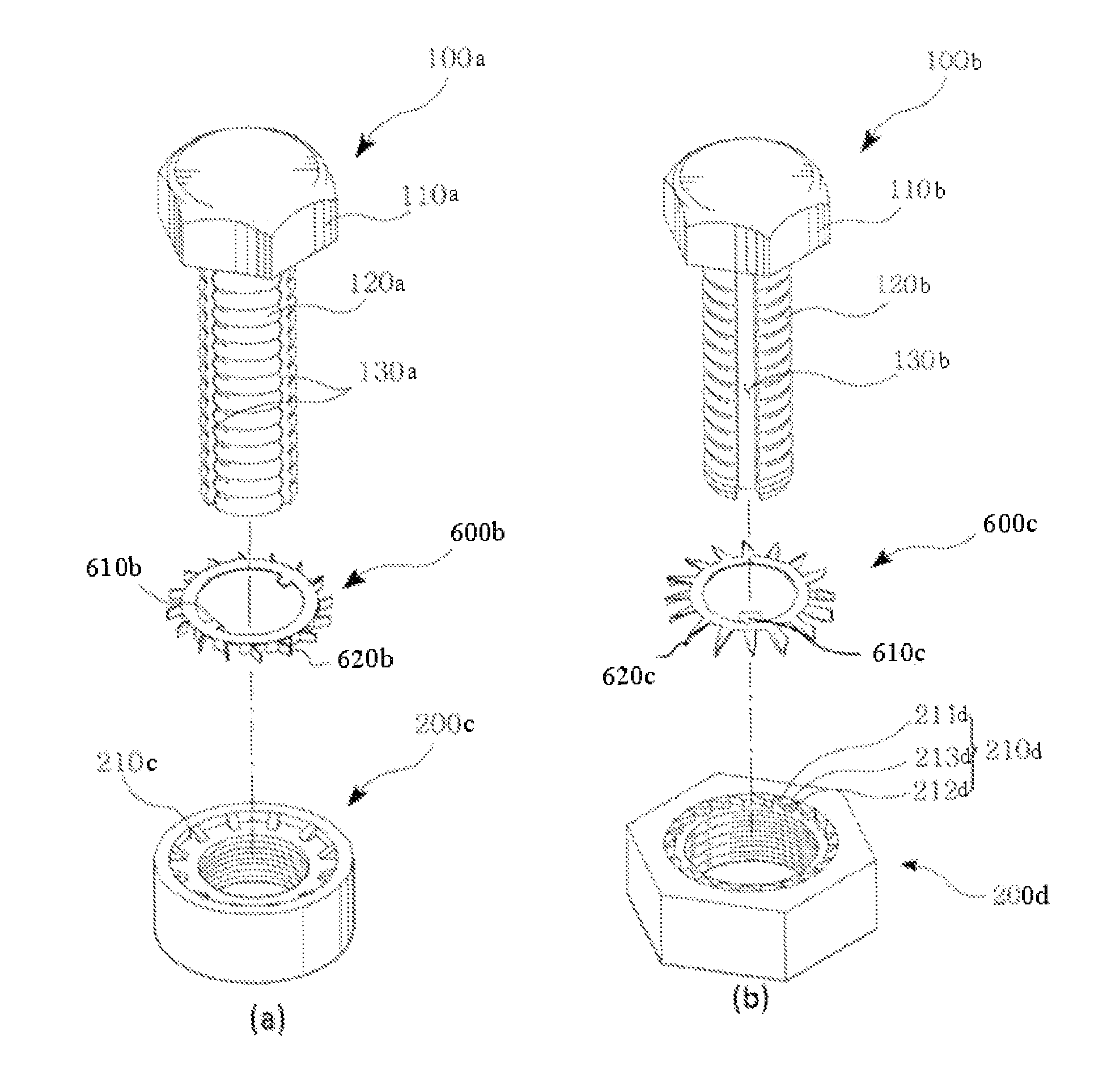

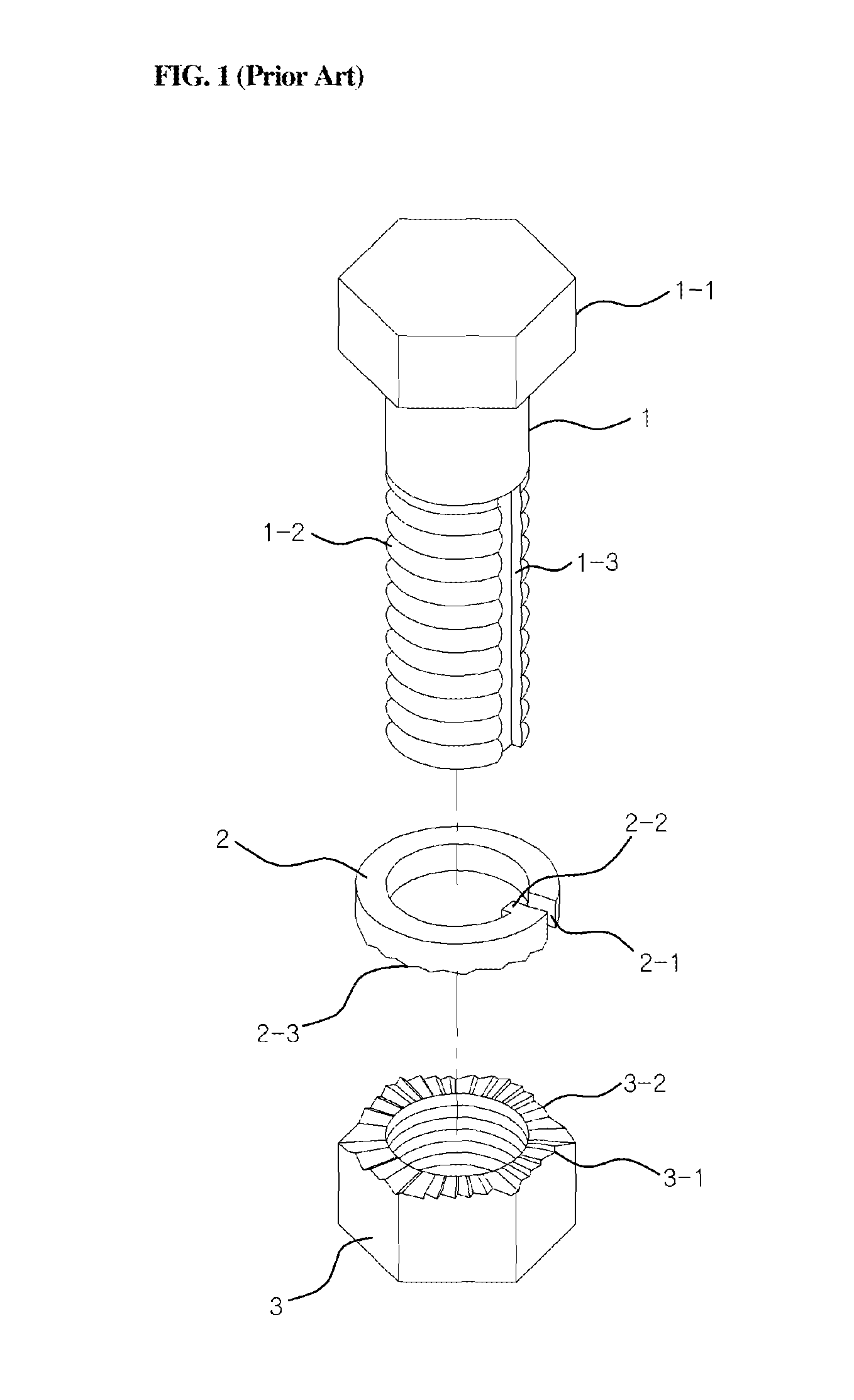

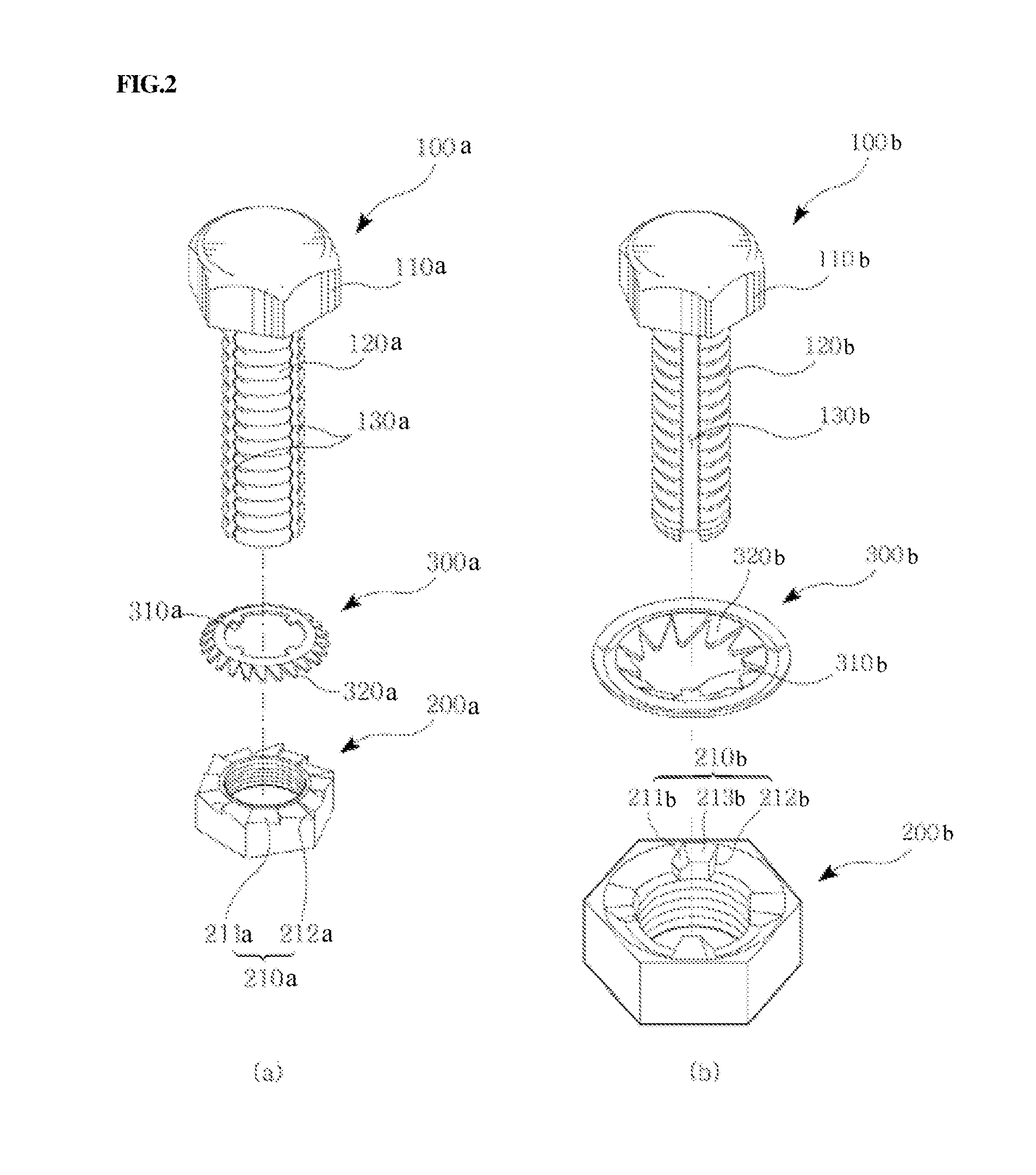

Self-locking bolt nut assembly

The present invention relates to a self-locking bolt-nut assembly. The bolt-nut assembly includes a bolt (100), a nut (200) tightened on the bolt (100), a washer (300) provided between the bolt (100) and the nut (200). The bolt (100) includes a bolt head (110) and a bolt body (120). The bolt body (120) has an external thread thereon. An insertion guide groove (130) is formed in the bolt body along the longitudinal direction. The nut (200) has stop protrusions (210) which are provided on the nut (200) and are arranged in a circumferential direction at regular intervals. The washer (300) includes a rotation-preventive protrusion (310) which protrudes from a circumferential inner edge of the washer (300) towards a center thereof and is inserted into the insertion guide groove (130), and elastic protrusions (320) which are provided on the washer (300) and are arranged in a circumferential direction at regular intervals. Thus, when the nut (200) which has been in contact with the washer (300) is tightened, the elastic protrusions (320) are elastically bent while passing over first surfaces of corresponding stop protrusions (210), and then are returned to original states thereof by elastic force so that elastic protrusions (320) are locked to second surfaces of the stop protrusions (210).

