Heat conduction insulating material, heat conduction insulating strip and preparation method thereof

A heat-conducting insulating material and heat-conducting insulating technology are applied in the fields of heat-conducting insulating materials, heat-conducting insulating sheets and preparing the heat-conducting insulating materials and heat-conducting insulating sheets, and can solve the problem of damage to material properties and insulating properties, increase in cost, and low surface energy of heat-conducting insulating materials, etc. problems, to achieve the effect of simplifying the preparation process and cost, good thermal conductivity and insulation performance, and ensuring insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

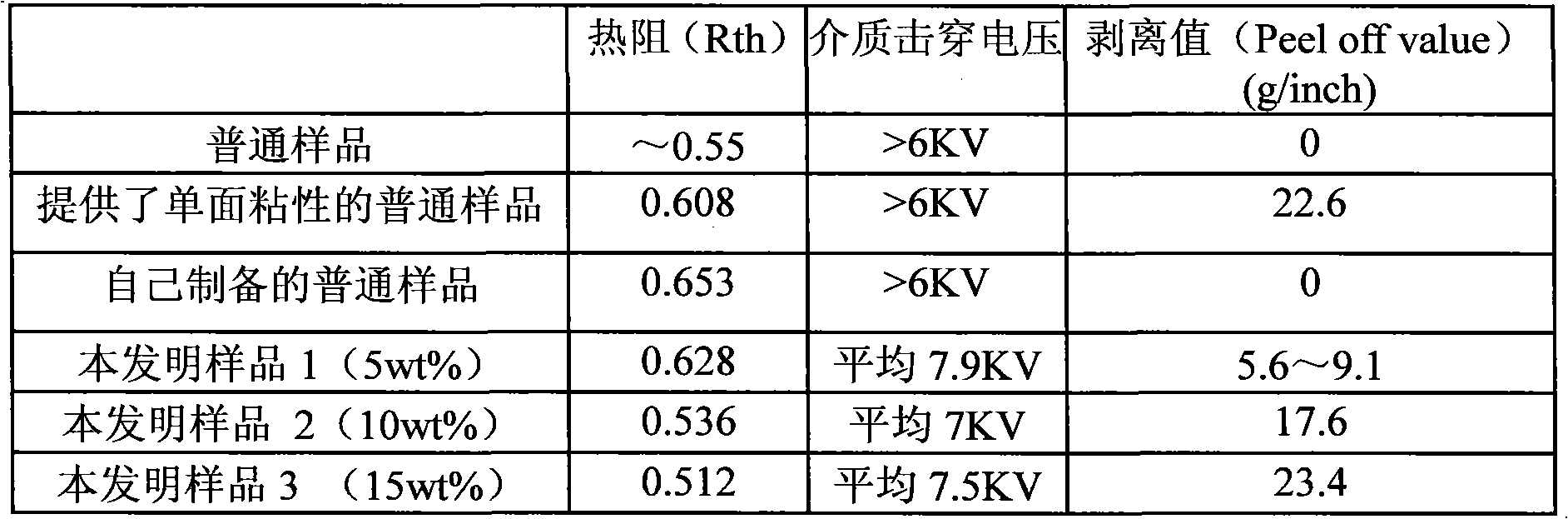

Examples

Embodiment 1

[0020] In the thermally conductive insulating material provided in this embodiment, the polymer matrix material is vinyl silicone resin, and the tackifying additive is vinyl MQ silicone resin.

[0021] In a specific example, the thermally conductive insulating material includes: 4 parts by weight of vinyl silicone resin, 1 part by weight of vinyl MQ silicone resin and 40 parts by weight of alumina particles with different particle sizes.

[0022] In another specific example, the thermally conductive insulating material includes: 20 parts by weight of vinyl silicone resin, 10 parts by weight of vinyl MQ silicone resin and 70 parts by weight of alumina particles with different particle sizes.

[0023] In another specific example, the thermally conductive insulating material includes: 40 parts by weight of vinyl silicone resin, 20 parts by weight of vinyl MQ silicone resin and 85 parts by weight of alumina particles with different particle sizes.

[0024] But the parts by weight ...

Embodiment 2

[0059] In this embodiment, the polymer matrix material is 4-40 parts by weight of polyisobutylene polymer. The low-molecular viscosity-increasing additive is 1-20 parts by weight of petroleum rosin resin. Here, 4-40 parts by weight and 1-20 parts by weight are just preferred cases, and the content can also be reasonably changed according to actual needs.

[0060] The thermally conductive insulating particles may be one or more selected from aluminum oxide, boron nitride, aluminum nitride, magnesium oxide and zinc oxide, and the amount used is, for example, 40-85 parts by weight. Here, 40-85 parts by weight is only a preferred example, and the content can also be reasonably changed according to actual needs.

[0061] For example, in a specific example, the thermally conductive insulating material includes: 4 parts by weight of polyisobutylene polymer, 1 part by weight of petroleum rosin resin, and 60 parts by weight of boron nitride and zinc oxide particles.

[0062] In anoth...

Embodiment 3

[0077] In this embodiment, the polymer matrix material is 4-40 parts by weight of silicone rubber. The low-molecular thickening additive is 1-20 parts by weight of silicone resin. Here, 4-40 parts by weight and 1-20 parts by weight are just preferred examples, and the content can also be reasonably changed according to actual needs.

[0078] The thermally conductive insulating particles may be one or more selected from aluminum oxide, boron nitride, aluminum nitride, magnesium oxide and zinc oxide, and the amount used is, for example, 40-85 parts by weight. Here, 40-85 parts by weight is only a preferred example, and the content can also be reasonably changed according to actual needs.

[0079] For example, in a specific example, the thermally conductive insulating material includes: 4 parts by weight of silicone rubber, 1 part by weight of silicone resin and 40 parts by weight of boron nitride particles.

[0080] In another specific example, the thermally conductive insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com