Parallel tensioning device of glass fiber protofilament cylinder

A tensioning device and glass fiber technology, which is applied in the direction of textiles and papermaking, can solve the problems of small round jumping of raw silk tubes, difficulty in ensuring manufacturing accuracy, etc., and achieve the effect of large bonding surface, wide range of tensioning diameters, and uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

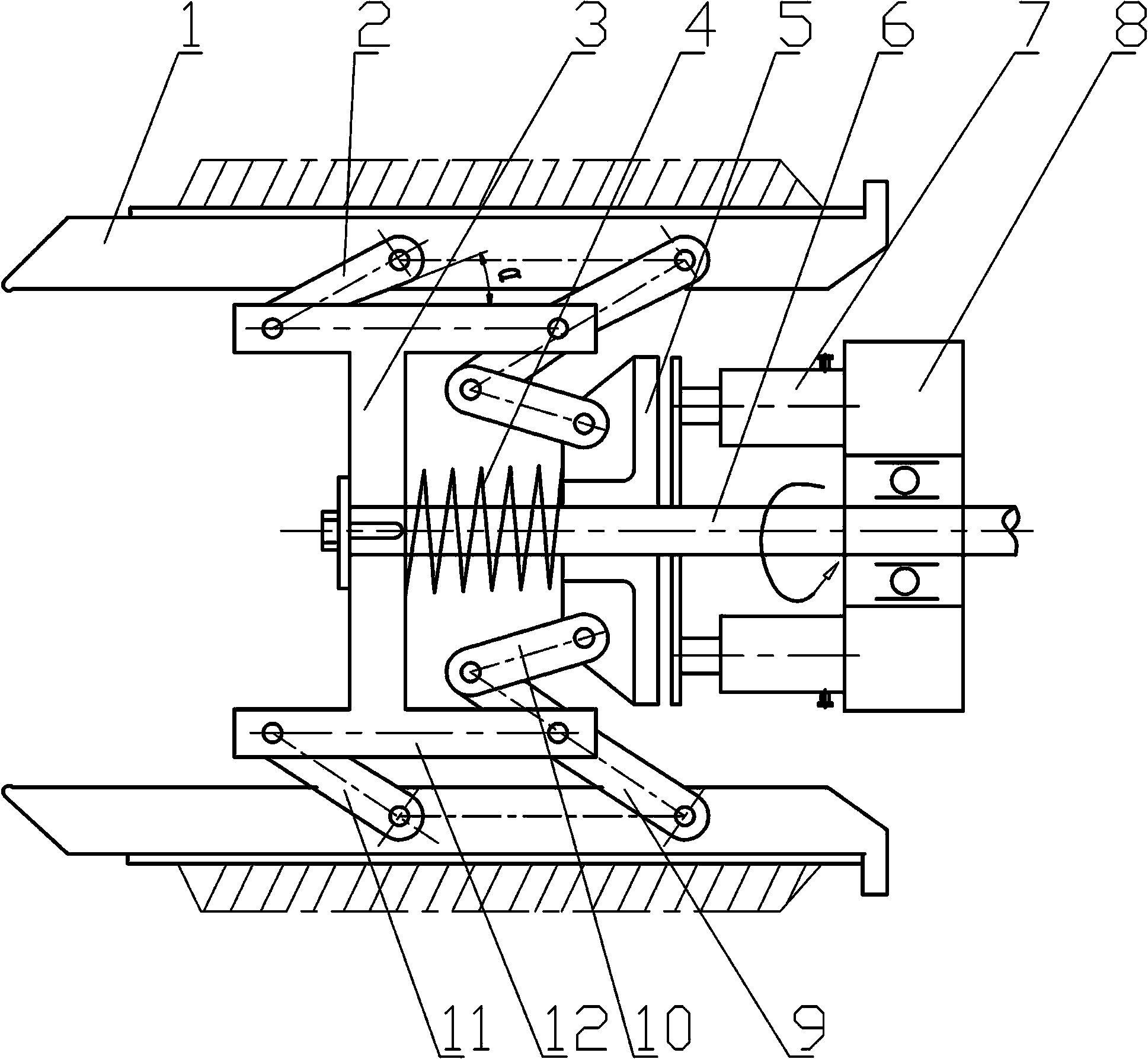

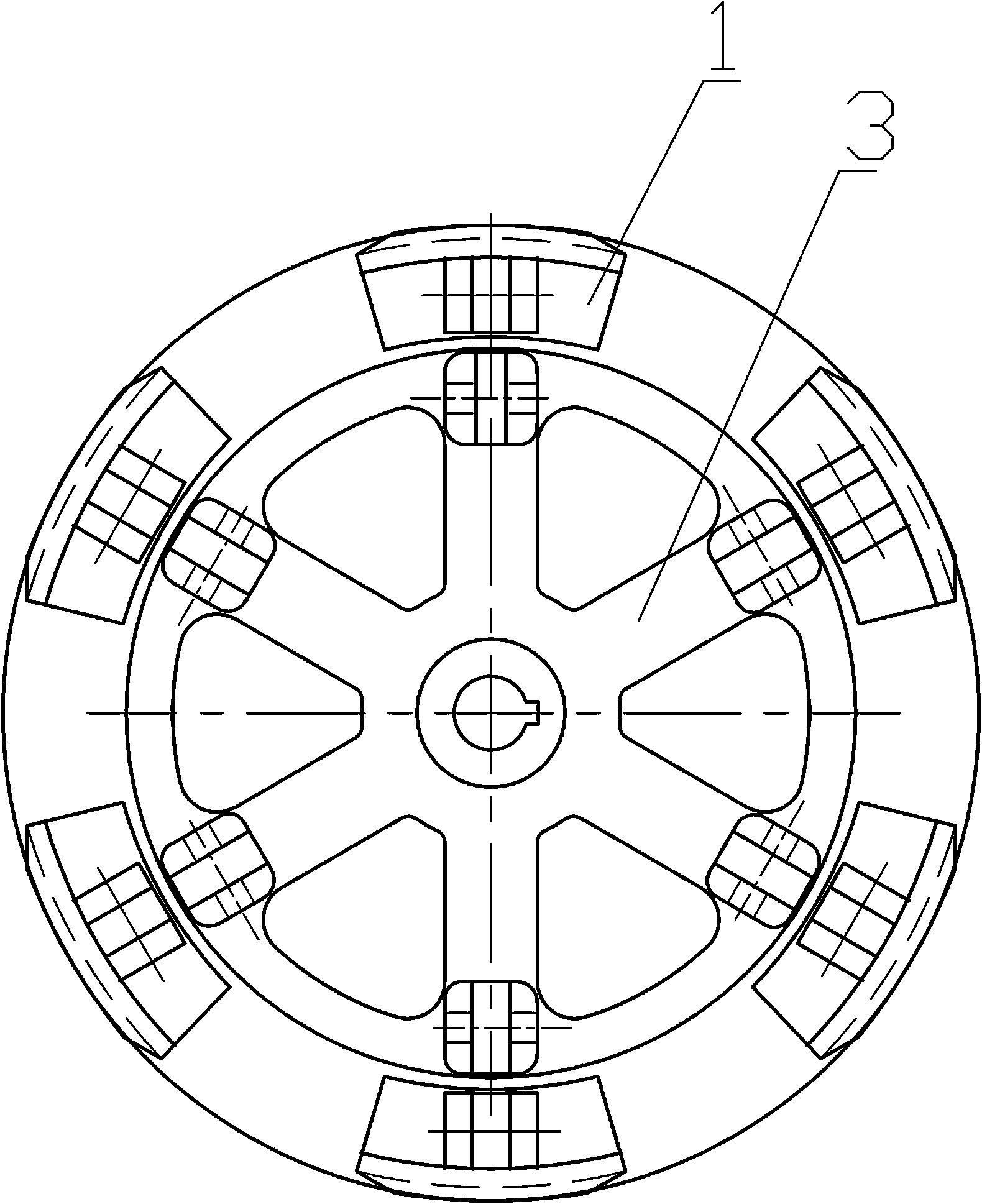

[0017] Such as figure 1 , figure 2 In, a parallel tensioning device for glass fiber precursor cylinders includes blades 1, a plurality of blades 1 distributed on the circumference are hinged with a connecting rod support 3 through a double-row linkage mechanism 2, and the connecting rod support 3 is connected to the central axis 6 is connected, the connecting rod sliding sleeve 5 can be slidably mounted on the central shaft 6 along the central axis 6, and the connecting rod sliding sleeve 5 is connected with the double-row linkage mechanism 2; the central shaft 6 is directly driven to rotate by a motor, or by Gear transmission mechanism or belt transmission transmission mechanism drives rotation.

[0018] In the optimized solution, the number of blades 1 is 6 pieces. 6 blades are evenly distributed on the circumference.

[0019] A side of the connecting rod sliding sleeve 5 away from the connecting rod sliding sleeve 5 is provided with a plurality of cylinders 7 that drive the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com