Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Low gas resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

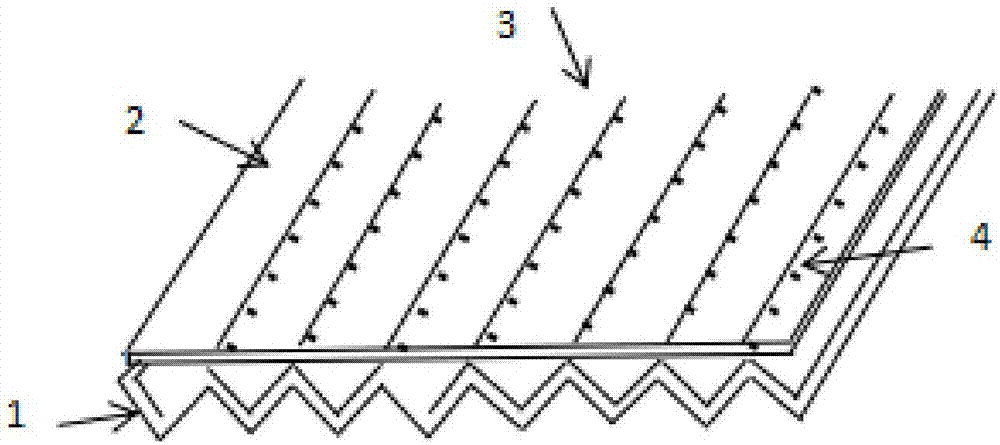

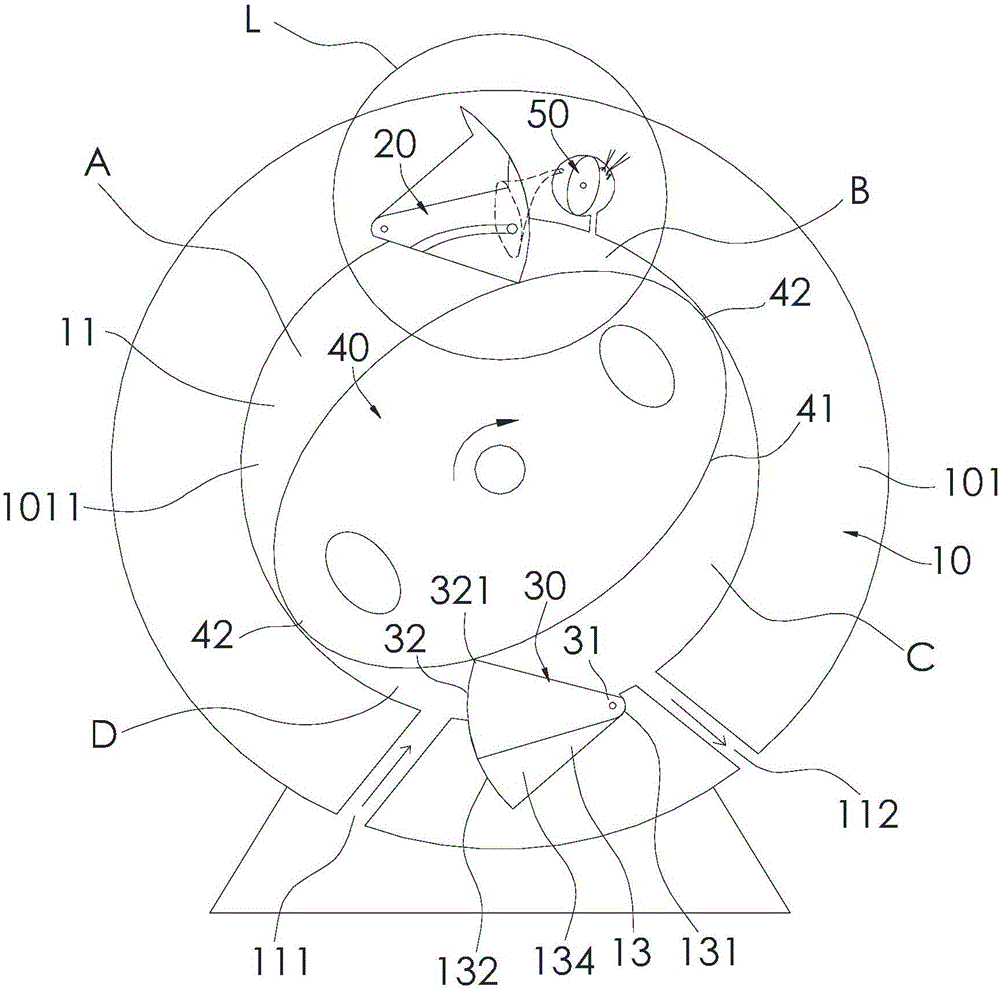

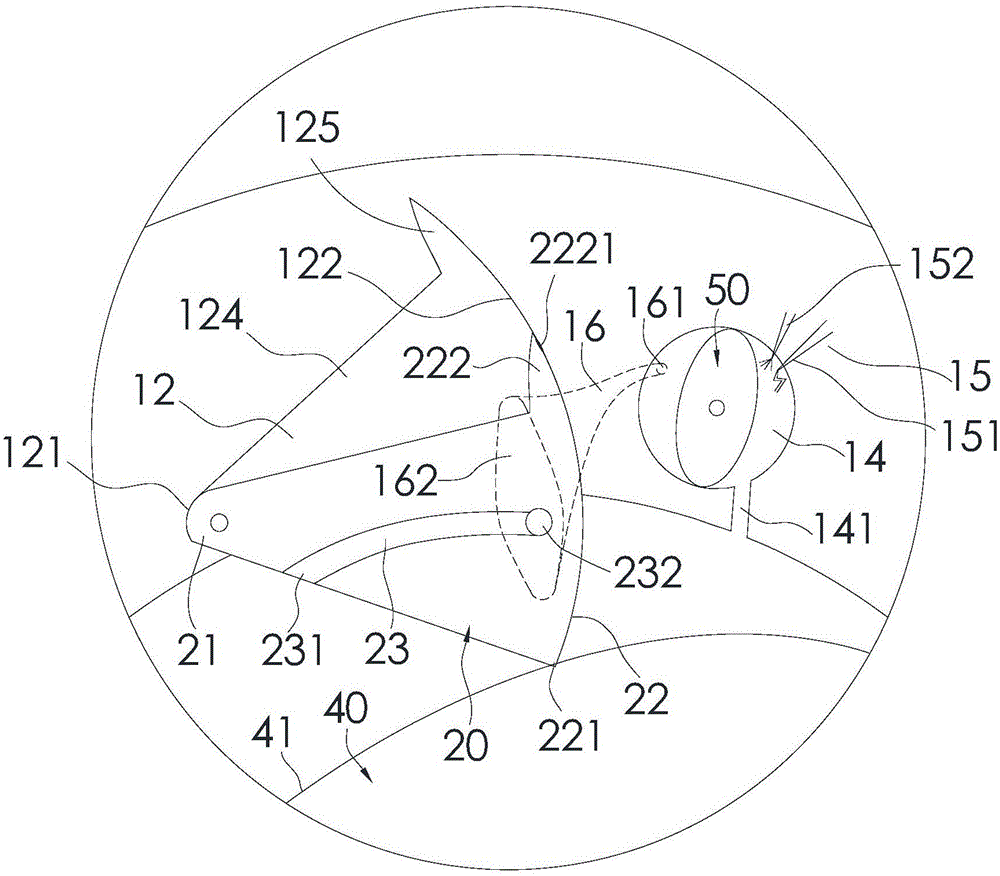

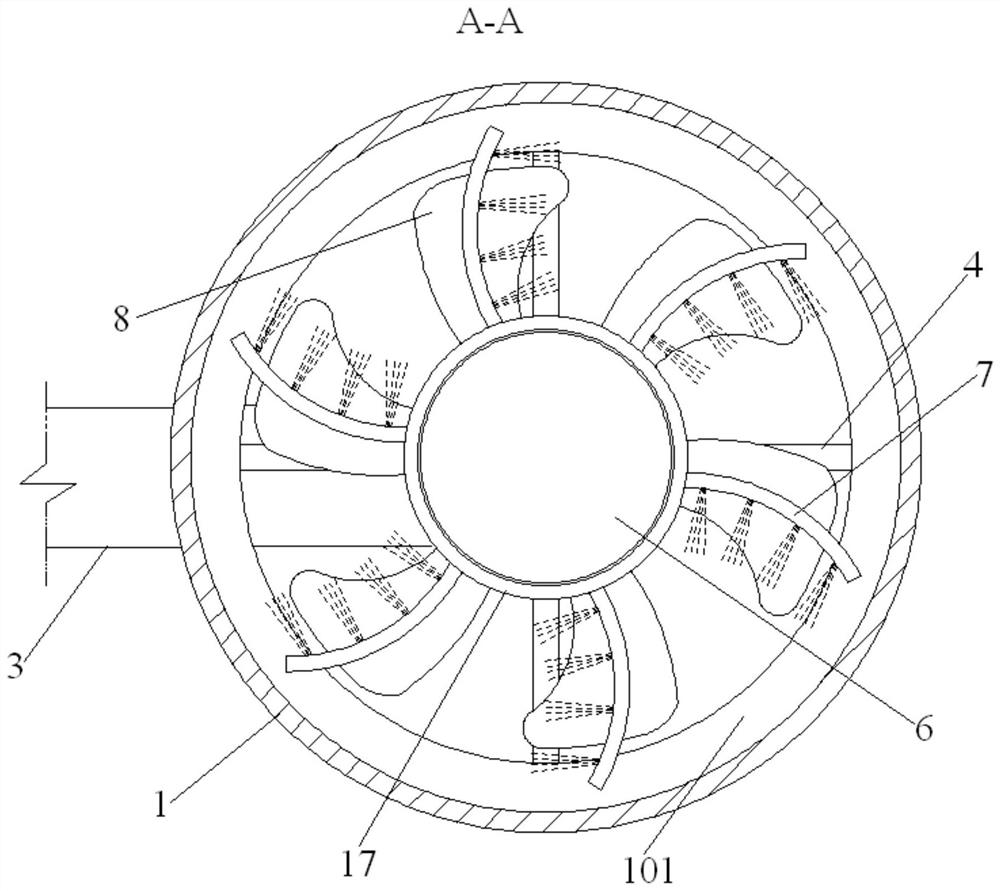

Plane material otter board stuffing type cross flow type hypergravity swinging bed and uses thereof

InactiveCN101254355ALow gas resistanceEnhanced mass transferUsing liquid separation agentFractional distillationHypergravityEngineering

