Battery

A technology for batteries and current collectors, applied to secondary batteries, battery pack parts, battery caps/end caps, etc. Effects of poor contact, suppression of increase in connection resistance, and stabilization of contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

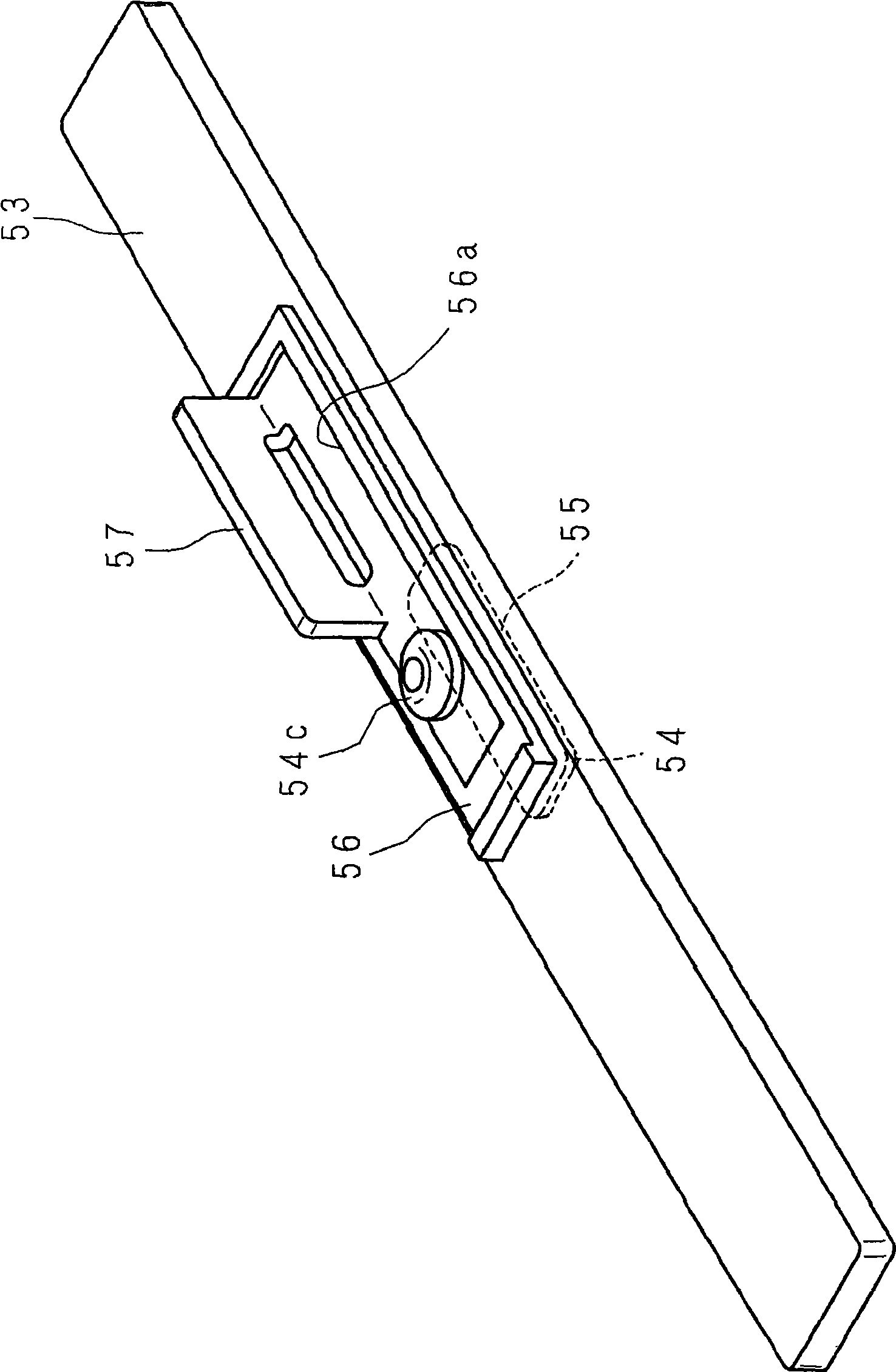

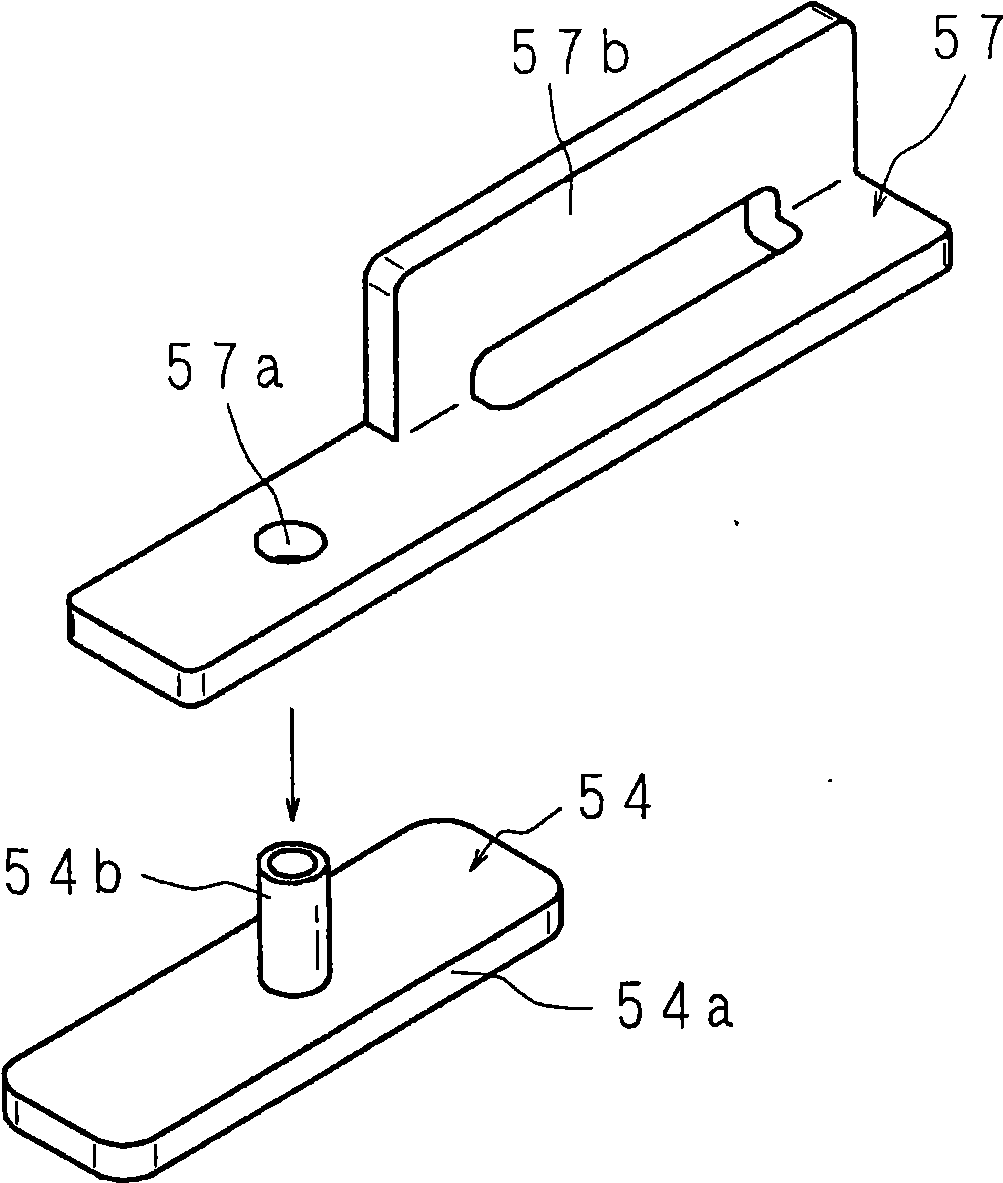

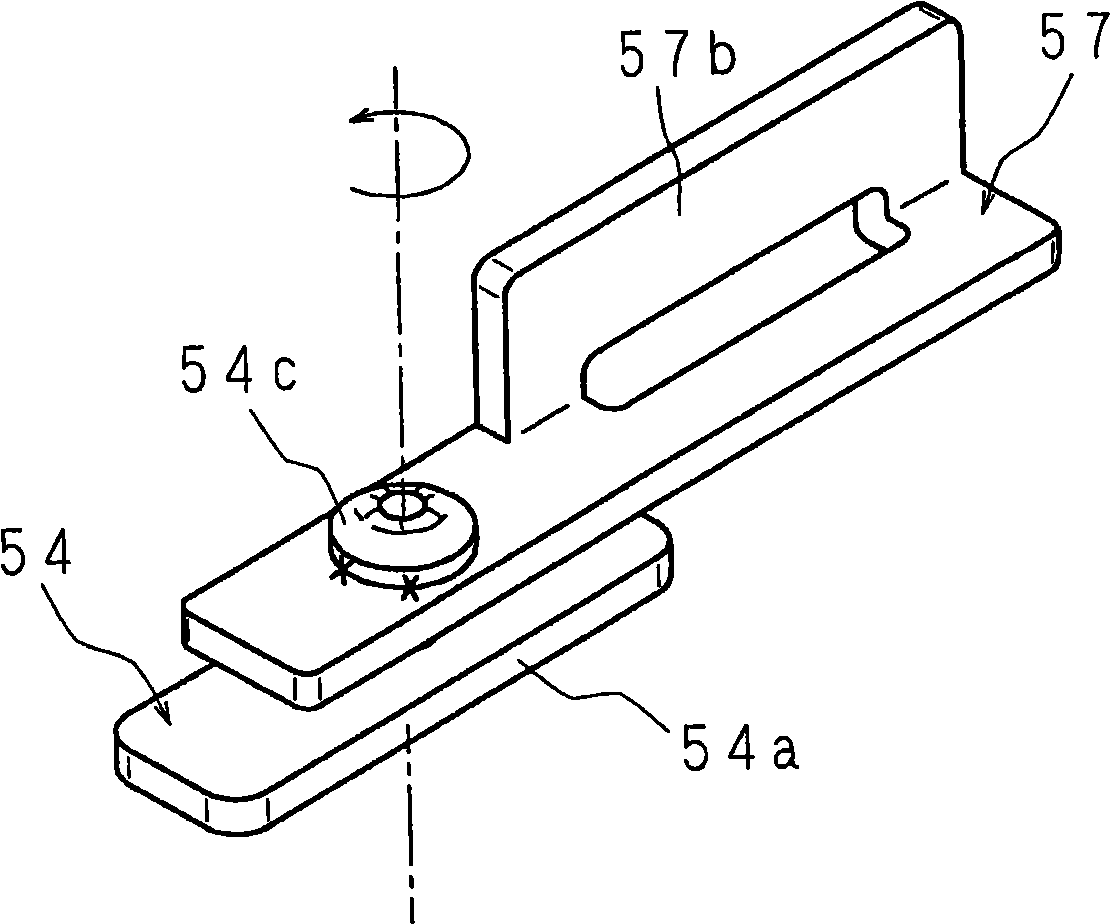

[0057] image 3 is a perspective view showing a lithium ion secondary battery (hereinafter referred to as a battery) 1 according to Embodiment 1, Figure 4 It is a perspective view of the state of the cover part 3 of the battery 1 seen from the back side, Figure 5 It is a partially cutaway side view showing the lid portion 3 . Figure 4 In , members connected to the recessed portion 32 described later are omitted.

[0058] A battery 1 accommodates a flat roll-shaped electrode group and a non-aqueous electrolyte (not shown) in a roughly cuboid-shaped aluminum casing 2 having an opening on one side, and covers the casing 2 with an aluminum cover 3 The flat rolled electrode group is obtained by winding a negative electrode plate formed