Owner:LEE SANG CHEOL

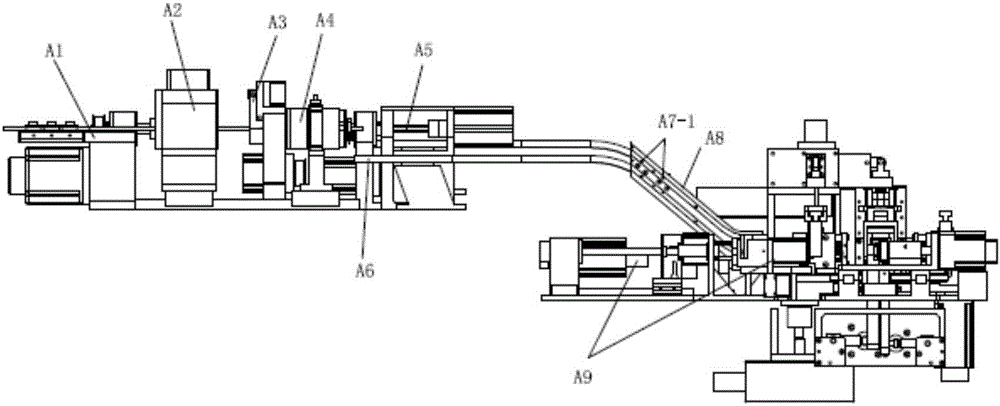

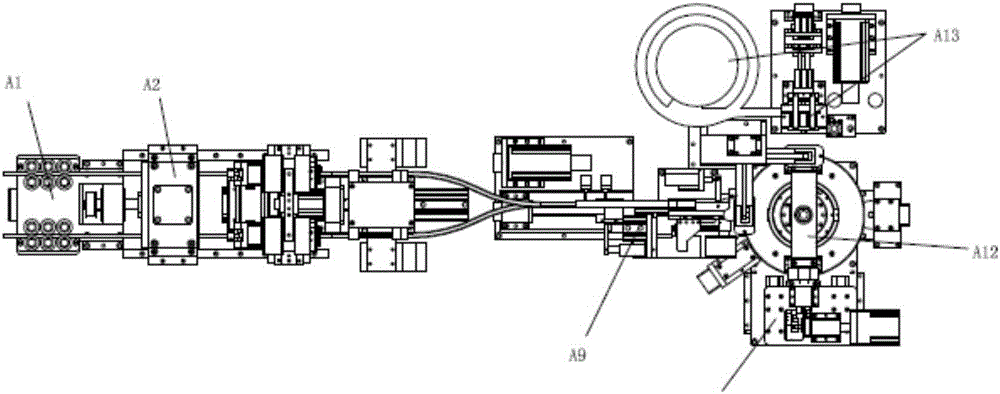

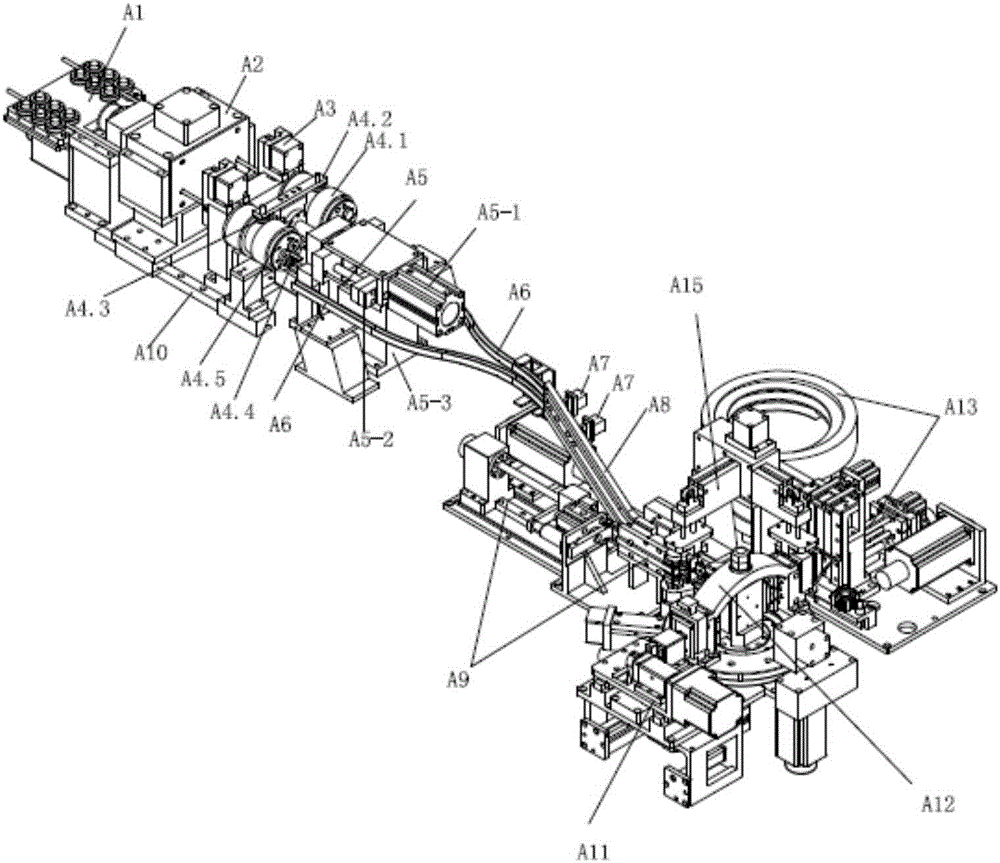

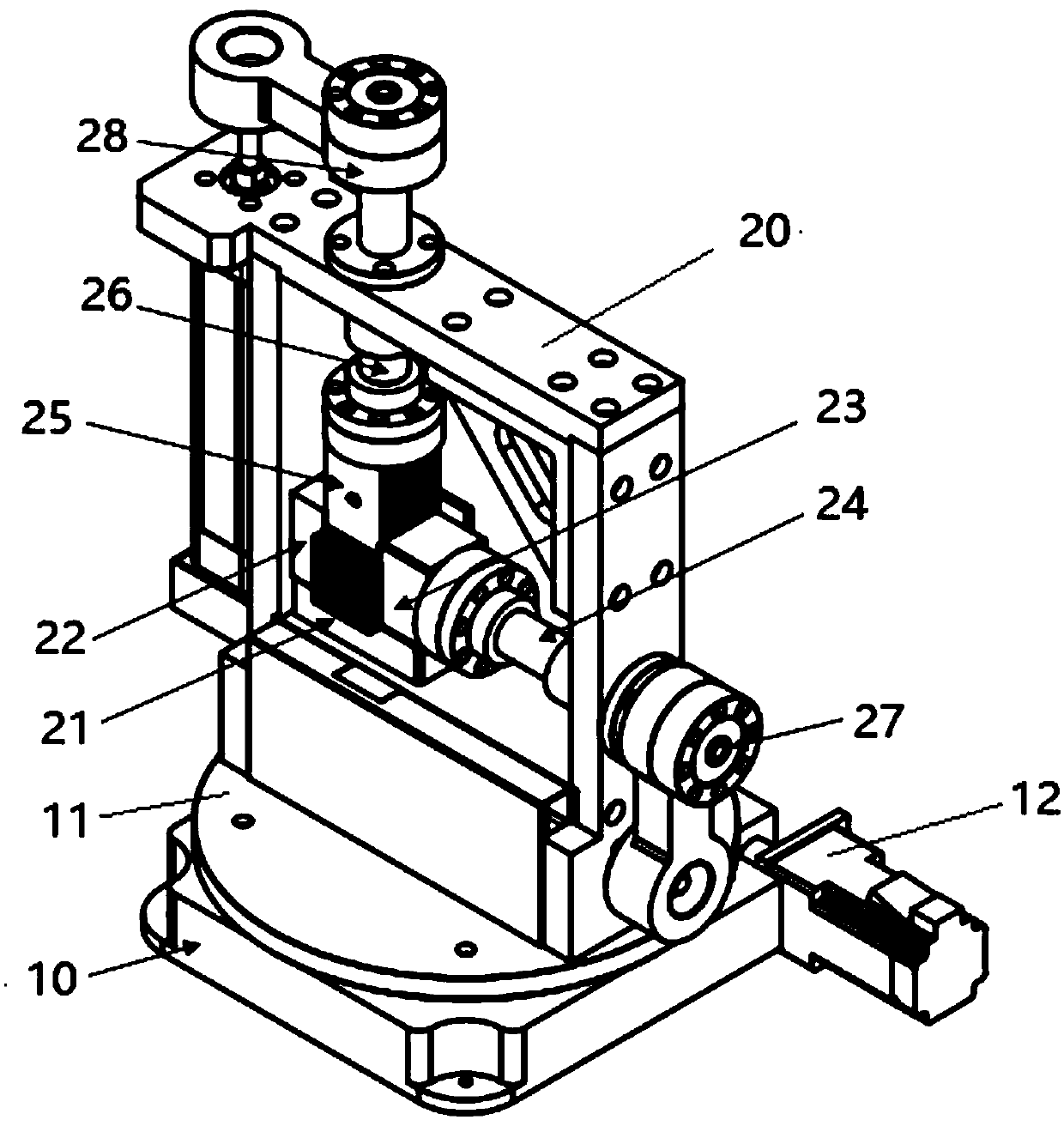

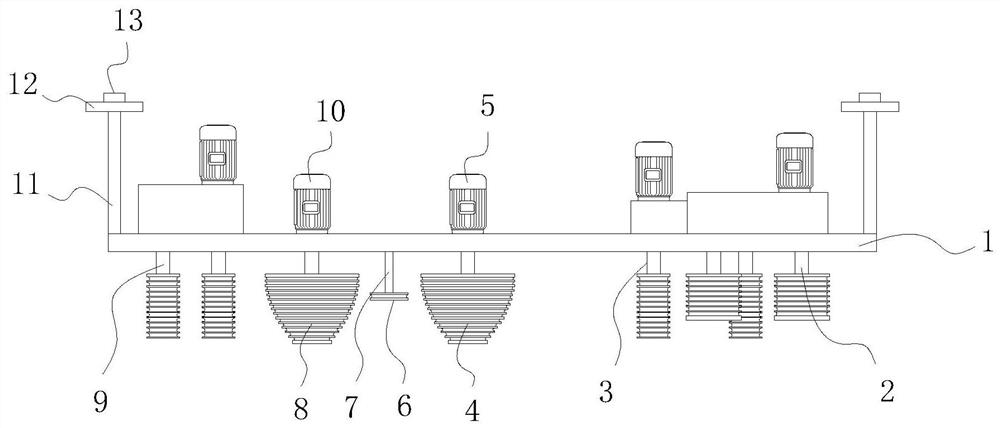

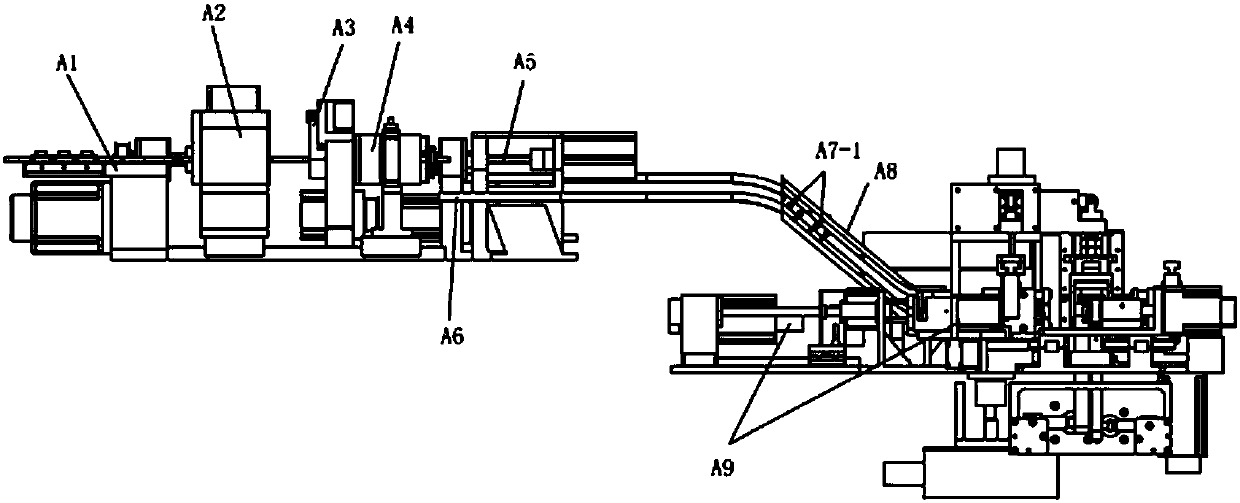

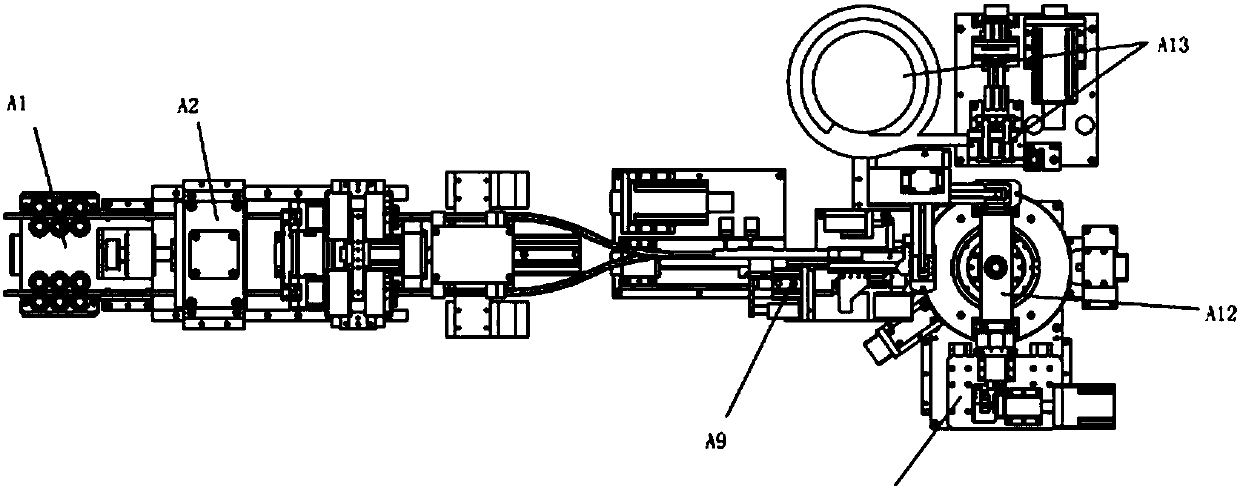

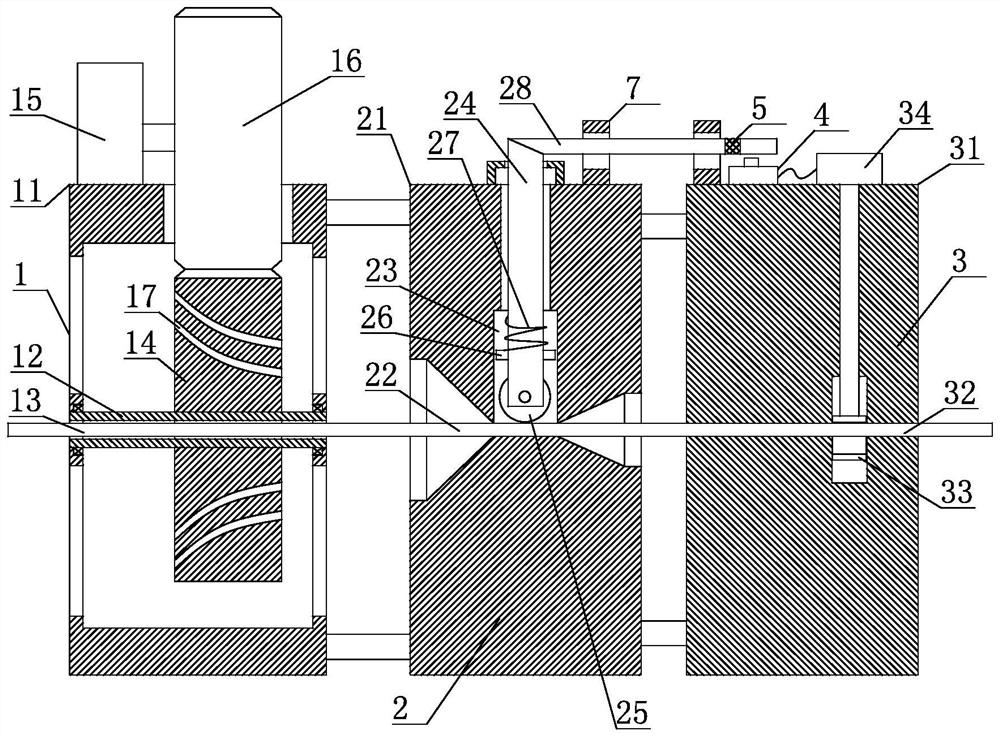

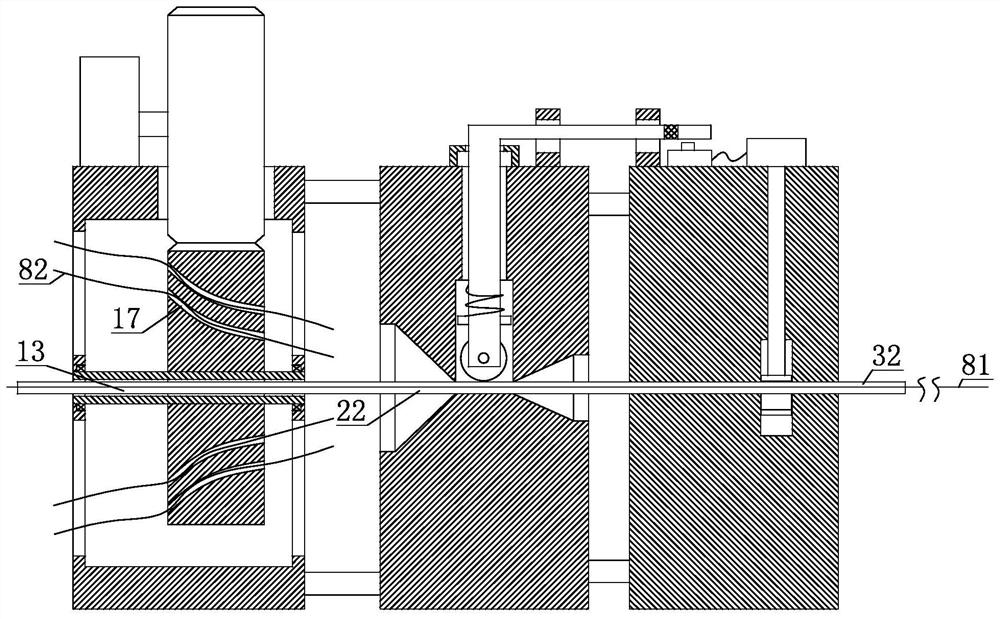

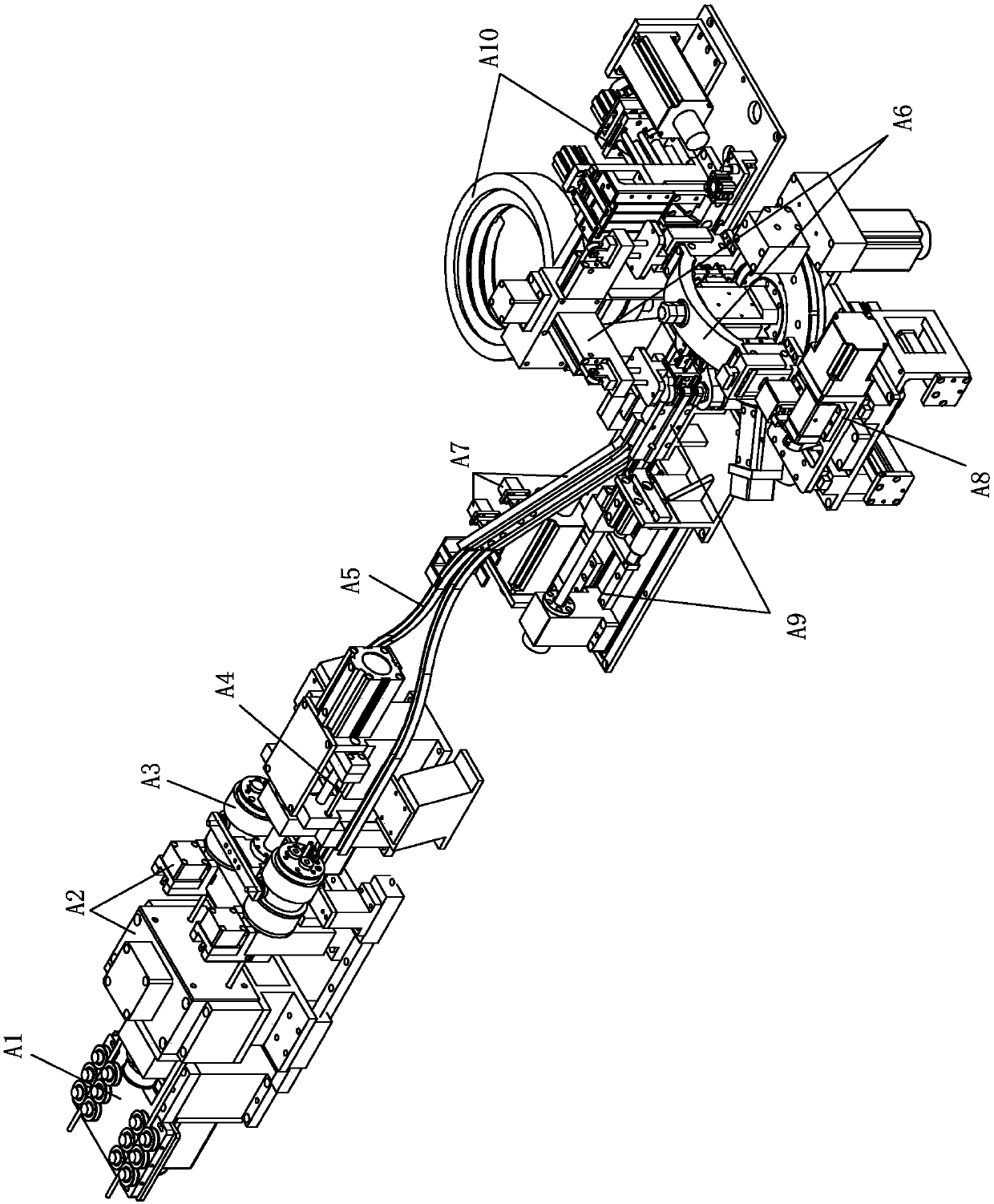

Automatic forming machine of thin-walled short U bent pipe with welding ring

ActiveCN106270239AEliminate wasteGuaranteed not to deformMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringFixed length

The invention discloses an automatic forming machine of a thin-walled short U bent pipe with a welding ring, relates to the technical field of automation equipment, and can continuously accomplish the forming of the thin-walled short U bent pipe and socket welding ring operation, so as to prevent a pipe wall from folds. The automatic forming machine comprises a feeding assembly, a pipe cutting assembly, a pipe bending assembly, a circumference position rotating assembly and a socket welding ring assembly, wherein the feeding assembly at least comprises a clamping mechanism and a No.1 driving mechanism; the No.1 driving mechanism drives the clamping mechanism to perform forward feeding; the pipe cutting assembly at least comprises a cutting tool mechanism and a No.2 driving mechanism; the No.2 driving mechanism drives a cutting tool to act; the pipe bending assembly at least comprises a fixed part, a semicircle die, a movable part and a No.3 driving mechanism; one end of a fixed length pipe is clamped at the fixed part; the other end of the fixed length pipe gets over the semicircle die and then is movably matched with the movable part; the circumference position rotating assembly at least comprises a rotating frame, a pipe clamping mechanism, a No.4 driving mechanism and a discharging cylinder; the socket welding ring assembly at least comprises a welding ring feeding unit, a welding ring guide unit and a socket welding ring unit; the socket welding ring unit pushes the welding ring to a straight pipe section of the thin-walled short U bent pipe.

Owner:TONGLU QIANDING TECH

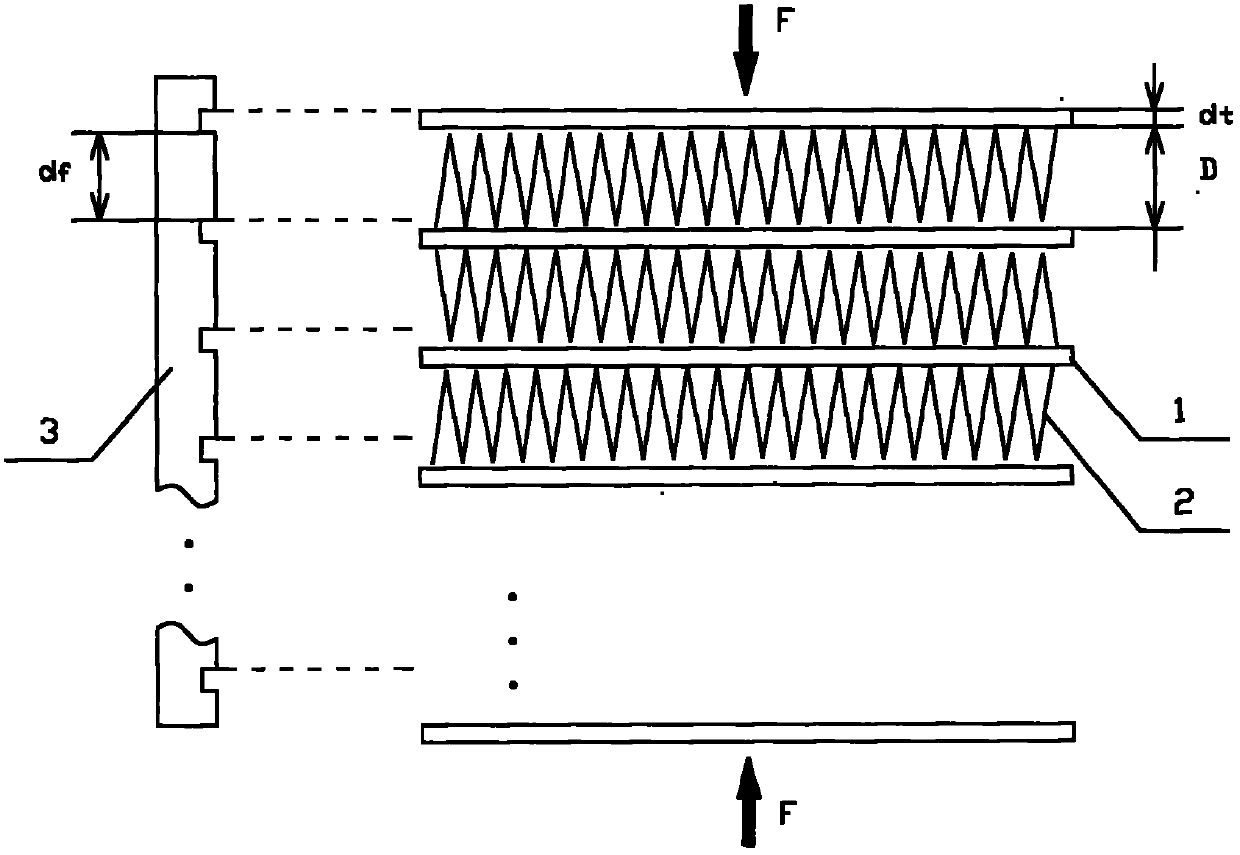

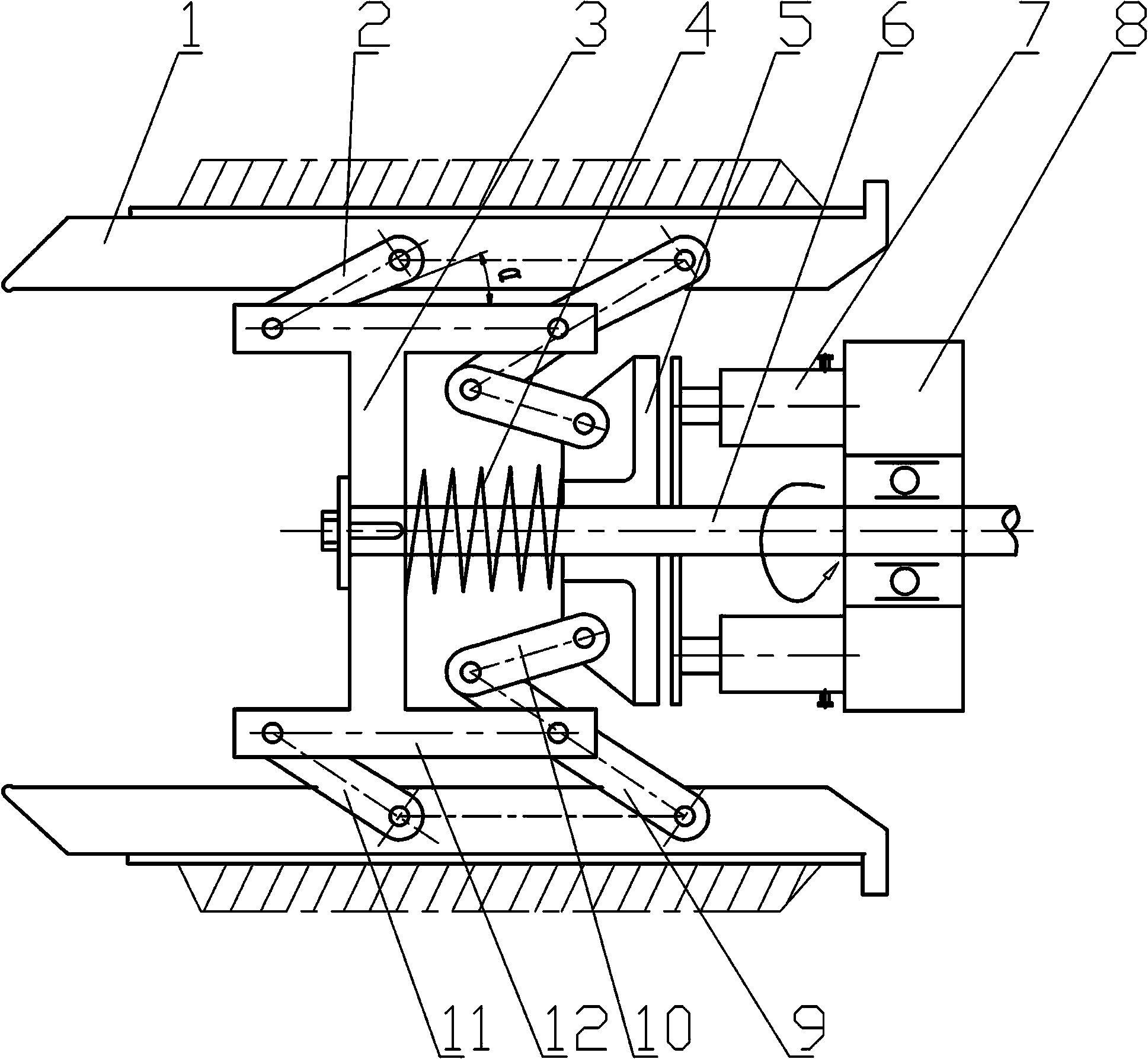

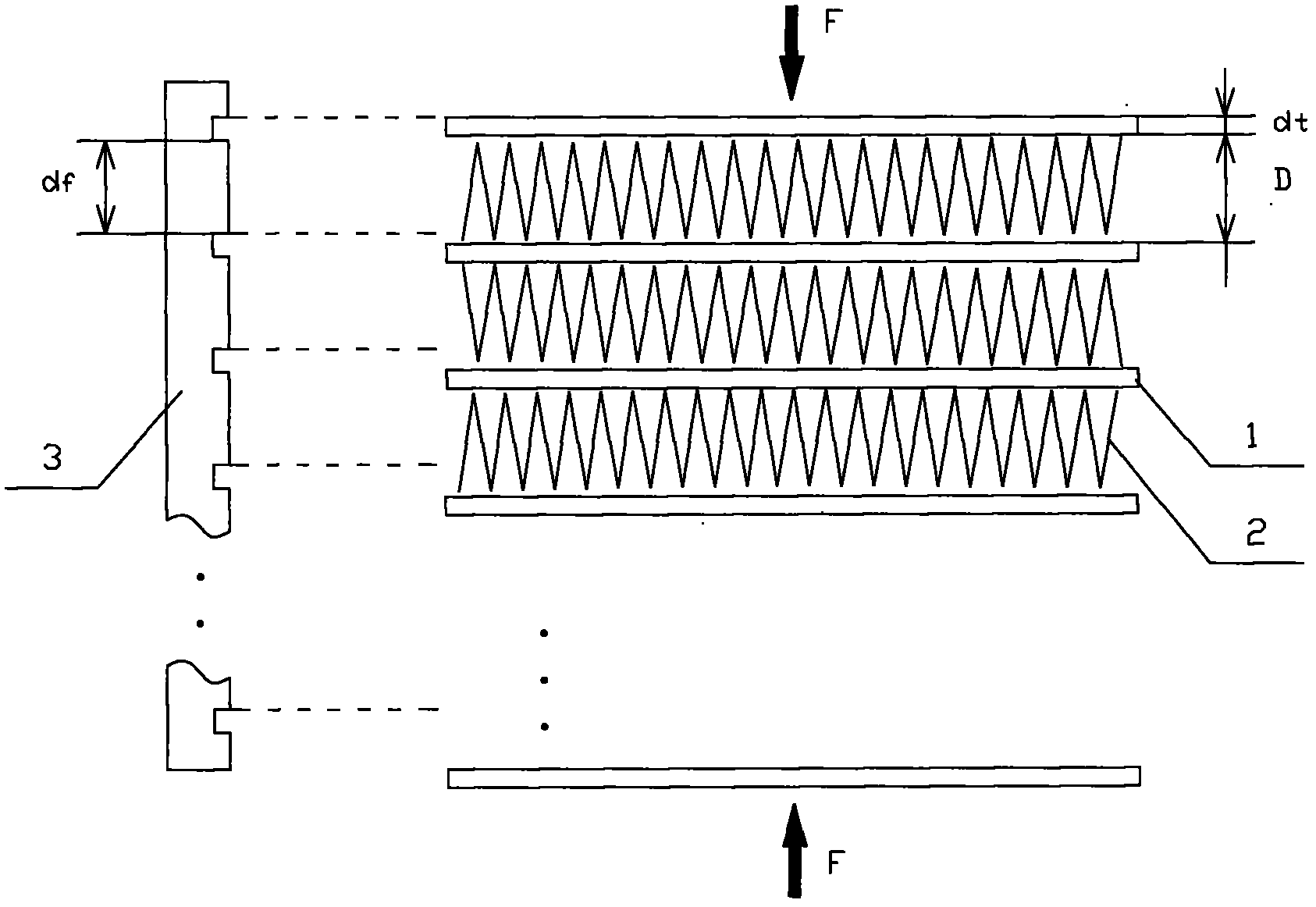

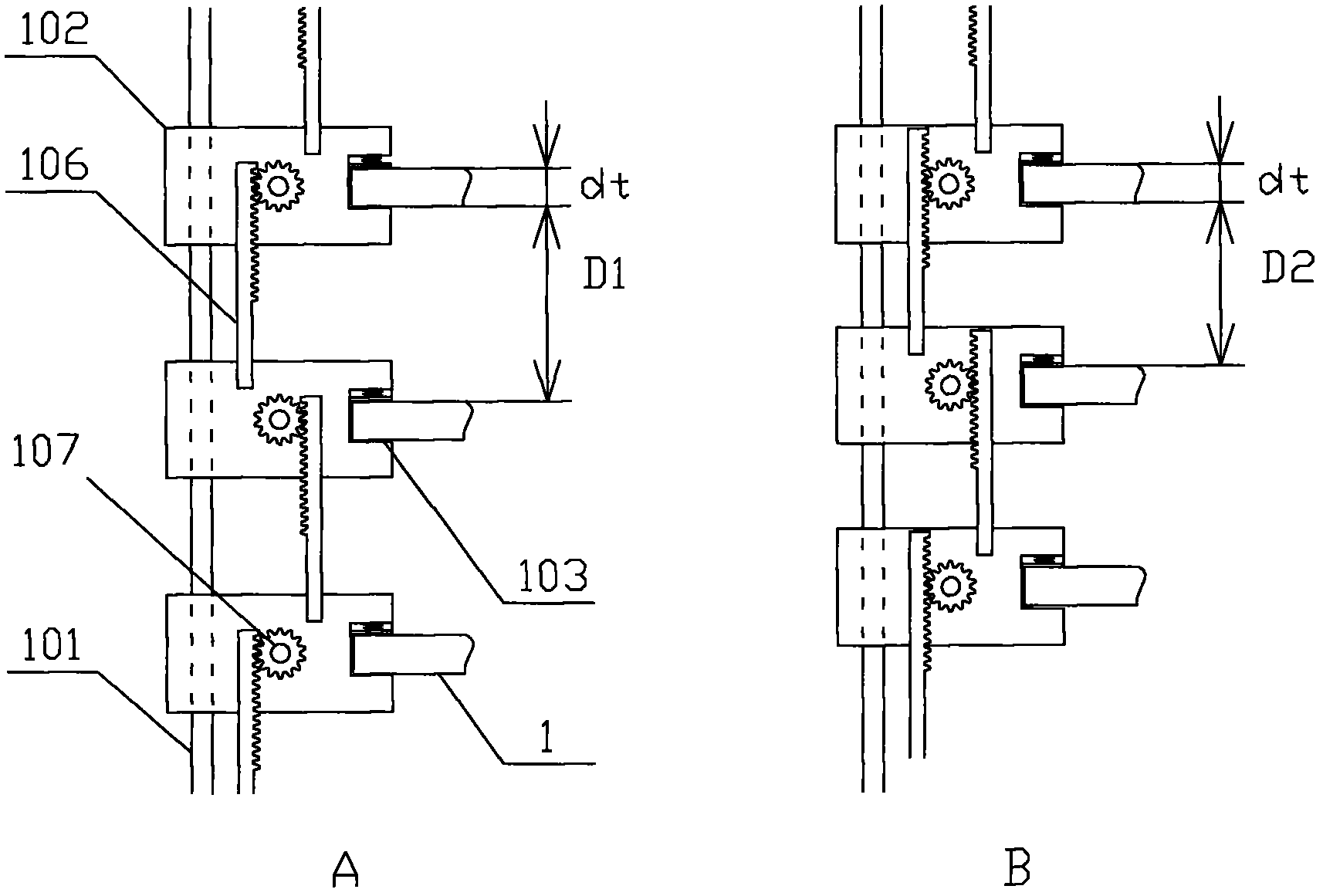

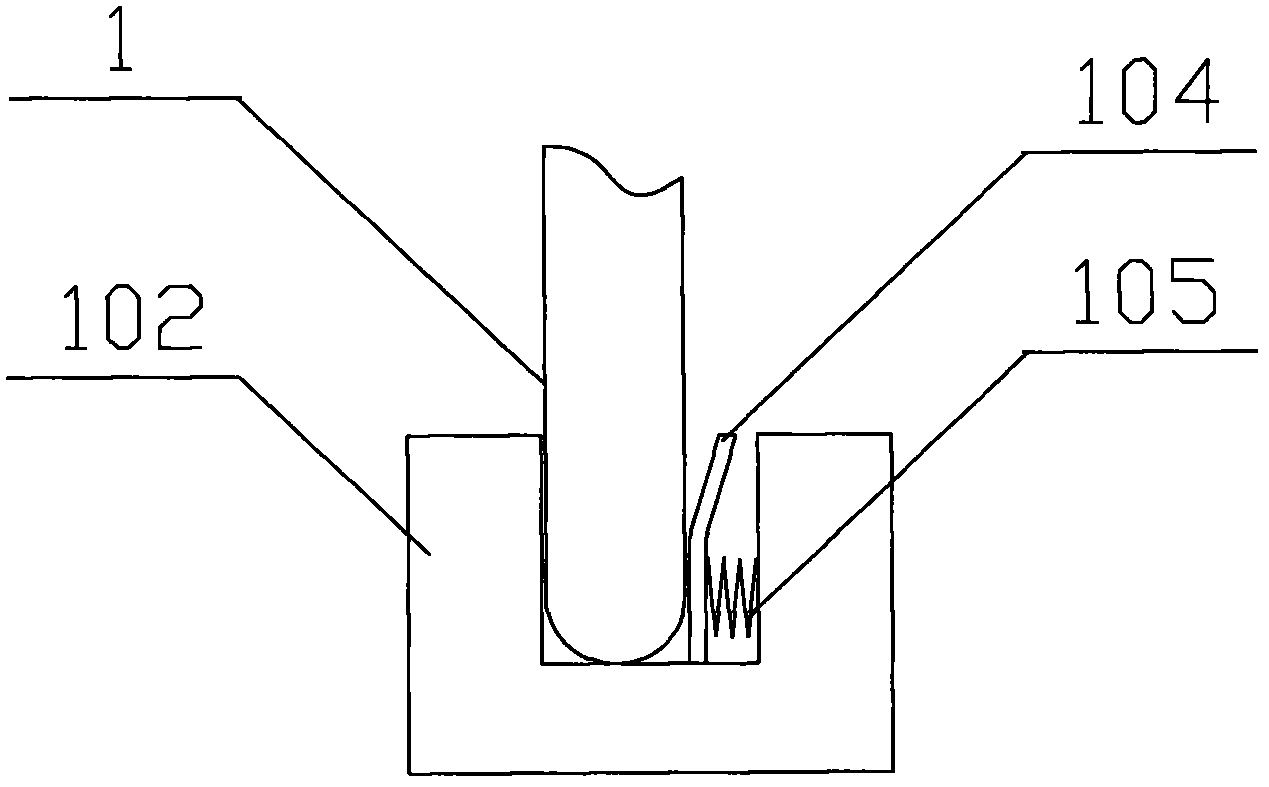

Finned tube locating fixture and assembly method of heat exchanger

InactiveCN102886666ASimple structural designEven by forceWork holdersMetal working apparatusEngineeringDislocation

The invention relates to a finned tube assembly technique method for manufacturing heat exchangers, provides a finned tube locating fixture of a heat exchanger, and aims to solve the problems that the operation efficiency is low, and dislocation is easy to occur when a group of finned flat tube bundles is tightened and assembled to a collecting tube. The finned tube locating fixture comprises a bracket, a driving mechanism and a group of tube fixators, wherein each tube fixator is provided with at least two locating points; and the tube fixators can be driven to move between a first locating point and a second locating point through the driving mechanism so as to drive each flat tube to reach the position corresponding to the slot of the collecting tube. Each flat tube and fin in the front and back directions are uniformly stressed and tightened through the finned tube locating fixture; the group of finned flat tube bundles is tightened at a set distance and position quickly, accurately and uniformly; the finned tube locating fixture is simple and reasonable in structure; and the production efficiency and precision of a finned tube locating assembly process are improved.