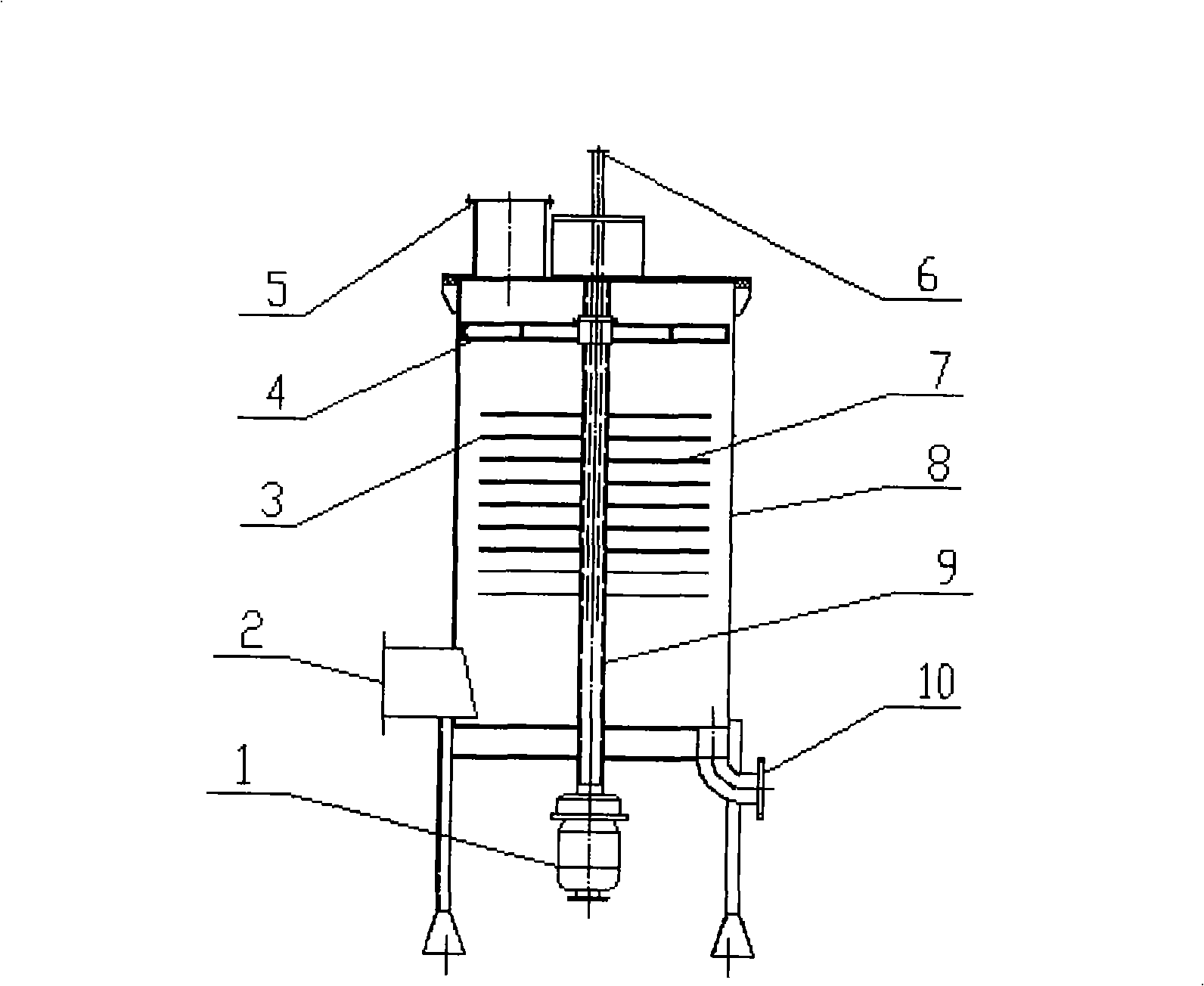

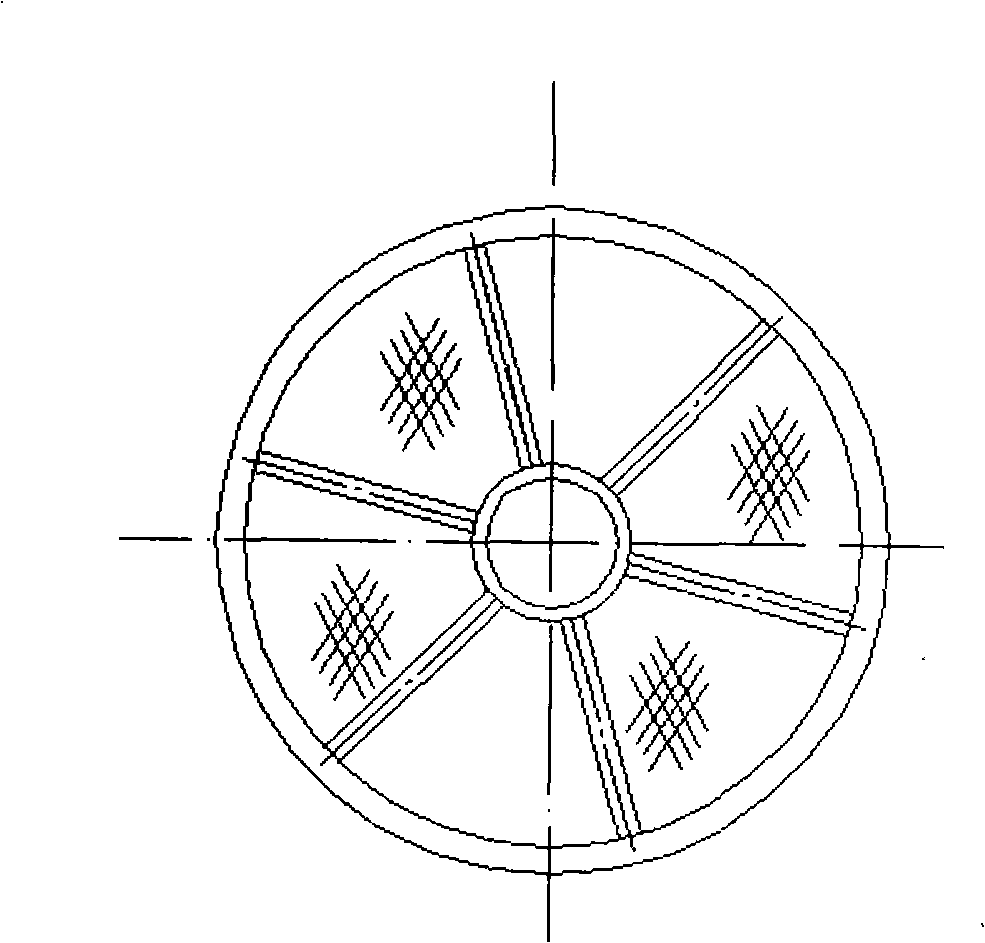

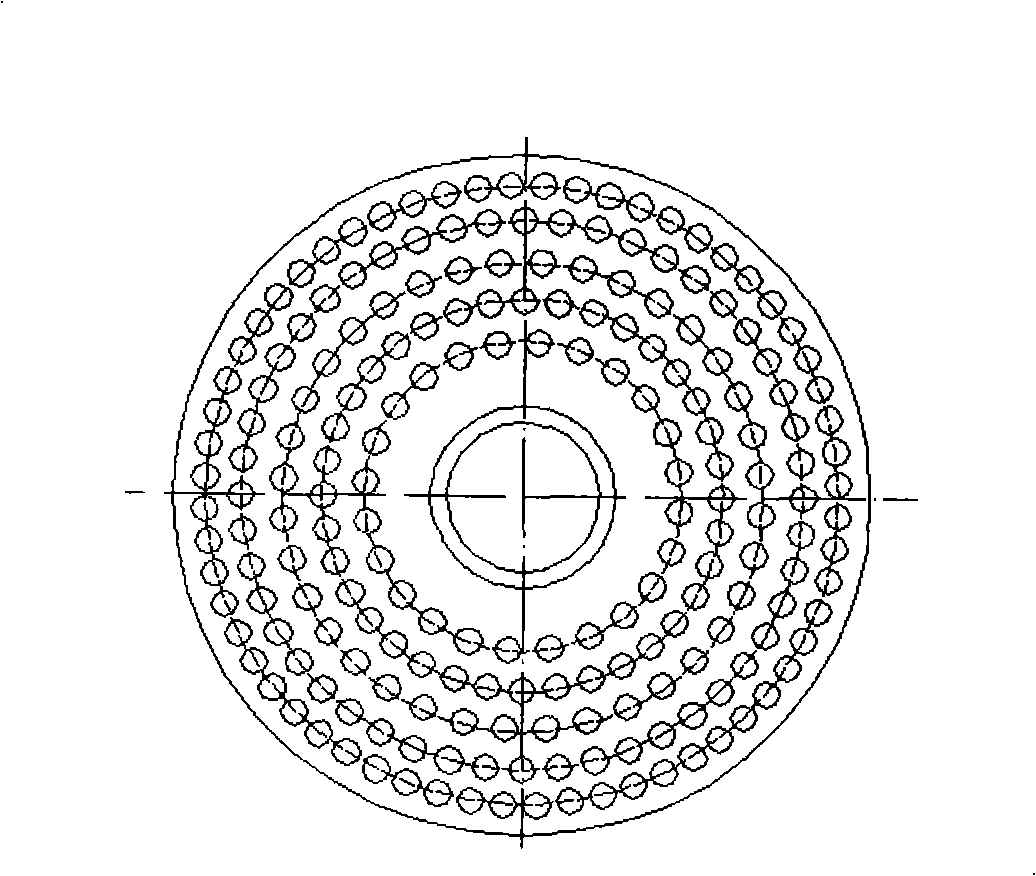

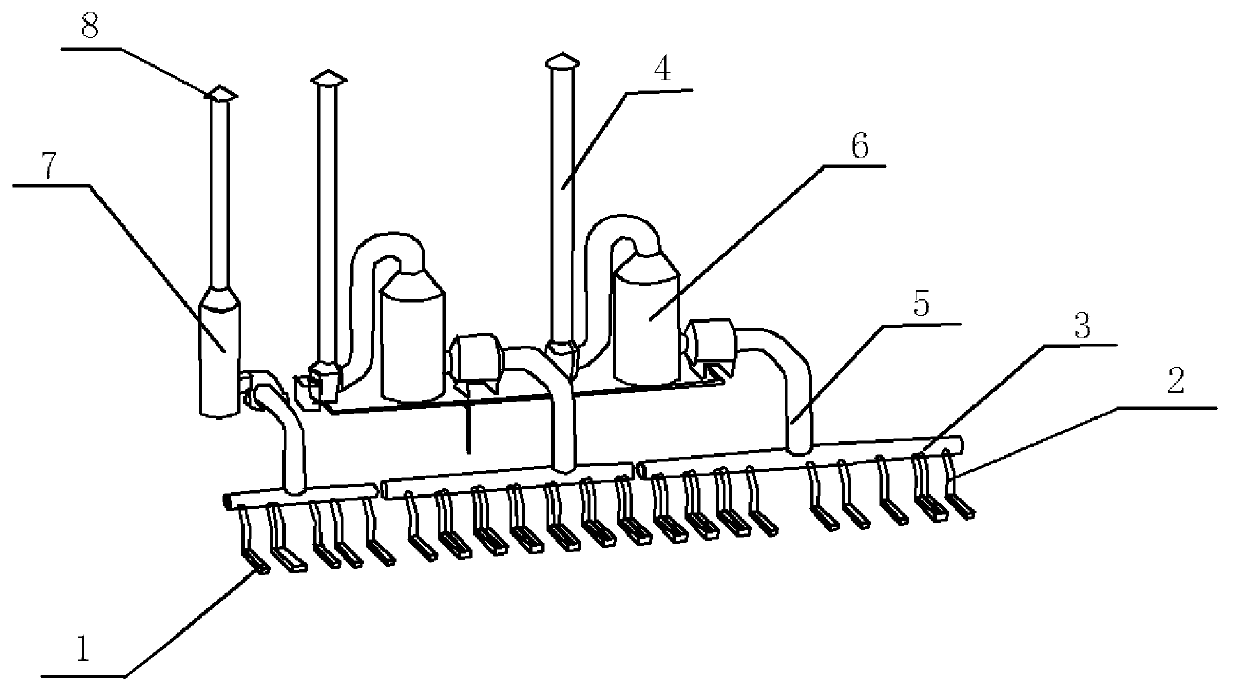

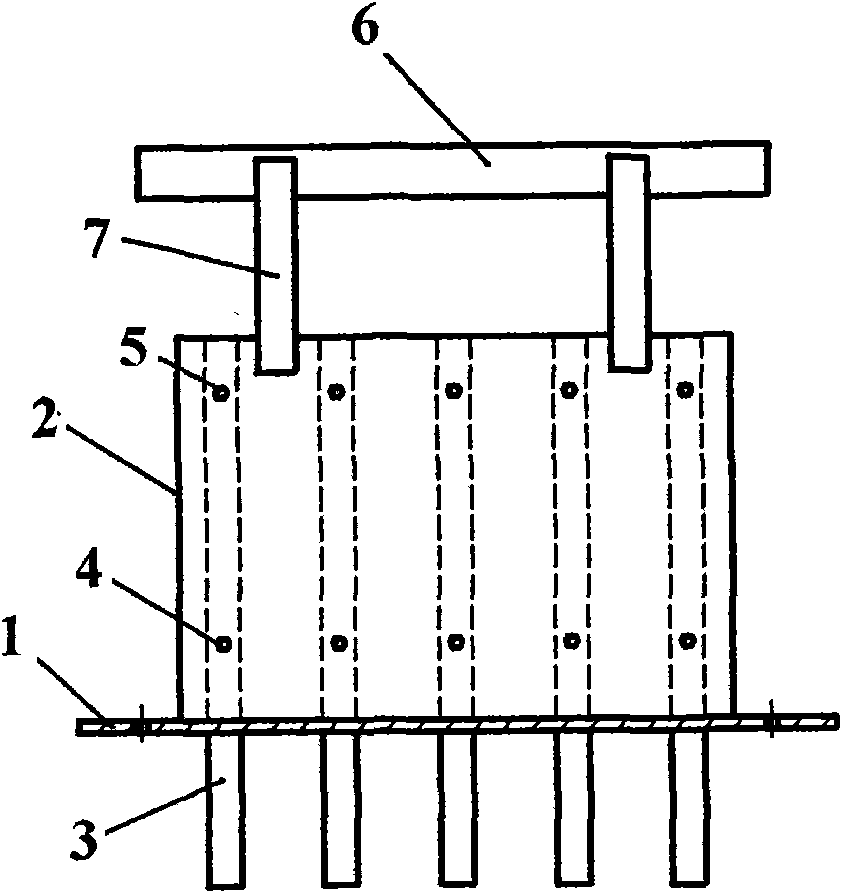

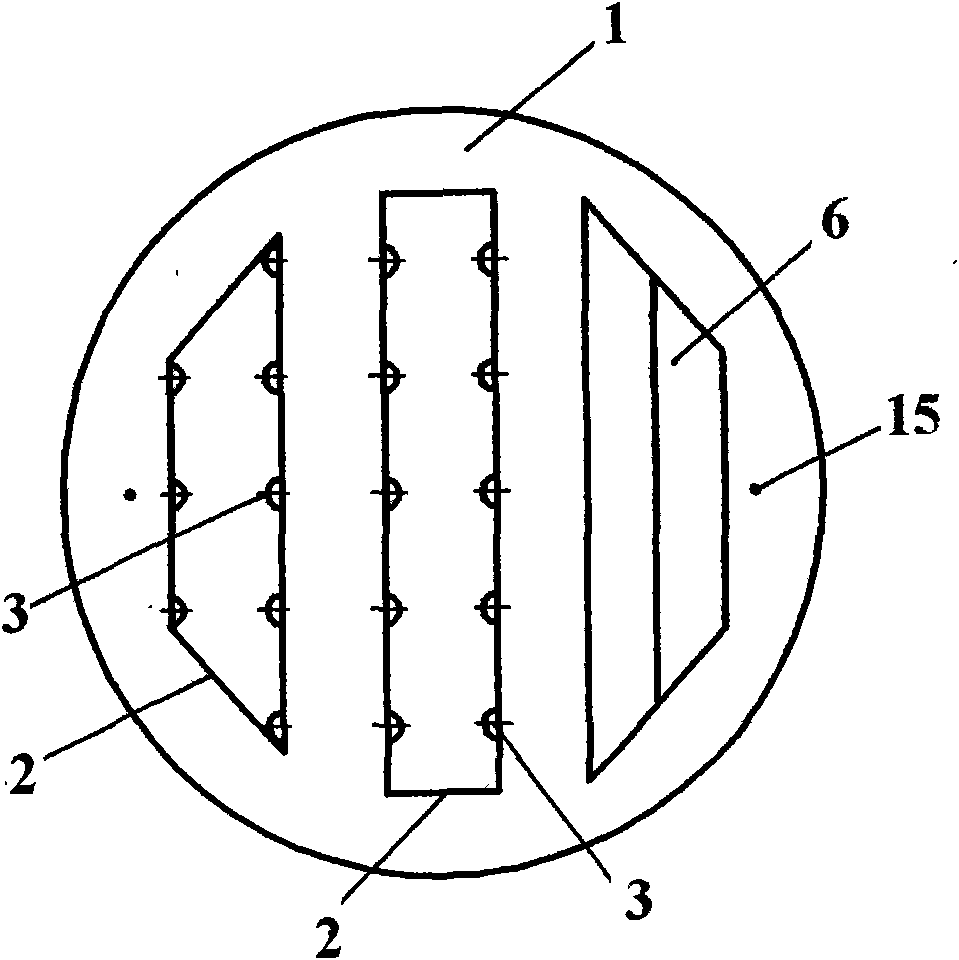

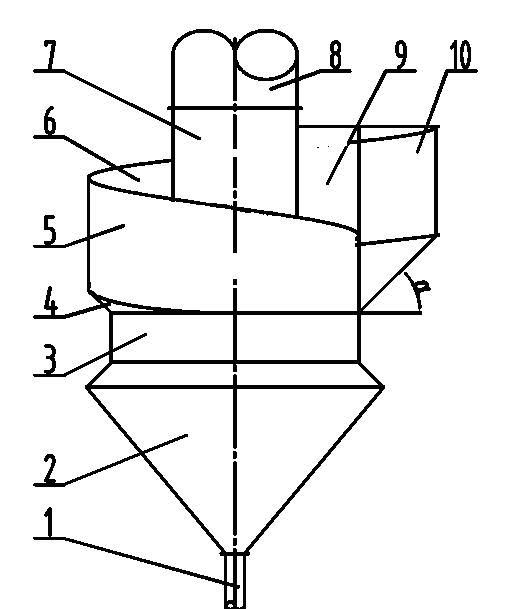

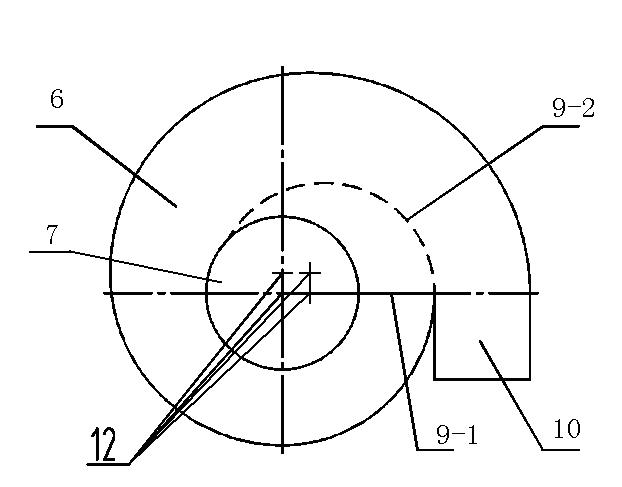

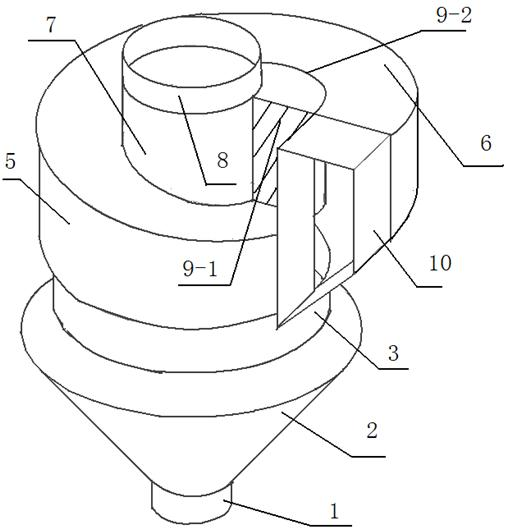

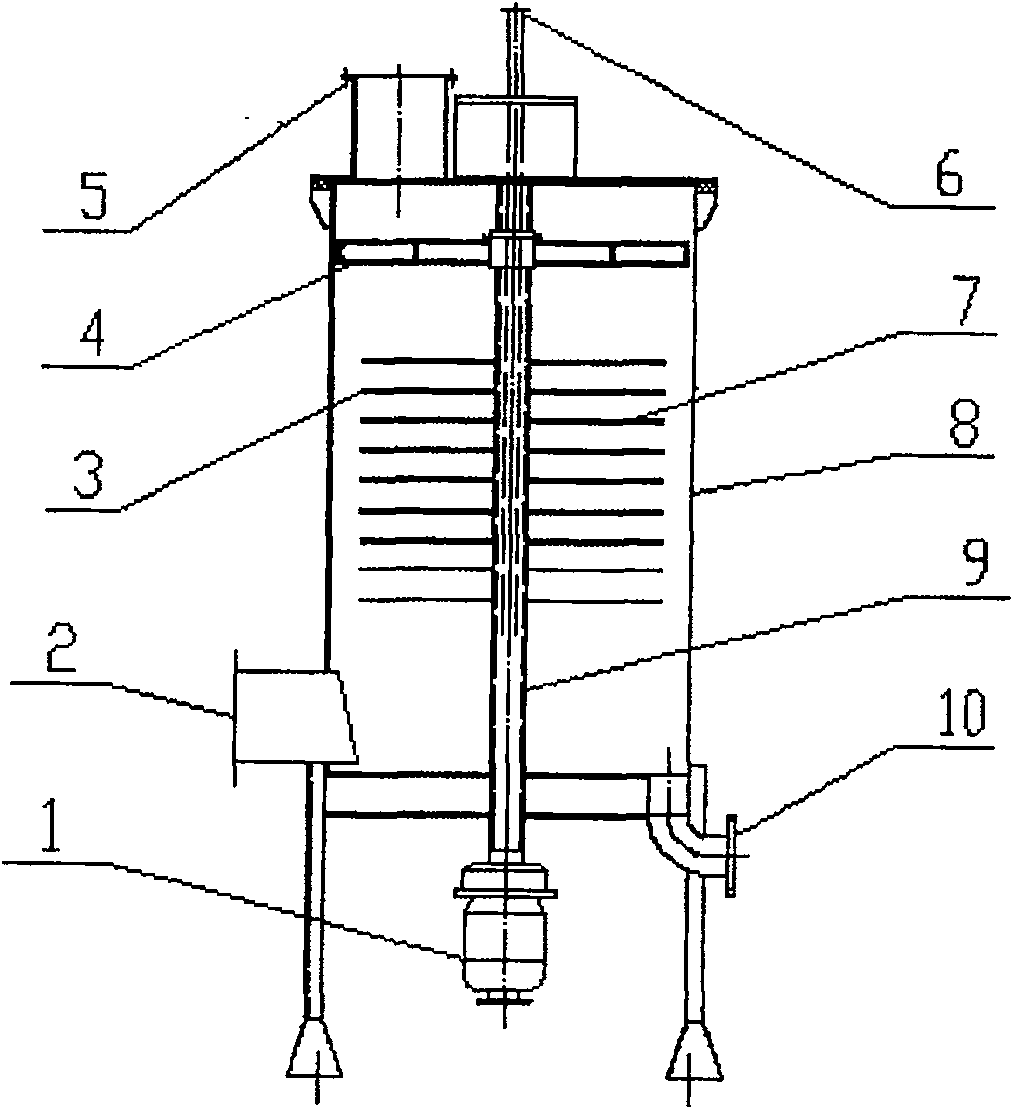

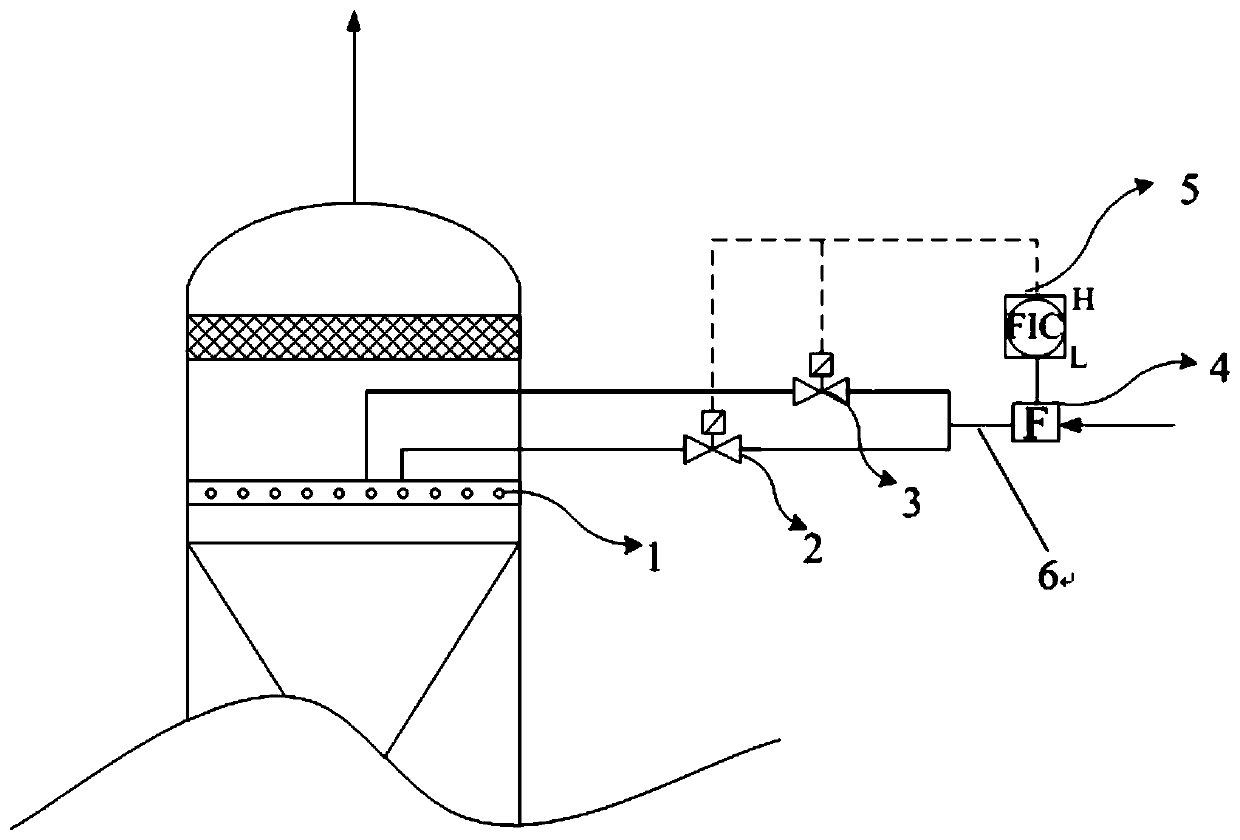

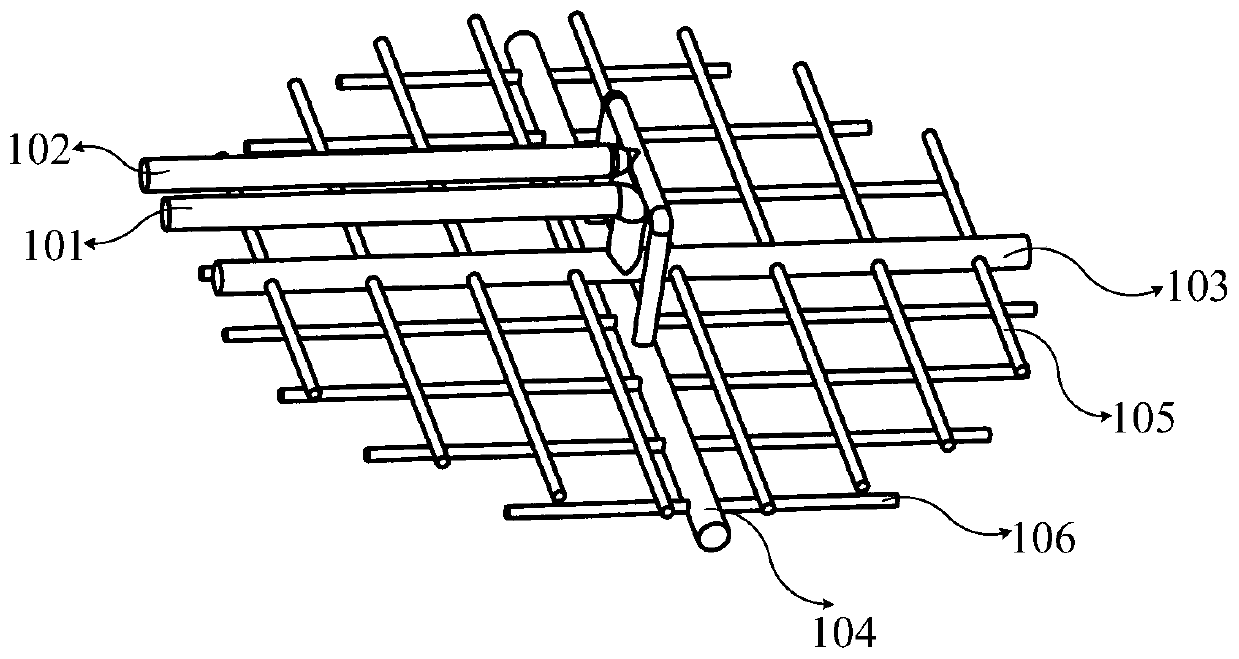

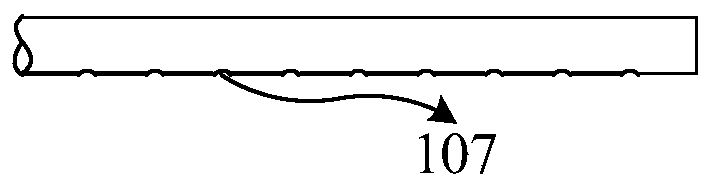

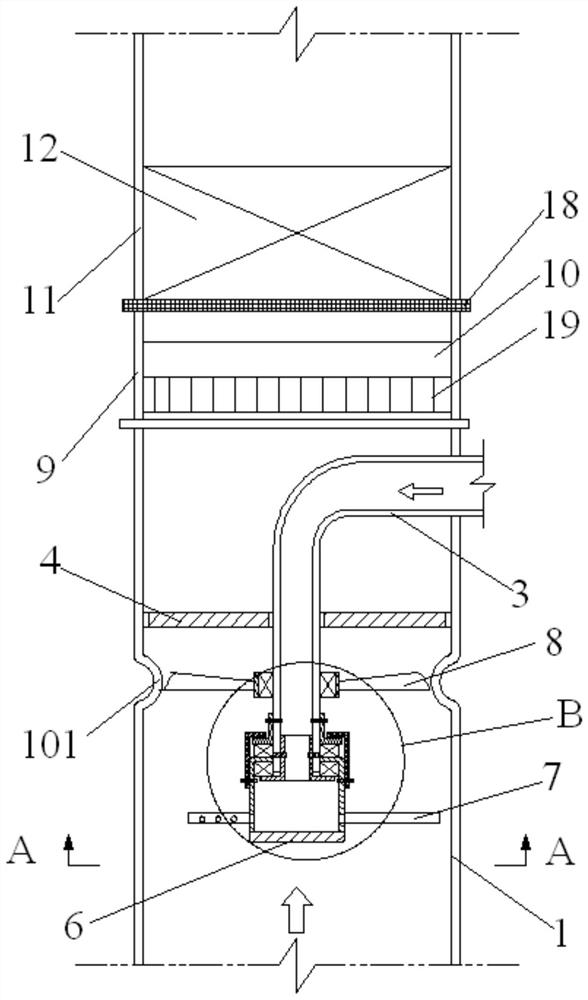

The invention discloses a planar otter board packing type crossflow super-gravity rotating packed bed, as well as the application thereof. The rotating packed bed comprises a rotating packed bed shell, a motor and a rotating shaft; the rotating shaft positioned in the shell is of a hollow structure, the middle of the rotating shaft is inserted with a middle water pipe with an opening, the water pipe is provided with a liquid inlet, and small holes are distributed on the rotating shaft. Planar otter boards are fixed on the rotating shaft, and are horizontally arranged, and axial distances are kept among the otter boards. The planar otter board packing type crossflow rotating packed bed can achieve the mass transfer and the heat transfer between gas and liquid, and improved dust removal efficiency, and can avoid the high loss of gas resistance , so as to obtain higher heat transfer and mass transfer coefficients and higher dust removal efficiency under the lower gas resistance, thereby having the value of being widely spread and applied in the industry.

Owner:SOUTH CHINA UNIV OF TECH

Catalyst for purifying volatile organic pollutant and ozone in air under normal temperature as well as preparation and use thereof

InactiveCN101298024ANo heating requiredSimple processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideOxygen

The invention discloses a method and a catalyst for simultaneously purifying volatile organic contaminants in the air and ozone under room temperature and application thereof. The purifying method is that: ozone is catalytically decomposed under room temperature to generate highly active oxygen atoms to further oxidize volatile organic contaminants in the air and at last carbon dioxide and water are generated; the catalyst takes three-dimensional porous metal as a vector, activated carbon, silicon oxide, aluminum oxide and compound materials thereof as a coating and transition metal oxides of Mn, Cu, Fe, Ni and Co as active components. The method can remove organic contaminants and ozone under room temperature at the same time without heating, the operation process is simple and the removal rate of ozone and organic contaminants is high. Meanwhile, the catalyst of the invention is prepared by impregnation, wherein, the process is simple; the catalyst has large specific surface area, low air resistance, excellent performance and low cost and can be widely applied to purifying industrial organic waste gas and organic contaminants in the rooms.

