Connector terminal

A connector terminal, terminal technology, applied in the direction of contact parts, etc., can solve the problems of large insertion force and removal force, terminal sliding is not very good, surface state is easy to change with time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The male terminal 1 and the female terminal 2 of Embodiment 1 are manufactured in the manner described below.

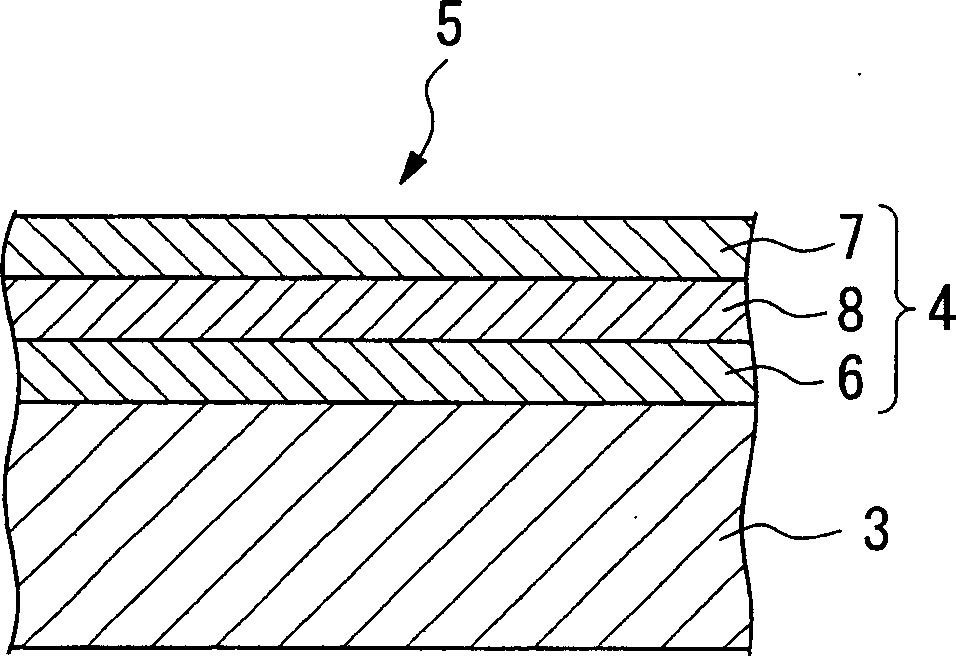

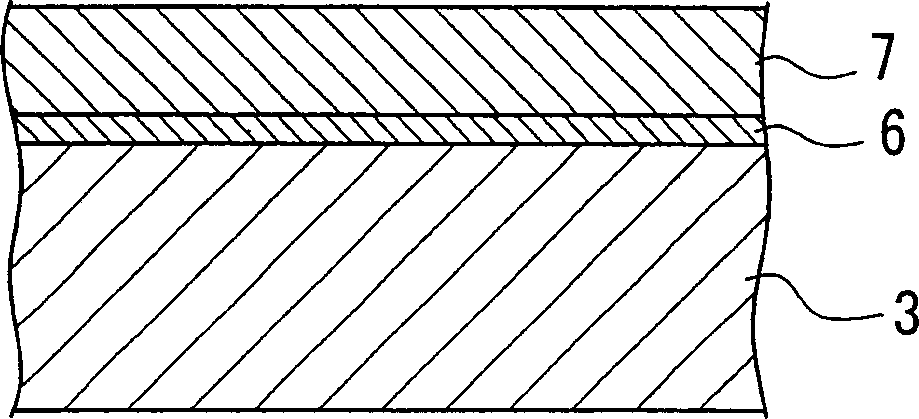

[0052] Copper alloy sheets (substrate materials) A and B shown in Table 1 were subjected to alkaline degreasing, electrolytic degreasing and activation treatment, and under the following conditions, after forming Cu layer 6 by electroplating Cu substrate, a pure Sn layer can be formed by Sn finishing plating 7, in order to obtain Sn-plated Cu alloy sheet. Next, the sheets were passed through a reducing atmosphere at temperatures of 250° and 300° for 10-80 seconds to perform reflow treatment and form a Cu-Sn alloy layer 8, and obtain surface-hardened electroplated Cu alloy sheets shown in Table 2.

[0053] Cu

thickness

(mm)

Composition (wt%)

feature

Non-Cu component

Cu and inevitable

free from impurities

tensile strength

(N / mm 2 )

extend

Elongation

Hardness (Hv)

...

Embodiment 2

[0062] A method of manufacturing the male terminal 1 and the female terminal 2 of Embodiment 2 will be described below.

[0063] Respectively anneal Sn-plated Cu alloy sheets C and D at 200-220°C for 30-10000 seconds, reflow Sn-plated Cu alloy sheets E and F, and hot-dip Sn-plated Cu alloy sheets G and H, so that A Cu-Sn alloy layer was obtained and quenched. As shown in Table 3, following the quenching treatment, the thickness of the pure Sn layer 7 and the thickness of the Cu—Sn alloy layer 8 were measured.

