Diaphragm installation device

A technology for installing devices and diaphragms, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of complex installation actions, large space occupation, and low production efficiency of backlight modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

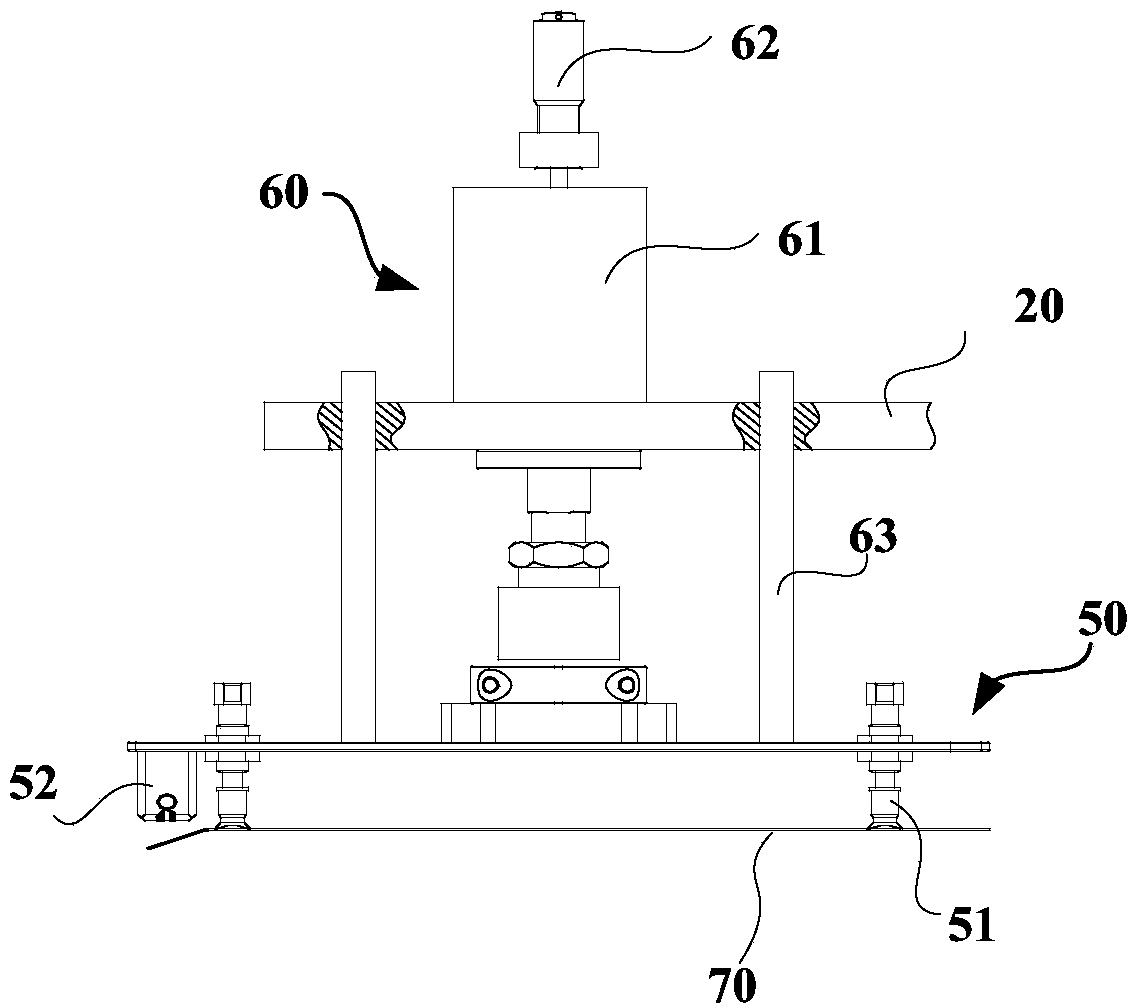

[0046] continue to refer image 3 , the lifting device 60 is a hydraulic cylinder or a cylinder 61, wherein the cylinder body of the cylinder 61 or the hydraulic cylinder is fixed on the support base 40, the connecting rod of the cylinder 61 or the hydraulic cylinder is fixedly connected with the suction cup device 50, and the cylinder 61 is pushed by air pressure or hydraulic pressure Or the connecting rod of the hydraulic cylinder, so as to realize the rise or fall of the suction cup device 50. During specific installation, the bottom of the cylinder body (the end away from the connecting rod) of the cylinder 61 can be fixed on the support base 40, or the One end of one end is fixed on the support seat 40, and the manufacturer can choose reasonably according to the size of the support seat 40, the height of the carrying device and the size of the air cylinder 61 or hydraulic cylinder during actual production.

[0047] When the air cylinder 61 or the hydraulic cylinder is use...

Embodiment 2

[0050] The lifting device 60 adopts a mechanical transmission mode. Specifically, the lifting device 60 includes: a rack slidably mounted on the support base 40 , and a motor fixed to the support base 40 , and the motor meshes with the rack through a gear.

[0051] At this time, one end of the rack is fixedly connected to the suction cup device 50 , and the other end is slidably assembled to the support seat 40 . Specifically, the support seat 40 has a protrusion, and the back side of the rack (the side opposite to the teeth) has a groove that is slidably fitted with the protrusion. And the lifting of the rack is controlled by the motor, thereby realizing the lifting of the sucker device 50 . Wherein, the motor can be a servo motor or a stepping motor, which has good controllability and motion stability.

[0052] In order to further improve the stability of the rack when moving, preferably, the support base 40 is provided with a through hole that is slidably fitted with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com