Owner:WESTERNHOUSE AUTOMATION CHANGZHOU

Self-locking bolt nut assembly

Owner:LEE SANG CHEOL

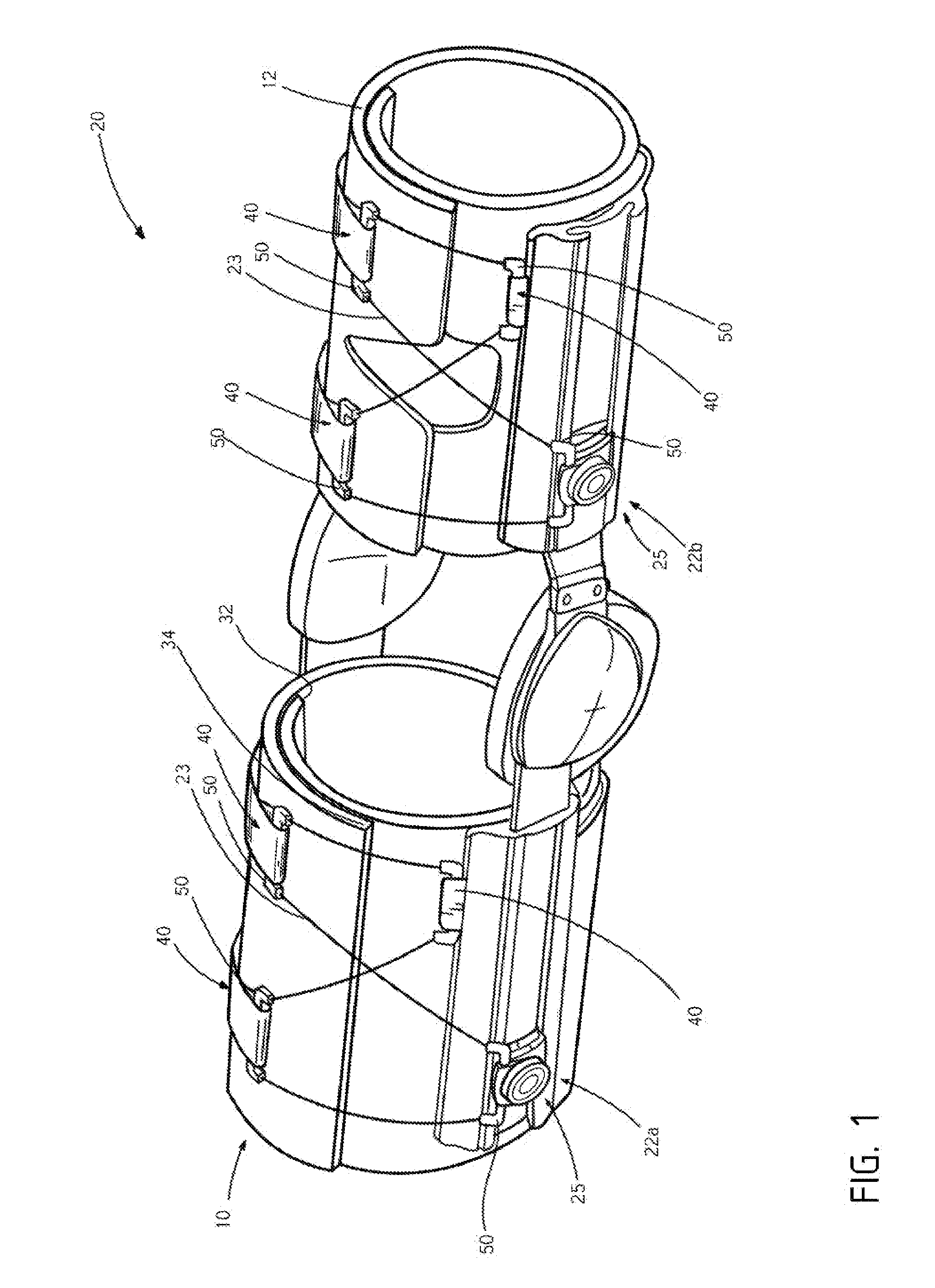

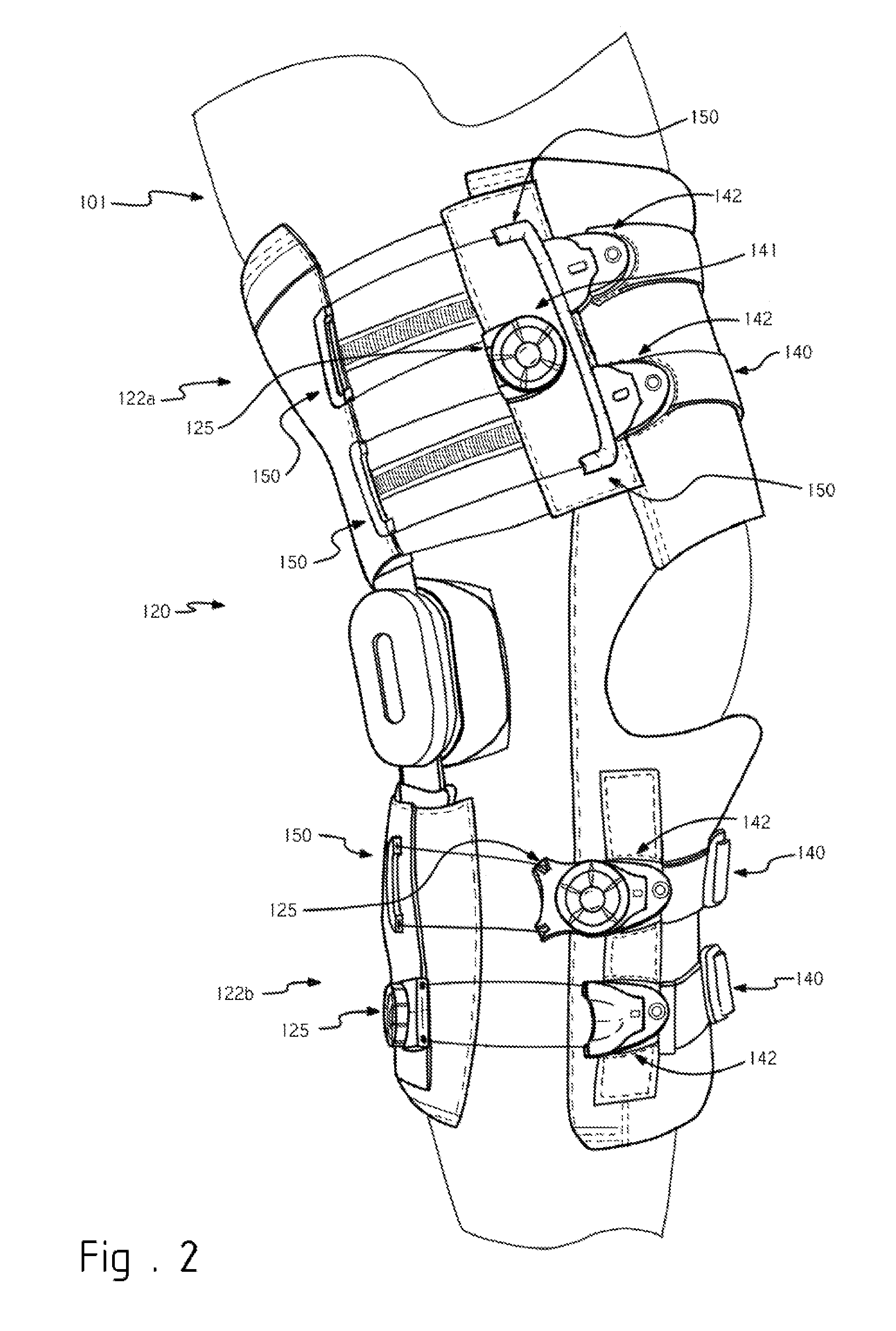

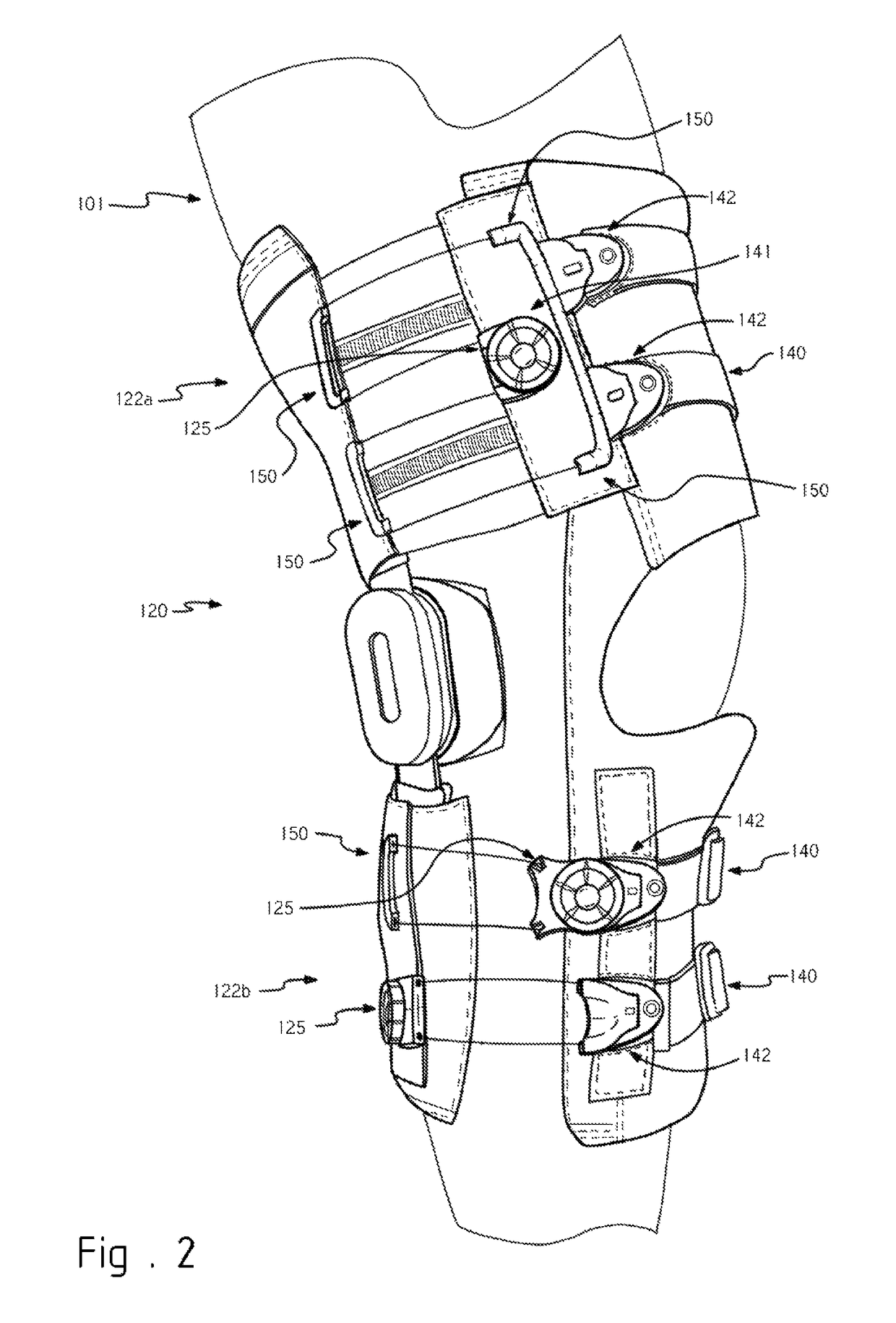

Methods and devices for providing automatic closure of prosthetics and orthotics

ActiveUS9872790B2Tighten evenlyIncrease displacementNon-surgical orthopedic devicesProsthesisKnee orthosisEngineering

According to an embodiment, a lacing system for opening and closing an article includes a tensioning device having a first mode of operation and a second mode of operation, a first tension member that is coupled with the tensioning device and tensionable thereby, and a second tension member that is coupled with the tensioning device and tensionable thereby. The tensioning device is configured to: effect tensioning of the first tension member to close and tighten the article upon operation of the tensioning device in the first mode of operation and effect tensioning of the second tension member to loosen and open the article upon operation of the tensioning device in the second mode of operation.

Owner:BOA TECHNOLOGY

Closure device for shoe

Owner:KELLEY SCOTT

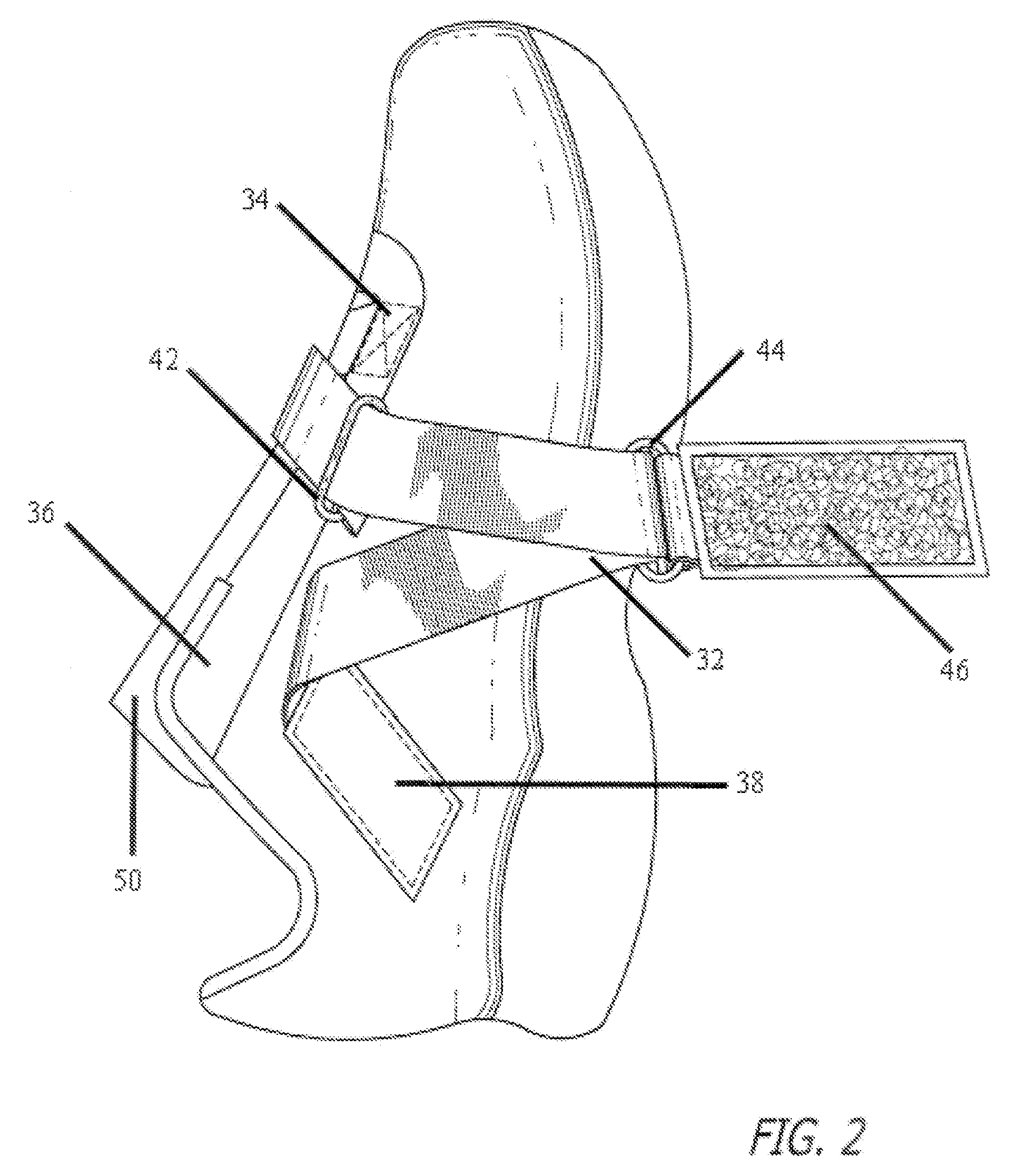

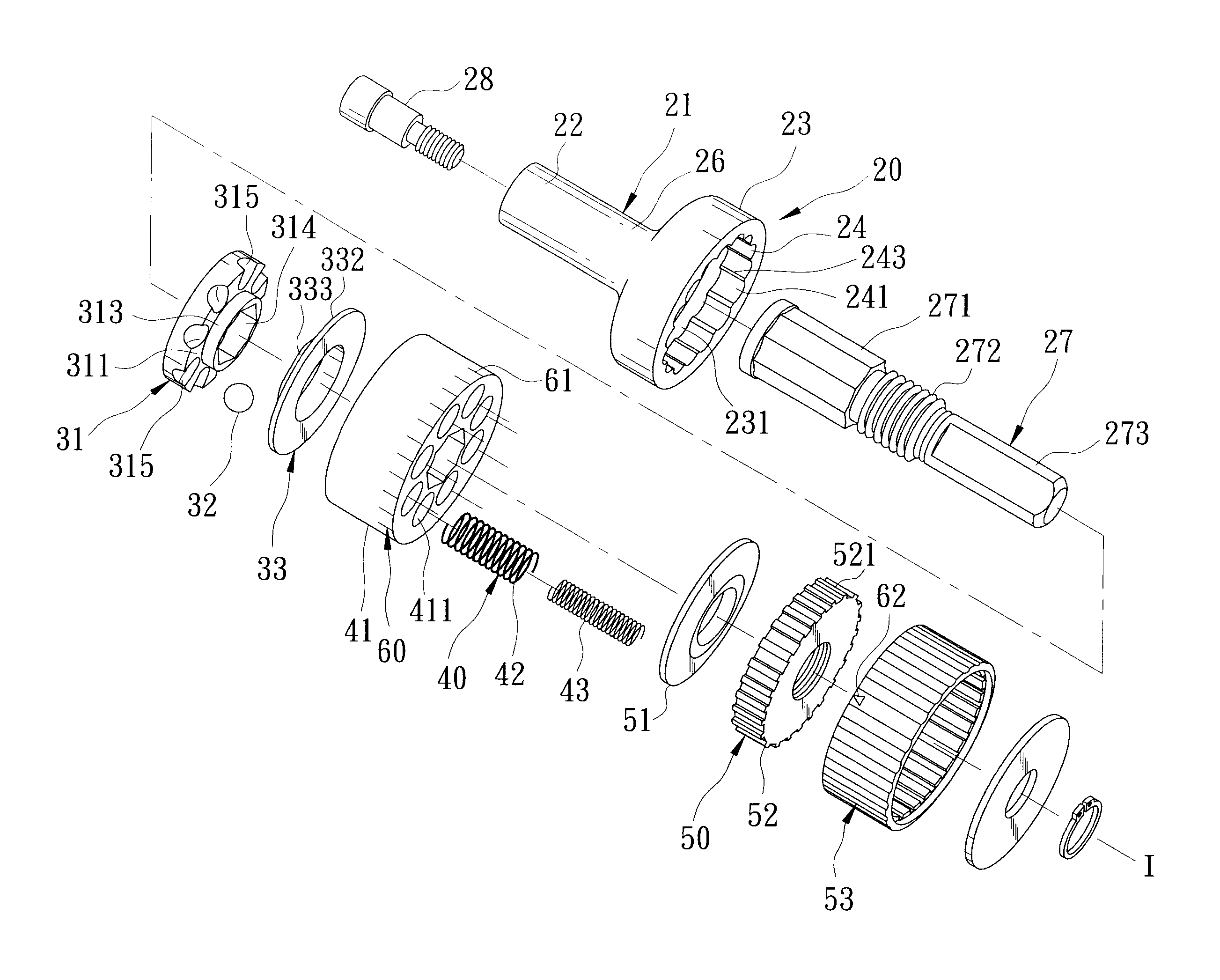

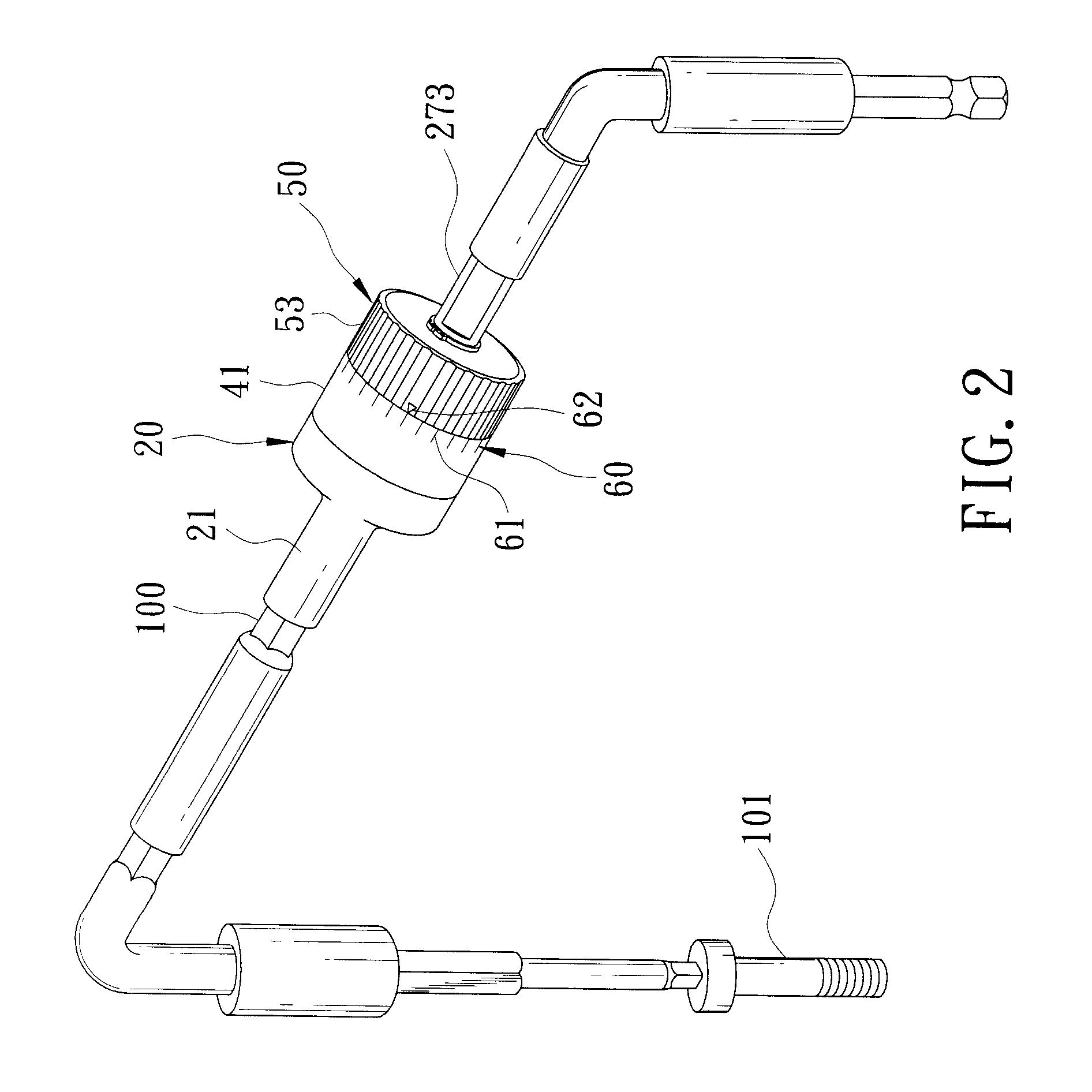

Adjustable torque limiting device for a click-type torque wrench

InactiveUS8371193B2Improve structural strengthHigh precisionSlip couplingSpannersEngineeringMechanical engineering