Owner:SHENZHEN GREEN WELCOME TECH +1

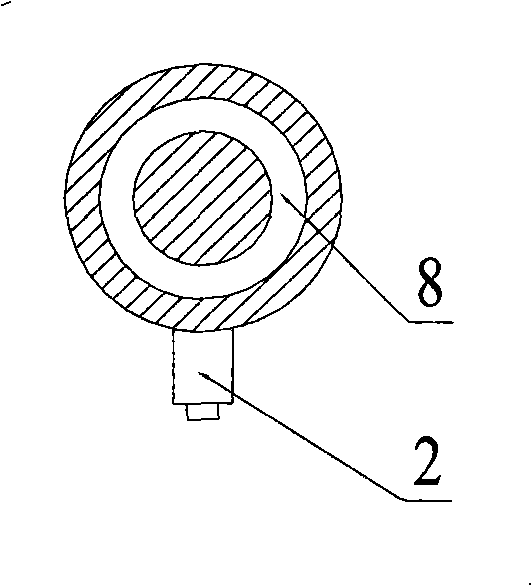

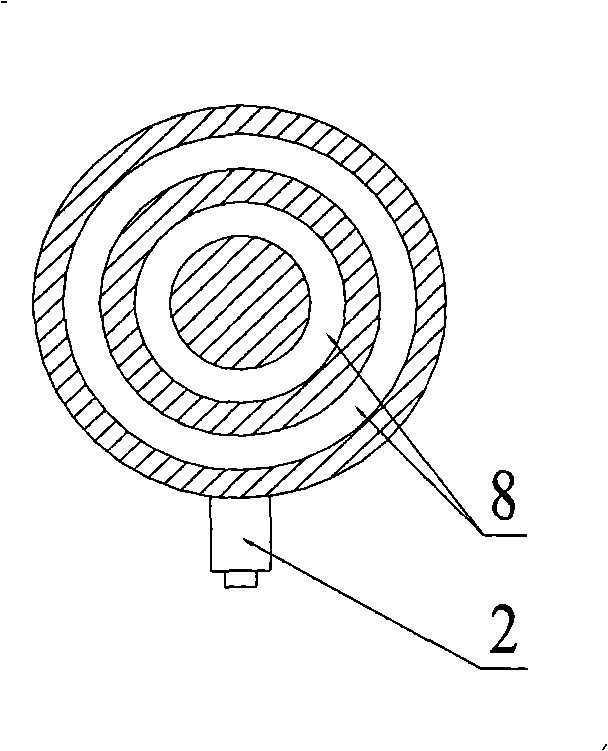

Multifunctional circular seam type gas supply element for steel melting

ActiveCN101487072AImprove furnace lifeSolve the worldwide metallurgical problem of low service lifeManufacturing convertersElectric furnaceWorking lifeAir separation

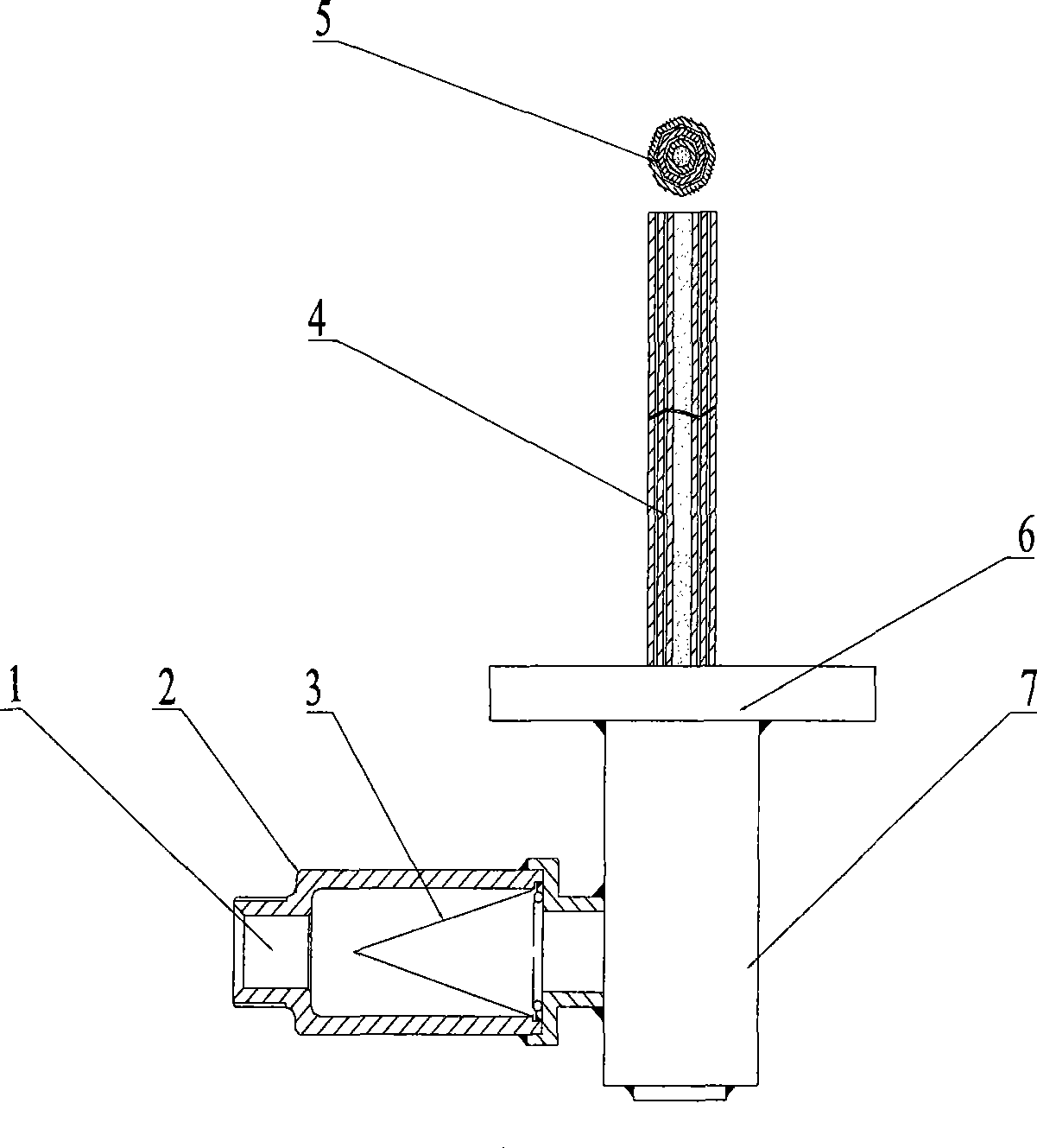

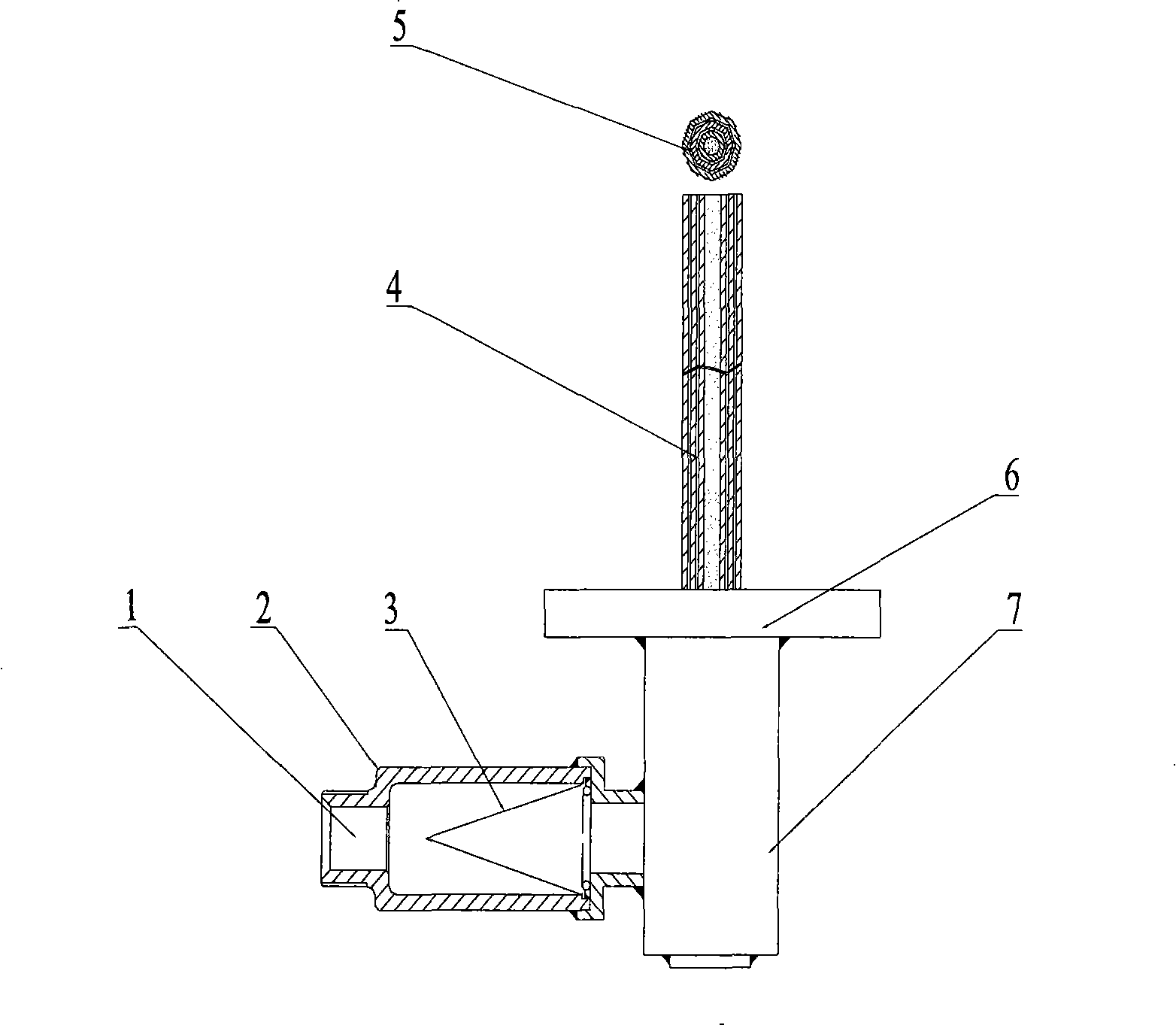

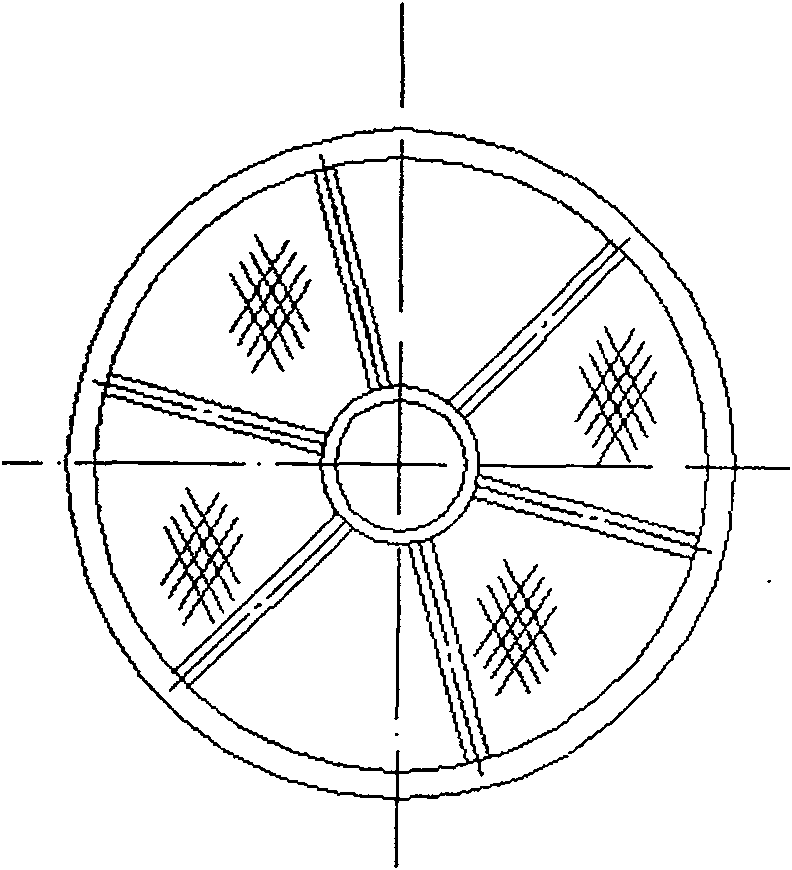

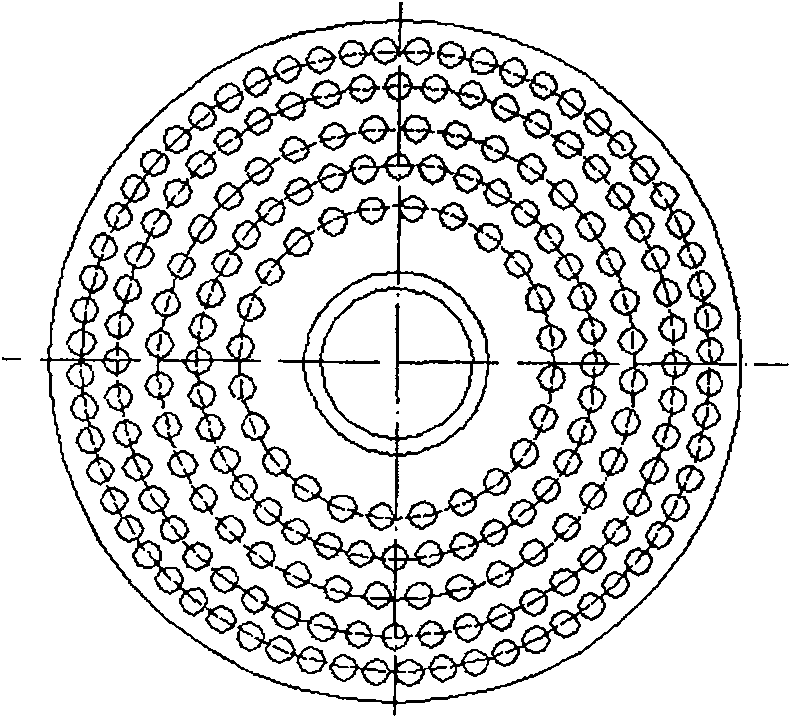

A steel-making multifunctional circular seam type air supply unit belongs to the steel-making technique field, and comprises a gas ejector pipe, a mounting flange, an air separation chamber and an air inlet chamber, wherein, the gas ejector pipe consists of 2 to 5 layers of pipes which are sheathed concentrically; the pipe in the innermost layer is called a central pipe; the seam width among circular seams among all the layers of the pipes is 0.2 to 3.0mm. A spot or a rib resurface-welded by stainless steel is used for ensuring the precise location of seam width and for preventing molten steel from moistening the interior wall of steel pipes, thus not easy to be jammed by pouring in. The gas ejector pipe is connected with the mounting flange which is connected with the air separation chamber used for distributing the air coming from the air inlet chamber to enter each circular seam of the gas ejector pipes to be sprayed out; and the air separation chamber is connected with the air inlet chamber. The steel-making multifunctional circular seam type air supply unit has the advantages of raising the furnace campaign to over 10000 with maximum over 30000 from 2000; and the complex blowing rate is 100 percent. The bottom blowing air supply unit is not replaced in the whole furnace campaign period, thus solving the problem of short working life of the combined blown converter, which is also a worldwide problem in metallurgy.

Owner:CENT IRON & STEEL RES INST

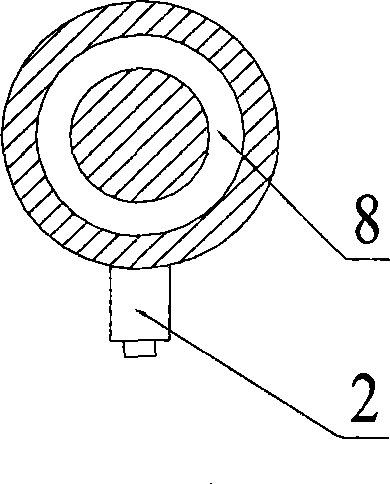

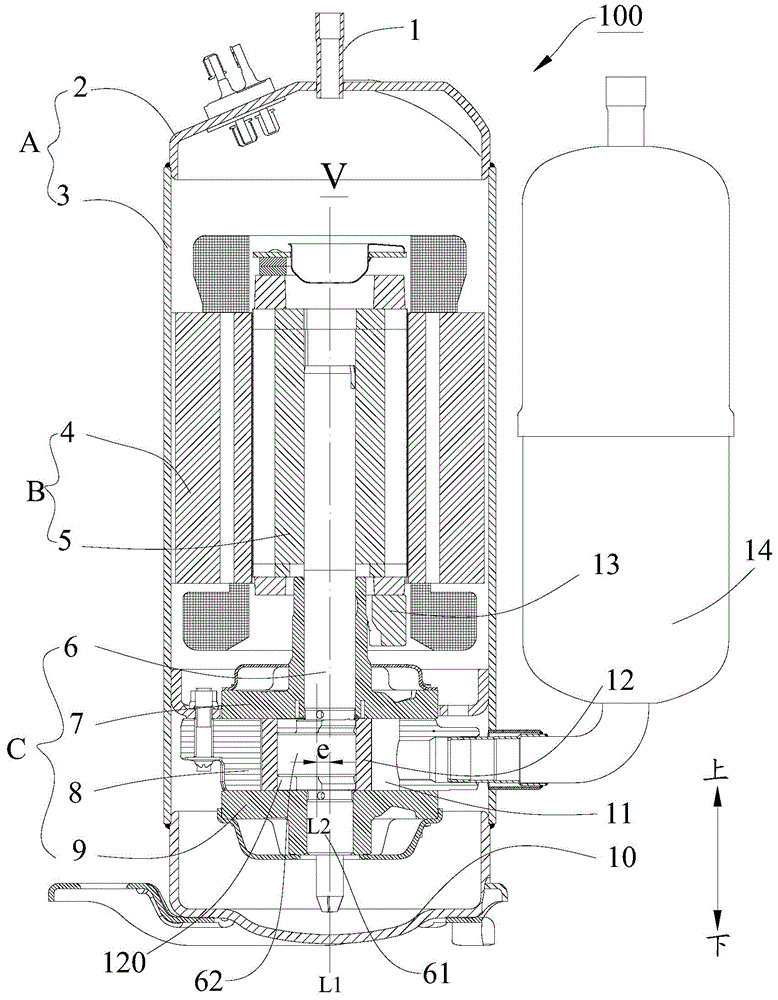

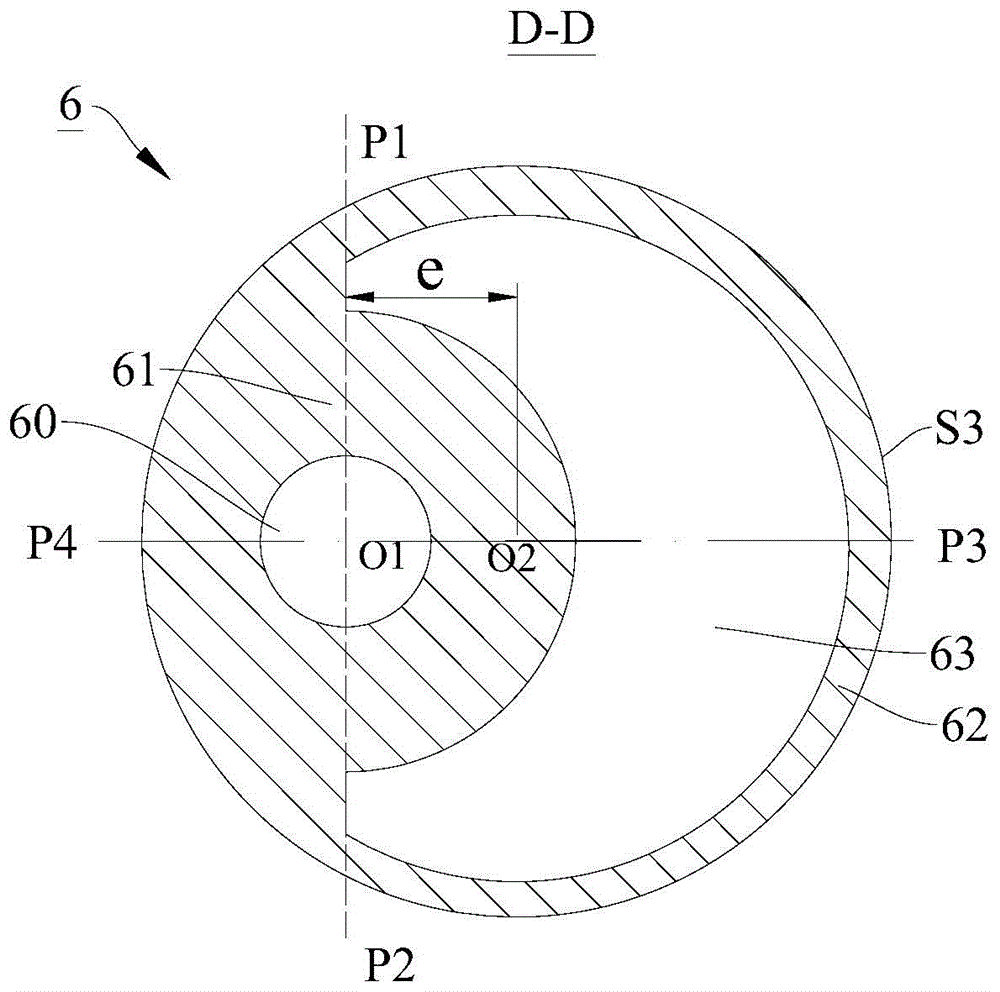

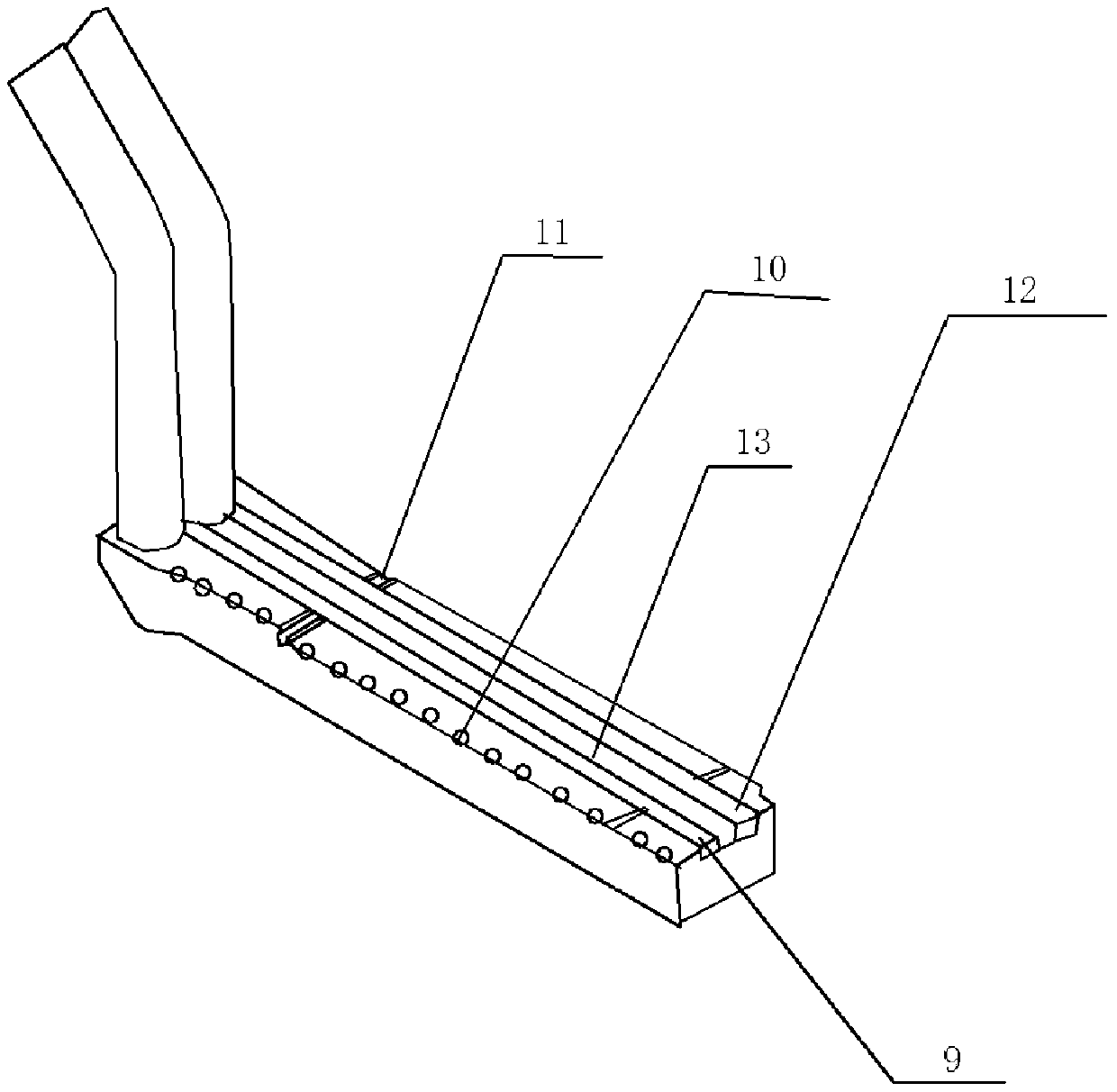

Rotary compressor and crankshaft thereof

InactiveCN104963868AReduce eccentric massReduce rotational eccentric inertia forceCrankshaftsRotary/oscillating piston pump componentsCentre of rotationEngineering

