Processing system for high-mountain green tea

A processing system and technology for alpine green tea, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of unstable tea quality, low space utilization rate of production workshop, large difference in product quality, etc. The effect of low system cost and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

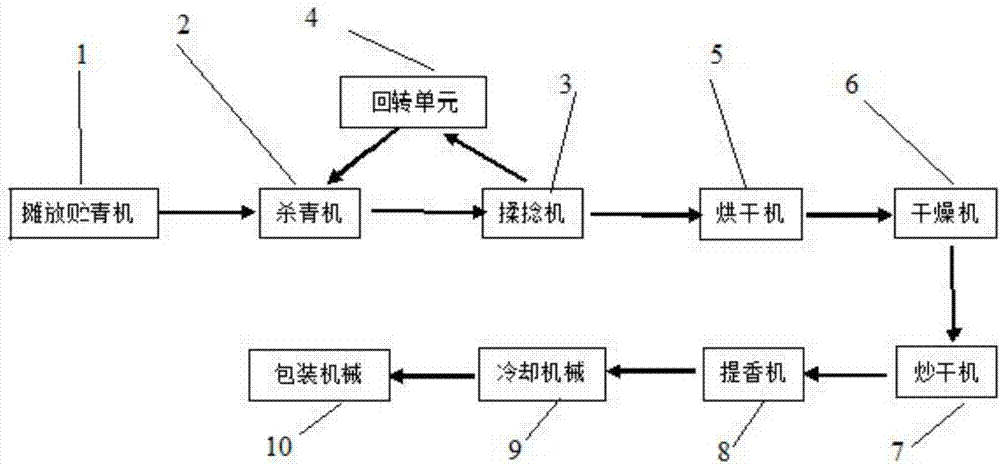

[0027] Such as figure 1 The processing system of a kind of alpine green tea includes spreading and putting green storage machine 1, killing green machine 2, kneading machine 3, drying machine 5, drying machine 6, frying drying machine 7, fragrance extracting machine 8, packaging machine 10, It is characterized in that the processing system of the high mountain green tea also includes a rotary unit 4 and a cooling machine 9, the input end of the rotary unit 4 is connected to the discharge port of the kneading machine 3, and the output end of the rotary unit 4 is connected to the greening machine. Machine 2 feeding port, constitute circulation, and described spreading silage storage machine 1 is connected to the feeding port of killing green machine 2, and the discharge port of described kneading machine 3 is connected to drier 5, and described drier 5 is connected To the drier 6, the drier 6 is connected to the frying machine 7, the frying machine 7 is connected to the aroma ex...

Embodiment 2

[0038] Such as figure 1 The processing system of a kind of alpine green tea includes spreading and putting green storage machine 1, killing green machine 2, kneading machine 3, drying machine 5, drying machine 6, frying drying machine 7, fragrance extracting machine 8, packaging machine 10, It is characterized in that the processing system of the high mountain green tea also includes a rotary unit 4 and a cooling machine 9, the input end of the rotary unit 4 is connected to the discharge port of the kneading machine 3, and the output end of the rotary unit 4 is connected to the greening machine. Machine 2 feeding port, constitute circulation, and described spreading silage storage machine 1 is connected to the feeding port of killing green machine 2, and the discharge port of described kneading machine 3 is connected to drier 5, and described drier 5 is connected To the drier 6, the drier 6 is connected to the frying machine 7, the frying machine 7 is connected to the aroma ex...

Embodiment 3

[0049] Such as figure 1 The processing system of a kind of alpine green tea includes spreading and putting green storage machine 1, killing green machine 2, kneading machine 3, drying machine 5, drying machine 6, frying drying machine 7, fragrance extracting machine 8, packaging machine 10, It is characterized in that the processing system of the high mountain green tea also includes a rotary unit 4 and a cooling machine 9, the input end of the rotary unit 4 is connected to the discharge port of the kneading machine 3, and the output end of the rotary unit 4 is connected to the greening machine. Machine 2 feeding port, constitute circulation, and described spreading silage storage machine 1 is connected to the feeding port of killing green machine 2, and the discharge port of described kneading machine 3 is connected to drier 5, and described drier 5 is connected To the drier 6, the drier 6 is connected to the frying machine 7, the frying machine 7 is connected to the aroma ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com