Owner:HUANG CHIN TAN

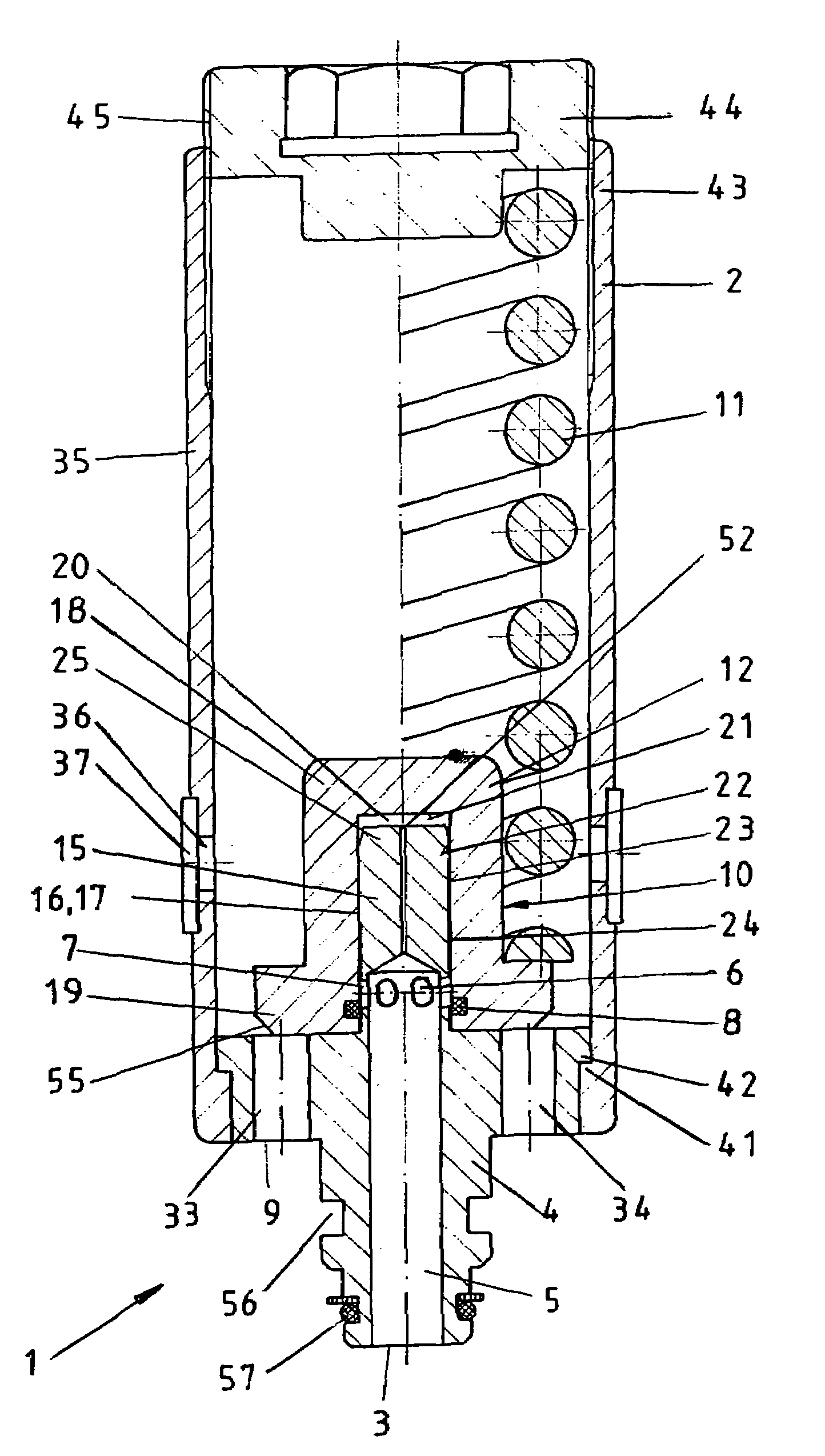

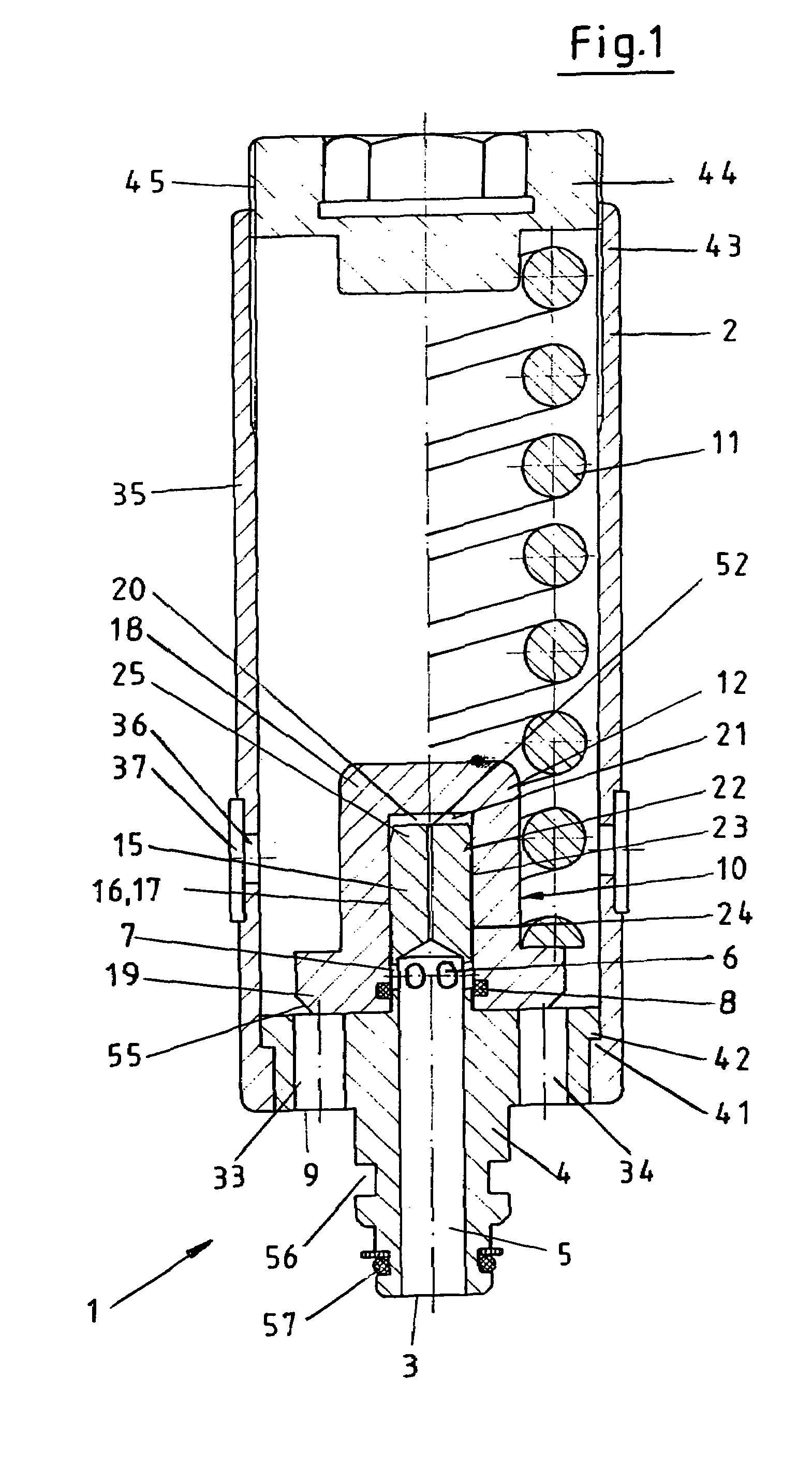

Pressure relief valve with direct hydraulic damping

To protect hydraulic assemblies, in particular to protect hydraulic brace systems, pressure relief valves 1 are used, the closing part 10 of which is formed by a piston 15, which is connected to the connection 4, and the valve spring retainer 12, which comprises said piston, is arranged displaceably thereon and accordingly has a cylindrical design. Between the connection 4, which is equipped with a blind hole 5 and radial bores 6, 7, and the displaceable closing part 10 and / or the correspondingly shaped valve spring retainer 12 a damping chamber 20 is formed, which is directly connected to the blind hole 5 and hence to the system pressure.

Owner:VOSS WOLFGANG

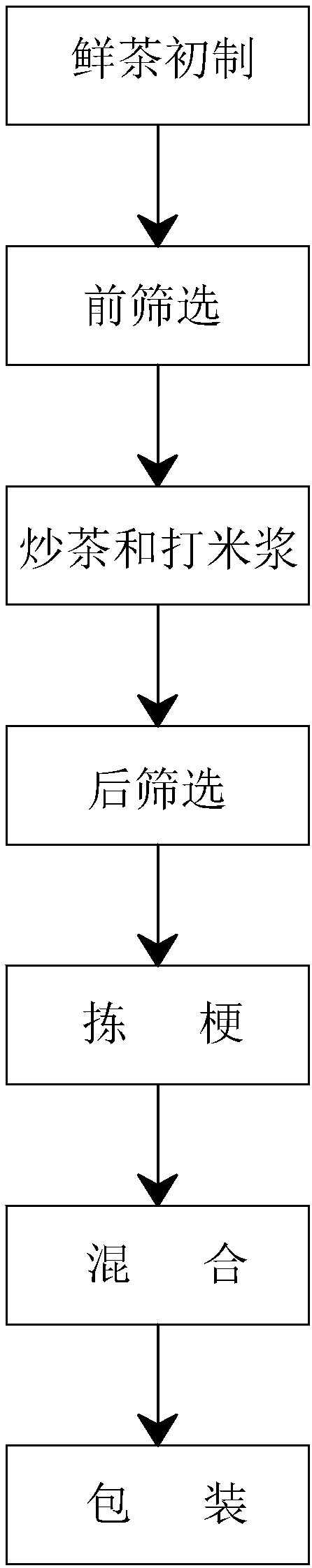

Gunpowder tea production process

The invention discloses a tea production process, discloses a gunpowder tea production process, and solves the problem that the quality and the taste of gunpowder tea are affected due to low tightnessof tightened gunpowder tea during the production process of the gunpowder tea. The gunpowder tea production process includes initial preparation and pre screening of fresh tea, frying of the tea, spraying of rice milk, post-screening, sorting, mixing and packaging; during the process of frying of the tea and spraying of the rice milk, the pre-screened tea is respectively fried to further reduce the moisture content of the tea, in the frying process, the rice milk is evenly sprayed on the tea, so that the surface of the tea is evenly coated with the rice milk, the moisture content of the friedtea is 6 to 7 %, the tea is curled into the gunpowder tea, the tea can be better tightened in the frying process, and the taste and the quality of the tea are better.

Owner:浙江诚茂控股集团有限公司

Battery

InactiveCN101533899AContact state is stablePrevent leakageFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineeringCurrent collector

A battery has current collectors and terminals in stable contacing status that represses the poor contact caused by applying impact such as falling, and fine quality and outer casing sealing performance. At a central portion of a lid (3) of a battery, a negative terminal (4), which has a T-shaped section view, is provided so as to be surrounded by a gasket (5) and pierce the lid (3). An insulator (6) is provided at the inner face side of the lid (3). A plate-like current collector (7) is placed in a recess (6a) of the insulator (6). Notches (72a) are provided at two positions of an insertion hole which is provided at one end portion side of the current collector (7). By inserting the negative terminal (4) into the insertion hole and crimping an end portion of a leg portion (42) of the negative terminal (4), the negative terminal (4) is fixed to the current collector (7) with a deforming part of the end portion eating into the notches (72a) and being locked.

Owner:GS YUASA INT LTD

High-precision glass fiber screen arrangement and fusion pressing device suitable for manufacturing microporous element

ActiveCN111580219AImprove angular resolutionPrecision layoutGlass making apparatusCoupling light guidesGlass fiberHorizontal orientation

The invention provides a high-precision glass fiber screen arrangement and fusion pressing device suitable for manufacturing a microporous element. The high-precision glass fiber screen arrangement and fusion pressing device comprises a base; a rotary table, rotatably arranged on the base; a support, fixed to the rotary table, being in a shape like a Chinese character 'hui' and being provided withfour right-angle interior angles; a Y-direction reference block, an X-direction reference block and an X-direction pressing block, pressed on the Y-direction reference block, and the X-direction transmission mechanism being arranged in the horizontal direction and driving the X-direction pressing block to slide on the Y-direction reference block and a reference plane limited by the Y-direction reference block; a Y-direction pressing block, pressed on the X-direction reference block along the vertical direction; a Y-direction transmission mechanism; a driving device, used for driving the X-direction transmission mechanism and the Y-direction transmission mechanism to move; a space defined by the X-direction reference block, the Y-direction reference block, the X-direction pressing block and the Y-direction pressing block forming the spatial position of screen segment arrangement and limiting the reference of screen segment arrangement. Precise screen arrangement and fusion pressing ofsquare, circular or hexagonal glass fibers and the like can be achieved, and the beneficial effect of being precise in arrangement is achieved.

Owner:NORTH NIGHT VISION TECH

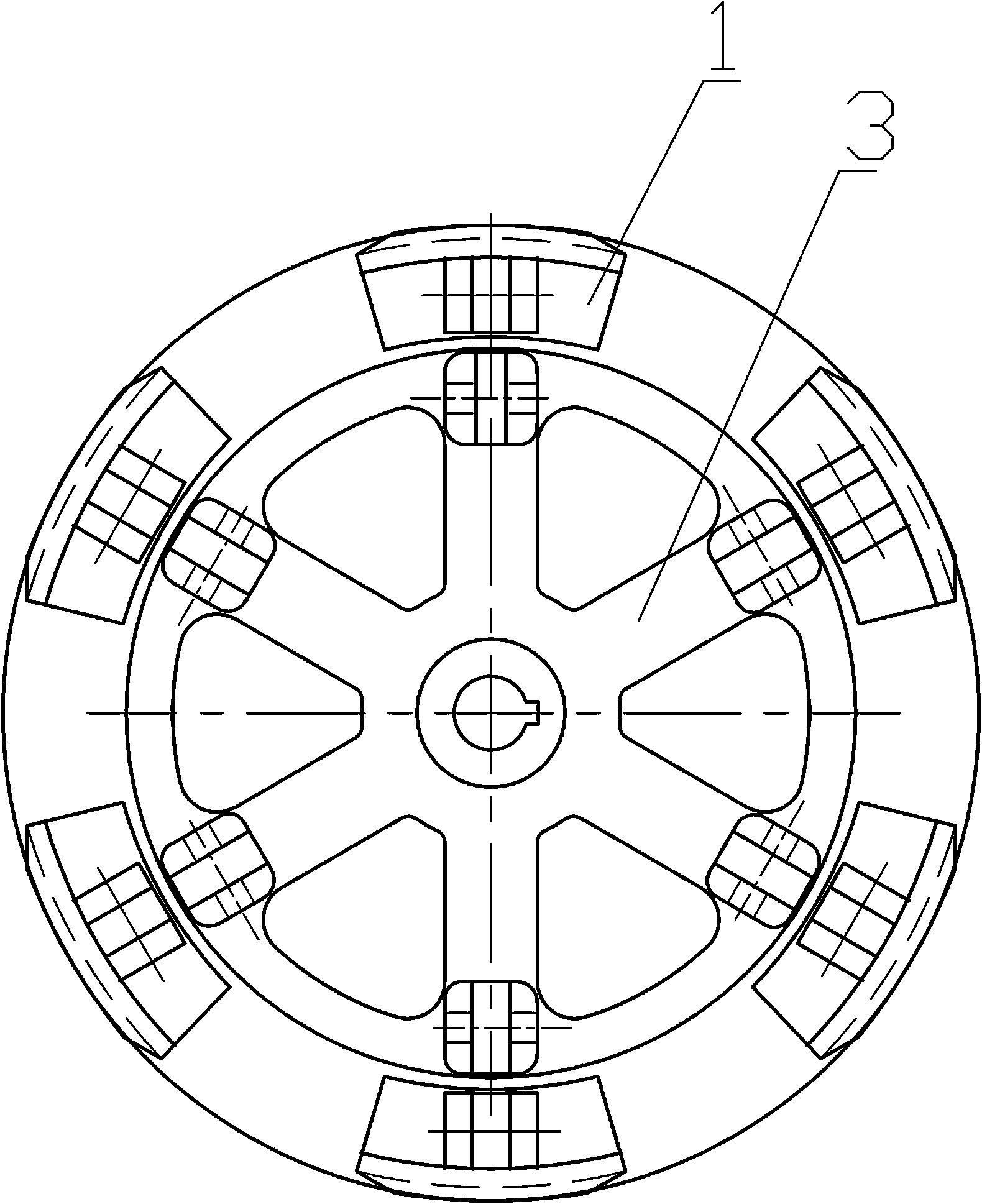

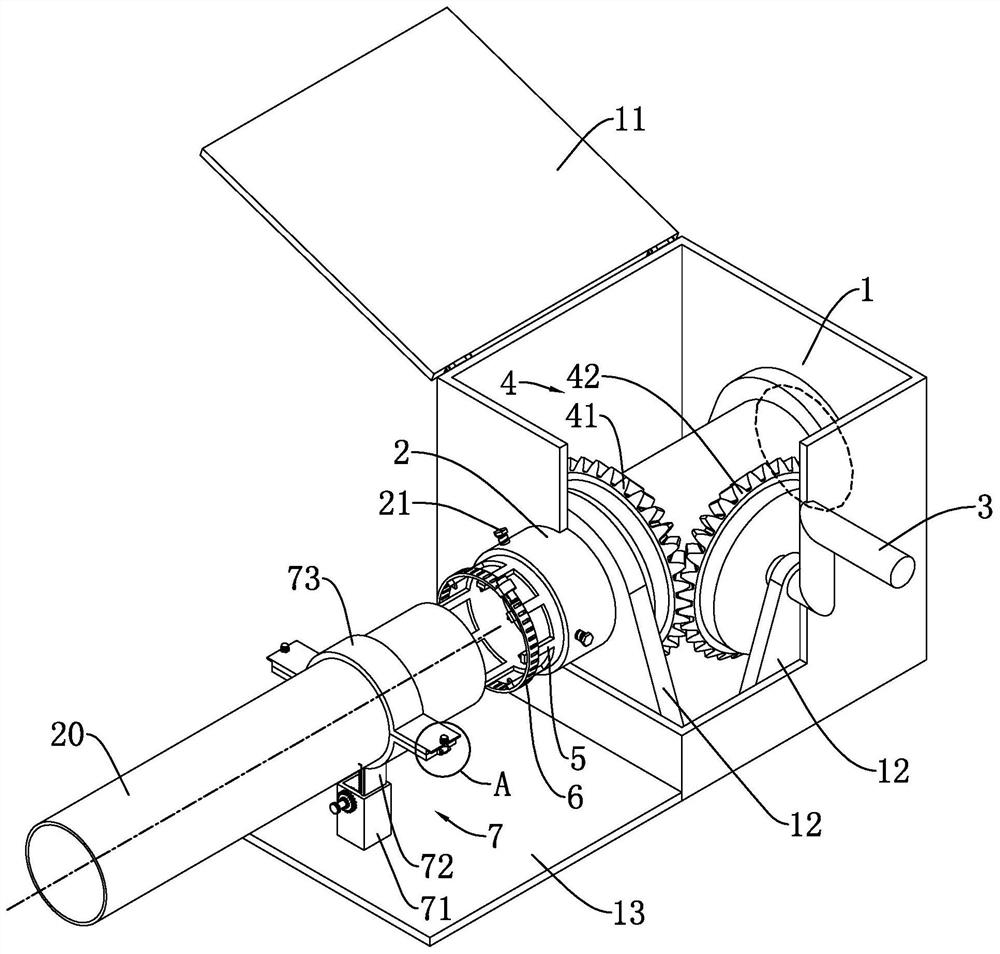

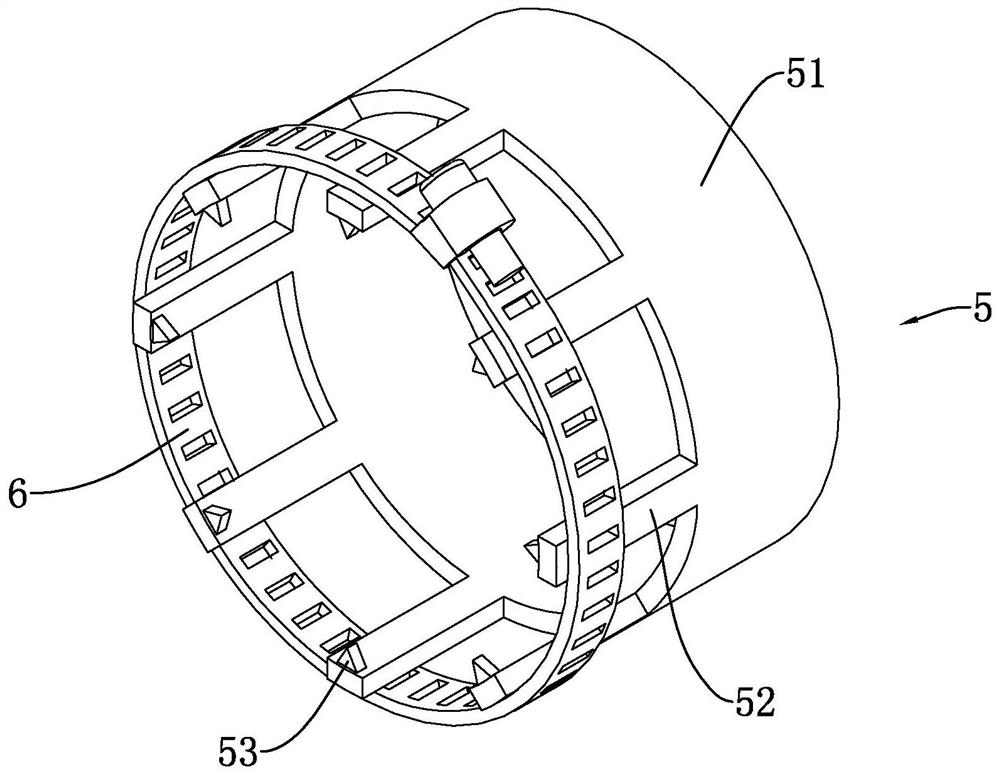

Parallel tensioning device of glass fiber protofilament cylinder

A parallel tensioning device of a glass fiber protofilament comprises a plurality of blades. The blades distributed on the circumference are hinged to a connecting rod support through a double-row connecting rod mechanism, the connecting rod support is connected with a central shaft, a connecting rod sliding sleeve can be installed on the central shaft along the central shaft in a sliding mode, and the connecting rod sliding sleeve is connected with the double-row connecting rod mechanism; a compression spring is arranged between the connecting rod support and the connecting rod sliding sleeve; one side, far away from the connecting rod sliding sleeve, of the connecting rod sliding sleeve is provided with a plurality of air cylinders driving the connecting rod sliding sleeve to slide along the central shaft; the other end of each air cylinder is connected with an air cylinder base. According to the parallel tensioning device of the glass fiber protofilament, an adopted quadrilateral mechanism is flexible in rotation, so that generated tension is even and the tensioning force is large. The torque of transmission of the double-row connecting rod mechanism is large, the driving blades are driven to enable the range of the tensioning diameter to be wide, and the parallel tensioning device is suitable for glass fiber protofilaments with different diameters. Due to the fact that the blades are supported by two connecting rods, the binding face is large, roundness is good, tensioning of the protofilament is even, and when the parallel tensioning device rotates, the phenomenon of looseness is avoided. The parallel tensioning device of the glass fiber protofilament is extremely suitable for active unwinding in the process of ultra-fine monofilament glass fibers.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

Finned tube locating fixture and assembly method of heat exchanger

InactiveCN102886666BSimple structural designEven by forceWork holdersMetal working apparatusEngineeringDislocation

The invention relates to a finned tube assembly technique method for manufacturing heat exchangers, provides a finned tube locating fixture of a heat exchanger, and aims to solve the problems that the operation efficiency is low, and dislocation is easy to occur when a group of finned flat tube bundles is tightened and assembled to a collecting tube. The finned tube locating fixture comprises a bracket, a driving mechanism and a group of tube fixators, wherein each tube fixator is provided with at least two locating points; and the tube fixators can be driven to move between a first locating point and a second locating point through the driving mechanism so as to drive each flat tube to reach the position corresponding to the slot of the collecting tube. Each flat tube and fin in the front and back directions are uniformly stressed and tightened through the finned tube locating fixture; the group of finned flat tube bundles is tightened at a set distance and position quickly, accurately and uniformly; the finned tube locating fixture is simple and reasonable in structure; and the production efficiency and precision of a finned tube locating assembly process are improved.