The invention discloses a rotary compressor and a crankshaft thereof. The crankshaft comprises a main shaft part and an eccentric part formed on the main shaft part, wherein a weight-reduction balance hole is formed in the eccentric part; and a ratio of the volume of the weight-reduction balance hole to the volume of the eccentric part is greater than or equal to 8%. According to the embodiment of the invention, the crankshaft can reduce eccentric mass of the crankshaft on the premise of keeping eccentricity of the crankshaft unchanged, can shorten a distance that the center of gravity of the crankshaft deviates from a rotary central axis, simultaneously can reduce rotary eccentric inertia force of the rotary compressor using the crankshaft, can reduce vibration and noises of the compressor, and can improve long-time operation reliability of the compressor. Moreover, due to the reduction of the rotary eccentric inertia force, the weight of a balance block in the compressor can be conveniently reduced, and even the balance block can be avoided, so that the manufacturing cost of the compressor is reduced; and meanwhile, gas resistance to the balance block during operation can be reduced, and the energy efficiency of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

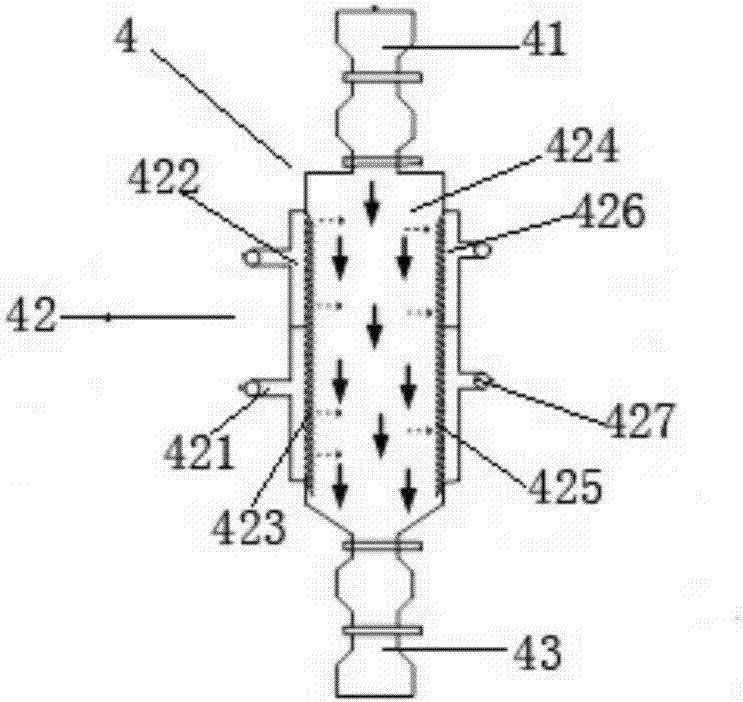

Chromium fog waste gas recovery treatment device

ActiveCN102995095AEfficient recyclingReduce emission concentrationCellsUsing liquid separation agentExhaust fumesLiquid tank

The invention discloses a chromium fog waste gas recovery treatment device which comprises a waste gas collecting device and a waste gas treatment device, wherein the waste gas collecting device consists of a rim exhaust hood (1), an air inlet pipe (2), and an air draft branch pipe header pipe (3), wherein the air inlet pipe (2) is connected with the rim exhaust hood (1) and the air draft branch pipe header pipe (3), the air draft branch pipe header pipe (3) is arranged at the upper end of the rim exhaust hood (1), an electroplating bath (11) is arranged at the lower end of the rim exhaust hood (1), and a gap is arranged at the lower end of the rim exhaust hood (1), at least three air draft holes (10) are arranged in the upper end of the rim exhaust hood (1), a movable cover plate (9) is arranged on the rim exhaust hood (1), the waste gas treatment device consists of a waste gas spraying purification tower (4), an air outlet pipe (5), a chromium fog recoverer (6) and a recovery liquid tank (7), and a funnel cap (8) is arranged at the upper end of the recovery liquid tank (7). By adopting the structure, the solution can be effectively recovered, and the emission concentration can be reduced.

Owner:无锡出新环保设备有限公司

Multifunctional slotted disc type liquid phase distributor

ActiveCN101607169ALow costReduce the overall heightDispersed particle separationFractional distillationSocial benefitsEngineering

The invention relates to a multifunctional slotted disc type liquid phase distributor which is formed by a supporting bottom disc, and is characterized in that the supporting bottom disc is fixedly connected with at least one paratactic rising air cylinder, the inner wall of which is provided with at least one drip tube, the lower part of the drip tube is provided with a drip hole, and the upper part thereof is provided with an overflow hole; a V-shaped liquid collecting plate having the same direction as the rising air cylinder is respectively arranged above the rising air cylinder. The distributor has three functions of liquid collection, liquid separation and gas separation and the like, and has the advantages of simple and compact structure, small volume, light weight, low manufacturing cost and high cost performance; the parameter adjustment range of all parts is large, and the operational flexibility ratio is within the range of 25-120%; the V-shaped liquid collecting plate can be used for catching droplet entrainment in the gas, so that the working efficiency is high; the distributing points are more, gas-liquid distribution is uniform, the gas resistance is small, and the drip hole and filler are not easy to pollute and block up, thus the liquid phase distributor is applicable to the production occasions which easily have entrainment and are easy to block up; in addition, the liquid phase distributor is convenient for installation and wide in application scope. After being popularized and applied, the liquid phase distributor has remarkable economical and social benefits.

Owner:SHALIN METALLIC PRODS JILIN CITY

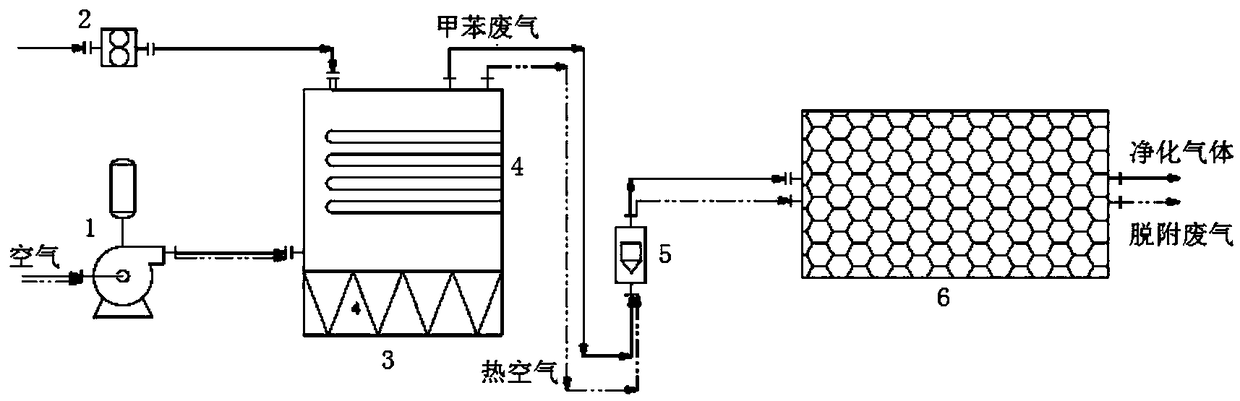

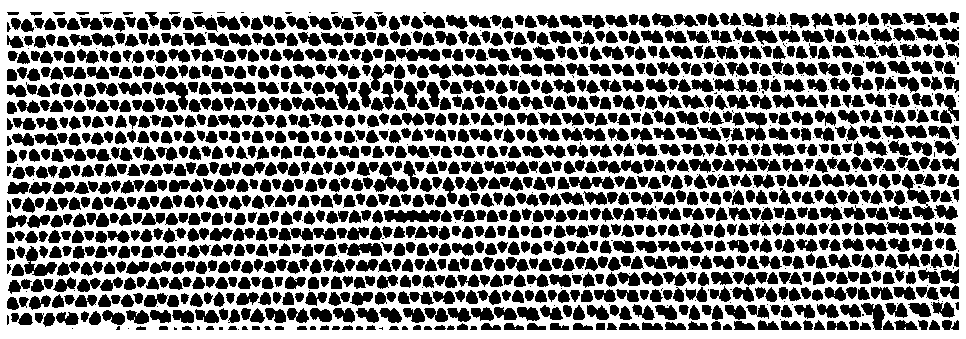

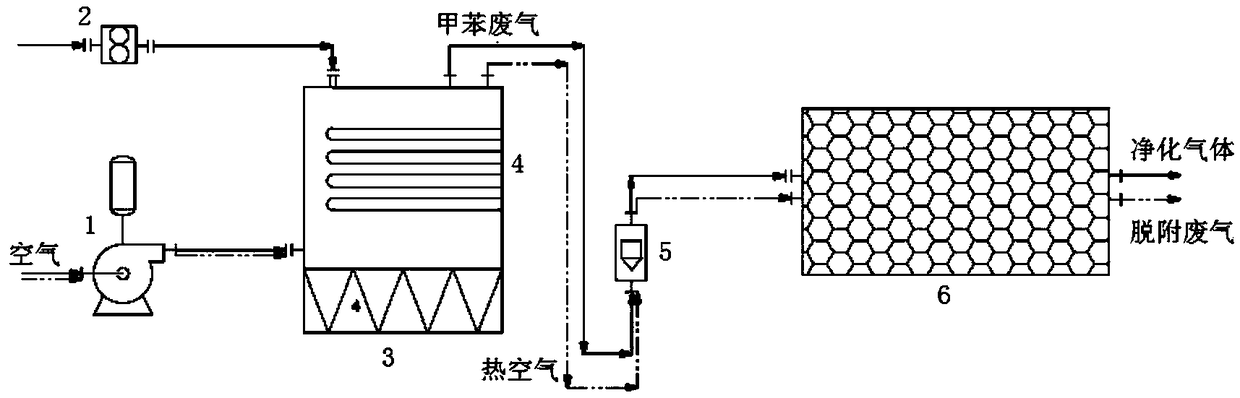

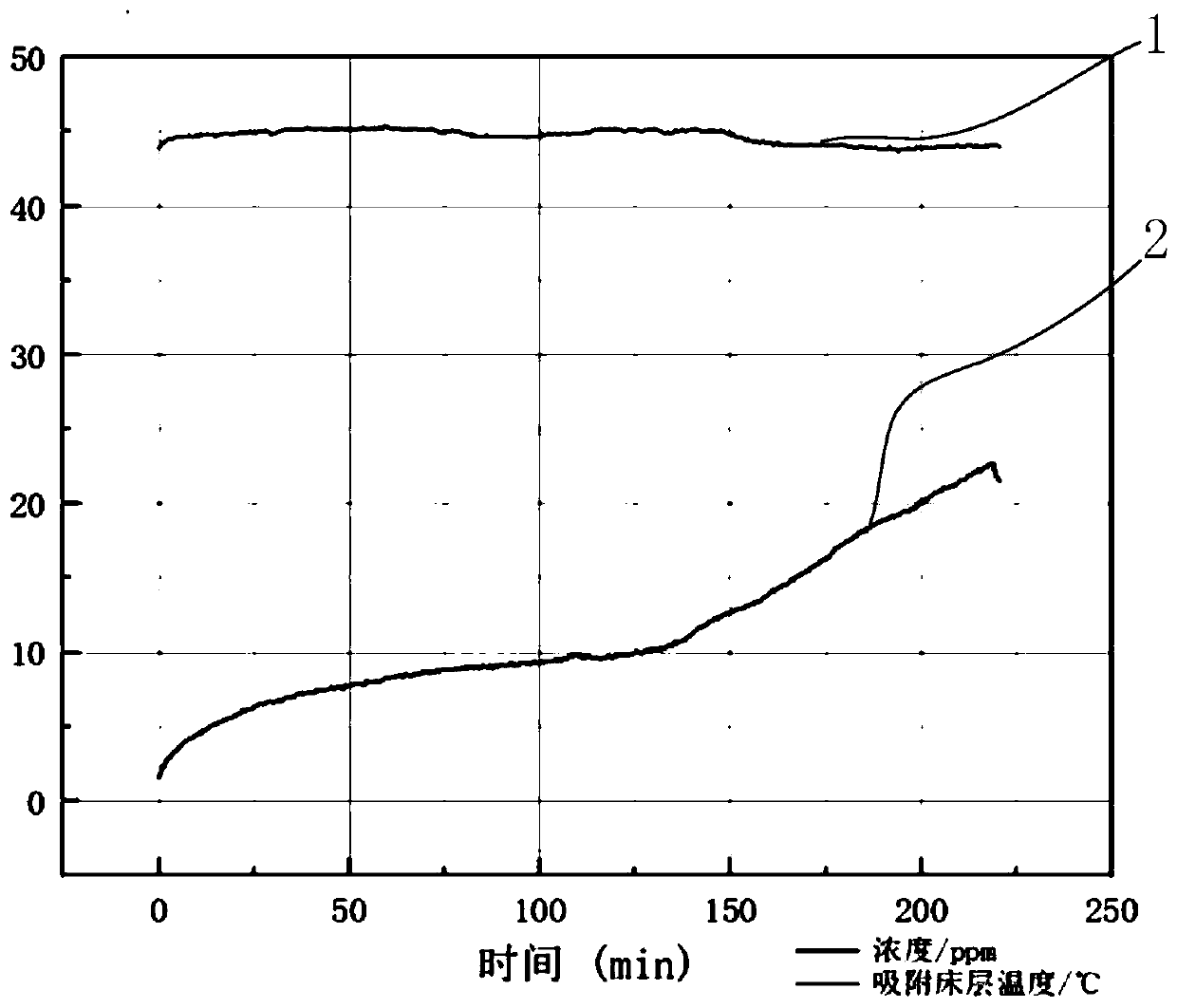

Efficient benzene VOCs gas adsorption molecular sieve and preparation method thereof

InactiveCN112337431AGood effectLight weightGas treatmentOther chemical processesMolecular sieveBenzene

The invention discloses anefficient benzene VOCs gas adsorption molecular sieve and a preparation method thereof. Molecular sieve slurry is composed of the following raw materials in parts by weight:2-4 parts of diatomite; 0.5-1.2 parts of attapulgite; 1.3-1.8 parts of kaolin; 1.3-1.8 parts of carbon powder; 0.5-1.2 part of ZSM-5 molecular sieve raw powder; and 4.2-6 parts of silica sol. The preparation method comprises the following steps of: soaking high-temperature-resistant powder with alkali liquor, washing the powder with water, and drying the powder to prepare a honeycomb mesh-shaped matrix; mixing the diatomite, attapulgite, kaolin, carbon powder and ZSM-5 molecular sieve raw powder, grinding the mixture into powder, sieving the powder, and uniformly mixing the powder with the silica sol aqueous solution to obtain slurry; immersing the surface of the honeycomb mesh-shaped matrix with the slurry, and obtaining a honeycomb carrier to which the slurry is attached after immersion;and drying the honeycomb carrier to which the slurry is attached, roasting the honeycomb carrier, and burning carbon powder after roasting, thereby greatly increasing the pores of the molecular sieve, and obtaining the efficient benzene VOCs gas adsorption molecular sieve. The molecular sieve provided by the invention has the characteristics of light specific gravity, small gas resistance, good adsorption effect on benzene VOCs, advanced pore system and recyclability.

Owner:萍乡市捷龙环保科技有限公司

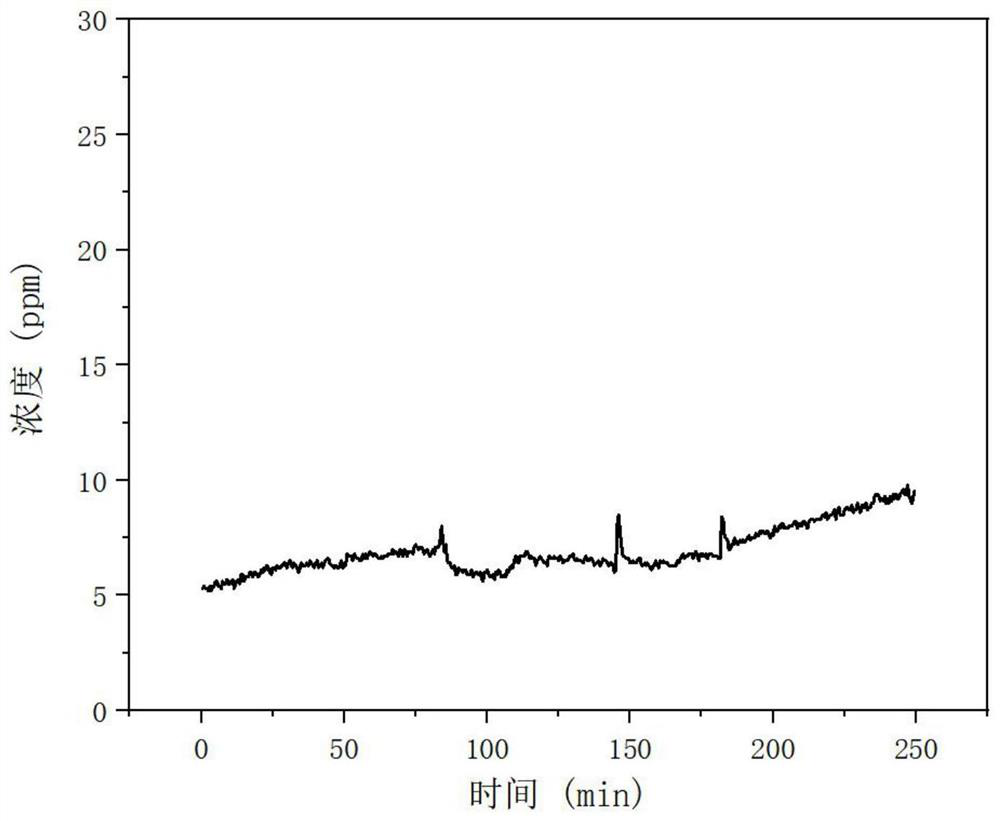

High-performance composite adsorbing material and preparing method and application thereof

InactiveCN109126696AImprove flame retardant performanceHigh mechanical strengthGas treatmentOther chemical processesFiberAdhesive

The invention discloses a high-performance composite adsorbing material and a preparing method and application thereof. The composite material is prepared from powdery zeolite, powdery active carbon,wood pulp fibers, special fibers, an insoluble fire retardant and an adhesive. Multiple components of the special fibers, the active carbon, the zeolite and the insoluble fire retardant are added intothe composite adsorbing material prepared with the method, and the composite adsorbing material has the advantages of being high in fire resistance, good in hydrophobicity, heat stability and chemical stability, developed in pore structure, large in specific area, high in mechanical strength, not prone to pulverization, controllable in gas channel, wide in application range and the like, and is particularly suitable for adsorption purification of all kinds of VOCs waste gas. According to the high-performance composite adsorbing material and the preparing method and application thereof, a source of raw materials is wide, the technology process is simple, fiber products (felt, bands, cloth and the like) with different forms can be freely processed, and the composite adsorbing material has the advantages of being high in adsorption capacity, capable of achieving in-situ regeneration and recycling, high in adsorption / desorption rate, small in pressure drop and the like in application of fixed bed adsorption and rotating wheel adsorption.

Owner:NANJING FORESTRY UNIV +1

High-performance zeolite composite adsorption material, and preparation method and application thereof

InactiveCN109012612AImprove flame retardant performanceLarge gas resistanceGas treatmentOther chemical processesFiberDesorption

The invention discloses a high-performance zeolite composite adsorption material, and a preparation method and an application thereof. The composite material is prepared from zeolite, wood pulp fibers, special fibers, a water-insoluble flame retardant and an adhesive. The zeolite, the special fibers and the water-insoluble flame retardant are added to the prepared composite adsorption material, sothe composite adsorption material has the characteristics of high flame retardancy, good hydrophobicity, good thermal stability, good chemical stability, well-developed pore structure, large specificsurface area, high mechanical strength, no efflorescence and adjustable gas passage, and is especially suitable for the adsorption and purification treatment of various VOCs waste gases. The above raw materials have wide sources, the technology process is simple, and the composite adsorption material can be freely processed to form fiber products (felt, belt and cloth) with different forms, and has the advantages of strong adsorption capacity, realization of in-situ regeneration and recycling, fast adsorption / desorption rate and small pressure drop when applied to fixed bed adsorption and rotary adsorption.

