Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1173 results about "Fluid Leak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

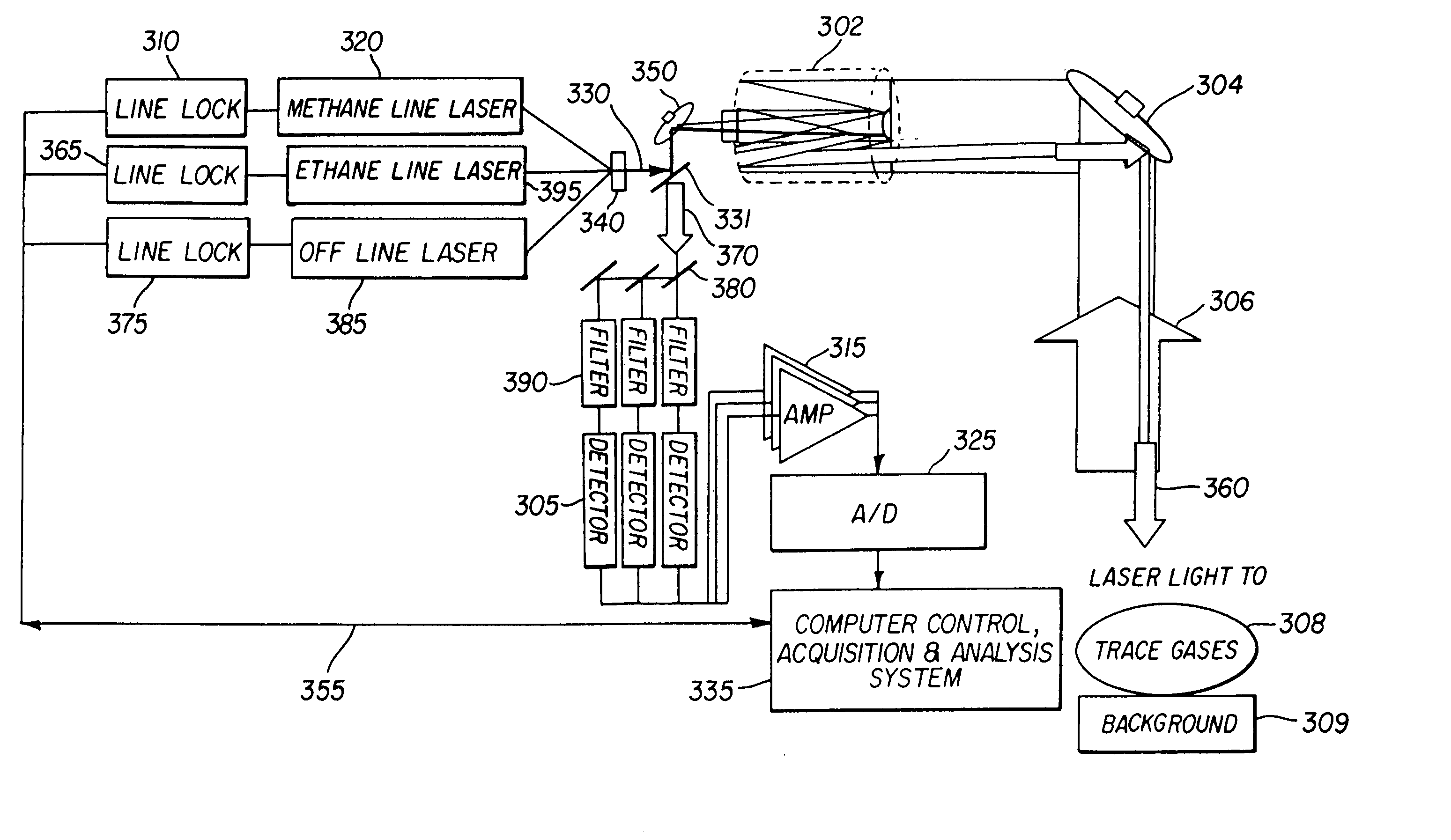

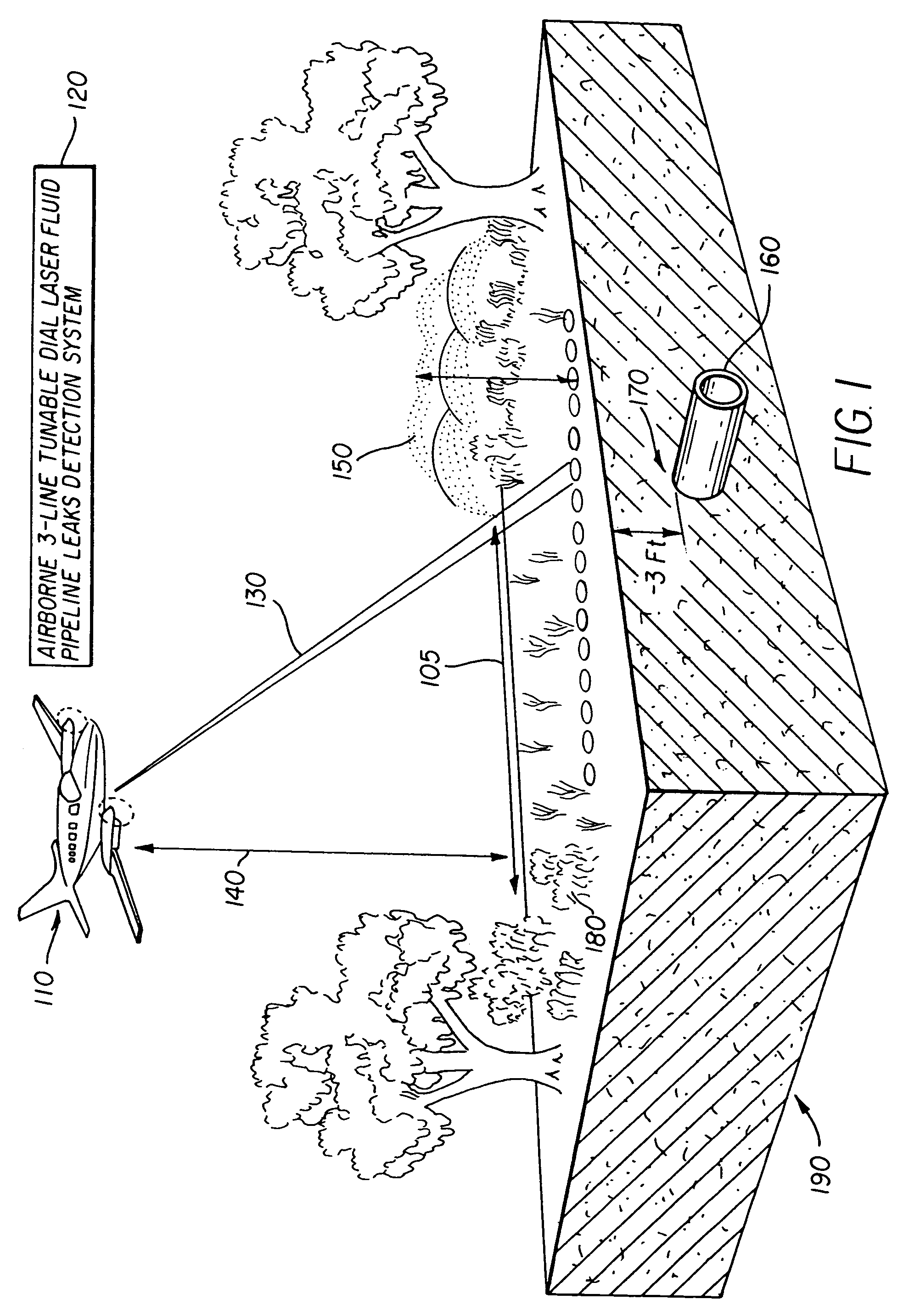

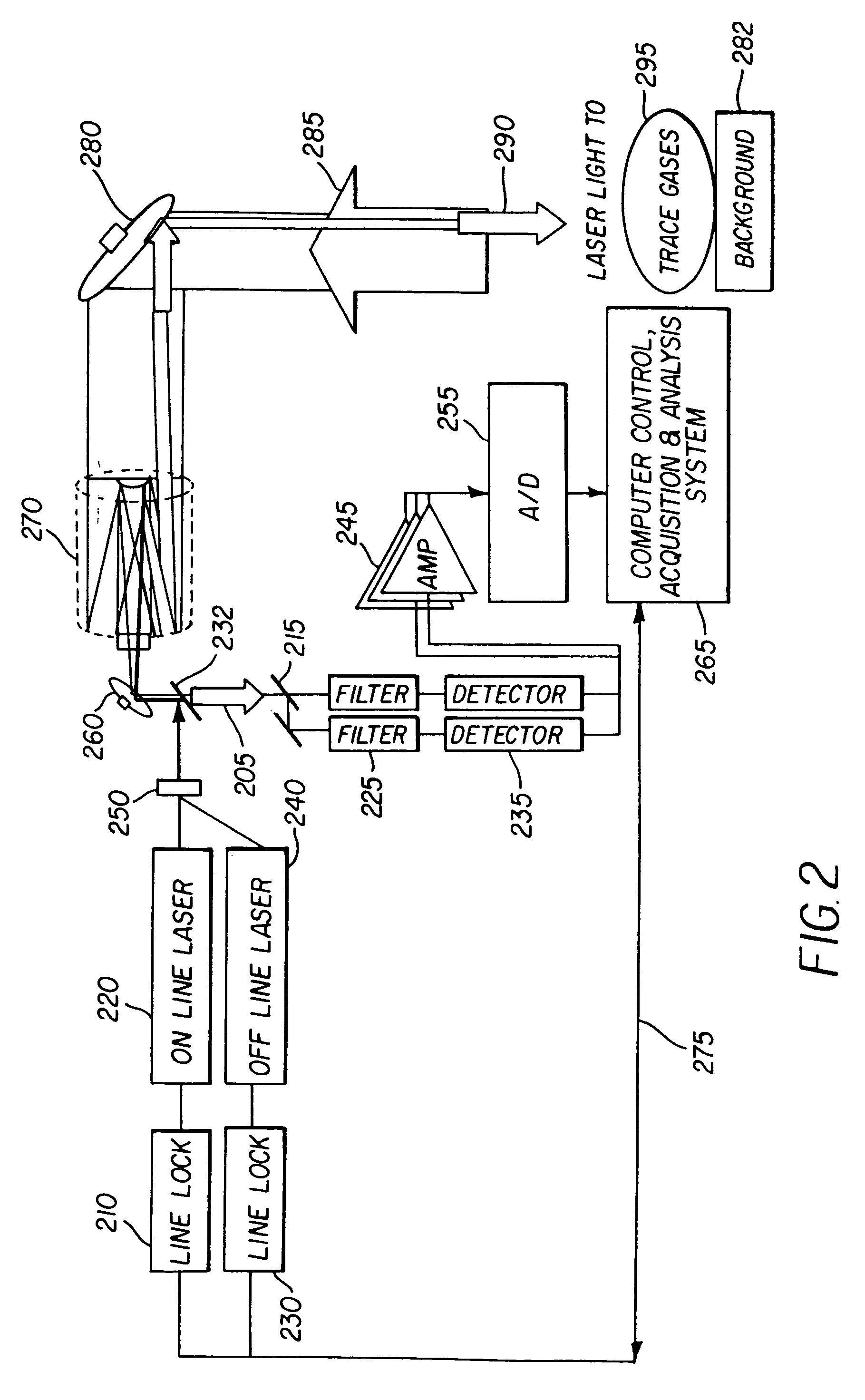

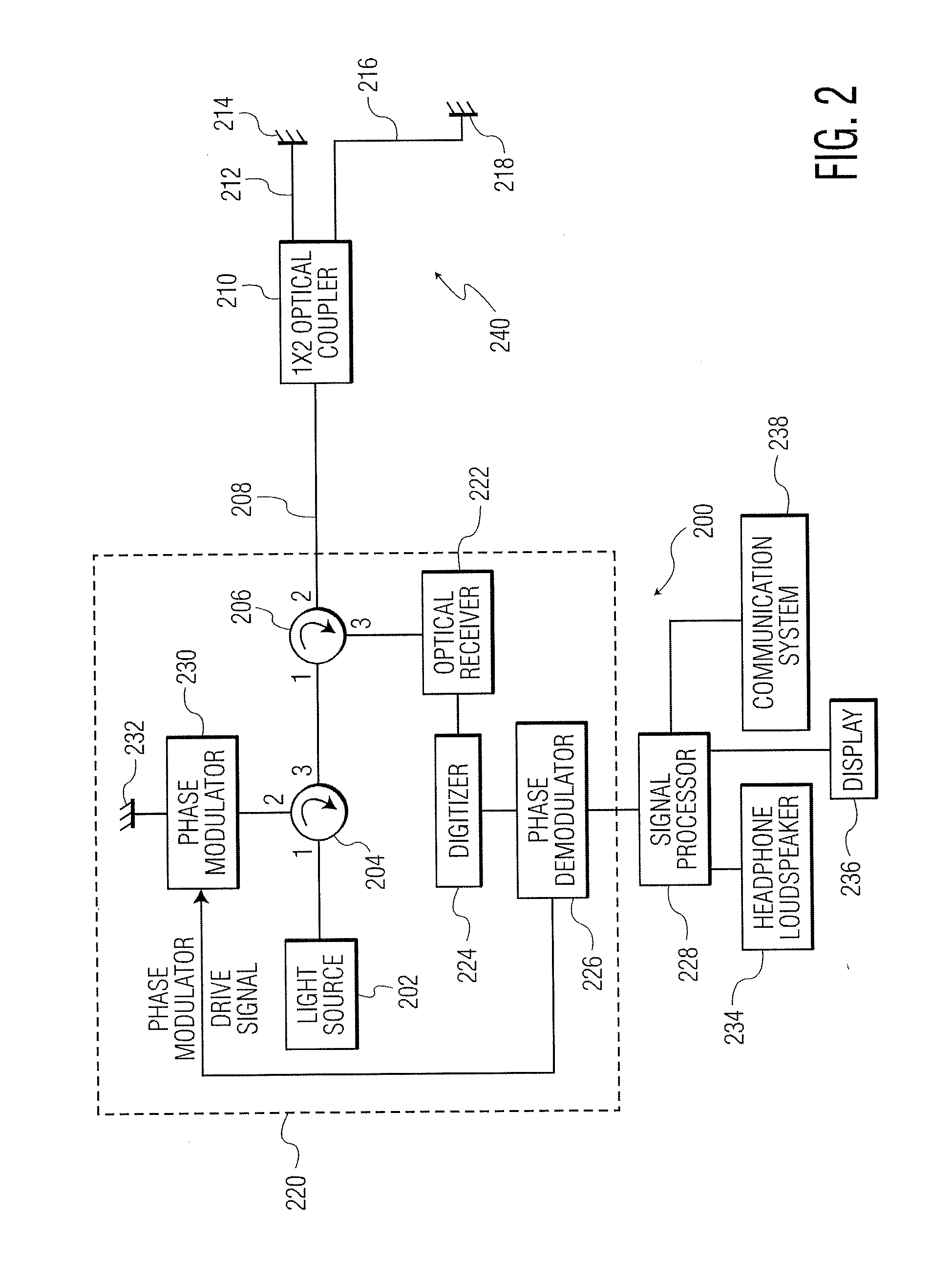

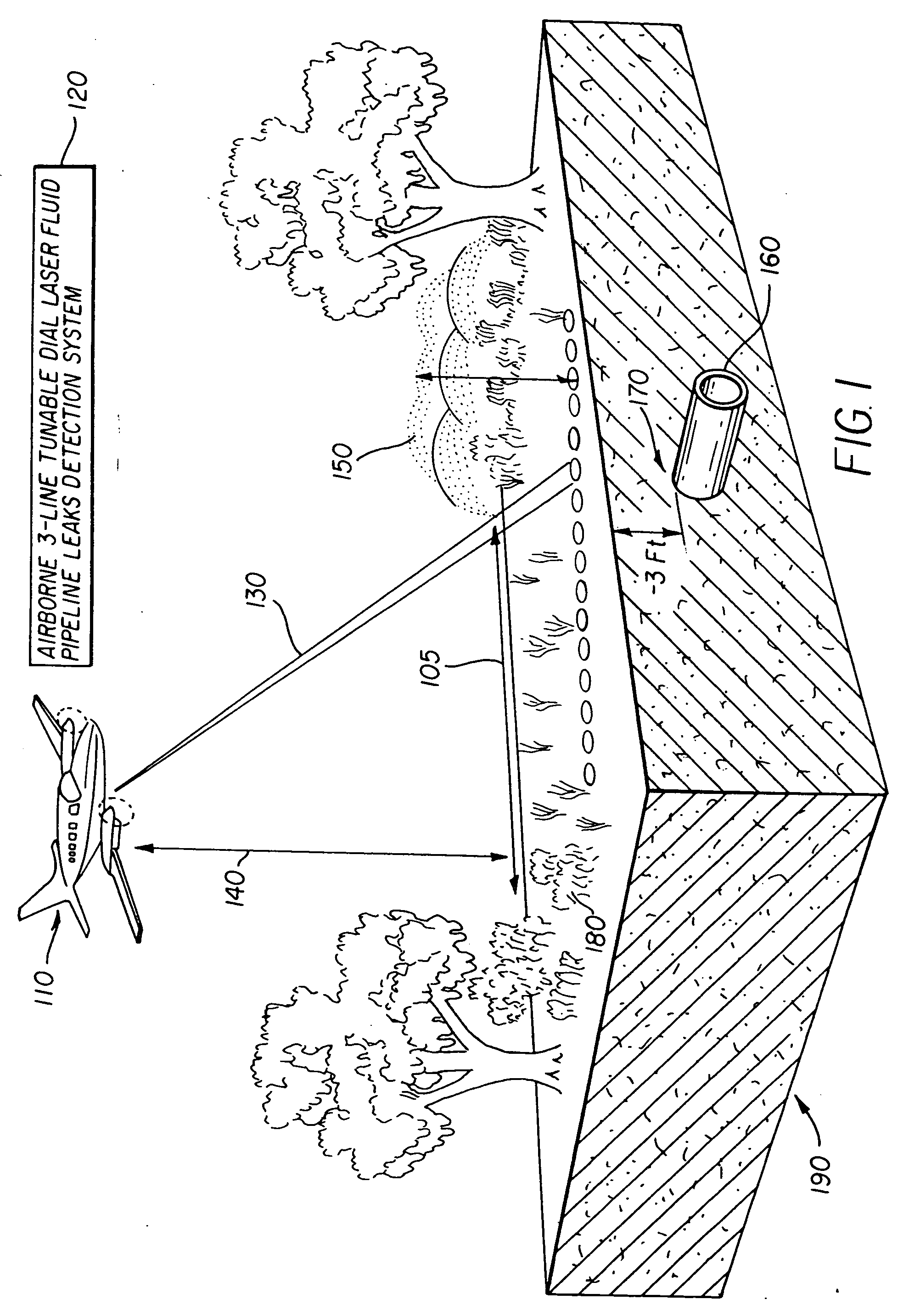

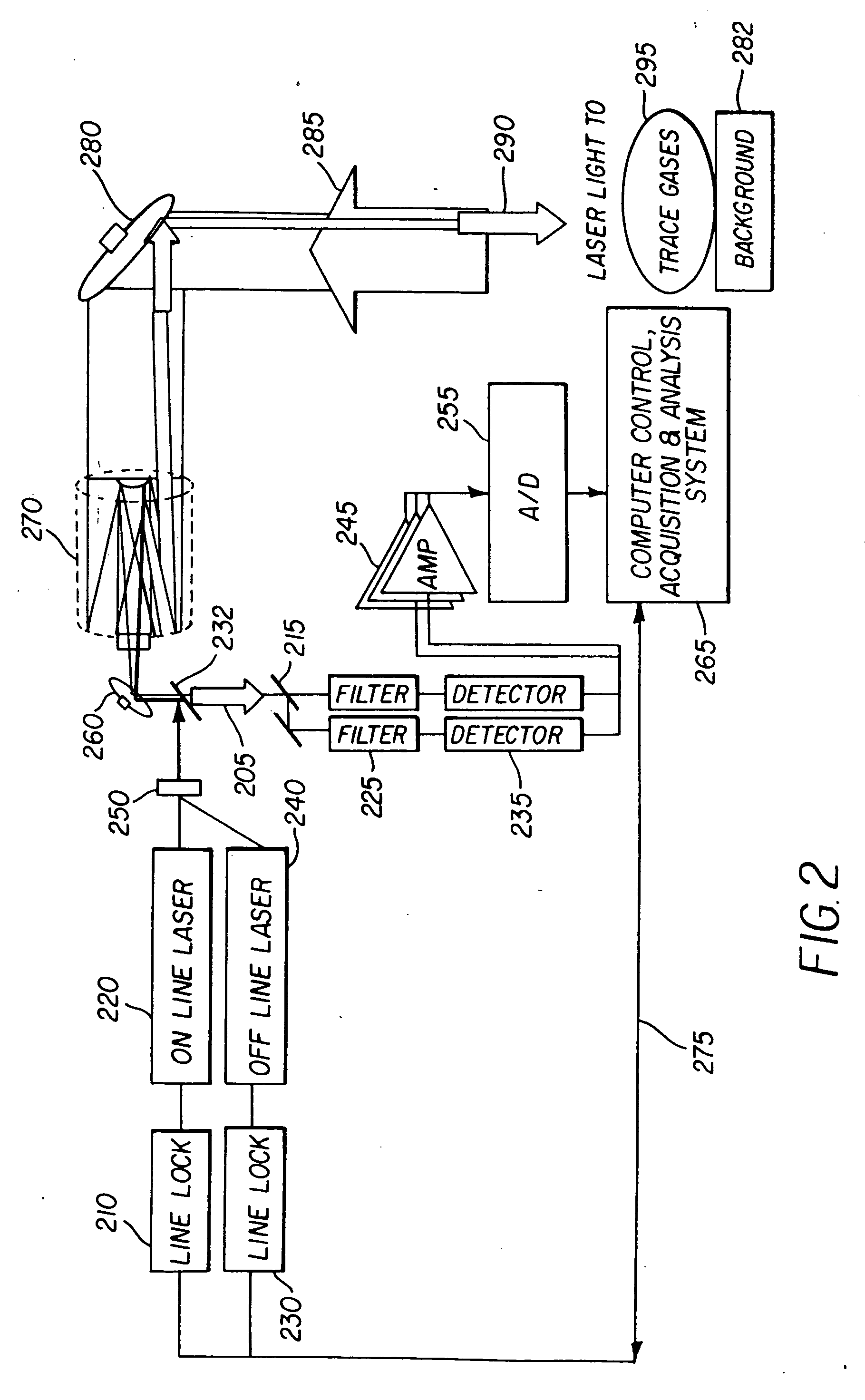

System and method for remote quantitative detection of fluid leaks from a natural gas or oil pipeline

ActiveUS6995846B2Reasonable wavelength conversion efficiencyColor/spectral properties measurementsPhotometry using electric radiation detectorsLaser lightSignal detector

A system for remote quantitative detection of fluid leaks from a natural gas or oil pipeline by use of an airborne platform; including at least one laser light source for nearly simultaneous illuminating two or more target fluids and a background, wherein the two or more target fluids are characterized by two or more absorption wavelengths, and wherein the background has a different wavelength than either of the two or more target fluids. The illumination source is pointed based on a positioning system while in a geometric area along a path two or more target fluids are scanned for using the illumination sources. A signal detector detects the two or more target fluids using quantitative signal processing. Also included are a controller, a path planning and path finding tool for the positioning of the airborne platform, and a communicator for communicating the presence of the detected leak.

Owner:HARRIS CORP

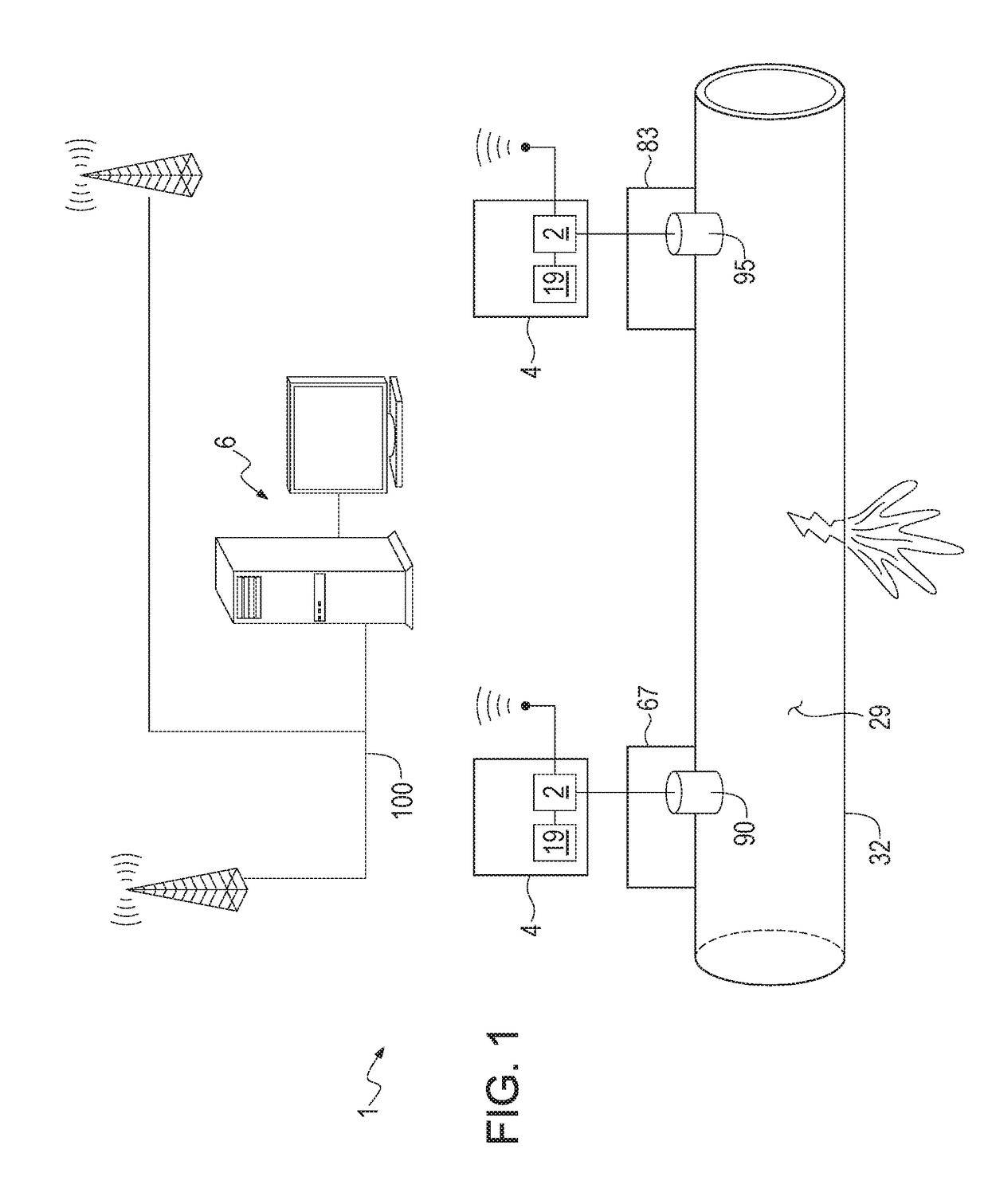

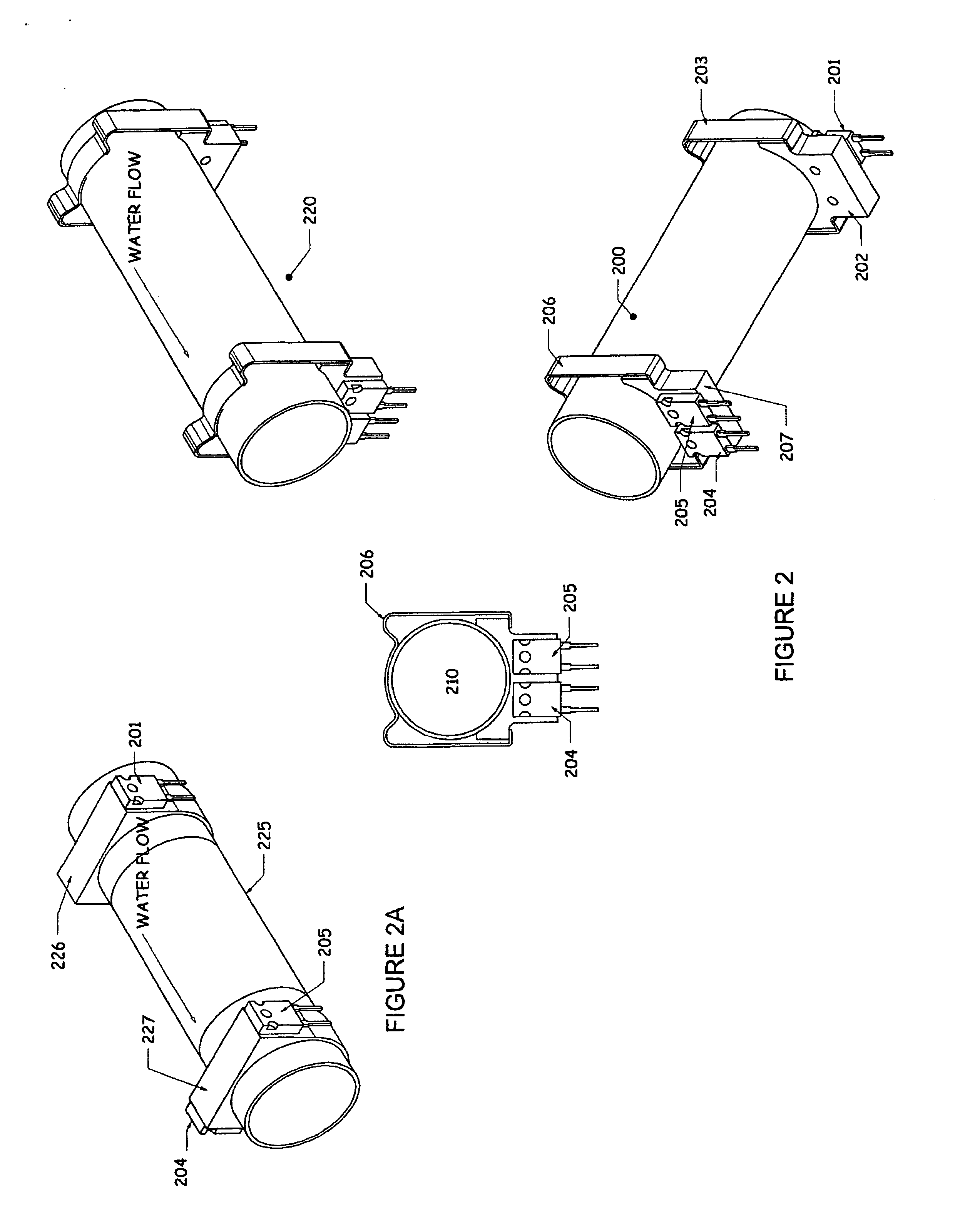

Ultrasonic Flow Meter Leak Detection System and Method

ActiveUS20170307466A1Well formedMeasurement of fluid loss/gain rateVolume/mass flow measurementUltrasonic sensorTransducer

The use of ultrasonic transducers installed in utility meters is provided for the detection of fluid leaks in a conduit. Such transducers are normally used to transmit acoustic waves in order to measure the velocity of fluid flow, but it is disclosed that such transducers are also capable of detecting leak noises in addition to such transmitted acoustic waves.