by coating a negative electrode mixture on a copper current collector and a positive electrode plate formed by coating a positive electrode mixture on an aluminum current collector through a separator. .

[0059] One end of the cover 3 is prov...

Embodiment approach 2

[0073] The battery of the second embodiment has the same configuration as the battery 1 of the first embodiment, and the rotation suppression structure of the joint portion between the negative terminal 4 and the current collector 11 is different from that of the first embodiment.

[0074] Figure 9 It is a perspective view showing a state in which the end of the negative electrode terminal 14 is inserted into the insertion hole 11a of the current collector 11, Figure 10 It is a longitudinal sectional view showing the main part of the battery cover.

[0075] Such as Figure 9 As shown, the current collector 11 is provided with protrusions 11 b , 11 b .

[0076] When inserting the end of the leg portion 14b of the negative terminal 14 into the insertion hole 11a and fastening the end to the current collector 11, as Figure 10 As shown, the protrusions 11b, 11b, . The protrusions 11b, 11b... are formed discontinuously around the periphery of the insertion hole 11a. Therefor...

Embodiment approach 3

[0079] The battery of the third embodiment has the same configuration as the battery 1 of the first embodiment, and the joint portion between the negative terminal 4 and the current collector 12 has a rotation suppressing structure combining the rotation suppressing structures of the first and second embodiments.

[0080] Figure 11 It is a perspective view showing a state in which the end portion of the negative electrode terminal 4 is inserted into the insertion hole 12 a of the current collector 12 .

[0081] Such as Figure 11 As shown, in the insertion hole 12a of the current collector 12, similarly to the current collector 7 of Embodiment 1, substantially semicircular cutouts 12b, 12b are provided, and further, the openings facing each other with the cutouts 12b, 12b in between are provided. The semi-annular protrusions 12c, 12c are provided in the state.

[0082] Due to the above configuration, when the end of the leg portion 42 of the negative terminal 4 is inserted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com