Owner:WESTERNHOUSE AUTOMATION CHANGZHOU

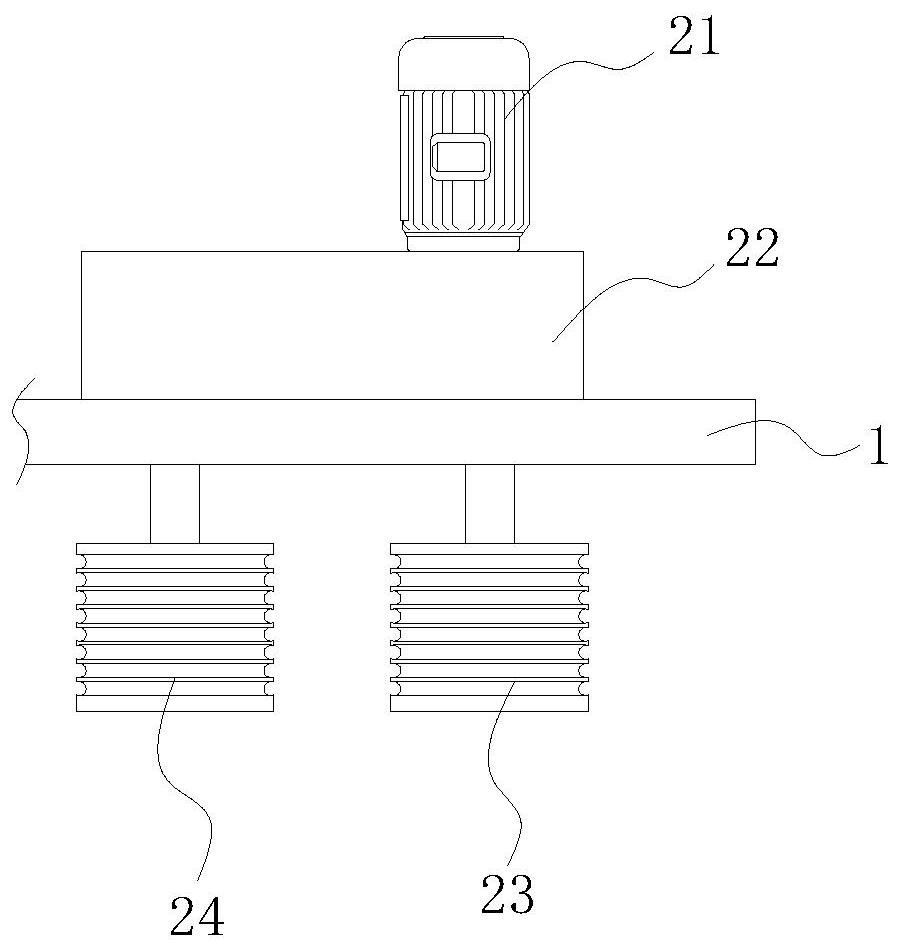

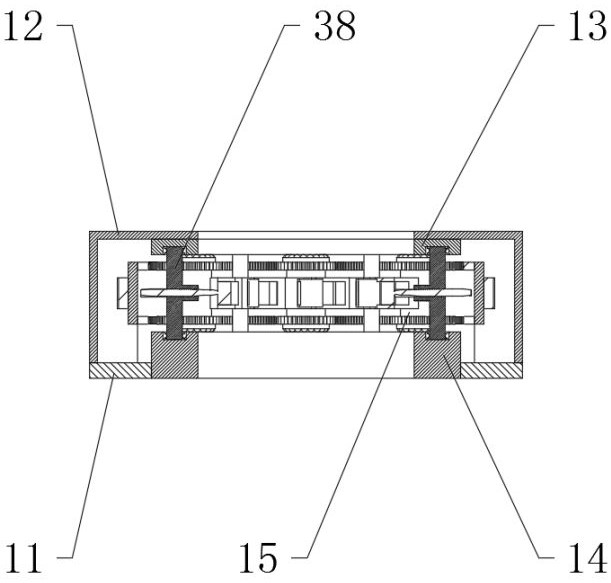

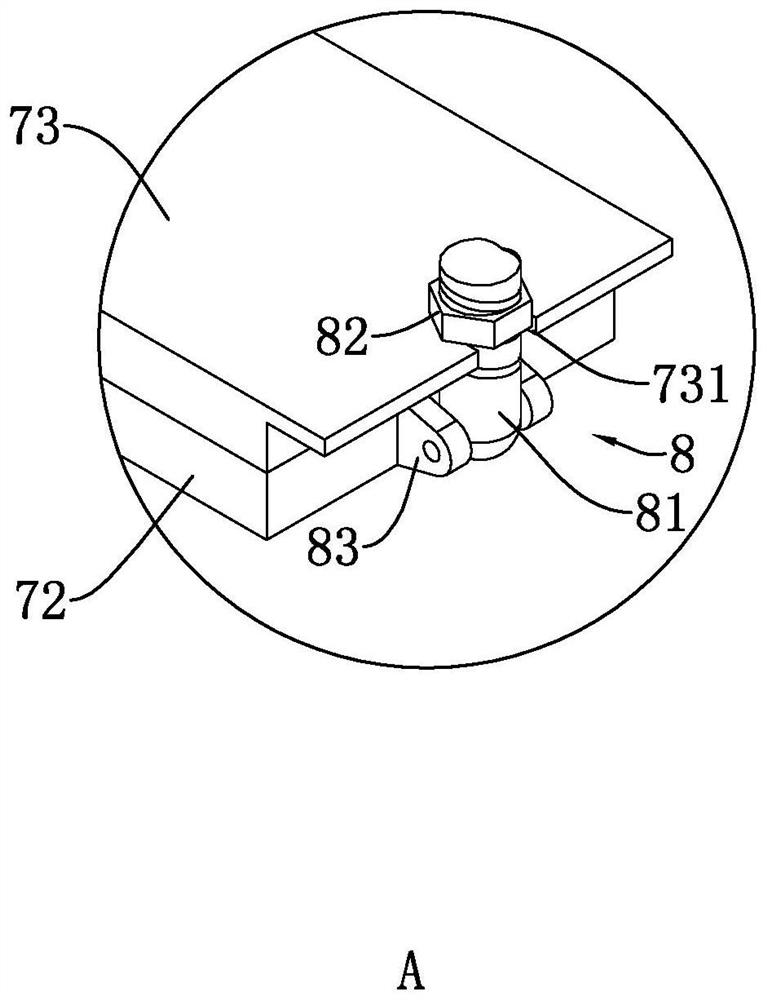

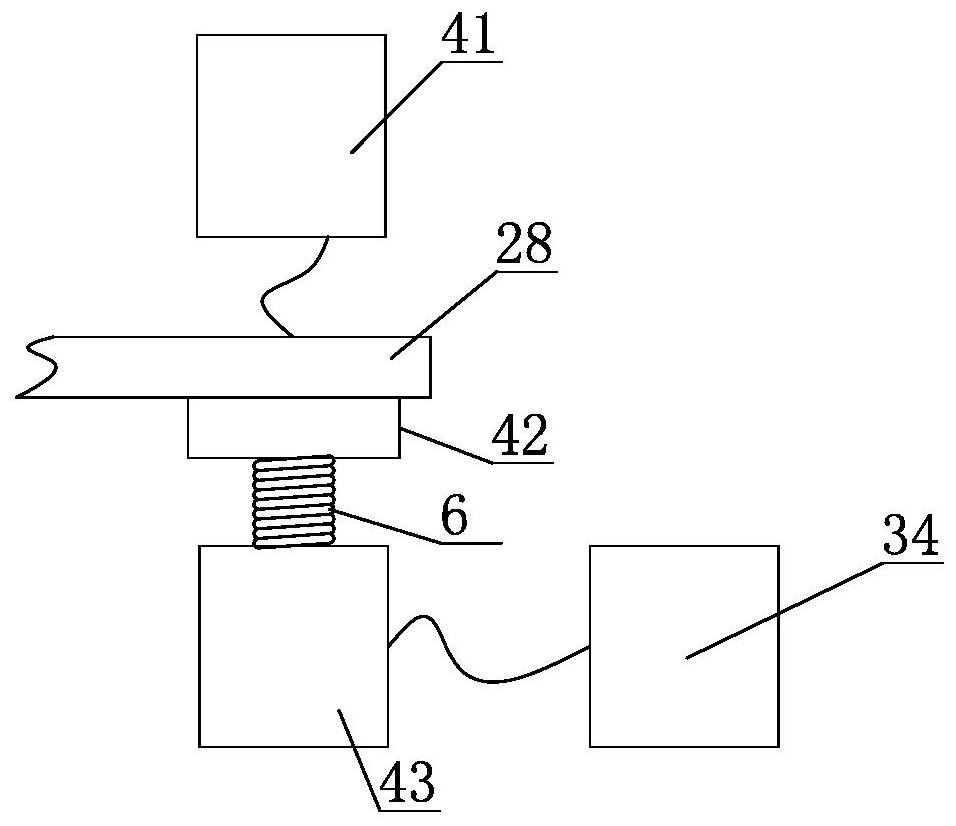

Control rope tensioning device

InactiveCN112431048APrevent springbackImprove tensioning efficiencyFilament handlingRope making machinesElectric machineryStructural engineering

The invention provides a control rope tensioning device. The control rope tensioning device comprises a carrier plate, a rope feeding assembly used for guiding a control rope to move is installed on one side face of the carrier plate, a first rope locking assembly used for preventing the control rope from rebounding is arranged obliquely below the rope feeding assembly, a second rope locking assembly used for preventing the control rope from rebounding is installed on the side, away from the first rope locking assembly, of one side face of the carrier plate, a first conical wheel and a secondconical wheel which rotate oppositely and are used for tensioning the control rope are arranged between the first rope locking assembly and the second rope locking assembly, the side, facing the carrier plate, of the first conical wheel is connected with the output end of a first gear motor through a rotating shaft, and the side, facing the carrier plate, of the second conical wheel is connected with the output end of a second gear motor through a rotating shaft. Compared with the prior art, the control rope tensioning device has the following beneficial effects that the tensioned control ropeis prevented from rebounding, the tensioning efficiency of the control rope is improved, step-by-step tensioning is achieved, and the stress of the control rope is evenly increased.

Owner:台州市和德绳业有限公司

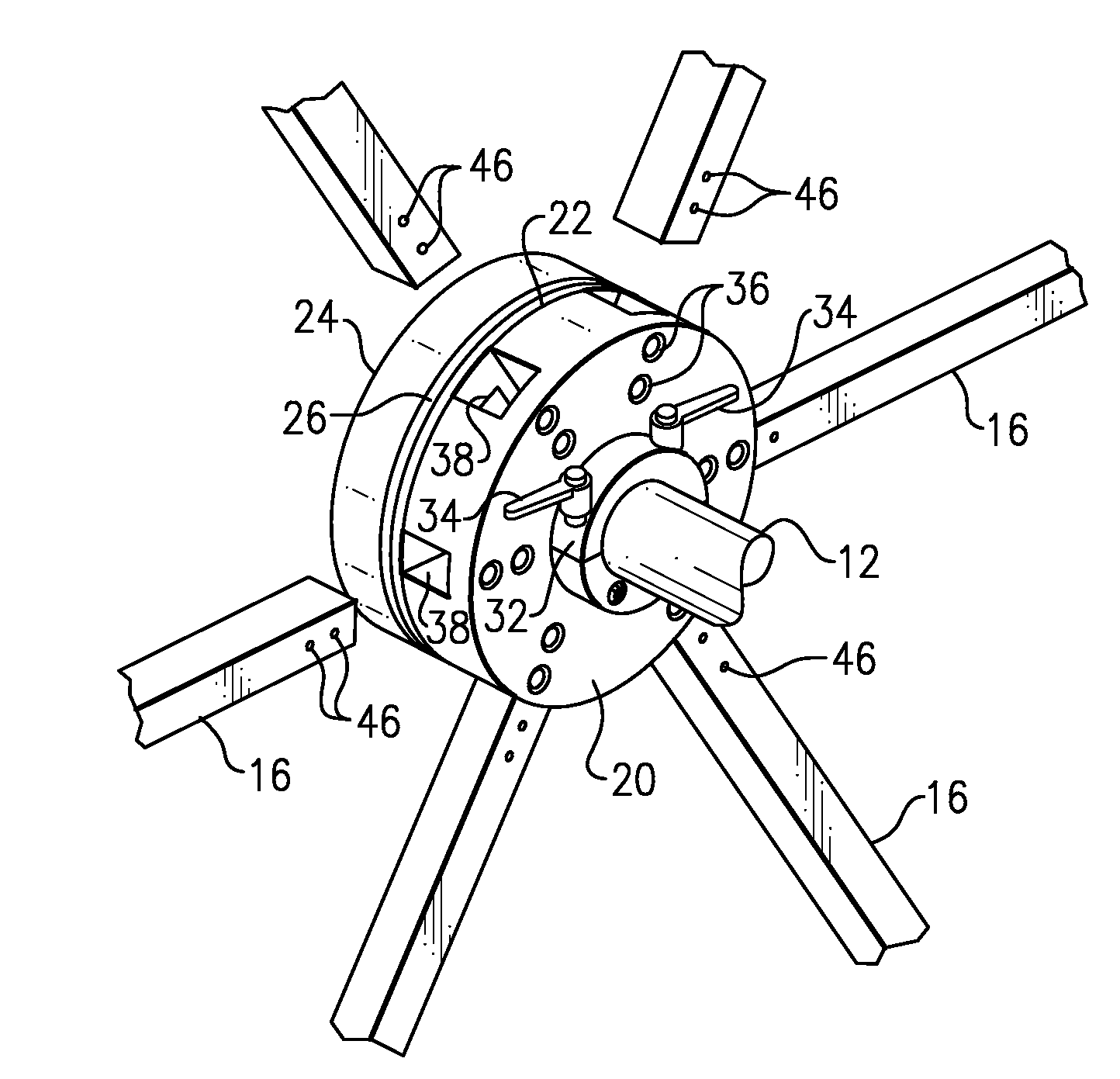

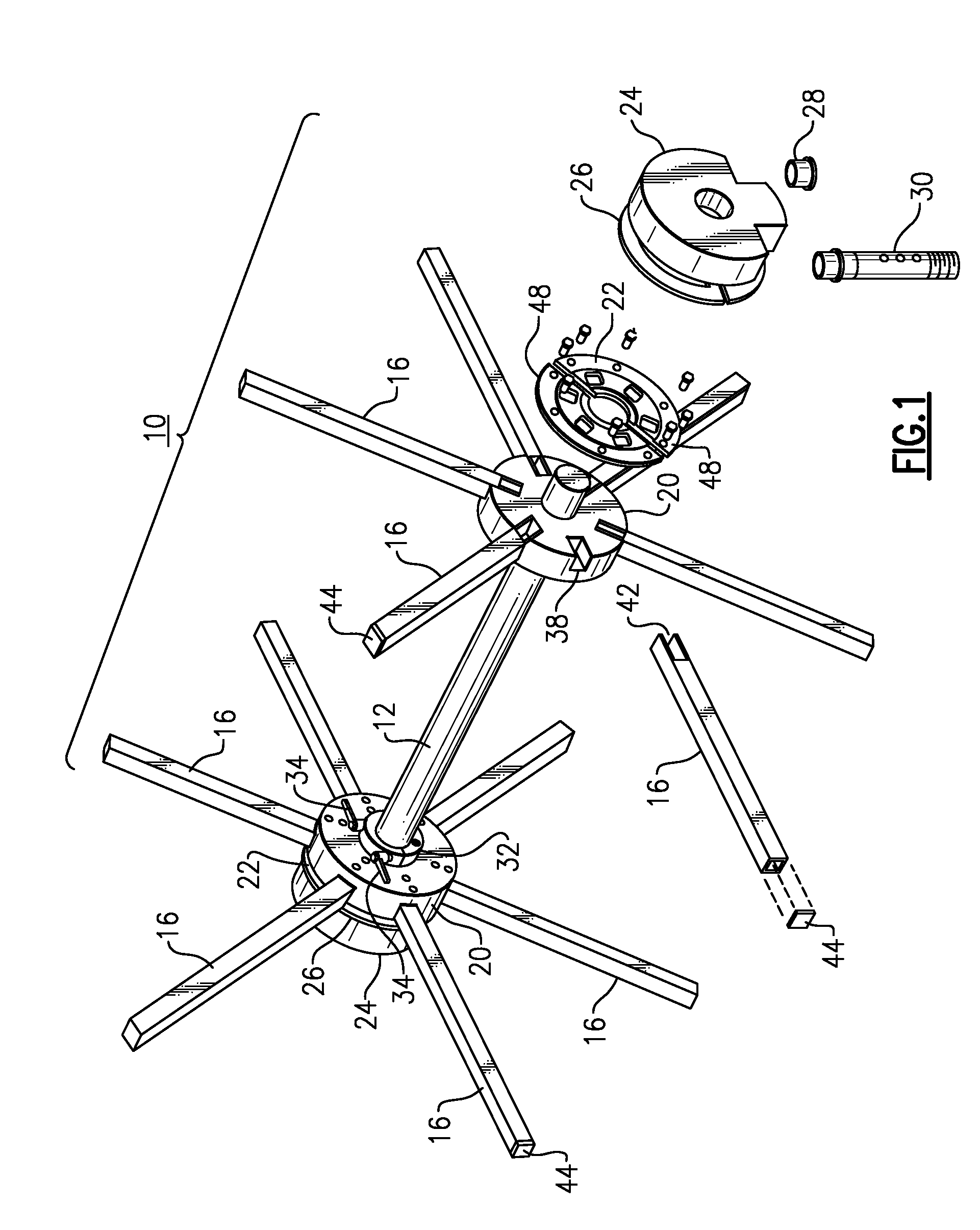

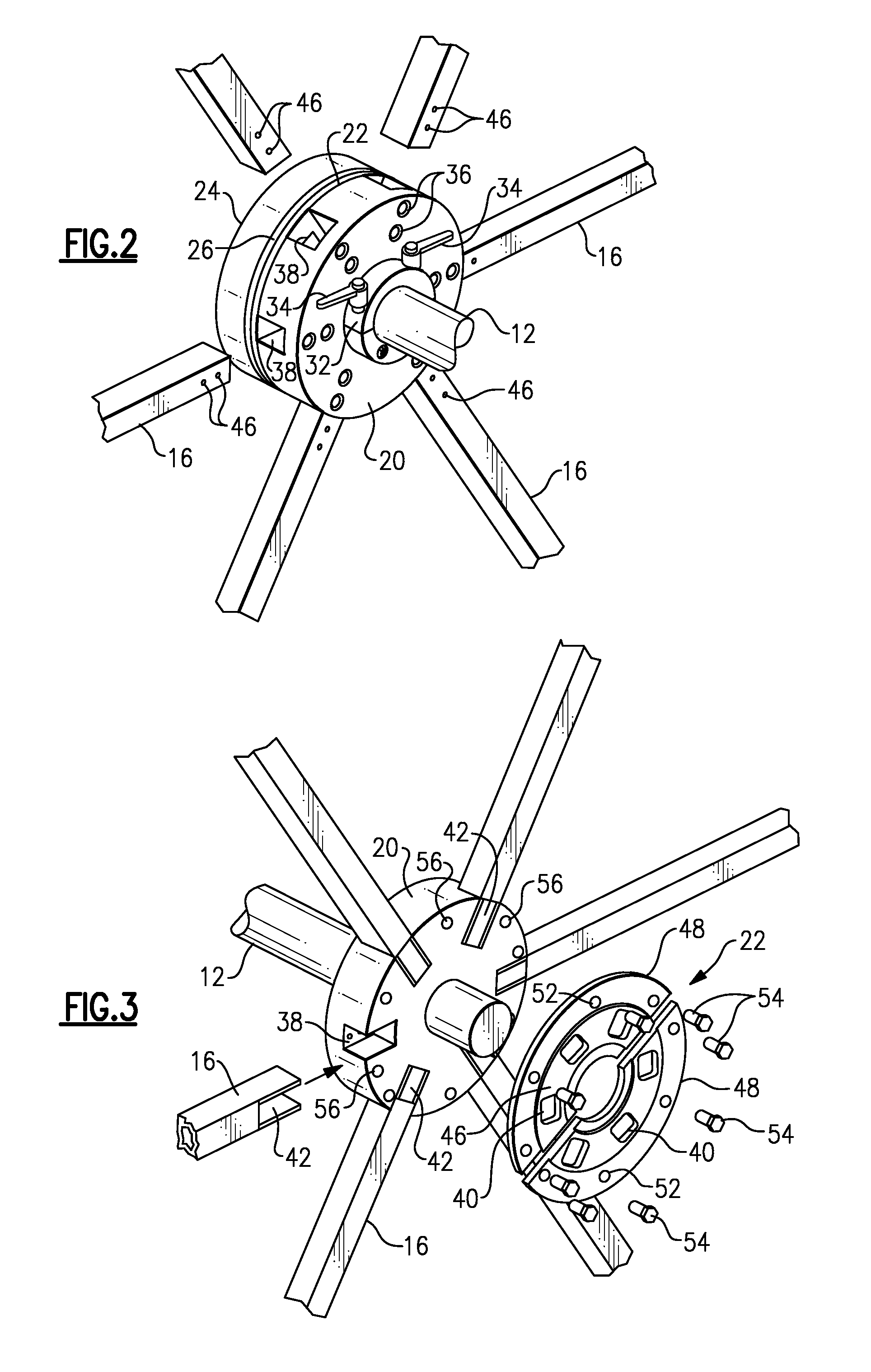

Tool-less Rotary Vacuum Wicketter Assembly

ActiveUS20090016856A1Avoid disadvantagesEasy and faster to serviceEnvelopes/bags making machineryBag making operationsDetentBody positions

A rotary vacuum wicketting arrangement has a rotary hub body positioned on a shaft or spindle and supporting a number of pickup arms, and a non-rotating vacuum spinning head that provides vacuum to the rotating hub body and pickup arms over a portion of their arcuate travel. The rotary hub body is provided with a lock ring formed or a pair of half rings with hand levers so that the position of the hub body on the shaft can be adjusted toollessly. The pickup arms are held in place in their sockets by ball and spring detents, so that they can be pulled out for cleaning and reinserted without tools. A friction fitted plug closes off the end of each arm.