Owner:JIANGSU RUIDA TECH CO LTD +1

High-performance adsorption film used for removing VOC exhaust gas

InactiveCN106861620AHigh densityLarge adsorption capacityGas treatmentOther chemical processesActivated carbonFiltration membrane

The invention is suitable for the field of protective articles, and provides high-performance adsorption film used for removing VOC exhaust gas. The film includes activated carbon fiber-type nonwoven fabric membranes and adsorbent particles. The adsorbent particles are clamped between the activated carbon fiber-type nonwoven fabric membranes and are fixed to the activated carbon fiber-type nonwoven fabric membranes through adhesive particles. The particle size of the adsorbent particles is 200-500 [mu]m. The particle size of the adhesive is one fourth to one third of the particle size of the adsorbent particles. In the film, the activated carbon fiber-type nonwoven fabric membranes are adopted as substrate filtration membranes, and activated carbon fibers when compared with activated carbon have higher adsorption capacity and higher adsorption-desorption speeds and have acid-resistant and alkali-resistant properties.

Owner:布和

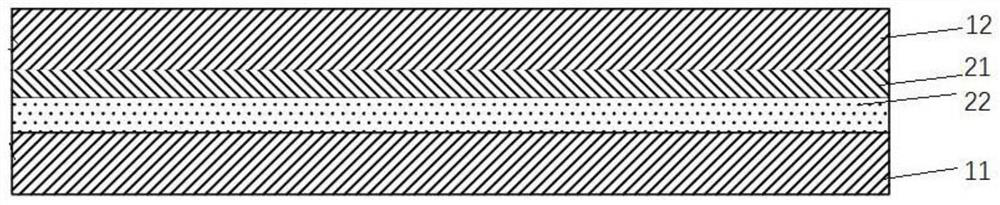

Filtering device with electrostatic spinning nanofiber cloth and mask

PendingCN112275045AImprove filtering effectPass smoothlyDispersed particle filtrationLayered productsPolymer scienceSpinning

The invention provides a filtering device with electrostatic spinning nanofiber cloth and a mask. The filtering device comprises the electrostatic spinning nanofiber cloth and melt-blown non-woven fabric. The melt-blown non-woven fabric is arranged on at least one side of the electrostatic spinning nanofiber cloth to form more than two layers of filtering structures with the electrostatic spinningnanofiber cloth; the filtering efficiency percentage of the melt-blown non-woven fabric to particles with the particle size of 0.02-10 mu m is M; the filtering efficiency percentage of the electrostatic spinning nanofiber cloth to particles with the particle size of 0.02-10 mu m is N; M / N is equal to 1.05-1.6. By setting the filtering efficiency value, a filtering combination of the electrostaticspinning nanofiber cloth and the melt-blown non-woven fabric is formed, a graded filtering structure with different filtering effects on substances such as solid particles, bacteria and viruses withdifferent sizes is formed, and meanwhile, the used gram weight is low and the porosity is high so that airflow cannot be blocked when high-speed airflow passes through the graded filtering structure,and thus the resistance pressure drop cannot be increased.

Owner:GUANGDONG KINGFA TECH CO LTD +1

Catalyst for purifying volatile organic pollutant and ozone in air under normal temperature as well as preparation and use thereof

InactiveCN101298024BNo heating requiredSimple processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSilicon oxideOxygen

Owner:SHENZHEN GREEN WELCOME TECH +1

Gas-solid separator

InactiveCN102430295ASimple structureImprove dust collection efficiencyDispersed particle separationGas solidProduct gas

The invention discloses a gas-solid separator. The gas-solid separator comprises a cone, a cylinder and an air channel, wherein the cone, the cylinder and the air channel are communicated from top to bottom. The gas-solid separator also provides a ventilating duct. The air channel coils on the ventilating duct. An opening of the top of the air channel is an air inlet. The bottom of the cone is provided with a discharging pipe. The top of the ventilating duct is provided with an air outlet. The bottom of the ventilating duct is communicated with the cone and the cylinder. A top surface of the air channel is a spiral cover plate having a downward spiral structure. The gas-solid separator has the advantages of simple structure, high dust collection efficiency, small gas resistance, small system height and diameter, and long service life.

Owner:NANJING XIPU CEMENT ENG GROUP

Multifunctional circular seam type gas supply element for steel melting

ActiveCN101487072BImprove furnace lifeSolve the worldwide metallurgical problem of low service lifeManufacturing convertersProcess efficiency improvementWorking lifeAir separation

A steel-making multifunctional circular seam type air supply unit belongs to the steel-making technique field, and comprises a gas ejector pipe, a mounting flange, an air separation chamber and an air inlet chamber, wherein, the gas ejector pipe consists of 2 to 5 layers of pipes which are sheathed concentrically; the pipe in the innermost layer is called a central pipe; the seam width among circular seams among all the layers of the pipes is 0.2 to 3.0mm. A spot or a rib resurface-welded by stainless steel is used for ensuring the precise location of seam width and for preventing molten steel from moistening the interior wall of steel pipes, thus not easy to be jammed by pouring in. The gas ejector pipe is connected with the mounting flange which is connected with the air separation chamber used for distributing the air coming from the air inlet chamber to enter each circular seam of the gas ejector pipes to be sprayed out; and the air separation chamber is connected with the air inlet chamber. The steel-making multifunctional circular seam type air supply unit has the advantages of raising the furnace campaign to over 10000 with maximum over 30000 from 2000; and the complex blowing rate is 100 percent. The bottom blowing air supply unit is not replaced in the whole furnace campaign period, thus solving the problem of short working life of the combined blown converter, which is also a worldwide problem in metallurgy.

Owner:CENT IRON & STEEL RES INST

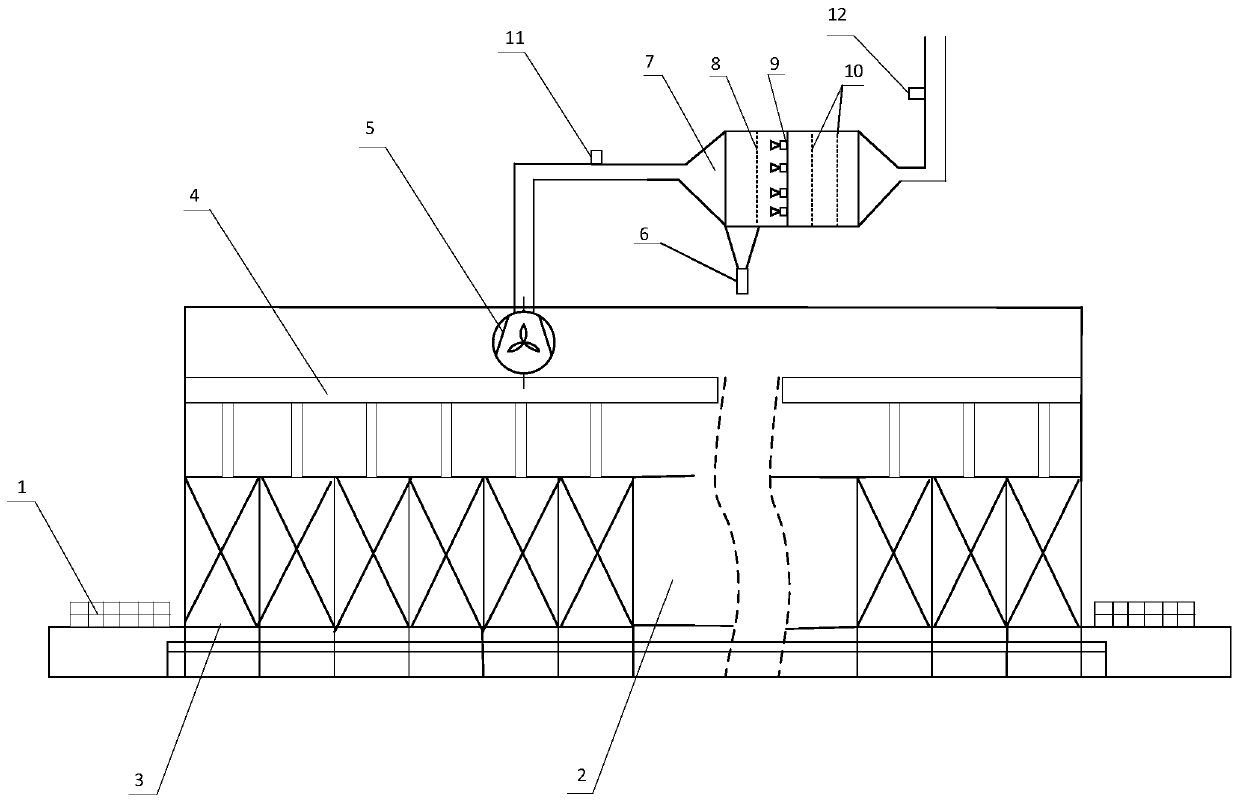

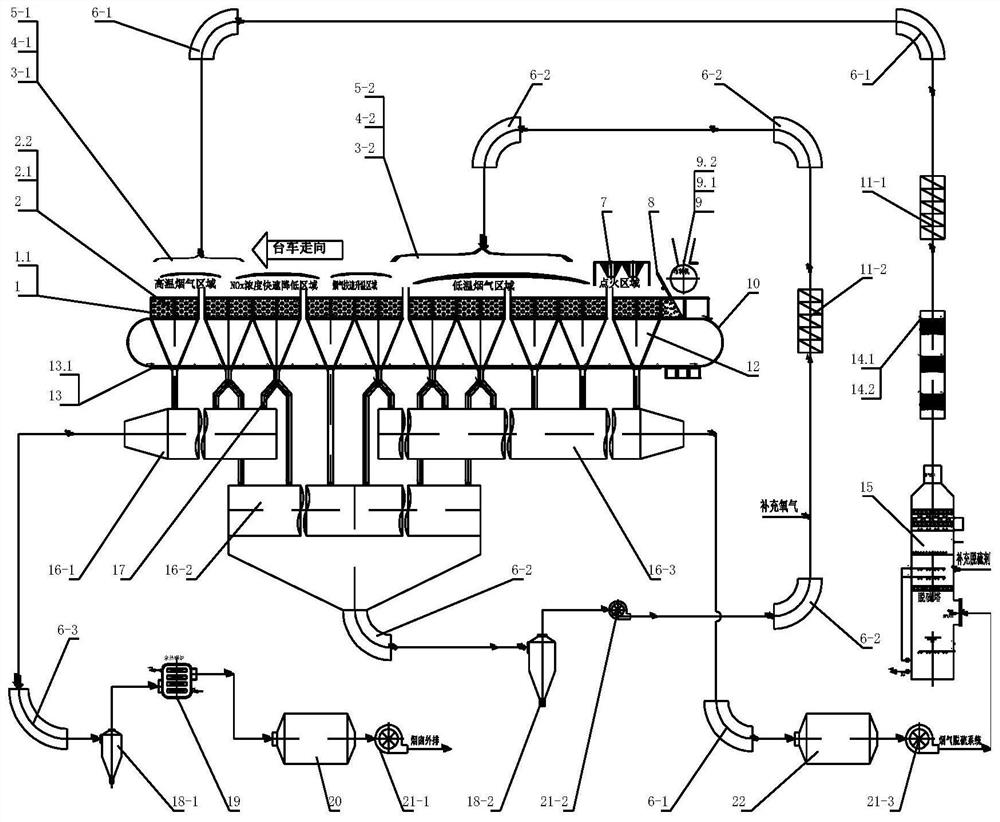

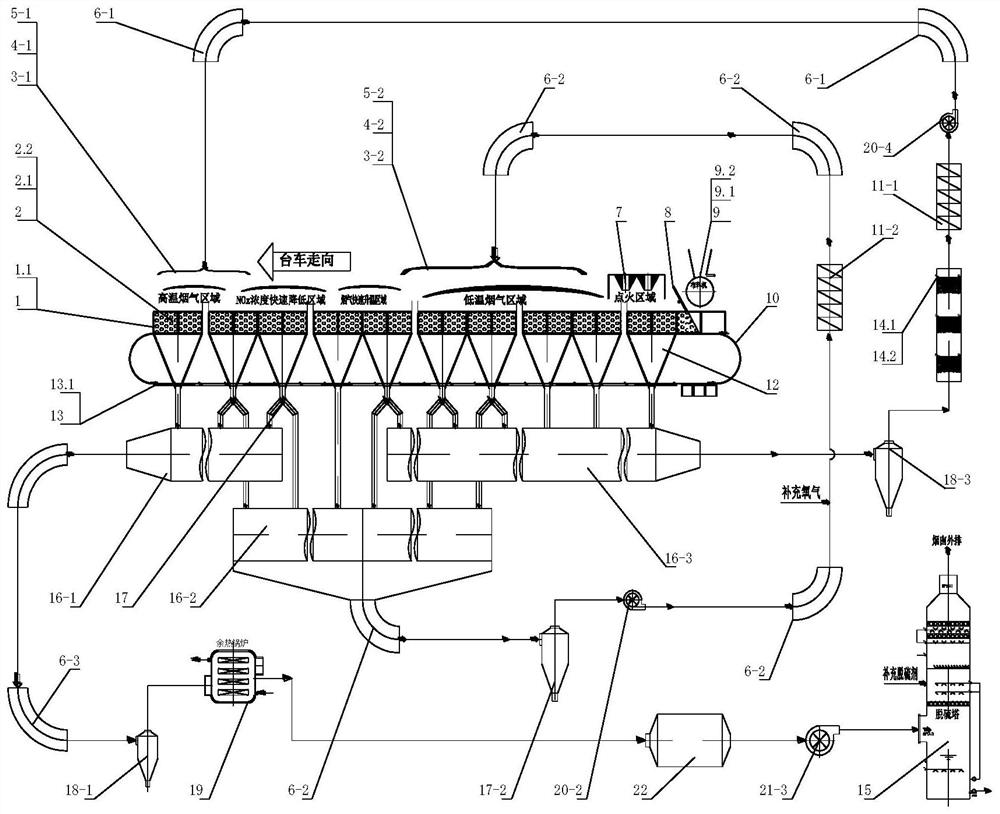

Device and method for treating escaped ammonia of tunnel kiln for calcining denitration catalyst

PendingCN110841477AImprove the capture effectReduce pollutionGas treatmentDispersed particle filtrationTunnel kilnPtru catalyst

The invention relates to the technical field of waste gas treatment of tunnel kilns, specifically to a device and a method for treating escaped ammonia of a tunnel kiln for calcining a denitration catalyst. The device comprises a tunnel kiln main body, a waste gas collecting pipeline arranged in the tunnel kiln main body, and a waste gas reactor connected with and arranged on the waste gas collecting pipeline, wherein an exhaust fan is arranged on a connecting pipeline of the waste gas reactor and the waste gas collecting pipeline; and a dust removal filter cloth layer, a blowback unit and a multi-stage ammonia removal filter cloth layer are sequentially arranged in the waste gas reactor in a direction from an inlet to an outlet. The device provided by the invention directly utilizes the waste gas collection pipeline in the tunnel kiln to convey waste gas to the waste gas reactor in a centralized manner, respectively treat and remove dust particles and the escaped ammonia through a filter cloth in the dust removal filter cloth layer, is reasonable in design, high in economical efficiency and small in occupied area, can efficiently remove ammonia and impurities from the waste gas ofthe tunnel kiln, effectively purifies the waste gas of the tunnel kiln, and greatly reduces air pollution caused by the waste gas of the tunnel kiln.

Owner:XIAN THERMAL POWER RES INST CO LTD

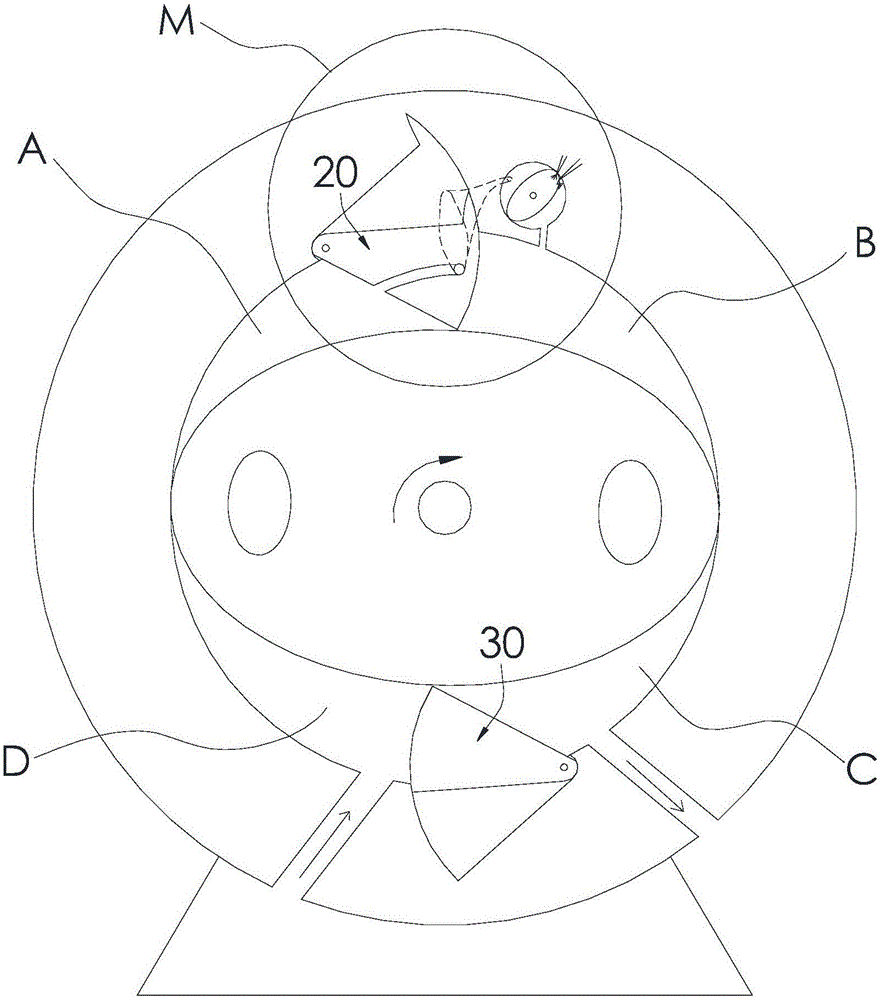

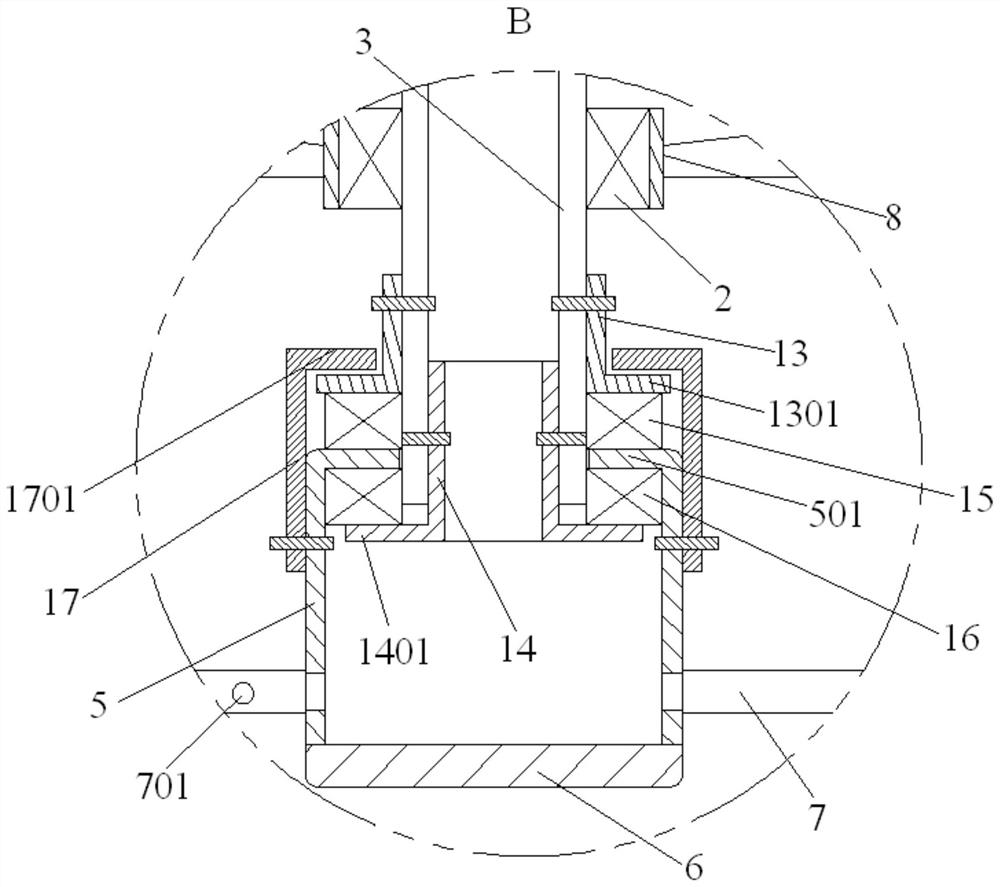

Rotor engine

ActiveCN105156206ALow gas resistanceConducive to combustionInternal combustion piston enginesPistonCombustion chamber

The invention discloses a rotor engine. The rotor engine comprises a casing, a first swing piston, a second swing piston, an engine rotor and a combustion chamber rotor, wherein a main chamber is formed at the inner part of the casing; a first piston groove and a second piston groove are formed in the side wall of the main chamber; the first swing piston comprises a first rotating part in rotating cooperation with a first pivoting part, and a first sliding part in airtight and sliding cooperation with a first cambered sliding surface; the second swing piston comprises a second rotating part in rotating cooperation with a second pivoting part, and a second sliding part in airtight and sliding cooperation with a second cambered sliding surface; the engine rotor can be mounted in the main chamber in a rotatable manner, and the center of the main chamber is positioned on a rotating shaft of the engine rotor; the combustion chamber rotor can be mounted in a combustion chamber in a rotatable manner, and the center of the combustion chamber is positioned on a rotating shaft of the combustion chamber rotor. The rotor engine disclosed by the invention is good in structural reliability, and high in working efficiency.

