Biaxial stretching polypropylene film and preparation method thereof

A technology of polypropylene film and biaxial stretching, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems affecting product quality, curling, unfavorable environmental protection, etc., to save production processes and reduce Production cost, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

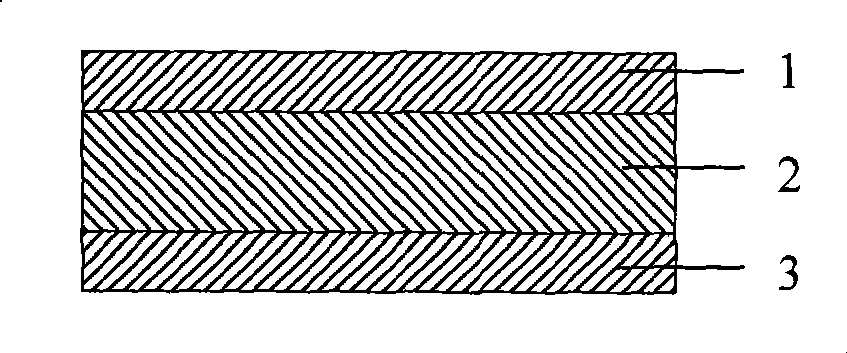

[0050] Embodiment 1 (three-layer coextrusion structure)

[0051] 1) After mixing 88% polypropylene resin HP 425 J (MFR: 3.1g / 10min), 2% antistatic masterbatch and 10% plasticizer (containing 50% petroleum resin) according to the proportion, Send it into the main extruder, the temperature of the main extruder is 210°C;

[0052] 2) Feed 100% ethylene-acrylic acid copolymer (acrylic acid monomer content is 9%, MFR is 2.0g / 10min) into an auxiliary extruder, and the temperature of the extruder is 180°C;

[0053] 3) Mix 98.5% polypropylene resin HP 425 J (MFR: 3.1g / 10min) and 1.5% anti-blocking masterbatch evenly and send it into another auxiliary extruder, the temperature of the extruder is 230°C;

[0054] 4) After the raw materials in the three extruders are melted and plasticized, they enter the same T-shaped die to form a melt with a three-layer co-extrusion structure of adhesive layer / polypropylene resin layer / polypropylene resin layer. The set temperature is 250°C;

[0055]...

Embodiment 2

[0060] Embodiment 2 (three-layer coextrusion structure)

[0061] 1) After mixing 88% polypropylene resin HP 425 J (MFR: 3.1g / 10min), 2% antistatic masterbatch and 10% plasticizer (containing 50% petroleum resin) according to the proportion, Send it into the main extruder, the set temperature of the main extruder is 200-250°C;

[0062] 2) Send 50% ethylene-alpha olefin copolymer (containing 5% petroleum resin) and 50% ethylene-methyl acrylate copolymer (EMA) into an auxiliary extruder, the set temperature of the extruder 200-290°C;

[0063] 3) Mix 98.0% polypropylene resin HP 425 J (MFR: 3.1g / 10min) and 2.0% anti-blocking masterbatch evenly and send it into another auxiliary extruder. The set temperature of the extruder is 190-250°C;

[0064] 4) After the raw materials in the three extruders are melted and plasticized, they enter the same T-shaped die to form a melt with a three-layer co-extrusion structure of adhesive layer / polypropylene resin layer / polypropylene resin laye...

Embodiment 3

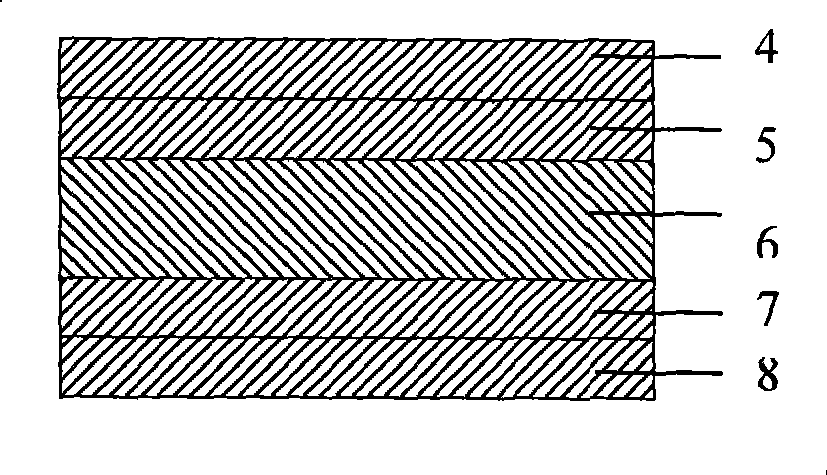

[0070] Embodiment 3 (five layers of co-extrusion structure)

[0071] 1) After mixing 88% polypropylene resin HP 425 J (MFR: 3.1g / 10min), 2% antistatic masterbatch, and 10% plasticizer (50% petroleum resin) according to the proportion, Send it into the main extruder, the set temperature of the main extruder is 230°C;

[0072] 2) After mixing 88% polypropylene resin HP 425 J (MFR: 3.1g / 10min), 2% antistatic masterbatch, and 10% plasticizer (containing 50% petroleum resin) according to the proportion, Sent to two interlayer extruders respectively, and the set temperature of the extruders is 230°C;

[0073] 3) Send 80% polyethylene and 20% ethylene-sodium (meth)acrylate into an auxiliary extruder, and the set temperature of the extruder is 290°C;

[0074] 4) Send 100% of the matting masterbatch into another auxiliary extruder, and the set temperature of the extruder is 220°C;

[0075] 5) After the raw materials in the five extruders are melted and plasticized, they enter the T-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com