Owner:PEARL TECH

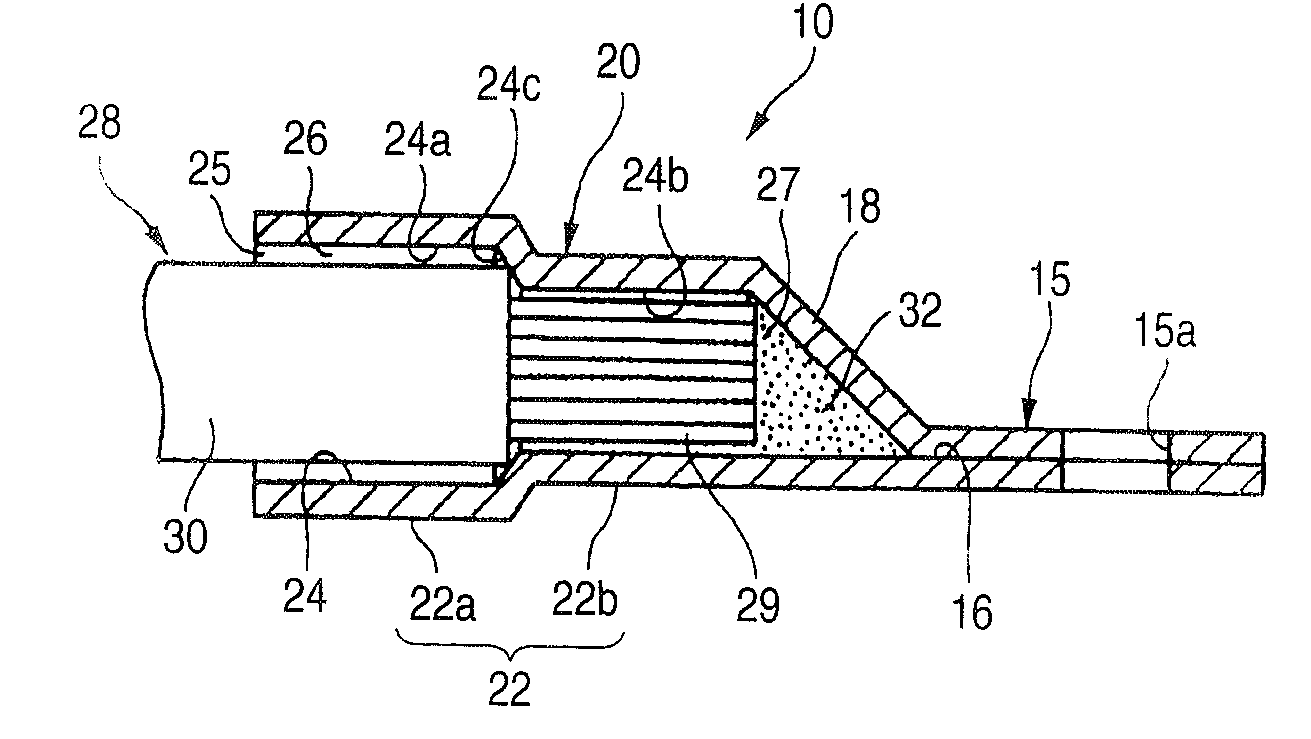

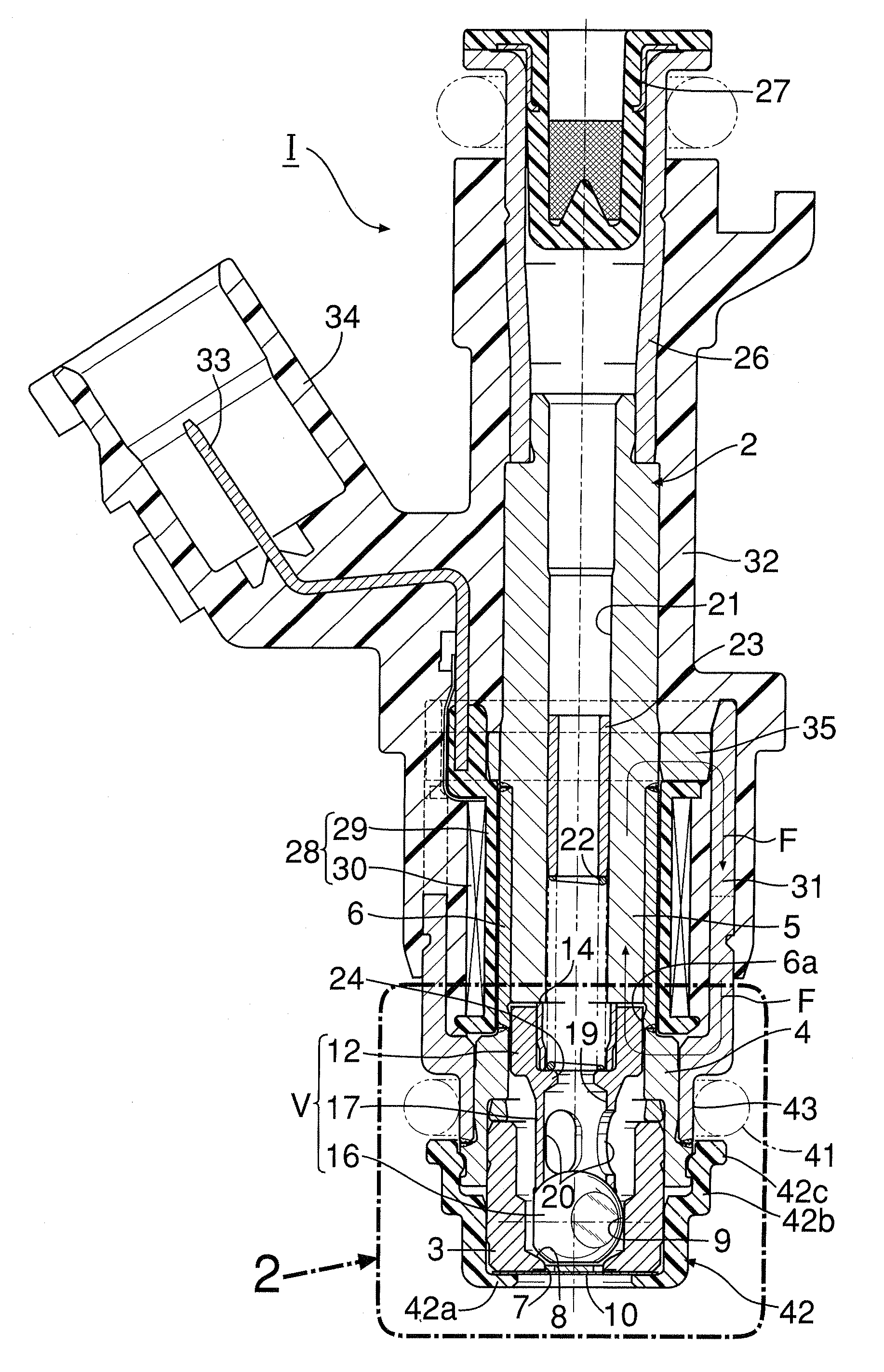

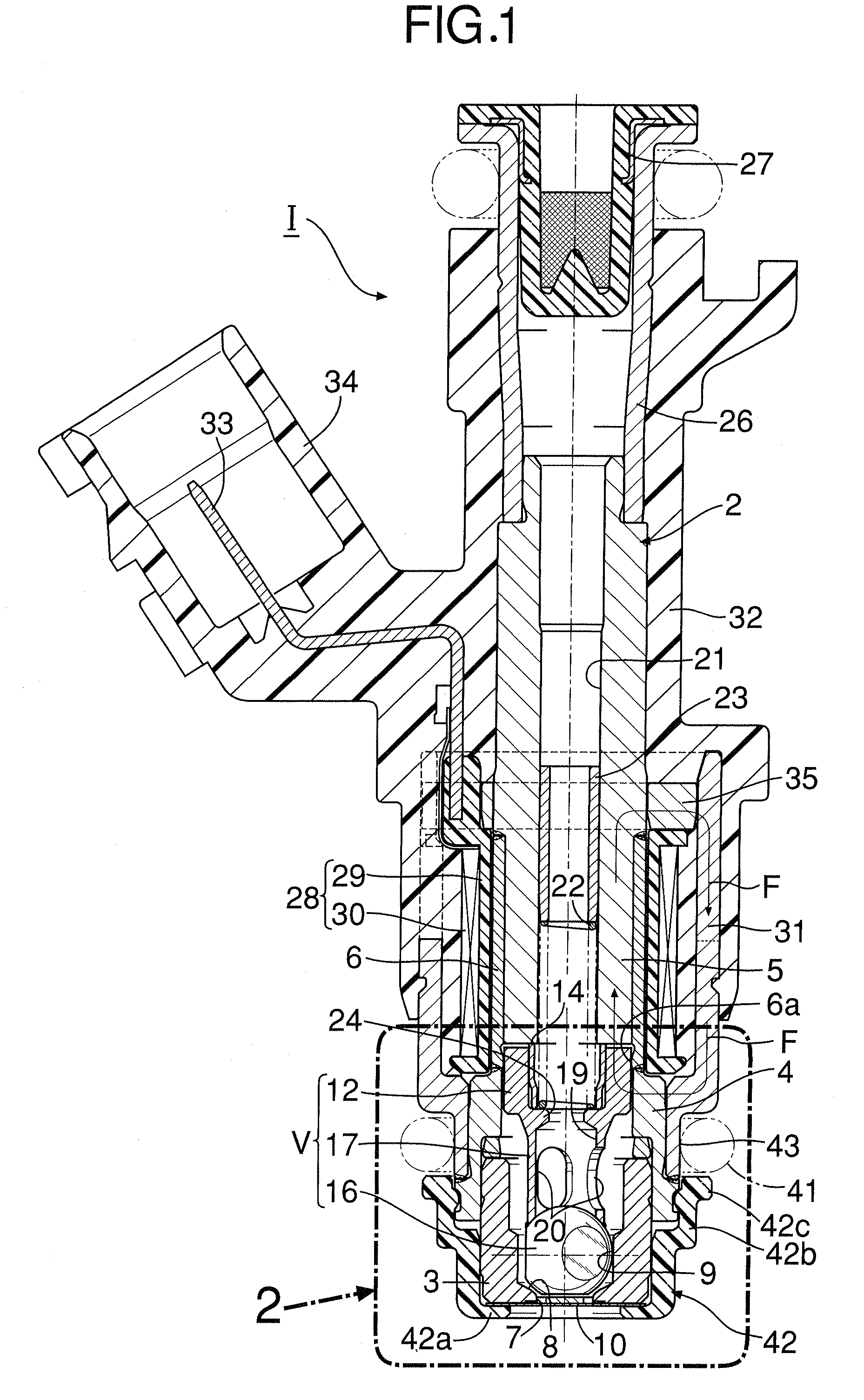

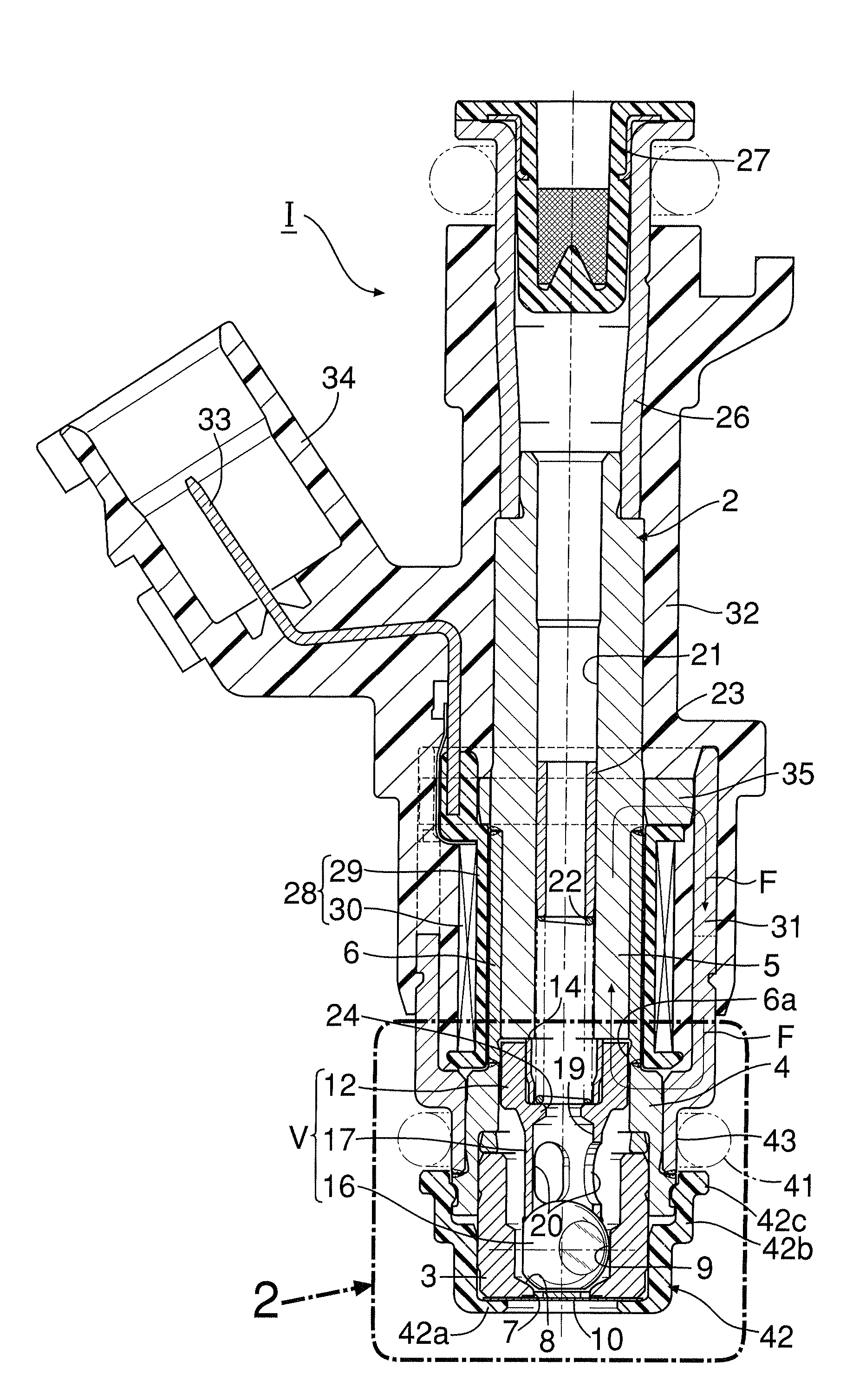

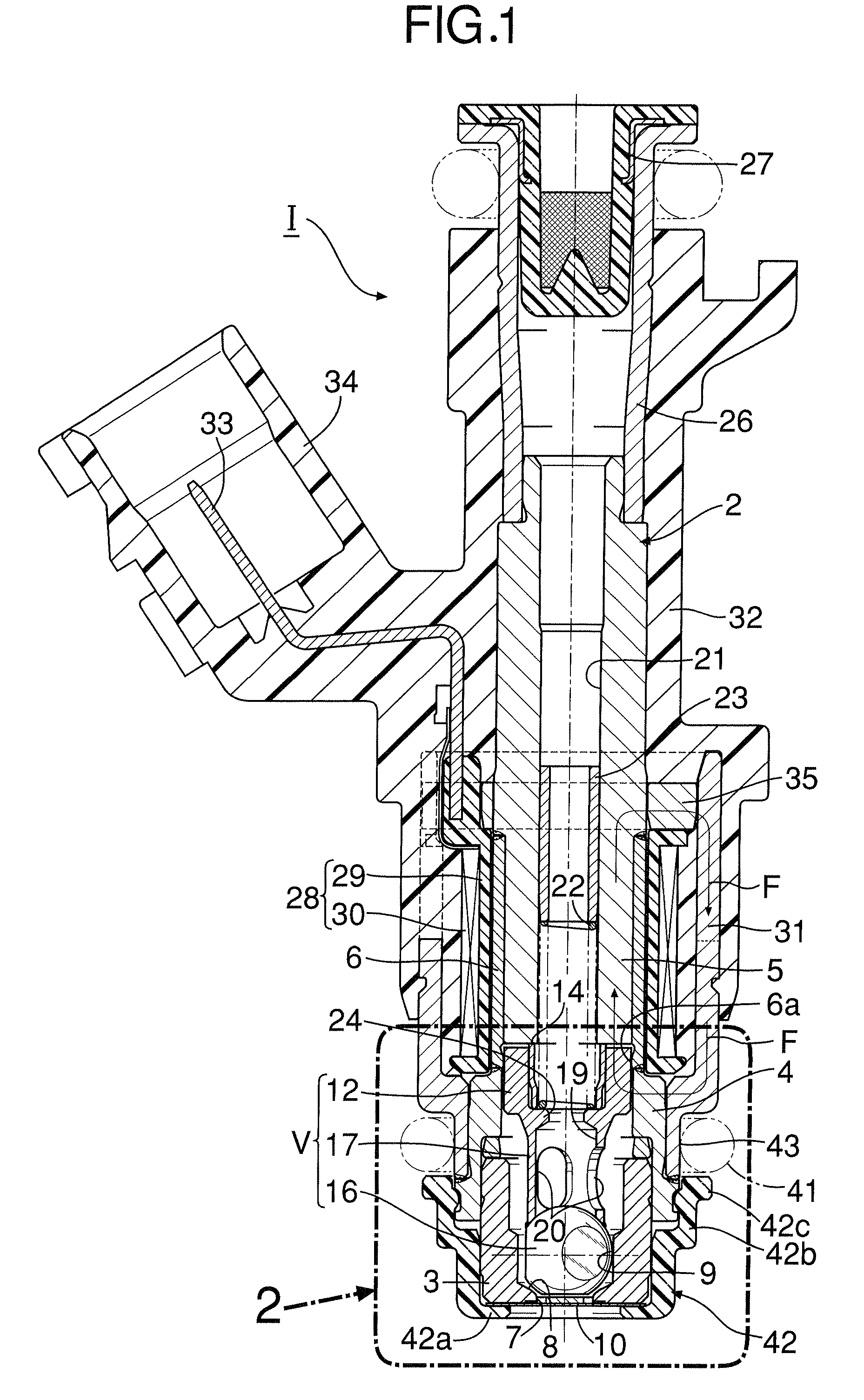

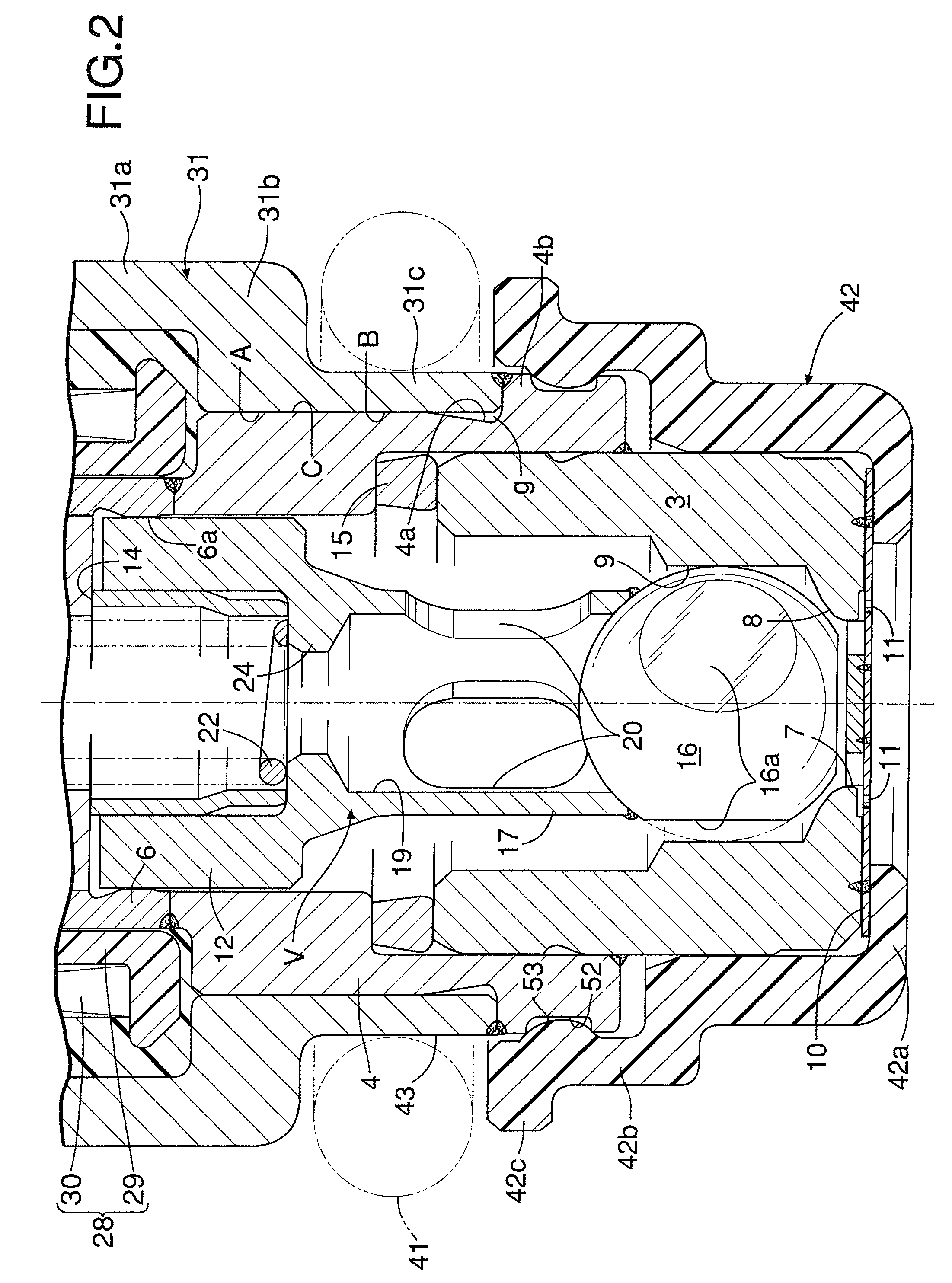

Electromagnetic fuel injection valve

InactiveUS20080217438A1Stable fuel injection characteristicImprove magnetic efficiencySpray nozzlesMachines/enginesEngineeringShaft collar

In an electromagnetic fuel injection valve, a valve housing is formed by sequentially connecting a valve seat member, a magnetic cylinder, a nonmagnetic collar, and a stationary core. A coil housing is fittingly fixed to an outer periphery of the magnetic cylinder, and houses a coil assembly provided in an outer periphery of the stationary core. The coil housing includes a shell part surrounding the coil housing, an annular bent part bent radially inward from a front end of the shell part, and a cylindrical boss part projecting forward from a front end of the annular bent part. An inner peripheral surface of the annular bent part and an inner peripheral surface of at least a rear half part of the boss part are shrinkage-fitted to an outer peripheral surface of the magnetic cylinder. Thus, it is possible to eliminate distortion propagating to the magnetic cylinder, and eliminate a gap from fitted portions between the magnetic cylinder and the coil housing to improve magnetic efficiency, thereby exerting stabile fuel injection characteristics.

Owner:KEIHIN CORP

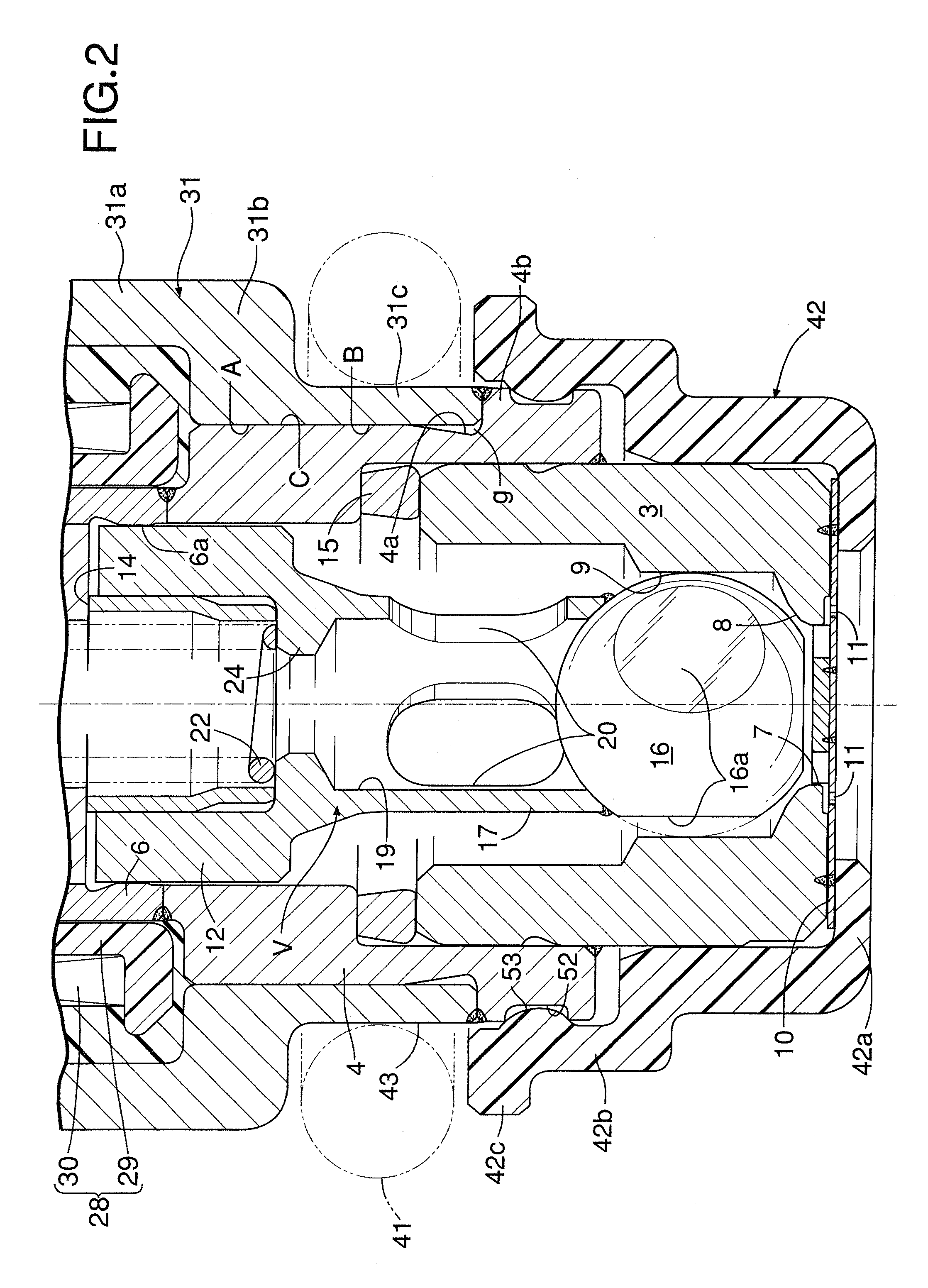

Wire tightening device and providing method therefor

The present invention provides a wire tightening device for improving the convenience of use by readily providing the device in shoes, comprising: a housing part fixed to the tongue of shoes to provide a ratchet-type gear in the inner circumference thereof, and having a cylindrical inner surface; a reel part rotatably arranged inside the housing part and providing tensile force to a wire for tightening both side covers of the shoes as the wire is wound; and a rotary cover for selectively rotating the reel part, wherein the housing part provides a coupling part placed on the top surface of the tongue in a position corresponding to a provision hole formed in the tongue, and a pressing surface part for pressing the bottom surface of the tongue according to the coupling, to the coupling part, of the coupling bar protruding from one surface for clamping and fixing the tongue by penetrating through the provision hole.

Owner:SHINKYUNG INC

Electromagnetic fuel injection valve

InactiveUS7775464B2Stable fuel injection characteristicImprove magnetic efficiencySpray nozzlesMachines/enginesEngineeringShaft collar

In an electromagnetic fuel injection valve, a valve housing is formed by sequentially connecting a valve seat member, a magnetic cylinder, a nonmagnetic collar, and a stationary core. A coil housing is fittingly fixed to an outer periphery of the magnetic cylinder, and houses a coil assembly provided in an outer periphery of the stationary core. The coil housing includes a shell part surrounding the coil housing, an annular bent part bent radially inward from a front end of the shell part, and a cylindrical boss part projecting forward from a front end of the annular bent part. An inner peripheral surface of the annular bent part and an inner peripheral surface of at least a rear half part of the boss part are shrinkage-fitted to an outer peripheral surface of the magnetic cylinder. Thus, it is possible to eliminate distortion propagating to the magnetic cylinder, and eliminate a gap from fitted portions between the magnetic cylinder and the coil housing to improve magnetic efficiency, thereby exerting stabile fuel injection characteristics.

Owner:KEIHIN CORP

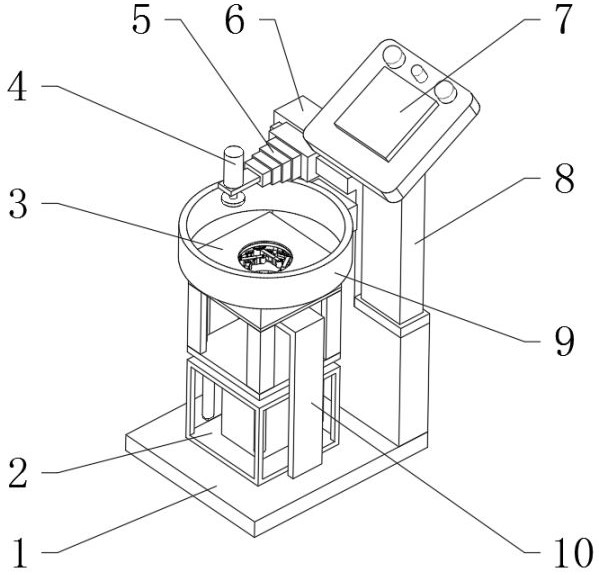

Precision detection device for optical fiber gyroscope production

InactiveCN113188534ATighten evenlyPrevent deviationSagnac effect gyrometersGyroscopeElectric machinery

The invention discloses a precision detection device for optical fiber gyroscope production, and relates to the technical field of optical fiber gyroscopes. The problem of axis deviation of an existing detection device is solved. The precision detection device specifically comprises a bottom plate, the outer wall of the top of the bottom plate is fixedly connected with an adjusting assembly, the outer wall of the top of the adjusting assembly is fixedly connected with a locking assembly, the locking assembly comprises a connecting plate and an end frame, the outer wall of the top of the connecting plate is fixedly connected with a cover shell, and the inner wall of the top of the cover shell is fixedly connected with an upper ring. By arranging the locking assembly, a power motor is started to drive an outer gear to rotate, the outer gear is meshed with an outer rack to drive a lantern ring to rotate, then an inner rack is meshed with an inner gear to drive a rotary drum to rotate, and a rotary arm rotates, so that a roller on the inner wall of an end frame is gradually tightened; at the moment, the optical fiber gyroscope is placed in the center area of the locking assembly, and the four power motors synchronously work, so that the roller can be uniformly tightened, and the axis of the gyroscope is prevented from deviating.