Owner:NEPTUNE TECH GROUP

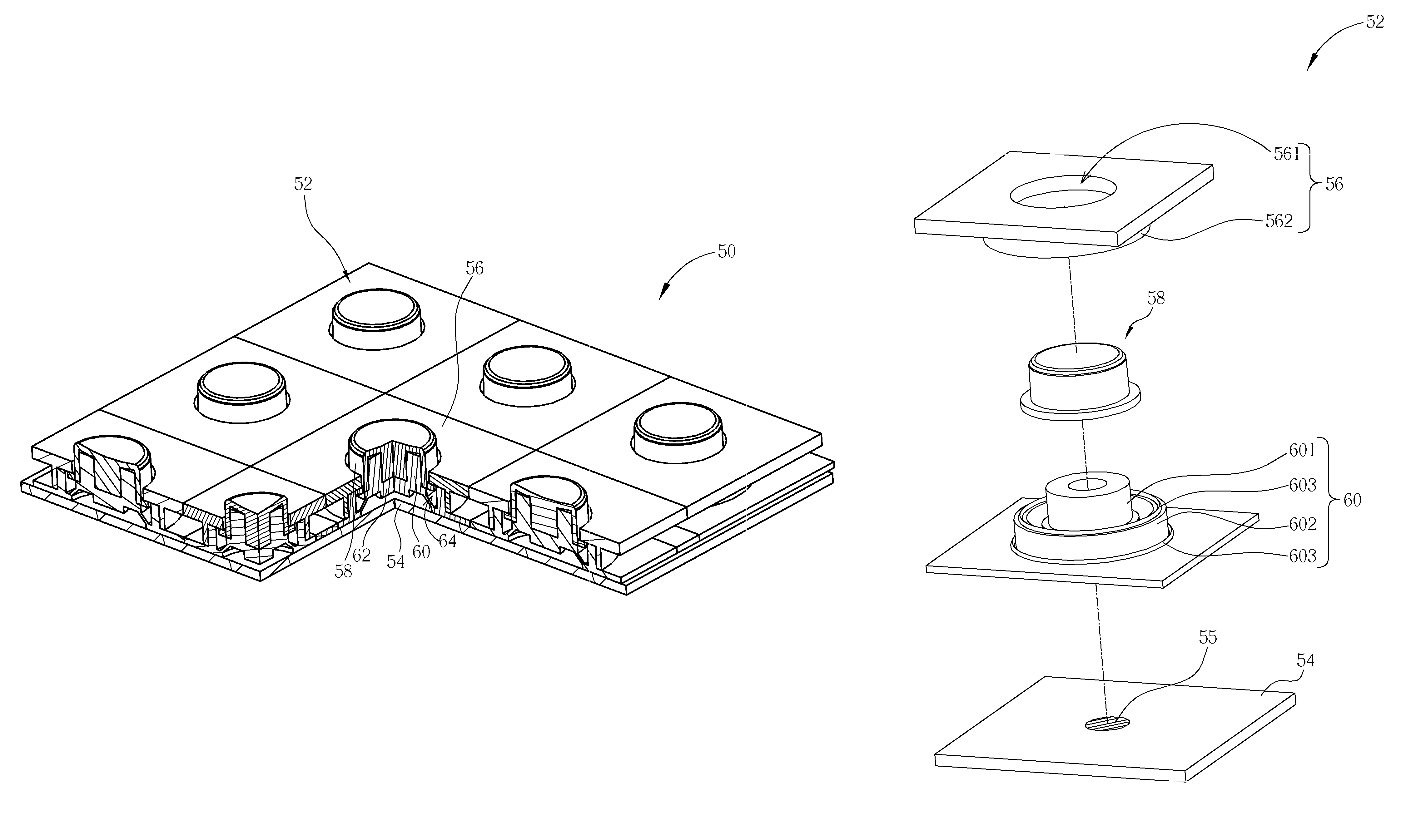

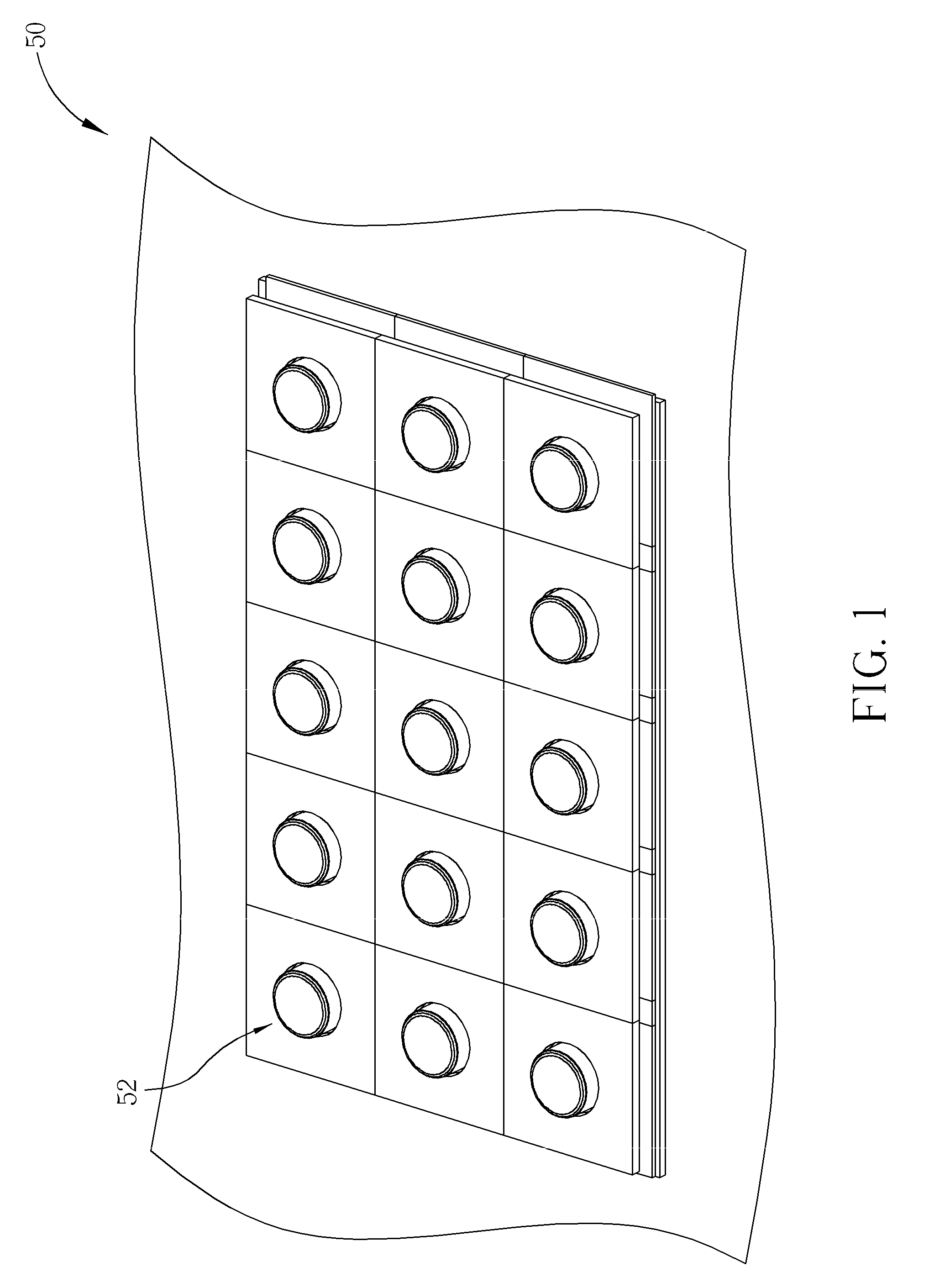

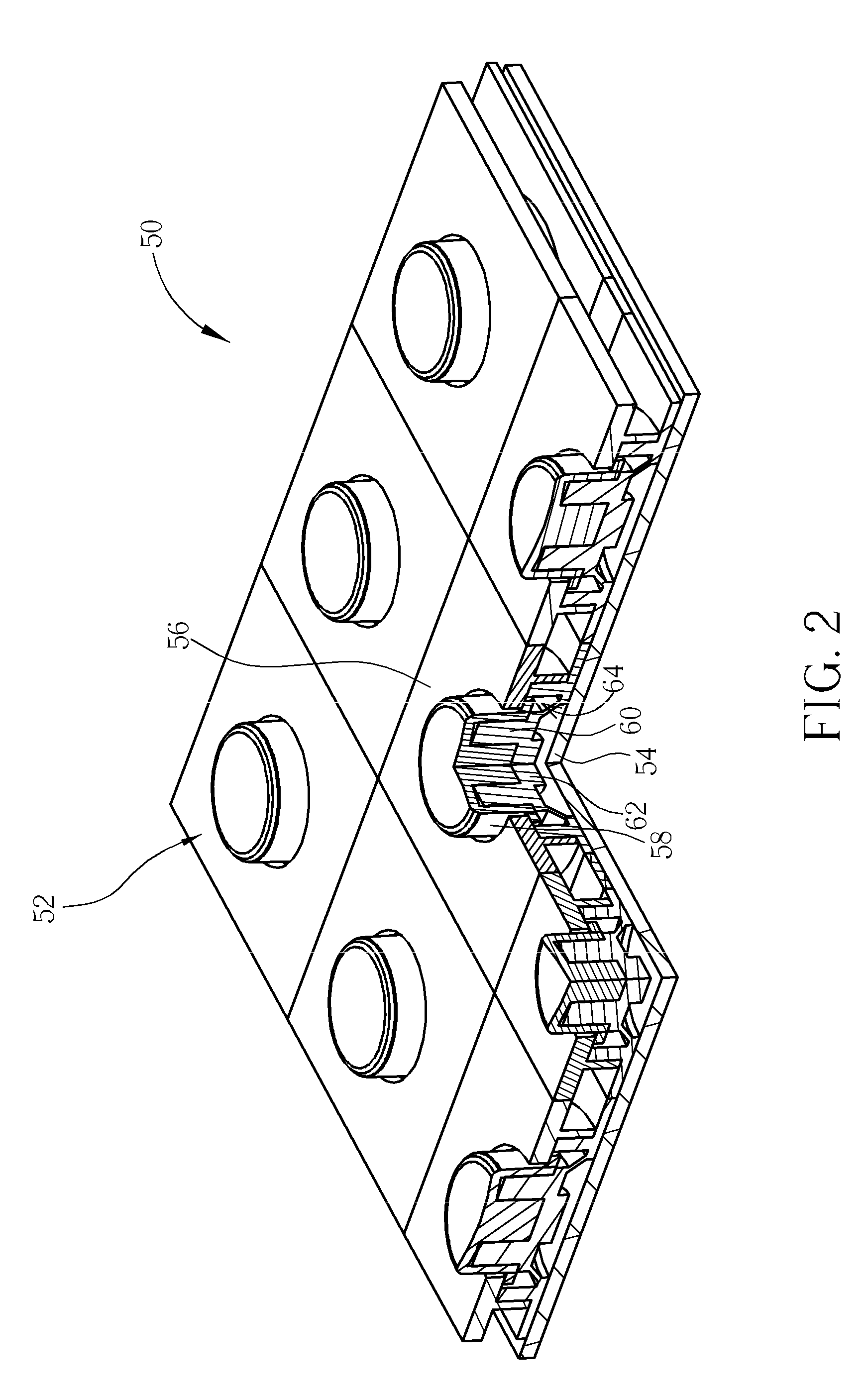

Key mechanism with waterproofing function and related electronic device

Owner:WISTRON CORP

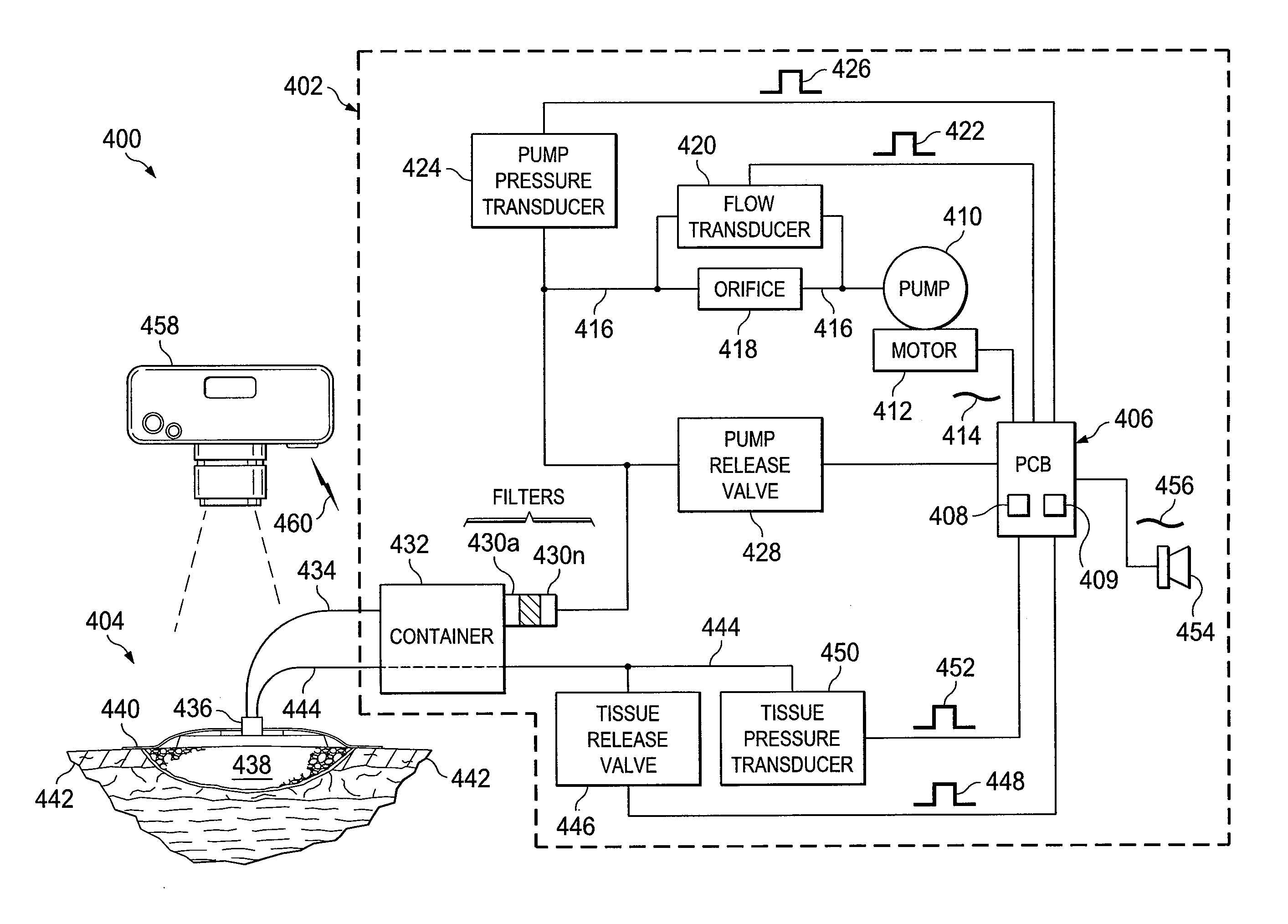

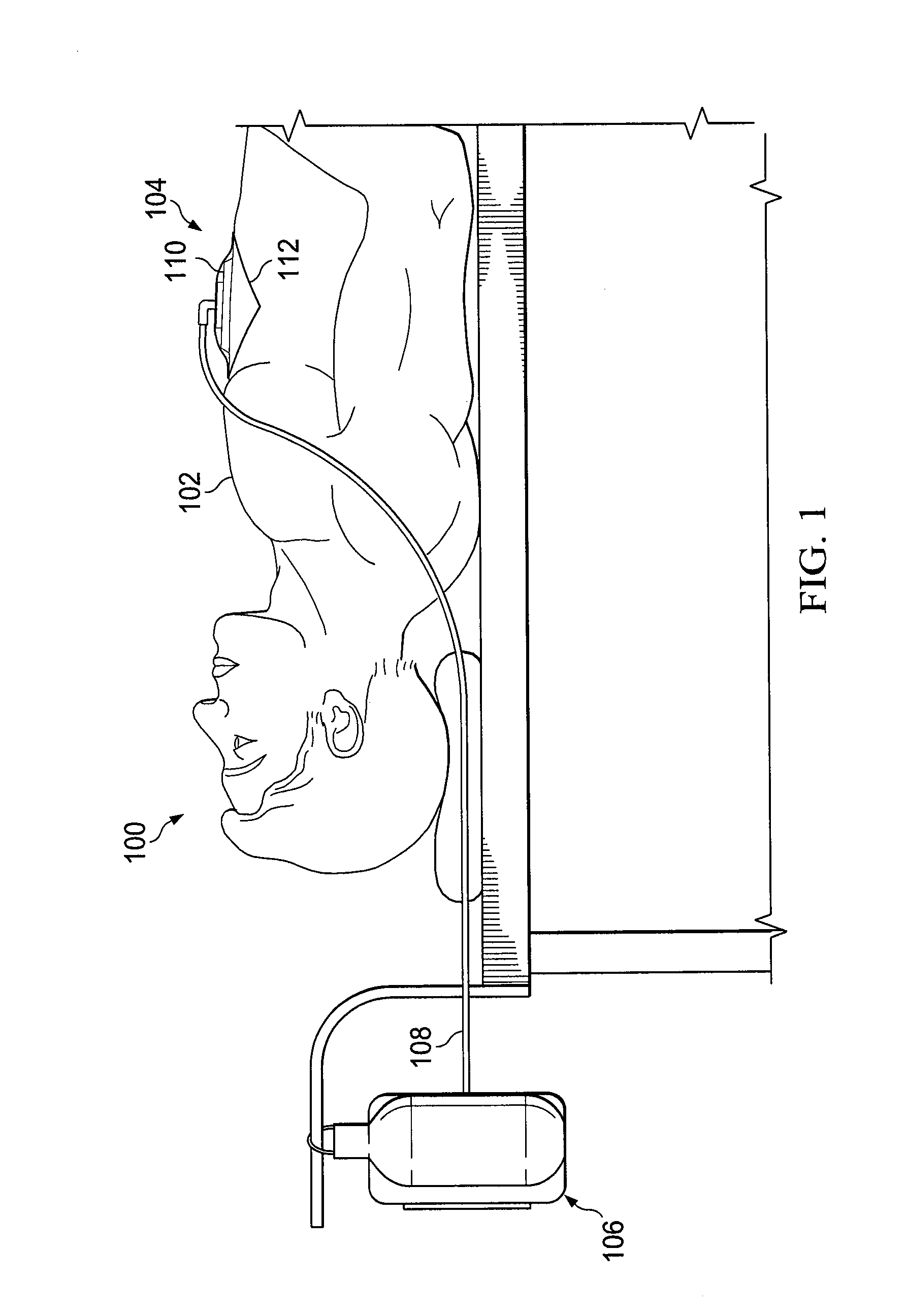

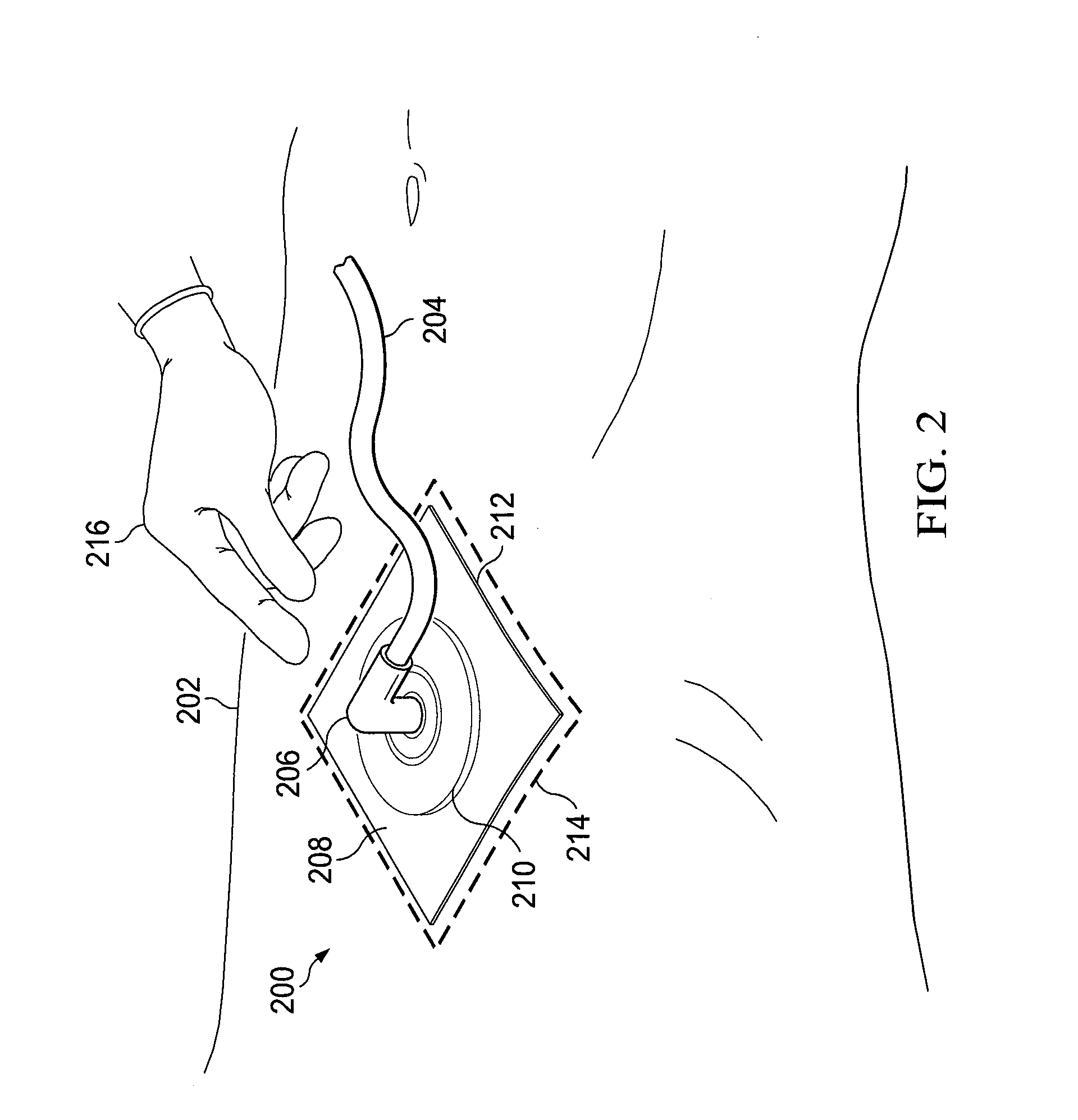

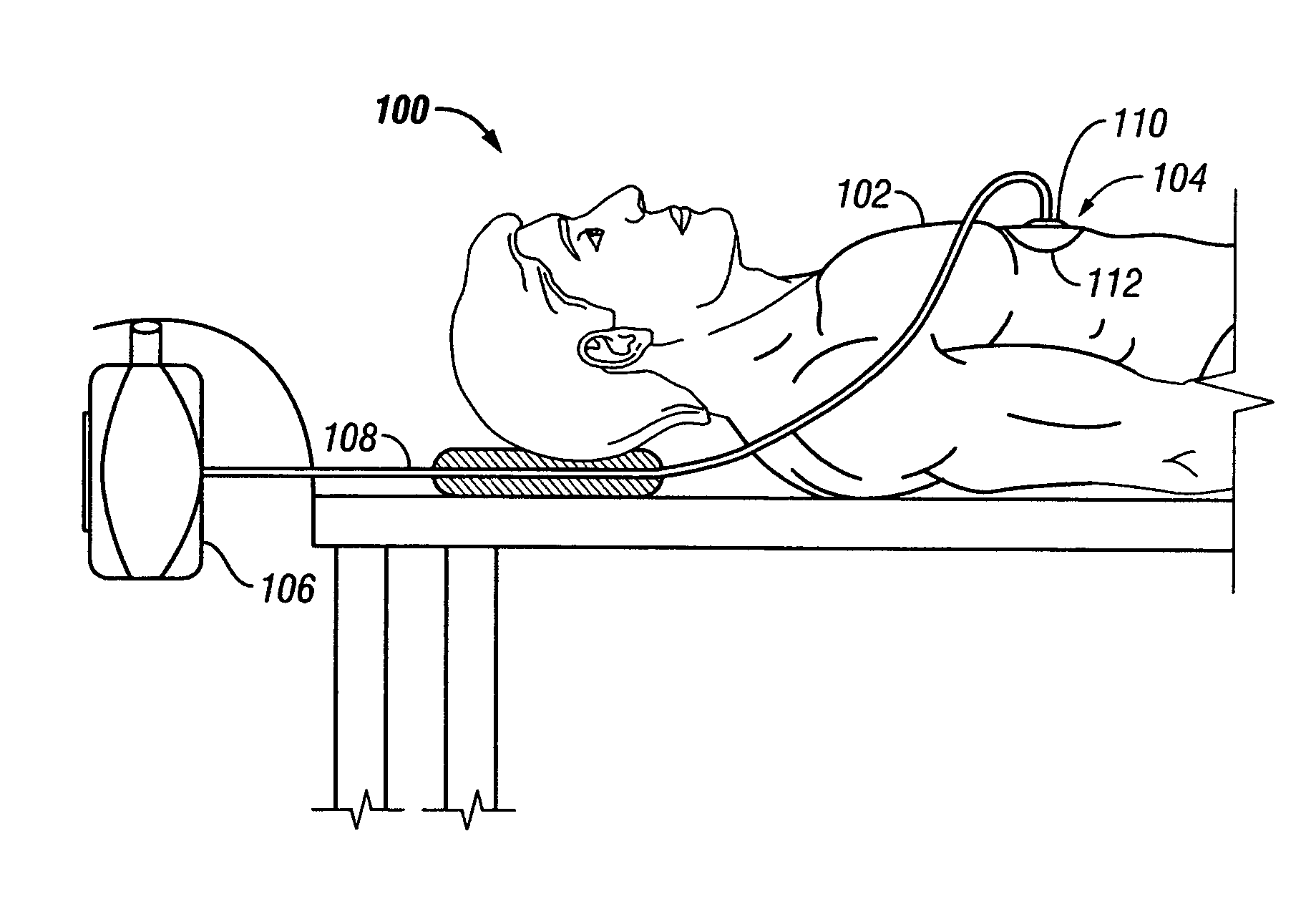

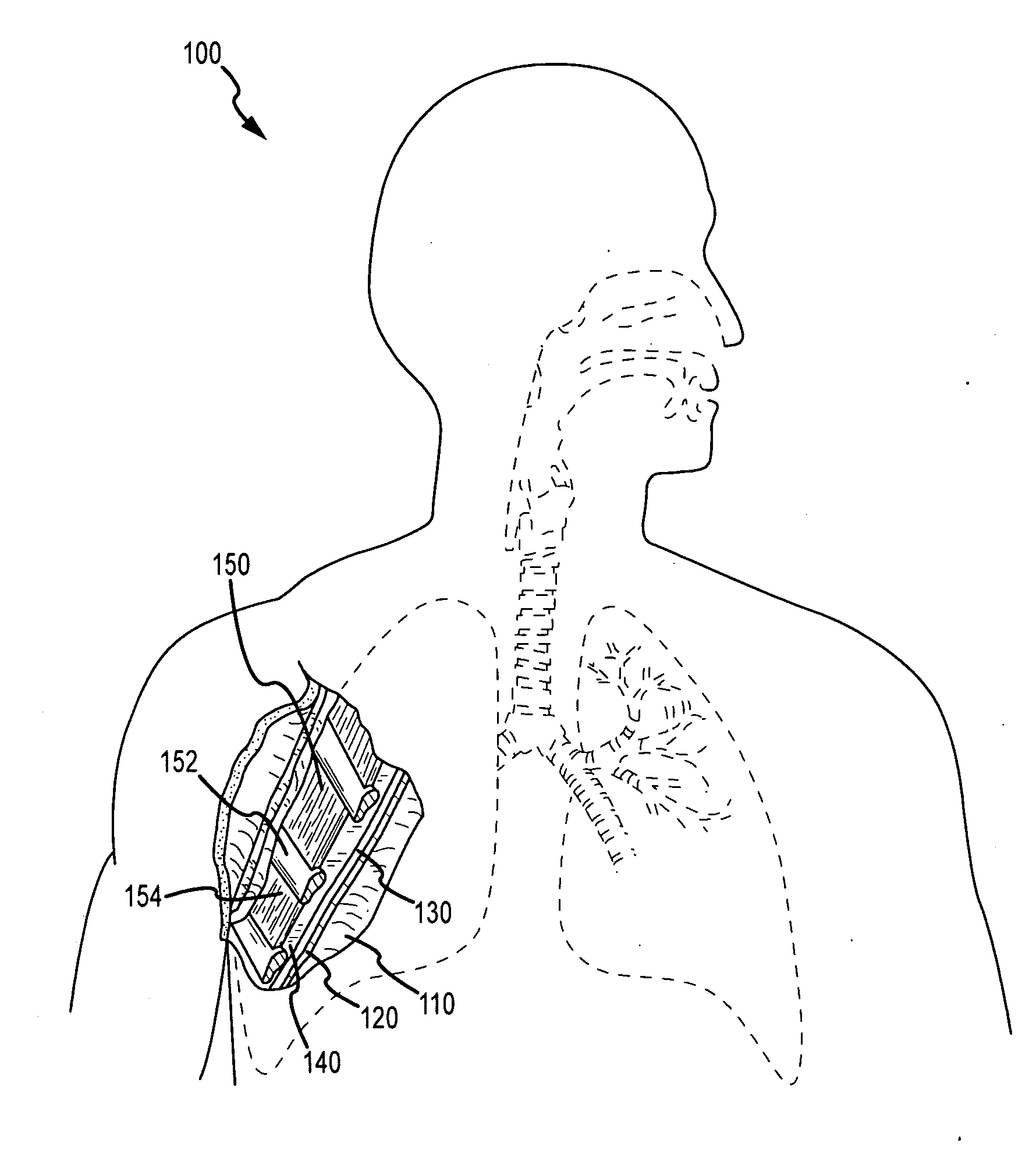

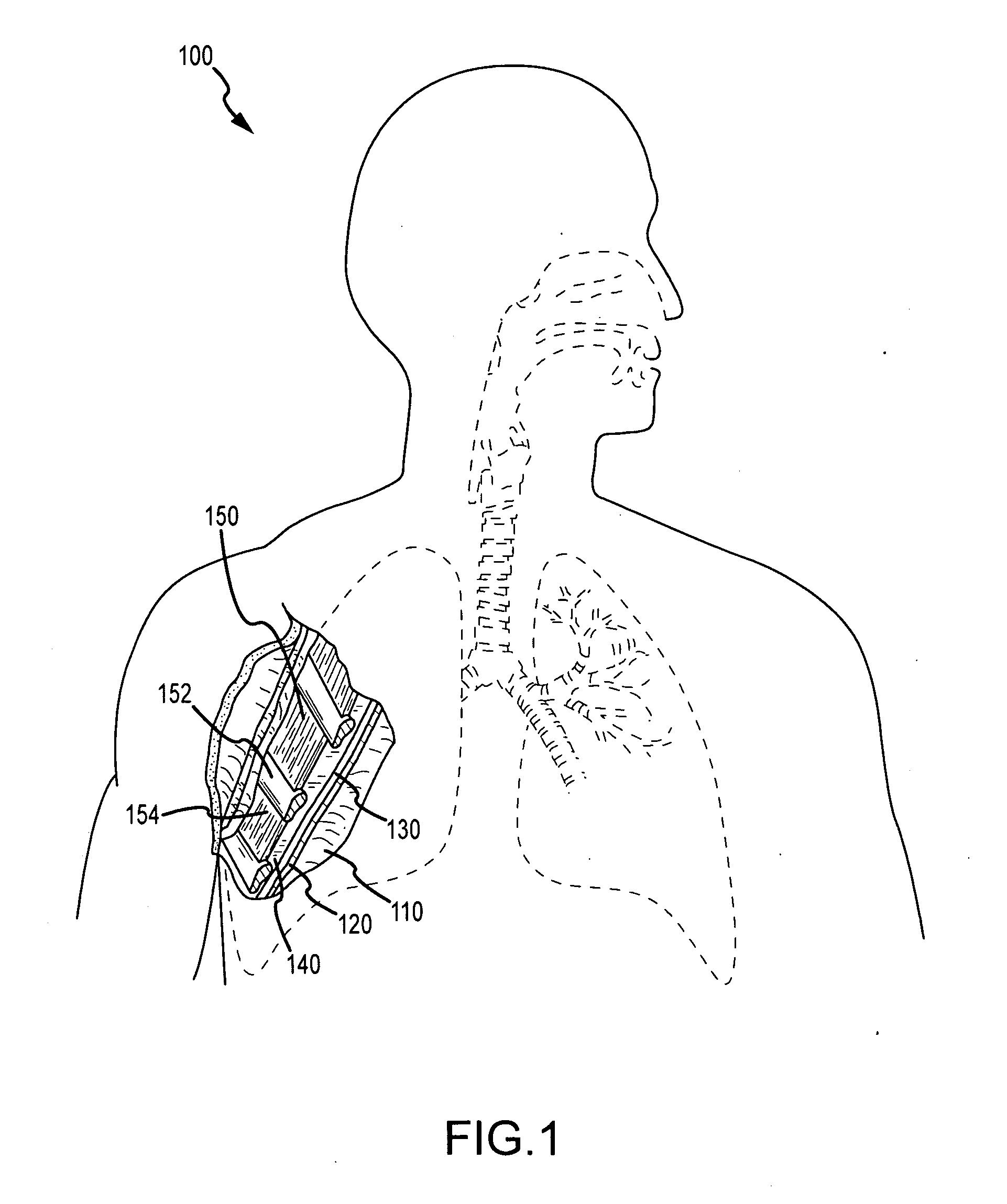

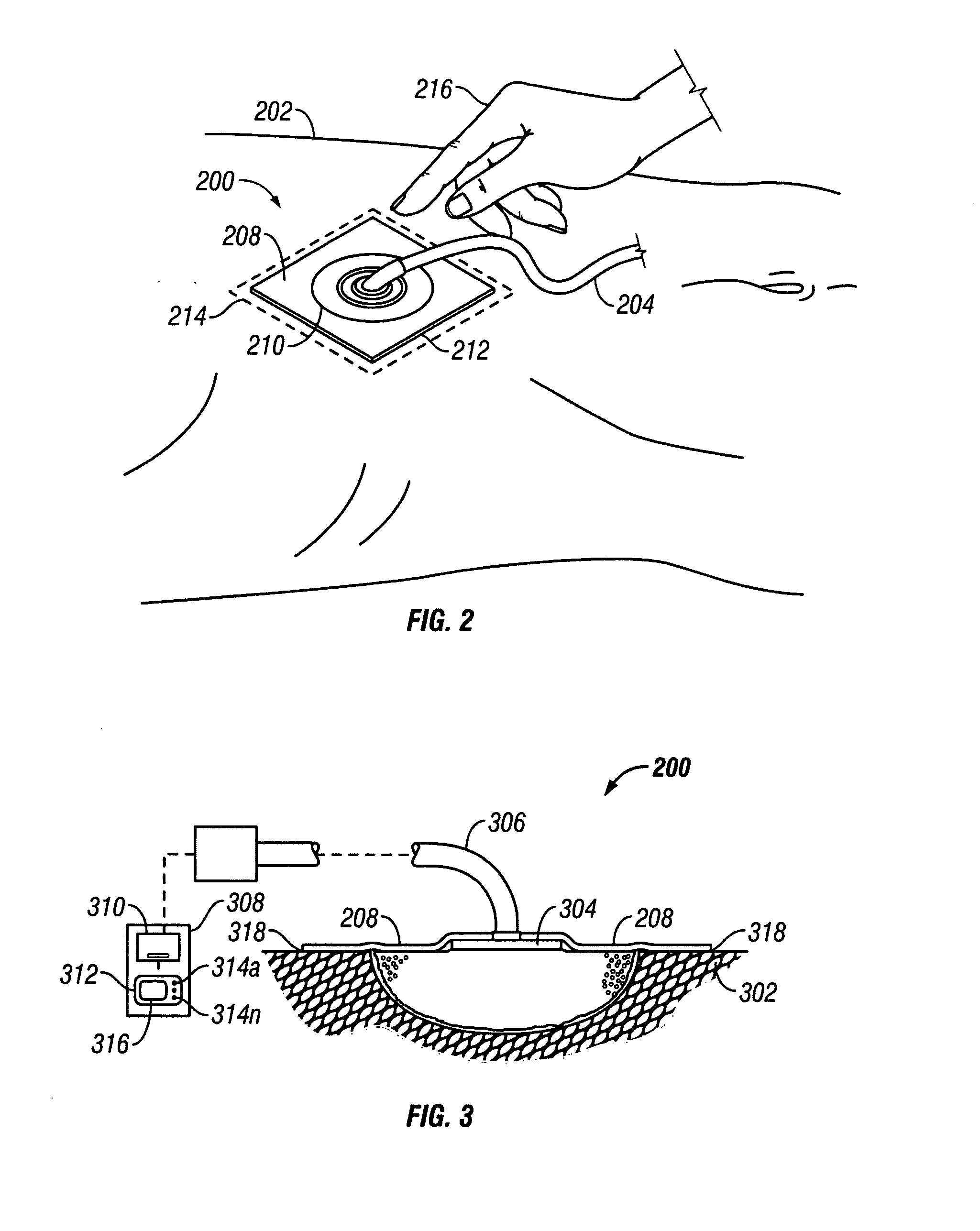

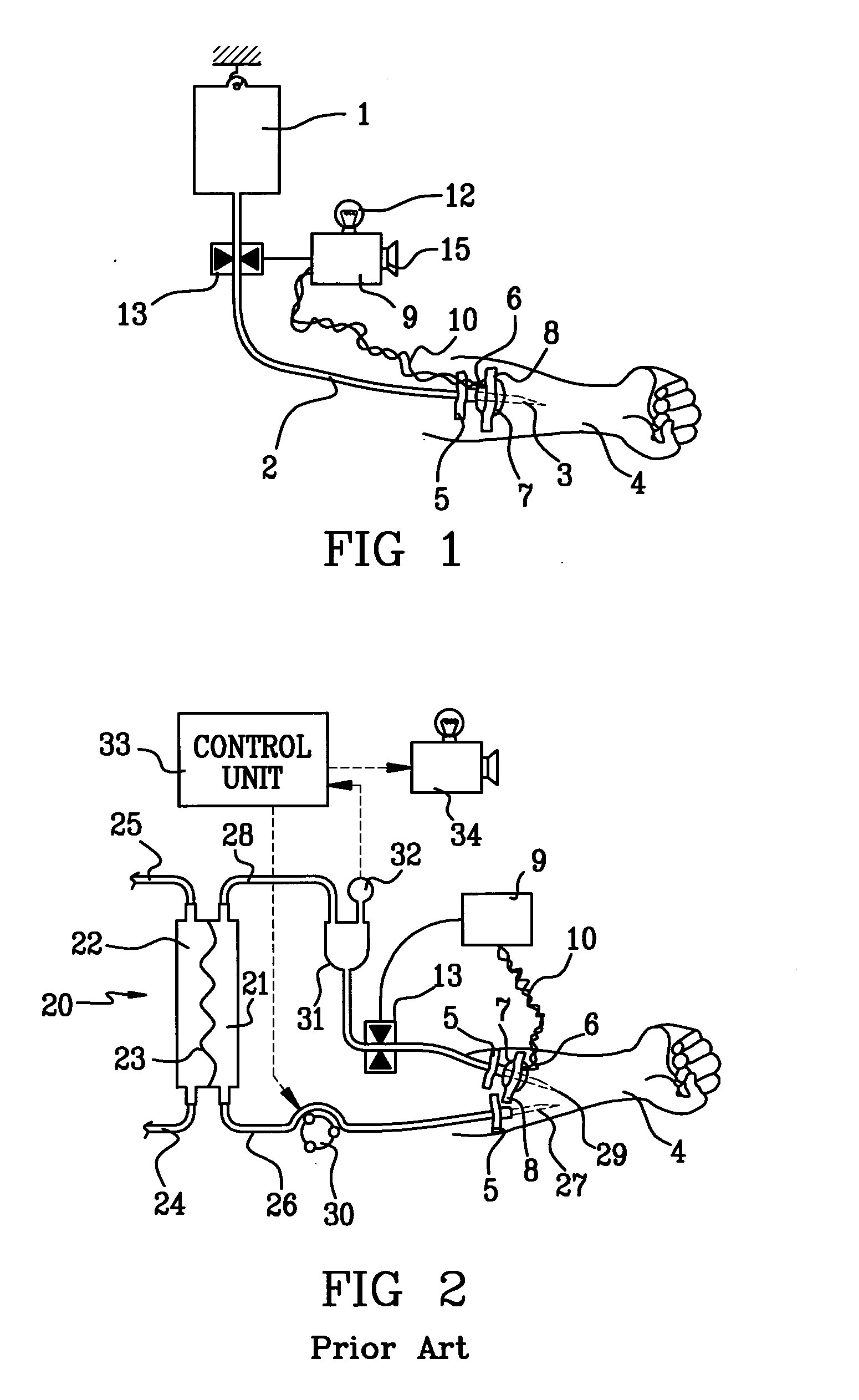

System and method for locating fluid leaks at a drape using sensing techniques

ActiveUS20110245682A1Avoid poor resultsLocation can be detectedDetection of fluid at leakage pointDiagnostics using lightUv spectrumBiomedical engineering

A system and method for determining location of a fluid leak at a drape of a reduced pressure delivery system being used on a tissue site of a patient may include applying a reduced pressure to the tissue site of the patient. The drape may be imaged to generate image data, and a determination of a location of a fluid leak of the drape may be made from the image data. As a result of the determination of the location of the fluid leak, the drape may be corrected. The imaging may be made in a non-visible spectrum. The non-visible spectrum may be in an IR spectrum or UV spectrum. In one embodiment, a fluid, such as compressed air, may be applied to the dressing via the interface between the drape and tissue of the patient to improve imaging in the non-visible spectrum.