Owner:袁政

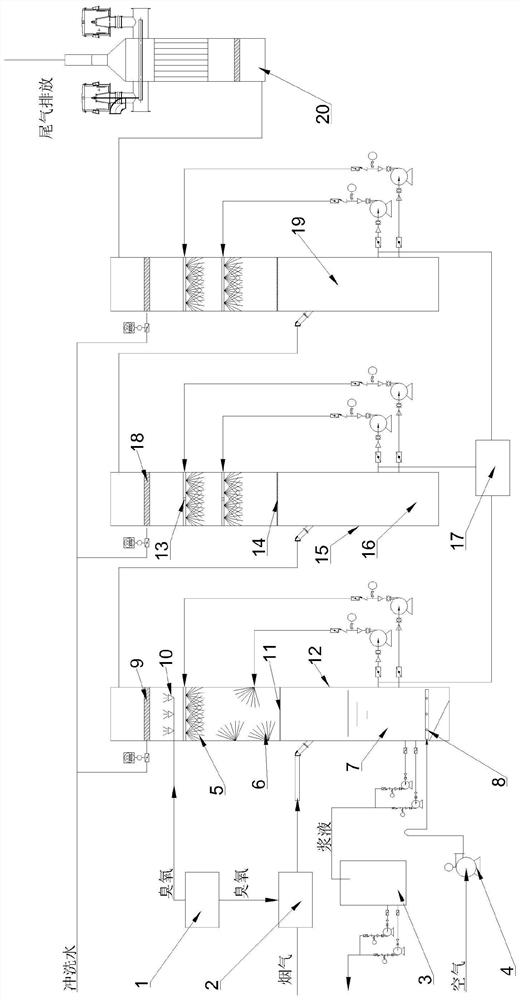

Flue gas desulfurization and denitrification system device and method adopting ozone oxidation in cooperation with multi-stage spraying

PendingCN112058048AImprove the flow fieldPromote absorptionCombination devicesGas treatmentFlue gasEnvironmental engineering

The invention provides a flue gas desulfurization and denitrification system device and a flue gas desulfurization and denitrification method adopting ozone oxidation in cooperation with multistage spraying. The desulfurization and denitrification system device comprises a mixing device, an oxidation absorption device and a spraying absorption device which are sequentially connected in the flowingdirection of flue gas, the interior of the oxidation absorption device is sequentially divided into an air inlet area, a spraying area, an oxidation area and an exhaust area which are communicated with one another in the air inlet direction, and an inclined spraying module is arranged on the inner wall, where the spraying area is located, of the shell; the mixing device is externally connected with an ozone generating device; and the ozone generating device is also connected to the shell where the oxidation zone of the oxidation absorption device is located. The desulfurization and denitrification method comprises the steps that flue gas and ozone are mixed and oxidized and then sequentially enter a spraying area and an oxidation area of the oxidation absorption device, the flue gas enters the spraying absorption device to be sprayed and absorbed again after being sprayed, absorbed and oxidized, and desulfurization and denitrification of the flue gas are completed. Ozone oxidation iscooperated with multi-stage inclined spraying, so that desulfurization and denitrification treatment can be effectively carried out on flue gas.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Plane otter board stuffing type cross flow type hypergravity swinging bed and uses thereof

InactiveCN100586525CLow gas resistanceEnhanced mass transferUsing liquid separation agentFractional distillationDust controlElectric machinery

The invention discloses a planar otter board packing type crossflow super-gravity rotating packed bed, as well as the application thereof. The rotating packed bed comprises a rotating packed bed shell, a motor and a rotating shaft; the rotating shaft positioned in the shell is of a hollow structure, the middle of the rotating shaft is inserted with a middle water pipe with an opening, the water pipe is provided with a liquid inlet, and small holes are distributed on the rotating shaft. Planar otter boards are fixed on the rotating shaft, and are horizontally arranged, and axial distances are kept among the otter boards. The planar otter board packing type crossflow rotating packed bed can achieve the mass transfer and the heat transfer between gas and liquid, and improved dust removal efficiency, and can avoid the high loss of gas resistance, so as to obtain higher heat transfer and mass transfer coefficients and higher dust removal efficiency under the lower gas resistance, thereby having the value of being widely spread and applied in the industry.