Owner:刘铭

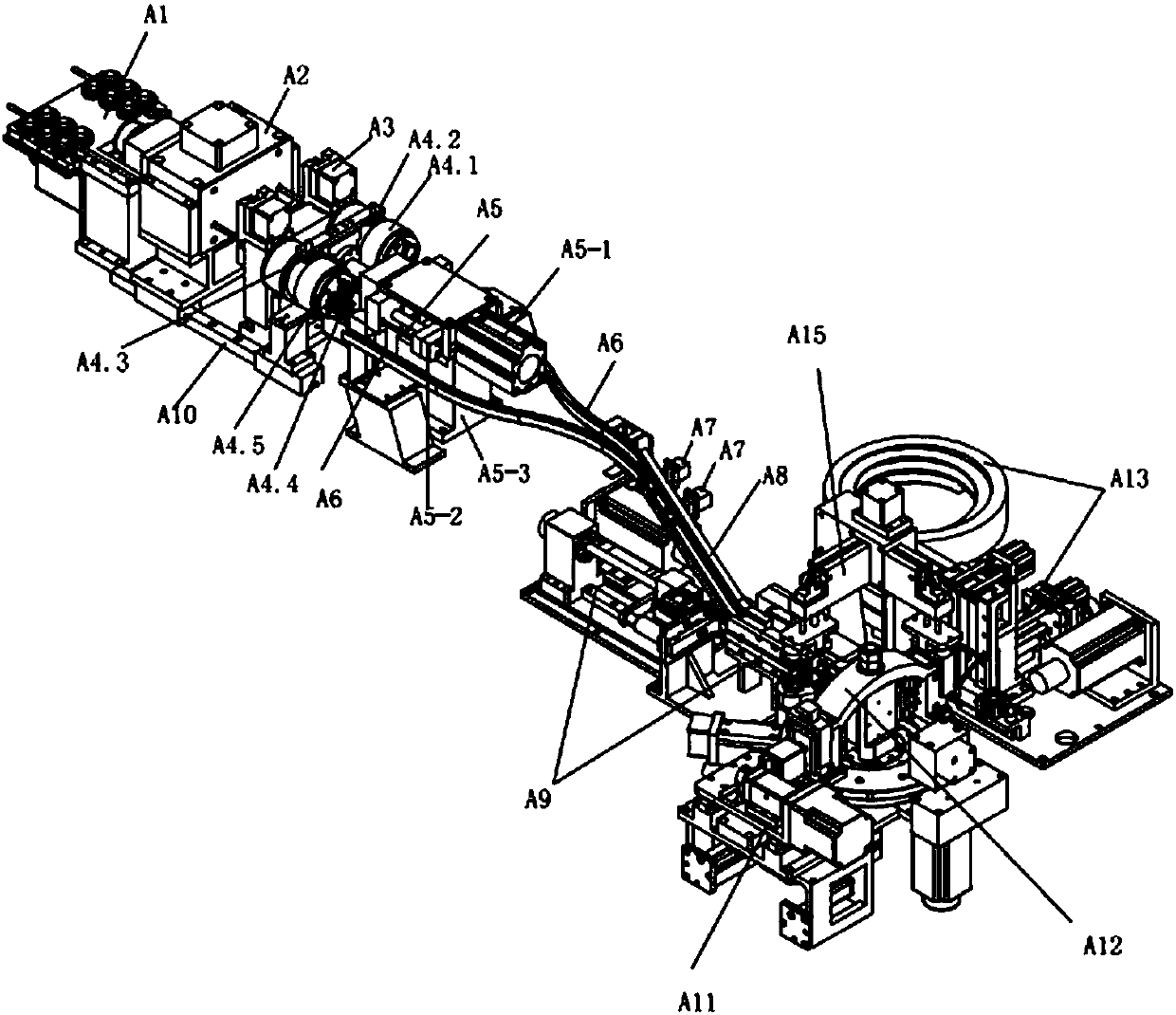

An automatic forming machine for thin-walled short u-bend pipe with welding ring

ActiveCN106270239BEliminate wasteGuaranteed not to deformMetal-working feeding devicesOther manufacturing equipments/toolsMolding machineStraight tube

The invention discloses an automatic forming machine of a thin-walled short U bent pipe with a welding ring, relates to the technical field of automation equipment, and can continuously accomplish the forming of the thin-walled short U bent pipe and socket welding ring operation, so as to prevent a pipe wall from folds. The automatic forming machine comprises a feeding assembly, a pipe cutting assembly, a pipe bending assembly, a circumference position rotating assembly and a socket welding ring assembly, wherein the feeding assembly at least comprises a clamping mechanism and a No.1 driving mechanism; the No.1 driving mechanism drives the clamping mechanism to perform forward feeding; the pipe cutting assembly at least comprises a cutting tool mechanism and a No.2 driving mechanism; the No.2 driving mechanism drives a cutting tool to act; the pipe bending assembly at least comprises a fixed part, a semicircle die, a movable part and a No.3 driving mechanism; one end of a fixed length pipe is clamped at the fixed part; the other end of the fixed length pipe gets over the semicircle die and then is movably matched with the movable part; the circumference position rotating assembly at least comprises a rotating frame, a pipe clamping mechanism, a No.4 driving mechanism and a discharging cylinder; the socket welding ring assembly at least comprises a welding ring feeding unit, a welding ring guide unit and a socket welding ring unit; the socket welding ring unit pushes the welding ring to a straight pipe section of the thin-walled short U bent pipe.

Owner:TONGLU QIANDING TECH

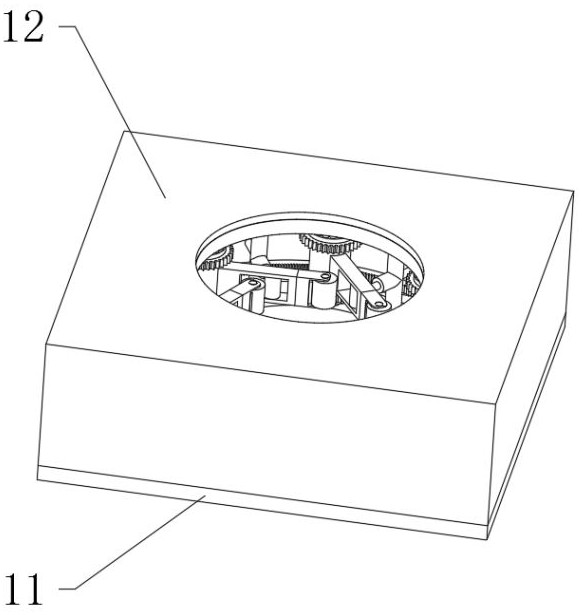

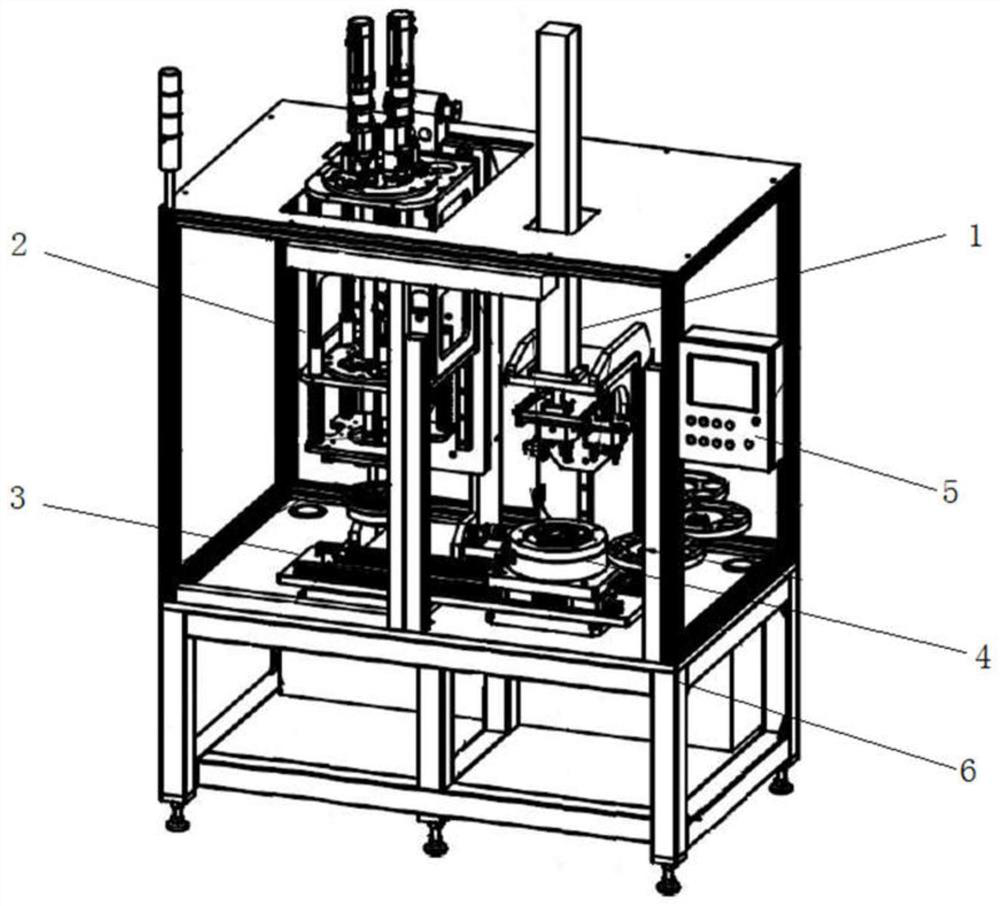

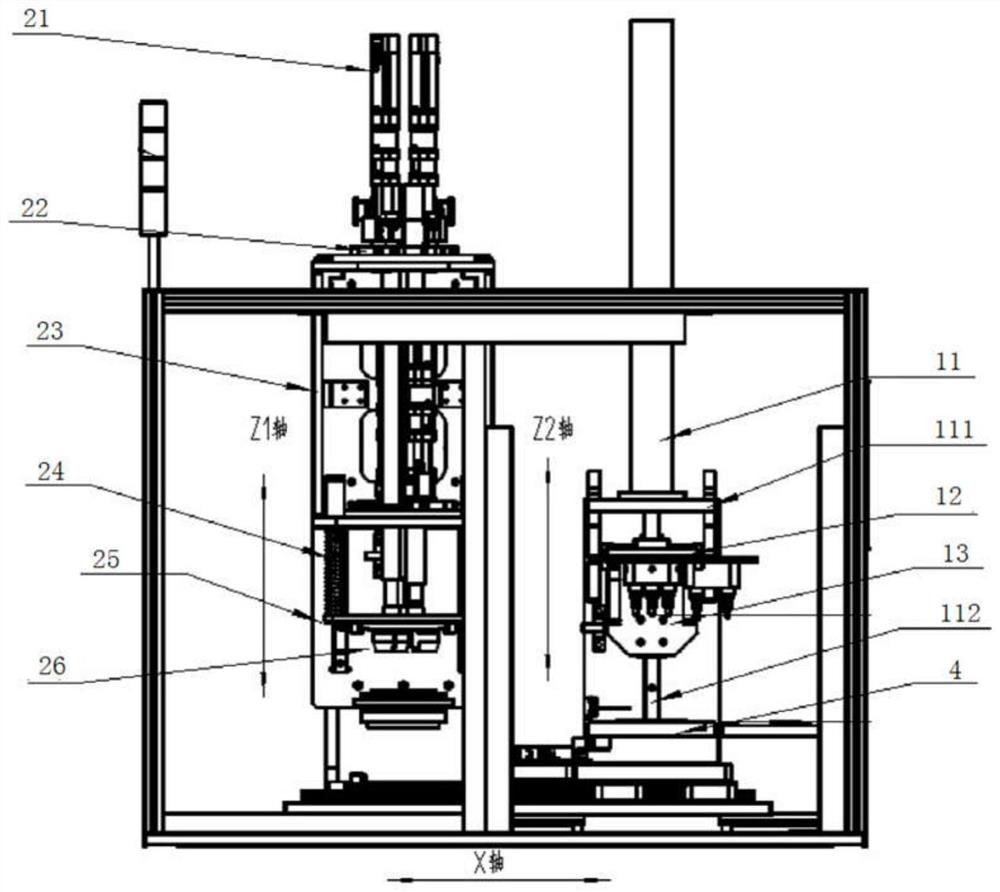

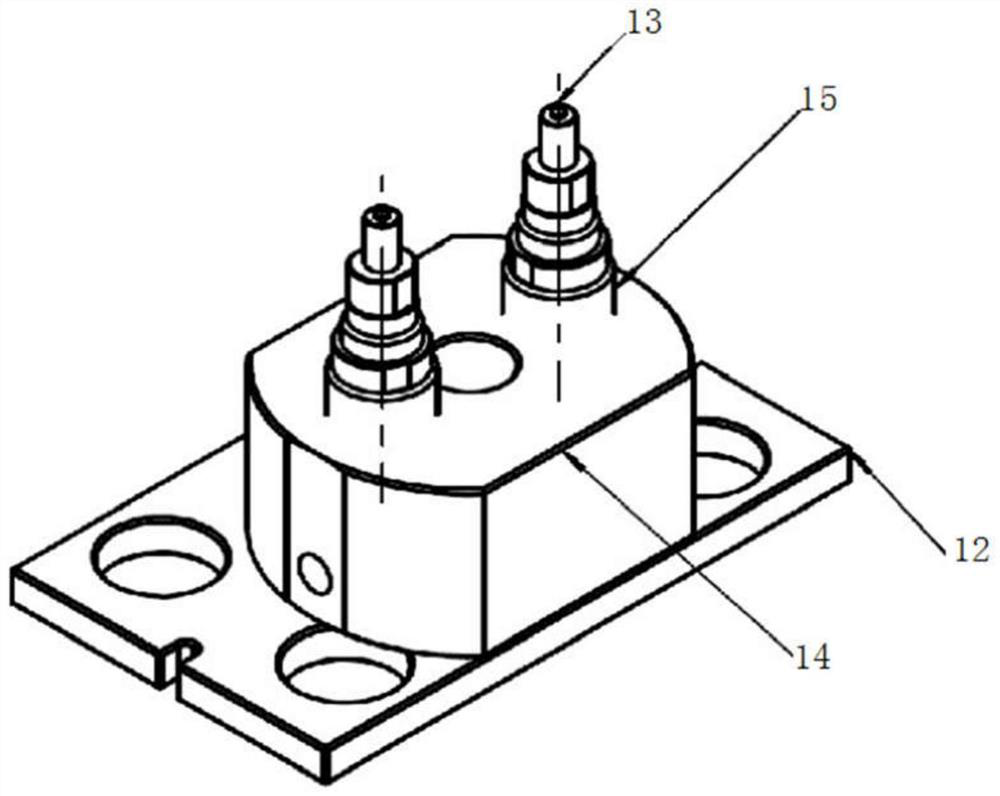

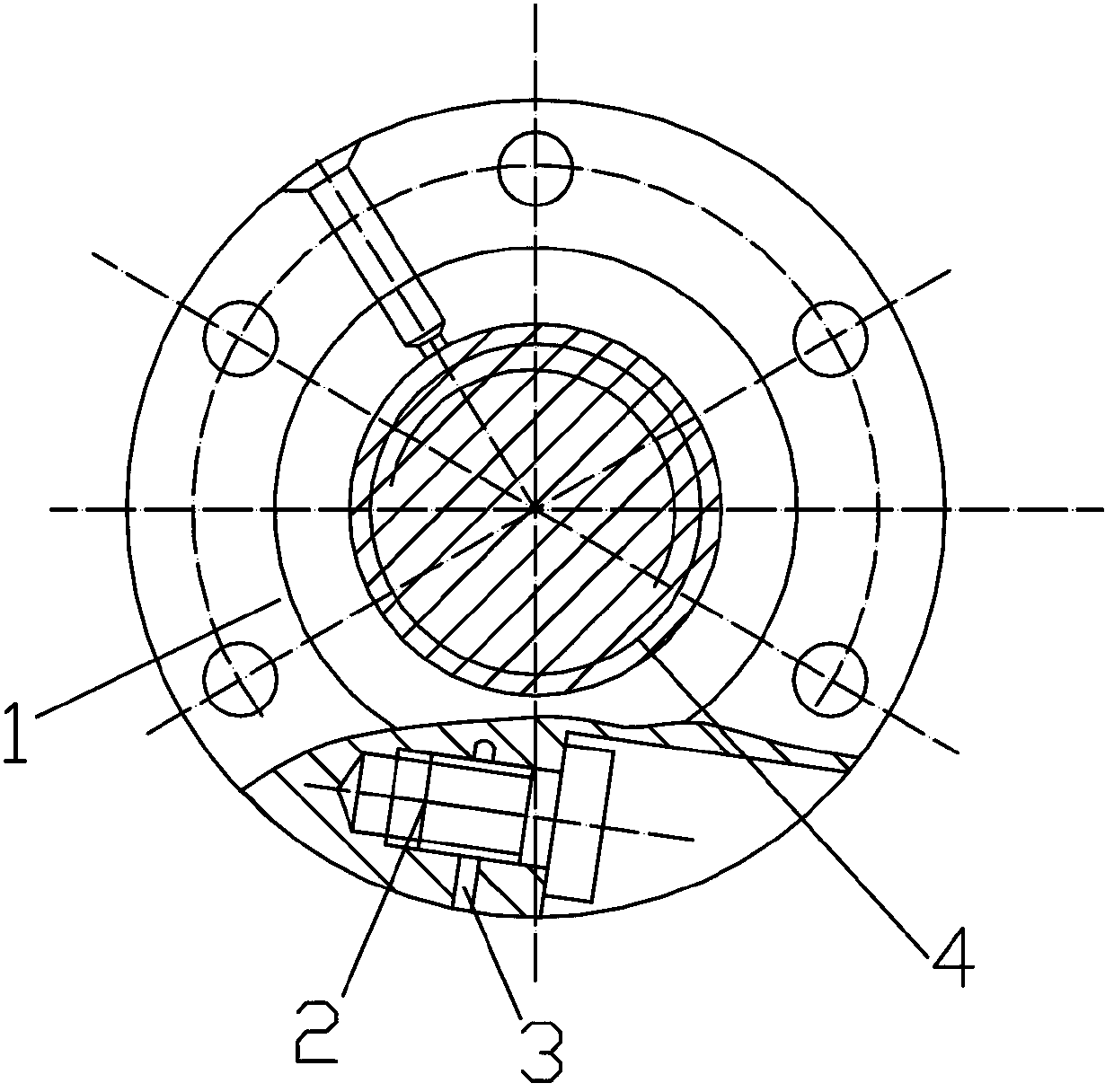

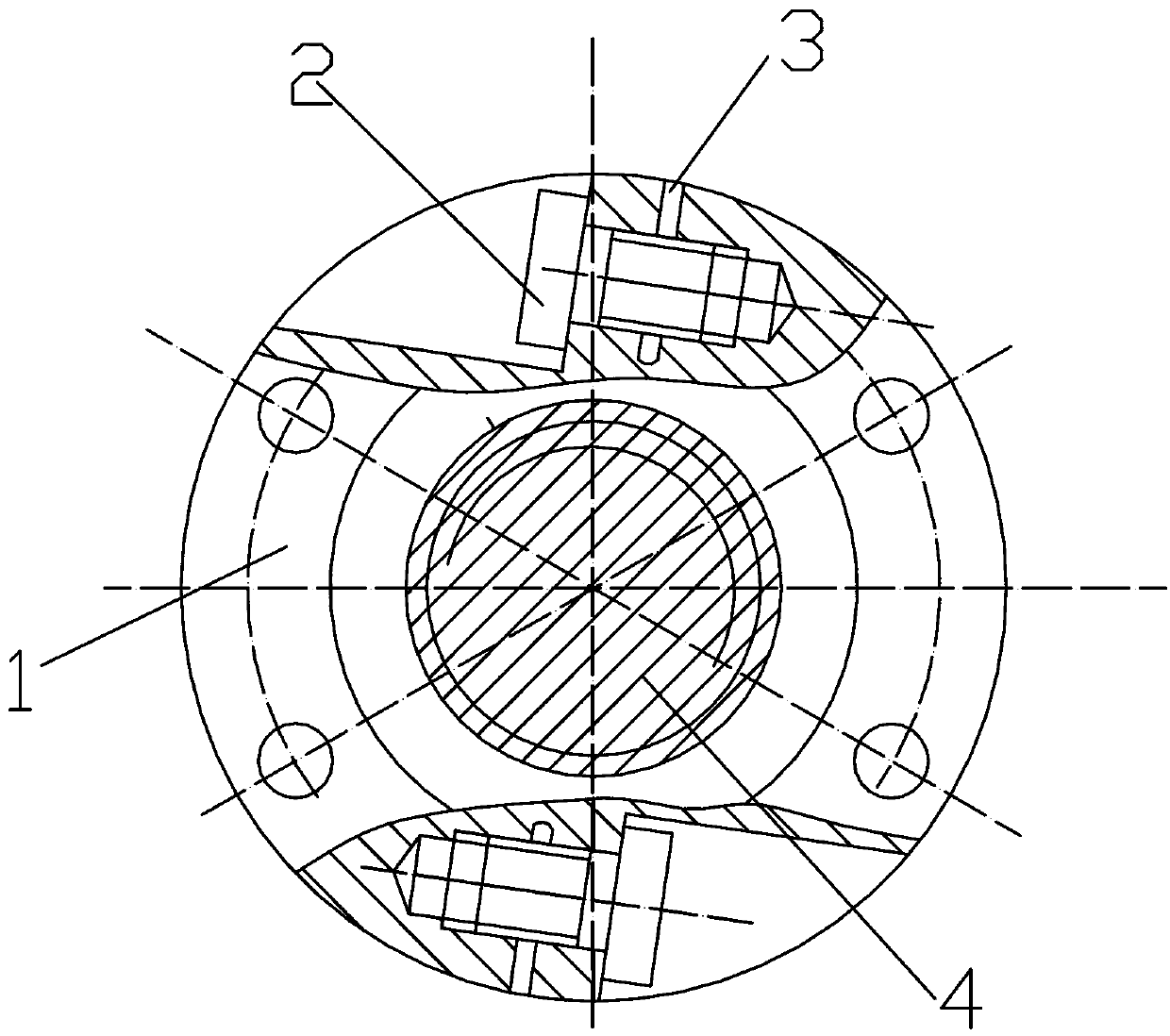

A kind of automatic assembly device and assembly method of screws and pins

ActiveCN113843605BTighten evenlyGuaranteed preloadMetal working apparatusReduction driveClassical mechanics

The invention discloses an automatic assembling device and assembling method of screws and pins, comprising a pin pressing module, a screw tightening module, a slide rail cylinder assembly, a rotatable carrier and a control cabinet. The device of the invention can realize the uniform and simultaneous pressing of the pins in the circumferential direction, realize the uniform tightening of a plurality of screws distributed in the circumferential direction, ensure the control of the torque torsion angle and the pressure during the assembly process of the reducer screws and the pins, and ensure the bearing after the pressing is installed. The preload can ensure the reliability of the reducer after assembly. The device can reduce the labor intensity of workers and improve assembly efficiency and qualification rate.

Owner:浙江环动机器人关节科技股份有限公司

Pipe cutting device used for cutting line pipe

PendingCN111774644AIncrease pressurePlay a protective effectPortable handheld shearing machinesStructural engineeringMechanical engineering

The invention discloses a pipe cutting device used for cutting a line pipe. The pipe cutting device comprises an installing shell provided with a cavity inside, an installing sleeve installed on the installing shell in a rotating manner, a force exerting part installed on the installing shell in a rotating manner, a transmission part and a cutting part, wherein the transmission part is located inthe installing shell and connects the installing sleeve with the force exerting part, and the cutting part is installed on the installing sleeve. The cutting part comprises a sleeve ring which is fixedly connected to the end, away from the transmission part, of the installing sleeve. Elastic clamping pieces are uniformly arranged on the sleeve ring at intervals. Cutting teeth are fixedly connectedto the sides, facing the axis of the sleeve ring, of the elastic clamping pieces. Fixing parts for stringing all the elastic clamping pieces as a whole are arranged on the outer sides of the elasticclamping pieces. The pipe cutting device used for cutting the line pipe can carry out ring cutting on the line pipe, the pipe shearing efficiency is improved, and the problems that a traditional toolis high in construction cost and labor is wasted are solved.

Owner:中铁十六局集团城市建设发展有限公司 +1

Device capable of eliminating gap between screw and nut

Owner:SUZHOU VOCATIONAL UNIV

An automatic winding device for pre-twisted wires of transmission lines

ActiveCN112186622BAchieve fasteningTighten evenlyApparatus for overhead lines/cablesEngineeringControl theory

The invention discloses an automatic winding device for pre-twisted conductors of transmission lines, and relates to the technical field of transmission line maintenance. It includes a winding mechanism, the winding mechanism includes a first support frame, a rotating shaft is arranged inside the first supporting frame, a first cable routing channel is arranged inside the rotating shaft, an induction mechanism is arranged on one side of the winding mechanism, and the The induction mechanism includes a second support frame, and a second routing channel is arranged inside the second support frame, and a tension mechanism is provided on one side of the induction mechanism, and the tension mechanism includes a third support frame, and the third support frame A third wiring channel is provided inside, an electric cylinder and a pressure sensing mechanism are provided on the upper part of the third support frame, the electric cylinder is connected to the pressure sensing mechanism, and a block is provided at the output end of the electric cylinder, and the The clamping block cooperates with the third routing channel. The beneficial effect of the present invention is that: one-handed operation can be realized and the winding is uniform.