Owner:3M INNOVATIVE PROPERTIES CO

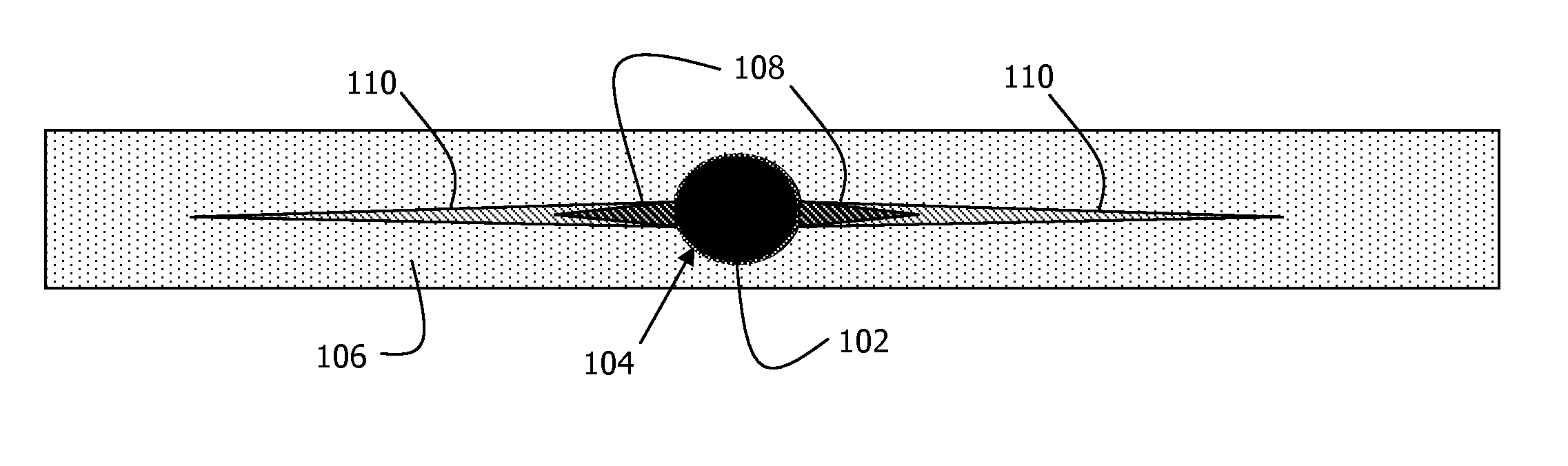

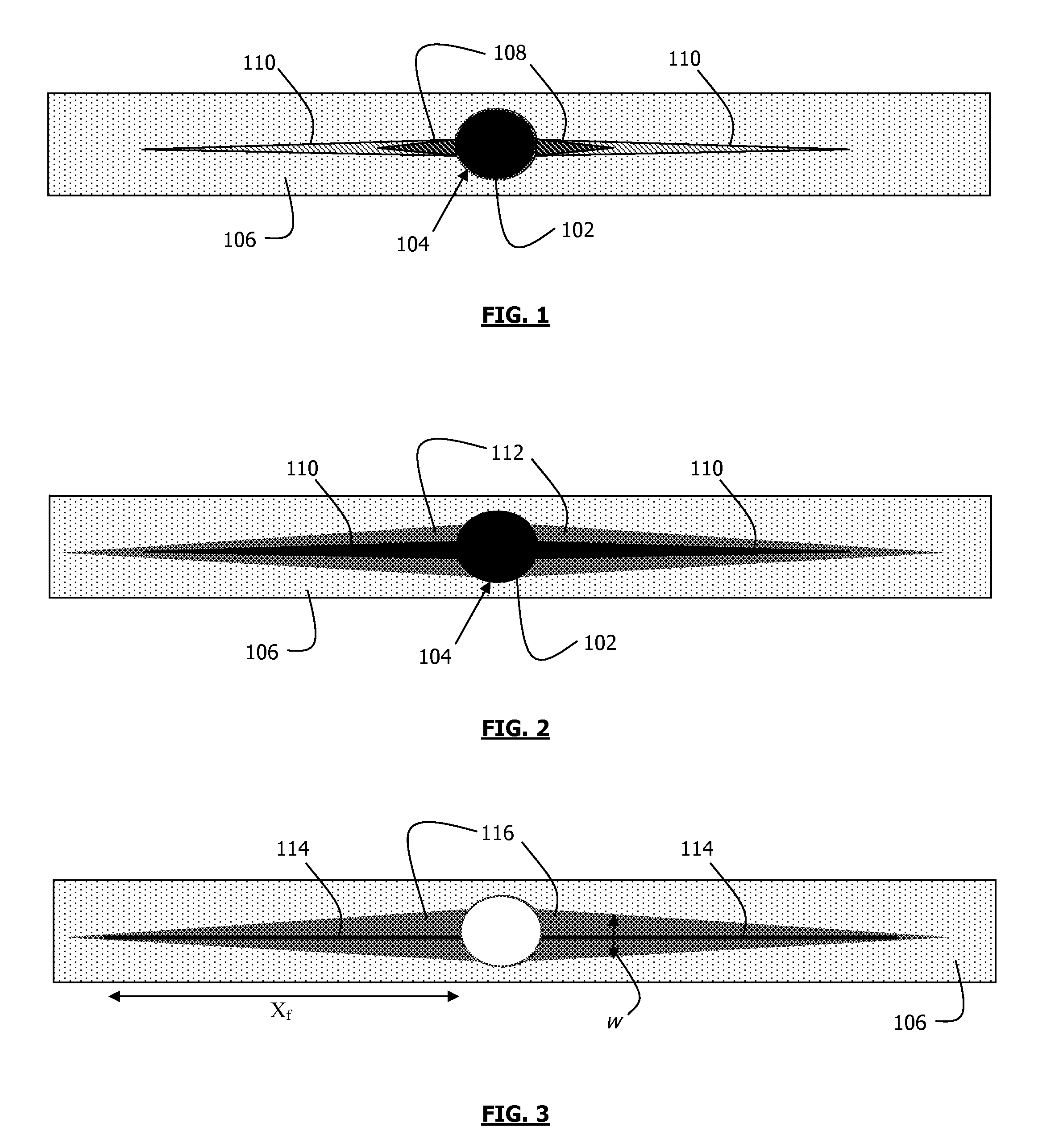

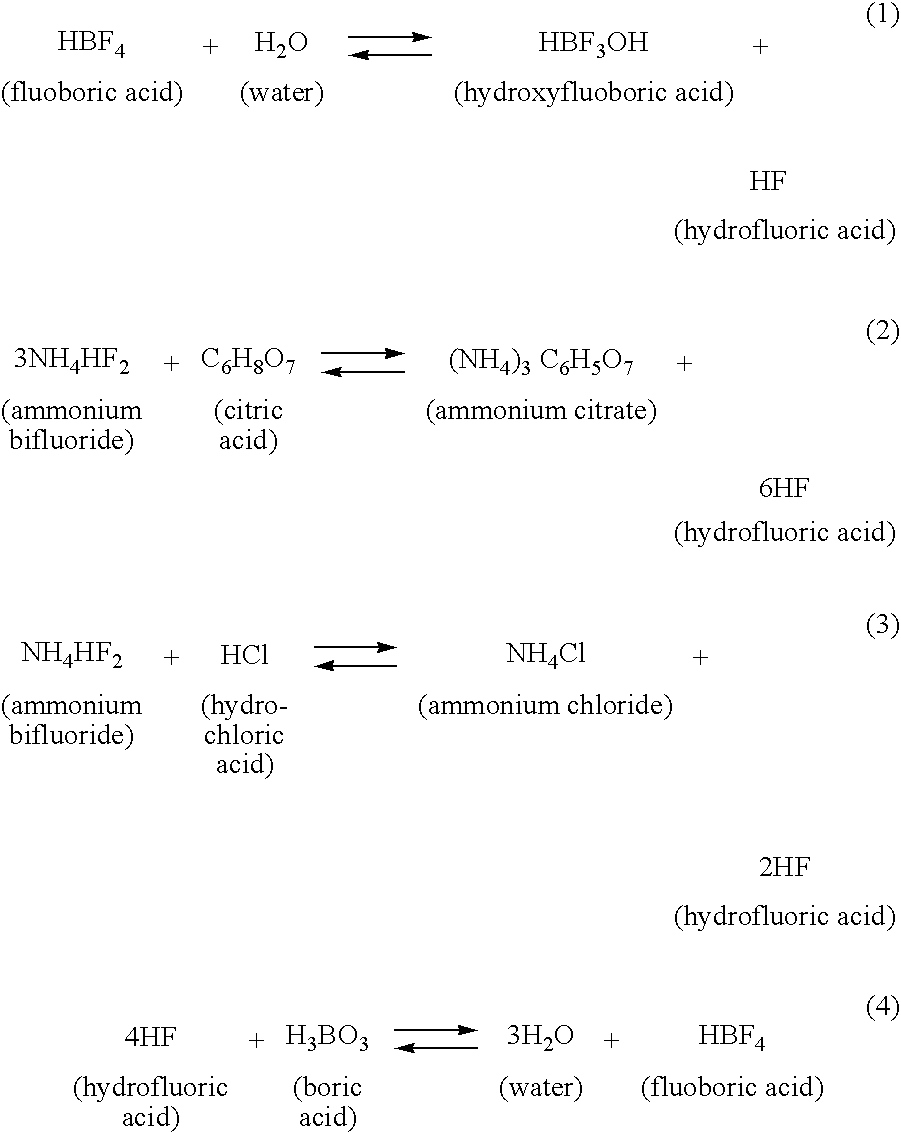

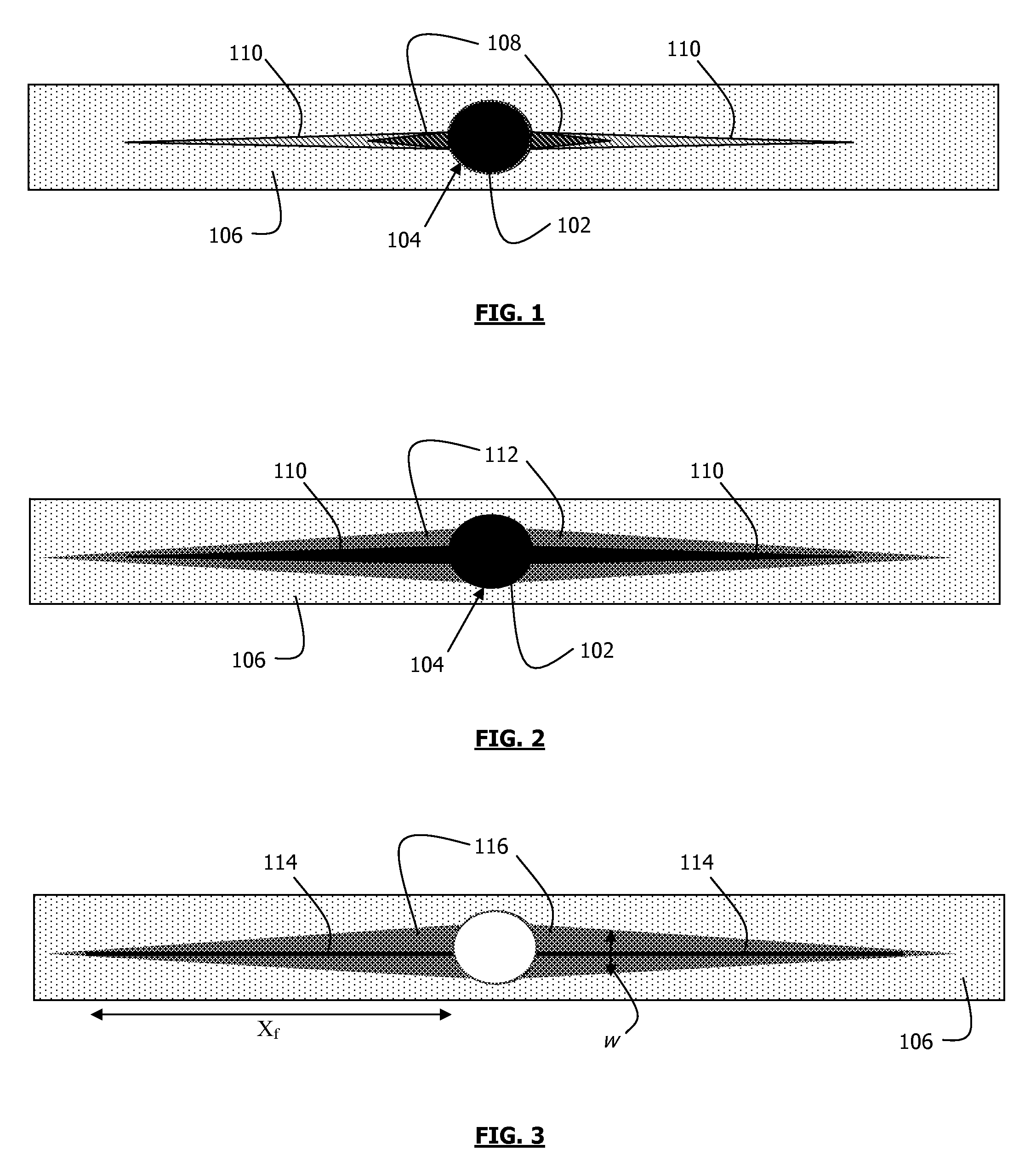

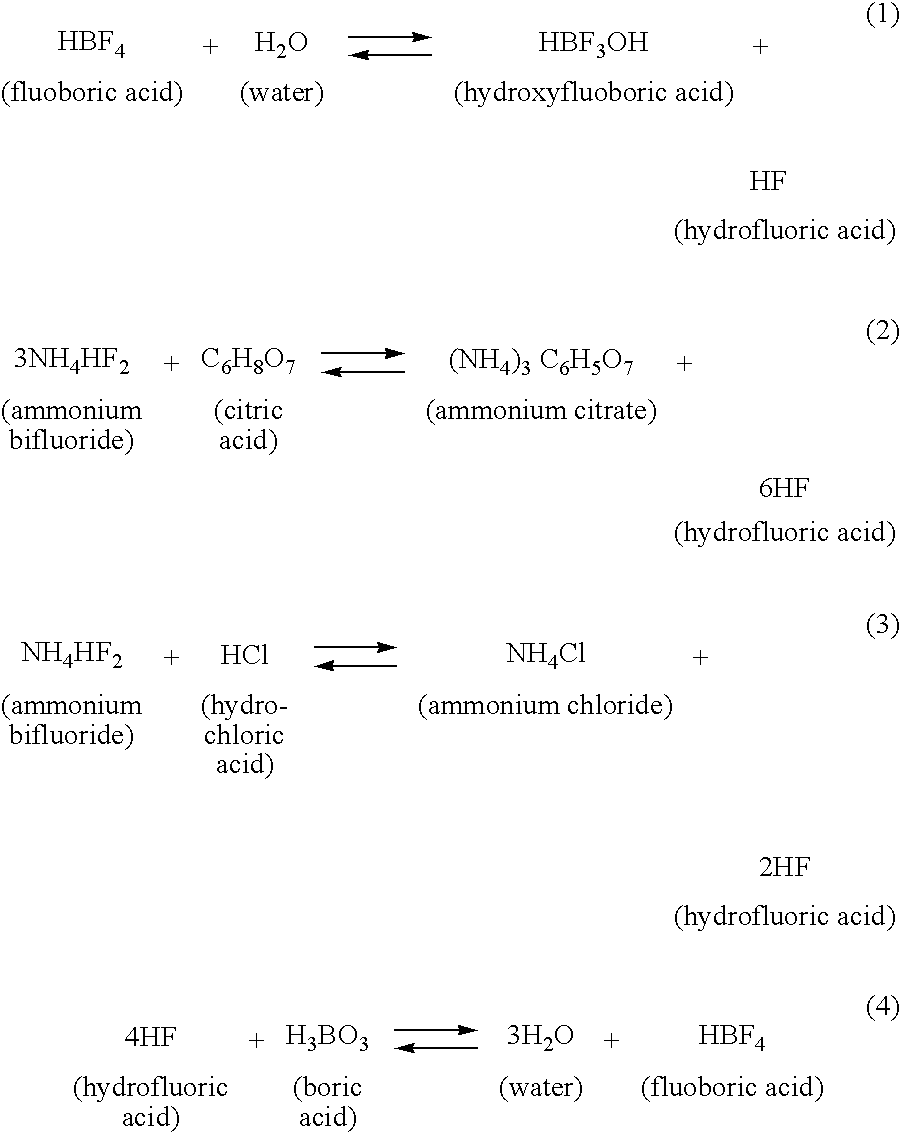

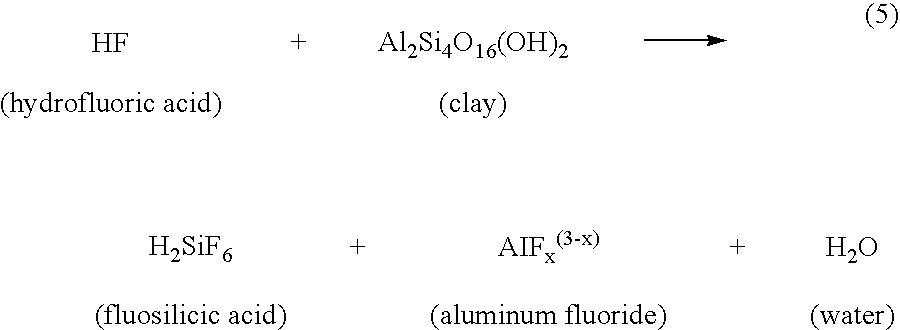

Method for Treating a Subterranean Formation

ActiveUS20070235189A1Improve permeabilityReduce penetrationFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

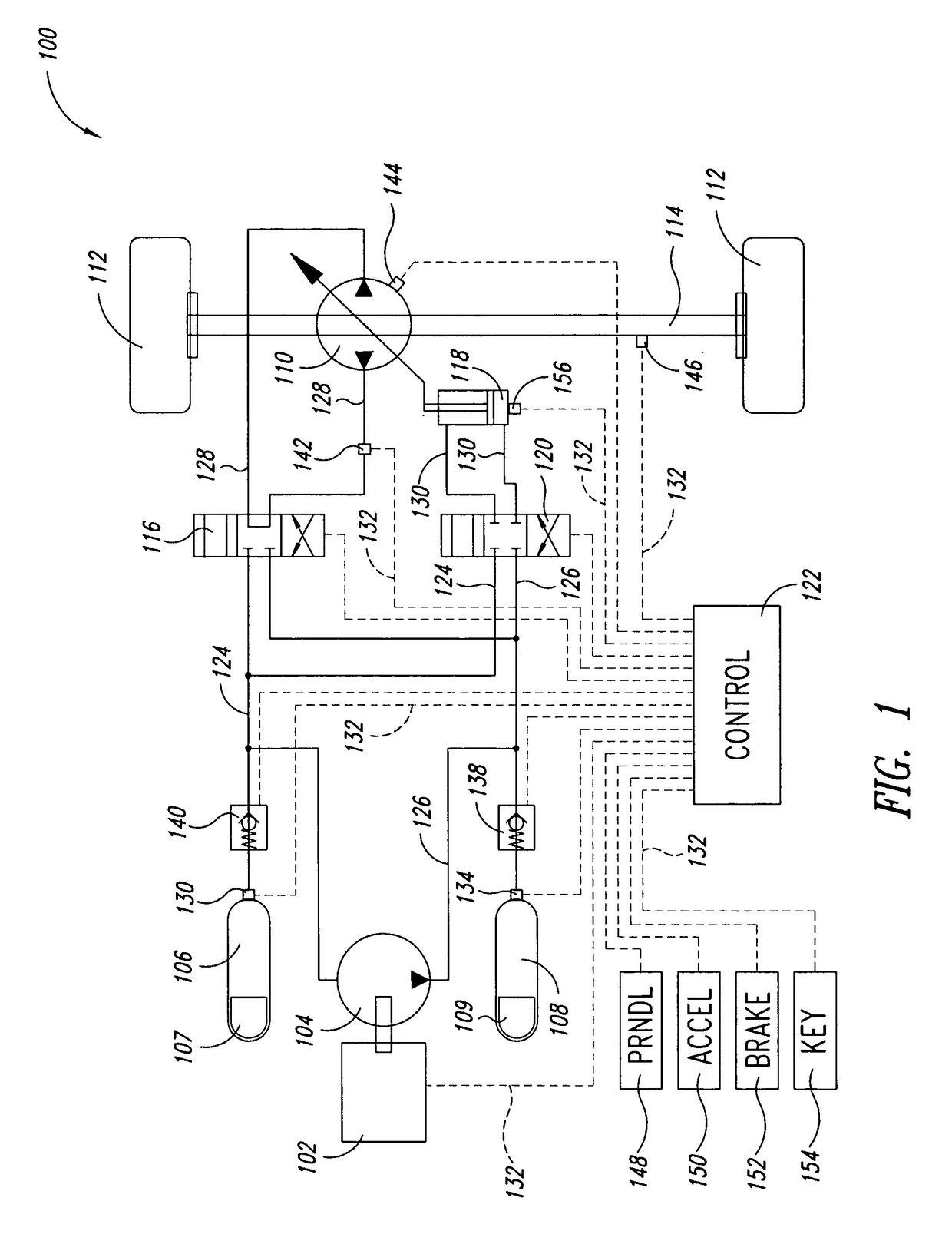

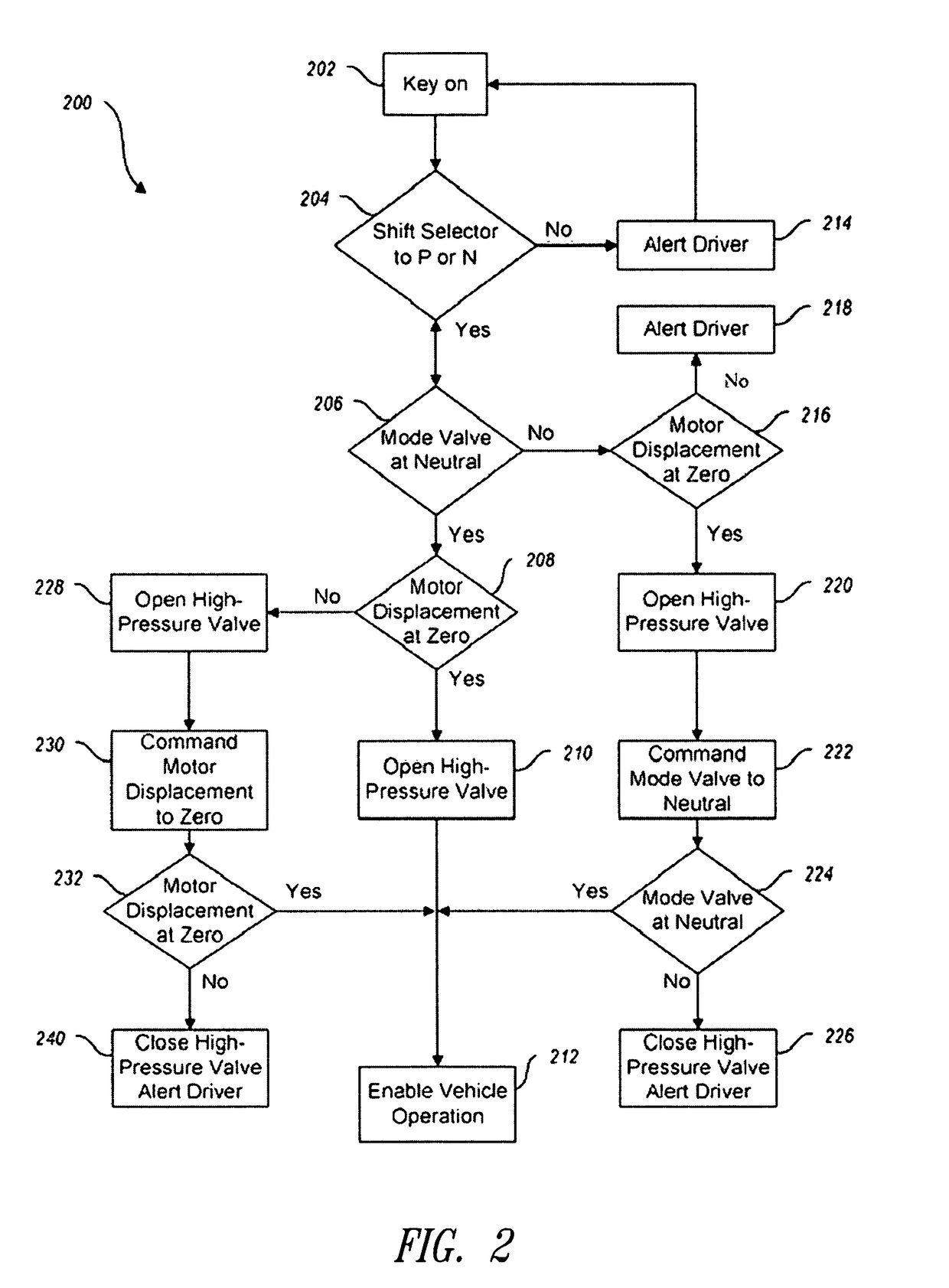

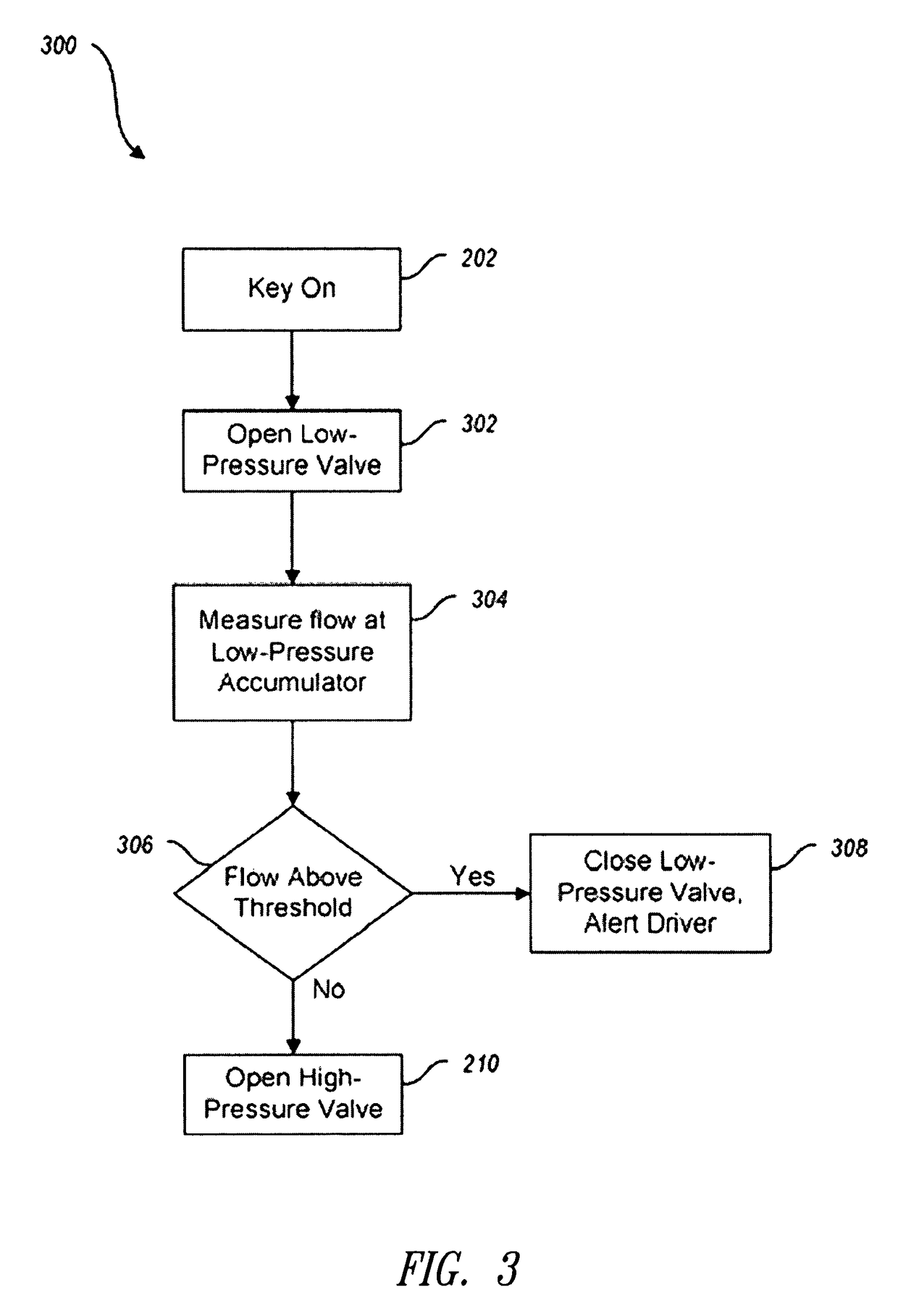

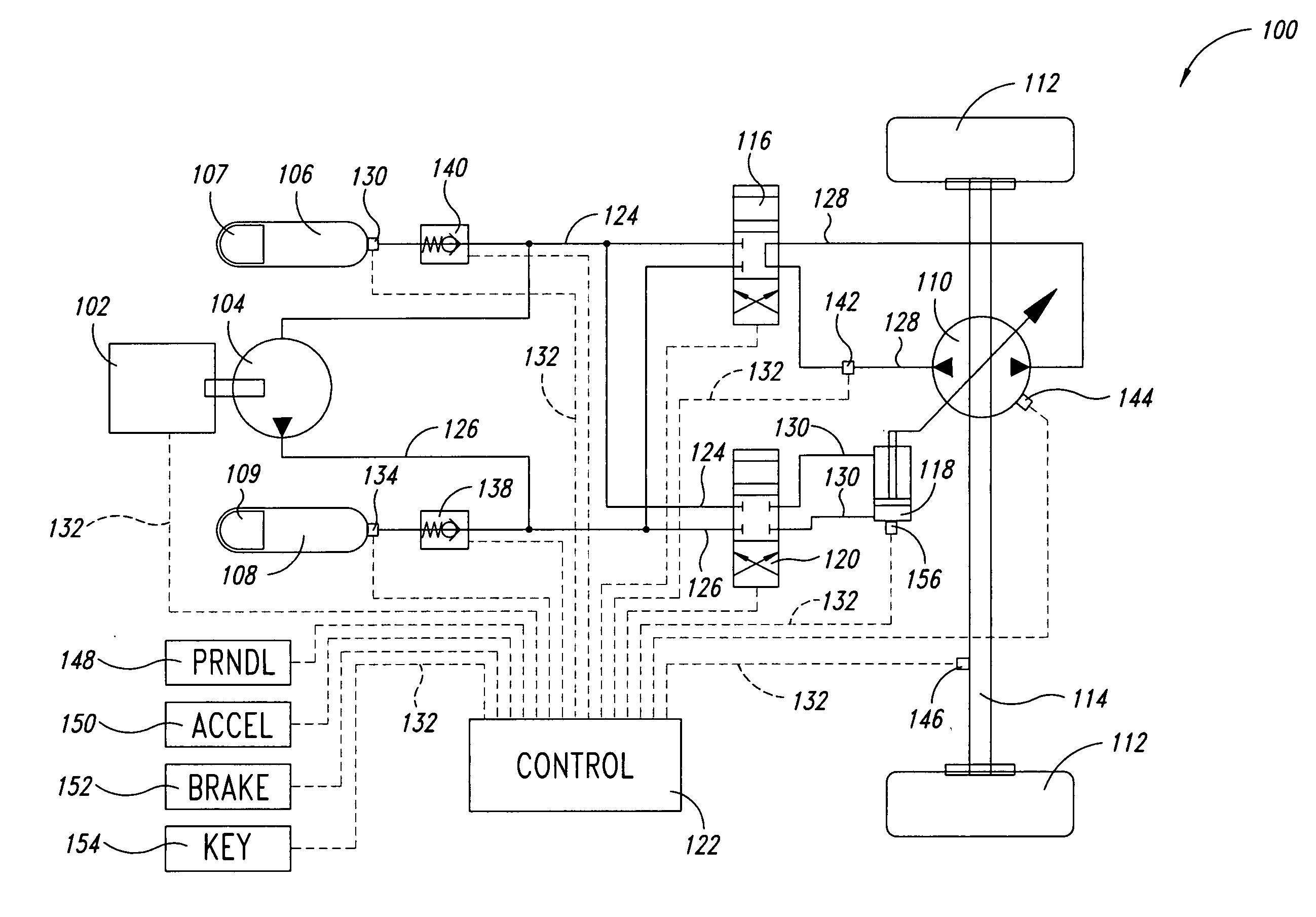

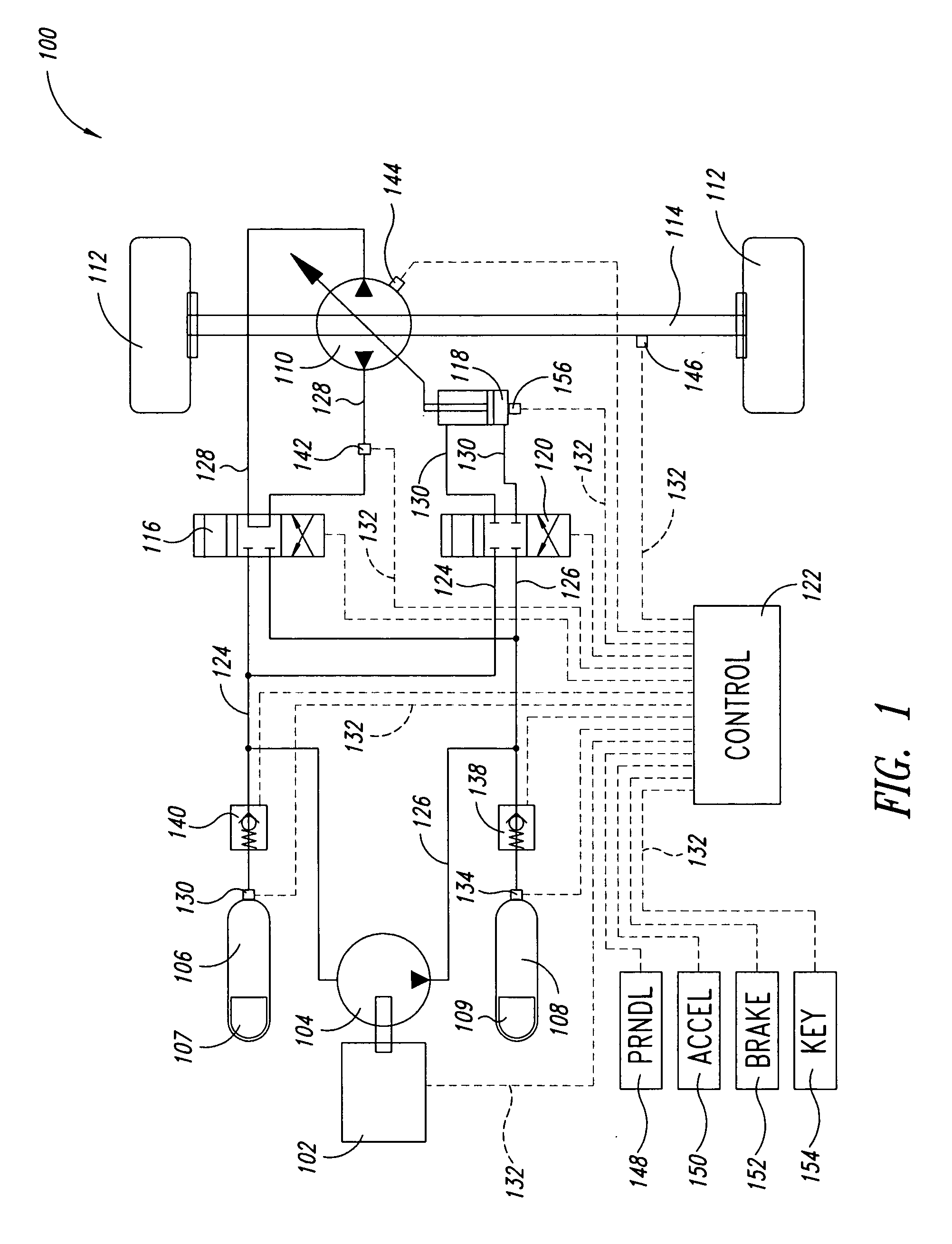

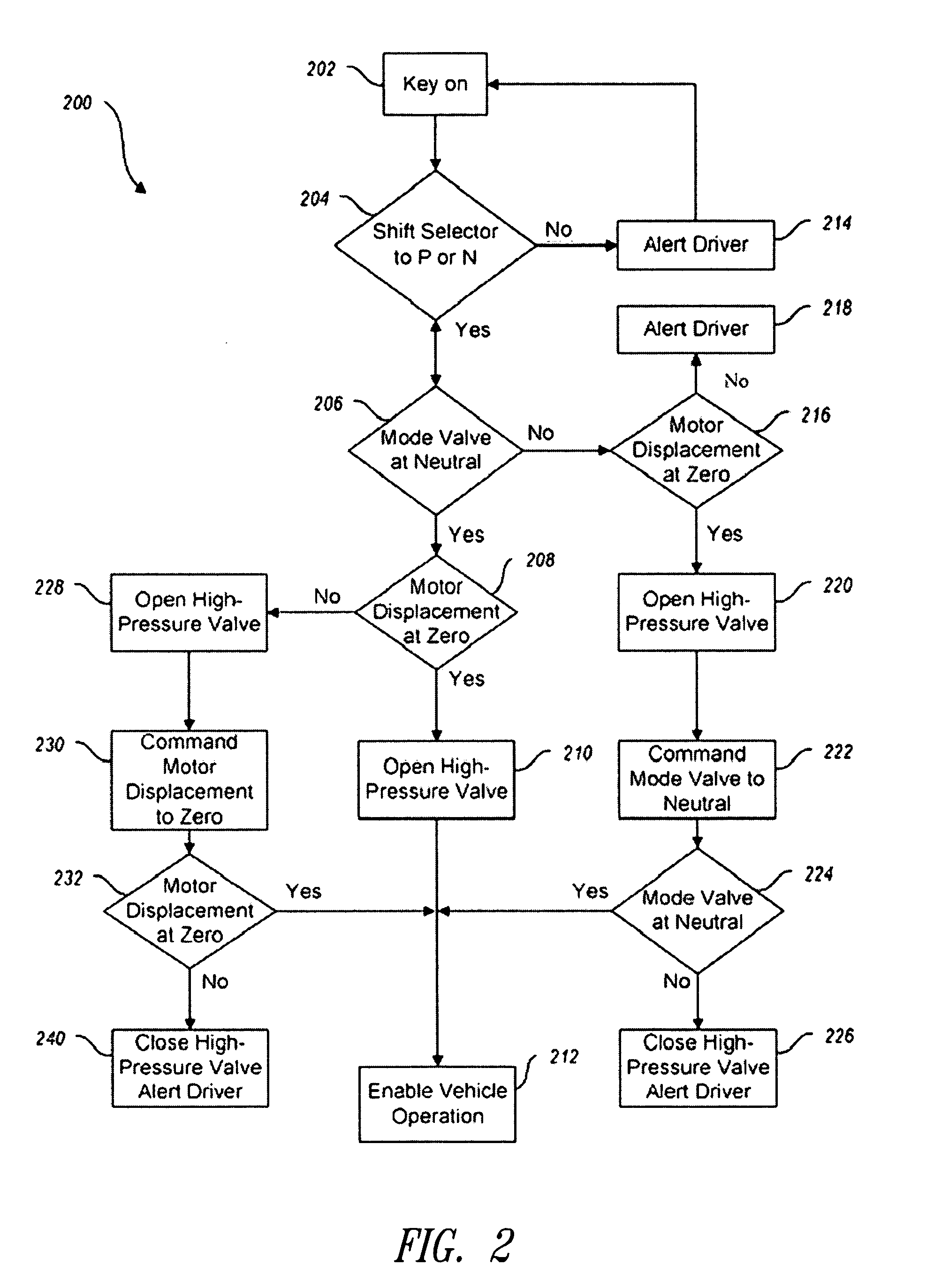

Hydraulic hybrid vehicle method of safe operation

InactiveUS8118132B2Gearing controlPlural diverse prime-mover propulsion mountingExternal combustion engineMode control

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENIVERONMENTAL PROTECTION AGENCY