Owner:SOUTH CHINA UNIV OF TECH

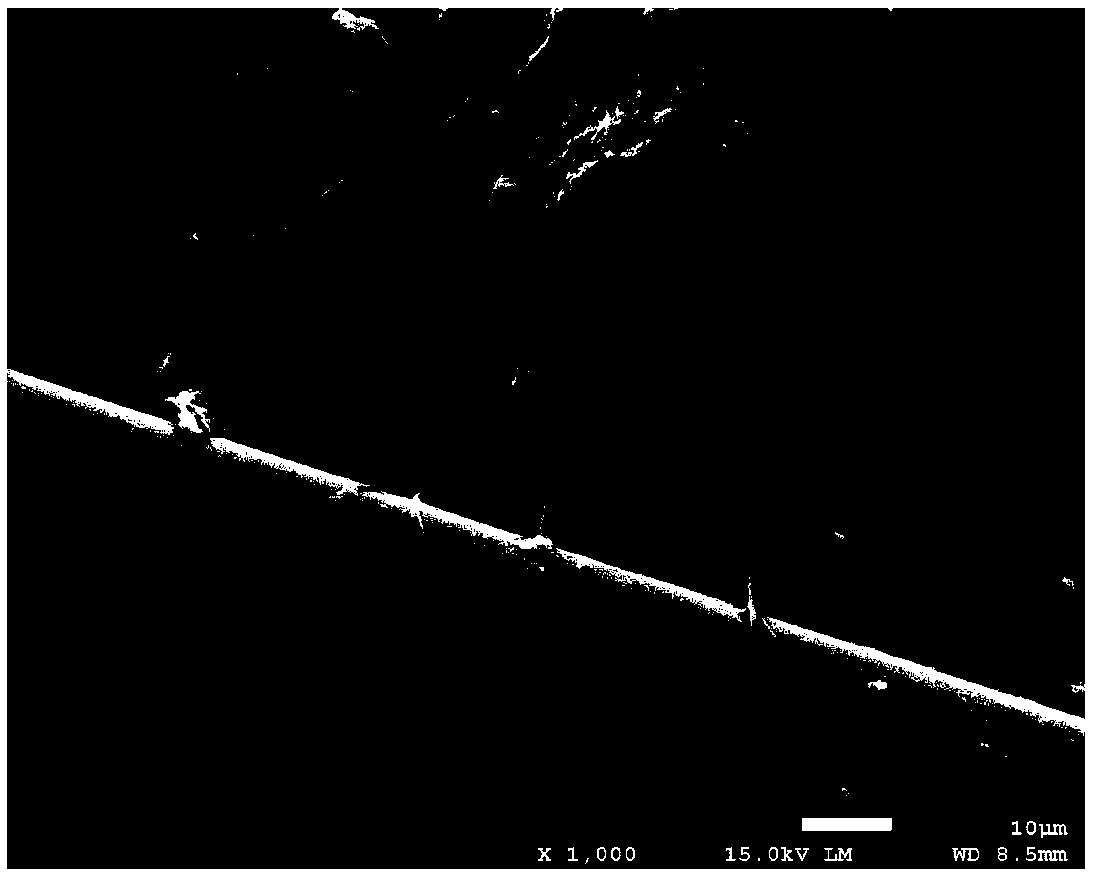

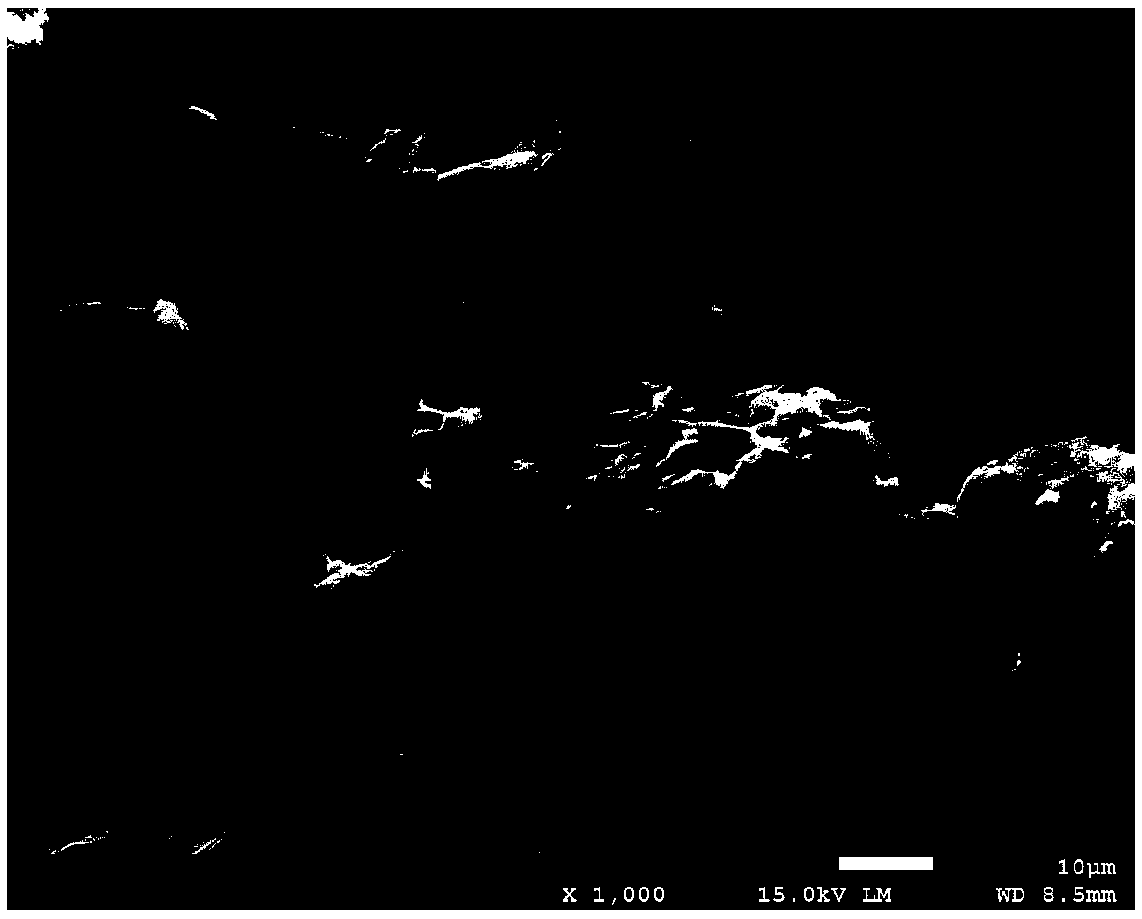

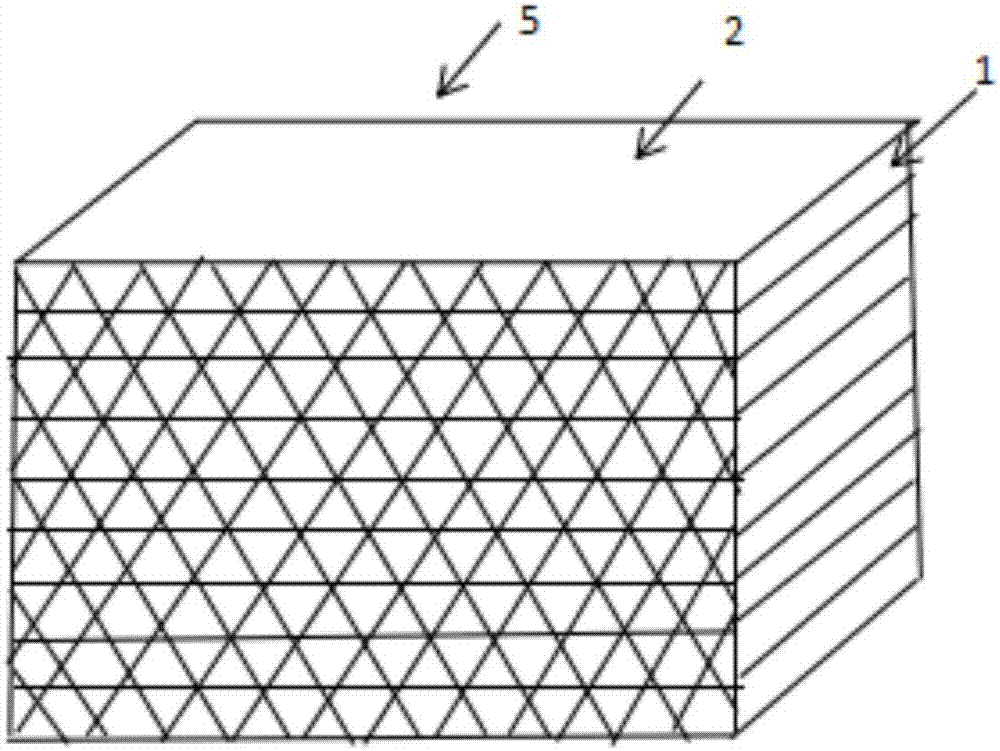

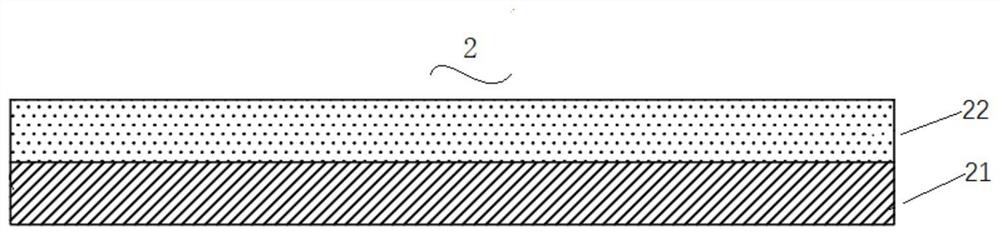

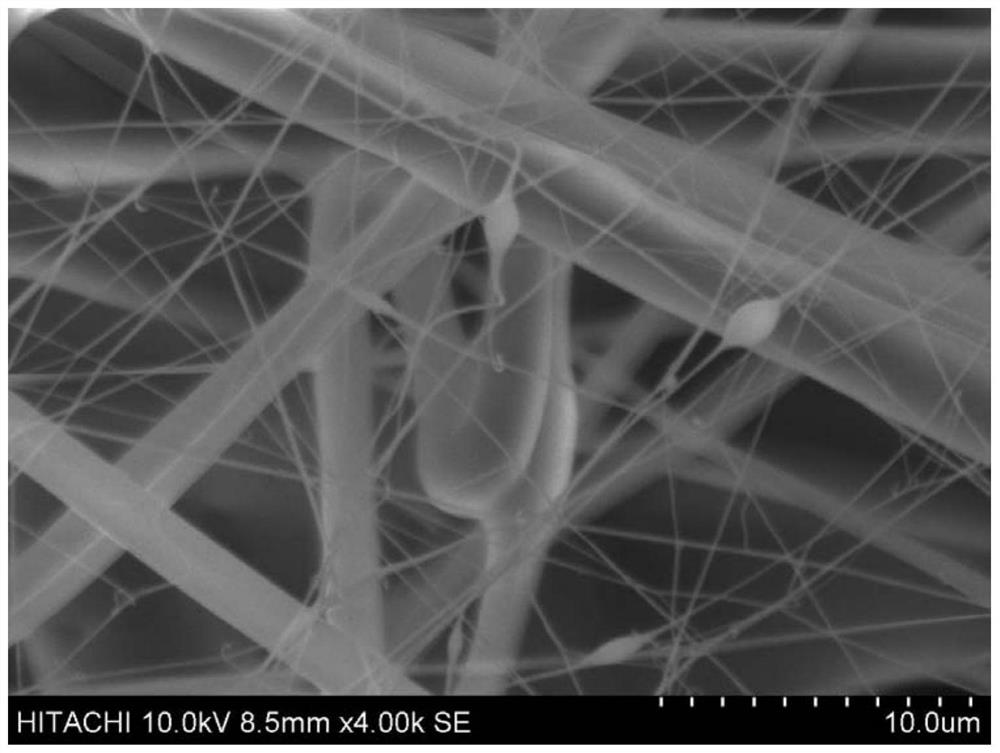

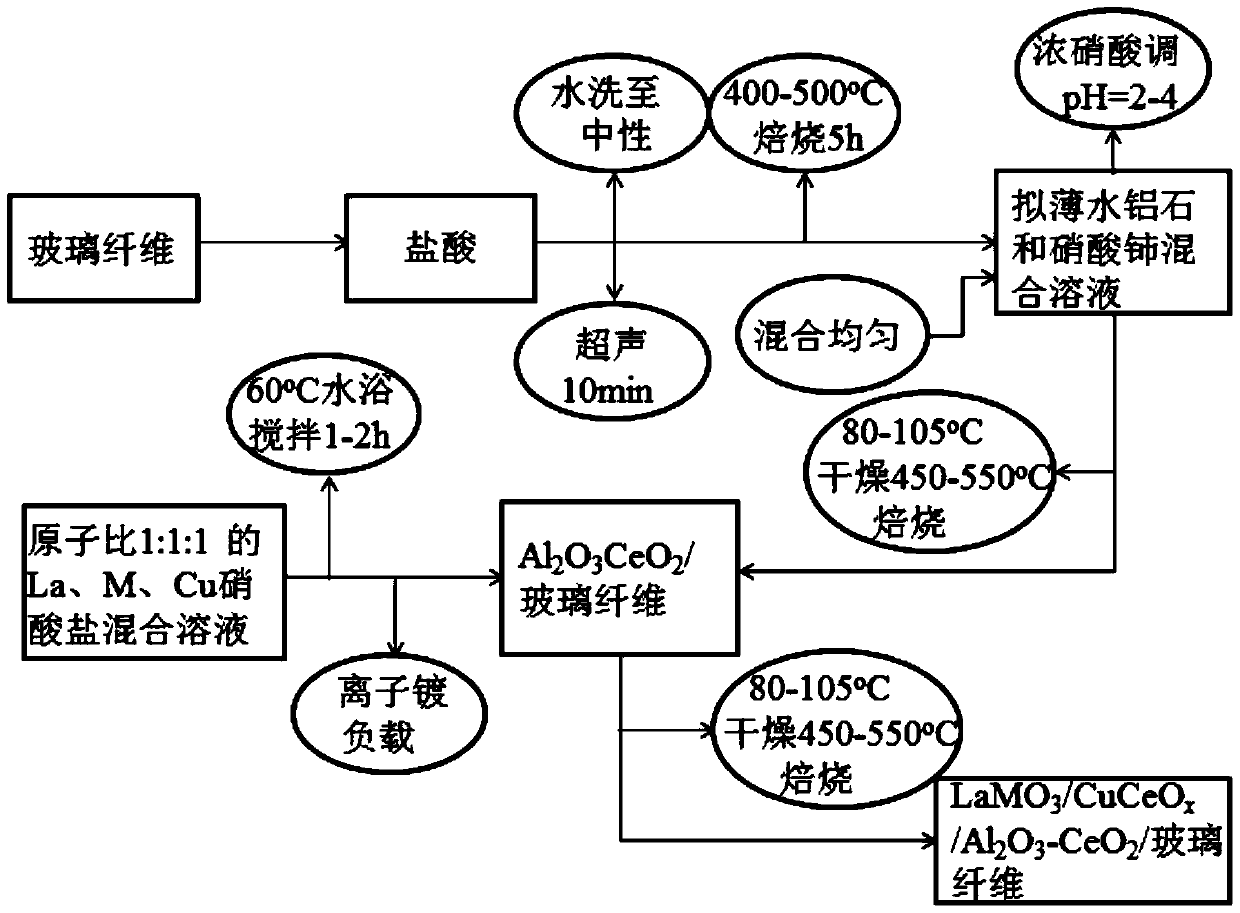

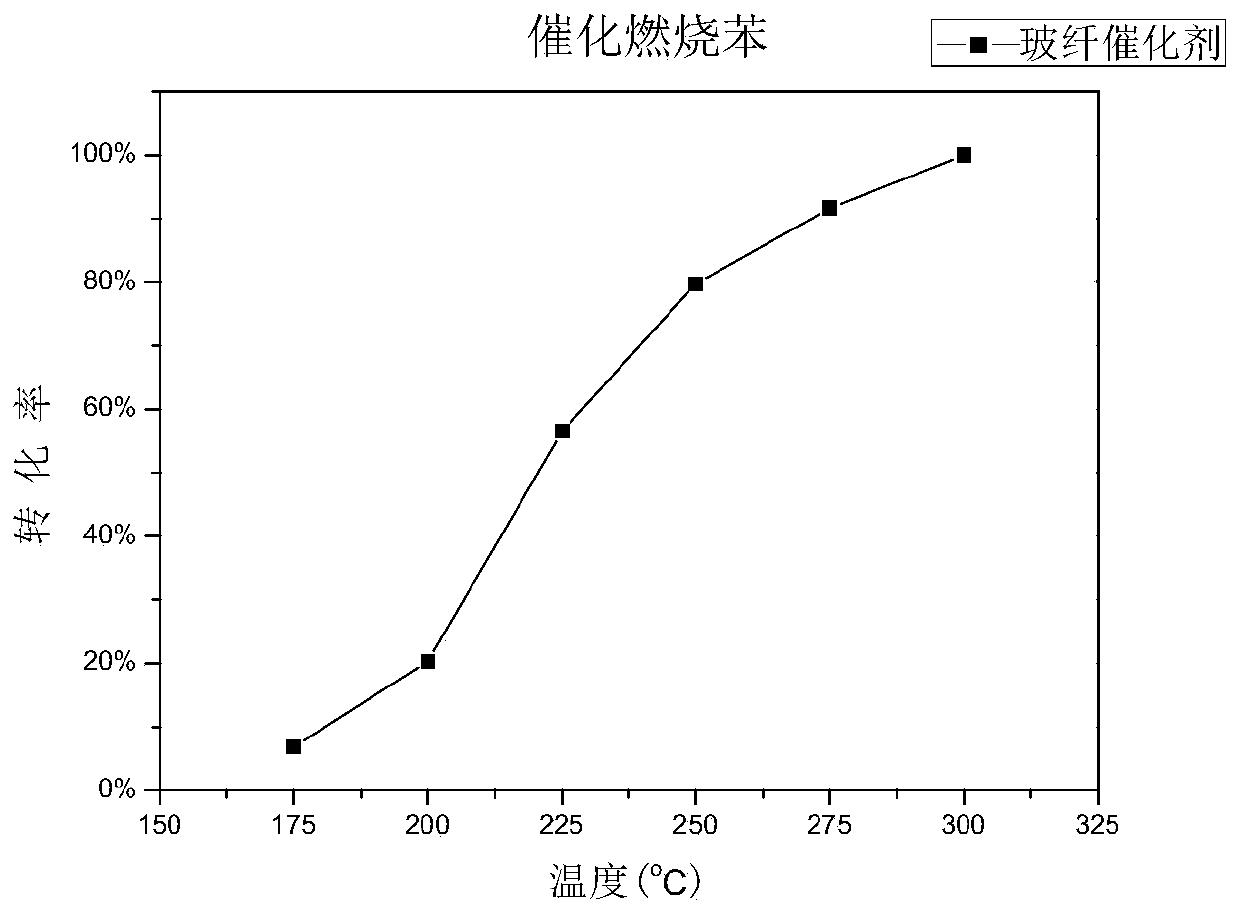

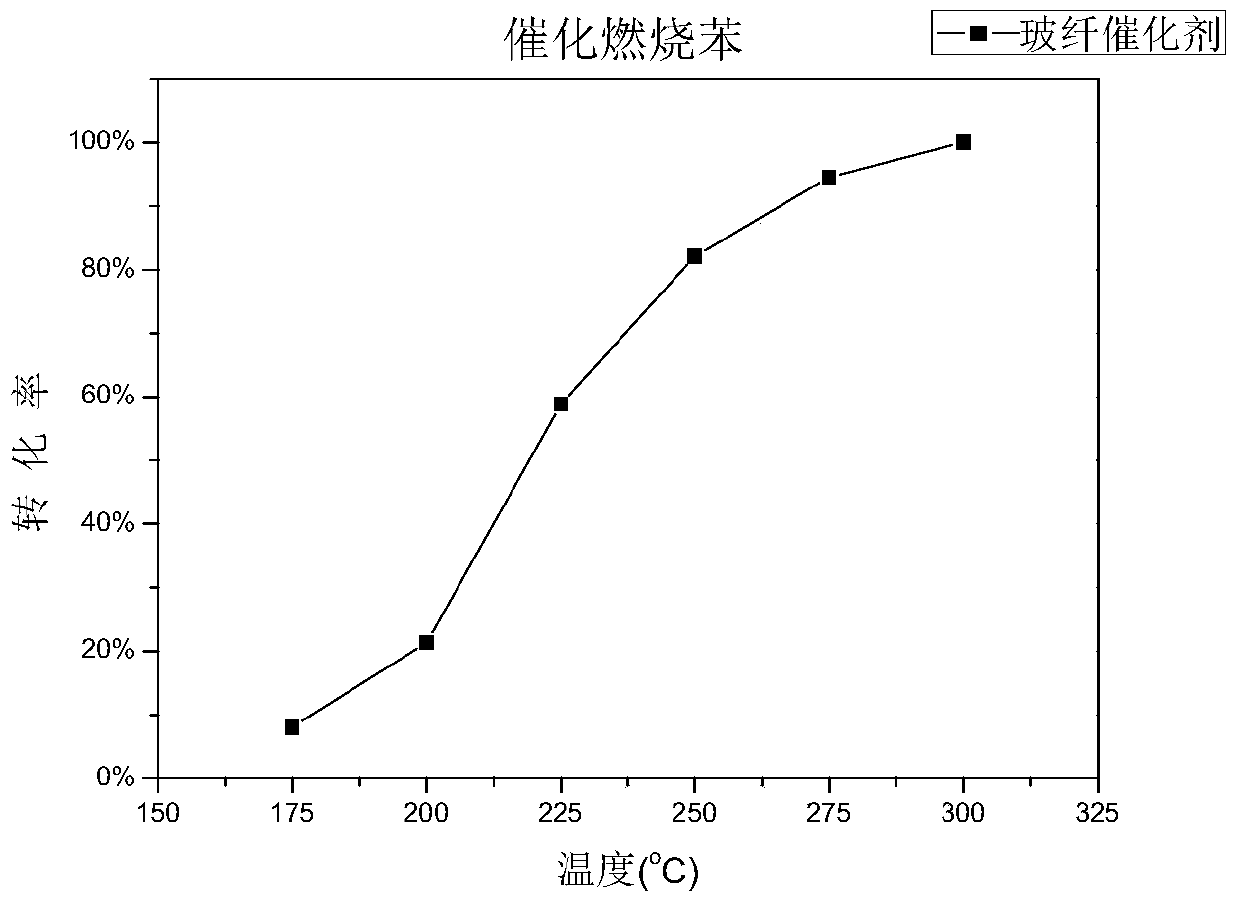

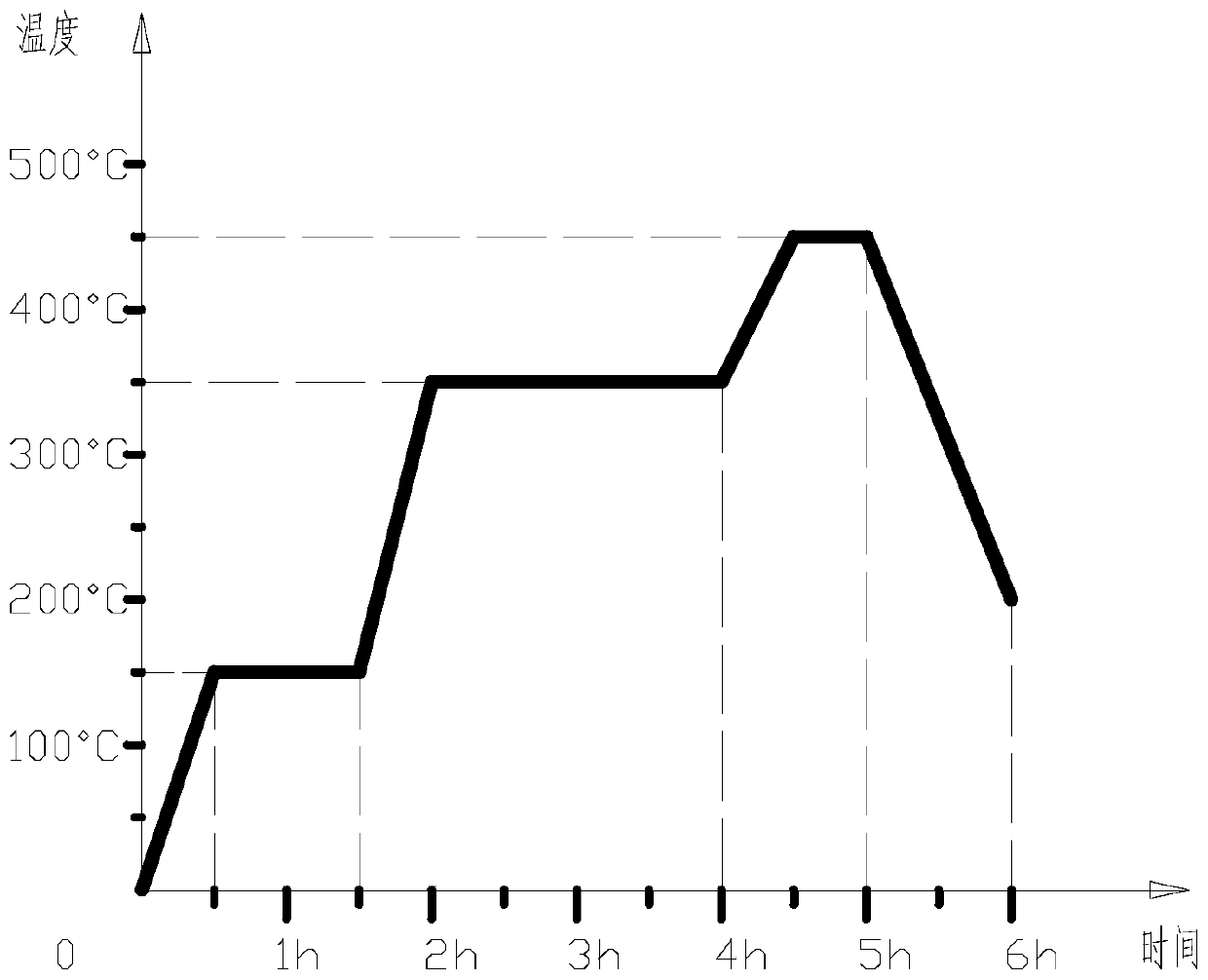

A flexible glass fiber-based catalyst for vocs catalytic combustion and its preparation method and application

ActiveCN105498789BLarge specific surface areaLow gas resistanceHeterogenous catalyst chemical elementsDispersed particle separationGlass fiberPtru catalyst

The invention provides a flexible glass fiber base catalyst used for VOCs catalytic combustion and a preparing method and application thereof. The catalyst has high activity, high heat stability and high mechanical performance, and is applied to the field of catalytic combustion for VOCs removal. A skeleton glass fiber of the catalyst is of a three-dimensional hole-like structure, and is high in porosity, and high in flexibility. When a catalytic combustion device operates, heat transfer is good, swelling coefficient is low, the catalyst is not sintered easily, and for some organic waste gas containing smoke, dust does not deposit on the surface of the catalyst easily.

Owner:NANJING TECH UNIV

High-fire-resistance composite adsorbing material and preparing method and application thereof

InactiveCN109126695AHigh mechanical strengthImprove hydrophobicityGas treatmentOther chemical processesFiberActivated carbon

The invention discloses a high-fire-resistance composite adsorbing material and a preparing method and application thereof. The composite material is prepared from powdery activated carbon, wood pulpfibers, special fibers, an insoluble flame retardant and an adhesive. According to the high-fire-resistance composite adsorbing material and the preparing method and application thereof, the special fibers and the insoluble flame retardant are compounded, the good flame retardant effect is achieved, and it is avoided that as a soluble fire retardant is used, the pore structure of the activated carbon is blocked; the composite adsorbing material simultaneously has the advantages of the special fibers and the activated carbon, also has the advantages of being good in fire resistance, hydrophobicity, heat stability and chemical stability, developed in pore structure, large in specific area, high in mechanical strength, not prone to pulverization and the like, and is particularly suitable foradsorption purification of all kinds of VOCs waste gas; a source of raw materials is wide, the technology process is simple, fiber products with different forms can be freely processed, and the composite adsorbing material has the advantages of being high in adsorption capacity, capable of achieving in-situ regeneration and recycling, high in adsorption / desorption rate, small in pressure drop andthe like in application of fixed bed adsorption and rotating wheel adsorption.

Owner:NANJING FORESTRY UNIV +1

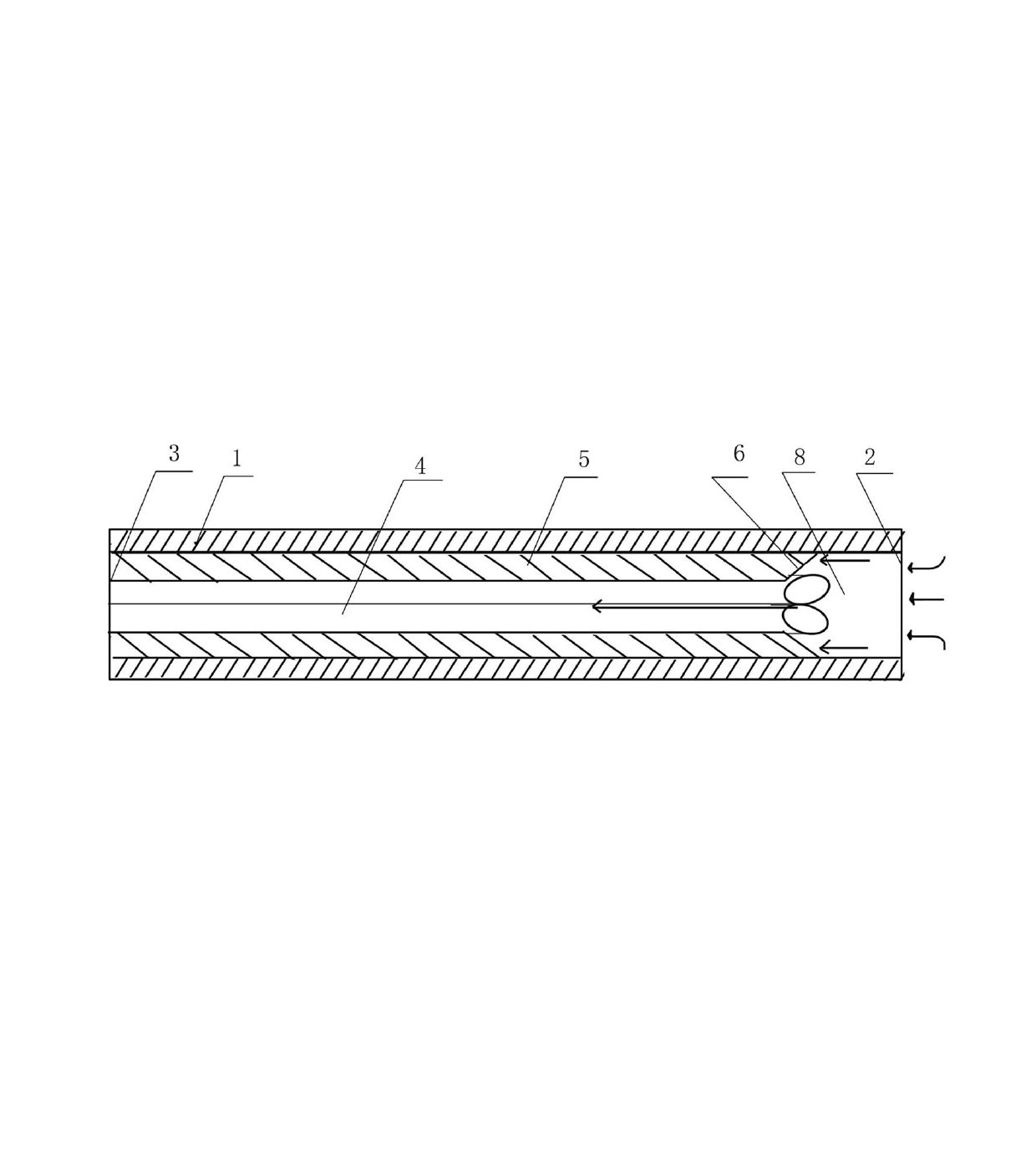

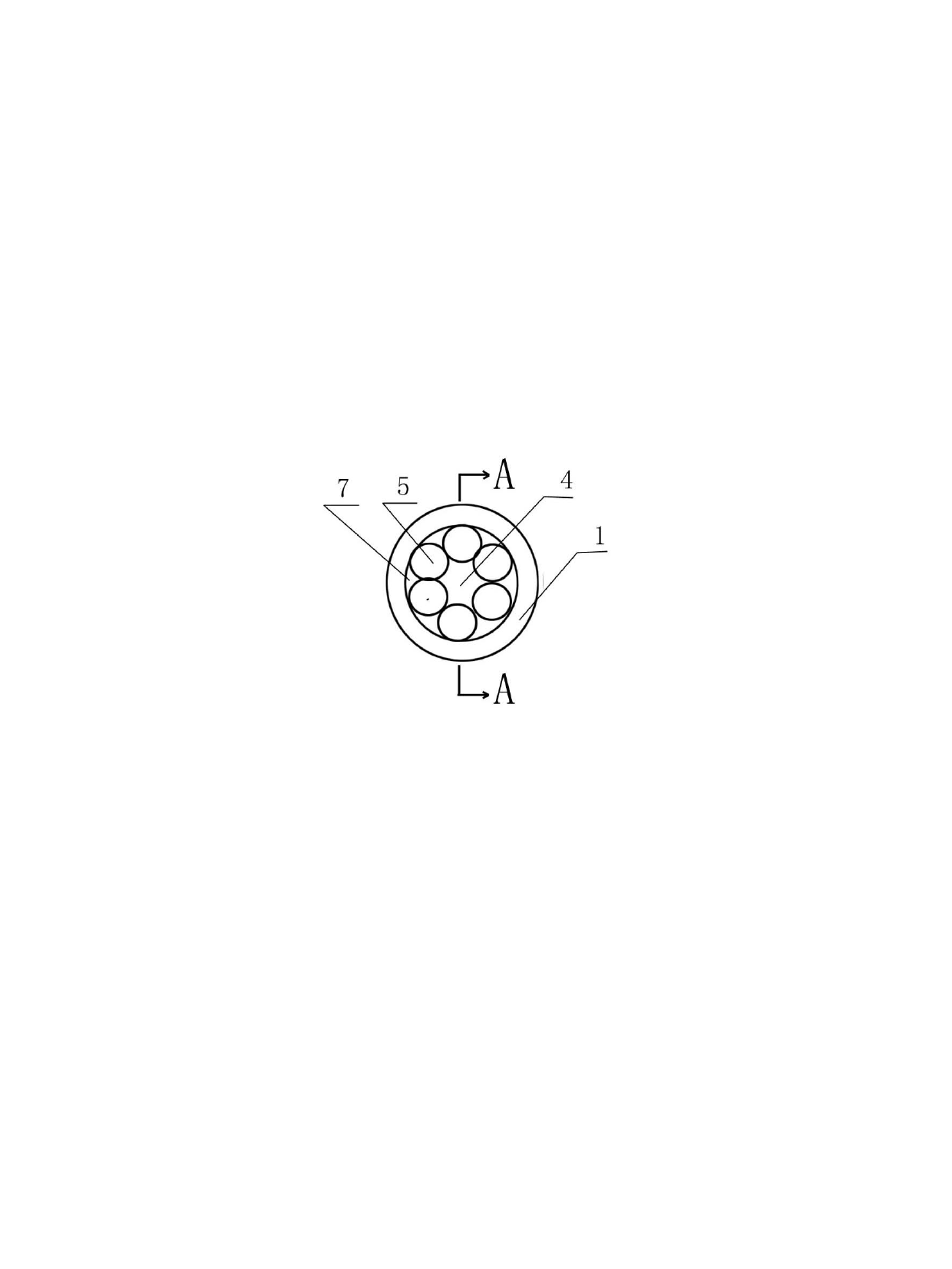

Quick metal cutting strip by means of combustion

The invention discloses a quick metal cutting strip by means of combustion, which comprises an iron pipe (1). One end of the iron pipe (1) serves as a gas inlet end (2), the other end of the iron pipe (1) serves as a gas outlet end (3), a gas channel I (4) is arranged in the center of the iron pipe (1), a plurality of galvanized iron wires (5) are uniformly inserted into the iron pipe (1) and are fixed in the iron pipe (1) after being tightly pressed by the iron pipe (1), the external section of each galvanized iron wire (5) is closely attached onto the inner wall of the iron pipe (1), the inner sides of the galvanized iron wires (5) enclose the gas channel I (4), a gap is reserved between the outer sides of each two adjacent galvanized iron wires (5), an independent gas channel II (7) is formed between each gap and the iron pipe (1), a safety area (8) is arranged among an end opening of the gas inlet end (2) and the galvanized iron wires (5) and is used for partitioning the galvanized iron wires (5) from an oxygen supply gas channel of a cutting gun, and the oxygen supply gas channel of the cutting gun is respectively communicated with the gas channel I (4) and the gas channels (7) through the safety area (8).

Owner:董山龙

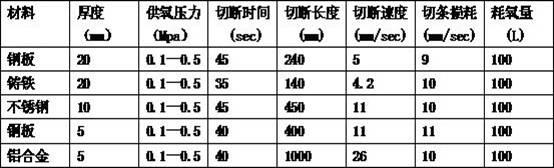

Pressure relief valve, respiratory support equipment air path and respiratory support equipment

The invention provides a pressure relief valve, a respiratory support equipment air path and respiratory support equipment. The pressure relief valve comprises a valve body, wherein the valve body is of a hollow structure provided with an air inlet and a pressure relief opening, a diaphragm is arranged on the lower portion of the valve body, the air inlet communicates with the pressure relief opening through a space above the diaphragm, and a driving device is arranged on the lower portion of the diaphragm and used for driving the diaphragm to move up and down. The air inlet and the pressure relief opening are formed in the upper portion of the pressure relief valve at the same time, control over the air flow is achieved by controlling the distance between the diaphragm and the pressure relief opening, the pressure relief valve is used for being connected with a branch of the respiratory support equipment air path and connected with a main path of the air path through one air inlet, the air resistance of the respiratory support equipment air path can be reduced, pressure control is achieved by controlling the pressure relief magnitude of the pressure relief valve on the branch, two or more pressure relief valves are combined for use in the air path according to use requirements, the pressure control range is expanded, and the pressure control precision is improved.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

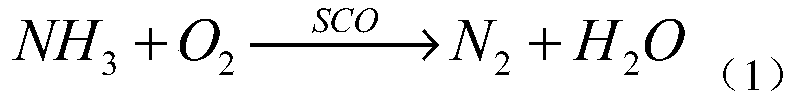

Online denitration process for sintering flue gas

ActiveCN112569758ASave investmentCut costsGas treatmentDispersed particle separationPtru catalystMetallurgy

The invention discloses an online denitration process for sintering flue gas. According to the technical scheme, the sintering flue gas online denitration process comprises the steps that sintering gas flow enters a sintering material layer under the suction effect of a draught fan to be subjected to combustion-supporting sintering to form sintering flue gas, and the sintering flue gas penetratesthrough the sintering material layer, a sintering machine trolley grate and an air bellow to enter a main flue; a sintering machine is sequentially divided into an ignition area, a low-temperature flue gas area, a flue gas rapid heating area, a NOx concentration rapid reduction area and a high-temperature flue gas area in the advancing direction of the trolley; the sintering flue gas is collectedthrough a low-temperature flue gas main flue, a high-NOx flue gas main flue and a high-temperature flue gas main flue, the sintering flue gas of the low-temperature flue gas main flue is mixed with ammonia gas, the mixture is led into a low-temperature flue gas circulation cover above a sintering material layer in a high-temperature flue gas area through a low-temperature flue gas pipeline to enter the sintering material layer again; and temperature rise is conducted in the sintering material layer, and reduction denitration is carried out under the catalytic action of iron-based multi-oxidesrich in the sintering material layer. The process is simple, a denitration catalyst does not need to be purchased, the occupied area is small, and the operation cost is low.