Owner:国网山东省电力公司建设公司 +2

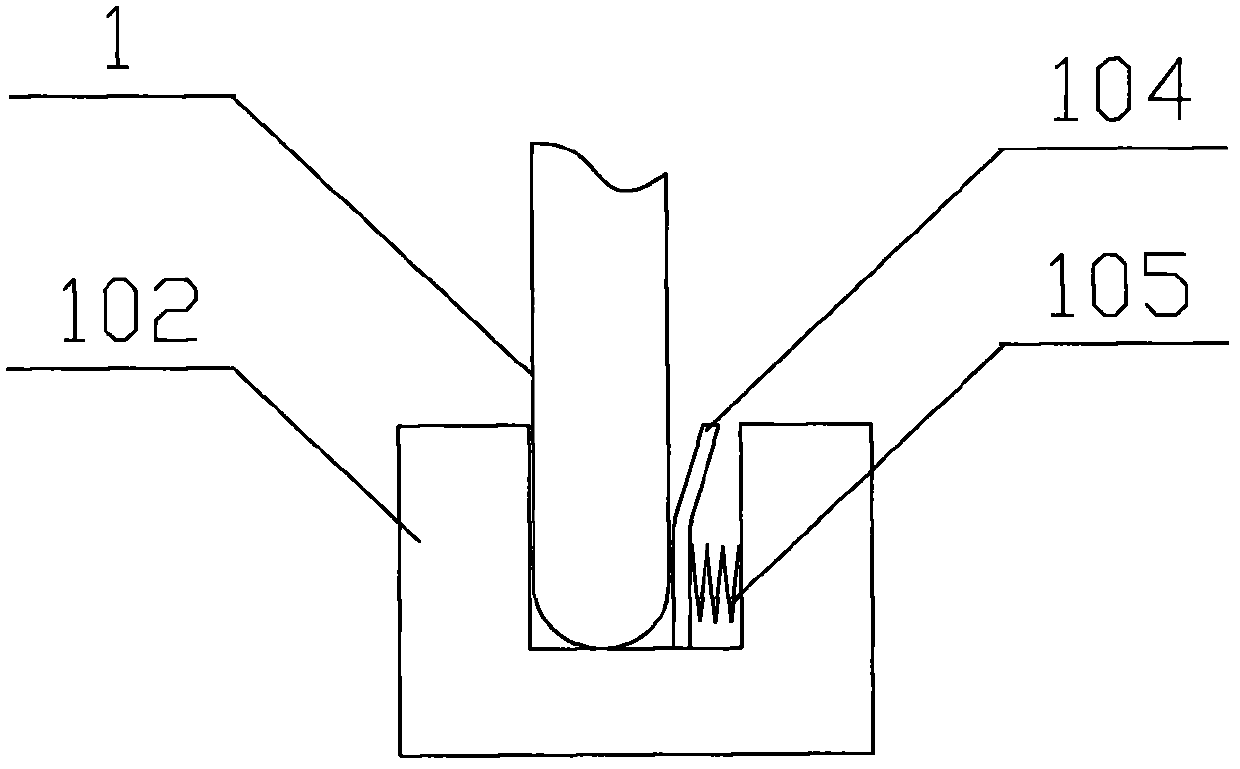

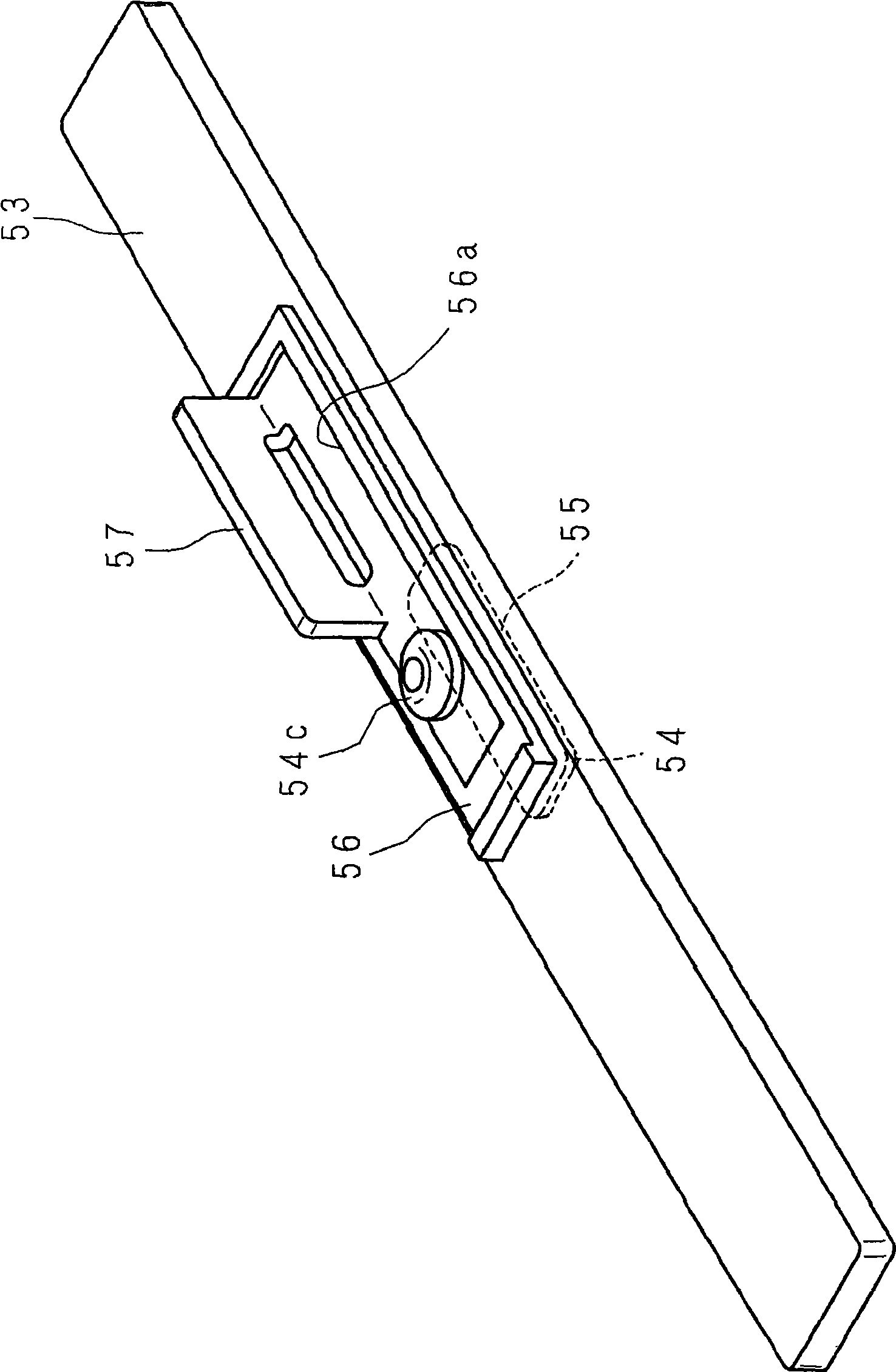

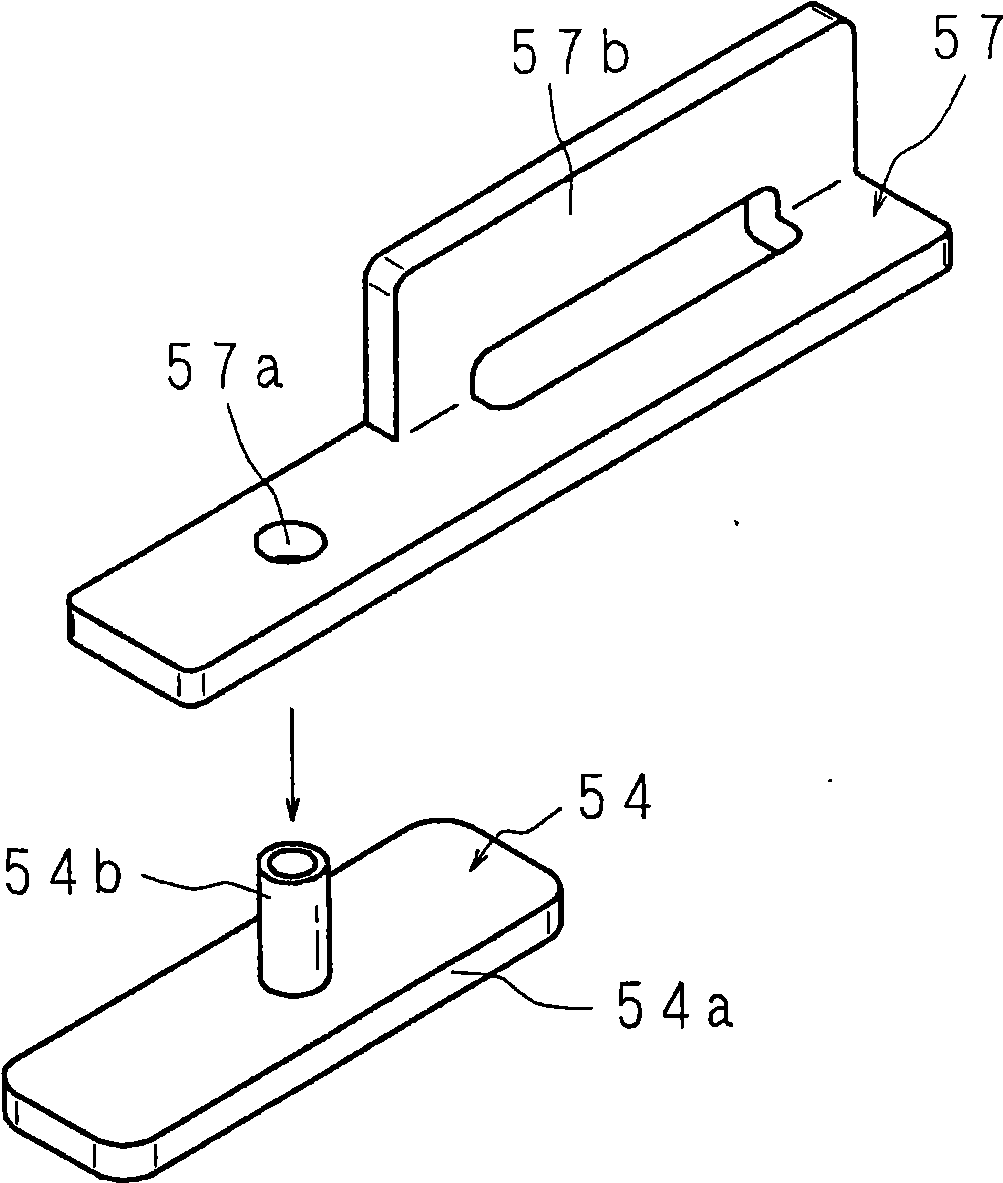

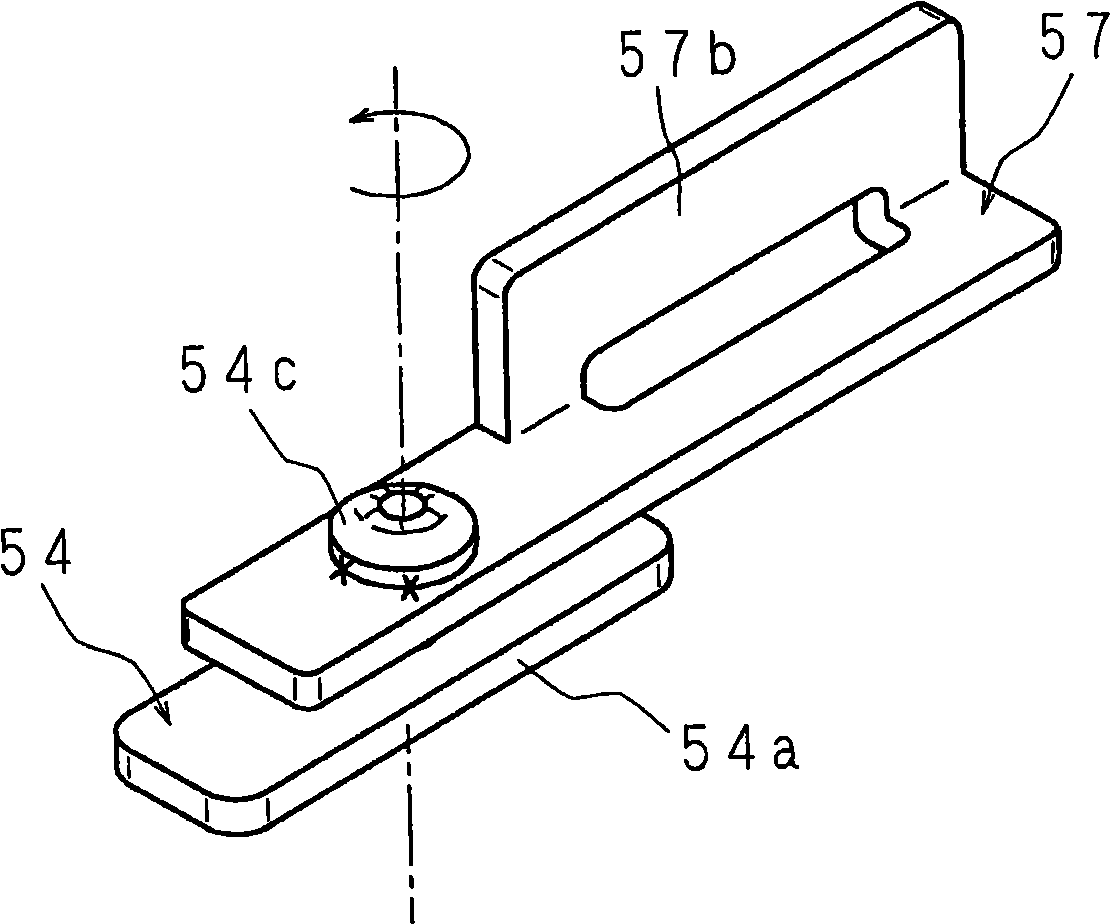

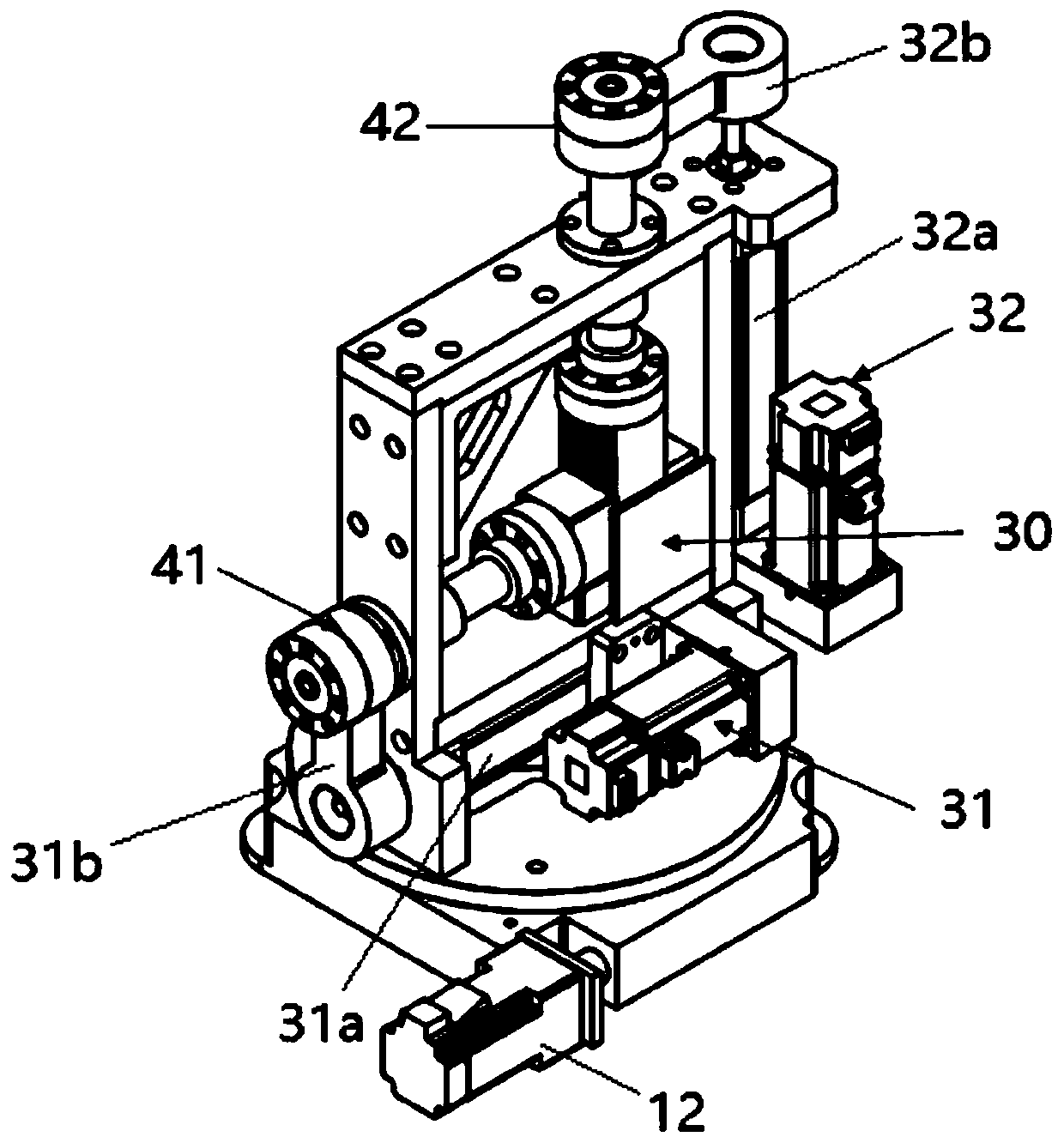

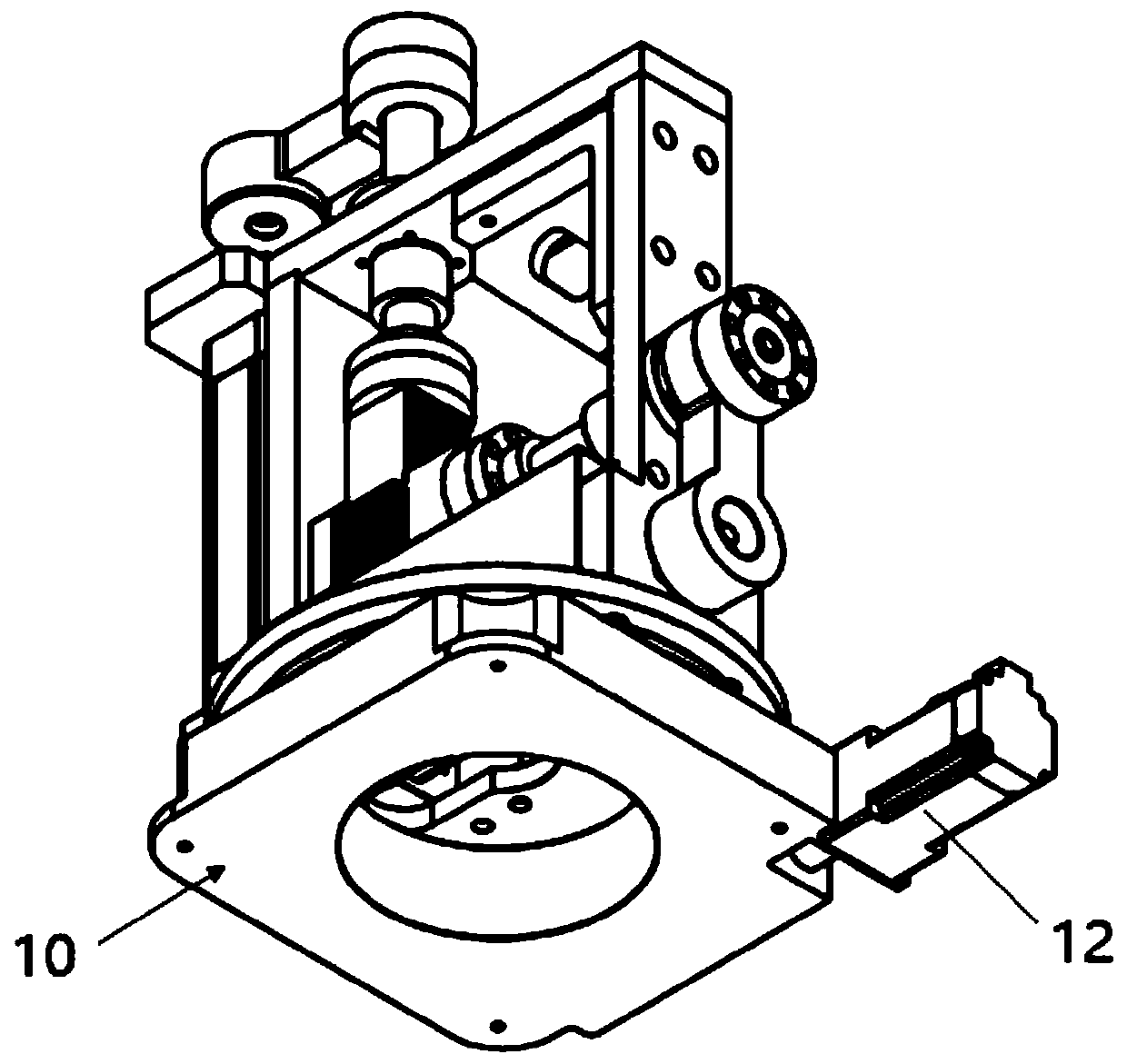

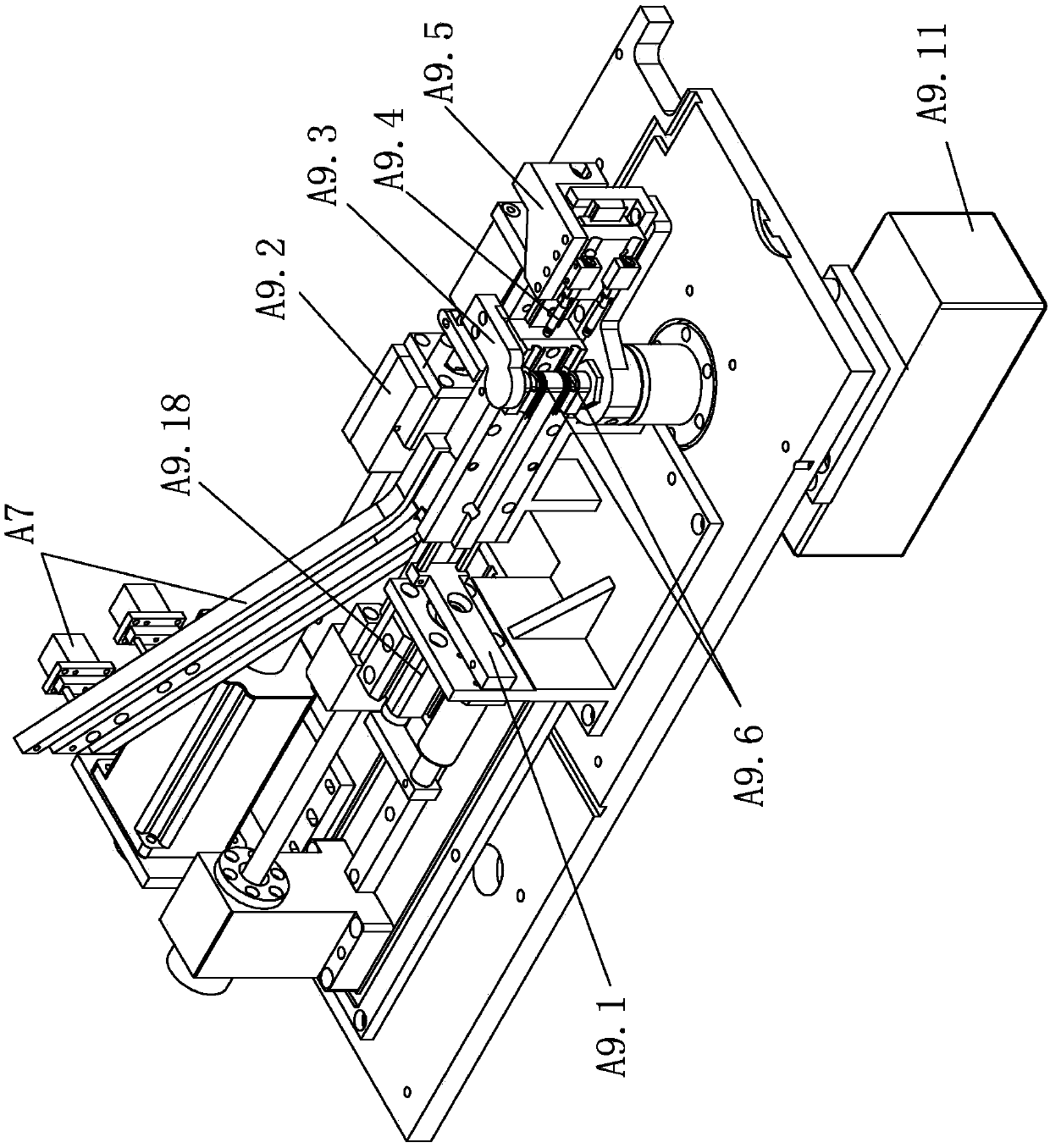

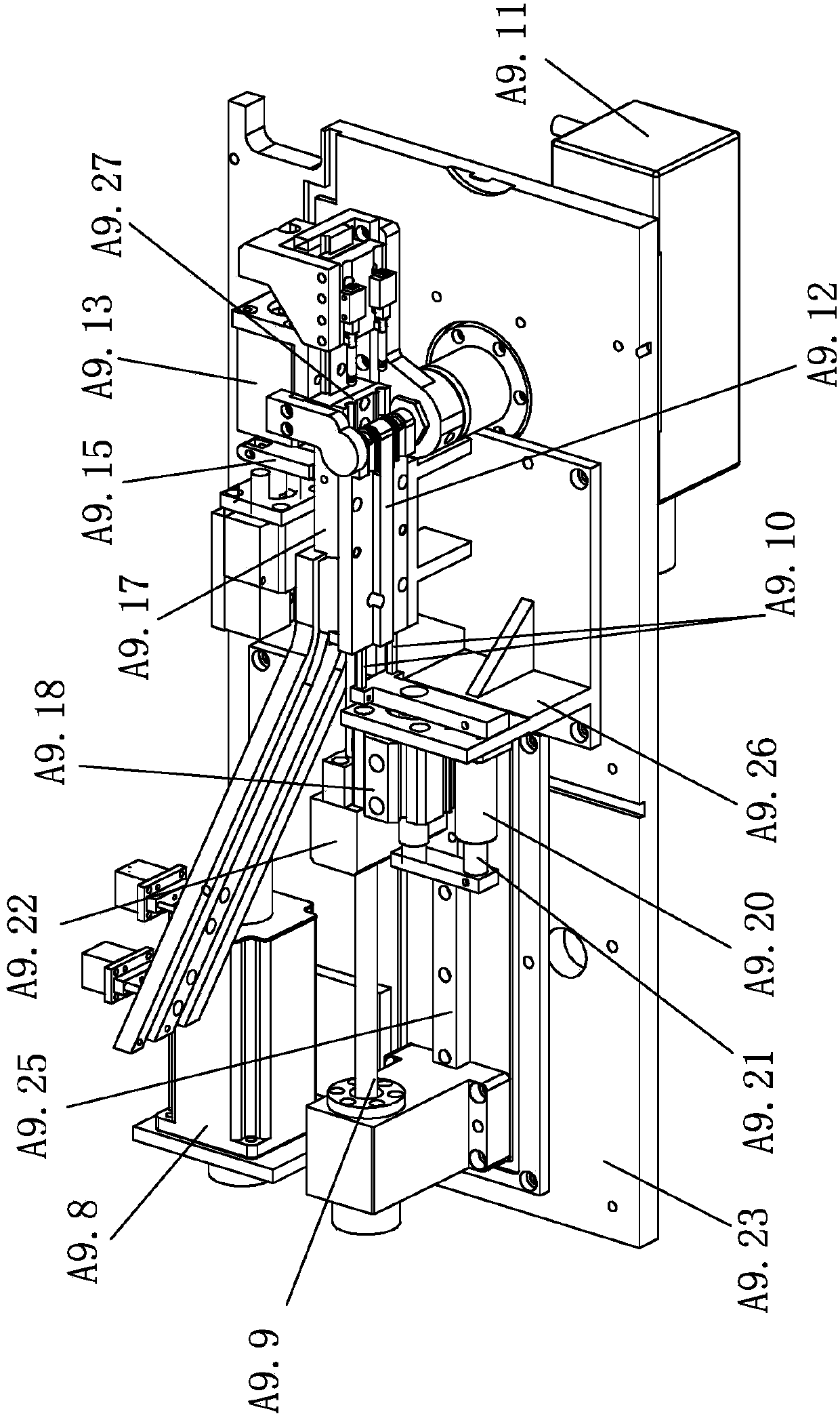

A pipe bending mechanism of a thin-walled short u-bend automatic forming machine

ActiveCN106270053BTighten evenlyLarge flow rateMetal-working feeding devicesPositioning devicesMolding machineFixed length

The invention relates to the technical field of automatic equipment, and discloses a pipe bending mechanism for an automatic thin-wall short U-shaped bent pipe forming machine. Bent pipe forming at the middle part of a thin-wall short U-shaped bent pipe can be finished, material waste can be effectively reduced, wrinkling of the pipe wall is avoided, the product quality and the service life are guaranteed, and the beneficial effects that the work efficiency is high, and the automation degree is high should be achieved. According to the adopted technical scheme, the pipe bending mechanism for the automatic thin-wall short U-shaped bent pipe forming machine is characterized by comprising at least one fixed part, a semicircle die, a movable part and a third drive mechanism, one end of a fixed-length pipe is clamped at the fixed part, after crossing the semicircle die, the other end of the fixed-length pipe is in movable fit to the movable part, the movable part is driven to swing through the third drive mechanism, a middle section of the fixed-length pipe is bent around the semicircle die to form an arc section, and the thin-wall short U-shaped bent pipe is formed.

Owner:TONGLU QIANDING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com