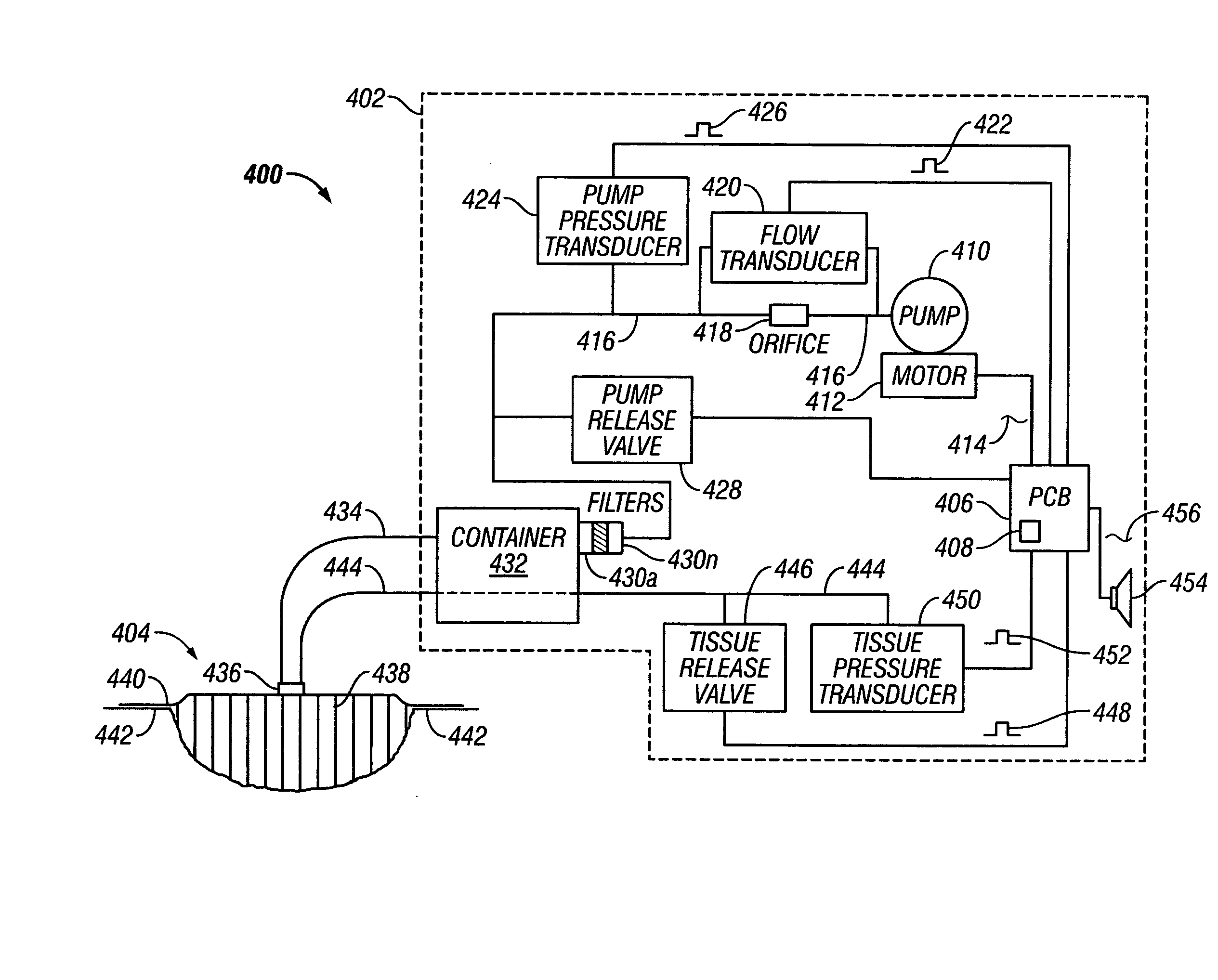

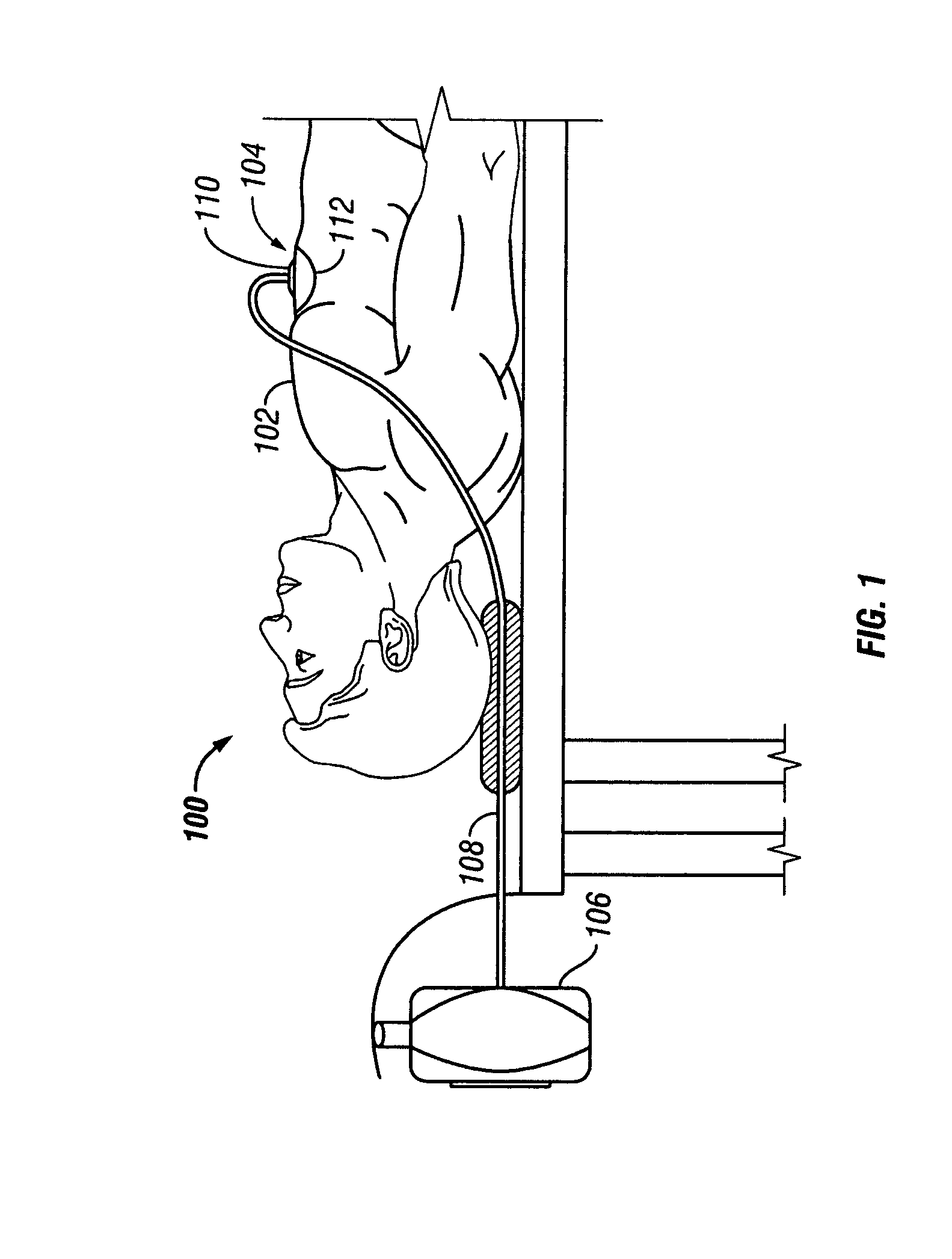

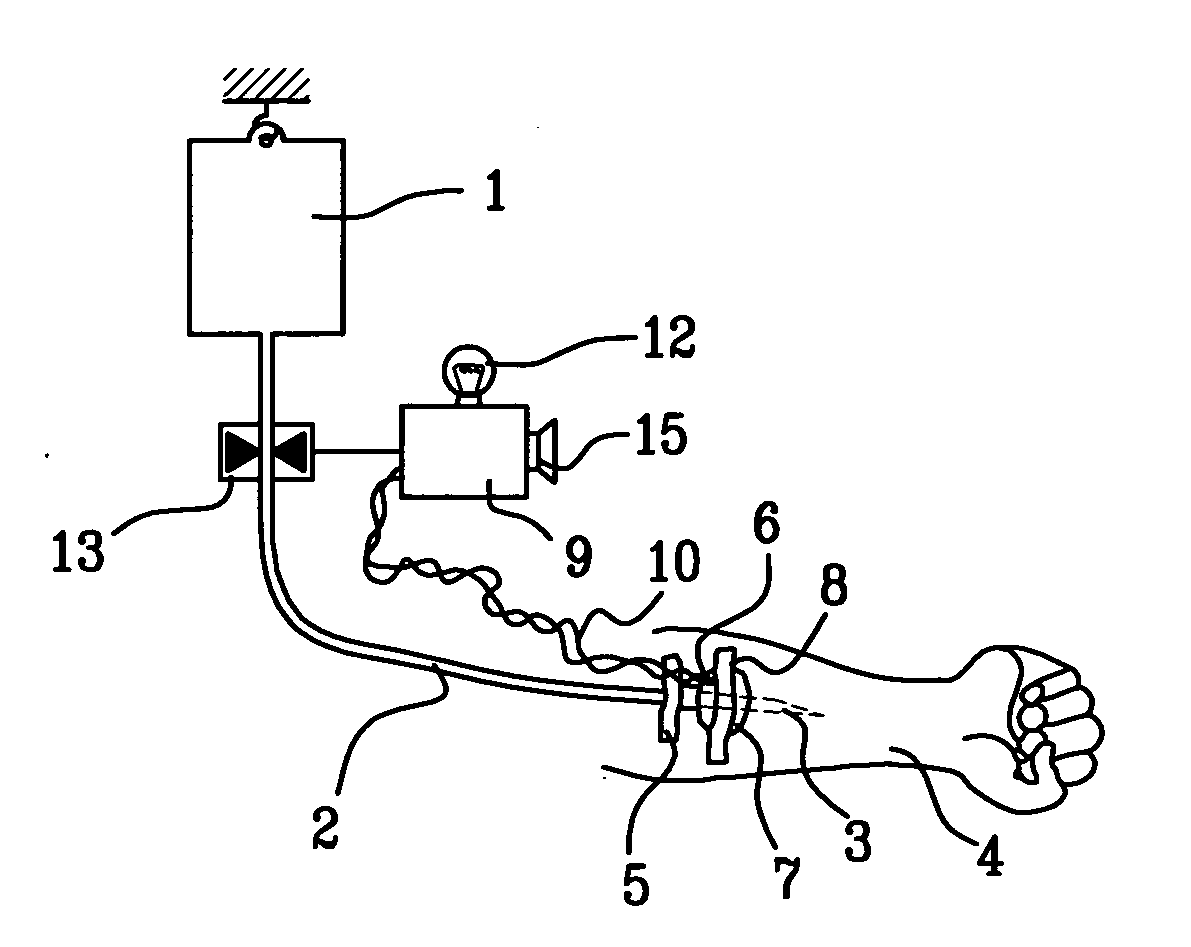

System and method for locating fluid leaks at a drape of a reduced pressure delivery system

A system and method for performing tissue therapy may include applying a reduced pressure to a tissue site of a patient. A fluid parameter associated with applying a reduced pressureto the tissue site may be sensed. An audible fluid leak location sound may be generated in response to sensing the fluid parameter. The audible fluid leak location sound may be altered in response to sensing that the fluid parameter changes. By altering the audible fluid leak location sound in response to sensing a change of the fluid parameter, a clinician may detect location of a fluid leak at the drape by applying force to the drape. The force applied to the drape may be a clinician pressing a finger onto an edge of the drape.

Owner:SOLVENTUM INTPROP CO

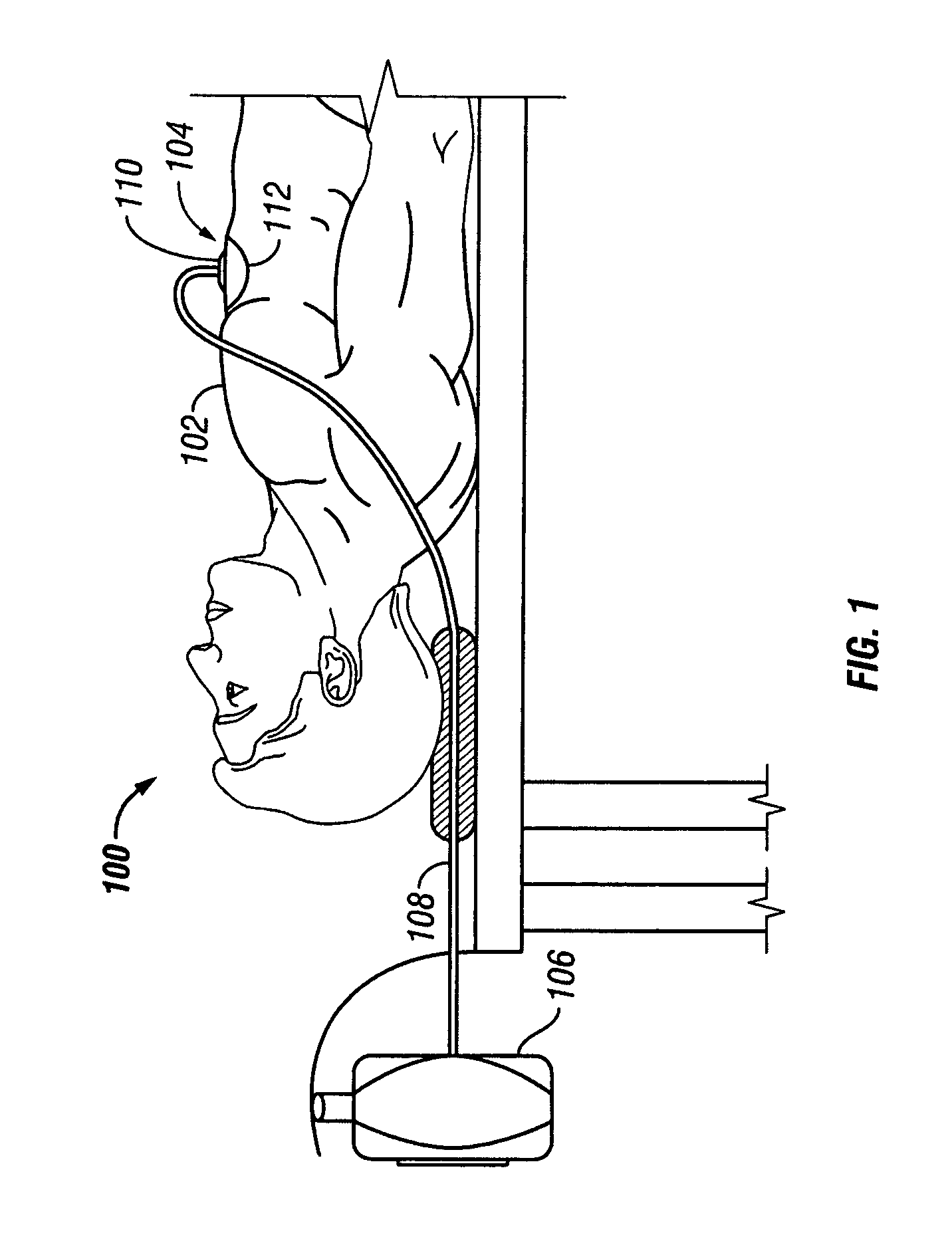

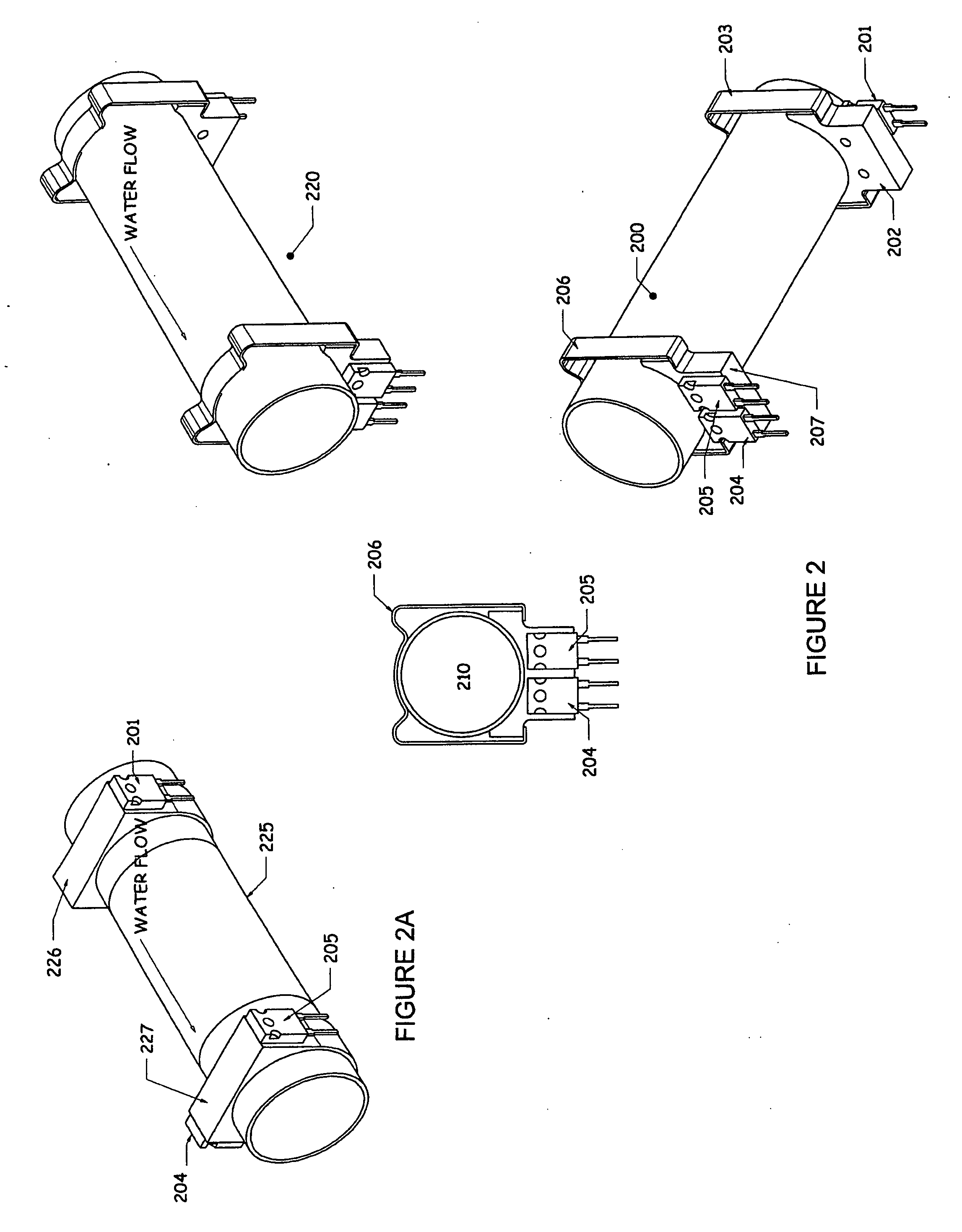

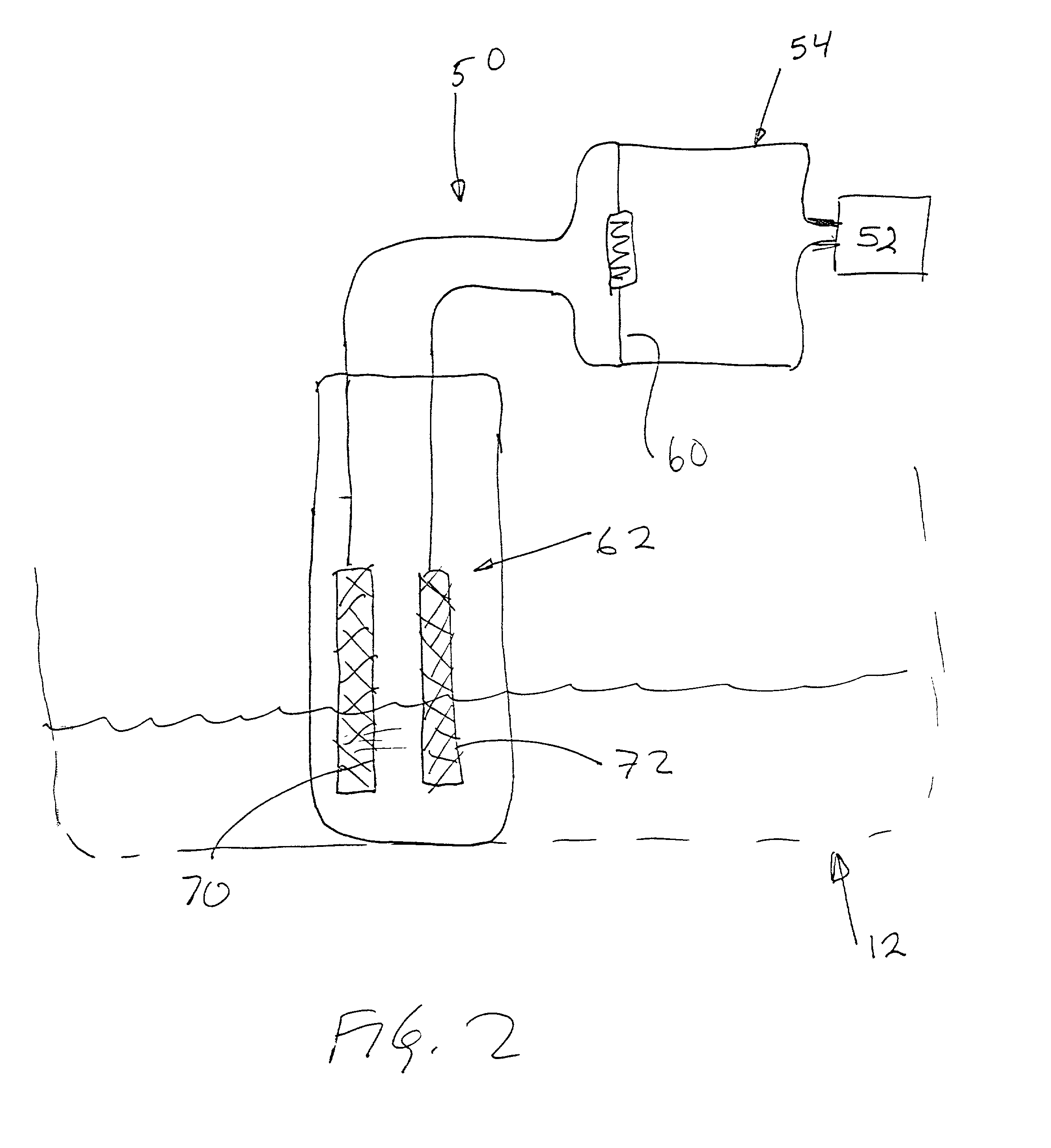

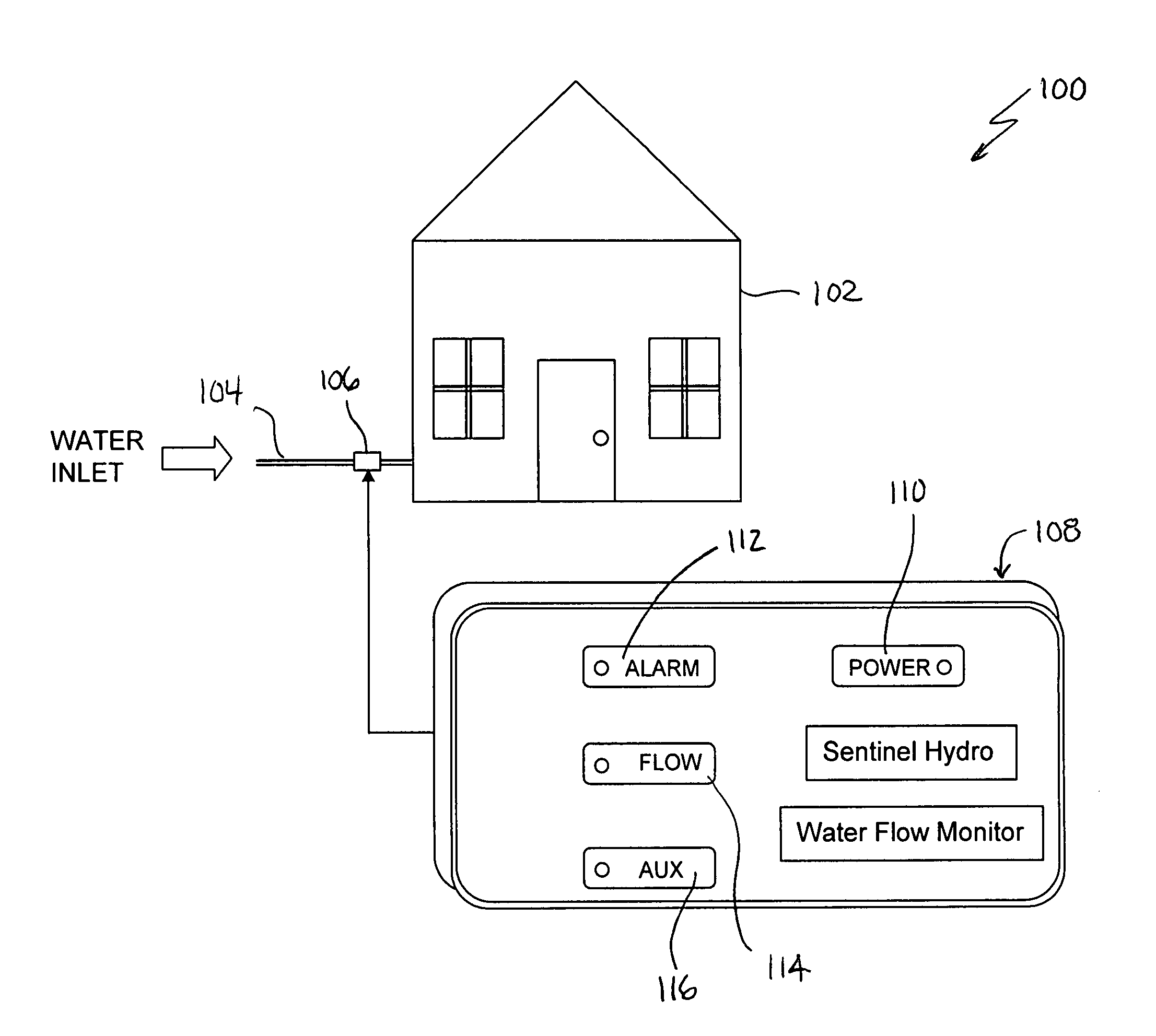

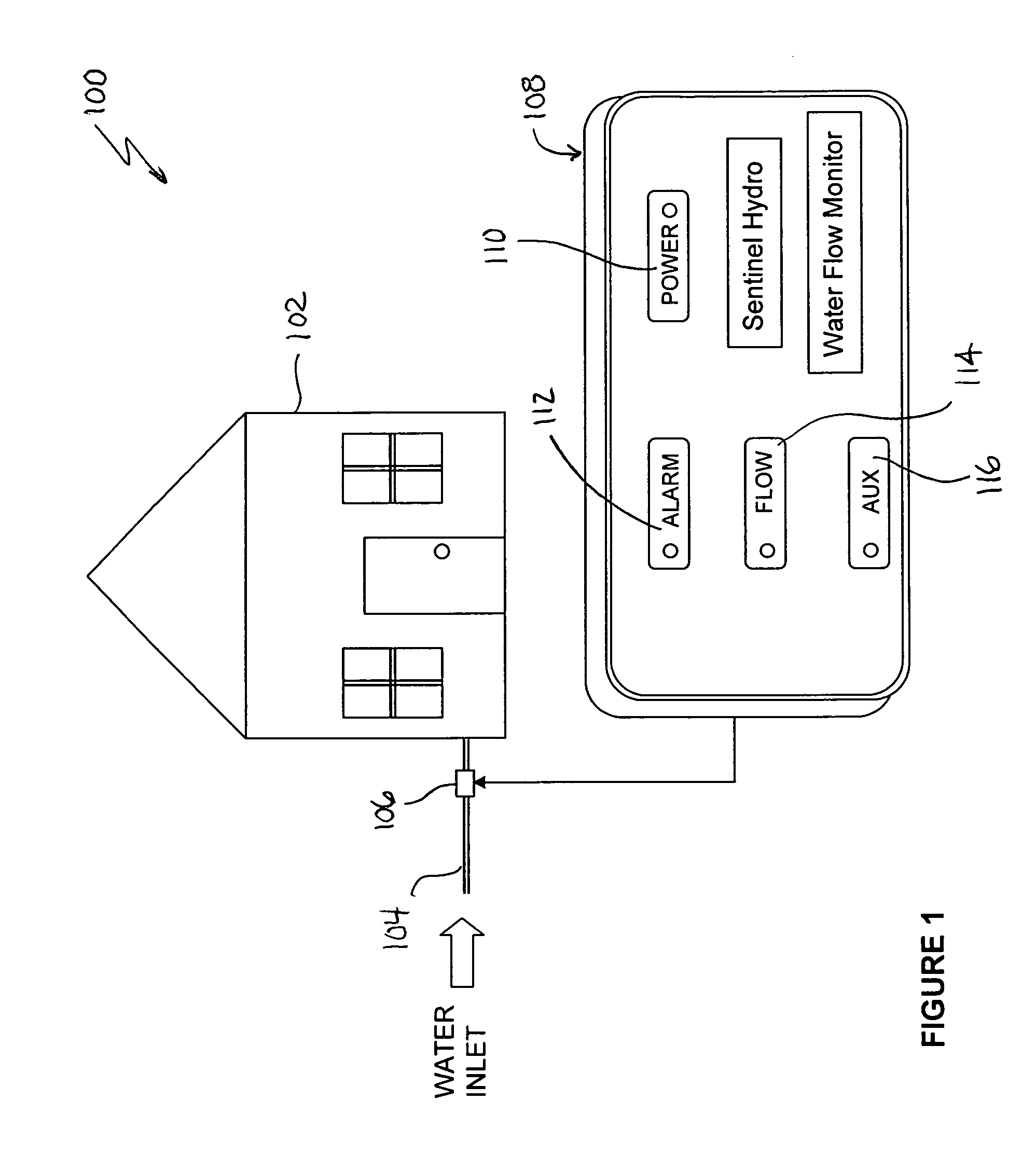

Non-invasive Thermal Dispersion Flow Meter with Chronometric Monitor for Fluid Leak Detection

ActiveUS20120180877A1Conservation promotedCost promotedDetection of fluid at leakage pointOperating means/releasing devices for valvesPropagation timeEngineering

A non-invasive thermal dispersion flow meter with chronometric monitor for fluid leak detection includes a heater, an ambient temperature sensor and a flow rate sensor which are configured to sense the temperature of a fluid in a conduit, and then monitor the flow of that fluid through the conduit. The fluid flow sensor is incorporated into a Wheatstone bridge circuit which is used to provide increased sensitivity to the outputs of the sensors. Based upon the ambient temperature sensor readings, the flow rate sensor and heater may be adjusted to optimize the operation of the system to detect leaks. An alternative embodiment utilizes a single sensor and separate heater which work together to determine heat propagation times which in turn is used to calculate flow rate.