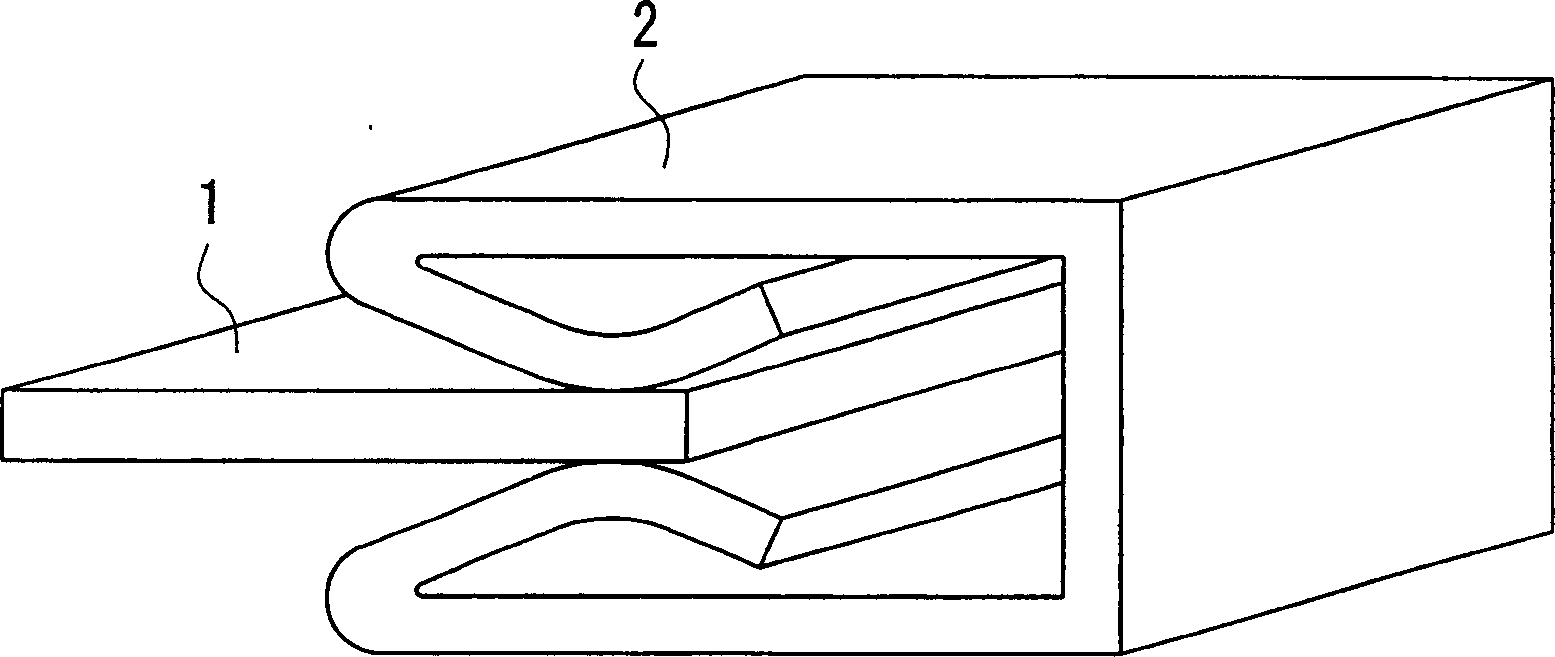

[0064] Utilize the electroplated Cu alloy plate can be manufactured with such as figure 1 The male terminal 1 and the female terminal 2 of the shape shown, and the respective sliding portions of the male terminal 1 and the female terminal 2 determine the difference in Vickers hardness value (HV) of the two. Table 3 shows these results. The maximum load was measured 10 times for each different combination during the insertion of the male terminal 1 into the female ter...

Embodiment 4

[0078] The electroplating condition of embodiment 4 [Ni electroplating condition]

[0079] Plating bath composition: 240g / l nickel sulfate, 45g / l nickel chloride, 30g / l boric acid; plating bath temperature: 35°C; current density: 2A / dm 2 [2%-Sn Cu alloy plating conditions]

[0080] Plating tank composition: 50g / l tin sulfate, 45g / l sulfuric acid, 1g / l TopFleet SC-S (trademark of Okuno Chemical Industry Co., Ltd.), 10ml / l Top Fleet Sc-R, 0.3ml / l Top Fleet Sc- 1; Plating tank temperature: 20°C, current density: 2A / dm 2 [Electroplating 19%-SnNi Alloy Conditions]

[0081] Plating bath composition: 500ml / l Pyroalloy SN Starter (trademark of Kagaku Sanyo Co., Ltd.), 20ml / l Pyroalloy SN makeup, 25g / l esterified tin; plating bath temperature: 40°C, current density: 1A / dm 2 [Electroplating 26%-SnNi Alloy Conditions]

[0082] Plating bath composition: 500ml / l Pyroalloy SN Start, 20ml / l Pyroalloy SN makeup; plating bath temperature: 40°C, current density: 1A / dm 2 [Conditions for Ag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com