Owner:江苏集萃冶金技术研究院有限公司 +2

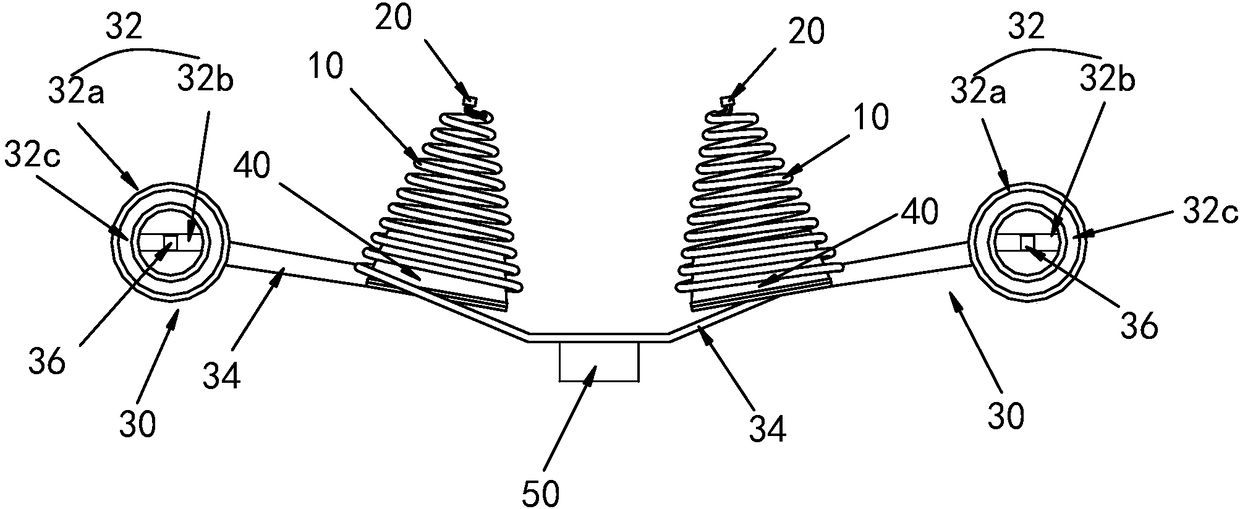

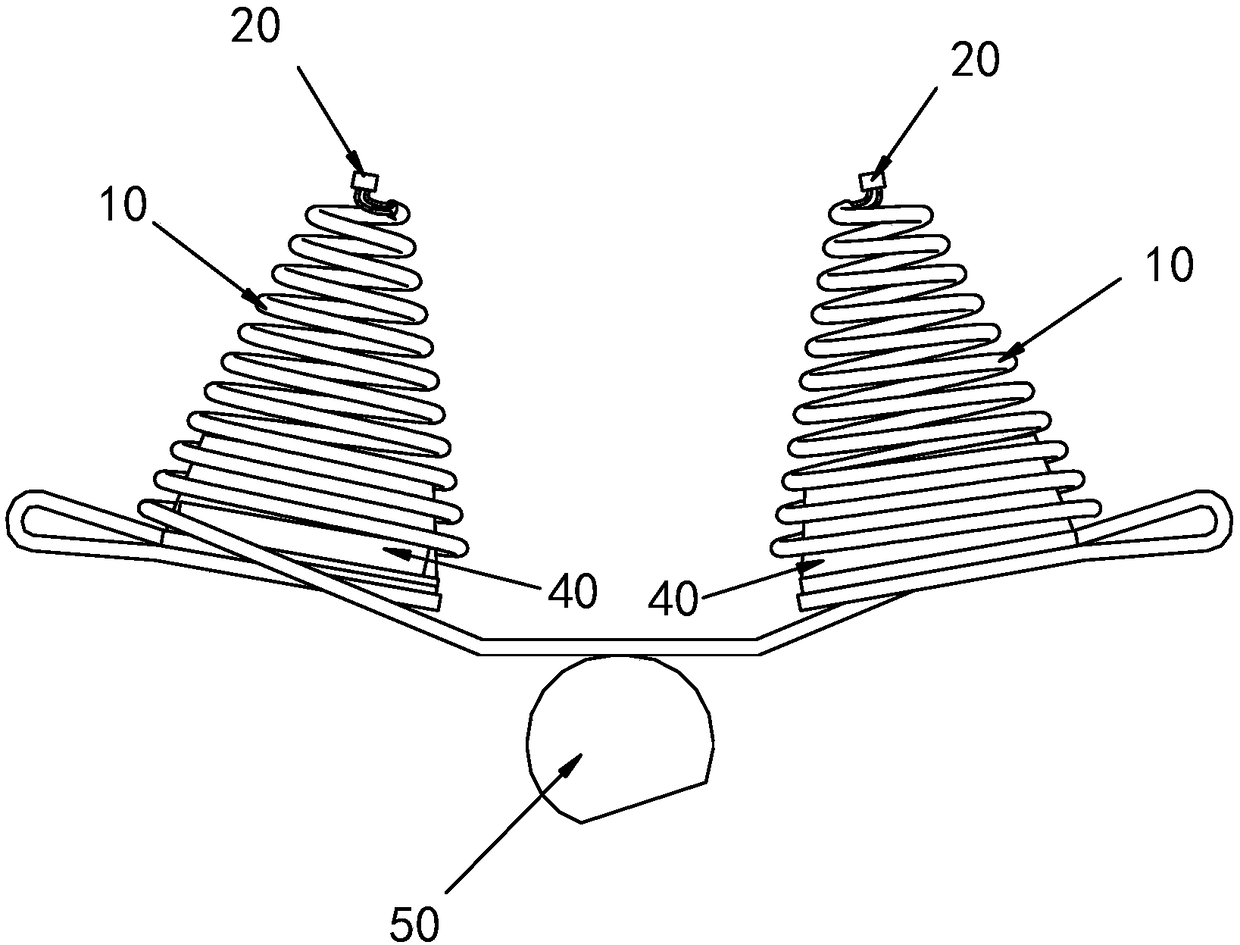

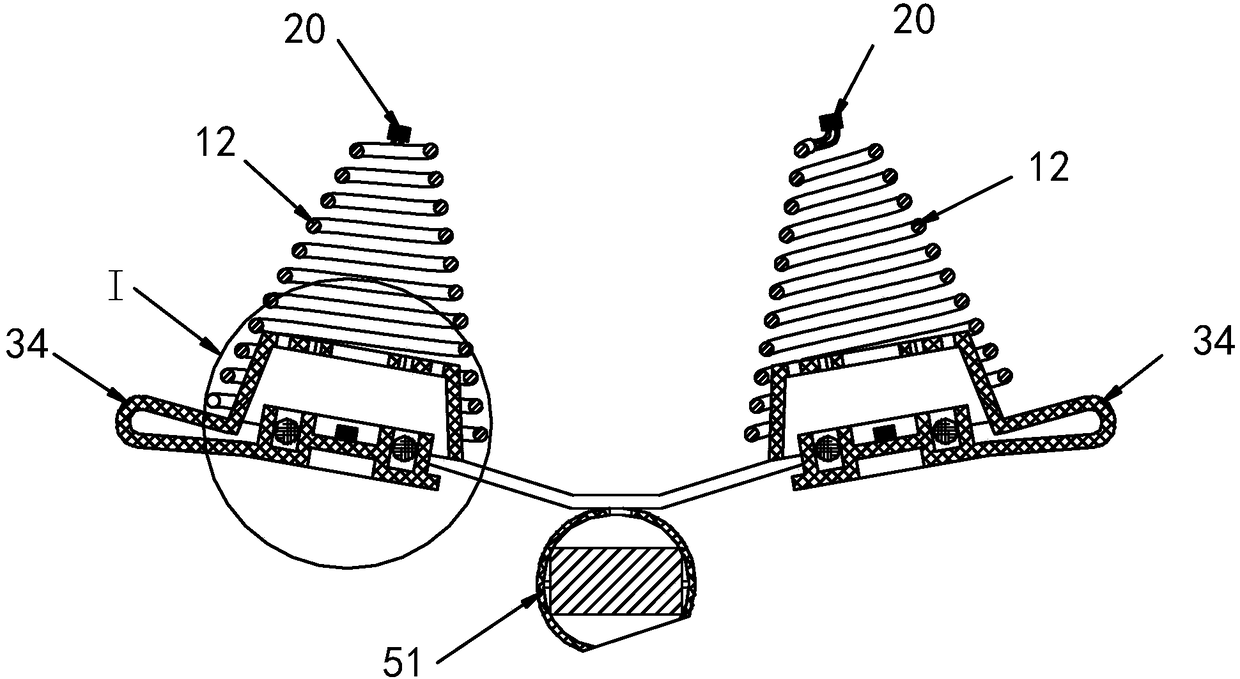

Multifunctional nose aerate instrument

InactiveCN108404280ALow gas resistanceWill not cause blockageSurgeryMedical devicesNasal cavityNostril

The invention discloses a multifunctional nose aerate instrument. The multifunctional nose aerate instrument comprises a conical spiral spring, an internal LED and a power supply device, wherein the small-caliber end of the conical spiral spring can be inserted into the nostril of a patient, and the conical spiral spring is spirally wound by a spring wire, an electric heating wire and a first conducting wire are arranged in the spring wire; the inner LED is arranged at the small-caliber end of the conical spiral spring; the power supply device is connected with the internal LED and the electric heating wire through the first conducting wire. According to the multifunctional nose aerate instrument provided by the invention, a small special matching spring tension force of the conical spiralspring is utilized to slightly expand the nostril to increase the airway ventilation efficiency of 5 percent to 25 percent, the gas resistance of the conical spiral spring is small and will not causeblockage, The conical spiral spring has the advantages of simple structure and convenient operation. At the same time, the multifunctional nose aerate instrument is used for irradiating the interiorof the nasal cavity with the internal LED, and is favorable for treating rhinitis.

Owner:谢昆宏

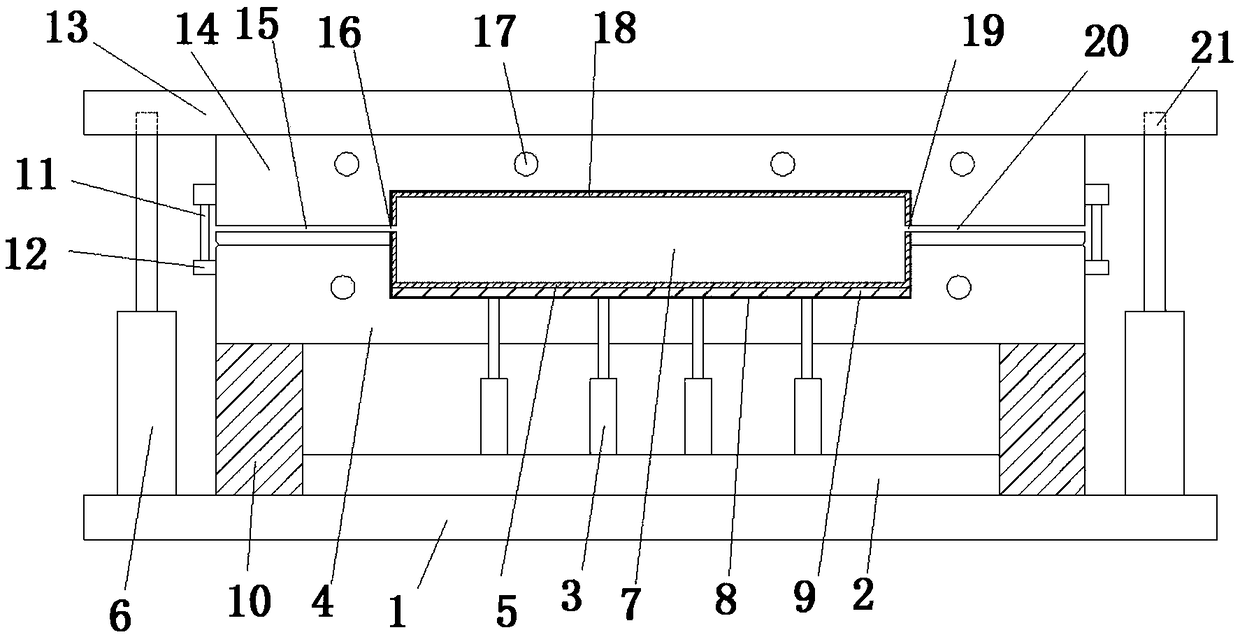

Refrigerating door foaming mold with good positioning accuracy and good demolding convenience

The invention discloses a refrigerating door foaming mold with good positioning accuracy and good demolding convenience, comprising a base. The upper end face of the base is provided with a hydrauliccylinder base; a lower mold is arranged below the hydraulic cylinder base; an upper mold is arranged above the lower mold; the upper mold and the lower mold form a foaming chamber; the upper end faceof the upper mold is provided with an upper mold mounting plate; each of four corners of the lower end face of the upper mold mounting plate is provided with a circular cavity; each of the four corners of the upper end face of the base is provided with a first hydraulic cylinder fitly connected with the corresponding circular cavity; the left and right ends of the foaming chamber are provided respectively with a gas discharge pipe connected with a gas pump and an injection pipe connected with a foaming gun head; a plurality of oil injection pipes are arranged in the upper mold and the lower mold; the surface of the foaming chamber is coated with polytetrafluoroethylene film. The defects of the prior art are overcome; positioning accuracy is good; demolding is easy; a product can be ejectedout quickly; the mode of material injecting along with gas extracting and the mode of injecting cold and hot oil into the oil injection pipe help greatly improve the quality of foamed plastic.

Owner:CHUZHOU MODERN MOLD MFG

High-efficiency oil fume adsorption molecular sieve and preparation method

InactiveCN110064362AImprove high temperature resistanceLow gas resistanceOther chemical processesDispersed particle separationFiberMolecular sieve

The invention discloses a high-efficiency oil fume adsorption molecular sieve and a preparation method. The molecular sieve is composed of a ceramic fiber carrier and a filler filling the ceramic fiber carrier; the filler is prepared from, by weight, 2-4 parts of diatomaceous earth, 0.5-1.2 parts of attapulgite, 1.3-1.8 parts of kaolin, 0.5-1.2 parts of 13x molecular sieve raw powder and 4.2-6 parts of silica sol. The preparation method comprises the steps that the ceramic fiber carrier is immersed with an alkali solution, washed with water and dried to prepare a honeycomb mesh-shaped base body; the diatomaceous earth, the attapulgite, the kaolin and the 13x molecular sieve raw powder are mixed, ground into powder, sieved and uniformly mixed with a silica sol aqueous solution to obtain slurry; the surface of the honeycomb mesh-shaped base body is submerged by the slurry for soaking, and a honeycomb carrier to which the slurry is attached is obtained after soaking; the honeycomb carrierto which the slurry is attached is dried and calcined to obtain the high-efficiency oil fume adsorption molecular sieve. The high-efficiency oil fume adsorption molecular sieve has the advantages ofbeing low in specific gravity, small in gas resistance, capable of achieving a good adsorption effect on various oil fumes, unlikely to be blocked and recyclable.

Owner:四川风林卓越环保科技有限公司

Distribution device and distribution method for high-operating-flexibility liquid

ActiveCN110251982ALow gas resistanceReduced installation level requirementsFractional distillationManufacturing cost reductionDistribution control

The invention discloses a distribution device and a distribution method for high-operating-flexibility liquid. The distribution device comprises a liquid distributor and a liquid distribution control system. The liquid distributor comprises a first feeding tube, a first liquid dispensing tube, a first liquid distributing tube, a second feeding tube, a second liquid dispensing tube and a second liquid distributing tube. Liquid distribution holes are evenly and equidistantly formed in the central line of the bottom side of each of the first liquid distributing tube and the second liquid distributing tube. The liquid distribution control system comprises a first control valve, a second control valve, a flow meter and a flow control interlocking system. The distribution device and the distribution method have the advantages that high-efficiency initial distribution of liquid in a rectification tower can be realized, high filling efficiency is achieved, the operating flexibility is high, the maximum operating flexibility of the liquid distributor can reach 1:13, stable operation can be realized in full load, the occupancy height is low, and the tower height and the manufacturing cost are reduced.

Owner:WANHUA CHEM GRP CO LTD +1

A scr denitration device

ActiveCN107321183BAvoid shakingWell mixedGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention discloses an SCR denitrification device which comprises a gas inlet mixing section, a rotating cylinder, a fan impeller, a rectification section and a catalysis section. A reducing agent supply pipe and a fixing frame are arranged inside the gas inlet mixing section, the outlet end of the reducing agent supply pipe is fixed to the fixing frame, the reducing agent supply pipe is led out of the gas inlet mixing section; the rotating cylinder is rotationally assembled at the outlet end of the reducing agent supply pipe, a plurality of spraying pipes are connected to the side wall of the rotating cylinder, a plurality of backlash spraying holes are uniformly formed in the side wall of each spraying pipe, and the axial lead of each backlash spraying hole and the axial lead of the rotating cylinder are orthogonal; a hub of the fan impeller is rotationally assembled on the side wall of the reducing agent supply pipe; the rectification section and the gas inlet mixing section are connected, and a rectification device is arranged inside the rectification section; one end of the catalysis section is connected with the rectification section, and the catalysis section is filled with a catalyzer module. According to the SCR denitrification device, the sprayed reducing agent can be mixed with boiler flue gas to be uniform within a short period of time, and the denitrification efficiency can be improved.

Owner:CHINA NEW ERA INT ENG CORP

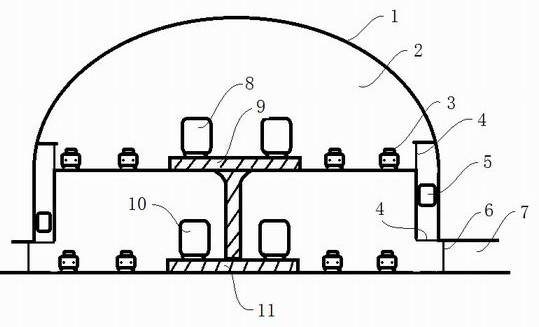

Pipeline traffic system

The invention aims at providing a traffic system aiming to abandon an existing traffic system design technical scheme thoroughly. The traffic system is filled with gas with the density smaller than the air density, and the problem of air resistance in the running process of a vehicle is well solved.

Owner:米建军

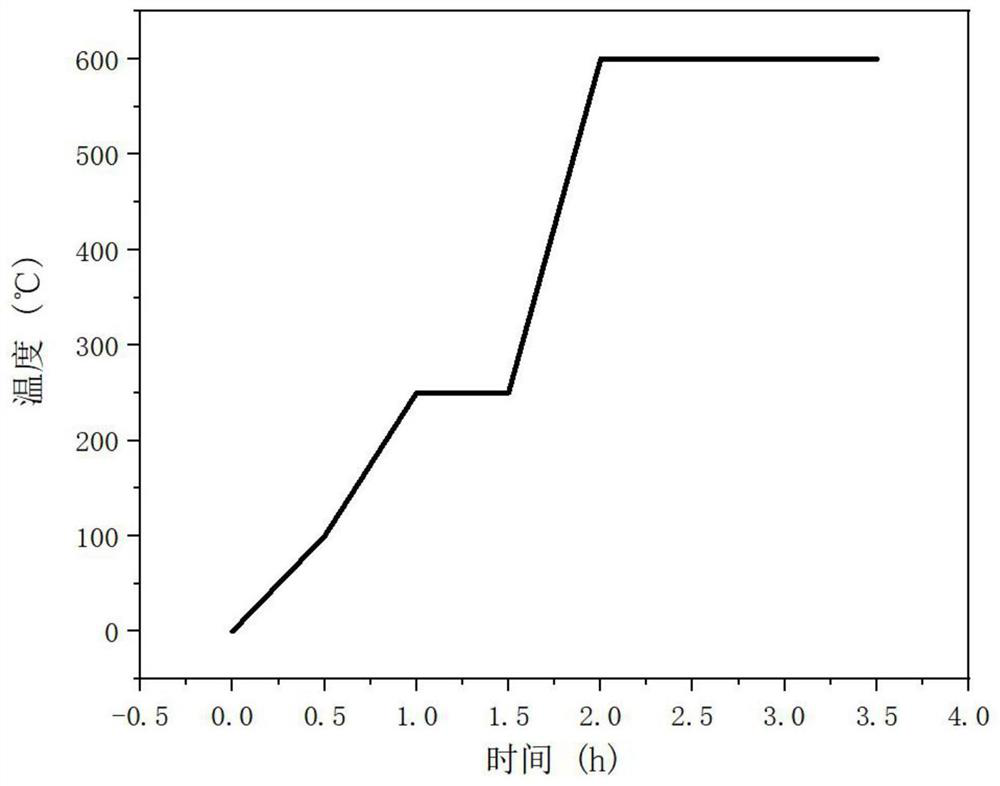

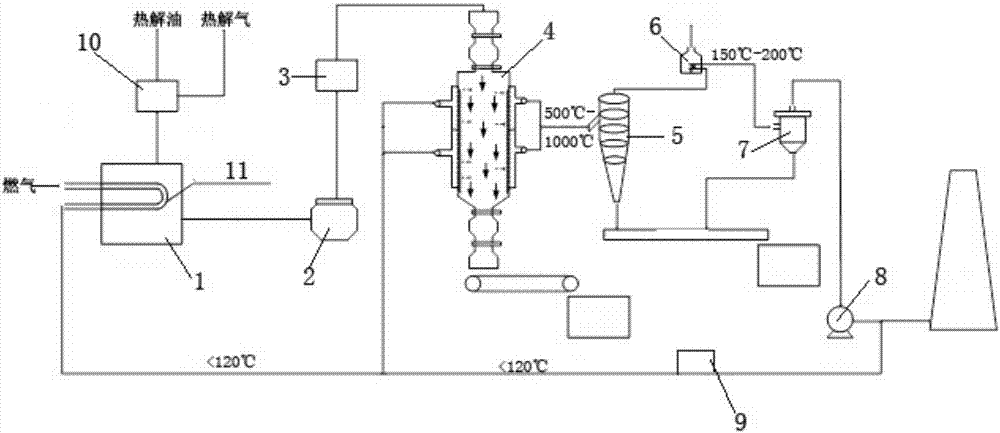

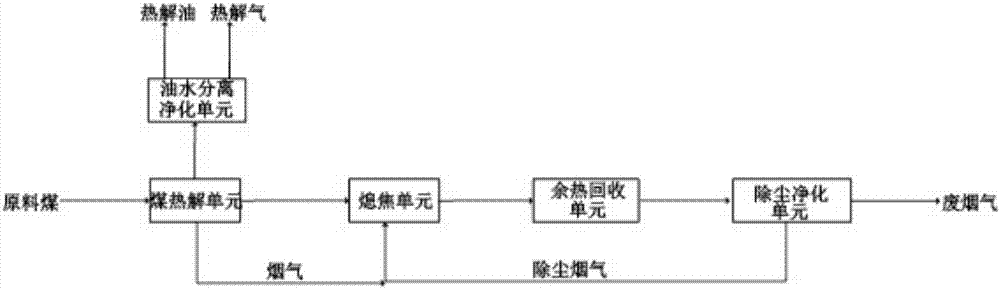

Coal pyrolysis system and method

PendingCN107987854ACompact structureSmall footprintCoke quenchingEnergy inputWaste heat recovery unitCombustion chamber

The invention discloses a coal pyrolysis system, which comprises a pyrolysis unit, a coke quenching unit, a waste heat recovery unit, a dust removal and purification unit and an oil-water separation and purification unit, wherein the pyrolysis unit, the coke quenching unit, the waste heat recovery unit and the dust removal and purification unit are connected in sequence; the pyrolysis unit comprises a pyrolysis reactor; the pyrolysis reactor takes a heat storage type radiant tube burner as a heating heat source; the oil-water separation and purification unit is connected with the pyrolysis unit for carrying out oil-water separation on crude gas generated by coal pyrolysis. According to the coal pyrolysis system, the heat storage type radiant tube burner is taken as the heating heat source,the temperature of discharged smoke generated by a combustion chamber is not lower than 200 DEG C, in addition, the discharged smoke flows in a radiation tube and is not mixed with the crude gas generated by coal pyrolysis, and the discharged smoke can be directly conveyed to the coke quenching unit to serve as a coke quenching gas carrier. The invention simultaneously provides a coal pyrolysis method which uses the coal pyrolysis system.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com