Owner:SENTINEL HYDROSOLUTIONS

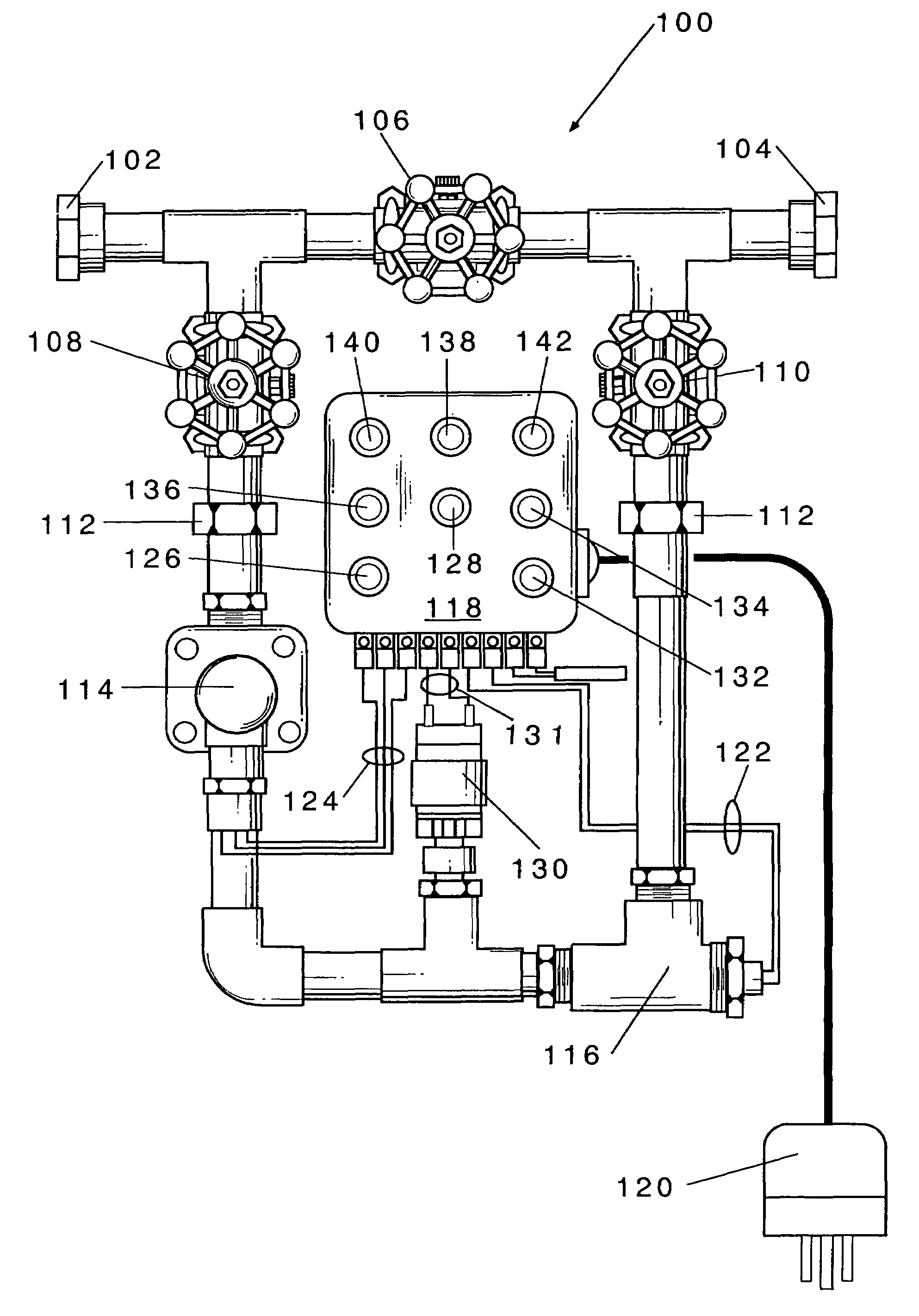

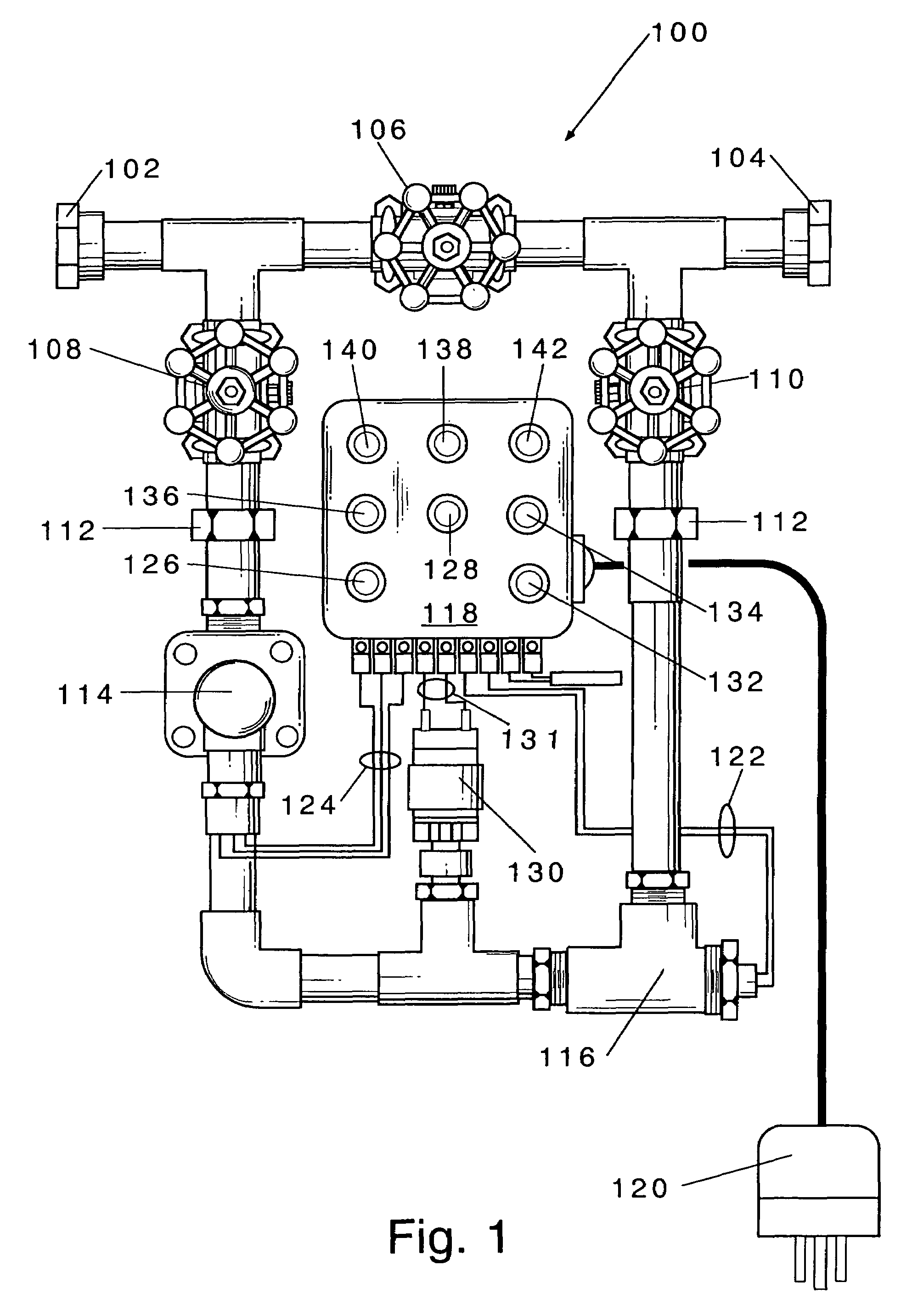

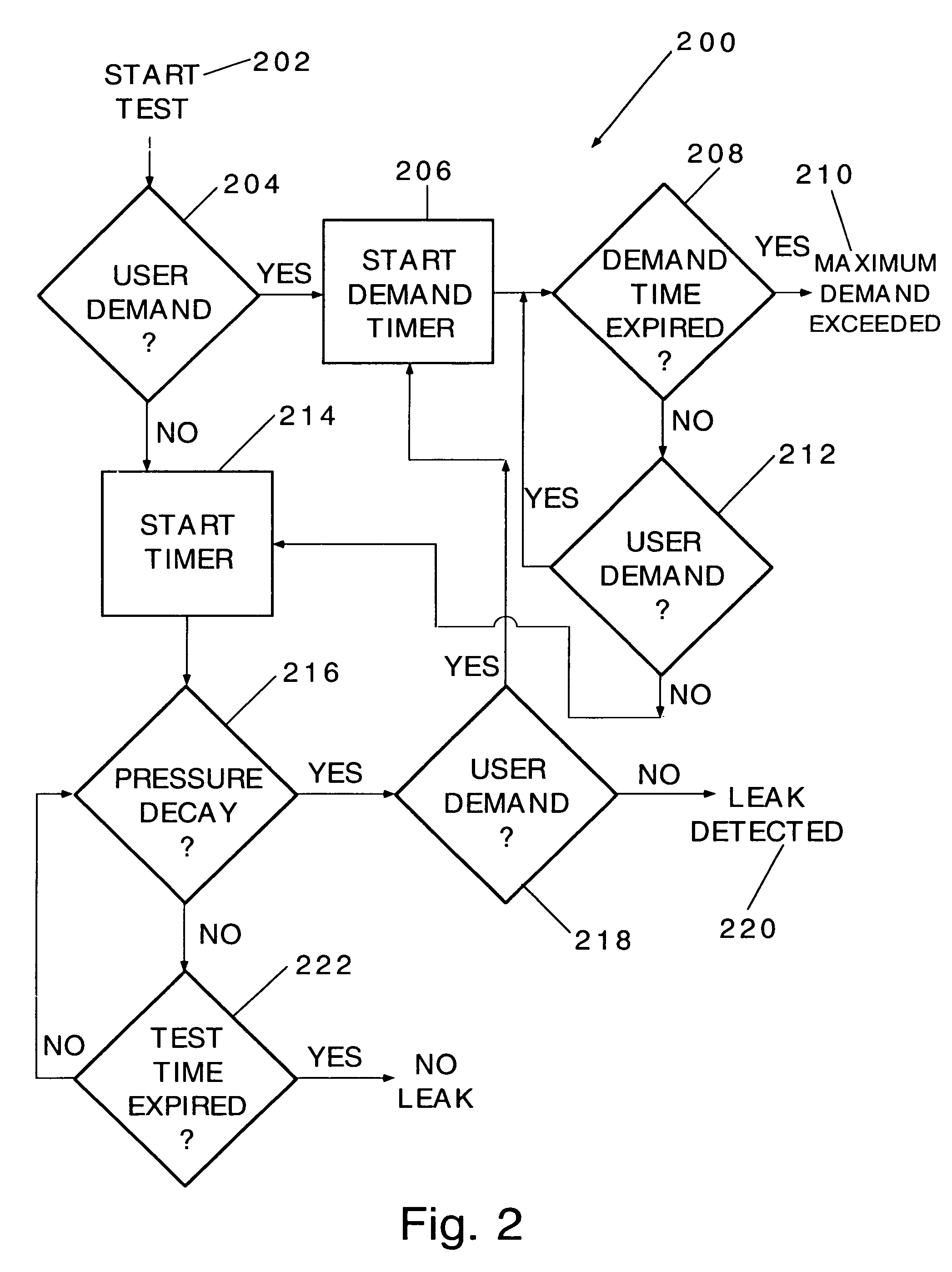

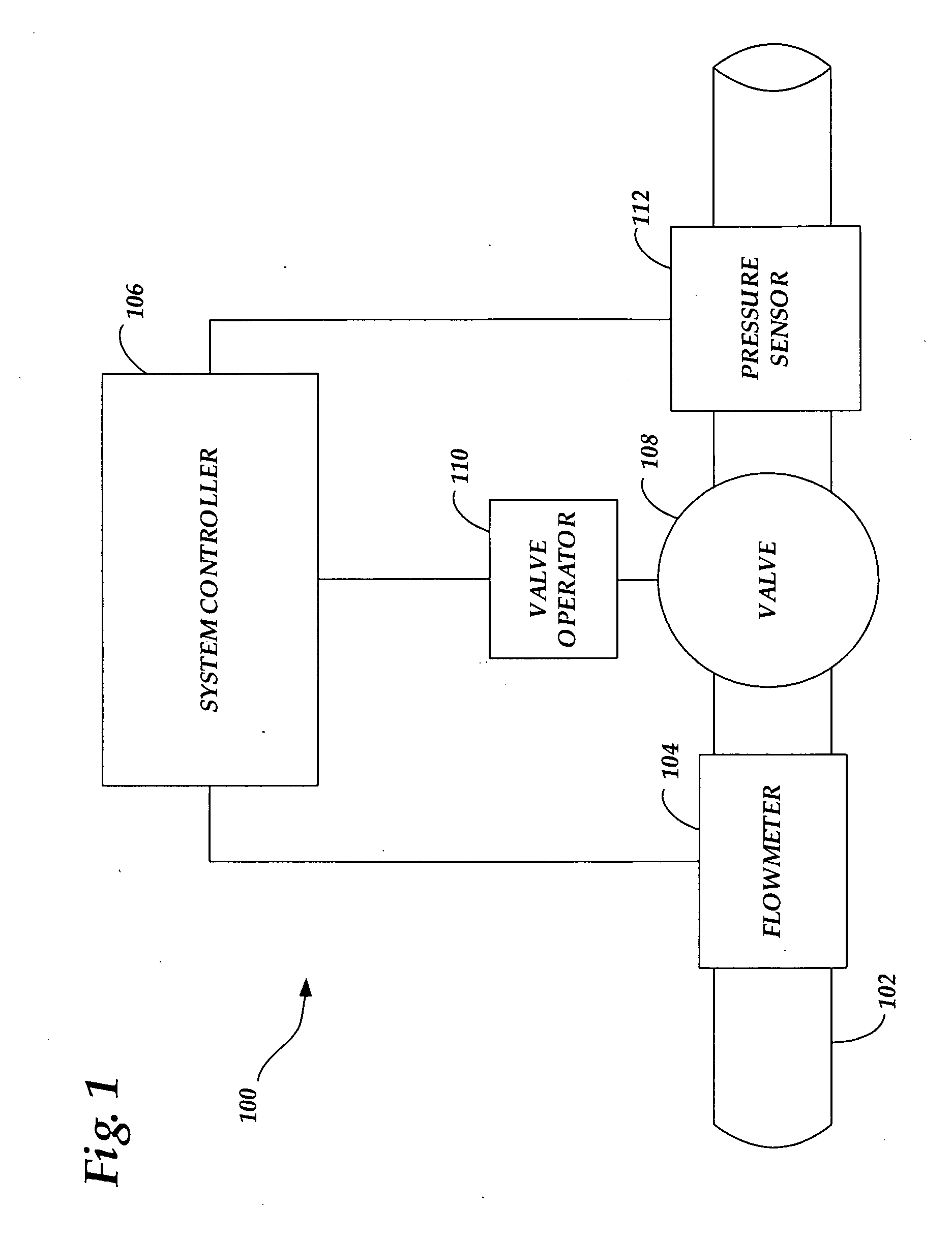

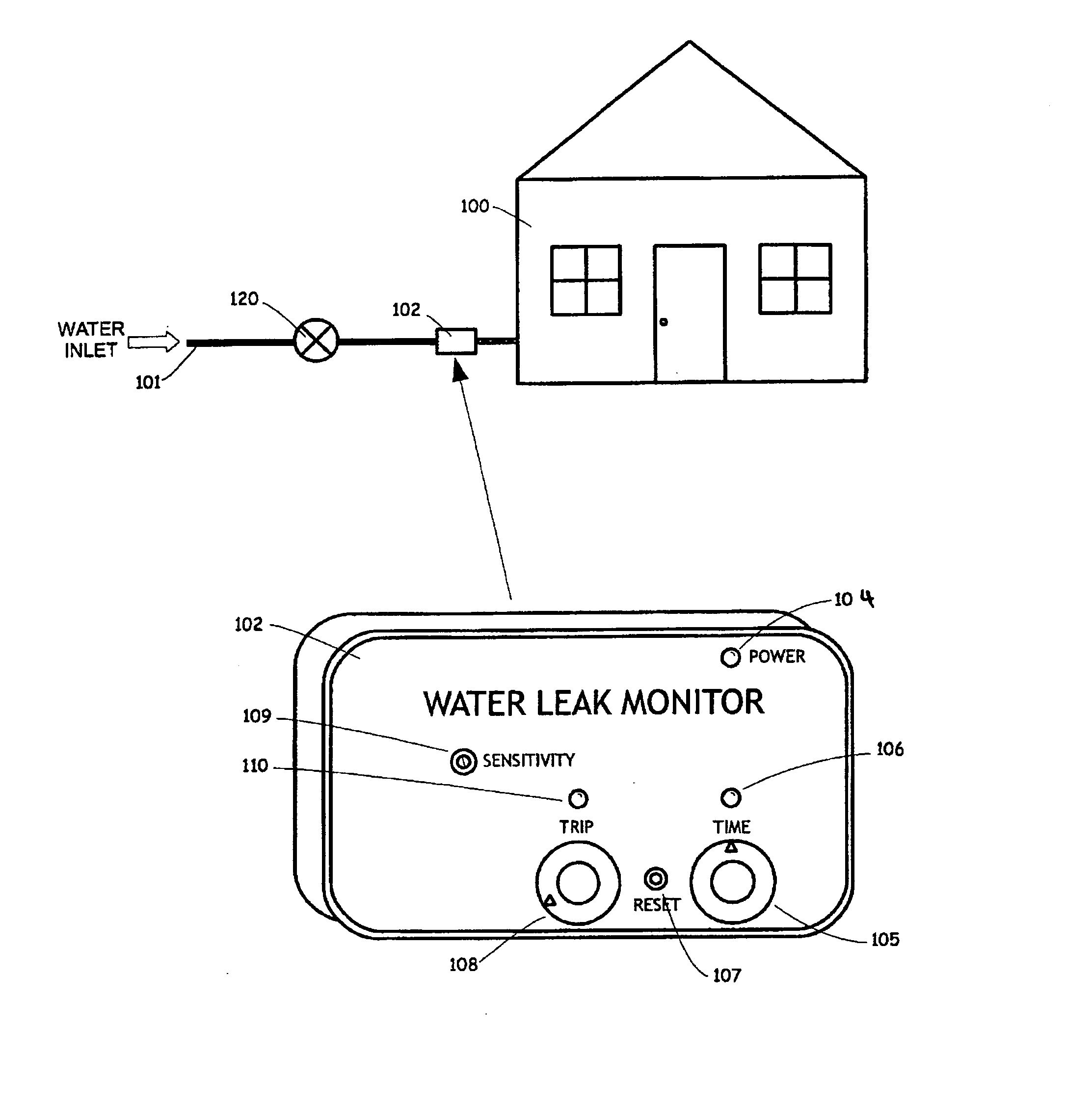

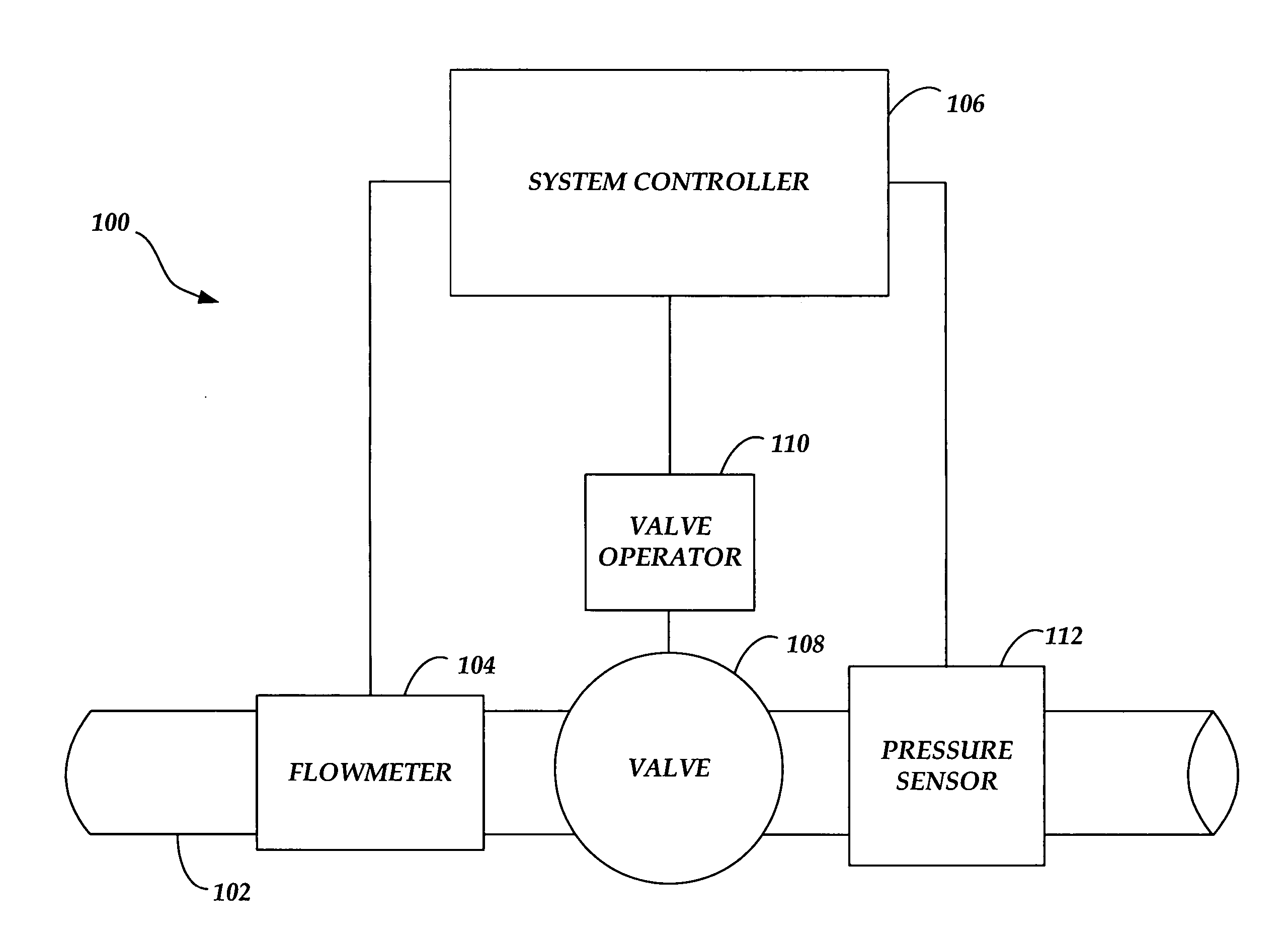

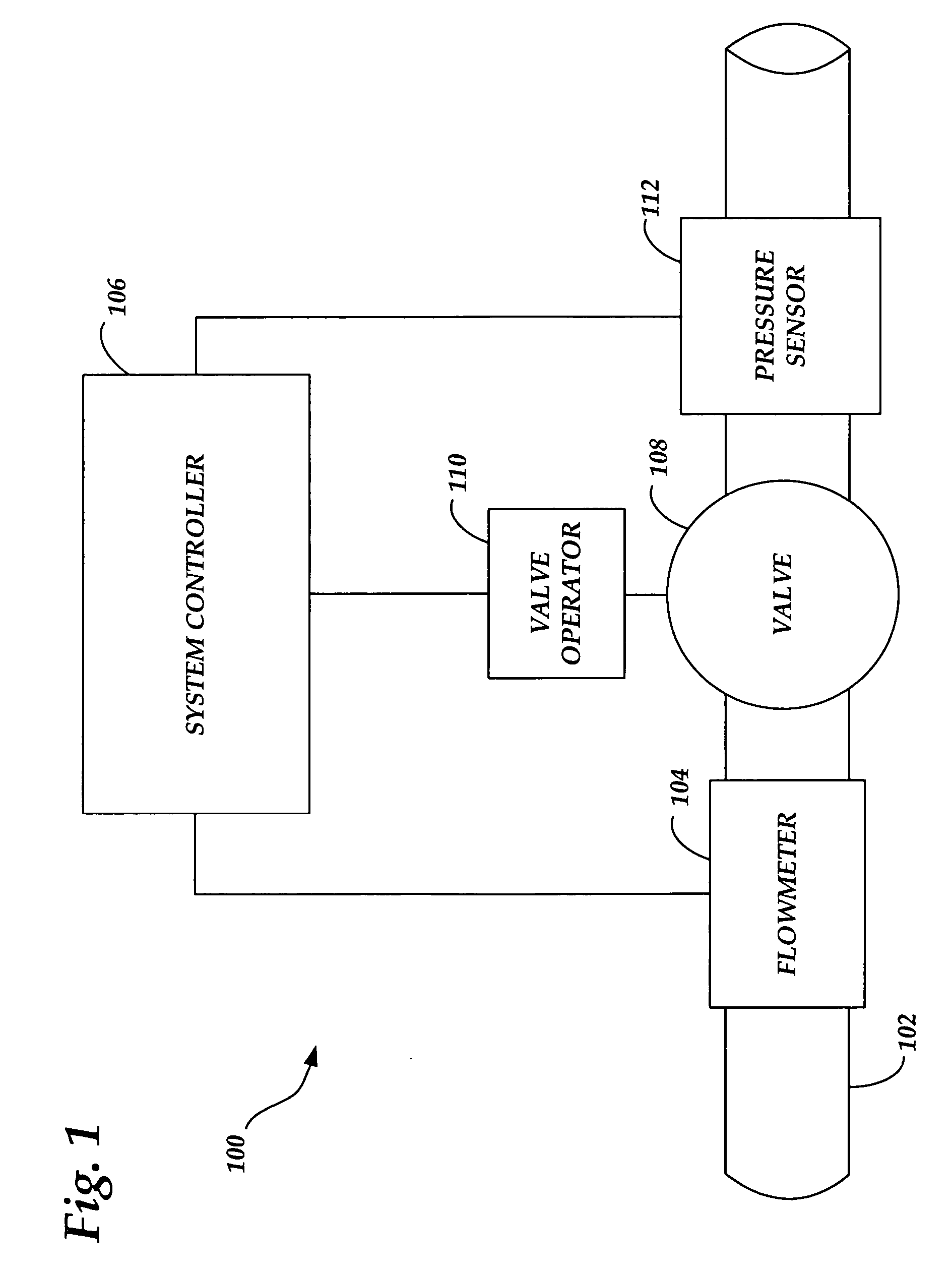

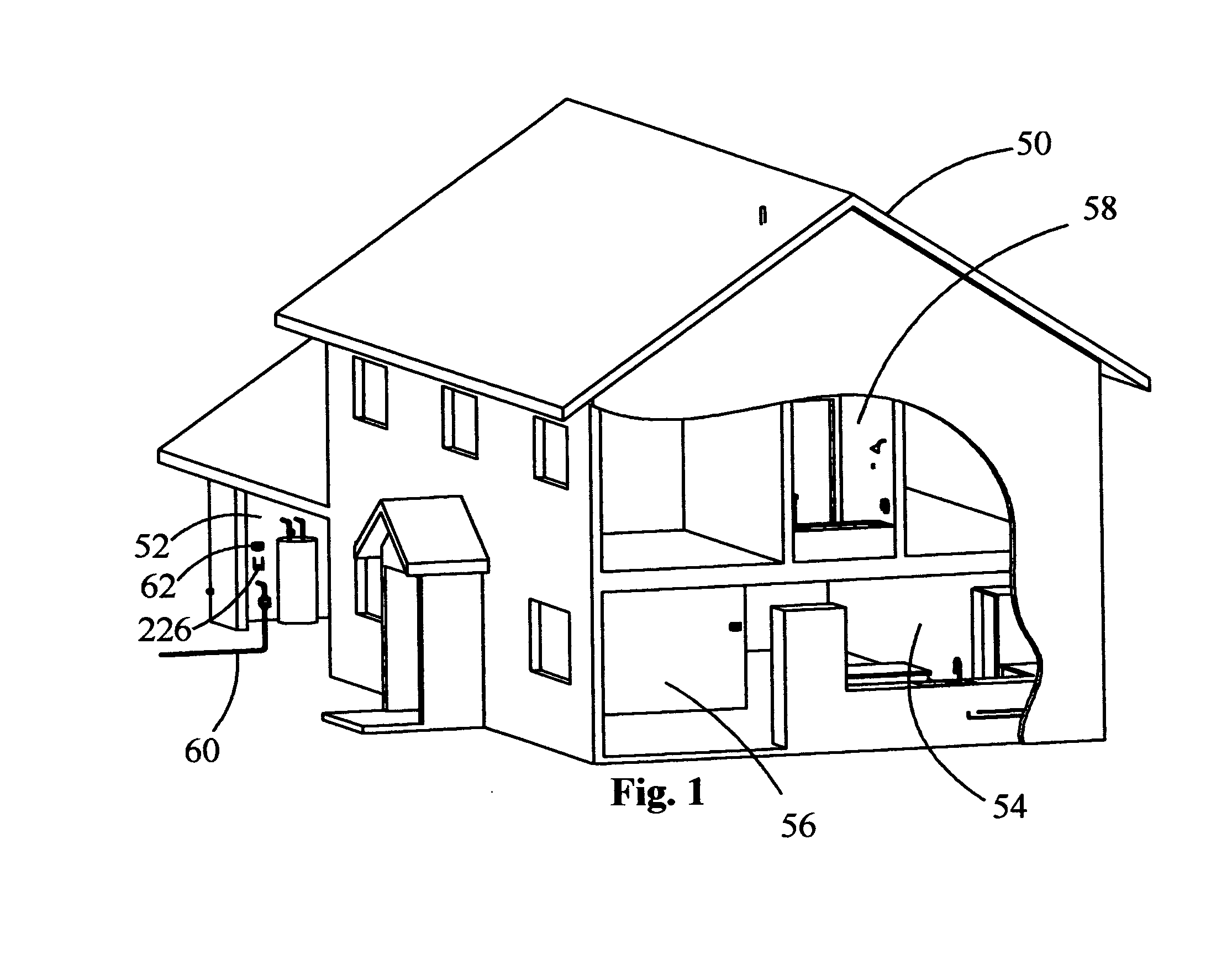

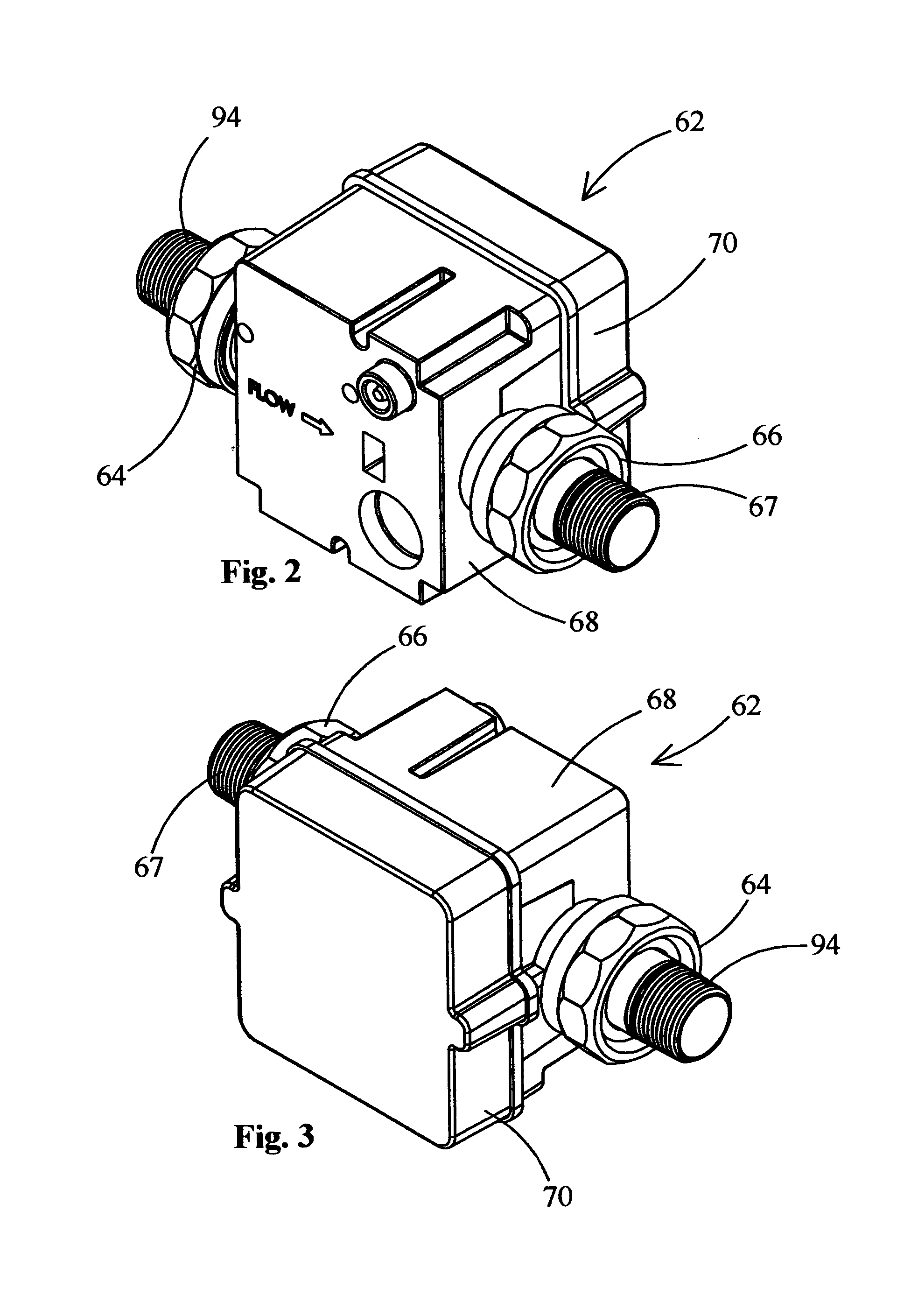

Leak detection and control

InactiveUS7574896B1Avoids complexity and uncertaintyImprove efficiencyMeasurement of fluid loss/gain rateRemote controlEngineering

Fluid leaks can be detected and controlled in a pressurized piping system. Apparatus for this includes control logic; in communication with the logic, a flow detector and / or a pressure detector, and a control valve. One or more of the following is or are provided also: the flow and pressure detectors are both present, and both as single units; the control logic, the flow and / or pressure detector(s) and the control valve are in close proximity to one another; and the control valve has a baseline condition of being shut off. A remote control device can remotely interact with the control logic. Pressure decay and / or flow properties can be employed. The fluid can be water as, for example, in a residential, commercial or institutional system.

