Dual-station chip test sorting machine

A chip testing and sorting machine technology, applied in the field of sorting machines, can solve the problems of low work efficiency, reduced efficiency, affecting processing efficiency, etc., and achieve the effect of improving the efficiency of raw tea and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

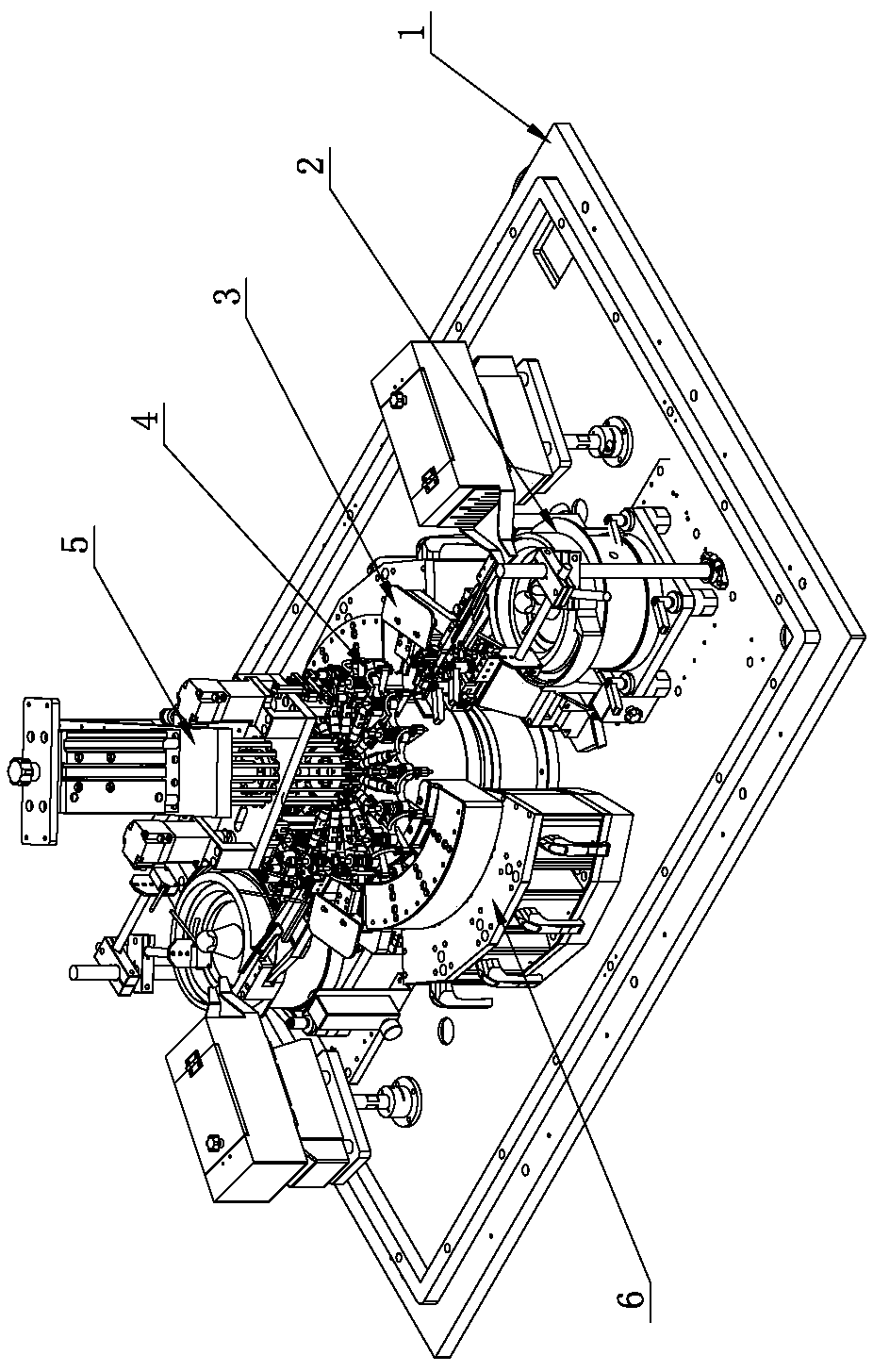

[0029] Such as Figure 1-13 A double-station chip testing and sorting machine shown includes a pair of feeding components 2, a pair of testing components 3, a turntable component 4, a pressing component 5 and a pair of distribution boxes 6 installed on the working platform 1. ;

