Continuous feeding system for polymerization of carbon fiber precursors

A carbon fiber precursor and feeding system technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unstable product quality, continuous production, low production efficiency, etc. Uniform and stable quality, reducing flammability and explosion, and improving the efficiency of raw tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the following detailed description is not considered to limit the present invention.

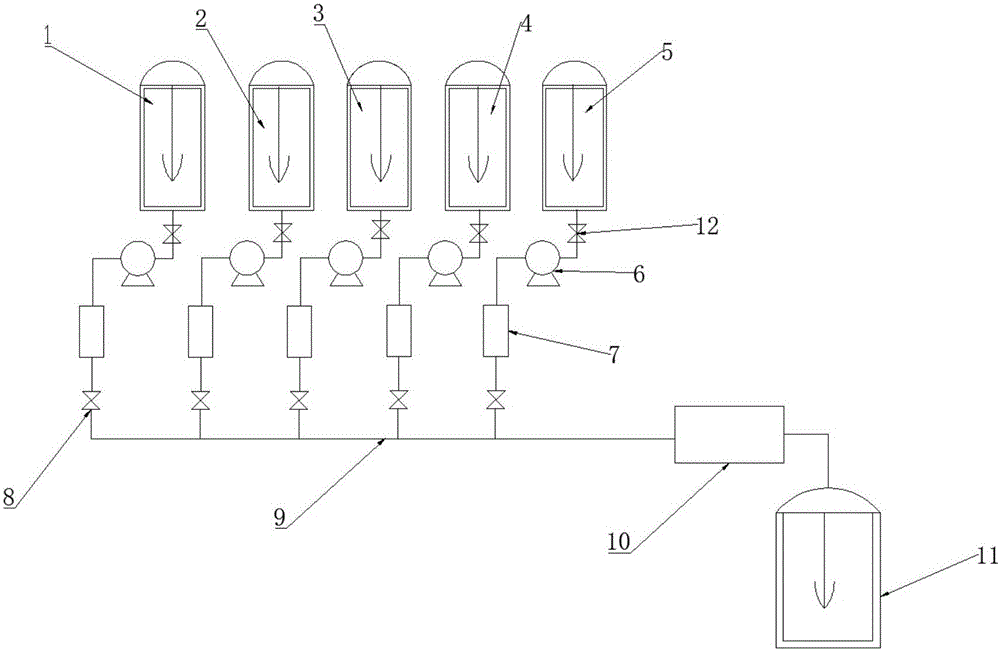

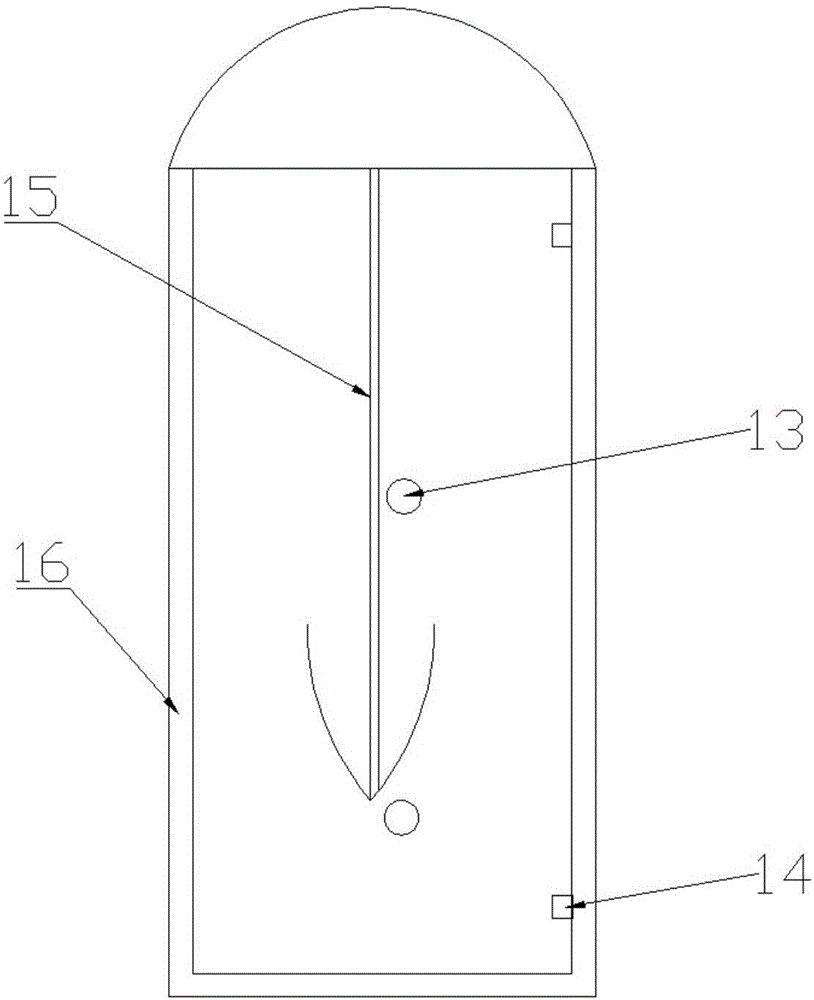

[0033] figure 1 It is a structural schematic diagram of a continuous feeding system for carbon fiber precursor polymerization in a preferred solution of the present invention. figure 2 It is a structural schematic diagram of a storage tank in a preferred solution of the present invention.

[0034] from figure 1 and 2 It can be seen that the carbon fiber precursor polymerization continuous feeding system is mainly composed of a dimethyl sulfoxide storage tank 1, an acrylonitrile storage tank 2, a monomer I storage tank, a monomer II storage tank, and an initiator storage tank 5. The pumps 6, mass flowmeters 7, regulating valves 8, manual valves 12, main pipes 9, static mixers 10 and mixed liquid storage tanks 11 connected to each storage tank are composed.

[0035] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com