Owner:MICHIGAN AGUA TECH

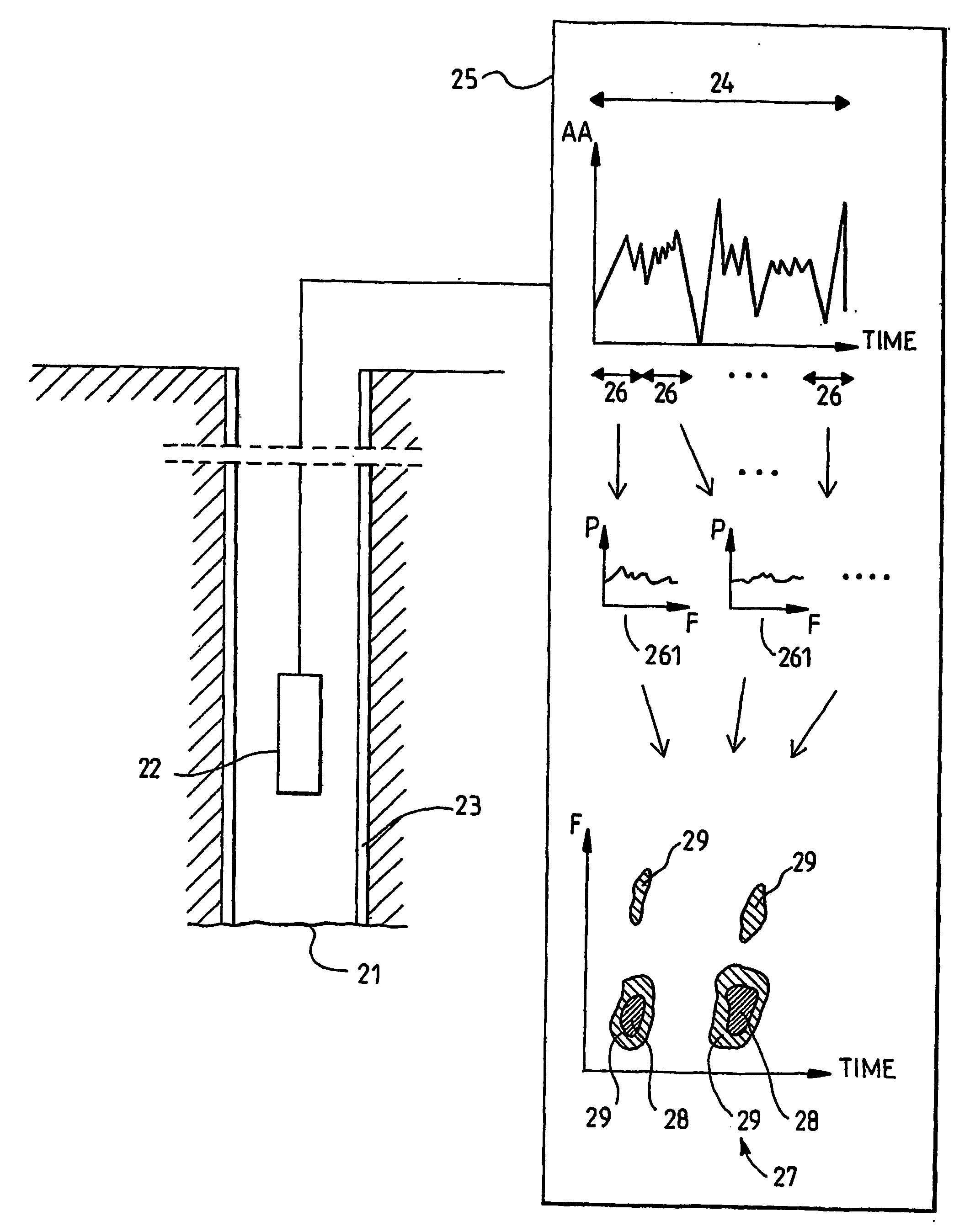

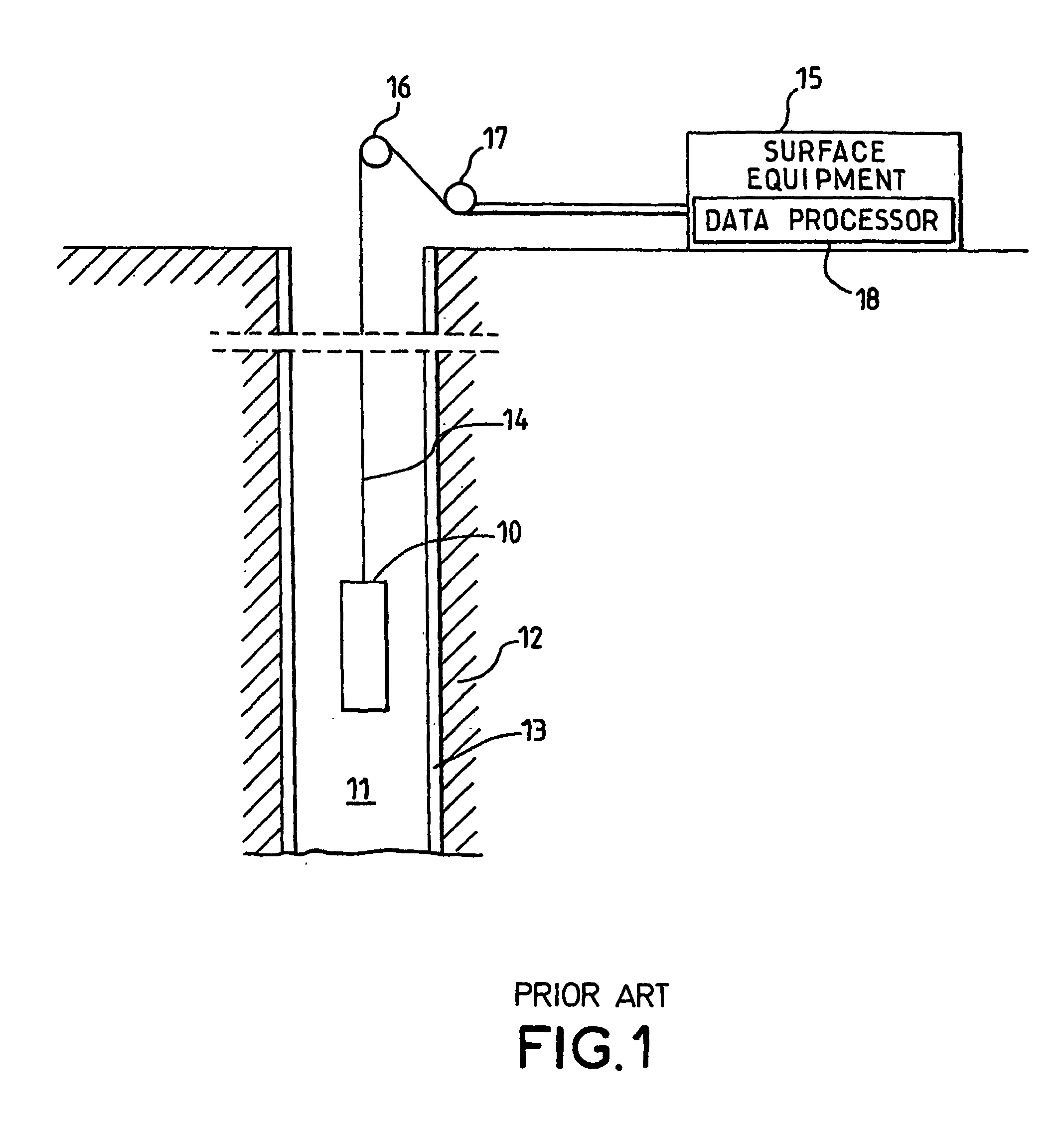

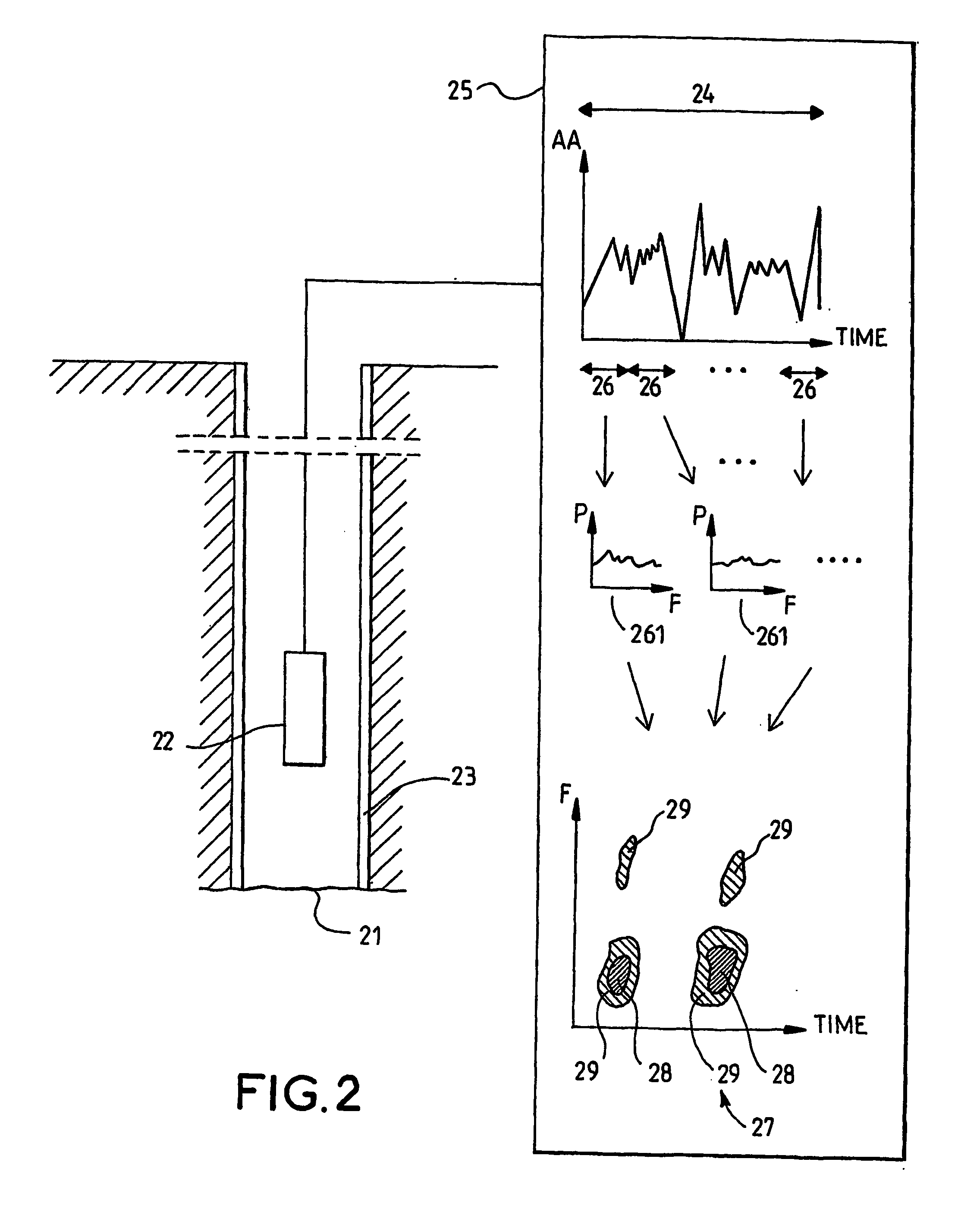

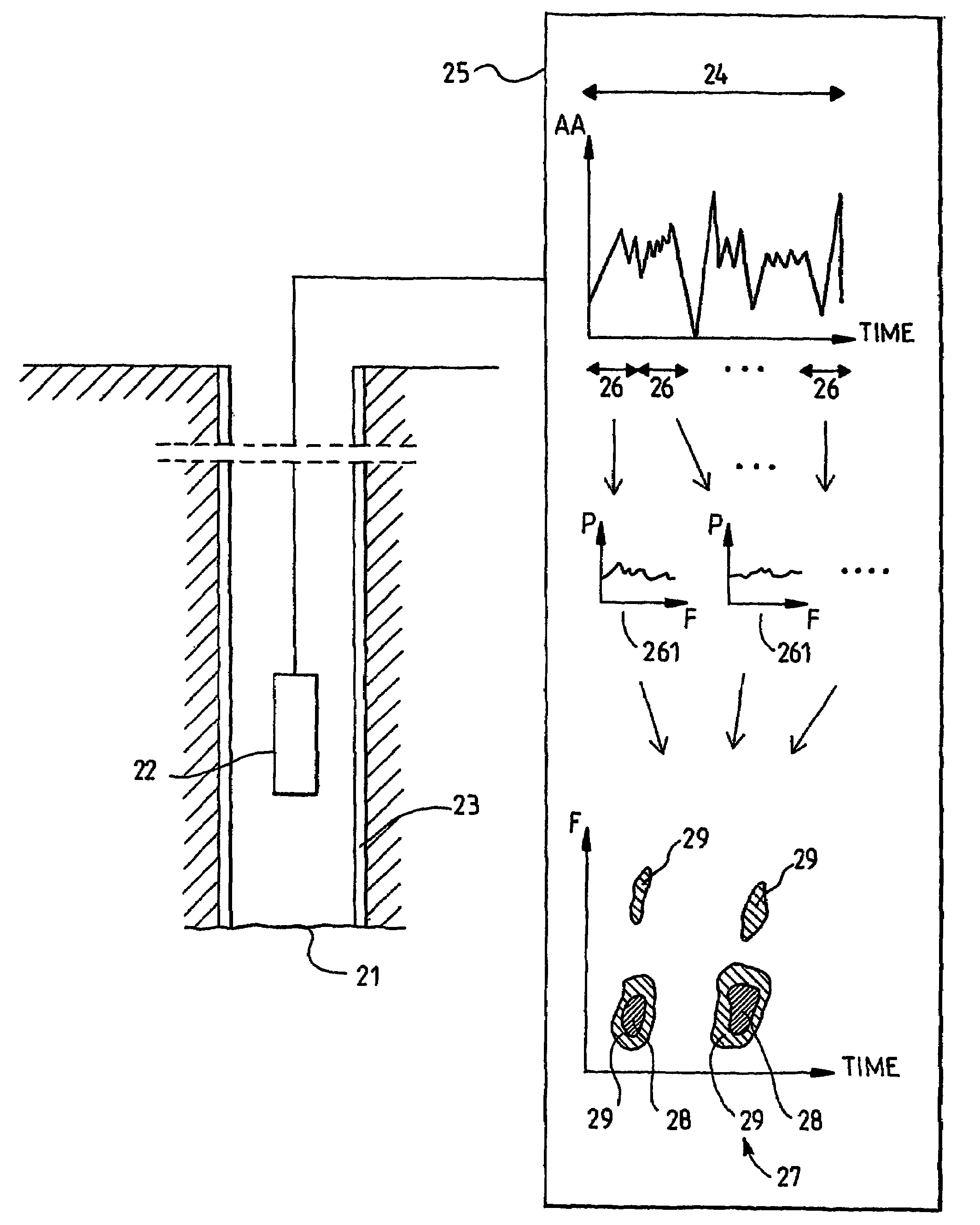

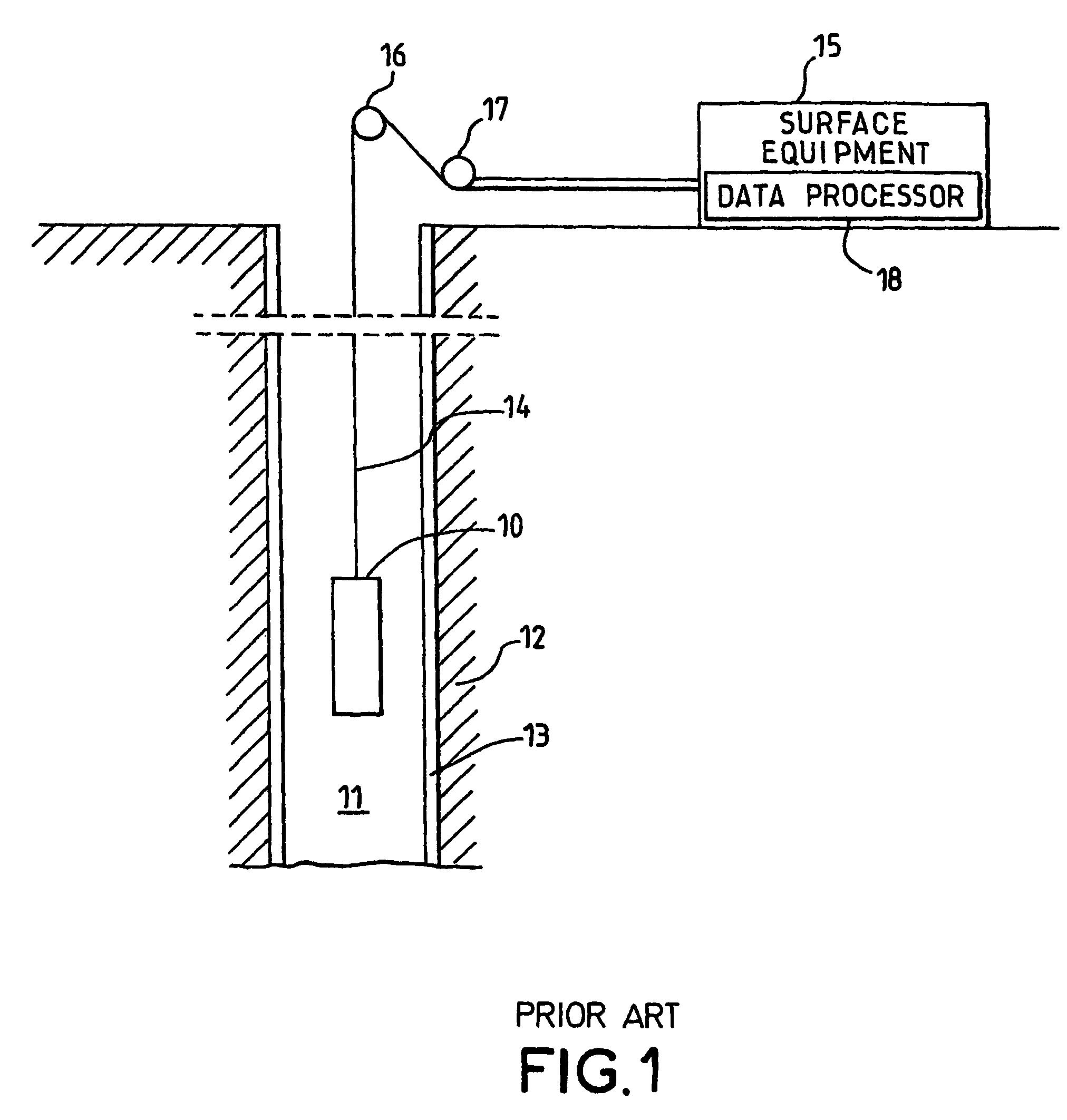

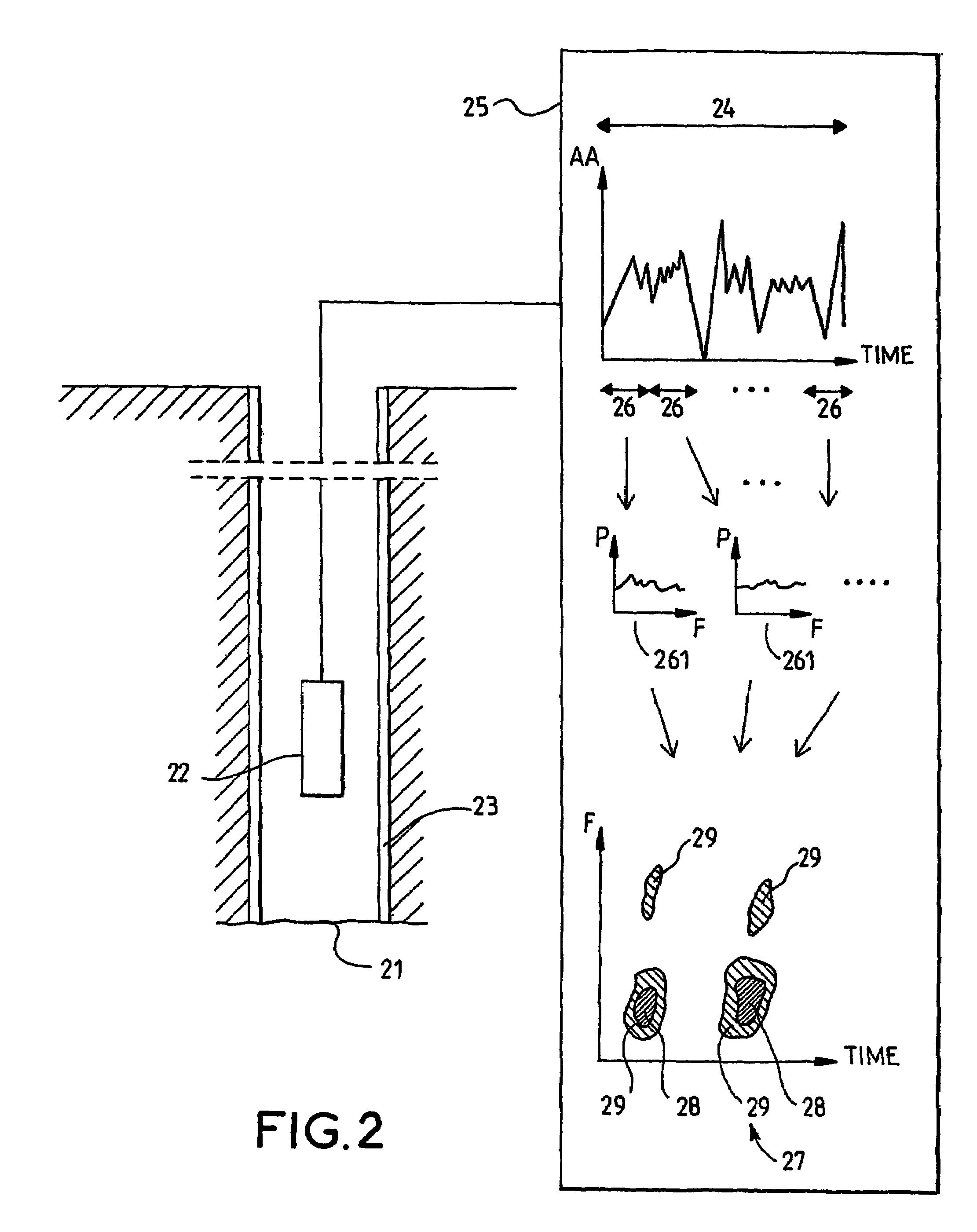

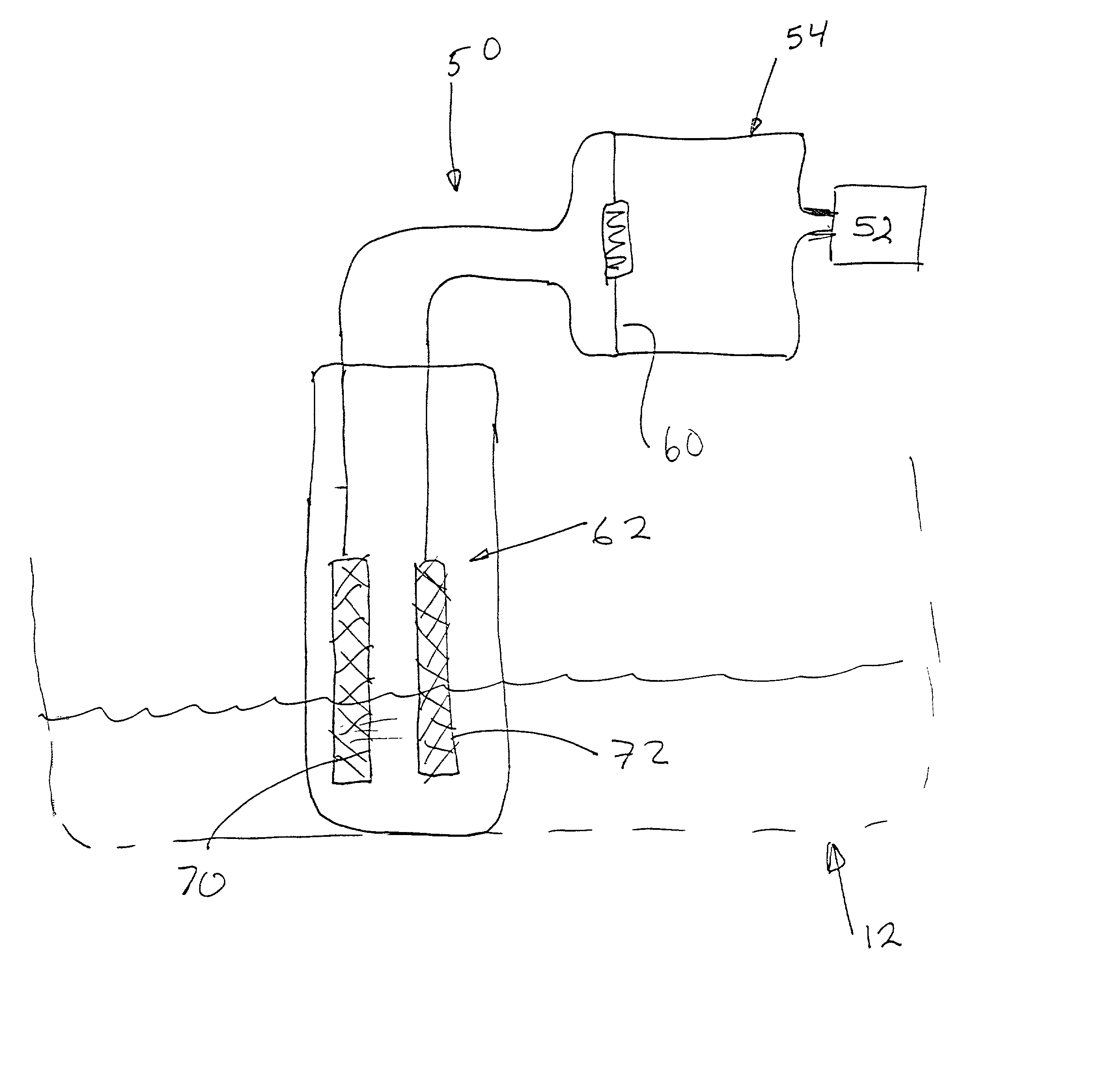

Method and apparatus for acoustic detection of a fluid leak behind a casing of a borehole

An acoustic detection of a discrete acoustic signal allows to detect a leak behind a casing (23) of a borehole. An acoustic amplitude (AA) is sampled during a recording time period (24;64) at a determined position along the tube. Time intervals (26;66) are defined inside of the recording time period (24), and for each time interval (26) the measured acoustic amplitudes are processed to obtain respectively a corresponding power-frequency spectrum (261). A plurality of the power-frequency spectra are analyzed to identify the discrete acoustic signal by detecting time and frequency dependant changes of power. Preferably the processing involves a Fourier transform analysis. A power-frequency time plot is used to conveniently identify the discrete acoustic event.

Owner:SCHLUMBERGER TECH CORP

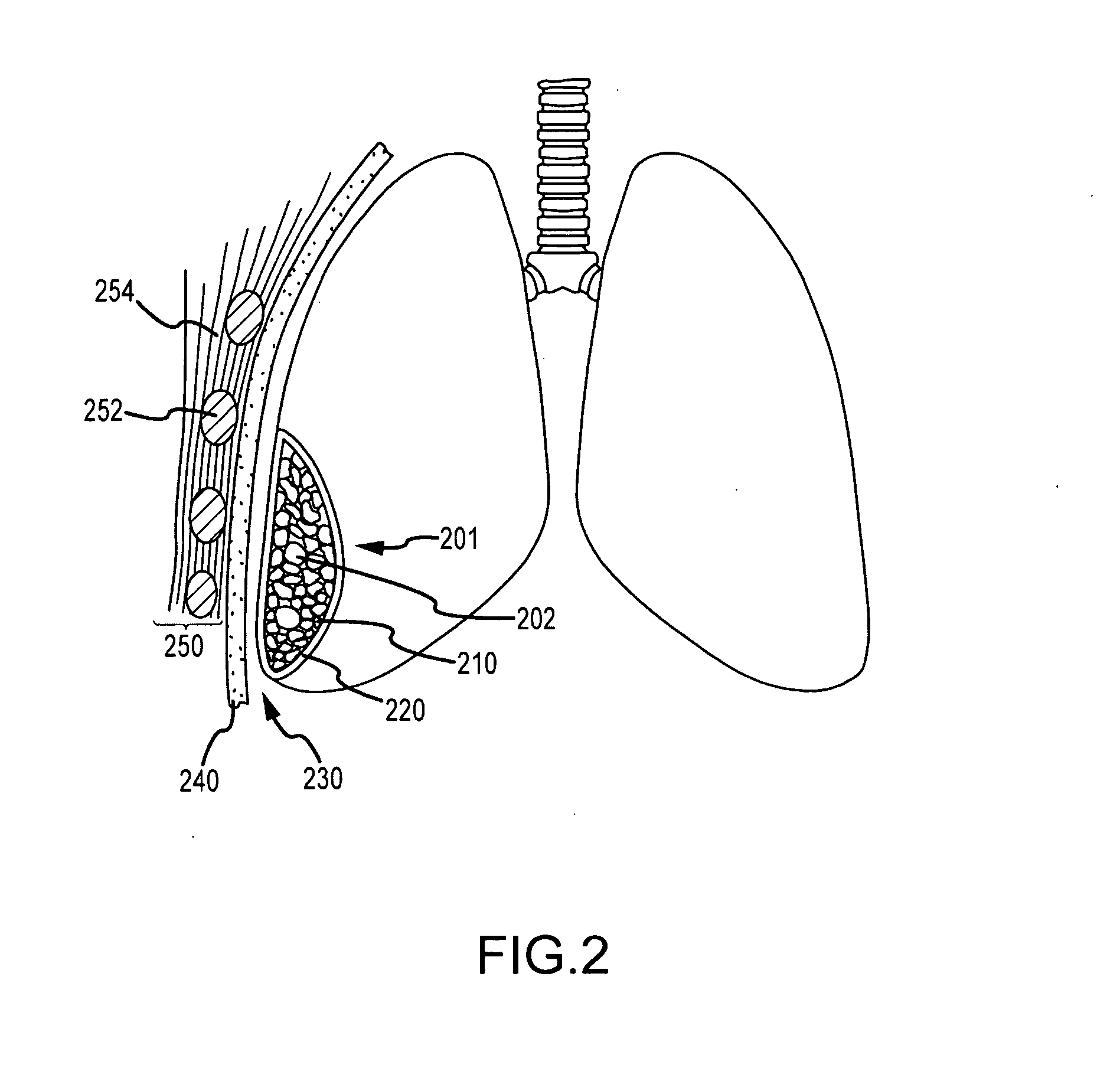

Use of a regenerative biofunctional collagen biomatrix for treating visceral or parietal defects

ActiveUS20090142396A1Avoiding and inhibiting persistent tissue leakImprove lung functionPowder deliveryPeptide/protein ingredientsSurgical treatmentTissue defect

Techniques for treating visceral or parietal membrane and tissue defects include the application of a collagen biomatrix to the defect to repair and regenerate a visceral or parietal membrane, for example in patients suffering tissue defects or undergoing visceral or parietal surgical treatment. Such approaches avoid persistent tissue leaks and their consequences such as fluid leaks and air leaks. The use of collagen biomatrix, optionally in conjunction with a fibrin sealant, an anti-adhesive, or both, can minimize tissue leaks or fluid leaks in injured patients suffering tissue defects or subjects undergoing surgery such as visceral or parietal resections and other operations.

Owner:BAXTER INT INC +1

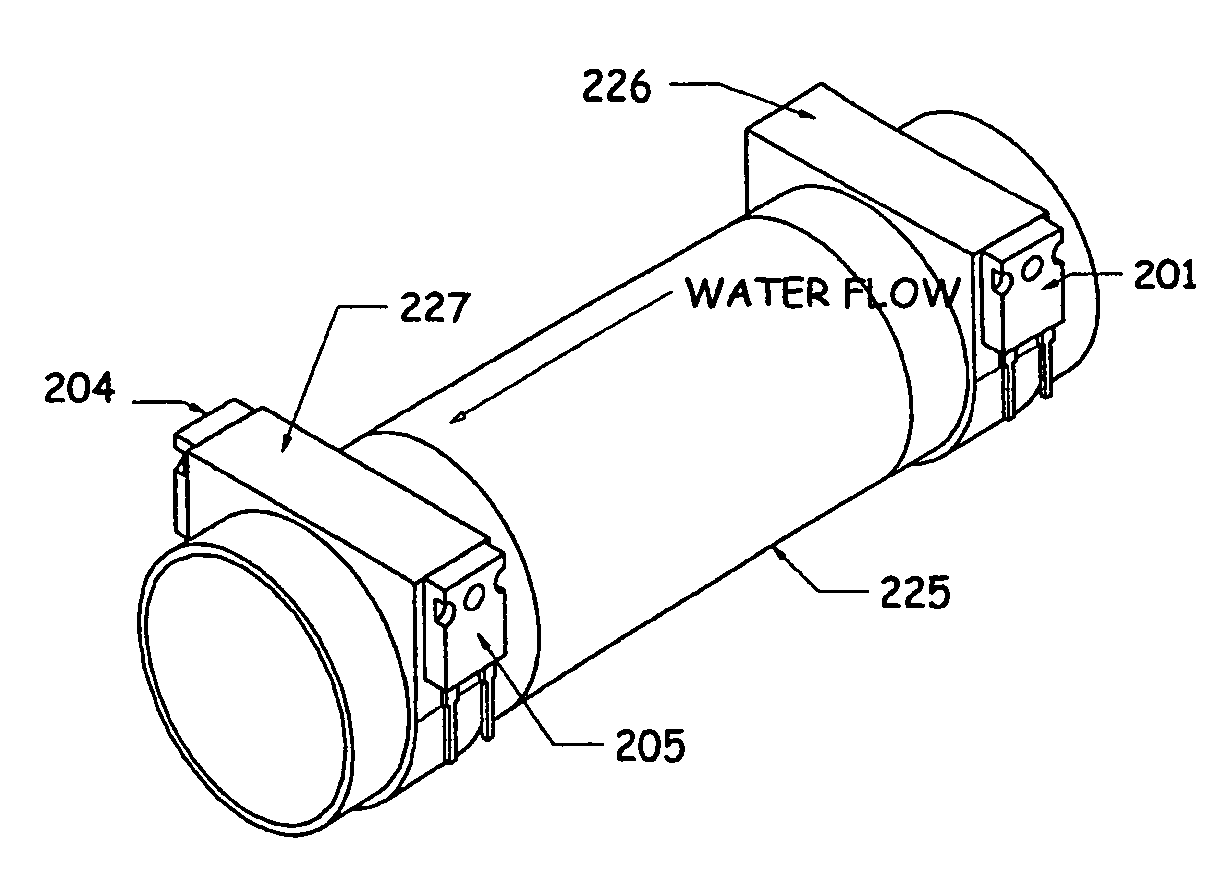

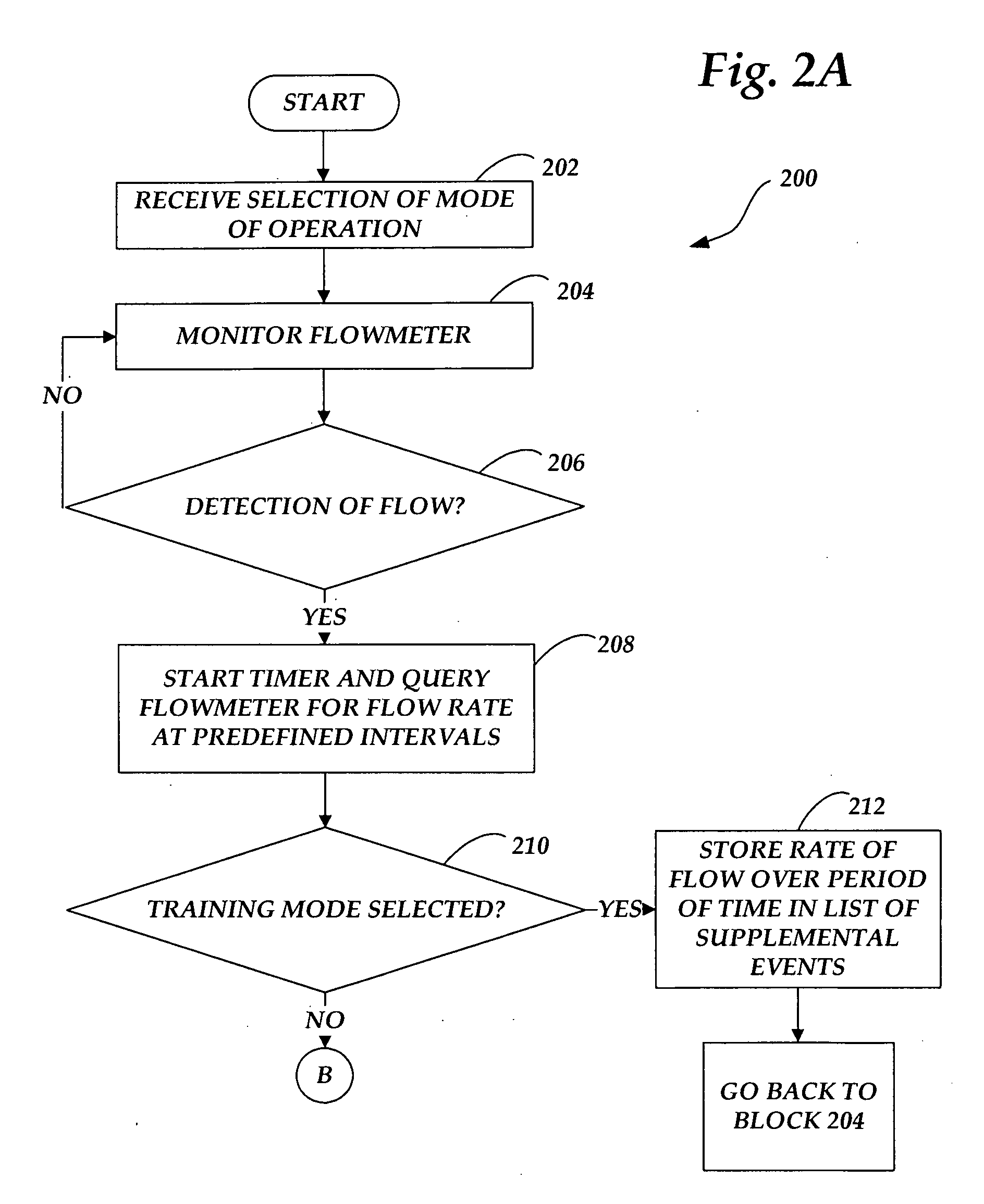

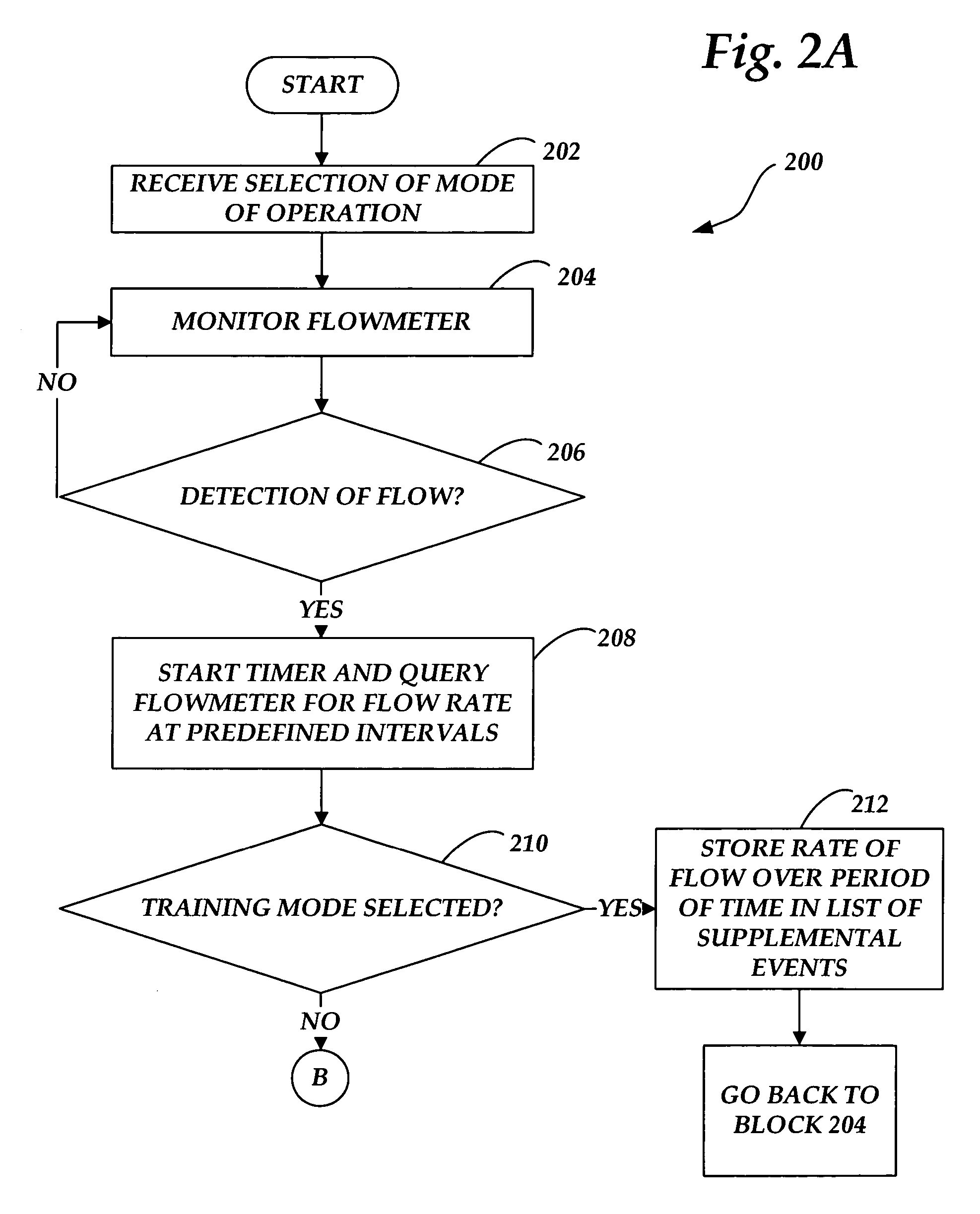

System and method for detecting and preventing fluid leaks

InactiveUS20100212748A1Operating means/releasing devices for valvesPipeline systemsEngineeringWater pipe

Systems and methods are provided for detecting and preventing fluid leaks. A rate of flow of a portion of fluid flowing through a fluid distribution network over a period of time is monitored. A determination is made whether the rate of flow of the fluid over the period of time is greater than zero but so low that it indicates a leak in the water pipe. If the rate of flow over the period of time indicates a leak, then the flow of the liquid through the system is stopped and an indication is provided that a leak has been detected.

Owner:DAVIDOFF JOHN ANDREW

System and method for locating fluid leaks at a drape of a reduced pressure delivery system

A system and method for performing tissue therapy may include applying a reduced pressure to a tissue site of a patient. A fluid parameter associated with applying a reduced pressureto the tissue site may be sensed. An audible fluid leak location sound may be generated in response to sensing the fluid parameter. The audible fluid leak location sound may be altered in response to sensing that the fluid parameter changes. By altering the audible fluid leak location sound in response to sensing a change of the fluid parameter, a clinician may detect location of a fluid leak at the drape by applying force to the drape. The force applied to the drape may be a clinician pressing a finger onto an edge of the drape.

Owner:KCI LICENSING INC

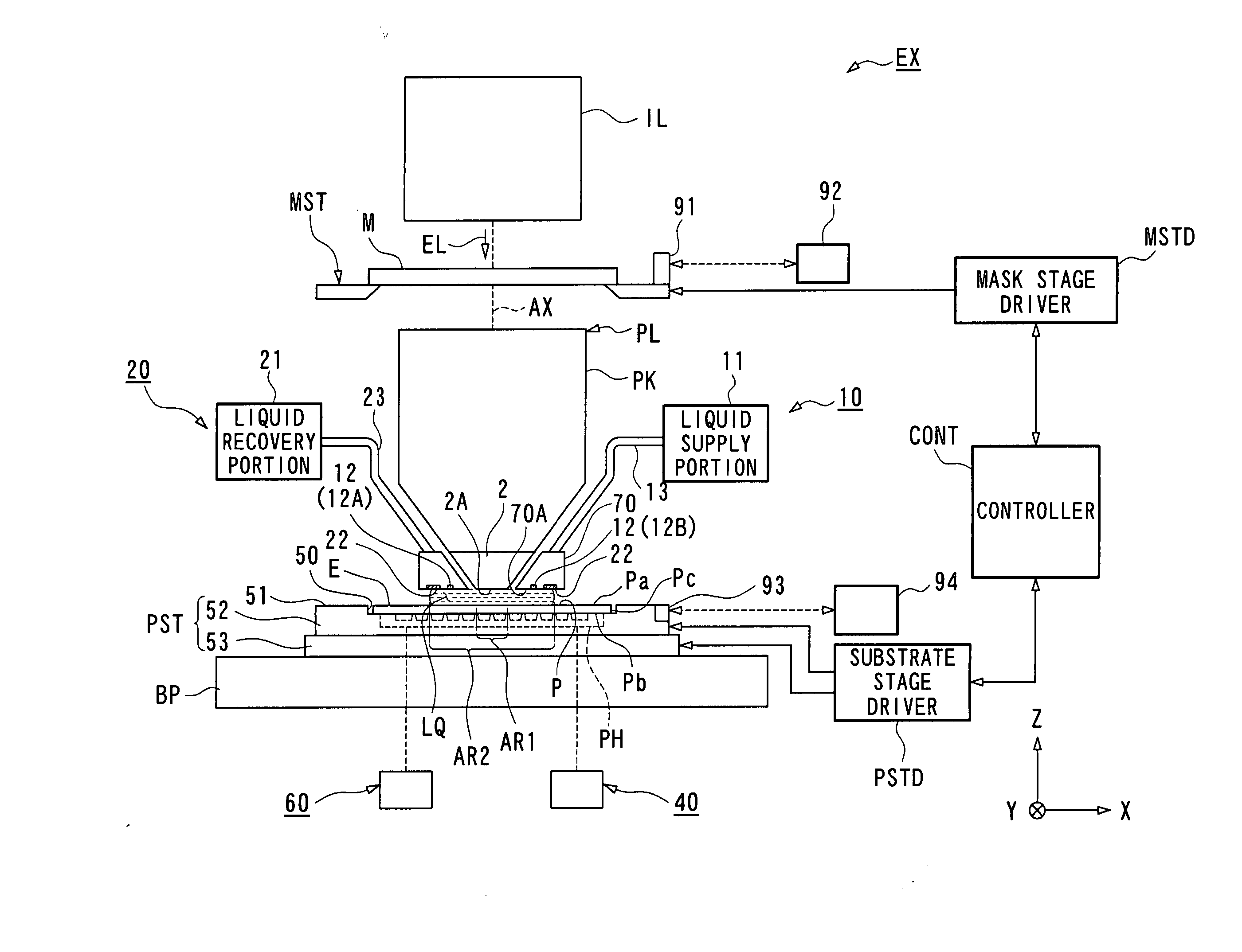

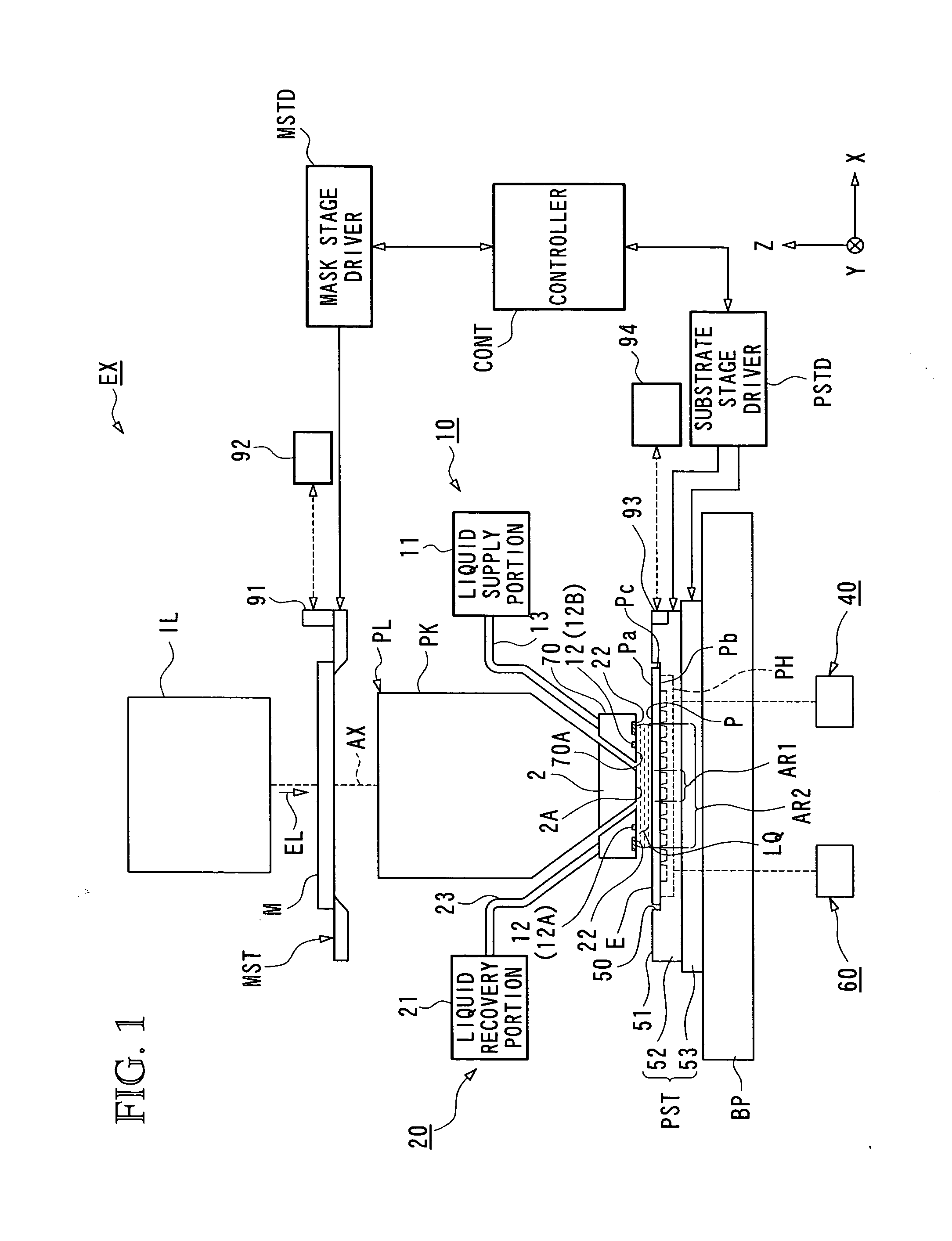

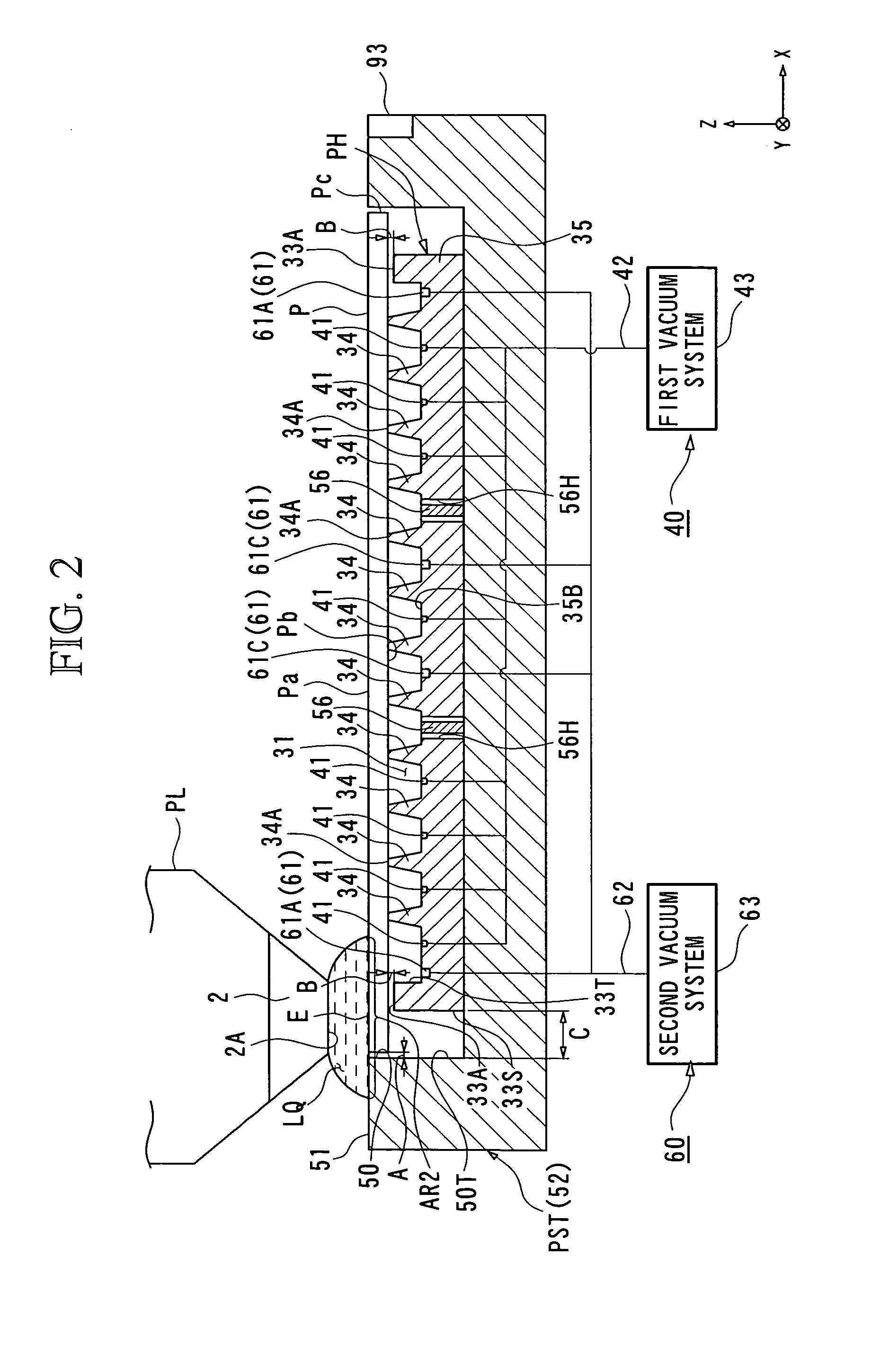

Exposure Apparatus and Device Manufacturing Method

InactiveUS20080043210A1Avoid it happening againSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringMechanical engineering

An exposure apparatus that can prevent disadvantages due to a leaked liquid is provided. The exposure apparatus includes: a substrate holder (PH) that includes a peripheral wall portion (33) and supporting portions (34) located on an inside of the peripheral wall portion (33) and that supports a substrate (P) with the supporting portions (34) by negatively pressurizing a space (31) surrounded by the peripheral wall portion (33); and a recovery mechanism that includes a collection inlets (61) provided on the inside of the peripheral wall portion (33) and a vacuum system (63) connected to the collection inlets (61), in which a liquid penetrated from an outer periphery of the substrate (P) is sucked and recovered, in the state with an upper surface (33A) of the peripheral wall portion (33) and a back surface (Pb) of the substrate (P) being spaced at a first distance.

Owner:NIKON CORP

Method and apparatus for acoustic detection of a fluid leak behind a casing of a borehole

An acoustic detection of a discrete acoustic signal allows to detect a leak behind a casing (23) of a borehole. An acoustic amplitude (AA) is sampled during a recording time period (24; 64) at a determined position along the tube. Time intervals (26; 66) are defined inside of the recording time period (24), and for each time interval (26) the measured acoustic amplitudes are processed to obtain respectively a corresponding power-frequency spectrum (261). A plurality of the power-frequency spectra are analyzed to identify the discrete acoustic signal by detecting time and frequency dependant changes of power. Preferably the processing involves a Fourier transform analysis. A power-frequency time plot is used to conveniently identify the discrete acoustic event.

