Universal fully-effective generating power machine

A power machine, all-purpose technology, applied in the direction of engine, wind power generation, engine components, etc., can solve problems such as difficulty in meeting grid connection requirements, low conversion rate, loss of water energy, wind energy and steam energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

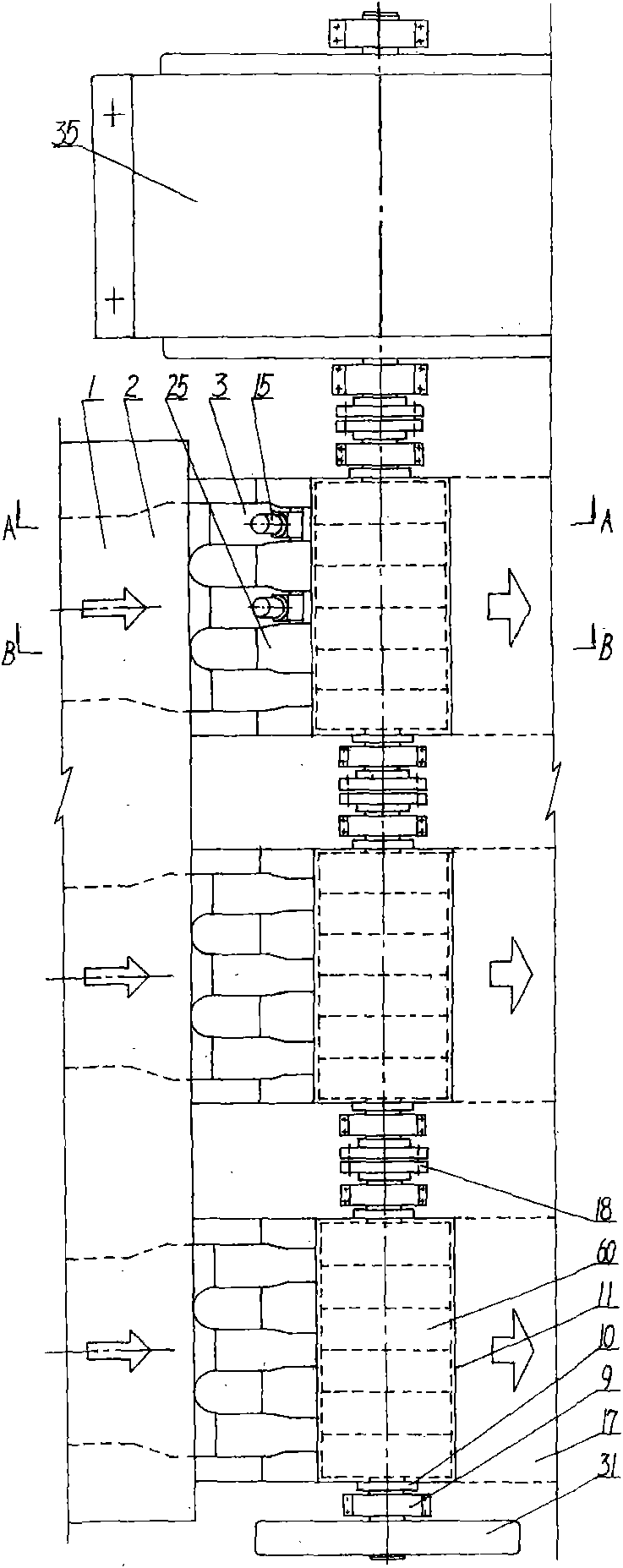

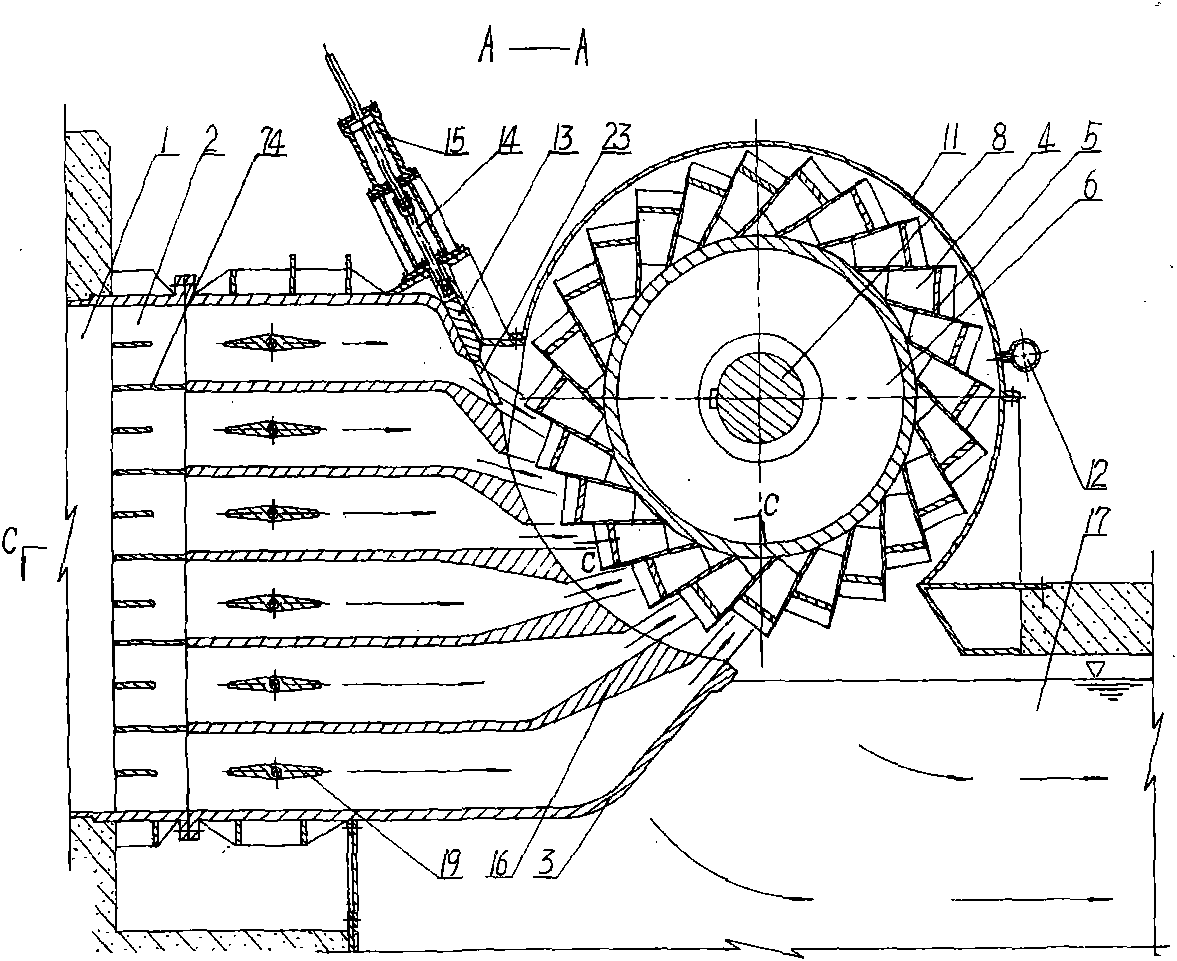

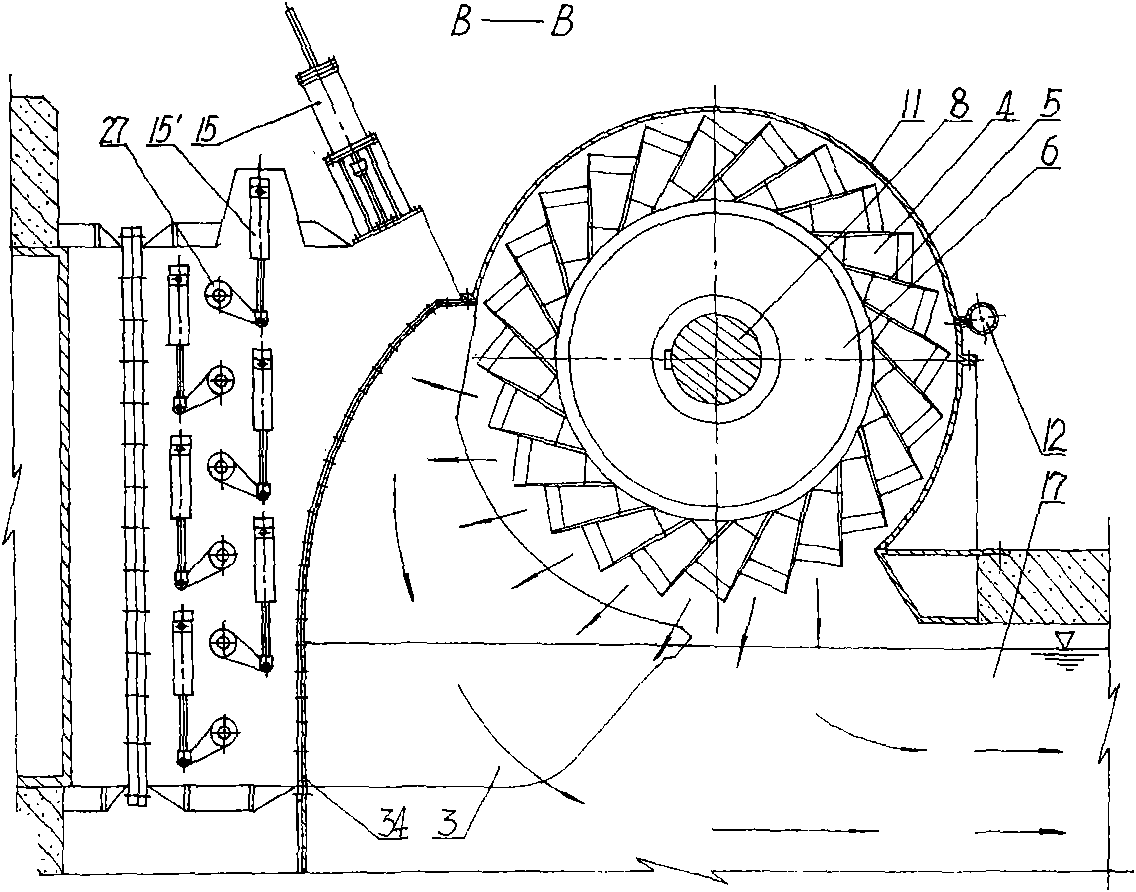

[0038] Figure 1 to Figure 9 A first embodiment of the invention is shown. This embodiment is an all-purpose full-effect water motor that converts water energy into rotational mechanical energy, and is a large-scale hydrodynamic generator set that drives a generator jointly after the main shafts of three all-purpose full-effect water motors are connected in sequence.

[0039] As shown in the figure: the water outlet ends of each pressure water delivery channel 1 are respectively connected with a drainage chamber 2, and the water outlet ends of the drainage chamber 2 are fixedly connected with three jet ports 3 with a certain distance from each other and a rectangular cross-sectional shape. . The inside of the jet port 3 is respectively provided with five deflectors 16 with different angles, and there is a certain distance between the two exit edges of the exit end of the deflector 16, so that the jet port 3 is divided into six rectangular exit ports 21 and other Correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com