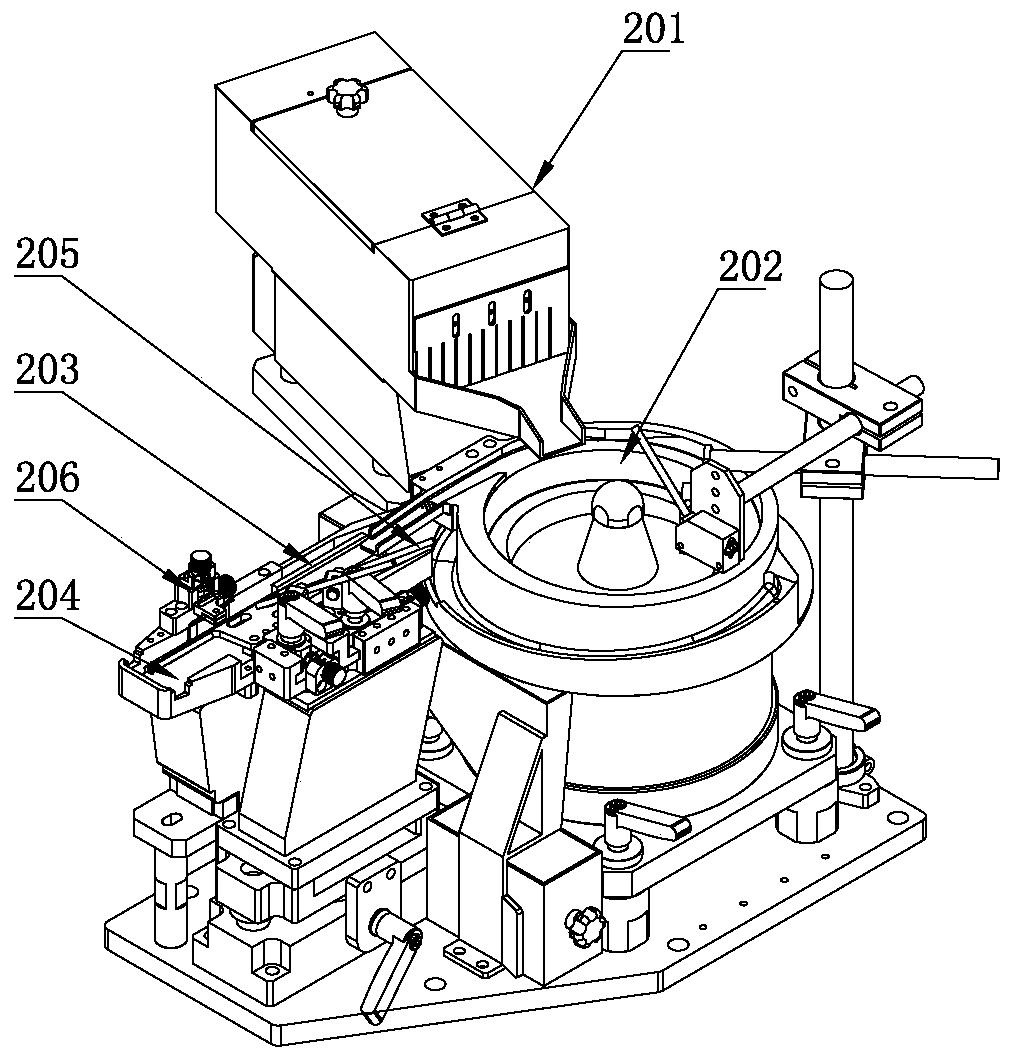

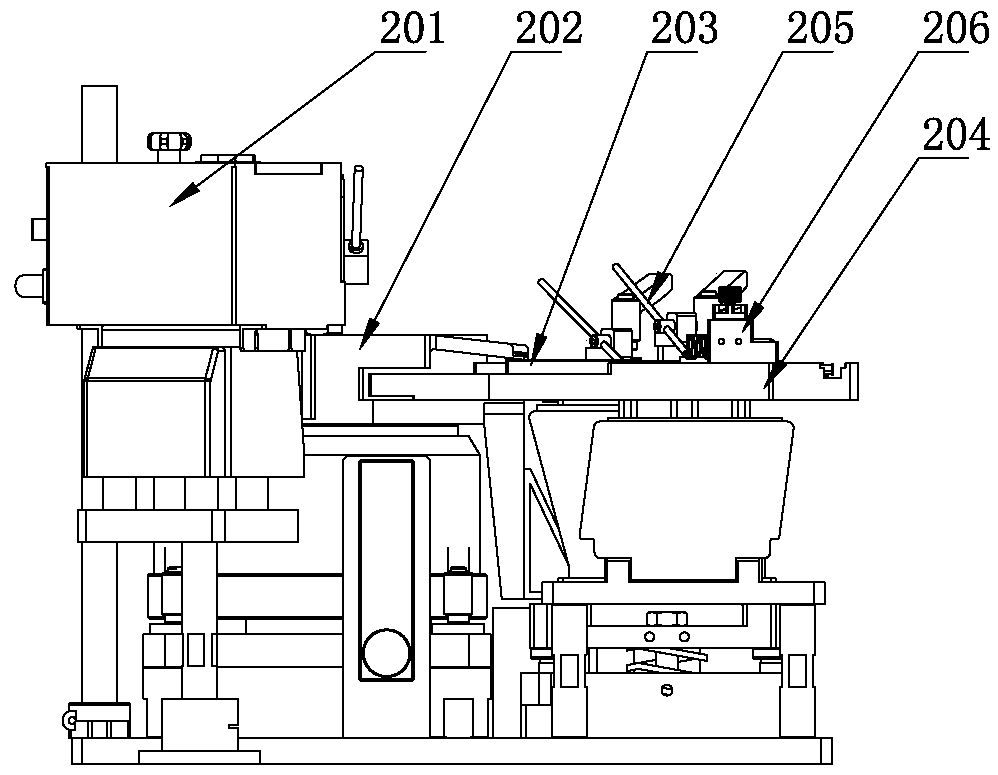

[0030] The feeding assembly 2 is used to transport the chip 7 to be tested into the testing assembly 3. The feeding assembly 2 includes a circular shock tray 202 that receives the chip 7 to be tested in the storage bin 201, and the outlet of the circular shock tray 202. The feed port is connected to the direct vibration feeding track 203, and the direct vibration recovery track 204 is arranged below the direct vibration feeding track 203. The discharge port of the direct vibration recovery track 204 is connected to the circular vibration feeding tray 202, and the end of the direct vibration feeding track 203 is connected to the turntable assembly. 4 docking, for the suction nozzle 402 on the turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com