Owner:SCHLUMBERGER TECH CORP

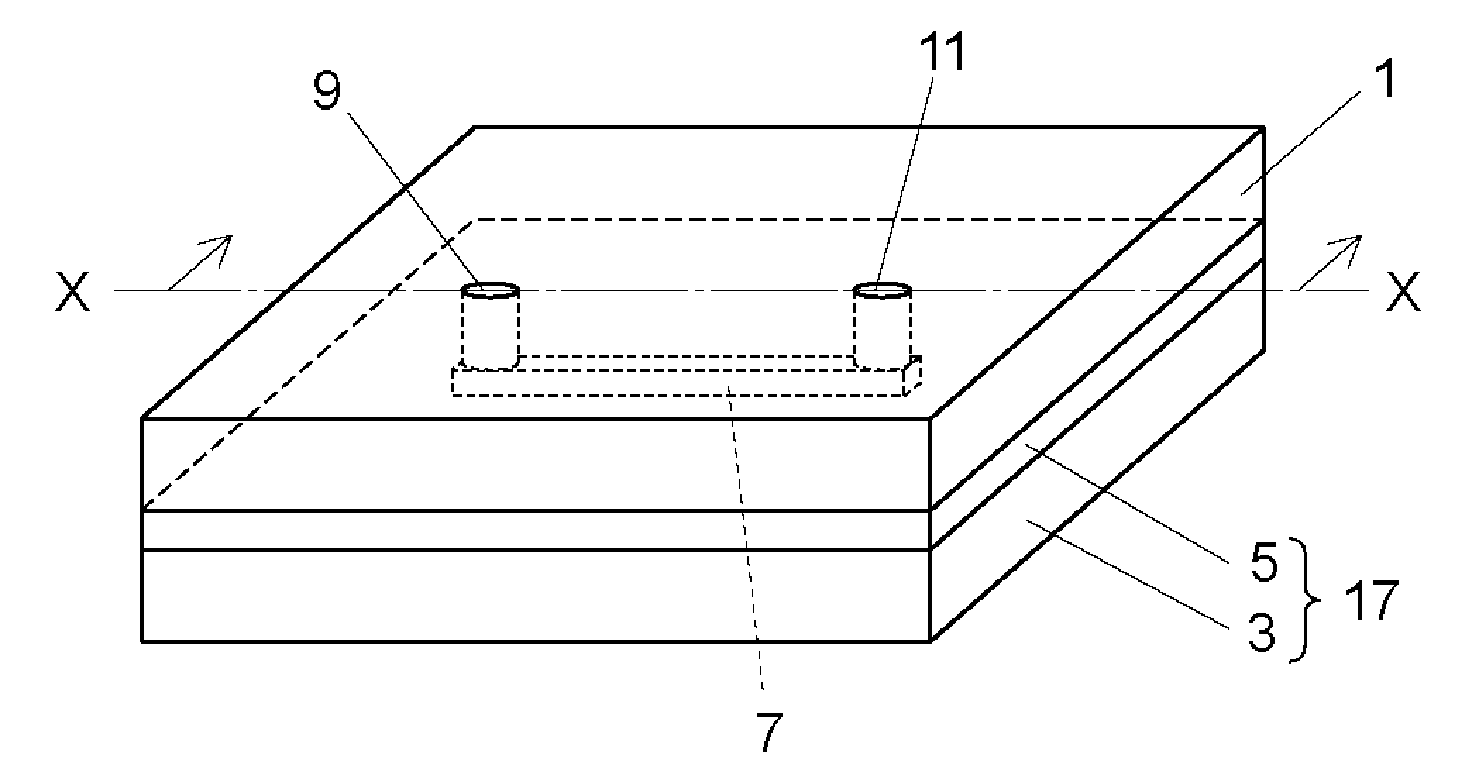

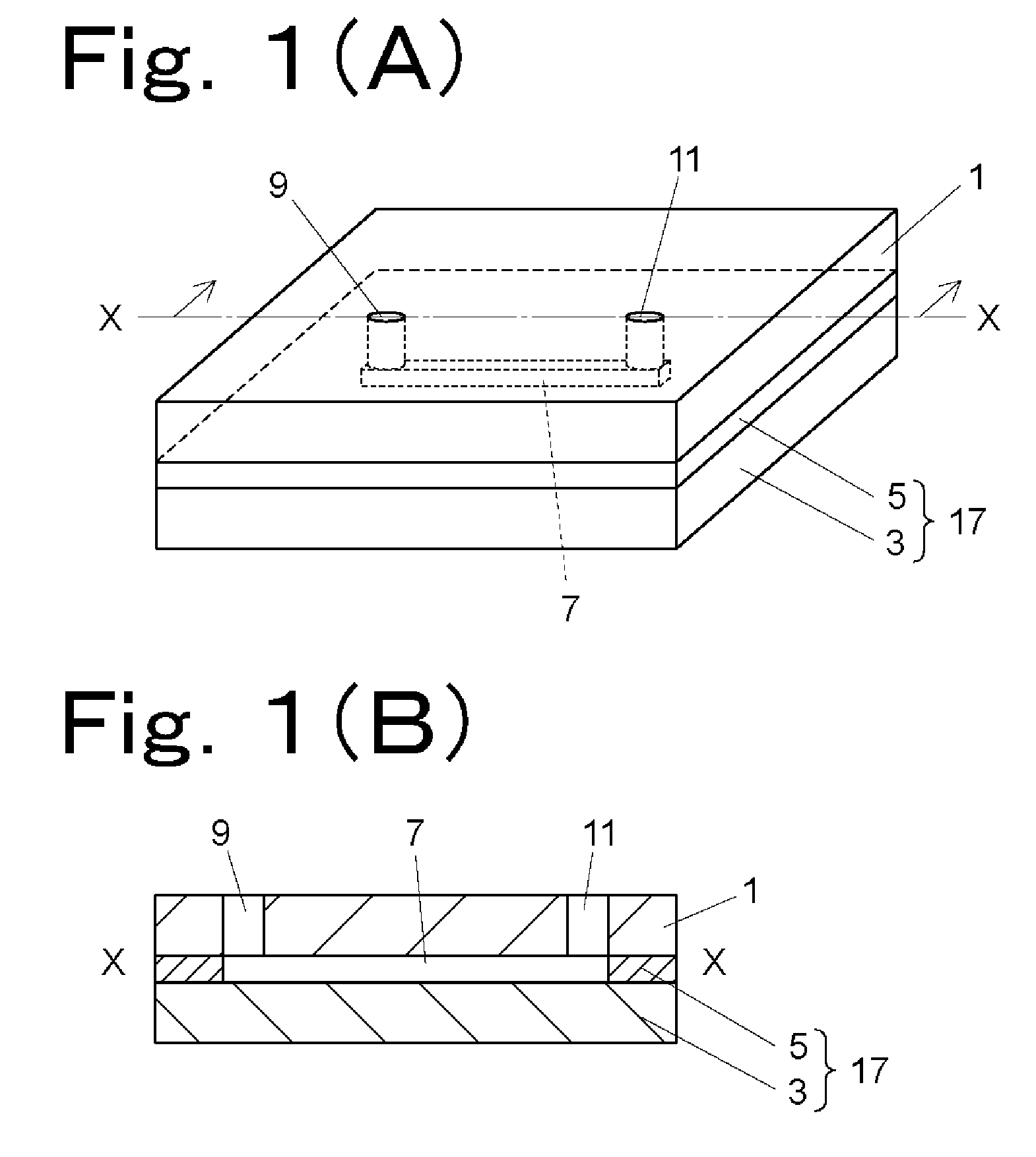

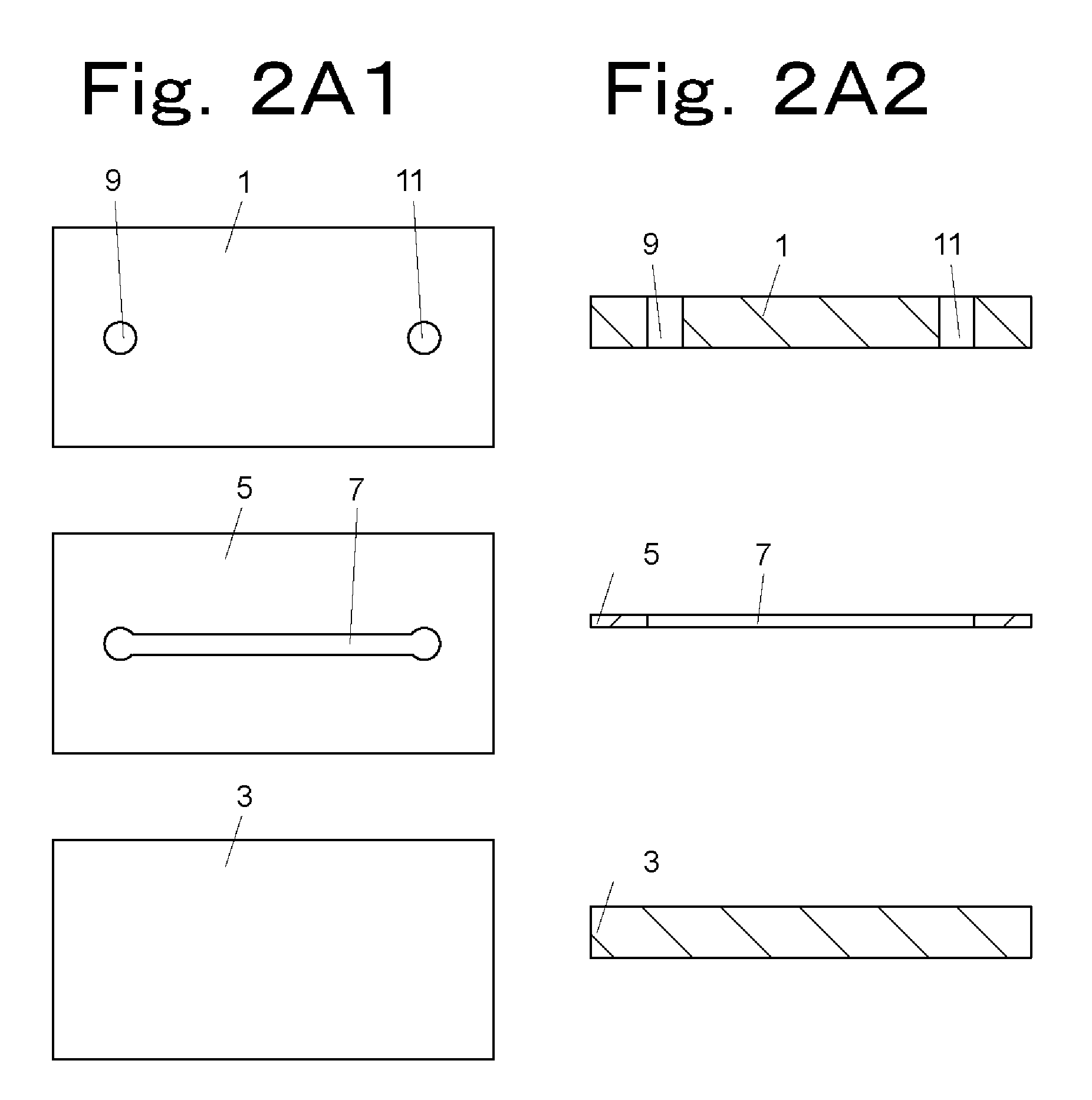

Flow cell and process for producing the same

InactiveUS20090114293A1High bonding strengthReduce gapComponent separationServomotor componentsFlat glassFlow cell

To provide a flow cell that is free from liquid leakage and excels in chemical resistance. There is provided a preferred form of flow cell comprising flat-plate glass substrate (3); adherent fluororesin sheet (5) having a groove as flow channel (7) made by cutting machining; and glass substrate (1) as lid member furnished with through-holes (9, 11) as fluid inlet and outlet at positions corresponding to both end portions of the groove. The fluororesin sheet (5) is interposed between the glass substrates (1, 3) and, while heating at a temperature not lower than the melting point of the fluororesin sheet (5), pressurized so that the glass substrates (1, 3) are bonded together by the fluororesin sheet (5) per se. Flow channel member (17) is constructed by the glass substrate (3) and, bonded thereonto, the fluororesin sheet (5).

Owner:SHIMADZU CORP

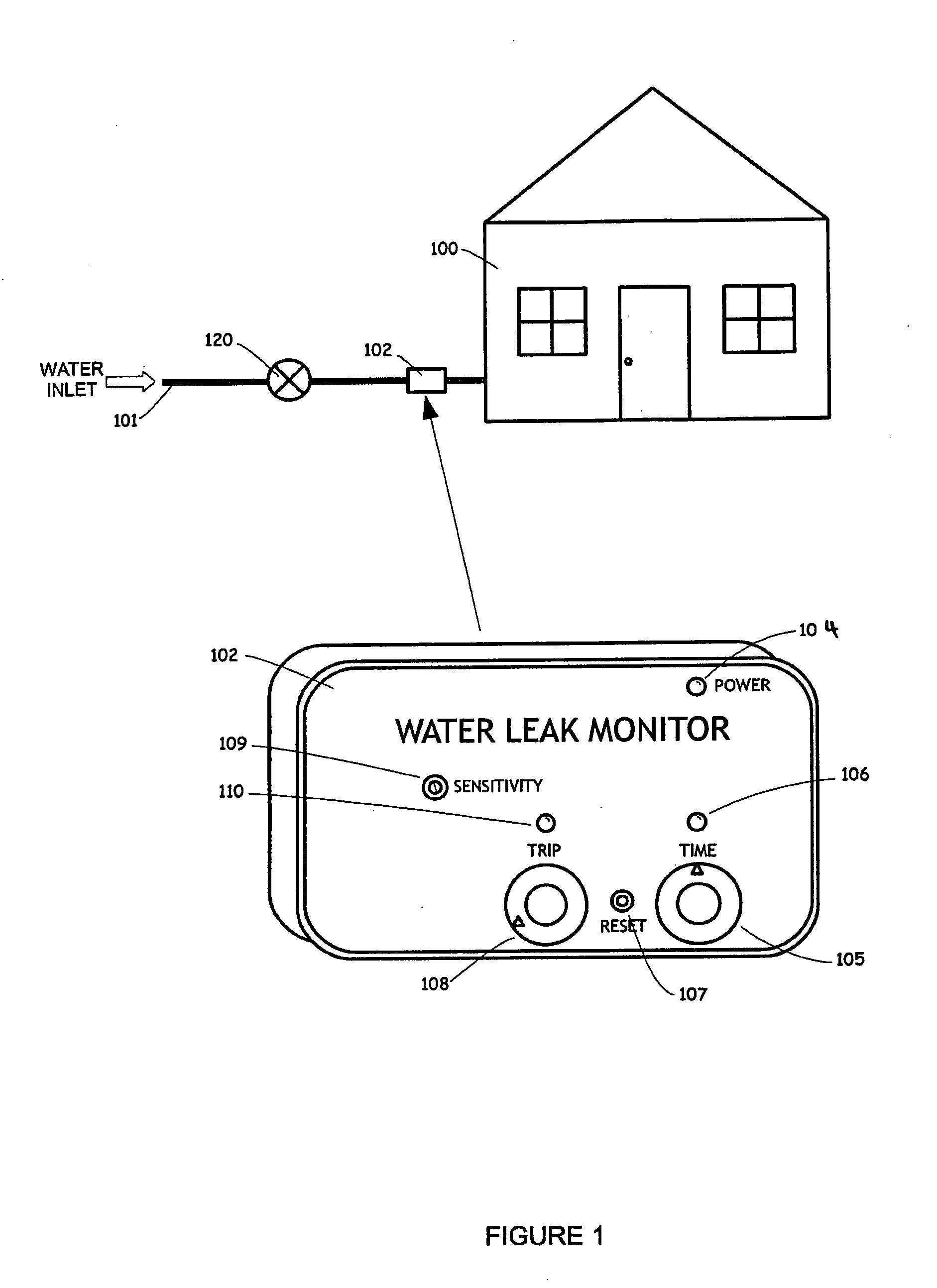

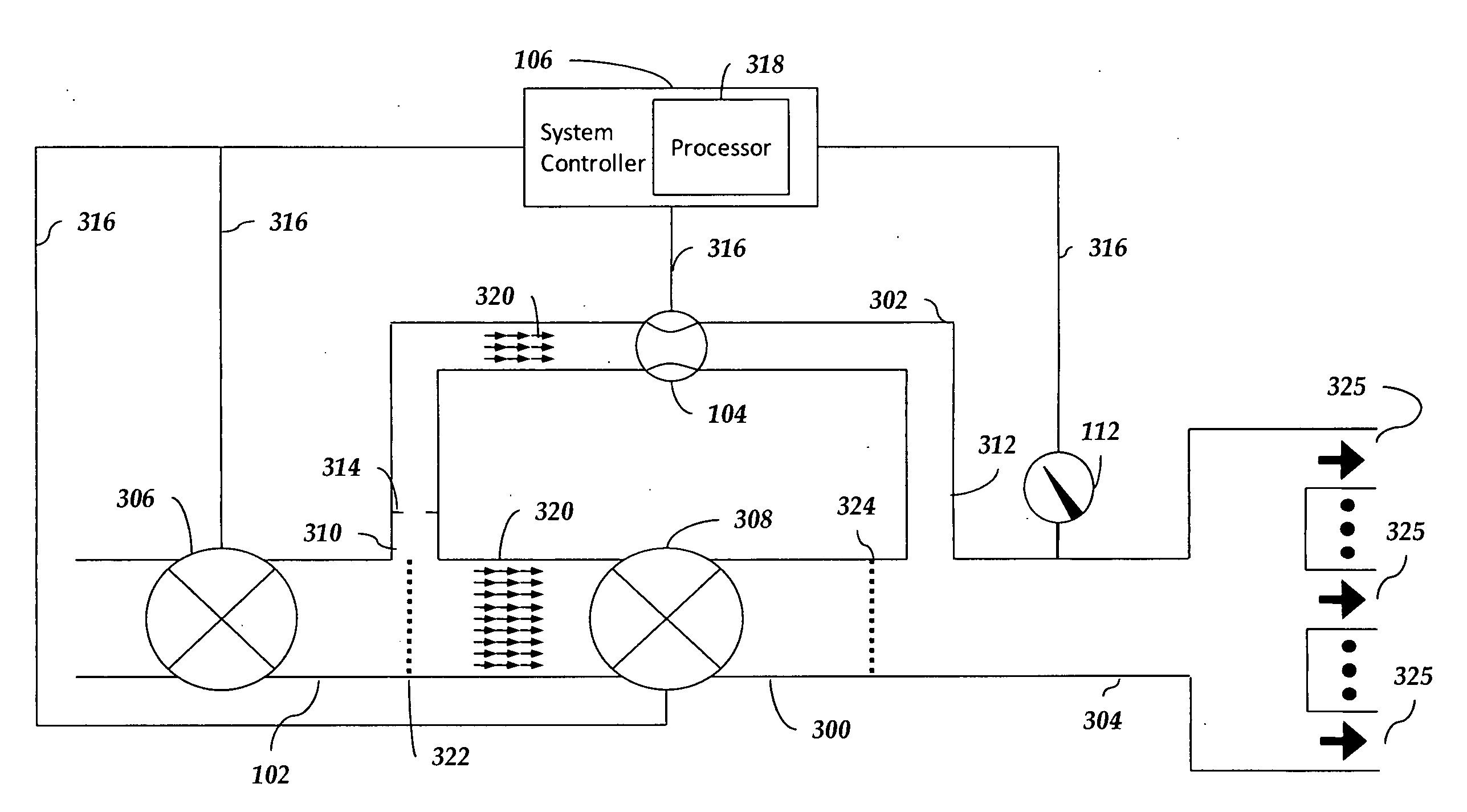

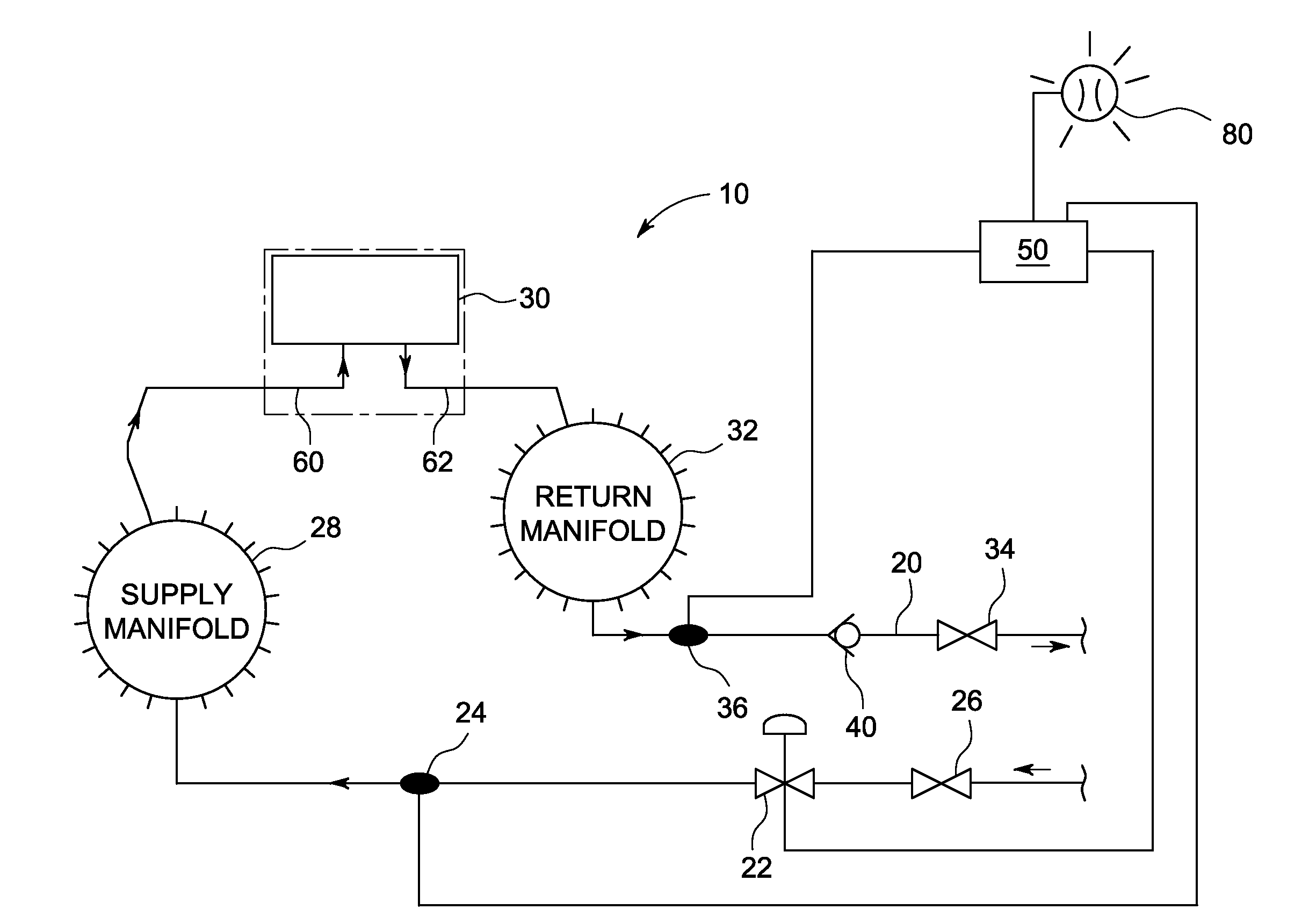

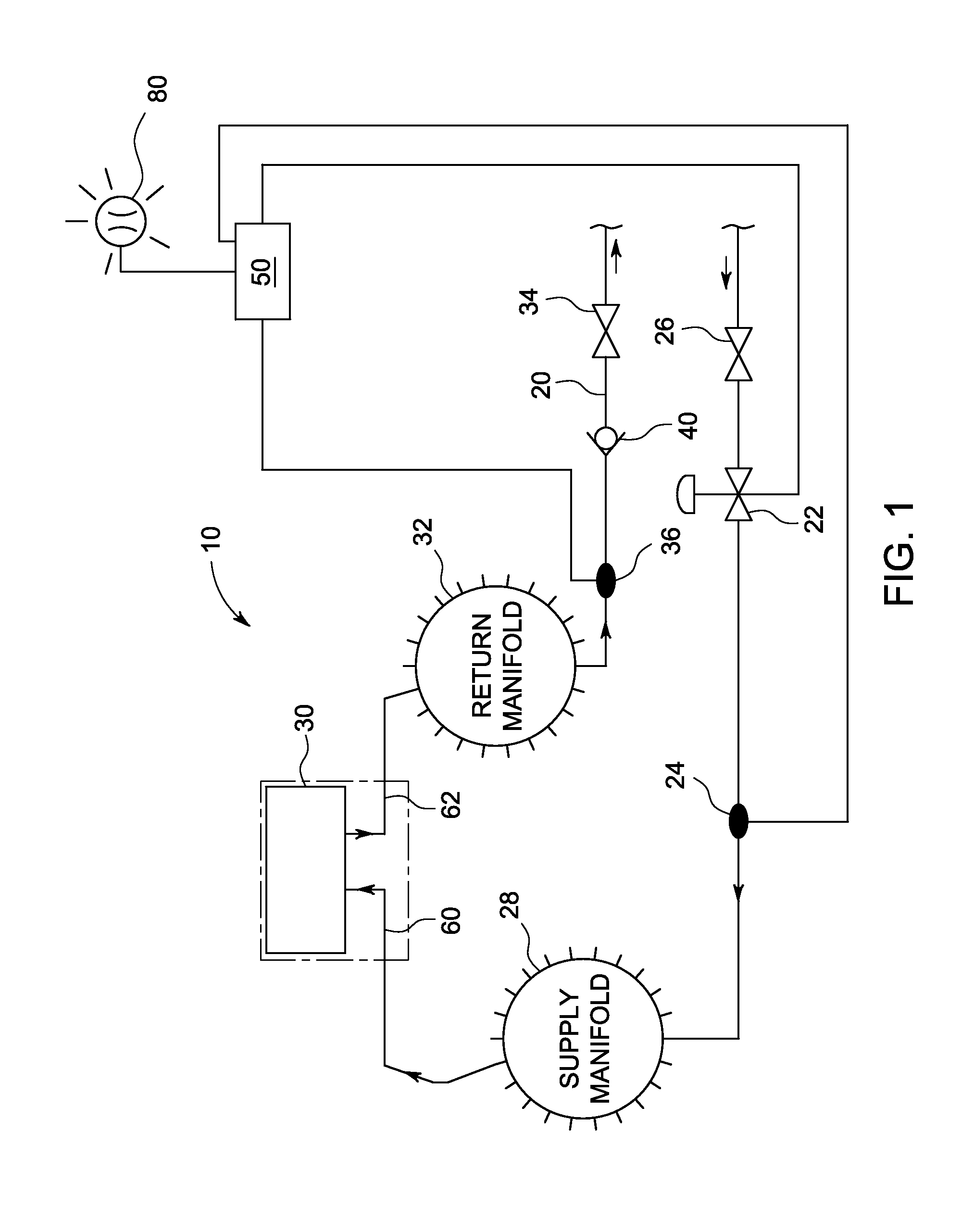

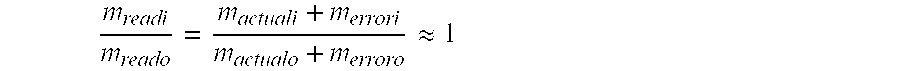

Fluid leak detection system

InactiveUS20120324985A1Measurement of fluid loss/gain rateTesting/calibration for volume flowEngineeringInlet flow

A fluid leak detection system is provided, and includes a fluid conduit, a fluid-cooled device having an inlet and an outlet, an inlet flow meter, an outlet flow meter, and a controller. The inlet flow meter is fluidly connected to the fluid conduit. The inlet flow meter monitors the inlet of the fluid-cooled device for an inlet temperature and an inlet flow rate. The inlet flow meter has an inlet flow meter drift versus process fluid temperature curve. The outlet flow meter is fluidly connected to the fluid conduit. The outlet flow meter monitors the outlet of the fluid-cooled device for an outlet temperature and an outlet flow rate. The outlet flow meter has an outlet flow meter drift versus process fluid temperature curve. The controller is in communication with the inlet flow meter and the outlet flow meter.

Owner:GENERAL ELECTRIC CO

Method for treating a subterranean formation

ActiveUS7306041B2Improve permeabilityHigher the percentage of acidFluid removalFlushingAcid fracturingHydraulic fracturing

Disclosed are acid fracturing methods for subterranean siliceous formations employing a viscous dissolving fluid to create a permeable conduit that bypasses the near wellbore damage. The viscous dissolving fluids used according to the invention are acid-fracturing treatment fluids containing a dissolving agent viscosified with a material such as a viscoelastic surfactant, and the fluid is injected into a sandstone formation at a pressure sufficient to create a hydraulic fracture. Also, the viscous dissolving fluid leaks off into the faces of the fracture thus “stimulating” the formation. Hence when the hydraulic fracture has closed there is a part of the formation that has been effectively stimulated, creating a pathway for fluids to preferentially flow to the wellbore. The formation may then be flowed back to produce a substantial volume of the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

Leak sensor for flowing electrolyte batteries

InactiveUS20030008203A1Primary cell to battery groupingPrimary cell maintainance/servicingEngineeringLeak detection

A leak detection system for a flowing electrolyte battery comprising a containment member associated with at least one of a stack of a flowing electrolyte battery and an electrolyte reservoir of a flowing electrolyte battery and a sensing member for sensing a fluid leak within the containment member.

Owner:LARGO CLEAN ENERGY CORP

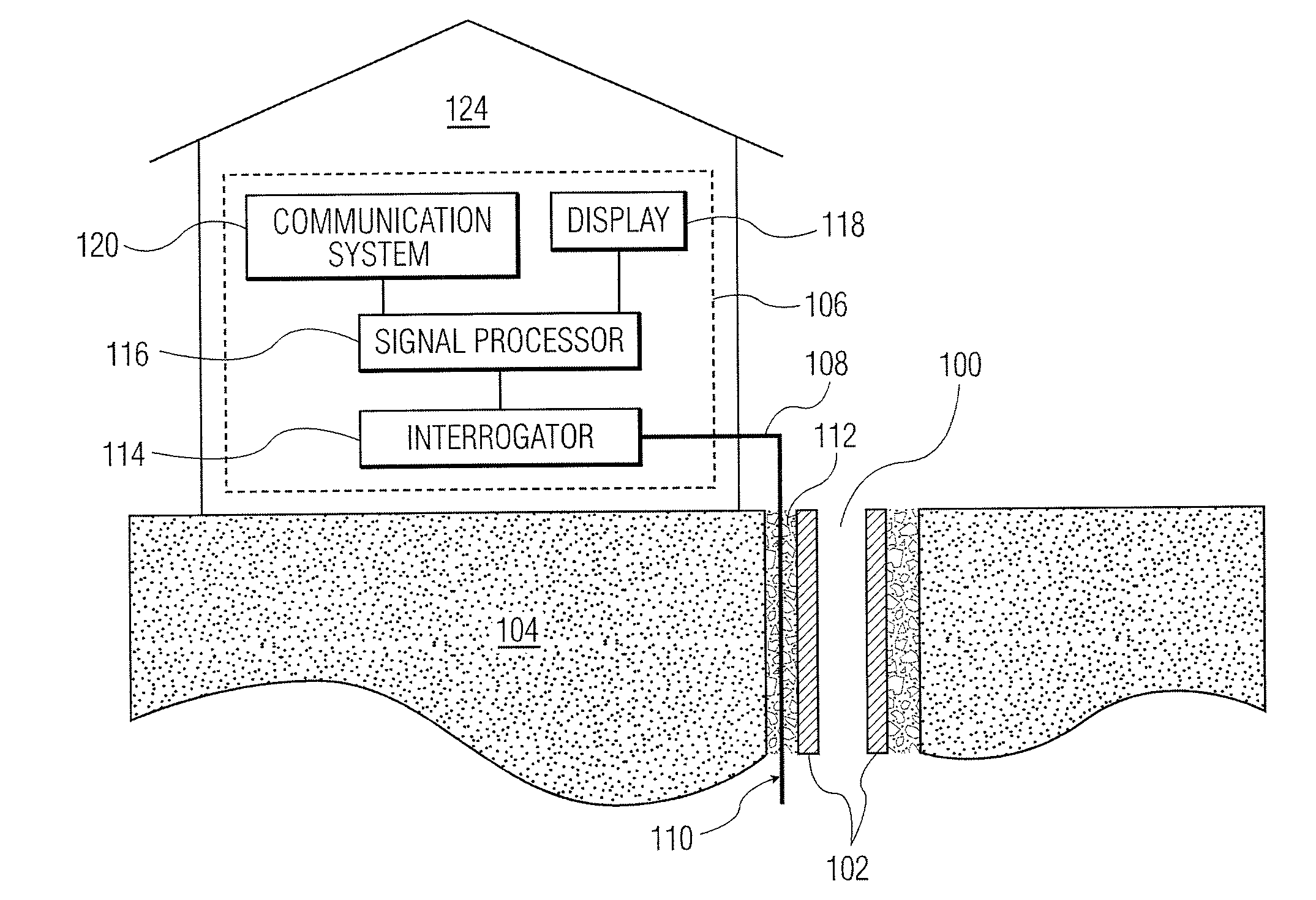

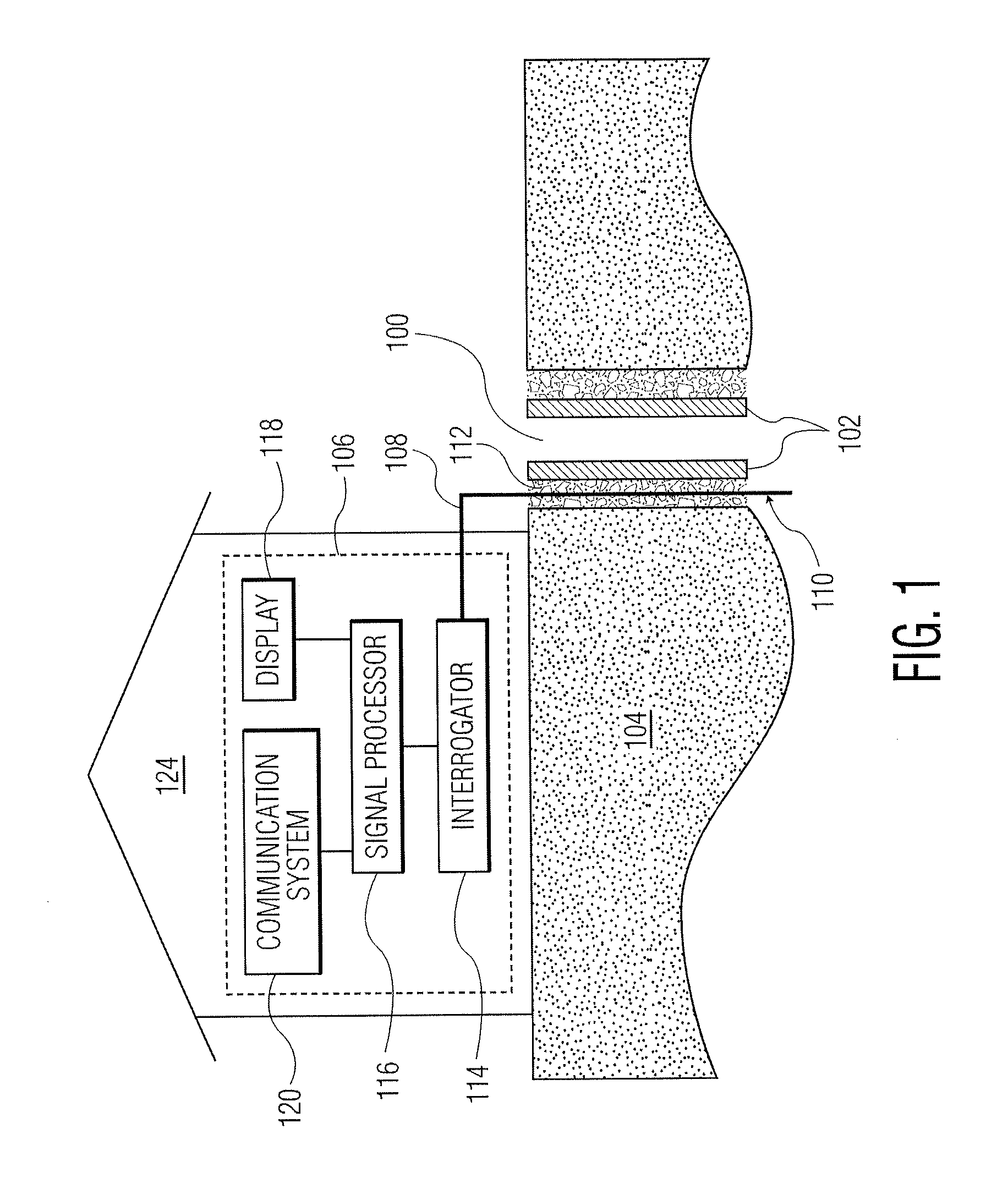

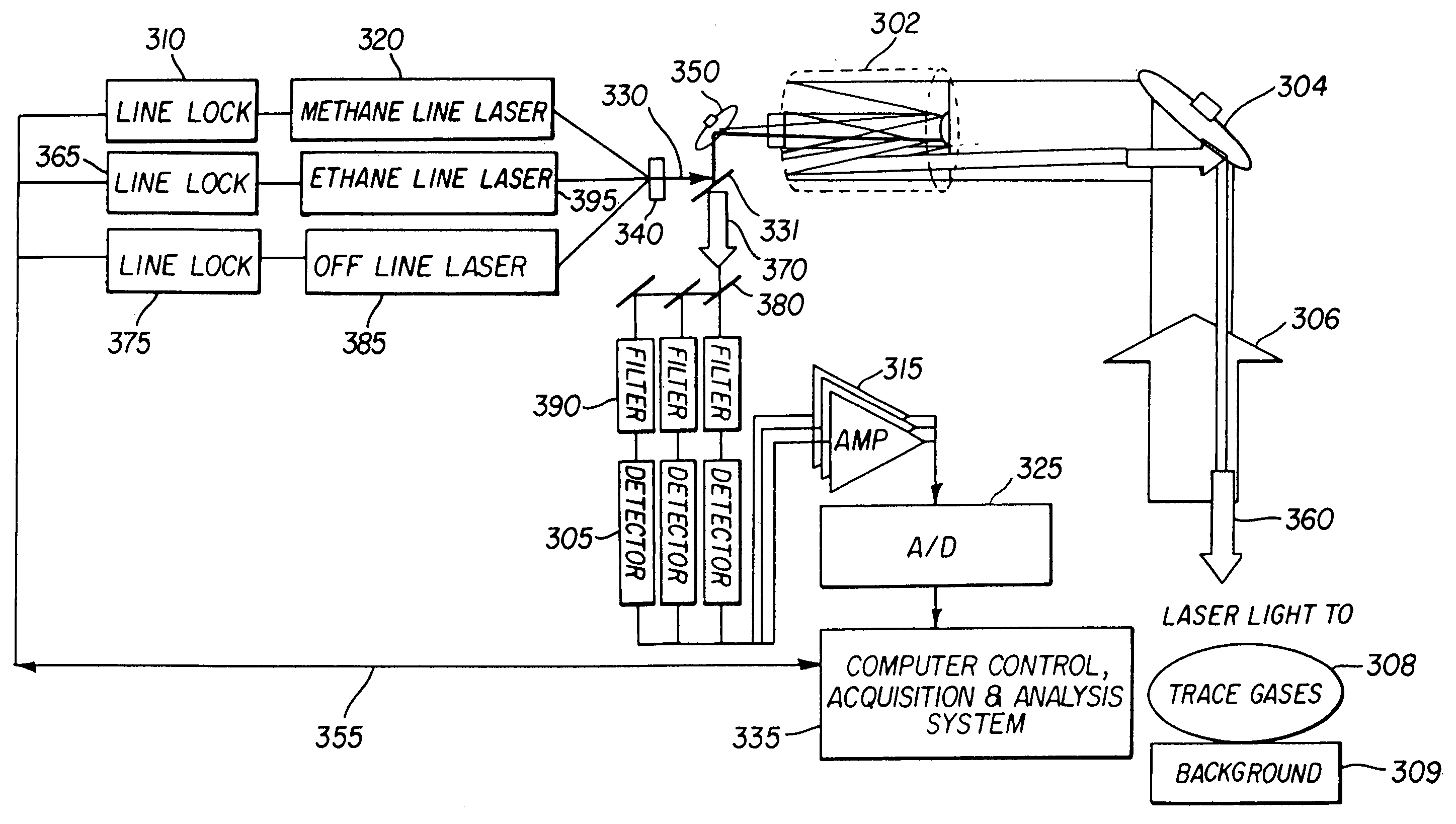

Wellbore leak detection systems and methods of using the same

A leak detection system for a wellbore. The leak detection system includes: (1) at least one sensor configured to be positioned outside of a casing of the wellbore; (2) an interrogation system for sending signals to, and receiving signals from, the at least one sensor; and (3) an optical lead cable disposed between the interrogation system and the at least one sensor. A method of detecting a fluid leak in a wellbore is also disclosed.

Owner:US SEISMIC SYST

Non-invasive Thermal Dispersion Flow Meter with Chronometric Monitor for Fluid Leak Detection and Freeze Burst Prevention

ActiveUS20140348205A1Conservation promotedCost promotedThermometer detailsVolume/mass flow measurementPropagation timeEngineering

A non-invasive thermal dispersion flow meter with chronometric monitor for fluid leak detection includes a heater, an ambient temperature sensor and a flow rate sensor which are configured to sense the temperature of a fluid in a conduit, and then monitor the flow of that fluid through the conduit. The fluid flow sensor is incorporated into a Wheatstone bridge circuit which is used to provide increased sensitivity to the outputs of the sensors. Based upon the ambient temperature sensor readings, the flow rate sensor and heater may be adjusted to optimize the operation of the system to detect leaks. An alternative embodiment utilizes a single sensor and separate heater which work together to determine heat propagation times which in turn is used to calculate flow rate. Based on the sensor readings, the flow may be adjusted to prevent damage and leaks by relieving the system of excess pressure.

Owner:SENTINEL HYDROSOLUTIONS

System and method for remote quantitative detection of fluid leaks from a natural gas or oil pipeline

ActiveUS20050134859A1Reasonable wavelength conversion efficiencyColor/spectral properties measurementsPhotometry using electric radiation detectorsLaser lightLength wave

A system for remote quantitative detection of fluid leaks from a natural gas or oil pipeline by use of an airborne platform; including at least one laser light source for nearly simultaneous illuminating two or more target fluids and a background, wherein the two or more target fluids are characterized by two or more absorption wavelengths, and wherein the background has a different wavelength than either of the two or more target fluids. The illumination source is pointed based on a positioning system while in a geometric area along a path two or more target fluids are scanned for using the illumination sources. A signal detector detects the two or more target fluids using quantitative signal processing. Also included are a controller, a path planning and path finding tool for the positioning of the airborne platform, and a communicator for communicating the presence of the detected leak.

Owner:HARRIS CORP

Thermal dispersion flow meter with chronometric monitor for fluid leak detection

ActiveUS7308824B2Volume/mass flow by thermal effectsFluid-tightness measurementEngineeringFluid Leak

A thermal dispersion flow meter with chronometric monitor for fluid leak detection includes an ambient temperature RTD sensor and a flow rate RTD sensor which are configured to sense the temperature of a fluid in a conduit, and then monitor the flow of that fluid through the conduit. The fluid flow RTD sensor is incorporated into a Wheatstone bridge circuit which is used to provide increased sensitivity to the outputs of the RTD sensors. Based upon the ambient temperature sensor readings, the flow rate RTD sensor may be adjusted to optimize the operation of the system to detect leaks, and on certain conditions, a controller may close a supply line valve to avoid flooding of a structure.

Owner:SENTINEL HYDROSOLUTIONS

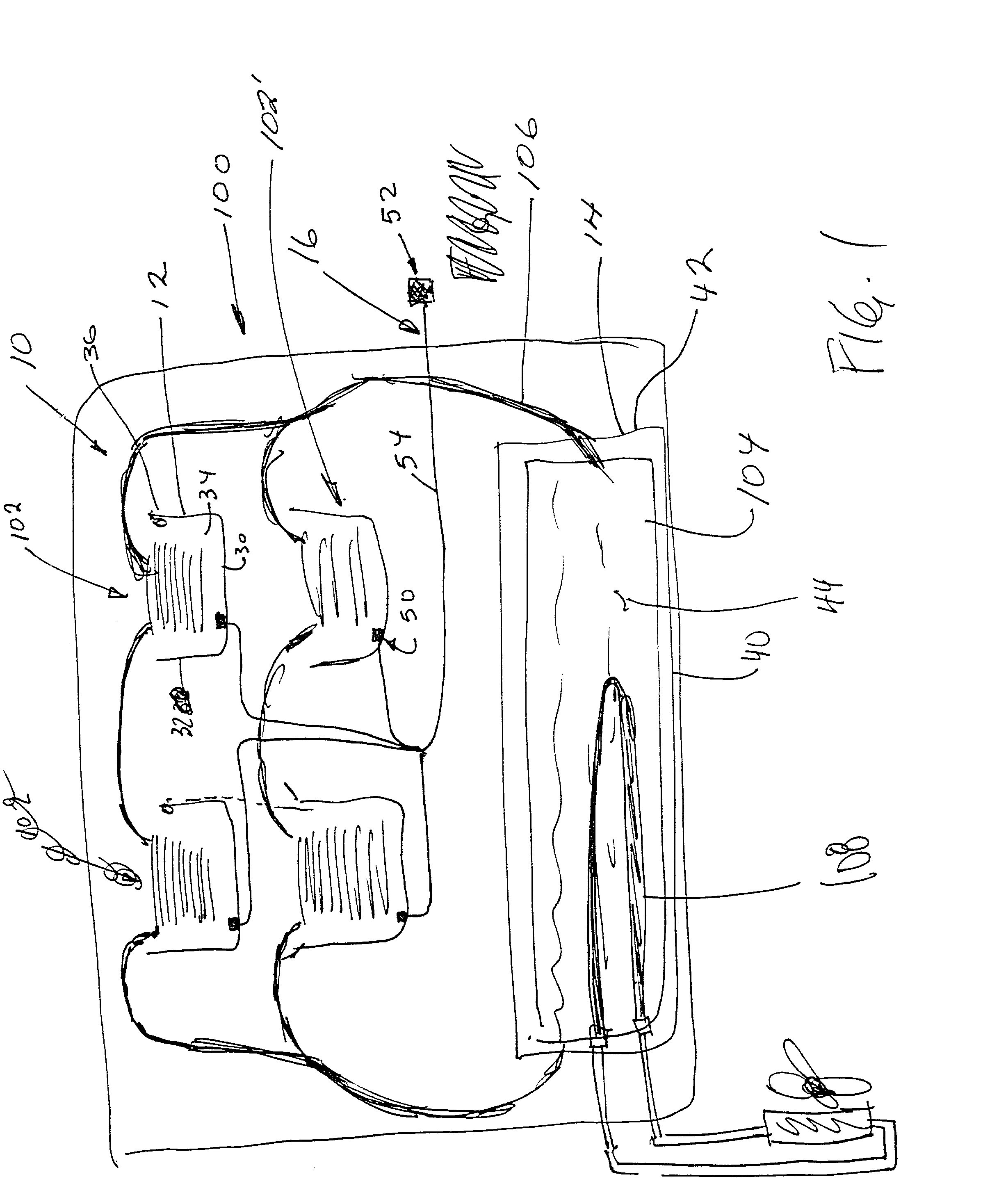

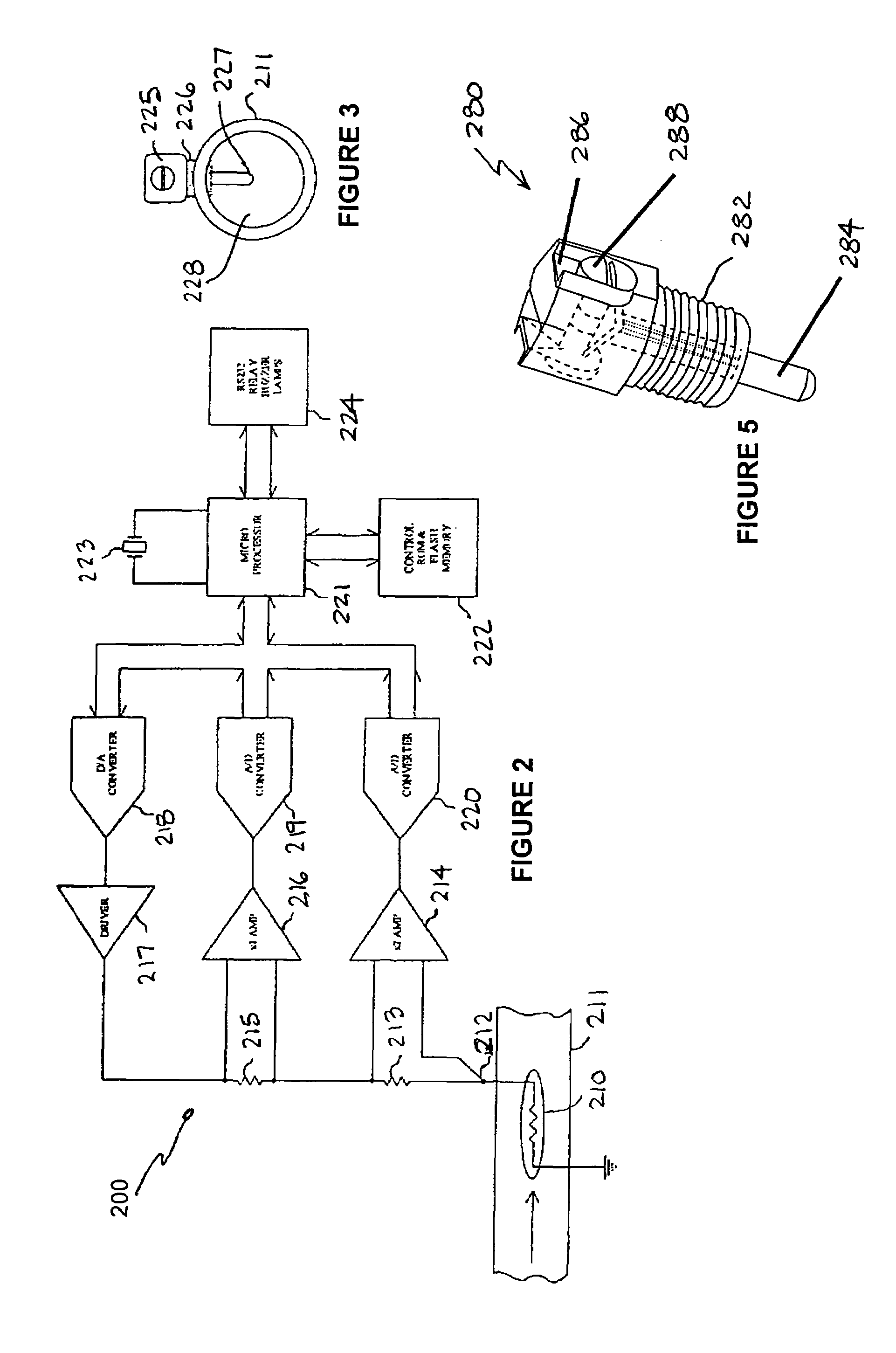

Hydraulic hybrid vehicle method of safe operation

InactiveUS20080093152A1Gearing controlPlural diverse prime-mover propulsion mountingMode controlExternal combustion engine

A hydraulic hybrid vehicle includes elements such as a hydraulic pump driven by an internal combustion engine and arranged to draw in low pressure fluid and pump the fluid at high pressure to an accumulator. A hydraulic motor is powered by the pressurized fluid. Safety processes are provided for detecting and addressing a number of conditions that may arise in the operation of the hydraulic hybrid vehicle, including an initialization procedure for start-up of the vehicle, a shut-down procedure, and procedures for detecting and responding to failure of the pump or motor, internal and external fluid leaks, and non-responsive actuation and mode control systems.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE U S ENIVERONMENTAL PROTECTION AGENCY

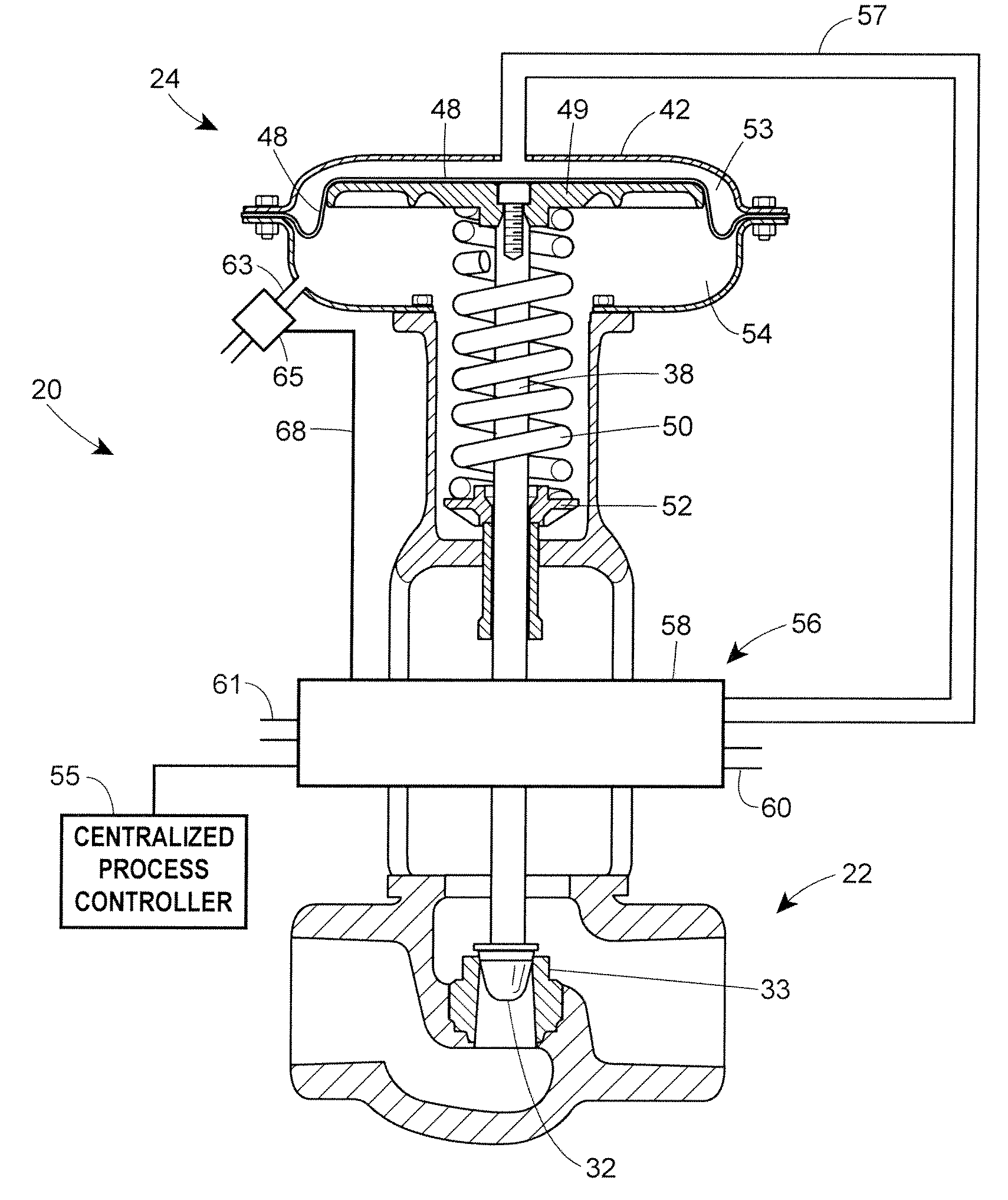

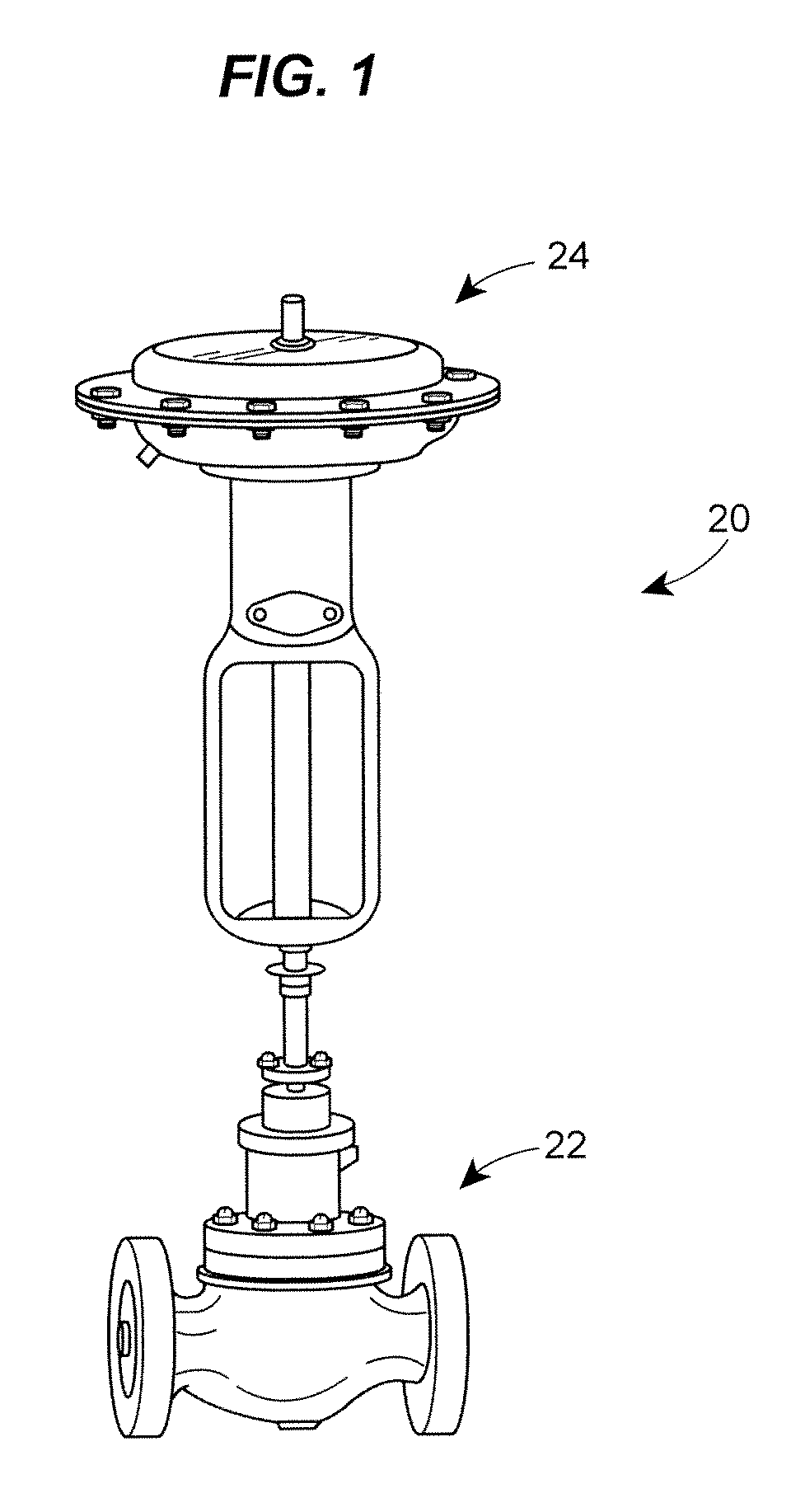

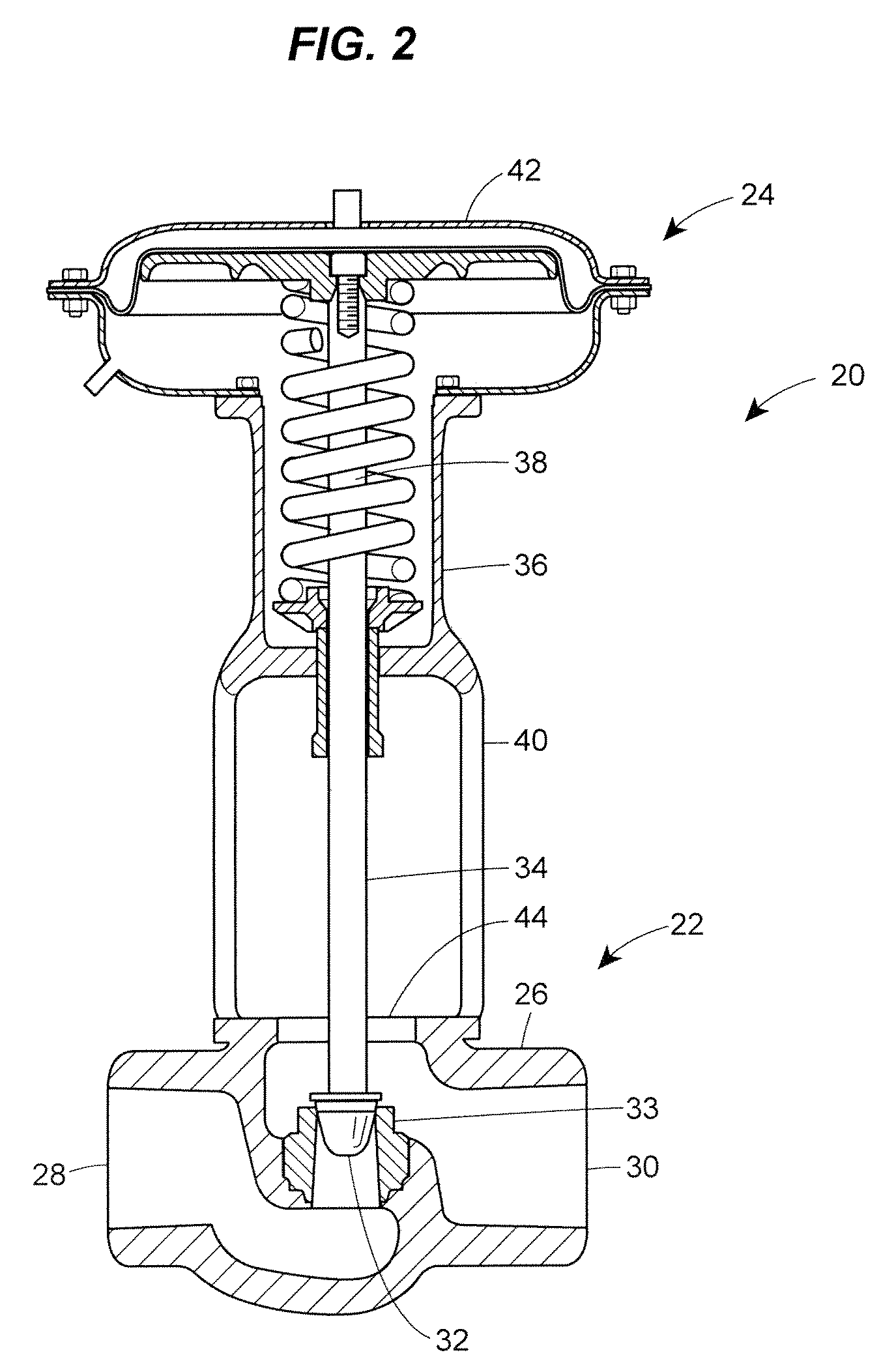

Device and Method for Determining a Failure Mode of a Pneumatic Control Valve Assembly

ActiveUS20110001070A1Operating means/releasing devices for valvesOther washing machinesControl lineControl valves

A control valve assembly is capable of diagnosing malfunctions in the control valve assembly and discerning a location of a control fluid leak in the control valve assembly. The control valve assembly includes a control valve, an actuator and a positioner. The actuator includes an actuator vent in an actuator housing, the actuator vent being connected to a flow switch. By determining a flow condition through the actuator vent, the positioner determines whether a control fluid leak is located in a control line or in a diaphragm.

Owner:FISHER CONTROLS INT LLC

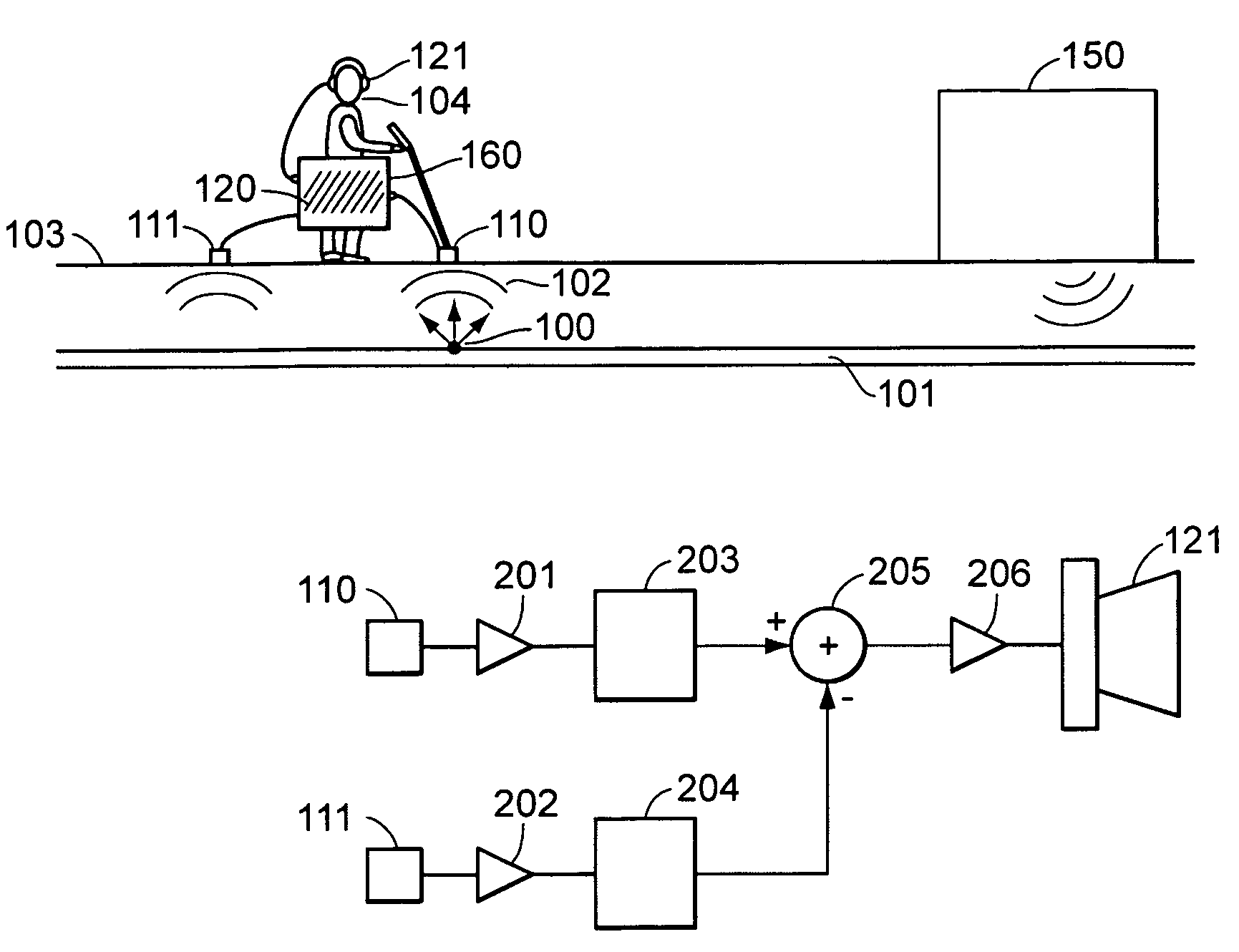

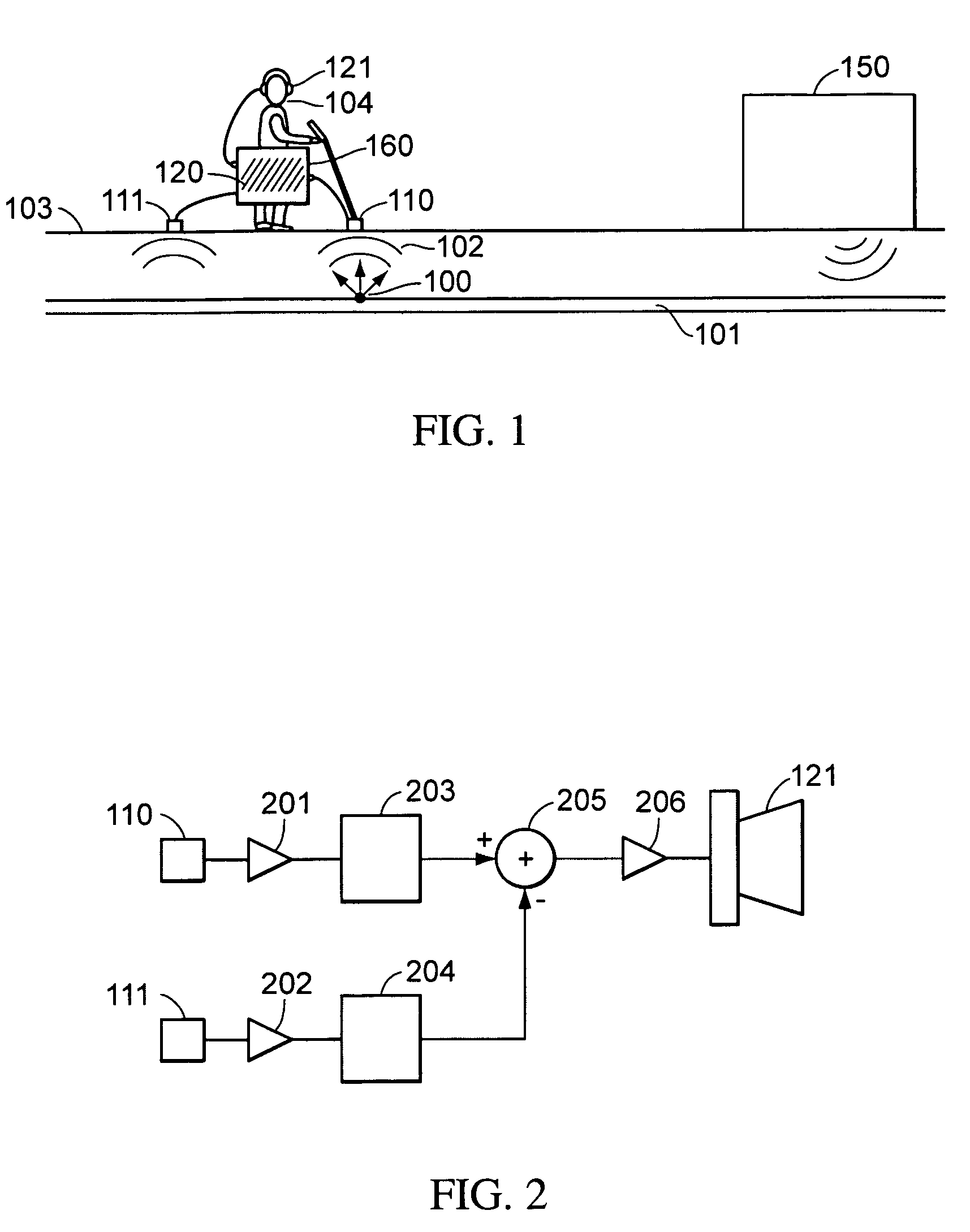

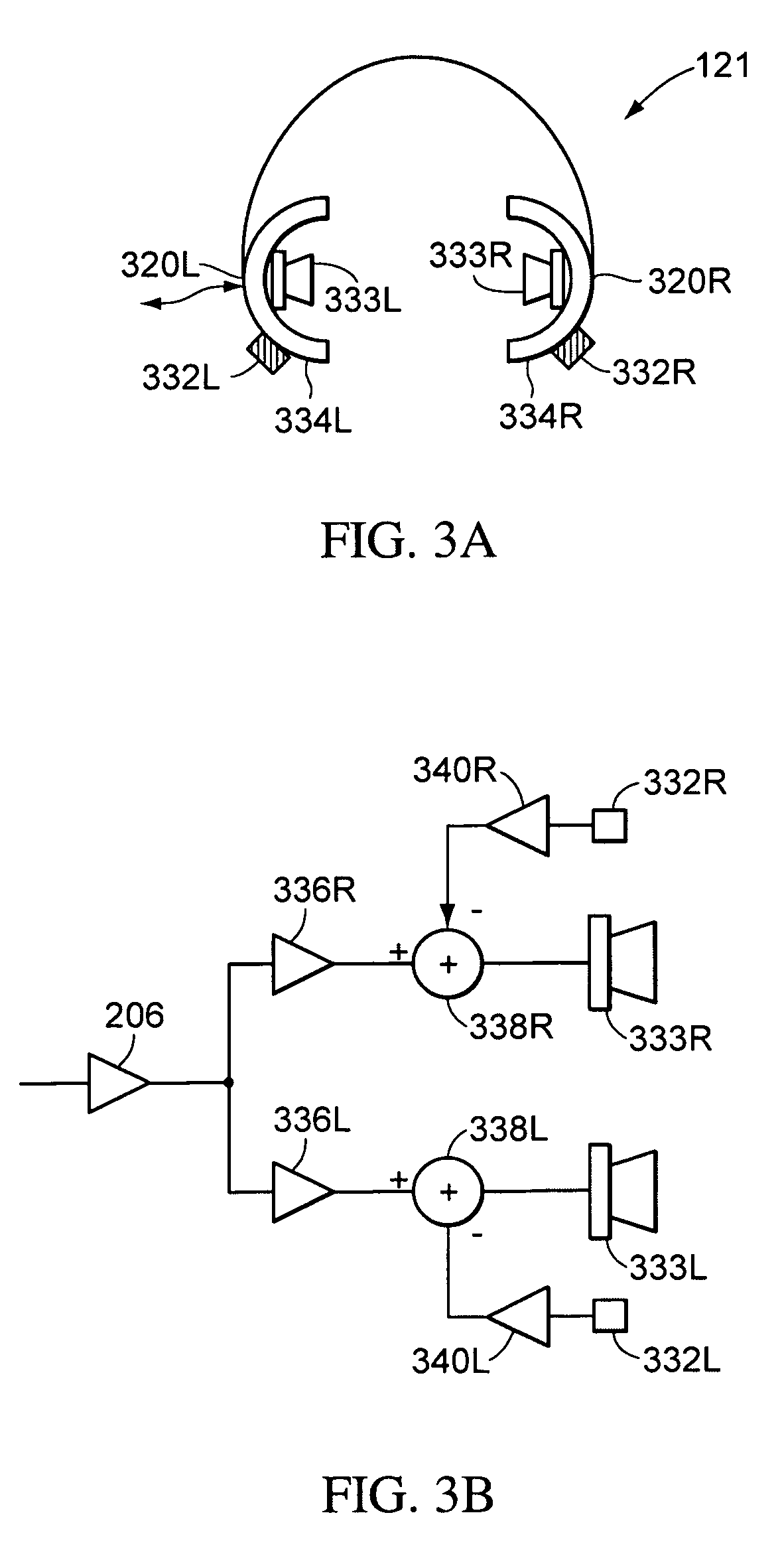

Acoustic detector with noise cancellation

ActiveUS7203322B1Reduce noiseEasily identifiableDetection of fluid at leakage pointMeasurement of fluid loss/gain rateNoise monitoringTransducer

An acoustic detector that includes active noise cancellation is presented. An acoustic detector converts sound waves, which include sound waves of interest as well as noise, to an electronic signal. An operator listens for a characteristic sound, for example the sound characteristic of fluid leaking from a pipe, as she varies the position of the transducer. At least one other acoustic detector is positioned in order to monitor noise. The electronic signal from the noise monitoring acoustic detector and the electronic signal from the acoustic detector are combined in a processor in order to cancel the noise. In some embodiments, the operator may adjust a cancellation band so that some frequencies are not cancelled. For example, the operator may adjust the cancellation band so that a co-worker's voice may be heard.

Owner:BUSAN TRANSPORTATION CORPORATION

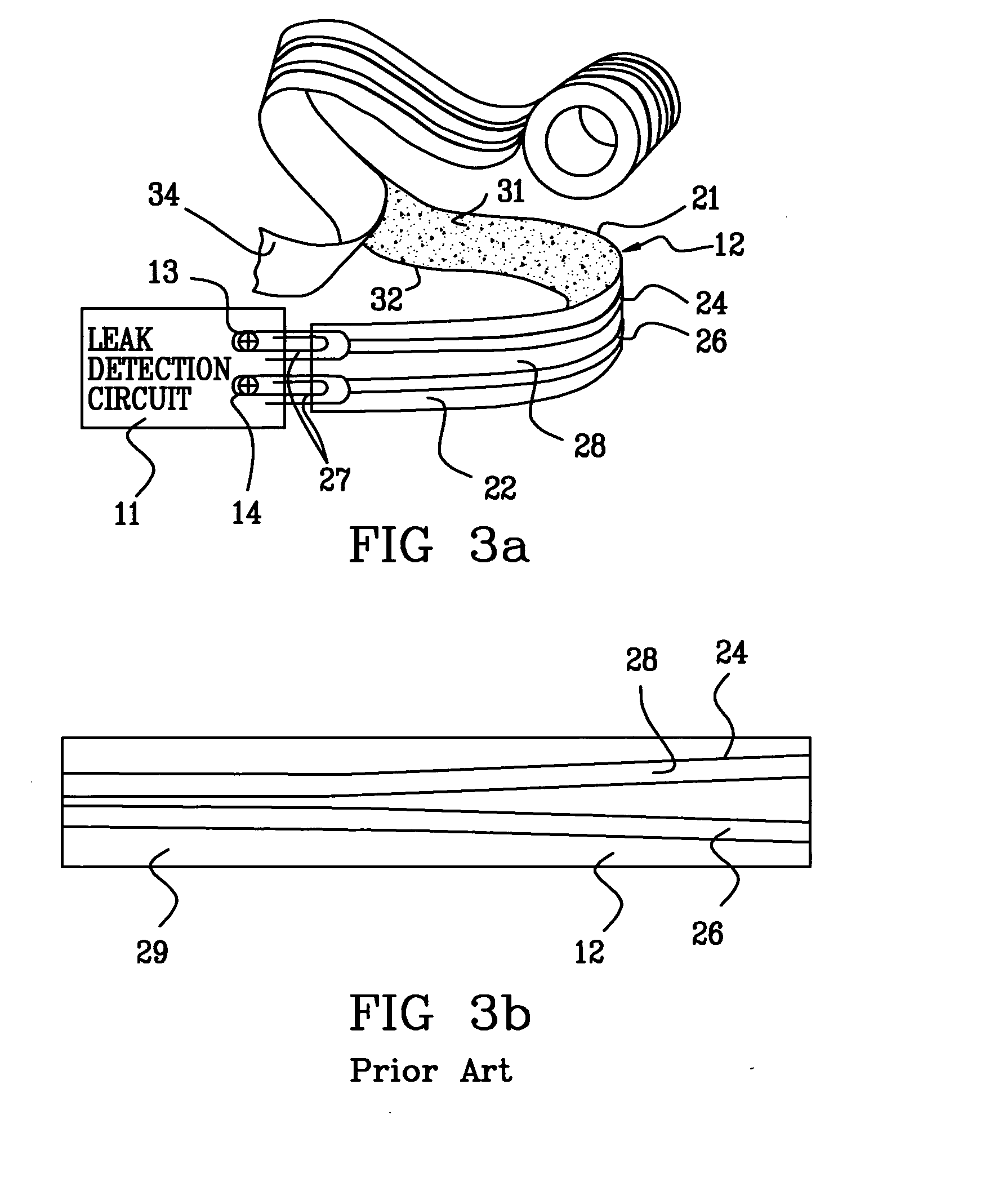

Probe for fluid leak detection with specific distal part

A disposable medical probe for detecting a leak of physiological fluid comprising a support layer, a conductive layer on top of the support layer, the conductive layer comprising two conducting electrodes both placed exclusively on each side of a longitudinal axis, the conductive layer defining two zones: a proximal zone with two proximal electrode parts being placed parallel to each other and being spaced apart by a constant distance d, and a distal zone with two distal electrode parts being spaced apart from each other by a gap e greater than said distance d, where the distal zone of the electrodes defines an increase in the gap between the distal parts of the electrodes, followed by a decrease in the gap between the distal parts of the electrodes.

Owner:GAMBRO LUNDIA AB

Systems and methods for detecting and preventing fluid leaks

InactiveUS20060260691A1Operating means/releasing devices for valvesFlow control using electric meansEngineeringFluid Leak

Owner:DAVIDOFF JOHN ANDREW

Sealing composition having corrosion inhibitor therein

A composition for sealing at least one fluid leak in heat exchange systems comprises at least one solvent, and fibrillated fiber in an amount and of a size sufficient to become entrained in and seal the one leak. At least one corrosion inhibitor is present in an amount sufficient to aid in prevention of corrosion of at least two metals. The corrosion inhibitor is compatible with coolants having organic acid corrosion inhibiting agents therein, and with coolants having silicate corrosion inhibiting agents therein.

Owner:PRESTONE PROD CORP

Fluid leak detector apparatus

ActiveUS9297467B1Significant water conservationMore water damageMeasurement of fluid loss/gain rateOperating means/releasing devices for valvesEngineeringLeak detection

A leak detection apparatus which is to detect a fluid leak in a closed fluid system and produce a display of the information of the leak on a display window of a control panel which may also be programmed to transmit that information to the human user such as a cell phone. The leak detection apparatus can be located in a closed position, not permitting flow of fluid within the closed fluid system, or in an open position permitting flow of fluid into the closed fluid system. During inactivity the closed fluid system is not capable of receiving fluid from a fluid supply pipe. During activity when fluid is being normally discharged from the closed fluid system the leak detection apparatus is to receive fluid from the fluid supply pipe.

Owner:NEW WORLD PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com